HANYOUNG NUX TD510, TD510-1N Operation Manual

Notice

This operation manual is protected by copyright and has all rights concerned.

Without prior consent from Hanyoung Nux Co., Ltd., any part of this document will

not be copied, reproduced, modified, or translated into another language.

This operation manual is provided "as is" and may be subject to changes without

prior notice.

Regarding this manual, Hanyoung Nux Co., Ltd. does not assure anything

including but not limited to implied marketability or conformance to certain purpose.

The accompanied programs are protected by copyright.

All product names, which are used in this document and product, are product

names, service marks, trademarks, or registered marks of the owners.

Hanyoung Nux Co., Ltd.

28, Gilpa-ro 71beon-gil, Nam-gu, Incheon, Korea

TEL : (82-32)876-4697

FAX : (82-32)876-4696

E-mail. overseas@hynux.com

Before starting

1. Checking of components

2. Safety cautions

3. Warranty

2

4

4

Installation

Operation

Screen block diagram

Function setting

Program

1. Installation site & cautions

2. How to install 5

3. Exterior & panel dimensions

4. Wiring

5. Terminal connection diagram

1. Name of section

2. Button operation

3. How to control numeric input panel

4. How to control character input panel

5. Name of control

1. Screen block diagram

1. Operation screen

2. Operation setting

3. PV graph view

4. Time/schedule setting

5. Event

1. Pattern setting

2. Pattern management

3. Pattern name setting

4. Pattern alarm setting

5. Time signal setting

6. Pattern graph

10

11

13

14

14

15

16

17

19

32

37

39

40

44

47

49

50

51

52

5

8

InstallationBefore starting

Operation

Screen block

diagram

Function setting Program System setting Specifications

System setting

Specifications

1. Sensor input setting

2. Control/transmission output

3. PID setting

4. Inner signal

5. ON/OFF signal

6. System alarm

7. DI configuration

8. DO configuration

9. System

1. Input specifications

2. Hardware specifications

3. Display specifications

4. Memory specifications

5. Installation environment

6. Engineering unit

54

56

58

61

64

66

67

72

78

82

82

85

85

85

86

1

Before starting

Thank you for purchasing Hanyoung Nux programmable temperature controller(Model: TD510).

This programmable temperature controller(Model: TD510) is a unit to control temperature consisting

of display and control. The display can be attached to a panel or VESA-mounted and is

connected to the control for communication. The control consists of power, control, and input/

output modules and can be fixed on DIN rail or attached on a panel using screws.

The operation manual describes product functions, how to install, cautions, and how to use. Read

and understand this document before starting the product.

Make sure that this operation manual will be delivered to an end user and kept in an accessible

location (This operation manual may be subject to changes for improvement and functional

changes without prior notice).

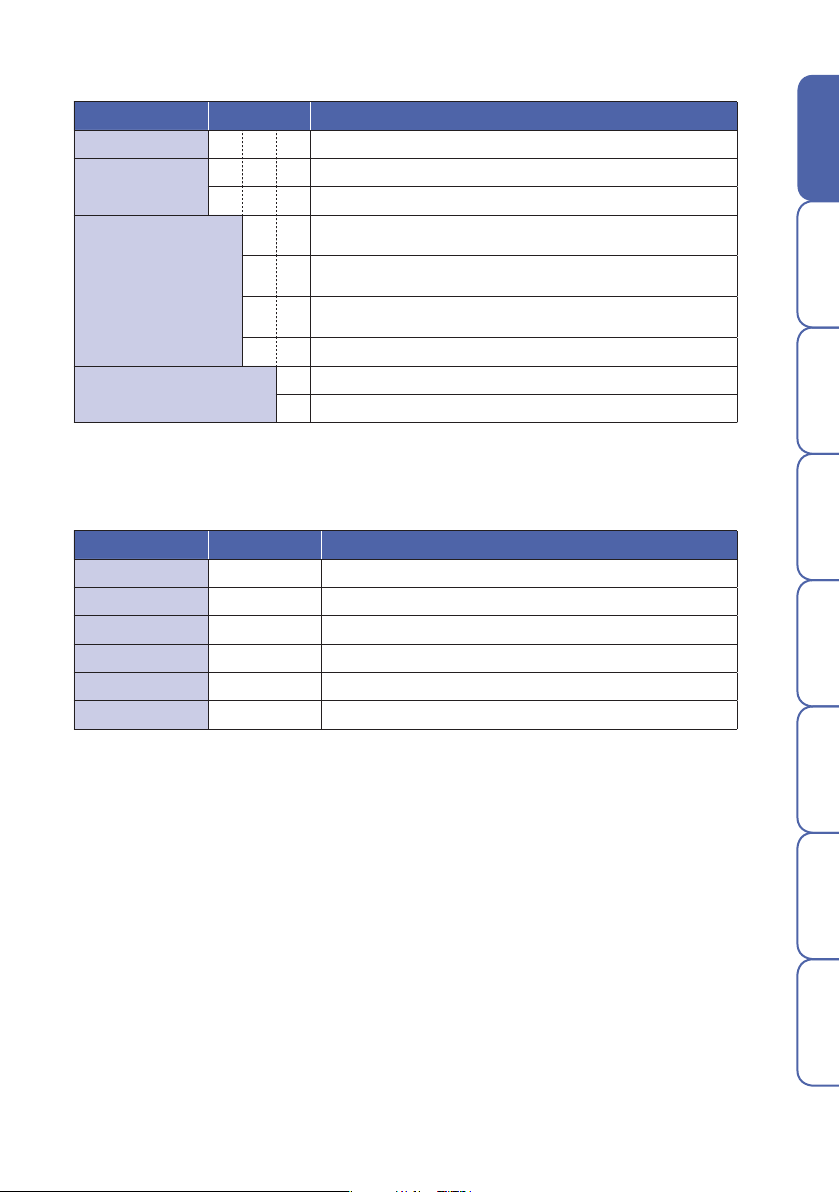

1. Checking of components

First of all, check the specifications referring to your order and see if there is any exterior damage or

missing component.

▶ Component

Display(TD510-1) Power module(TM-PWR) Control module(TD510-MAIN)

Programmable Temperature & Humidity Controller

Input module(TM-DI) Output module(TM-DO) Input/output module(TM-DIO)

Communication

cable(1.5 m)

Bracket 4EA

250-Ω resistor

2EA

3P communication

Connector

2

SD card

Operation

manual

▶ Model name

Model Code Description

TD510- ☐ ☐ ☐ Programmable temperature controller

Display

Input/output

Language

※ This product consists of the display and control(power, control, input, and output modules).

(Up to 32 contact input/output points, respectively)

1 Display(5.7" TFT LCD)

N None

1

2

3

N No input/output

8 input points/6 output points(1 module)+Power module

+Control module

8 input points/14 output points(2 modules)+Power module

+Control module

16 input points/16 output points(3 modules)+Power module

+Control module

S Korean, English, and Chinese(Simplified)

T Korean, English, and Chinese(Traditional)

▶ Components

Product Model Description

Display TD510-1N☐ Display(5.7" TFT LCD)

Control module TD510-MAIN Temperature 2-channel control module

Power module TM-PWR Power module

Input module TM-DI Module with 16 input points

Output module TM-DO Module with 8 output points

Input/output module TM-DIO Module with 8 input and 6 output points

Before starting

Installation

Operation

Screen block

diagram

Function setting Program System setting Specifications

3

2. Safety cautions

The cautions are categorized into Danger, Warning, and Caution according to seriousness.

Danger

Warning

Caution

● The operation manual may be subject to changes for improvement without prior notice.

● To protect and secure the product and system connected, use the product according to the

safety instructions of this manual.

● We are not liable for any damage caused by negligence or not following the instructions.

● To protect and secure the product and system connected, install any separate or external circuit

outside of the product.

● Do not remove, repair, or modify it without prior consent. It may cause electric shock, fire, and

malfunction.

● Avoid any strong impact. It may cause damage or malfunction to the product.

● To disconnect the main power, install a switch or circuit breaker.

If not followed, it may lead to death or serious injury.

If not followed, it might lead to death or serious injury.

If not followed, it may lead to minor injury or damage to assets.

3. Warning

●

We are not liable for any condition other than those specified warranty conditions.

●

If a user or third party is damaged in using this product due to unforeseeable defect or natural

disaster, we are not liable for any loss or indirect damage.

●

The warranty is valid for 1 year from a date of purchase and is applicable to any failure found

in normal use conditions.

●

For any failure found after the warranty period, paid service may be provided according to our

regulations.

Programmable Temperature & Humidity Controller

●

Any of followings will be repaired at a cost even if it is fund in the warranty period.

•Failure attributable to user (e.g. Initialization due to lost password)

•Failure attributable to a natural disaster (e.g. fire, flood, etc.)

•Failure attributable to relocation after installation

•Failure attributable to unauthorized modification or damage

•Failure attributable to unstable power supply

●

If you require A/S, contact your dealer or Hanyoung Nux Co., Ltd..

4

Installation

1. Installation site & cautions

Before starting

● It may cause electric shock so install in on the panel first.

● Avoid following locations.

• Where people might unintentionally contact a terminal

• Where there is strong vibration, impact, or electromagnetic field

• Where it is exposed to a corrosive or inflammable gas

• Where the temperature changes sharply or there is much humid, dust, or salt

• Where it is directly exposed to direct sunlight or the temperature is extreme

• Where there are combustibles around

● The case and front section are made of fire-retardant polycarbonate but do not install it directly on a

combustible.

● Keep away any device or wire that may cause noise. Enough preheating is required especially under

0℃. Keep away any heat-radiating device.

● For wiring, disconnect the entire power.

● This product works at 100 - 240 V a.c. / 50 - 60 ㎐ without special setting. Apply rating only.

It may lead to fire or electric shock.

● Do not touch it with wet hand. You may be electrically shocked.

● Follow conventional cautions in order to reduce the risk of fire, electric shock, and injury.

● For grounding, refer to how to install. (Grounding resistance : 100 Ω or less)

● Keep ventilation and the radiating hole free.

● The over voltage protective level is Category II(IEC 60664-1) and use environment is Pollution Degree.

● Do not use a sharp object or force to touch the screen.

● The external terminals(sensor input, communication, and control output terminals) must be connected

to separate circuits with at least reinforced insulation from dangerous voltage sections.

● To disconnect the main power, install a switch or circuit breaker.

Installation

Operation

Screen block

diagram

Function setting Program System setting Specifications

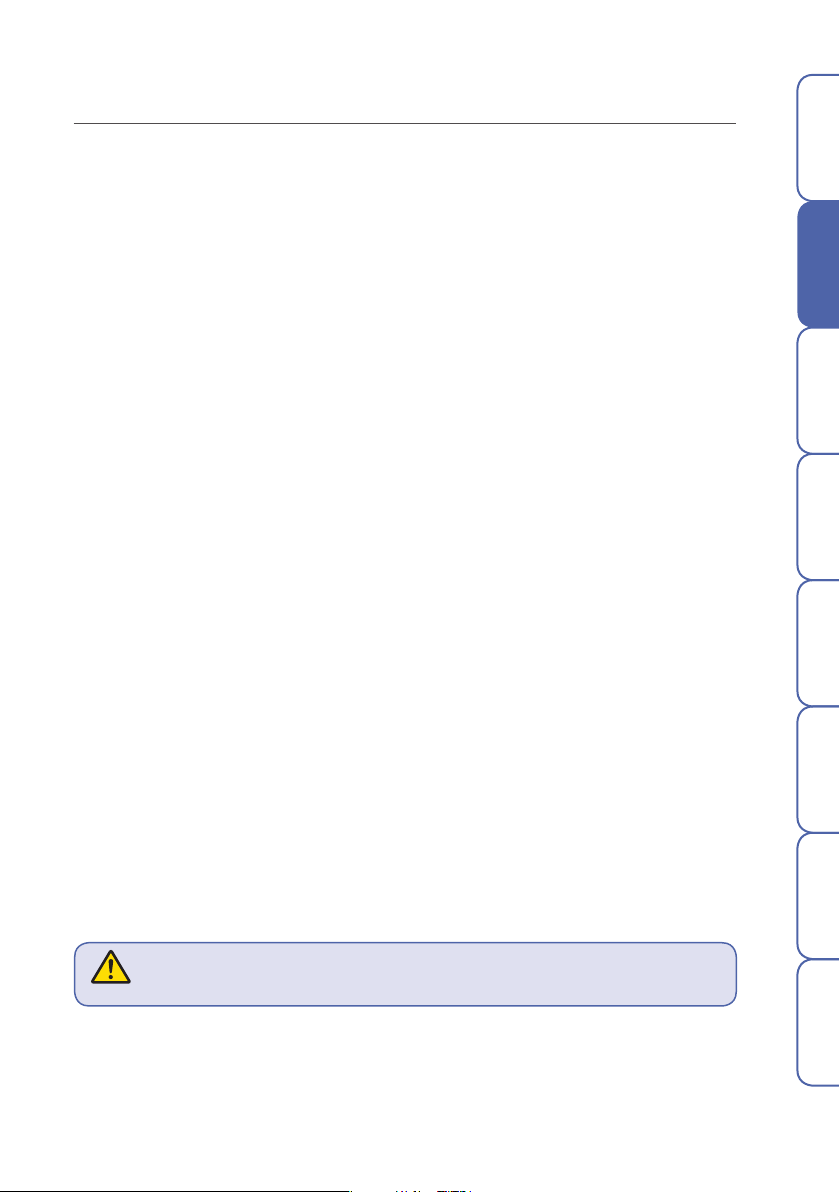

2. How to install

Before installing it, disconnect the power. Do not touch a terminal because it may lead to

electric shock.

Danger

●

Use 2-5mm thick panels.

●

Insert this device from the front of panel.

●

Connect dedicated clamps to the clamping grooves and fix them with bolts.

(Before fully tightening the clamps, position them in place).

5

▶Display

(1) How to attach panel

Fig. 1) How to attach a panel

The tightening torque must be 0.5 N·m or less for clamping.

Forcible tightening may lead to deformation or damage.

Caution

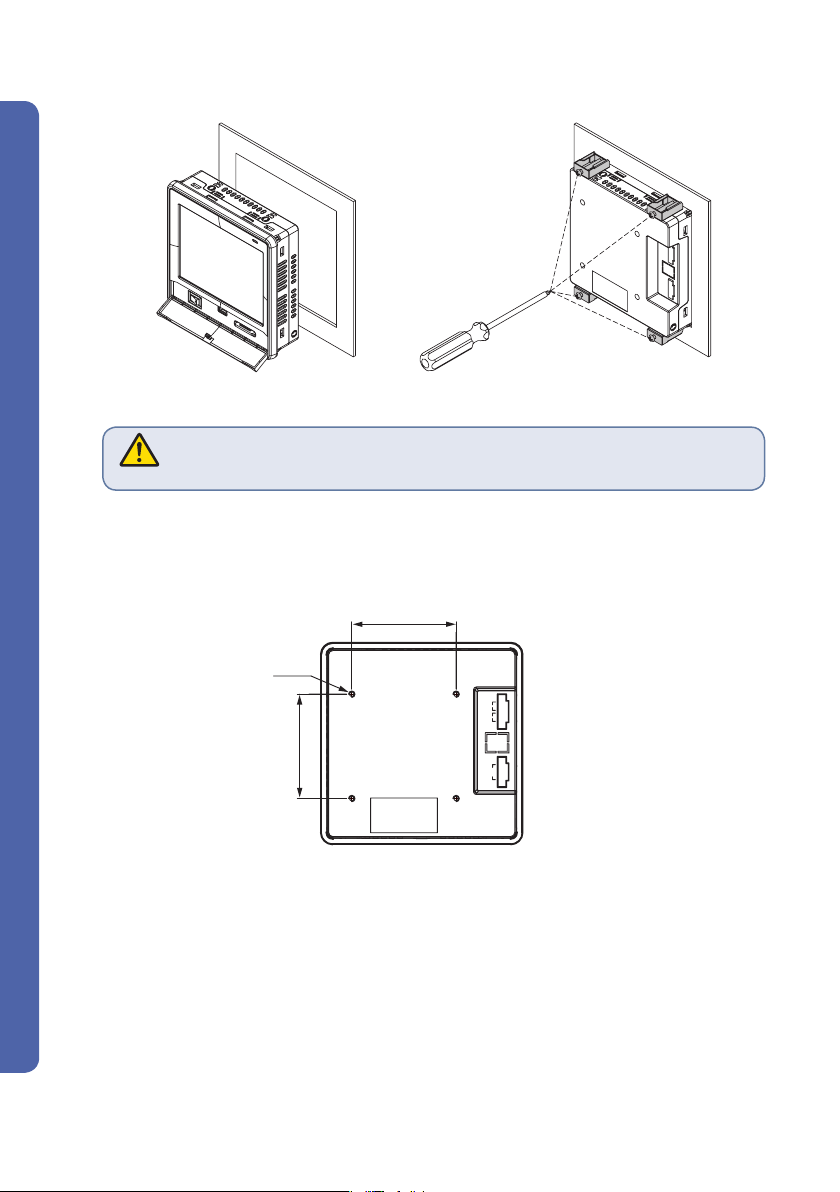

(2) How to install VESA mount

Connect an M4 X 7L bolt into a VESA hole.

75.0

4-M4

+

1

DC 5V

2

3

COM1

4

75.0

5

6

7

COM2

8

Programmable Temperature & Humidity Controller

6

▶Control

TM-DO

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-DO

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-DO

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-DO

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

1) How to install DIN rail

Before starting

Ⓐ

Installation

Ⓑ

Operation

① Connect the top hook(A) of bottom of

floor to the DIN rail and press it(B) in

②

Check if it is fixed by pushing

up the mounting bracket.

order to install it.

●

How to install module

TD510 series module can connect up to 7 units. Any module must be installed vertically.

TM-DO

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

TM-DO

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

① Push a module aside

in order to connect it to a

connector.

TM-DO

③

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

TM-DO

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

TM-DO

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

TM-DO

PWR

RY2

RY1

RY3

RY4

RY6

RY5

RY7

RY8

ADR

② Fix a module on

both ends using

stoppers.

Screen block

diagram

Function setting Program System setting Specifications

7

2) How to attach panel

POWER용 MAIN용

① Referring to the hole dimensions on the left, find where to install it.

② Push outside the top and bottom hooks for fixing screws at the bottom of modules.

③ Fix it with an M3 screw.

●

POWER

●

Main, input/output, input, and output

Ø4.2

113

4.2

5.5

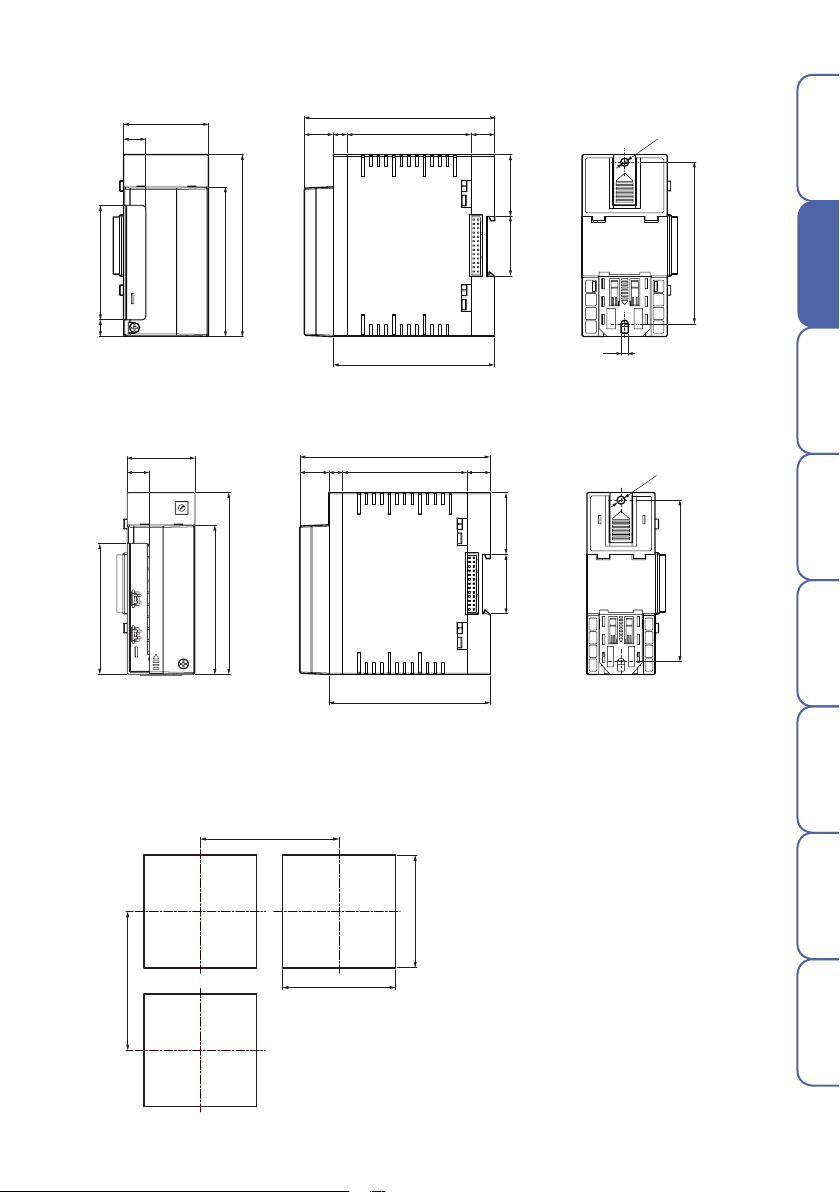

3. Exterior & panel dimensions

▶Display

(Unit : ㎜)

145.0

145.0

42.3

8.8

4-M4

75.0

35.5

75.0

24.7

Ø4.2

113

4.2

+

1

DC 5V

2

3

COM1

4

5

6

7

COM2

8

5.5

Programmable Temperature & Humidity Controller

8

145.0

145.0

8.8

42.3

+

1

2

3

4

5

-

DC 5V

6

7

8

COM1

COM2

75.0

75.0

24.7

35.5

4-M4

▶Power module

50.0

13.0

(Unit : ㎜)

Before starting

112.0

8.017.0

73.2

13.8

Ø4.2

36.3

107.0

67.0

88.0

10.0

95.0

▶Control, input, output, and input/output modules

40.0

13.0

77.0

88.0

▶Panel dimensions

107.0

(Unit : ㎜)

17.0

112.0

8.0

73.2

13.8

95.0

35

(Unit : ㎜)

36.3

35

95.0

4.2

Operation

Screen block

Installation

Ø4.2

95.0

diagram

Function setting Program System setting Specifications

170.0

170.0

138.0

+0.5

-0

138.0

+0.5

-0

9

4. Wiring

Before wiring, disconnect the power. Do not touch a terminal

because it may lead to electric shock.

Danger

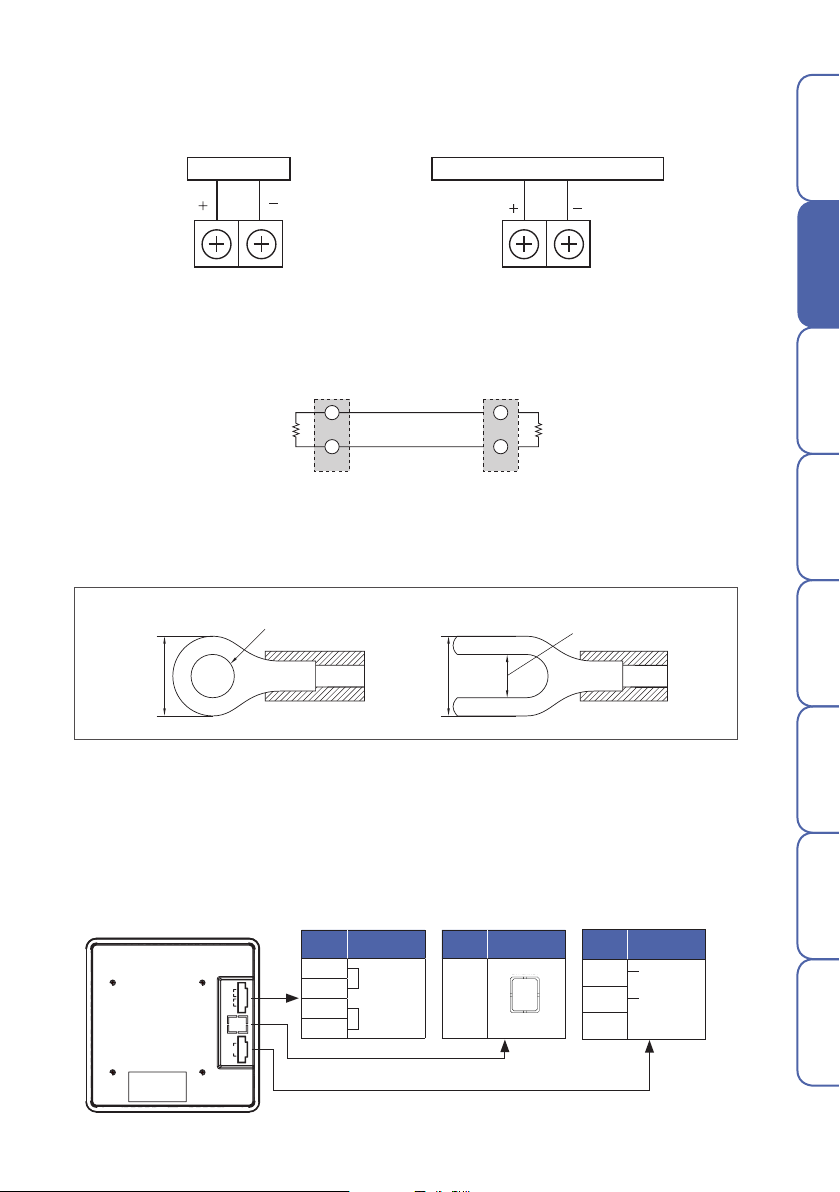

▶ Power connection

Vinyl-insulated wire(0.9 - 2.0 ㎟ (KSC 3304)) must be used.

Too much noise may lead to damage or malfunction to the device.

Use line filter to remove the noise.

Caution

▶ FG wiring

Vinyl-insulated wire(2.0 ㎟ (KSC 3304)) must be used. It must be grounded at 3 points or

more with 100 Ω or less resistance.

▶ Relay output wiring

Inductive load(L) including motor, solenoid, and external relay may lead to malfunction.

It must be connected in parallel with CR filter for AC circuit and diodes for DC circuit.

Caution

TD510 TD510

Relay output

terminal

Inductive load

Extern DC power

L L

Diode

Fig. 2) Connection of relay

Relay output

terminal

▶ Input wiring

Input wire must use shielded cable and be wired with certain distance from

the power and ground circuits. RTD sensor must be 3-wire type with the same wiring

Caution

resistance.

•Enclosure must be grounded at 3 points or more(100 Ω or less of grounding resistance)

using 2 ㎟ or bigger cable.

Programmable Temperature & Humidity Controller

●

•Input signal and output lines must be of shielded cable with 1 grounding point.

•Thermoresistor input must be wired with no resistance difference between 3 wires.

Caution

•Input/output signal line must be isolated from power line.

•To use current input, attach 250 Ω 0.1 % resistor at both ends of input terminal.

Sensor input

●

Thermoresistor input●Thermocouple input●DC voltage input●DC current input

T.C

Extern AC power

CR filter

Inductive load

10

Terminating

T.C

●

Thermocouple input

●

DC voltage input●DC current input

●

DO

TM-DO

DIDIOMAINPOWER

TM-PWR

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

COM1RUN COM2

TM-DIO

ADR

PWR

RY2

RY6

RY1

RY5

RY3RY4

TH510-MAIN

ADR

TM-DI

ADR

PWR

Wiring of temperature control and transmission output

●

Temperature control output

●

Temperature transmission output

SSR or SCR Recording and indicating instrument, etc..

▶ Communication wiring

Connect terminating resistors(100 - 200 Ω, 0.25 W) at both ends of communication cable.

Before starting

Installation

Operation

Master

Terminating

resistor

RTX+

RTX-

Fig. 3) How to wire for communication

▶ Terminal specifications

Power/Input/Output – M3 screw

3 ㎜ or more

6 ㎜ or

Fig. 4) Solderless terminal

5. Terminal connection diagram

▶ Display

Terminal

+

1

DC 5V

2

3

COM1

4

5

6

7

COM2

8

No.

1

2

3

4

Power

+

DC 5V

-

COM1 (control)

6 ㎜ or

Terminal

No.

TD510

RTX+

RTX-

resistor

Screen block

diagram

Function setting Program System setting Specifications

3 ㎜ or more

Ethernet

Terminal

5

No.

6

7

8

RS485

communication

RTX+

RTX-

11

DO

TM-DO

DIDIOMAINPOWER

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

COM1RUN COM2

TM-DIO

ADR

PWR

RY2

RY6

RY1

RY5

RY3RY4

TH510-MAIN

ADR

TM-DI

ADR

PWR

▶ Power module

DO

TM-DO

DIDIOMAINPOWER

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-DI

ADR

PWR

DO

TM-DO

DIDIOMAINPOWER

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

DO

TM-DO

DIDIOMAINPOWER

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-DIO

ADR

PWR

RY2

RY6

RY1

RY5

RY3RY4

TM-DI

ADR

PWR

DO

TM-DO

DIDIOMAINPOWER

ADR

PWR

RY2

RY6

RY1

RY5

RY3

RY7

RY4

RY8

TM-PWR

Terminal

No.

L

N

F.G

Power

100 - 240 V a.c.

50 - 60 ㎐

22 VA

▶ Control module

TH510-MAIN

ADR

TRX+ TRX-

Terminal

No.

1 10

2 11

3 12

4 13

5 14

6 15

7 16

8 17

9 18

1 2 3 4

POWER

5 V d.c.

COM1RUN COM2

Power

Terminal

CH1

+

H.OUT H.OUT

-

(SCR/SSR) (SCR/SSR)

+

C.OUT/RET C.OUT/RE T

-

A

RTD

B

+

T.C

mV/V

-

B

CH2

No.

+

-

+

-

A

B

+

T.C

-

B

RTD

mV/V

▶ Input module

TM-DIO

PWR

RY2

RY1

RY3RY4

RY6

RY5

Terminal

ADR

No.

1 10

Input(1~8)

Terminal

No.

Input(9~16)

▶ Output module

TM-DI

PWR

Terminal

No.

ADR

2 11

3 12

4 13

5 14

6 15

7 16

8 17

9 18

▶ Input/output module

TM-DI

PWR

ADR

Programmable Temperature & Humidity Controller

Terminal

Input(1~8)

No.

1

2 11

3 12

4 13

5 14

6 15

7 16

8 17

9 18

Terminal

No.

10

Output(1~6)

COM

COM

COM

Output(1~4)

Terminal

1 10

RY1

2 11

3 12

4 13

RY2

5 14

6 15

RY3

7 16

8 17

RY4

9 18

No.

Output(5~8)

RY5

RY6

RY7

RY8

12

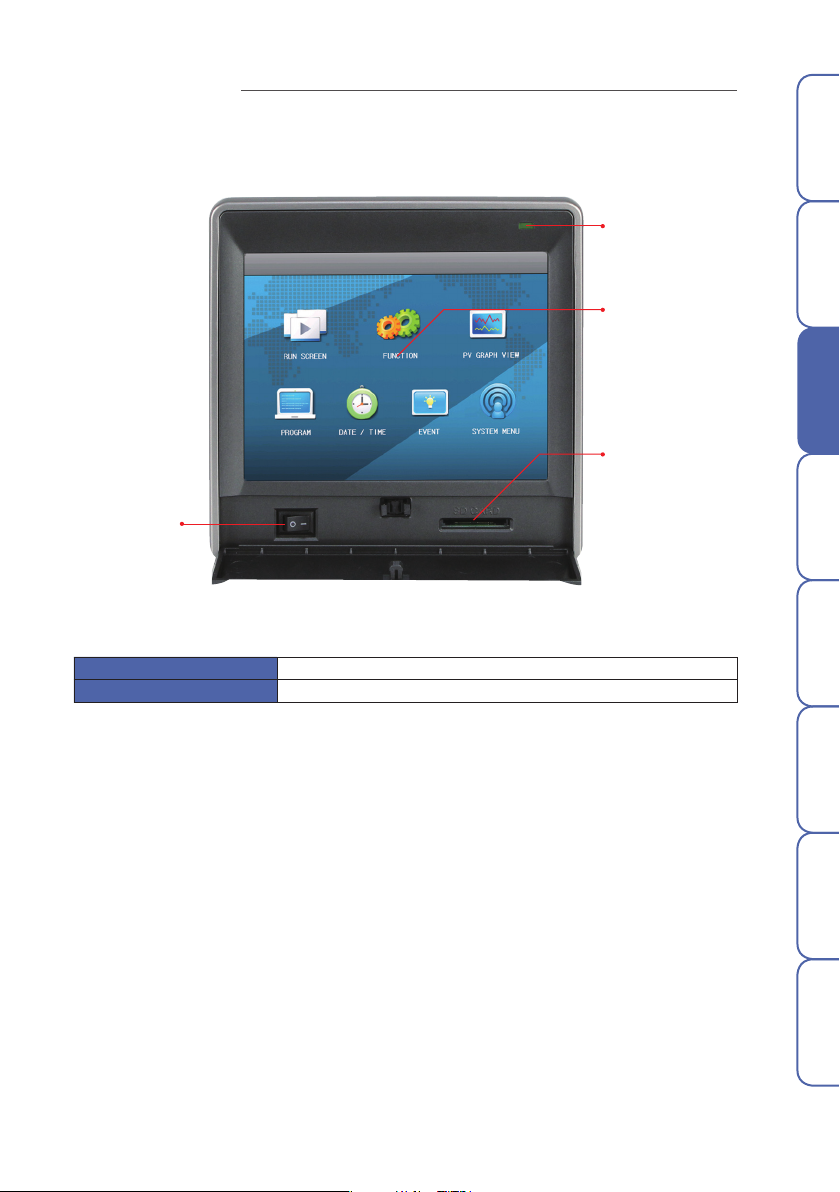

Operation

1. Name of section

Before starting

Power switch

Fig. 5) Main menu

[ Front LED ]

Back light OFF STOP (Red lamp ON), RUN (Red lamp OFF)

Back light ON STOP (Green lamp ON), RUN (Green lamp OFF)

Front LED

Display

SD card slot

Installation

Operation

Screen block

diagram

Function setting Program System setting Specification

13

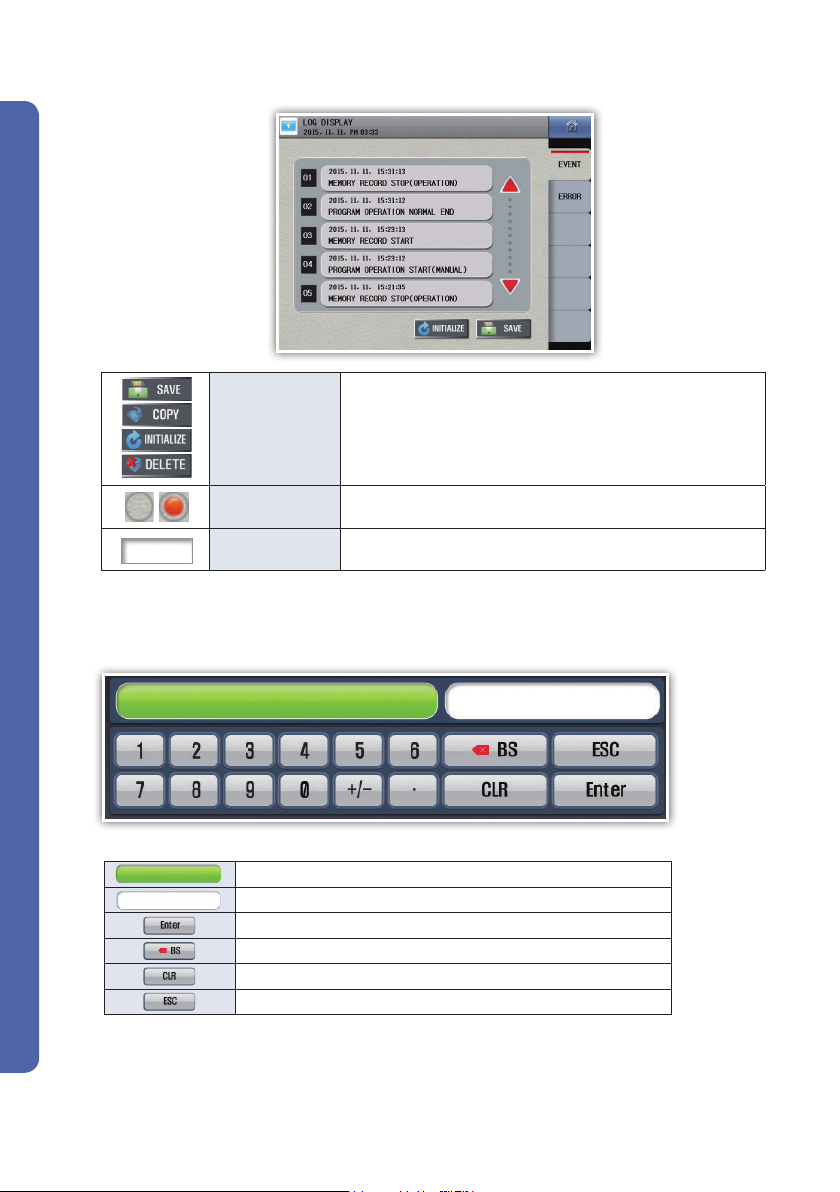

2. Button operation

Run button Runs corresponding operation immediately.

Select button Selects one of items.

Input box

※ If the button is not active or can't be set, it sounds buzzer(beep) and doesn't run.

Displays ansets numbers and characters.

Press it to display the numeric or character input panel.

3. How to control numeric input panel

Programmable Temperature & Humidity Controller

※ If a setting range is exceeded, it sounds buzzer(beep) and doesn't run.

Displays parameter names and setting ranges.

Displays setting values.

Registers setting values.

Remove the last digit of setting value.

Remove the entire setting value.

Cancel setting and hide input panel.

Fig. 6) Numeric input panel

14

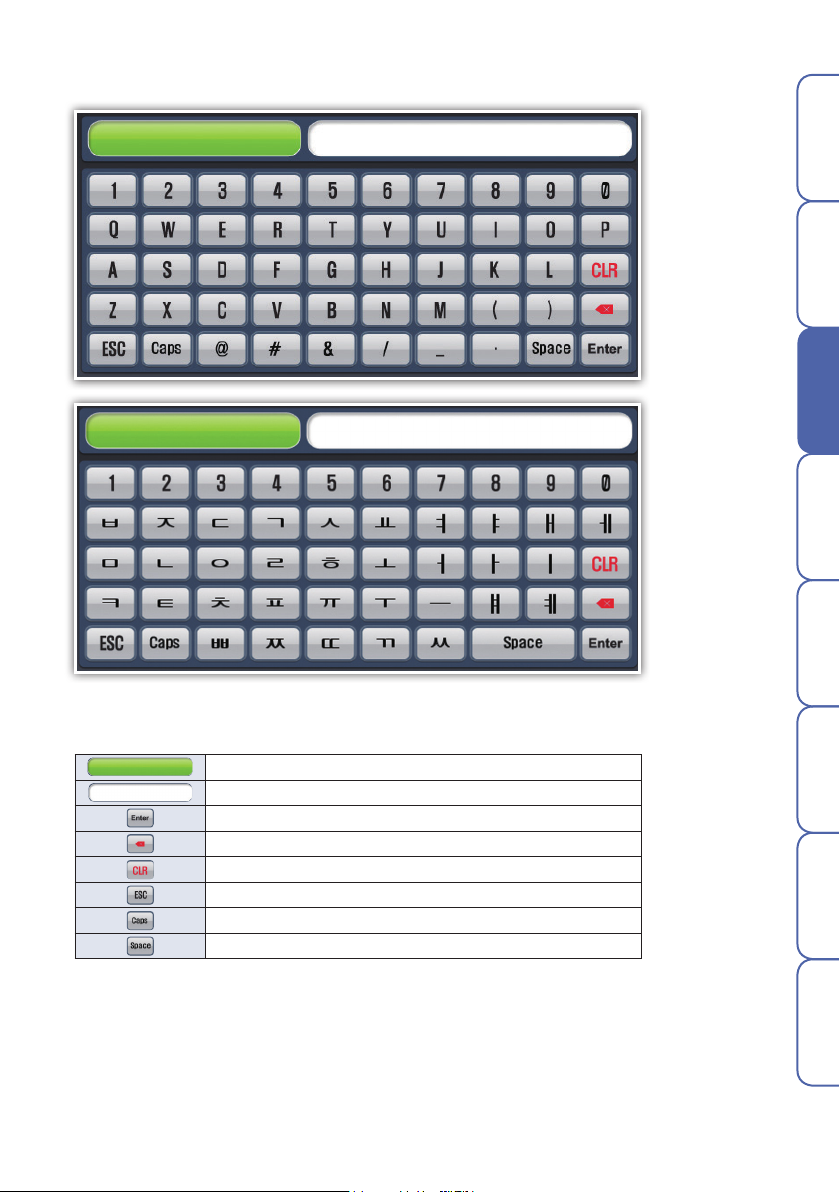

4. How to control character input panel

Before starting

Installation

Operation

Screen block

diagram

Function setting Program System setting Specification

Fig. 7) Character input panel

Displays parameter names.

Displays setting characters.

Registers setting characters.

Remove the last digit of setting characters.

Remove the entire setting value.

Cancel setting and hide input panel.

Switches between Korean and English upper or lower cases.

Blank.

15

5. Name of control

▶ Control module

[ LED specifications ]

RUN Lamp ON with power connected. Lamp OFF with power disconnected.

COM1 Displays communication state of the display and control. (OFF when OK.)

COM2 Displays communication state of the control and I/O. (OFF when OK.)

▶ Input/output module

[ LED specifications ]

PWR Lamp ON with power connected.

RLY1 ~ RLY8 Lamp ON with corresponding DO operation.

Programmable Temperature & Humidity Controller

16

Screen block diagram

1. Screen block diagram

Power ON

Splash

Operation screen1 Operation screen2 Graph view screen

Before starting

Installation

Menu screen

Operation screen

Operation setting

PV graph view

Program

Time/schedule setting

Event

Operation screen1, Operation screen2, and Graph view screen

Operation setting : Constant-value/program, change rate, fuzzy, and channel tag settings

Function setting : Power saving operation, buzzer, recovery of power failure,

operation screen, and switch time settings

Save setting : Save interval, media, and parameter upload/download settings

Graph : Background color and file save name

Saved graph view and copy data from internal memory to SD card

Pattern name

Pattern setting

Edit

pattern

Current time setting and weekly scheduling

Display/Delete event history and save to SD card

Sensor input

Sensor type

calibration

Pattern

management

Copy/Delete

pattern

information

Transmission output

Edit pattern

Control/

transmission output

Control output

setting

name

Pattern alarm

setting

Target,

type, and

parameter

PID setting

PID section

setting at gain

Time signal

setting

Time setting

ON/OFF

Inner signal

Target, type, and

operation range

Pattern

graph

ON/OFF signal

ON/OFF signal

Operation

Screen block

diagram

Function setting Program System setting Specifications

System menu

System alarm

Target and type

DI configuration

Input state,

operation type,

operation method,

and name

DO configuration

Relay No. and

parameter

settings

System

Language, product

specifications,

communication

setting, and memory

17

Function setting

② ③①

⑤④ ⑥ ⑦

Fig. 8) Main menu

No. Name Description

1 Operation screen Go to operation screen[Constant-value/Program].

2 Operation setting Go to operation setting screen.

3 PV graph view Go to saved PV graph screen.

4 Program Go to program setting(pattern setting, graph, etc.) screen.

5 Time/schedule setting Go to current time and schedule setting screen.

6 Event Go to event and error history screen.

7 System menu Go to system setting[sensor input, control output, and PID] screen.

Programmable Temperature & Humidity Controller

18

1. Operation screen

1-1. Constant-value operation screen

1) Constant-value operation 1 screen

- Constant-value/program operation may be changed in [Main menu] - [Operation setting] - [Operation setting].

- Start and end of operation may be run in the operation screen 1 and 2.

▶ Concurrent control

- Concurrent/individual operation may be changed in [Main menu] – [System menu] – [System] – [Memory&Specifications].

- Press Run button in the center left of stop screen of constant-value screen 1 in order to switch to the constant-value

operation 1 operation screen.

②

③ ④

⑦

⑪

⑧

Before starting

Installation

①

⑥

⑤

⑲

⑬

⑫

Fig. 9) Stop screen of constant-value operation screen 1(Concurrent control)

⑭

No. Description

1 Displays state of SD card.

2 Runs hidden menu pane. Click the same to hide menu pane.

3 Go to operation 2 screen.

4 Go to main menu screen.

5 Displays temperature measurement(PV).

6 Displays unit of channel 1.

7 Displays heating control output(H.MV) of channel 1. (For heating/cooling control)

8 Displays cooling control output(C.MV) of channel 1. (For heating/cooling control)

9 Enter target setting value(TSV) for channel 1.

10 Enter current setting value(NSV) for channel 1. (Displayed during operation only).

11 Displays ascending/descending/holding state of channel 1.

12 Displays measurement(PV) of channel 2.

13 Displays unit of channel 2.

14 Displays heating control output(H.MV) of channel 2. (For heating/cooling control)

15 Displays cooling control output(C.MV) of channel 2. (For heating/cooling control)

16 Enter target setting value(TSV) for channel 2.

17 Enter current setting value(NSV) for channel 2. (Displayed during operation only).

18 Displays ascending/descending/holding state of channel 2.

19 Run/stop button.

20 Displays general operation state messages.

21 Displays operation time.

⑱⑳ ㉑

Fig. 10) Operation screen of constant-value operation screen 1(Concurrent control)

⑮

⑨

⑩

⑯

⑰

Operation

Screen block

diagram

Function setting Program System setting Specifications

19

▶ Individual control

Fig. 11) Stop screen of constant-value operation screen 1

(Individual control)

Fig. 12) Operation screen of constant-value operation screen 1

(Individual control)

▶ Menu pane

①

②

③

Fig. 13) Menu pane of constant-value operation screen 1

(Concurrent control)

No. Description

Auto tuning is enabled during constant-value control operation and run with current setting

1

values.

Press User-defined button to run assigned relay in

2

Programmable Temperature & Humidity Controller

[Main menu] – [System menu] – [DO configuration].

3 Go to DI state check screen.

Fig. 14) Menu pane of constant-value operation screen 1

(Individual control)

20

2) Constant-value operation 2 screen

▶ Concurrent control

- Press Run button in the center left of stop screen of constant-value screen 2 in order to switch

to the constant-value operation screen 2 operation screen.

Before starting

①

⑥

⑭

⑤

②

⑦③ ④

⑮

Fig. 15) Stop screen of constant-value operation

⑫

⑪

⑩

Fig. 16) Operation screen of constant-value operation 2(Ch.1)

⑯

⑰

⑧

⑨

⑬

Installation

Operation

Screen block

diagram

Function setting Program System setting Specifications

Fig. 17) Stop screen of constant-value operation 2(Ch.2)

Fig. 18) Operation screen of constant-value operation 2(Ch.2)

21

No. Description

1 Displays state of SD card.

2 Runs hidden menu pane. Click the same to hide menu pane.

3 Go to operation 3 screen.

4 Go to main menu screen.

5 Switch channel (Ch.1 ↔ Ch.2)

6 Displays measurement(PV) of channel.

7 Displays unit of channel.

8 Displays heating control output(H.MV) of channel. (For heating/cooling control)

9 Displays cooling control output(C.MV) of channel. (For heating/cooling control)

10 Enter target setting value(TSV) for channel.

11 Enter current setting value(NSV) for channel. (Displayed during operation only).

12 Displays ascending/descending/holding state of channel.

13 Enter PID No. for channel.

14 Run/stop button.

Indicates input/output signal state.

Press it to display 2nd indicator pane.

15

(Up to 16 in 1 screen so up to 32 in total).

* Indicators of operation screen can be set in

[Main menu] – [System menu] – [System] – [Indicator].

16 Displays general operation state messages.

17 Displays operation time.

No indicator setting.

Set IS1 to indicator.

IS1 disabled.

Set IS1 to indicator.

IS1 enabled.

▶ Individual control

Programmable Temperature & Humidity Controller

Fig. 19) Stop screen of constant-value operation 2(Ch.1)

Fig. 21) Stop screen of constant-value operation 2(Ch.2)

Fig. 20) Operation screen of constant-value operation 2(Ch.1)

Fig. 22) Operation screen of constant-value operation 2(Ch.2)

22

▶ Menu pane

①

Before starting

②

③

Fig. 23) Menu pane of constant-value operation 2 screen(Ch.1)

No. Description

1

Auto tuning is enabled during constant-value control operation and run with current setting values.

Press User-defined button to run assigned relay in

2

[Main menu] – [System menu] – [DO configuration].

3 Go to DI state check screen.

Fig. 24) Menu pane of constant-value operation 2 screen(Ch.2)

3) Constant-value operation 3 screen (Graph view screen)

▶ Common

① ② ③

⑤

④

Installation

Operation

Screen block

diagram

Function setting Program System setting Specifications

Fig. 25) Constant-value operation 3 screen

No. Description

1 Runs hidden menu pane. Click the same to hide menu pane.

2 Go to constant-value operation 1 screen.

3 Go to main menu screen.

4 Displays measurement, setting value, and output of current operation channel in a graph.

5 Set the data display with the check box. Graph is not displayed with OFF selected.

User can set background color(white/black), drawing(line and dot), and line thickness(1 or 2 pixels) of graph.

It can be changed in [Main menu] - [Operation setting] - [Graph].

※ Once the operation is started, the graph is being drawn accordingly. The flow of graph depends on the

save interval.

Fig. 26) Menu pane of constant-value operation 3 screen

23

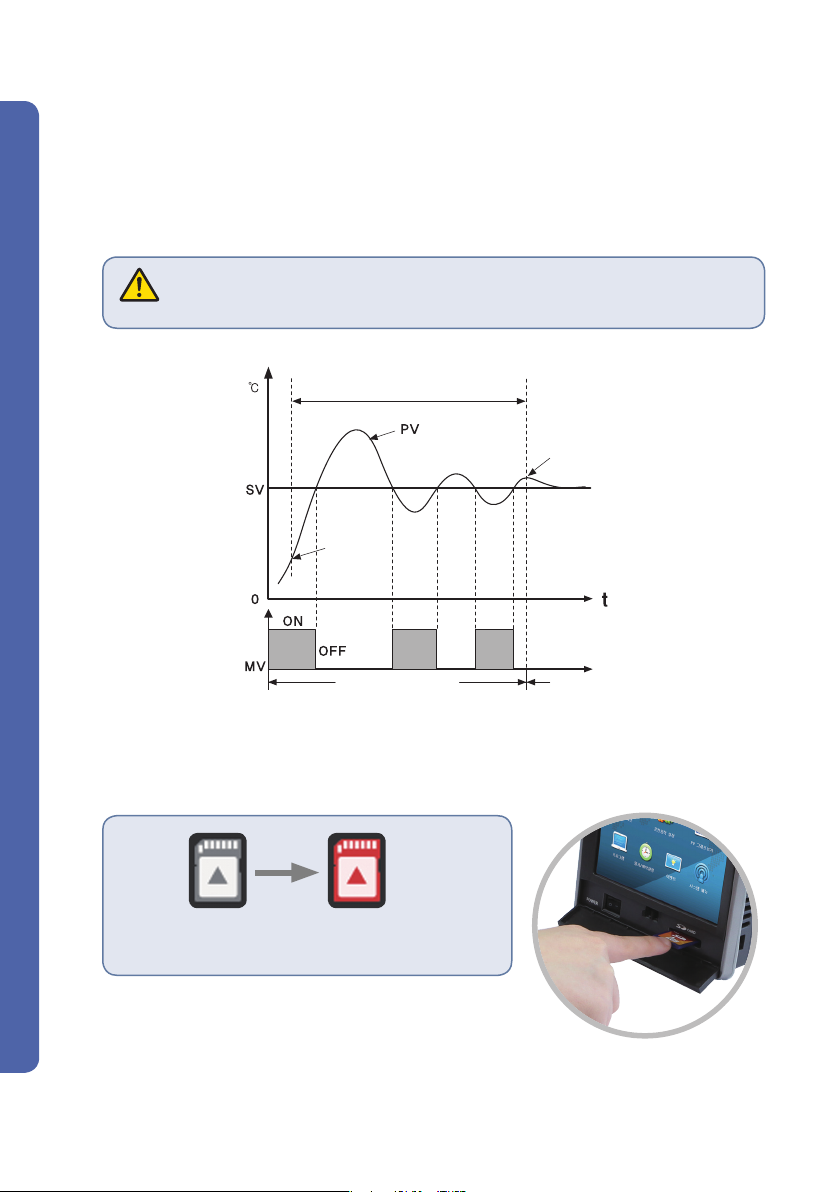

●

How to Auto Tuning

PID auto tuning is a function for the controller to automatically measure characteristics of control target

in order to calculate and set best PID values. Auto tuning gives ON/OFF control output based on the

setting values and calculates PID integer by measuring hunting cycle and amplitude.

Enter setting values(SV) in the constant-value control mode; run; press button pane; and press

temperature or humidity auto tuning button to run auto tuning. With the auto tuning setting, if zone

selection is set to AUTO, the calculated PID value of zone is automatically saved.

If zone selection is set to MANUAL, it is saved to a specified PID zone.

- If the auto tuning is not completed within 24 hours, it is abandoned. However,

the control operation is continued.

Caution

- If the auto tuning is forcibly ended, PID value is maintained same as before the forcible end.

PID auto tuning section

End of AT

Start of AT

ON/OFF operation PID control section

▶ Recording to SD card

Firstly, insert an SD card as shown.

Programmable Temperature & Humidity Controller

· SD card is recognized as shown.

· If the SD card is not recognized, you can't record to it.

24

1-2. Program operation screen

1) Program operation 1 screen

▶ Concurrent control

- Press Run button in the center left of stop screen of program operation screen 1 in order to switch to the

program operation 1 operation screen.

② ⑩

③ ④

①

⑥

⑤

㉑

⑫

⑬

Fig. 27) Stop screen of program operation screen 1

(Concurrent control)

No. Description

1 Displays state of SD card.

2 Runs hidden menu pane. Click the same to hide menu pane.

3 Go to operation 2 screen.

4 Go to main menu screen.

5 Displays measurement(PV) of channel 1.

6 Displays unit of channel 1.

7 Displays heating control output(H.MV) of channel 1.

8 Displays cooling control output(C.MV) of channel 1. (For heating/cooling control)

9 Enter current setting value(NSV) for channel 1. (Displayed during operation only).

10 Displays ascending/descending/holding state of channel 1.

11 Displays tag name of channel 1 (which may be changed with operation setting).

12 Displays measurement(PV) of channel 2.

13 Displays unit of channel 2.

14 Displays heating control output(H.MV) of channel 2.

15 Displays cooling control output(C.MV) of channel 2. (For heating/cooling control)

16 Enter current setting value(NSV) for channel 2. (Displayed during operation only).

17 Displays ascending/descending/holding state of channel 2.

18 Displays tag name of channel 2 (which may be changed with operation setting).

19 Enter pattern No. for operation.

20 Enter seg No. for operation.

21 Run/stop button.

22

Displays general operation state messages.

23 Displays operation time.

⑰

Fig. 28) Operation screen of program operation screen 1

(Concurrent control)

⑪

⑱

㉒ ㉓ ⑮

⑦

⑲

⑧

⑨

⑳

⑭

⑯

Before starting

Installation

Operation

Screen block

diagram

Function setting Program System setting Specifications

25

Loading...

Loading...