HANYOUNG NUX NP200 User Manual

User Manual

NP200

PROGRAMMABLE TEMPERATURE CONTROLLER

This user manual intended for use with NP200 VER: 010

or newer controllers. Please check your model number.

3

TABLE OF CONTENTS

1. Safety Cautions

2. Model Code

3. Wiring

4. Dimensions

5. Input & Output

5-1. Input Signal and Measurement Range

5-2. Output Type

6. Part Name and Functions

6-1. Description of LED Display

6-2. Front Panel Key Functions

6-3. LCD Displays

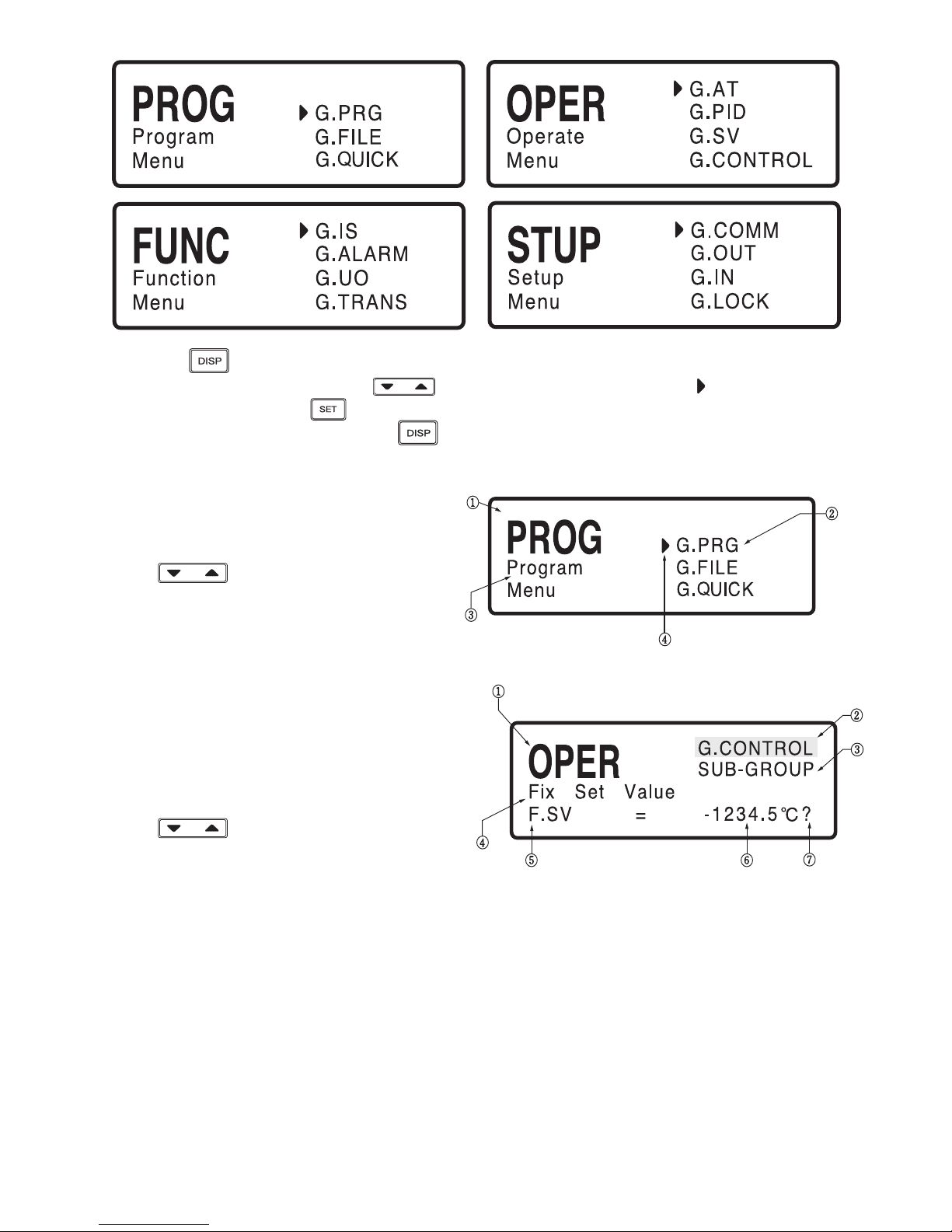

7. Menu Display

8. Setting Guideline

8-1. Program Menu

8-2. Operation Menu

8-3. Function Menu (FUNC)

8-4. Setup Menu

9. Initial Setting Description

9-1.Menu Display

9-2. Setting Example

10. Menu (Group) Setting Description

10-1. Program Menu

10-2. Operation Menu

10-3. Function Menu

10-4. Setting Menu

11. Specification

12. NP200 Communication Map

4

7

7

7

8

8

8

9

9

10

11

16

20

20

22

23

25

27

27

28

35

35

46

53

59

64

68

4

1. Safety Cautions

Alerts declared in the manual are classified to Danger, Warning and Caution by their criticality.

Danger DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury

Warning Warning indicates a potentially hazardous situation, which,

if not avoided, could result in death or serious injury.

Caution Caution used without the safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in minor or moderate injury, property damage.

Danger

Warning

Caution

1. The information in this manual is subject to chage without prior notice.

2. Before using the product you have purchased, check to make sure that it is exactly what you ordered.

3. On receipt of goods, please check for any damage or abnormality that have occurred during shipping

4. Envirionmental Conditions : Operating Temperature Range: 0 to 50 °C

Operating and Storage Humidity: 35 to 85% max. RH non-condensing

5. Do not use this product in the presence of TOXIC, CORROSIVE, FLAMMABLE, and OXIDIZING gases.

6. Do not use this product at any place with direct vibration or impact.

7. Do not use this product in the presence of water, oil, medical substances, moisture, dust, salt or iron contents.

(Use at the Pollution Degree 1~2)

8. Do not use organic solvents such as alcohol or benzene for this prodcts.

The bezel should only be cleaned with a soft cloth and neutral PH detergent.

9. Do not use this product at any place with excessive induction lesion, static electricity or magnetic noise.

10. Do not use this product at any place with possible thermal accumulation due to direct sunlight or heat radiation

11. Install this product at place no higher than 2,000m in altitude.

12. Attach the bractets(2pcs) on the holes of the panel and tighten with a screwdriver.

Fixing torque is about 14.7 N·cm (1.5 kg·cm)

1. If there is a possibility of an accident caused by errors or malfunctions of this product,

install external protection circuit to prevent the accident.

2. This product does not contain an electric switch or fuse, so the user needs to install

a separate electric switch or fuse externally. (Fuse rating : 250 V 0.5A)

3. When setting, “Input type selection number” must be selected in the Group Input(G.In) and also

“Output type selection number” must be selected in the Group Output(G.Out) before moving to other group.

If not, data of other group will be changed to the initial stage.

4. To prevent defection or malfunction of this product, supply proper power voltage in accordance with the rating.

5. To prevent electric shock or devise malfunction of this product, do not supply the power until the wiring is completed.

6. Since this product is not designed with explosion-protective structure, do not use it at any place with

flammable or explosive gas.

7. Do not disassemble, modify, revise or repair this product. This may cause malfunction, electric shock or fire.

8. Installation and removal of this product should be done while the power is off. Or it may cause malfunction or electric shock.

9. If the product is used in a manner not specified by the manufacturer, it may cause injuries or property damages.

10. To avoid an electric shock, the controller is intended to be mounted into an enclosed panel during its operation.

Do not touch or contact the input/output terminals, an electric shock may occur.

Danger

Warning

Caution

5

13. In case of water intrusion, the inspection is required to check the possiblity of electric leakage or fire.

14. Use a compensating cable for connecting thermocouples.

15. The lead wire resistance is small for RTD input use and please use the one which has no resistance

difference to 3 wires.

16. To avoid inductive noise to input wires, seperate from the power and output wires.

17. Keep input wires away from output wires, otherwise using shielded wires recommended.

18. Use non-grounded sensor to R.T.D and thermocouple

19. If there is excessive noise from the power supply, using insulating transformer and

noise filter is recommended. The noise filter must be attached to a panel grounded,

and the wire between the filter output side and power supplyterminal must be as short as possible.

20. It is effective to use a twisted cable for power supply against noise

21. If alarm function is not set correctly, alarm output can not be operated at a trouble.

22. When replacing the sensor, please turn OFF the power supply.

23. Use an extra relay when the frequency of operation is rather high. In this case,

SSR output type is recommended.

•Electromagnetic switch : Proportional cycle time is Min. 20 sec

•SSR : Proportional cycle time is Min. 1 sec

•Contact output life : Mechanically Min.10 million times (no load)

Eletrically Min. 100 thousand times (rated load)

•SSR drive pulse voltage, 4 - 20 mA DC are not insulated with internal circuit

24. The instrument has IP65 protection grade. But to guarantee its grade and specification,

make sure to use rubber seals when installing the instrument to panel.

25. Do not connect anything to the unused terminals.

26. After checking polarity of terminal, connect wires at the correct position.

27.

When the product is installed to a panel, use a circuit breaker or switch in conformity with IEC847-1 or IEC947-3.

28. Switches and circuit breakers should be installed nearby the products for prompt and convenient operation.

29. In case of using swtiches and circuit breakers, please display instruction message on the panel e.g.

"Power is disconnected by operating switches or circuit breaker."

30. For the continuous and safe use of this product, the periodical maintenance is recommended.

31. Some parts of this product have limited life span, and others are changed by their usage.

32. The warranty period is 1 year and limited to the product including parts properly and in normal manner used

.

33. The heater power supply and the instrument power supply should be connected using the same power

supply when using heater break alarm.

34. After the power is on, the preparation time for contact output is required.

In case of use for signals of external interlock circuit, use with a delay relay.

35. After replacing into new products, make sure that all parameter settings are same as the previous products.

6

●

NP200 Series Programmable Temperature Controller

Versatility is a key advantage of NP200 Programmable Temperature

Controller. The following features are incorporated into NP200 to

maximize user benefits. NP200 programs 30 patterns with 300

segments (each pattern can have maximum 99 segments). The

high performance CPU allows great accuracy (+/-0.1%) and

sampling time (100ms). Also, NP200 has multiple inputs (19 types),

multiple outputs (3 types), auto-tuning (2 types), time signal (5),

heat & cooling output, level PID calculation and control, and

emergency output functions. Large back-light display clearly

indicates unit monitored, program running, elapsed time,

temperature, and operation mode.

User Output

The User can set a parameter that activates the desired control output up to 10

(From U1 through U10).

User Output includes:

① Alarm (ALARM 1~4) ② Time signal (TS1~TS5) ③ Inner signal (IS1~IS5)

④ Pattern end (PTEND) ⑤ Program run (RUN) ⑥ Fixed control mode (FIX)

⑦ Reset mode (RST) ⑧ Hold (HOLD) ⑨ Wait (WAIT)

⑩ Output during the manual control (MAN) ⑪ Output during the ascending segment

⑫ Output during the descending segment ⑬ Output during the soak segment

(Be sure that U10 is assigned to Cooling Operation Output,

if a controller is the Heating/Cooling model)

Heating/Cooling PID Control

In program control

Heating/Cooling control outputs the PID operational result in two types of signal, that is, for

heating and for cooling. You can choose either PID control or ON/OFF control for the output

of heating side and cooling side. If you set the proportional value(P) of heating side as 〞

0〟 the ON/OFF control is selected for the heating side, while the fixing of the band(Pc) of

cooling side 〞0〟 chooses the ON/OFF control for cooling side. . Moreover, you can choose

one method among heating side output, cooling side output, relay output, voltage pulse

output and current output and apply the controling function with it.

Universal Input/Output

his controller has two types of auto-tuning as STD(standard type) and LOW

(Low PV type is the value 10% lower than the set value)

2 Type of Auto Tuning Mode

(Standard/Low PV)

This controller has two types of auto-tuning as STD(standard type) and LOW

(Low PV type is the value 10% lower than the set value)

Level PID Operation

The input range is divided into four levels and differnt PID group is applied to each level.

If you choose Level function, the PID group is automatically selected by Level irrespective of PID

number or Set Value Number(SVNO). You can apply different PID data to different range to get

an optimum PID value in wide temperatare range.

● Key Features & Benefits

7

[Unit : mm]

● Dimension

● Panel Cutout

Minimum

Model Number Function

NP200-

Programmable Controller (96 X 96 mm)

Control Type

0

Universal Type

1

Heating/Cooling Type

Option

0

None

1

RS422 / 485 (Communication Function)

2

DI 4 Points(External Signal Input)

3

RS422 / 485(Communication Function), DI 4Points

2. Model Code

3. Wiring

4. Dimensions

※ DI 1~3 Standard, DI 4~7 Option

8

※ Display Range : -5 % ~ +105 % of Above Range *1 : 0 ℃bellow : ±0.2 % of FS ±1digit

*2 : 0 ~ 400 ℃의 range : ±5 % of FS ±2digit

5-2. Output Type

5-1. Input Signal and Measurement Range

5. Input & Output

Input Signal Input Code Range (℃) Accuracy

Thermocouple

K *1 K1 -200.0 ~ 1370.0

±0.10 % of FS

±1digit

K *1 K2 -200.0 ~ 1000.0

J *1 J -200.0 ~ 1200.0

E *1 E -200.0 ~ 1000.0

T *1 T -200.0 ~ 400.0

R R 0 ~ 1700

±0.15 % of FS

±1digit

B *2 B 0 ~ 1800

S S 0 ~ 1700

L *1 L -200.0 ~ 900.0 ±0.1 % of FS ±1digit

N N -200.0 ~ 1300.0 ±0.2 % of FS ±1digit

U *1 U -200.0 ~ 400.0

±0.1 % of FS

±1digit

W W 0 ~ 2300

PlatinelⅡ

Platinel2 0.0

~

1300.0

R.T.D

JPt100 JPT100 -200.0 ~ 500.0

Pt100 PT100 -200.0 ~ 640.0

Direct

Voltage (V)

1 - 5 V 1/5 V

Range of Scalling

SL-L ~ SL-H = -2000 ~ 14000

*When using current input, use a resistor

250 Ω 0.1 % on input terminal (between

No.19 and 20) to convert 4~20mV

0 - 10 V 0/10 V

Direct

Voltage (mV)

-10 - 20 mV -10/20 mV

0 - 100 mV 0/100 mV

Direct 4 - 20 mA d.c. 1/5 V**

Classification

Output(OUT)

(Heating/

Cooling side)

OUT1 OUT2

Relay Output

SSR/SCR(Current Output)

U10

SSR/SCR

(Current Output)

Np200 – 0

(Universal)

RLY (Relay) ON-OFF Control

(U 10) (Retransmission)

SSR SSR OutPut

SCR 4 - 20 mA

RLY (Relay) Relay Output

NP200 – 1

(Heating/

Cooling)

SSR / SSR SSR Output

(U 10) SSR Output

SCR / SSR 4 - 20 mA

Relay / SSR Relay Output (Retransmission)

SSR / SCR SSR Output

(U 10) 4 - 20 mA

SCR / SCR 4 - 20 mA

Relay / SCR Relay Output (Retransmission)

SSR / Relay SSR Output

Relay Output (Retransmission)

SCR / Relay 4 - 20 mA

Relay / Relay Relay Output

9

6-1. LED Displays

6. Part Name and Functions

LED Indication Description

① Lamp This display lights during the ascending ramp segment (UP).

② Lamp

This display lights during the soak segment (SOAK).

③ Lamp This display lights during the descending ramp segment (DOWN).

④ U1~U10 Lamp

This display lights when the User Output (U1~U10) is activated by

the prescribed parameter.

⑤ PRG Lamp This display lights during the temperature control program running (Program run).

⑥ RST Lamp This display lights when the controller operation has been paused through RESET.

⑦ FIX Lamp This display lights when the controller operation is controlled through FIX .

⑧ HOLD Lamp This display lights when the program has been paused through HOLD.

⑨ OUT Lamp

This display lights when the Control Output (OUT-1) is activated.

If output is variable, the display lights proportionally.

⑩ MAN/AT Lamp

This display lights during the manual control (MAN).

If a controller is in AUTO control mode, this display lights when an

auto-tuning (AT) is in-process.

지시치(PV)표시기

LCD 화면

LCD Display

LCD Display

10

6-2. Front Panel Key Functions

- Push the key until you feel pressure.

- Do not push sharp objects (such as pencil) on key. Otherwise, it may cause damage or malfunction.

* You may push the key for one second or longer.

Key Descriptions

⑪ (RUN/HOLD)*

• Used to activate selected Pattern Number.

•

Pressing RUN/HOLD key for at least 1 second activates Segment Hold (pausing).

• Pressing RUN/HOLD key for at least 1 second deactivates

Segment Hold (pausing) and resume operation (RUN).

⑫ (SET)

• Used to input Parameter.

• Used to input Control Mode.

•

Used to verify and bypass Parameter settings when in the parameter Group Display.

• Pressing SET key for at least 3 seconds switches between

the Operating Display and Menu Display.

⑬ (RESET)*

• Pressing REST key after a program runs will reset the controller

to STOP mode and end all programs.

• Pressing REST key after a program runs will reset the controller

RESET mode and end all FIXs.

⑭ (FIX)*

• Used to change Operation mode to FIX mode.

•

Pressing FIX key after a program runs/or in Stop will reset the controller to FIX mode.

⑮ (STEP)*

• Pressing STEP key after a program runs will pause the running segment

and activate next segment.

⑯ (DISPLAY)

• Used to change the Operating Display (LCD: Liquid Crystal Display).

• Used to switch menu display (PROG, OPER, FUNC and STUP).

• Used to return back to the previous display.

⑰

(PTN UP/DOWN)

•Pressing PTN key will change pattern number.

•Pressing SHIFT key will change the digit(s) of Set Value.

⑱ (UP /DOWN )

• Used to change the value of digits when setting parameters.

• Used to move between parameter groups.

• Pressing UP/DOWN key activates Key Speed.

⑲ PV DISPLAY

• This display indicates the Process Value (PV) while a program is running.

• Temperature display range

(Below zero (-) comes in first place of five digit number.)

~

지시치(PV)표시기

LCD 화면

지시값(PV)표시기

LCD 화면

CAUTION

11

6-3. LCD Displays

1) Program Run

2) Fixed Control (FIX)

· Operating display consists of five sub-displays.

· Press for display switching.

① SV : This display indicates the set value that currently is

being monitored and programmed.

② ℃ : This display indicates the temperature unit as below

Direct current (d.c. V) : temperature unit of U.UNIT.

Thermocouple or RTD : temperature unit of UNIT.

③ PT

: This display indicates the pattern number.

④ SEGNO :

This display indicates the running segment (Now SEG) and total number of programmed segments (Total SEG).

⑤ TIME

:

This display indicates the remaining time of running segment (hr./Min.:**h** or Min./Sec.:**m**).

⑥ REPEAT : This display indicates the number(s) of repeated and total number of repeats (Now Repeat / Total Repeat).

If Total Repeat is Continue or Now Repeat exceeds 99, the display indicates [∞].

① SV: This display indicates the set value that currently is being monitored and programmed.

② ℃: This display indicates the temperature unit as below:

Direct current (d.c. V): temperature unit of U.UNIT;

Thermocouple or RTD: temperature unit of UNIT.

③ ? : This display blink "?" when SV is changed by pressing key during the FIX mode.

●

Operating Display

●

Set Value (SV) Display

[Heating model: SV Display at Fix Mode] [Heating/Cooling model, SV Display at Fix Mode]

12

1) OUT : This display indicates the output value of Heating model.

2) HEAT OUT : This display indicates the heating output value of Heating/Cooling model.

COOL OUT : This display indicates the cooling output value of Heating/Cooling model.

3) SV : This display indicates the set value that currently being monitored and programed during PROG or FIX Mode.

This display indicates the minimum value of setting range during RESET mode.

4) PID : This display indicates PID GROUP number that currently being controlled.

5) AUTO/MAN : This display indicates the output mode that currently being monitored. Use key to change

the required output mode during manual (MAN) mode.

3) Reset

1) Auto Mode, Heating model

2) Auto Mode, Heating/Cooling model

3) Manual Mode, Heating model 4) Manual Mode, Heating/Cooling model

① SV : This display indicates the minimum value

of setting range.

② ℃ : This display indicates the current temperature unit.

③ PT : This display indicate the current Pattern

(Use key to change the required pattern type)

④ SEGNO : This display indicate total number of programmed

segments and END.SEG of the current pattern. (END.SEG / Total SEG)

※ Total SEG and END.SEG

•If the latest programmed SEG is larger than ENG.SEG, Total SEG displays END.SEG.

•If END.SEG is same to/or larger than the latest SEG, Total SEG displays the latest programmed SEG.

【Ex. 1】 If 10SEGs are programmed while END.SEG is 8SEG, then Total SEG is 8SEG.

【Ex. 2】 If 5SEGs are programmed while END.SEG is 7SEG, then Total SEG is 5SEG.

【Ex. 3】 If 5SEGs are programmed while END.SEG is OFF, Total SEG is 5SEG.

●

Output (OUT) Display

지시치(PV)표시기

LCD 화면

지시값(PV)표시기

LCD 화면

13

1) SV of selected pattern number (on Display-1: setup)

is shown in the graphic image as below.

2) Maximum 9 segments are displayed.

The current segment is indicated in bold-black bar on x-axis.

However, above bold-black bar disappears during the Fixed

Control or Reset Mode.

3) Use key to change the required segment from 1 through 9.

4) P** indicates the pattern number that currently being selected (FIX, RESET) or operated (PROG).

5) S** indicates the segment number that currently being operated. However, S- - presents during the Fixed Control or Reset Mode.

6) 01 indicates the first segment number among others that currently being displayed.

7) indicates the graph that is not currently being displayed( : right, : left, : both).

8) Vertical bar ① indicates END.SEG.

●

Graph Display

1) User Output display indicates programmed parameters from 1 through 10.

2) The current User Output Number is heightened.

For instance, above display shows Pattern End Signal is being generated and User Output 8 is being activated.

3) Programmable User Output Display parameters are as below:

●

User Output Display

•U1 is Inner Signal 1 • U7 is Alarm 3

•U2 is Inner Signal 2 • U8 is Pattern End Signal

• U3 is Time Signal 1 • U9 is Pattern Up Signal

• U4 is Time Signal 2

• U5 is Alarm 1 • U10 is inactive.

• U6 is Alarm 2

【Display below means:】

• OFF : “ ---- ”

• Alarm 1 ~ 4 : “ALM1” ~ “ALM4”

• Time Signal 1 ~ 5 : “TS1” ~ “TS5”

• Inner Signal 1 ~ 5 : “IS1” ~ “IS5”

• Pattern End Signal : “END”

• Pattern Up Signal : “UP”

• Pattern Down Signal : “DOWN”

• Pattern Soak Signal : “SOAK”

• Program Run : “PROG”

• Fix Run : “FIX”

• Reset : “RST”

• Hold : “HOLD”

• Wait : “WAIT”

14

1) uto (AUTO) Output 2) Manual (MAN) Output

1) Menu displayed on LCD screen consists of groups and sub-groups as blow:

●

Auto & Manual Display

●

Power-On Display

●

Menu Display

① AUTO » MAN indicates that the current output mode is AUTO, MAN » AUTO indicates that the current

output mode is MANUAL.

② If AUTO/MAN is locked, this display is inactive .

※ For instance, if current output mode is AUTO and pressing key will change from output mode to MANUAL

and MAN » AUTO will be displayed.

1) PV Display

D1 D2 D3 D4 D5

2) SV Display

① Characters shown in D1 ~ D3 indicate NP200 model.

② Character show in D4 indicates temperature controller

type (0: Heating; 1: Heating/Cooling)

③ Character show in D5 indicates additional

information of temperature controller

(0: none, 1: Communication,2 : Four Digital Inputs,

3: Communication/Four Digital Inputs)

① Characters in top-left indicate NP200 model,

controller type and additional information.

② Character in bottom indicates Version number.

Menu Group Sub-group

PROG (Program)

G.PRG (Program Group)

G.FILE (File Group)

G.QUICK (Quick Menu Group)

INFORM (Pattern/Segment Information)

PT.EDIT (Pattern Edit)

SEG.EDIT (Segment Edit)

OPER (Operation)

G.AT (Auto-Tuning Group)

G.PID (PID Group)

G.SV (Set-up Group)

G.CONTROL (Control Group)

-

FUNC (Function)

G.IS (Inner Signal)

G.ALARM (Alarm Group)

G.UO (User Output Group)

G.TRANS (Transfer Group)

-

STUP (Set-up)

G.COMM (Communication group)

G.OUT (Output group)

G.IN (Input Group)

G.LOCK (Locking group)

-

15

① Pressing key will alter Menu displays.

② Sub-groups are displayed on left. Use key to change the required sub-group ( indicates the selected

Sub-Group Menu). Pressing key will confirm the selected sub-group.

③ For returning back to Menu display, press key.

2) Menu Display Parameters

3) Group Display Parameters

① This display indicates the Menu name.

② This display indicates the Group name.

③ This display indicates the full name of Menu.

④ Use key to change the required

sub-group.

① This display indicates the Menu name

② This display indicates the Group name.

③ This display indicates the Sub-Group .

④ This display indicates the full name of Parameter.

⑤ This display indicates the Parameter name.

⑥ This display indicates the Parameter value.

⑦

Use key to change the Parameter value.

?-display blinks when the Parameter value is changed.

16

QUICK

1) Operation screen

AT.M

AT ALPHA

PIDSL

ARW SVNO LEVEL

SV1 TIME

SV2

END TIME

SV3 DI

SV4

PWR.MD

1.P 2.P 3.P 4.P

PLDSL=1 PLDSL=2 PLDSL=3 PLDSL=4

1.I 2.I 3.I 4.I

1.D 2.D 3.D 4.D

1.MR 2.MR 3.M 4.MR

1.Pc 2.Pc 3.Pc 4.Pc

1.Ic 2.Ic 3.Ic 4.Ic

1.Dc 2.Dc 3.Dc 4.Dc

1.DB 2.DB 3.DB 4.DB

1.LVL 2.LVL LVLD

b

a

c

k

s

i

d

e

* 5th operation screen

would not be displayed

when LOCK A/M=0.

SV screen

OUT screen

GRAPH screen

USER OUT screen

AUTO/MAN

Power ON

3 s

7. Menu Display

2) Menu screen

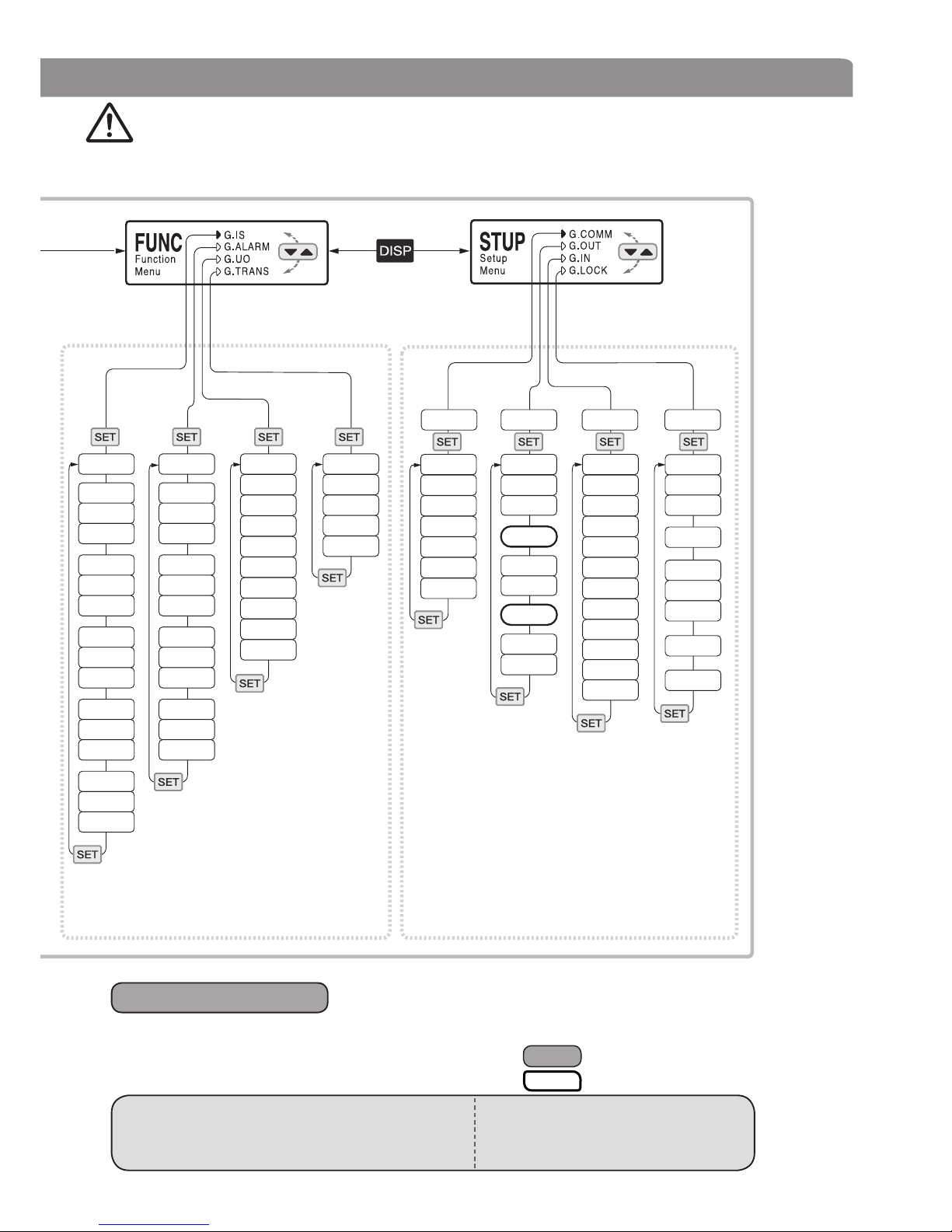

Caution

Prior to the other group settings, “Input Group (G.IN)”, then “Output

Group (G.OUT)” should be set firstly.

If other groups are set before Input group or Output group setting, the

value should be changed according to the Input / Output setting value.

17

IS.MD AL.MD U1

U4

U7

U2

U5

U8

U3

U6

U9

U10

IS1

IS2

IS3

IS4

IS5

A1TY

A2TY

A3TY

A4TY

TRANS

PWD PWD

OUT

HYS

OL-H

PR-S INP

STP FR-H

RJC

RP.T SL-H

B.OUT

▽/△

PROG

O.ACT

HEO

P.INIT

OL-L

BPS UNIT

DLN FR-L

FILT

PT.NO

OPER

HCT

CCT

CEO

PRI U.UNIT

SL-L

ADR DP-P

BIAS

RUN

FUNC

PWD.C

A/M

PWD PWD

ADJ.H

IS1H

IS2H

IS3H

IS4H

IS5H

A1DB

A2DB

A3DB

A4DB

TRANS.H

ADJ.L

IS1L

IS2L

IS3L

IS4L

IS5L

AL-1

AL-2

A3-3

AL-4

TRANS.L

●Menu Setting Screen

- Menu setting is recommended after program operation is off.

- It is to prevent setting value changed according to a certain set-up parameter setting.

- Some parameter may not indicated due to its mode & additional specification of controller,

control type selection etc.

The controller starts from the same operating mode as

when the device was OFF. But if the device was in

program mode, will follow ST.MD

: OPTION

: H/C TYPE시

• AUTO operation MODE : Starts control from HEO set value

• MAN operation MODE : Starts control from

HEO set value

* : In ON/OFF (OUT=0) control SKIP

In MAN control, AT GROUP is

● When power is ON

CAUTIION

*

*

*

*

18

SV screen

OUT - screen

GRAPH screen

USER OUT screen

AUTO/MAN screen

Power ON

3 s

3 s

1~30

0~99

SEG.NO=0 SEG.NO=1 SEG.NO=2

SEG.NO=99

PT.NO

SEG.NO

WZ 1.PID 2.PID 99.PID

1.ALM 2.ALM

99.ALM

1.SV 2.SV 99.SV

1.TM 2.TM 99.TM

1.TS1 2.TS1 99.TS1

1.TS1 ON 2.TS1 ON 99.TS1 ON

1.TS2 ON 2.TS2 ON 99.TS2 ON

1.TS3 ON 2.TS3 ON 99.TS3 ON

1.TS4 ON 2.TS4 ON 99.TS4 ON

1.TS5 ON 2.TS5 ON 99.TS5 ON

1.TS1 OFF 2.TS1 OFF

99.TS1 OFF

1.TS2 OFF 2.TS2 OFF

99.TS2 OFF

1.TS3 OFF 2.TS3 OFF

99.TS3 OFF

1.TS4 OFF 2.TS4 OFF

99.TS4 OFF

1.TS5 OFF 2.TS5 OFF

99.TS5 OFF

1.TS2 2.TS2 99.TS2

1.TS3 2.TS3 99.TS3

1.TS4 2.TS4 99.TS4

1.TS5 1.TS5 99.TS5

REPEAT

TS.MD

ST.SV

END.SEG

END.MD

END.TM

END.PT

WTM

ST.MD

1) Operation screen

* 5th operation screen

would not be displayed

when LOCK A/M=0.

2) menu screen

19

INFORM PT.EDIT SEG.EDIT

PT.NO

USE

G.PRG

G.FIL

G.AT

G.PID

G.SV

G.CTRL

G.IS

G.ALARM

G.UO

G.TRANS

G.COMM

G.OUT

G.IN

G.LOCK

INSERT

DELETE

COPY S

USED/

TOTAL

Pattern

USED/

TOTAL

Segment

USED

Segment

by Pattern

PT.n

COPY D

DELETE

F.INIT

*1

Starts operation from operation mode before Power off. But in program mode,

operation will be followed by ST.MD.

*If you ON USE menu, display will be

changed as below (Group will be

display only ON menu).

*

● Operation when Power ON

• AUTO operation MODE: Starts from HEO set value

•

MAN operation MODE: Starts from HEO set value

*1 PATTERN number selection (1~3)

by Keys with DIRECT ENTRY

20

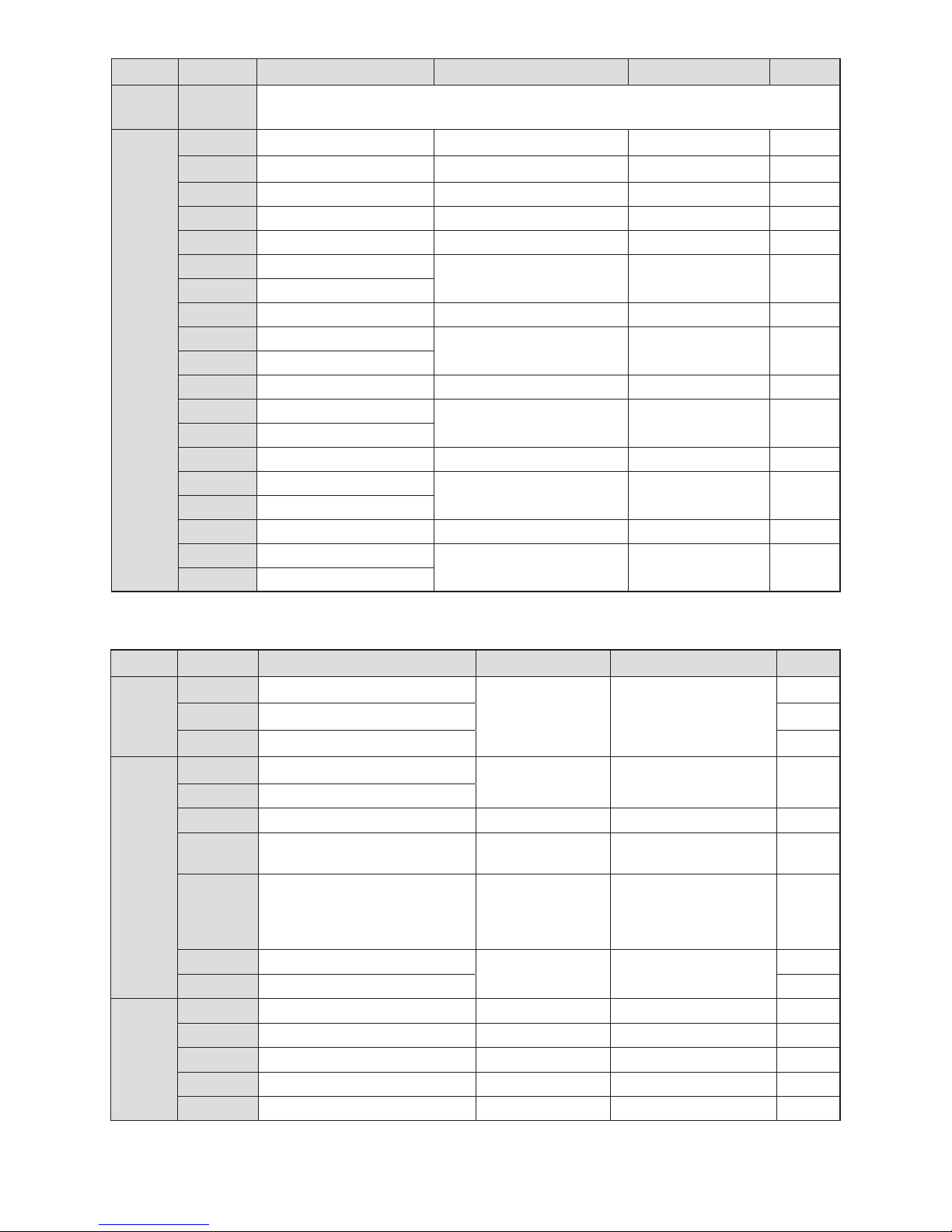

8. Setting Guidline

CAUTION

Prior to the other group settings, “Input Group (G.IN)”,

then “Output Group (G.OUT)” should be set firstly.

If other groups are set before Input group or Output group setting, the value should

be changed according to the Input / Output setting value.

8-1. Program Menu(PROG)

●

Program Group (G.PRG)

Classification

Signal Parameter Set-up range Display Condition Default

Entry

PT.NO Pattern Number Selector 1 ~ 30

Always

1

SEG.NO Segment Number Selector

0 ~ 99 0

WZ Wait Zone

OFF, 0 ~ 10 % (EUS) OFF

WTM Wait Time

OFF, 0.01 ~ 99.59 (TIME) OFF

REPEAT Repeat Set

CONTINUE / 1 ~ 99 1

TS.MD Time Signal Mode NONE, ON/OFF1~5, TIME1~5 ON/OFF1

ST.SV Start Set Value

0 ~ 100 % (EU) EU (0 %)

ST.MD Start Mode

SSV, PV1, PV2 SSV

END.SEG Pattern End Segment

OFF, 1 ~ 99

OFF

END.MD Pattern End Mode

RESET, HOLD, FIX, LINK RESET

END.TM End Signal Time

OFF, 0.01 ~ 99.59 (TIME) OFF

LINK.PT Link Pattern

1 ~ 30

END.MD = LINK 1

01. PID 01. PID NO. Select

1 ~ 4 Always 1

01. ALM 01. ALM NO.Select

OFF, 1 ~ 15 Always OFF

01. SV 01. Set Value

0 ~100 % (EU)

Always

EU (0 %)

01. TM 01. Segment Time

OFF, 0.00 ~ 99.59 (TIME) OFF

01. TS1 Time Signal 1

OFF, ON Always OFF

TS1 ON 01. TS1 on Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

1.TS1 = ON

00.00

TS1 OFF 01. TS1 OFF Time

01. TS2 Time Signal 2

OFF, ON Always OFF

TS2 ON 01. TS2 on Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

1.TS2 = ON

00.00

TS2 OFF 01. TS2 OFF Time

01. TS3 Time Signal 3

OFF, ON Always OFF

TS3 ON 01. TS3 on Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

1.TS3 = ON

00.00

TS3 OFF 01. TS3 OFF Time

01. TS4 Time Signal 4

OFF, ON Always OFF

TS4 ON 01. TS4 on Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

1.TS4 = ON

00.00

TS4 OFF 01. TS4 OFF Time

01. TS5 Time Signal 5

OFF, ON Always OFF

TS5 ON 01. TS5 on Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

1.TS5 = ON

00.00

TS5 OFF 01. TS5 OFF Time

SEG. NO = 0SEG. NO = 1

21

Classification

Signal Parameter Setting range Display condition Default

INFORM

Pattern USED / TOTAL (30)

DISPLAY ONLY Always

0 / 30

Segment USED / TOTAL (300)

0 / 300

PT. n Used Segment by Pattern

0 / 0

PT. EDIT

COPY. S Copy Source

OFF / 1 ~ 30

Pattern

Always

COPY. S ≠ OFF

OFF

COPY. D Copy Destination

RESULT Result of File

– COPY. S = 1 ~ 30 -

DELETE Delete Pattern Number OFF / 1 ~ 30

Pattern

COPY. D = 1 ~ 30 OFF

RESULT Result of File CMD –

COPY. S = 1 ~ 30

COPY. D = 1 ~ 30

DELETE = 1 ~ 30

-

F.INIT File All Initialize

(Program initializing)

NO, YES Always

OFF

CONFIRM Really File Init ?

ON

SEG.

EDIT

PT. NO Pattern Number Select

1 ~ 30 Pattern Always 1

INSERT Insert Segment Number

OFF / 1 ~ 99 seg PT.NO = 1 ~ 30 OFF

RESULT Result of File CMD

- INSERT = 1 ~ 98 -

DELETE Delete Segment Number

OFF / 1 ~ 99 seg Always OFF

RESULT Result of File CMD

– DELETE = 1 ~ 99 -

Classification

Signal Parameter Set-up range Display Condition Default

SEG. NO

= 2~98

99. PID PID NO. Select

1 ~ 4 PID control level=OFF 1

99.ALM ALM NO.Select

OFF, 1~15 Always OFF

99. SV Set Value 1 0 ~ 100 % (EU) Always EU (0 %)

99. TM Segment Time 1 OFF, 0.00 ~ 99.59 (TIME) Always OFF

99. TS1 Time Signal 1 OFF, ON Always OFF

TS1 ON TS1 ON Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

99.TS1 = ON

00.00

TS1 OFF TS1 OFF Time

99. TS2 Time Signal 2 OFF, ON Always OFF

TS2 ON TS2 ON Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

99.TS2 = ON

00.00

TS2 OFF TS2 OFF Time

99. TS3 Time Signal 3 OFF, ON Always OFF

TS3 ON TS3 ON Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

99.TS3 = ON

00.00

TS3 OFF TS3 OFF Time

99. TS4 Time Signal 4 OFF, ON Always OFF

TS4 ON TS4 ON Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

99.TS4 = ON

00.00

TS4 OFF TS4 OFF Time

99. TS5 Time Signal 5 OFF, ON Always OFF

TS5 ON TS5 ON Time

00.00 ~ 99.59 (TIME)

TS.MD = Time

99.TS5 = ON

00.00

TS5 OFF TS5 OFF Time

SEG. NO = 99

●

File Group (G.FILE)

22

Menu

Code

Parameter Setting Range Display Condition

Default

Value

G.QUICK

USE Quick menu use or not

OFF / ON Always

OFF

G.PRG

PRG Group use or not

ON

G.FILE FILE Group use or not

G.AT

AT Group use or not

G.PID

PID Group use or not

G.SV SV Group use or not

G.CTRL CTRL Group use or not

G.IS IS Group use or not

G.ALARM ALARM Group use or not

G.UO UO Group use or not

G.TRANS TRANS Group use or not

G.COMM COMM Group use or not

G.OUT OUT Group use or not

G.IN IN Group use or not

G.LOCK LOCK Group use or not

Menu Code Parameter Setting Range Display Condition

Default

Value

AT. MD Auto Tuning Mode Selection STD, LOW *1 AUTO & PID STD

AT Auto Tuning OFF, ON, Auto (*2) AUTO & PID제어시 OFF

8-2. Operating Menu (OPER)

●

Auto tuning Group (G.AT) : Only display when program operation status

●

PID Group (G.PID)

✽1 ; Low : Auto Tuning Starts as -10% of SV ✽2 Auto is displayed when LEVEL=ON in Control Group

Menu Code Parameter Setting Range

Display

Condition

Default

Value

ARW Anti - Reset Wind up AUTO, 50.0 ~ 200.0 % PID Control 50.0

ALPHA Alpha 0 ~ 100 PID Control 50

PIDSL PID Group Select

0 ~ 4 (Set 1 ~ 4 to move to next parameter

) PID Control 0

n.P Proportional band 0.1 (H/C Type : 0.0) ~ 999.9 % PID Control 5.0 %

n.I Integral time

OFF / 1 ~ 6000 s (Sec.) PID Control

240 s

n.D Derivative time 60 s

n.MR Manual reset -0.5 ~ 105.0 % (%) I = OFF 50.0%

n.Pc

Proportional band of cooling side

0.0 (ON/OFF control) / 0.1 ~ 999.9 %

HC TYPE

5.0 %

n.Ic Integral time of cooling side OFF / 1 ~ 6000 s 240 s

n.Dc

Derivative time of cooling side

OFF / 1 ~ 6000 s 60 s

n.DB

Dead band of Heating-Cooling side

-100.0 ~ 50.0 % 3.0 %

n.LVL PID Level n

EU (0) ≤ 1.LVL ≤ 2.LVL ≤ EU (100 %) (EU)

LEVEL = ON EU (100%)

LVLD Reference DEV OFF / EUS (0 ~ 100 %) (EU) LEVEL = ON EUS (0.5%)

●

Quick Menu Group (G.QUICK)

● Using of Auto Tuning

- Please do not use Auto Tuning as following controls

- Quick response controller such as flow control and press control

- Controller output should not be ON /OFF even for a short time.

- Controller should not have big load to the control part

- Fluctuation of set value gives bad effect on product quality

Caution

23

Menu Code Parameter Setting Range

Display

Condition

Default Value

FIX SV

SVNO Set Value NO, Select 1 ~ 4 Always 1

SV1 Set Value 1

EU (0 ~ 100 %) (EU) Always EU (0 %)

SV2 Set Value 2

SV3 Set Value 3

SV4 Set Value 4

Menu Code Parameter Setting Range

Display

Condition

Default Value

LEVEL Level PID OFF, ON PID OFF

TIME Time Unit HH:MM, MM:SS Always HH.MM

END.TM Time Unit HH:MM, MM:SS Always HH.MM

DI Digital Input Enable OFF / ON DI OPTION시 OFF

PWR. MD Power ON Mode HOT, COOL Always COOL

Menu Code Parameter Setting Range

Display

Condition

Default Value

IS.MD Inner Signal Mode TSV, NSV, PV

Always

TSV

IS1

IS1 Inner Signal 1 OFF, ON OFF

IS1H Inner Signal 1 High IS1L + 1digit + EU (100 %)

IS1 = ON

EU (100 %)

IS1L Inner Signal 1 Low EU (0 %) ~ IS1H - 1digit EU (0 %)

IS2

IS2 Inner Signal 2 OFF, ON Always OFF

IS2H Inner Signal 2 High IS2L + 1digit + EU (100 %)

IS2 = ON

EU (100 %)

IS2L Inner Signal 2 Low EU (0 %) ~ IS2H - 1digit EU (0 %)

IS3

IS3 Inner Signal 3 OFF, ON Always OFF

IS3H Inner Signal 3 High IS3L + 1digit + EU (100 %)

IS3 = ON

EU (100 %)

IS3L Inner Signal 3 Low EU (0 %)~ IS3H - 1digit EU (0 %)

IS4

IS4 Inner Signal 4 OFF, ON Always OFF

IS4H Inner Signal 4 High IS4L + 1digit + EU (100 %)

IS4 = ON

EU (100 %)

IS4L Inner Signal 4 Low EU (0 %) ~ IS4H - 1digit EU (0 %)

IS5

IS5 Inner Signal 5 OFF, ON Always OFF

IS5H Inner Signal 5 High IS5L + 1digit + EU (100 %)

IS5 = ON

EU (100 %)

IS5L Inner Signal 5 Low EU (0 %) ~ IS5H - 1digit EUS (0 %)

●

Set Value Group (G.SV)

●

Control Group (G.CONTROL)

8-3. Function Menu (FUNC)

●

Inner Signal Group (G.IS)

Loading...

Loading...