ABOUT THIS MANUAL

Thank you very much for purchasing HANYOUN NUX product.

This instruction manual includes details of product functionality, installation method,

cautions, usage, and others. Read and be fully aware of contents before use of product.

Also, provide this manual in order for end user use, and at easily accessible place

anytime.

* Contents of this manual are subject to change without prior notice.

* For questions, and errors regarding contents of this manual,

contact our company or business offices.

* Unpermitted reprinting and duplication of all or part of contents of

this manual are strictly prohibited.

■Services (A/S)

* For A/S request of this company’s product, please contact outlets,

sales office nearby or head office of our company.

* If you like onsite visit service, please send the request after speaking

Multi Loop Controller

with A/S Center personnel on the phone.

* Prior to sending request, please check if questions and answers for the same

problems are posted in the FAQ section of homepage.

HANYOUNG NUX

28, 71Beon-gil, Gilpa-ro, Nam-gu, Incheon, 402-205, Korea

TEL : (032)867-0941 (main phone line)

FAX : (032) 868-5899

URL : http://www.hynux.com

E-mail : sdt@hynux.com

TABLE OF CONTENTS

1. Before starting

2. Installation

3. Run

4. Specifications

1.1. Overview

1.2. Product verification

1.3. Safety cautions

2.1. Installation location and cautions

2.2 Exterior dimensions of product

2.3 Connection diagram 8

2.4 Power supply and communications interface(RS485/RS232C)

2.5 Event output unit connections

3.1 Protocol composition

3.2 Register composition

3.2.1 ML-D2H register composition

3.2.2 ML-D2H register description

3.2.3 ML-D4의 register composition

3.2.4 ML-D4 register description

3.3 Manipulation and working

3.3.1 Input section

3.3.2 Control section

3.3.3 Event section

3.3.4 Status indication and set up

3.3.5 Warning occurrence and handling

11

12

18

18

20

25

27

32

32

34

40

44

47

48

2

Before staring Installation Operation Specifications

2

4

5

6

9

1

1. BEFORE STARTING

1.1 Overview

■ML Series product family

Multi-channel temperature control system (ML-D, ML-D2H), event output (ML-E)

■ Module composition method (Individual product is called “Unit”)

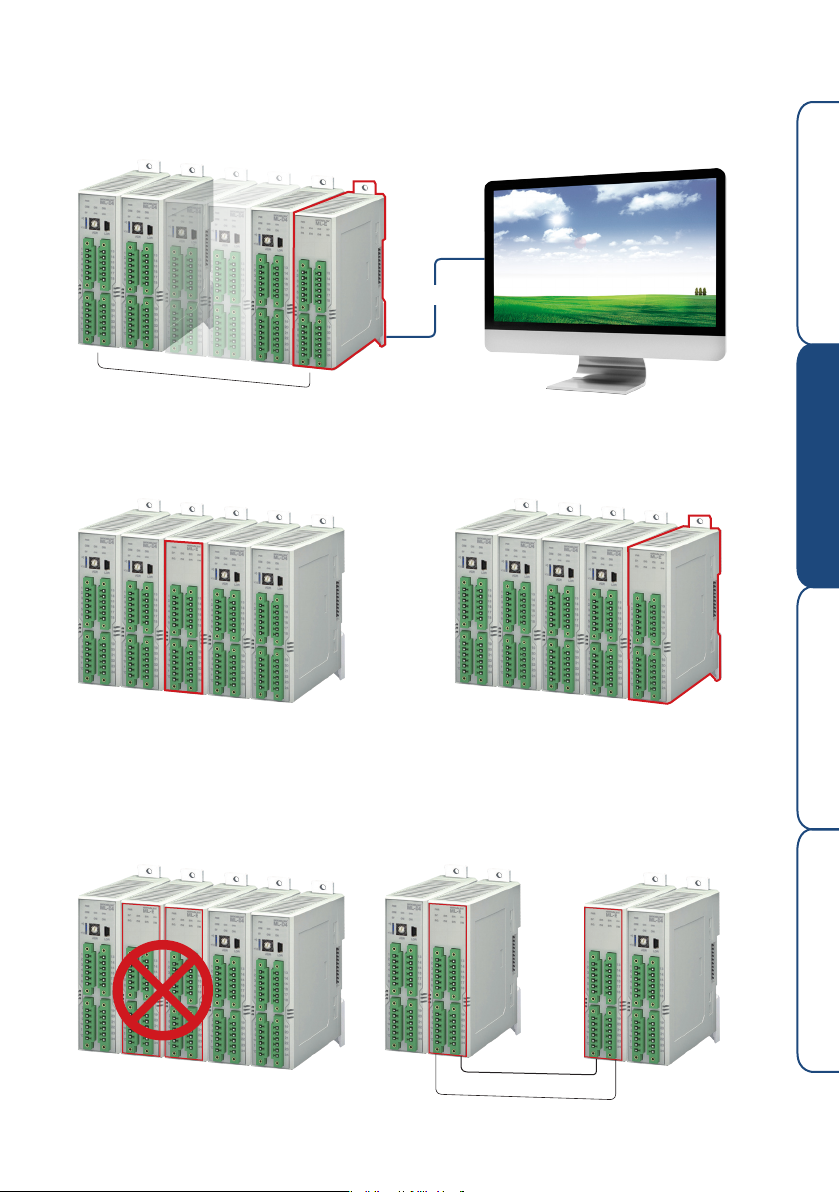

ML Series products can be made up as one module by connecting maximum of 31 units without wiring

work, and only one Unit is connected to power cable and communications line (RS485). Event output

(ML-E) is not included in maximum connection quantity, and only one Unit is connected during module

composition and used.

■ Product run through communications connection

For RS232C and RS485 communications method, this product supports PC-Link, PC-Link with SUM,

Modbus, ASCII/RTU protocols. Through individual communication with product, it is operated with

reading/writing of Register address defined based on function. Basic functions such as control and

monitoring can be tested or operated using operating program provided in the computer.

RS485 communications : For use, connect to communications terminal at low part, and this standard is

used when operating multiple units since communications are achieved only

through address set as switch in front side.

RS232C communications : For use, connect to Loader Jack at front part, and only connected unit is

communicated regardless of front side switch setup. It is for unit’s initial setting.

■ Input type

Thermocouple (12 types) : K, J, E, T, R, B, S, L, N, U, W, PL2

RTD (2 types) : Pt100, KPt100

DC voltage (3 types) : 0 – 10 V, 1 -5 V, 0 – 100 mV

Direct current (4 – 20 mA) : Set input type as direct current (1 -5 V), attach 250 Ω of electric resistance

at both ends of input terminal

Current Transformer (CT) : 2 channel, AC 1 – 50A (primary current measuring range), apply only to ML-D2H

■ Control output type

Depending on output type of model composition, fixed in one among REALY, voltage pulse (SSR), and

Multi Loop Controller

current output (SCR).

■ Control method

2 DOF (Degree of Freedom) PID control (auto tuning support), ON/OFF control

ML-D2H: 2 Channel, Universal control (Selectable Heating or cooling control) or Heating/Cooling

simultaneous controlling

ML-D4: 4 Channel, Universal control (Selectable Heating or cooling control)

■ Installation

Can attach onto panel by fixing in DIN 35 mm standard rail or using screw

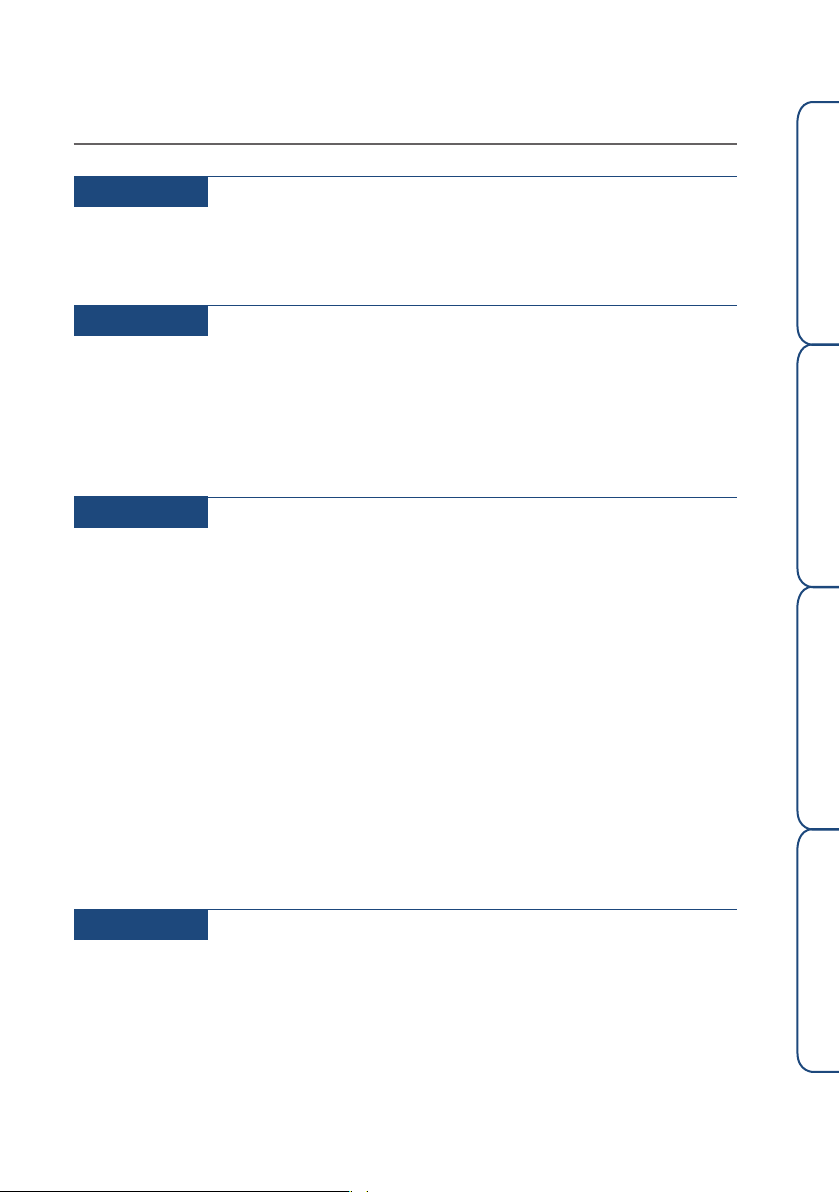

1.2 Product verification

For product purchase, please first verify desired specifications, and then damages in exterior and parts

insufficiency. And contact sales department of this company if found different specifications, exterior damage, or

parts insufficiency.

ML - SERIES

Module Type Temperature Control System

INSTRUCTION MANUAL

Body

6-pin terminal

4 EA

5-pin terminal

1 EA

2

RS232C

communications cable

(optional)

Instruction manual

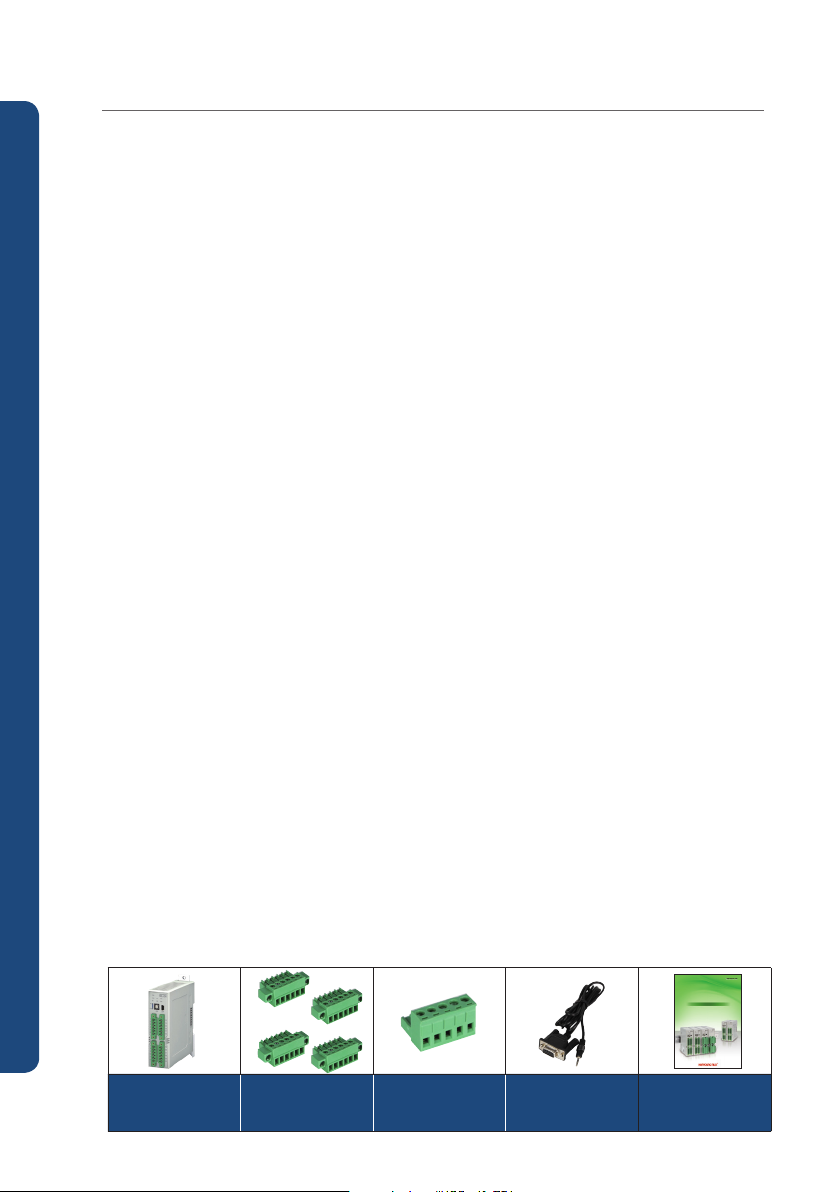

1.2.1 Model composition

■ Module type temperature controller (ML-D2H)

Model Code Details

ML-D 2 H ☐ Module type temperature controller

Number of

channels

Function H

Output type

█ Module type temperature controller (ML-D4)

Model Code Details

ML-D ☐ ☐ Module type temperature control system

Number of

channels

Output type

Ex: Temperature control system 4 channel relay output : ML-D4M

2 2 channel

Heating/cooling control (simultaneous), heater break

alarm (HBA)

OUT1

(heating)

MM

OUT2

(cooling)

OUT1

(heating)

SM

OUT2

(cooling)

OUT1

(heating)

SS

OUT2

(cooling)

4 4 channel

M Relay output

S SSR output (12 V d.c.)

C SCR output (4 -20 mA d.c.)

Relay output

SSR / SCR (4 -20 mA d.c.)

parameter optional output

Relay output

SSR / SCR (4 -20 mA d.c.)

parameter optional output

Before staring Installation Operation Specifications

█ Module type event output (ML-E)

Model Code Details

ML- E Module type event output unit

3

1.3. Safety Cautions

1.3.1 Cautions for safety

● For protection and safety of product and system connected to product,

please use product according to safety instructions of this manual.

● The company will not be held responsible for all safety related issues and loss caused by

carelessness and others, for use or treatment not following directions of instruction manual.

● For protection and safety of product and system connected to product, if required to install

additional safety circuit and others, please make sure to install on external side of this product.

● Do not disassemble, repair, and renovate at self discretion,

as it may cause product damage and malfunctions.

● Do not give shock to product, this can cause product damage or malfunction

1.3.2 Quality assurance

● Unless specified in terms of quality assurance of this company, no guarantee or compensation

will be provided for this product.

● If damage is caused to user or third party due to defects and inevitable accidents that are

impossible to predict by this company, the company, on any occasion, will not be responsible

for loss, indirect damages, and others

1.3.3 About quality assurance terms of this product

● Product warranty period is one year from purchase date of this product, and for breakdowns

occurred during normal usage according to this instruction manual, free repair service will be

provided for such product only.

● For repair to breakdowns occurred after warranty expiration of this product,

it will be repaired at cost (actual expense), based on company specified guidelines.

● For problems below, repairs will be provided at cost even for breakdown during

Multi Loop Controller

warranty repair period.

- Breakdown due to user’s fault

- Breakdown due to natural disasters

- Breakdown due to transfer and others after product installation

- Breakdown due to improper product modifications or losses

- Breakdown due to power supply problem such as power supply instability

● If A/S is required due to breakdown and others, please contact purchase outlet and

our company sales department.

4

2. Installation

2.1 Installation place and cautions

2.1.1 Installation place

● To avoid risk of electric shock, use after panel penal is installed to this product.

● Do not install product at following places.

- Place that people can come into contact with terminal without awareness.

- Place directly exposed to mechanical vibrations or shocks

- Place exposed to corrosive gas or combustible gas

- Place with large change of temperatures

- Place with overly high temperature or low temperature

- Place exposed with direct sun light

- Place greatly influenced by electronic wave

- Place high in humidity

- Place with combustible items in surroundings in the event of fire

- Place with a lot of dust or salinity

2.1.2 Caution

● In case of wiring, cut off power sources of all instruments before start of wiring work

● This product operates at DC24 V. There is danger of electric shocks and fire if other than

rated power supply is used.

●To use ML Series as one module by connecting several units, connect power to only one unit.

● When connecting DC 24 V power source, use rated power supply by calculating total power

consumption of module to use. Using power supply less than total power consumption of

module can cause abnormal run and malfunction.

● Do not operate with wet hands as there is risk of electric shocks.

● For installation and usage, follow directions specified in instruction manual.

● Do not supply power before connection for devices of this product is completed.

● Do not block heat opening of this product as it can cause breakdown.

● Make sure not to touch terminal when current is flowing as there is risk of electric shock.

Before staring Installation Operation Specifications

100

100

• For module body installation

mm

or separation, please secure

proper interval of over 100 mm

considering communications

terminal connector and others.

mm

5

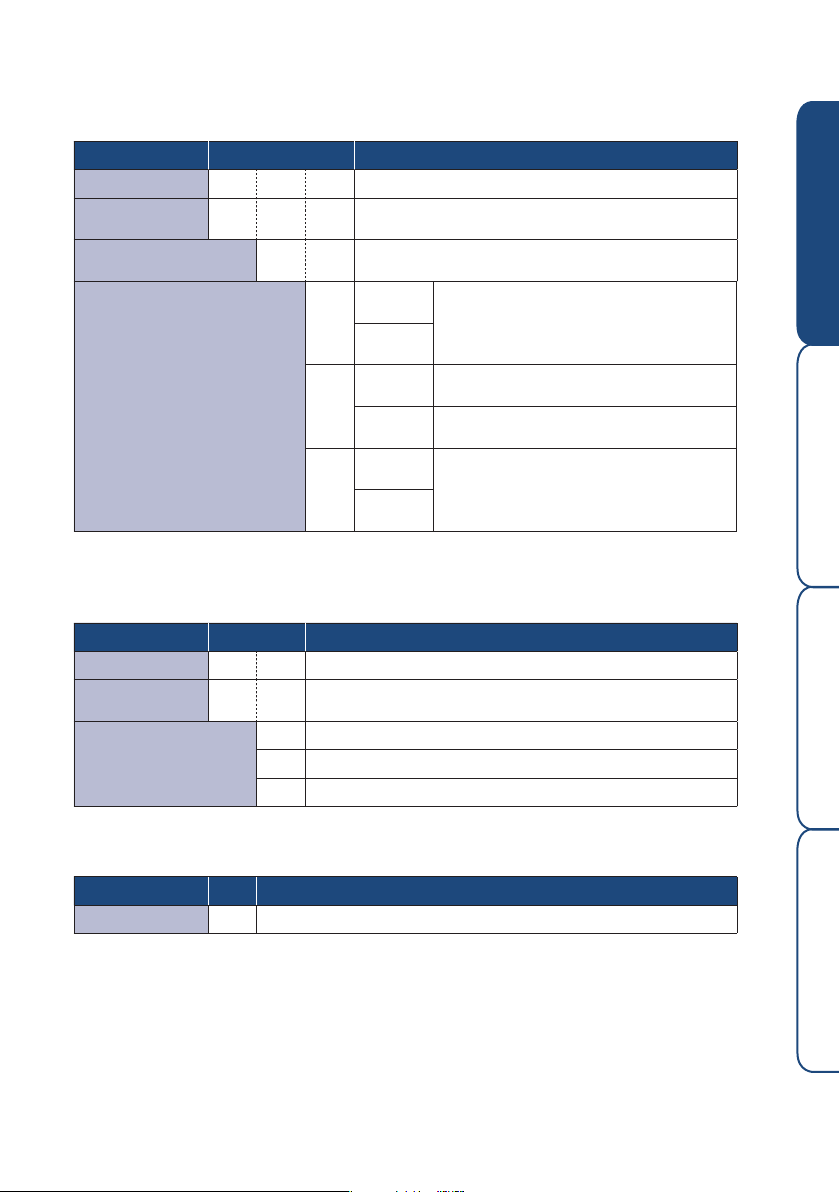

2.2 Connection diagram

2.2.1 Name of each part

█ ML-D2H

③

④

⑤

⑥

⑨

█ ML-D4

Multi Loop Controller

③

④

⑤

⑥

⑨

No. Name Function

①

① Status indication LED

②

② Loader Jack

③ Unit address switch

⑦

Unit extension

④

address switch

⑤

⑧

※ If unit extension address switch is positioned at “+16” and unit address

switch is positioned at “1,” RS485 communications address is set to “1+16=17.”

CH 1 terminal

⑥

⑦

CH 2 terminal

⑧

Power source and

⑨

communications

termina

Power supply, communication, event, control

output, heater break event indication

RS232C communication input terminal

RS485 communication address setting switch

(0~15)

RS485 communication extension address setting

switch (0 /+16)

Temperature input and current transformer (CT)

input terminal

OUT 1: heating control output terminal

OUT 2: cooling control output terminal

Temperature input and current transformer (CT)

input terminal

OUT 1: heating control output terminal

OUT 2: cooling control output terminal

RS485 communications and 24 V d.c. input

terminal

①

No. Name Function

②

① Status indication LED

② Loader Jack RS232C communication input terminal

⑦

③ Unit address switch

Unit extension

④

address switch

⑤ CH 1 terminal

⑧

⑥

CH 2 terminal

⑦ CH 3 terminal

⑧ CH 4 terminal

Power supply and

⑨

communications

terminal

※ If unit extension address switch is positioned at “+16” and unit address

switch is positioned at “1,” RS485 communications address is set to “1+16=17.”

Power supply, communication, event,

control output indication

RS485 communication address setting switch

(0~15)

RS485 communication extension address

setting switch (0 /+16)

Input signal (sensor)

Temperature input and control output terminal

RS485 communications and

24 V d.c. input terminal

6

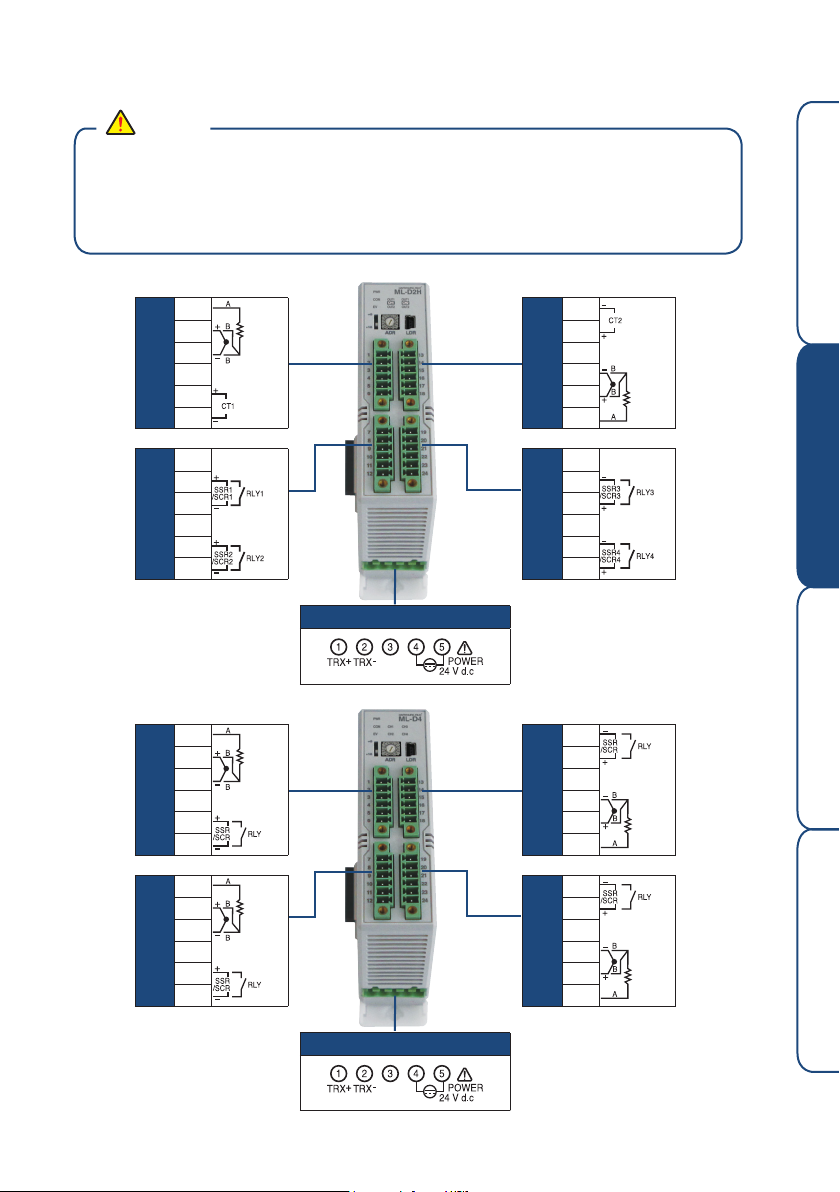

2.2.2 Connection method

Caution

● Before connecting devices, make sure that current is not flowing through connection cable

by cutting off voltage to all instruments to be supplied with power

● As there is danger of electric shock while current is flowing, make sure not to touch terminal.

● Make sure to connect after disconnecting power source voltage.

● For users, do not touch other than above mentioned terminals here.

● ML-D2H

Before staring Installation Operation Specifications

● ML-D4

1 CH

1 CH

1 CH

2 CH

1

2

3

4

5

6

7

OUT1

8

9

10

OUT2

11

12

Power supply section

13

14

15

2 CH

16

17

18

19

OUT2

20

21

2 CH

22

OUT1

23

24

※ 24 V d.c. terminal

has no polarity of (+)

(-) for power supply

connection

1

INPUT

2

3

4

OUT

5

6

7

INPUT

8

9

10

11

OUT

12

3 CH

4 CH

13

14

15

16

17

18

19

20

21

22

23

24

OUT

INPUT

OUT

INPUT

Power supply section

※ 24 V d.c. terminal has

no polarity of (+) (-) for

power supply connection

7

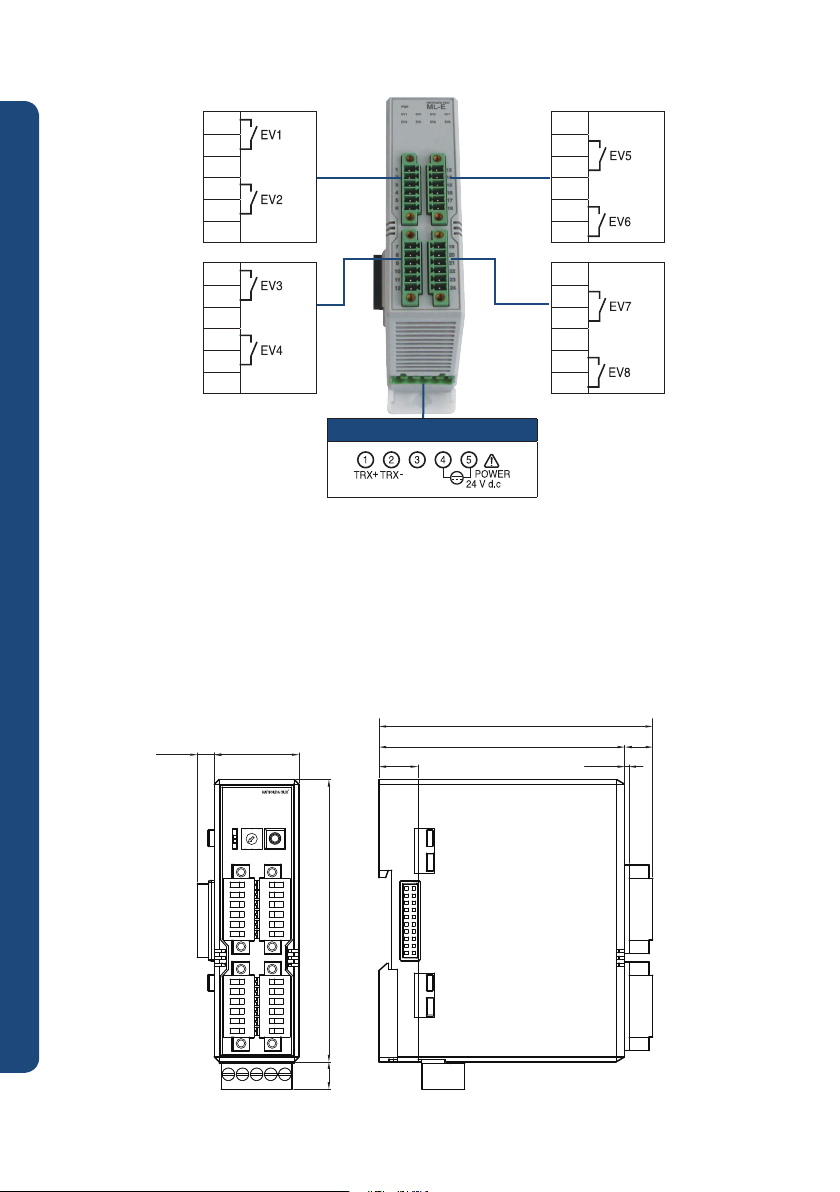

● ML-E

1

2

3

4

5

6

7

8

9

10

11

12

2 . 3 E x t e r i o r d i m e n s i o n

Multi Loop Controller

30.006.00

Power supply section

87.00

13

14

15

16

17

18

19

20

21

22

23

24

※ 24 V d.c. terminal

has no polarity of (+)

(-) for power supply

connection

Unit : ㎜

96.90

9.90

1.5013.75

PWR

ML-D4

COMEVCH1

CH3

CH2

CH4

+0

+16

ADR

LDR

100.009.70

The dimensions of ML-D2H and ML-D4 are same

※

8

2.4 Power supply and communications interface (RS485/RS232C)

Master

TRX+

TRX-

TRX+

TRX-

TRX+

TRX-

TRX+

TRX-

24 V

GND

24 V

GND

24 V

GND

24 V

GND

(24 V DC)

2.4.1 Power supply and communications interface

● When using ML Series as one module by connecting several units, supply power cable and

communications line to only one unit. Required maximum power capacity is 32 units X 7 W= 224 W

when making up 32 unit module. (Refer to power supply specification)

<Example of proper use>

● 2 wire type communication and power source connection

Master

Terminating

resisters

TRX+

TRX-

(24 V DC)

24 V

<Example of incorrect use>

M-D Module

Composition

TRX+

TRX+

TRX+

TRX-

TRX-

TRX-

24 V

24 V

24 V

Terminating

resisters

Before staring Installation Operation Specifications

GND

● 4 wire type communication and power source connection

Terminating

resisters

Master

TX+

TX-

RX+

RX-

(24 V DC)

24 V

GND

GND

※ Dotted line is connected

automatically during module

composition.

TRX+

TRX-

24 V

GND

※ Dotted line is connected

automatically during module

composition.

GND

M-D Module

Composition

TRX+

TRX-

24 V

GND

GND

TRX+

TRX-

24 V

GND

Terminating

resisters

9

2.4.2 RS232C communication

RS232C communication is used to control one Unit, and communicates only with Loader Jack.

For RS232C communication, despite Address setting switch, automatic setup is provided such as

communications Address "1", protocal "PC-LINK", communication speed "9,600bps",

start bit "1 bit", data length "8 bit", parity bit "even number”, stop bit "1 bit." Even with RS232C

communication, remote control and monitoring of connected unit is possible.

2.4.3 RS485 communication

Individual control is also possible using RS485 communication with unit address set as Unit

Address switch. Unit address setting is possible from No. 1 to No. 31. For setting below address

Multi Loop Controller

No. 15, unit address switch is set from No. 1 to No. 15 with unit address extension switch "+0"

and for setting address over No. 15, unit address switch No. 0 to No. 15 is set with unit extension

switch positioned at "+16". If unit extension switch is positioned at "+16" and unit address switch

at "1", RS485 communication address is set as "1+16=17".

RS232C

10

RS485

31 Units

2.5 Event output unit (ML-E) connections

●

ML-E has no communications address, and sends output by receiving signal with side

connector during module composition.

RS485

Before staring Installation Operation Specifications

Mamimum 32 units

(Max. 31: if ML-E not included)

●

ML-E can be located and connected anywhere during module composition.

ML-E

●

When making up as one module, only 1 unit should be connected.

ML-E

ML-E

If several units of ML-E need to be used, it can be achieved by connecting power supply cable

and communication line with wiring method, instead of side connector.

ML-E

Power supply line

Communications cable

11

3. Run

3.1 Protocol composition

● Overview

- This product supports RS232C/485 communications, basic functions can be tested or operated

such as control, monitoring, and others using operating program provided in the computer.

- Protocols supported include PC-Link, PC-Link with SUM, Modbus, ASCII, Modbus RTU.

3.1.1 PC-LINK protocol

- Communication of product is performed with ASC II character string, defined Register can be read and written.

<Frame structure>

STX Address Command Data CR LF

STX 01 ~ 99 Refer to each Command 0x0D 0x0A

● Communications command

- This product uses following communication Command.

Command Detail

D R S D Register consecutive reading

D R R D Register random reading

D W S D Register consecutive writing

D W R D Register random writing

W H O Indication of own information

Multi Loop Controller

● Use of communication Command

⑴ DRS Command

- Use when reading value of consecutive D Register

- On frame, enter number of data to be read and D Register number

<Transmission frame>

Byte size

1 2 3 1 2 1 4 1 1

12

Description STX Address DRS

EA : 01~32

D Register : start D Register

<Reception frame>

Byte size

Description STX Address DRS

Data: Hexadecimal number Word data string

1 2 3 1 2 1 4 1 ... 1 4 1 1

,

OK

EA

,

Data(1)

,

D Register CR LF

,

...

,

Data(n) CR LF

,

⑵ DRR Command

- Use when reading random D Register value

- On frame, enter number of data to be read and D Register number on frame

<Transmission frame>

Byte size

1 2 3 1 2 1 4 1 ... 1 4 1 1

Before staring Installation Operation Specifications

Description STX Address DRR

EA : 01~32

EA

,

D Register(1)

,

D Register(n) CR LF

...

,

,

<Reception frame>

Byte size

Description ST X Address DRR

Data: Hexadecimal number Word data string

1 2 3 1 2 1 4 1 ... 1 4 1 1

EA

,

D Register(1)

,

D Register(n) CR LF

...

,

,

⑶ DWS Command

- Use when writing series of D Register values

- On frame, enter number of data to write, D Register number and each data

<Transmission frame>

Byte size

Description STX Address DWS,EA,D Register,Data(1)

EA: 01~15

D Register: start D Register

Data: Hexadecimal number data string

1 2 3 1 2 1 4 1 4 1 ... 1 4 1 1

Data(n) CR LF

...

,

,

<Reception frame>

Byte size

Description ST X Address DWS

1 2 3 1 2 1 1

,

OK CR LF

⑷ DWR Command

- Use when writing random D Register value

- On frame, enter number of data to write and D Register number and each data

<Transmission frame>

Byte size 1 2 3 1 2 1 4 1 4 1 ... 1 4 1 4 1 1

Description

EA: 01~15

Data: Hexadecimal number word data string

STX

Address

DWR,EA,D Register(1),Data(1)

<Reception frame>

Byte size

Description ST X Address DWR

1 2 3 1 2 1 1

D Register(n),Data(n)

...

,

,

,

OK CR LF

CR LF

13

⑸ WHO Command

- Can see product info. with WHO Command

<Transmission frame>

Byte size

Description STX Address WHO CR LFA

1 2 3 1 1

Reception frame

Byte size

1 2 3 1 2 1 - 1 1

Description STX Address WHO

- : Byte size changes depending on model name and version

⑹ Reply at error

- When receiving Command, this product transmits reception frame proper to corresponding frame

However, if there is an error in reception Command, following NG Frame is transmitted.

<Transmission frame>

Byte size

Description STX Address Command

- Details of NG Code are as follows

NG Code Name Details

Multi Loop Controller

1 2 3 1 2 2 1 1

0x01 Command Not used Command

0x02 Register Not used Register

0x03 Number

0x04 Data Data is out of Hex (0x0 ~ 0xF)

0x08 Delim Terminating string (CR, LF) error

0x10 SUM Inconsistent SUM value

0x18 Over range Value exceeding provided address scope

0x00 Misc Others

3.1.2 PC-LINK with SUM protocal

- Protocol that CHECK SUM is added to PC-LINK Protocol

<Frame structure>

STX Address Command Data SUM CR LF

STX 01 ~ 99 Refer to each Command

OK

,

,

Name & Version CR LF

,

NG NG Code CR LF

Number of communications and number of

Data do not match

Check

SUM

0x0D

0x0A

14

•

Check Sum is value generated by adding every 1 Byte of string ASCII code until SUM

• Convert generated value into 2 characters of Hexadecimal number

ex) STX 0 1 WH 0 4 F CR LF

Check Sum=4F, Check Sum = “0”(0x30) + “1”(0x31)+”W”(0x57+”H”(0x48)+”O”(0x4F)

=0x30 + 0x31 + 0x57 + 0x48 + 0x4F= 0x14F

As Check Sum is 1byte character, it becomes 0x4F, and then this changes to ASCII Code “4F.”

3.1.3 MODBUS-RTU Protocol

● Frame structure

Frame

heading

character

none 8 bit 8 bit n x 8 bit 16 bit None

CRC : Cyclic Redundancy Check

● Function code

Function code Code detail

03 Register multiple reading (n EA)

06 Register single writing (1 EA)

08 Diagnosis function (LOOP-BACK TEST)

16 Register multiple writing (n EA)

● Function code 03 (READ MULTIPLE REGISTERS)

With function code 03, consecutive register details can be read at once. Number of data to be read at

once varies depending on line condition and transmission speed within the frame. One transmission frame

should be less than 255 bytes.

<Transmission frame>

Serial number Details Size Ex.

0 Frame head character None 1 Device number 8 bit 01 h

2 Function code (03) 8 bit 03 h

3 Reading start register (high) 8 bit 75 h

4 Reading start register (low) 8 bit 36 h

5 Number of data to be read (high) 8 bit 00 h

6 Number of data to be read (low) 8 bit 05 h

7 Frame confirmation CRC (low) 8 bit XX h

8 Frame confirmation CRC (high) 8 bit XX h

9 Frame terminating character None -

Instrument

no.

Function

code

Data

Frame

confirmation CRC

Frame

terminating character

Before staring Installation Operation Specifications

<Reception frame>

Serial number Details Size Ex.

0 Frame head character None 1 Device number 8 bit 01 h

2 Function code (03) 8 bit 06 h

3 Number of data read and transmitted 8 bit dd h

4 Read data 1 (high) 8 bit dd h

5 Read data 1 (low) 8 bit dd h

... ... ... ...

n - 4 Read data n (high) 8 bit dd h

n – 3 Read data n (low) 8 bit dd h

n – 2 Frame confirmation CRC (low) 8 bit XX h

n – 1 Frame confirmation CRC (high) 8 bit XX h

n Frame terminating character None ...

15

● Function code 06 (WRITE SINGLE REGISTER)

With function code 06, details of one certain register can be recorded.

<Transmission frame>

Serial number Details Size Ex.

0 Frame head character None -

1 Device number 8 bit 01 h

2 Function code (06) 8 bit 06 h

3 Record start register (high) 8 bit 75 h

4 Record start register (low)

5 Recorded data (high) 8 bit 00 h

6 Recorded data (low) 8 bit 05 h

7 Frame confirmation CRC (low) 8 bit XX h

8 Frame confirmation CRC (high) 8 bit XX h

9 Frame terminating character None -

<Reception frame>

Serial number Details Size Ex.

0 Frame head character None -

1 Device number 8 bit 01 h

2 Function code (06) 8 bit 06 h

3 Record start register (high) 8 bit dd h

4 Record start register (low) 8 bit dd h

5 Recorded data (high) 8 bit dd h

6 Recorded data (low) 8 bit dd h

7 Frame confirmation CRC (low) 8 bit xx h

8 Frame confirmation CRC (high) 8 bit xx h

9 Frame terminating character None -

8 bit 36 h

Multi Loop Controller

● Function code 08 (LOOP-BACK TEST)

With function code 08, self diagnosis test can be performed.

<Transmission frame>

Serial number Details Size Ex.

0 Frame head character None -

1 Device number 8 bit 01 h

2 Function code (08) 8 bit 08 h

3 Diagnosis code (high) 8 bit 00 h

4 Diagnosis code (low) 8 bit 01 h

5 Transmission data (high) 8 bit 12 h

6 Transmission data (high) 8 bit 34 h

7 Frame confirmation CRC (low) 8 bit XX h

8 Frame confirmation CRC (high) 8 bit XX h

9 Frame terminating character None ...

16

<Reception frame>

Serial number Details Size Ex.

0 Frame head character None ...

1 Device number 8 bit 01 h

2 Function code (08) 8 bit 08 h

3 Diagnosis code (high) 8 bit 00 h

4

5

6 Transmission data (high) 8 bit 34 h

7 Frame confirmation CRC (low) 8 bit XX h

8 Frame confirmation CRC (high) 8 bit XX h

9 Frame terminating character None ...

Diagnosis code (low) 8 bit

Transmission data (high) 8 bit 12 h

01 h

● Function code 16 (WRITE MULTIPLE REGISTER)

With function code 16, consecutive register details can be written. Number of data to be written at a time

is depending on line condition and transmission speed within the frame. One transmission frame should be

less than 255 bytes.

<Transmission frame>

Serial number Details Size Ex.

0 Frame head character None ...

1 Device number 8 bit 01 h

2 Function code (16) 8 bit 10 h

3 Record start register (high) 8 bit 75 h

4 Record start register (low) 8 bit 36 h

5 Number of data to record (high) 8 bit 00 h

6 Number of data to record (high) 8 bit 05 h

7 Number of data to transmit (WORD) 8 bit 05 h

8 Data to record 1 (high) 8 bit dd h

9 Data to record 1 (low) 8 bit dd h

... ... ... ...

n - 4 Data to record n (high) 8 bit dd h

n – 3 Data to record n (low) 8 bit dd h

n – 2 Frame confirmation CRC (low) 8 bit XX h

n – 1 Frame confirmation CRC (high) 8 bit XX h

n Frame terminating character None ...

Before staring Installation Operation Specifications

<Reception frame>

Serial number Details Size Ex.

0 Frame head character None ...

1 Device number 8 bit 01 h

2 Function code (16) 8 bit 10 h

3 Record start register (high) 8 bit 75 h

4 Record start register (low) 8 bit 36 h

5 Number of data recorded (high) 8 bit 00 h

6 Number of data recorded (high) 8 bit 05 h

7 Frame confirmation CRC (low) 8 bit XX h

8 Frame confirmation CRC (high) 8 bit XX h

9 Frame terminating character None ...

17

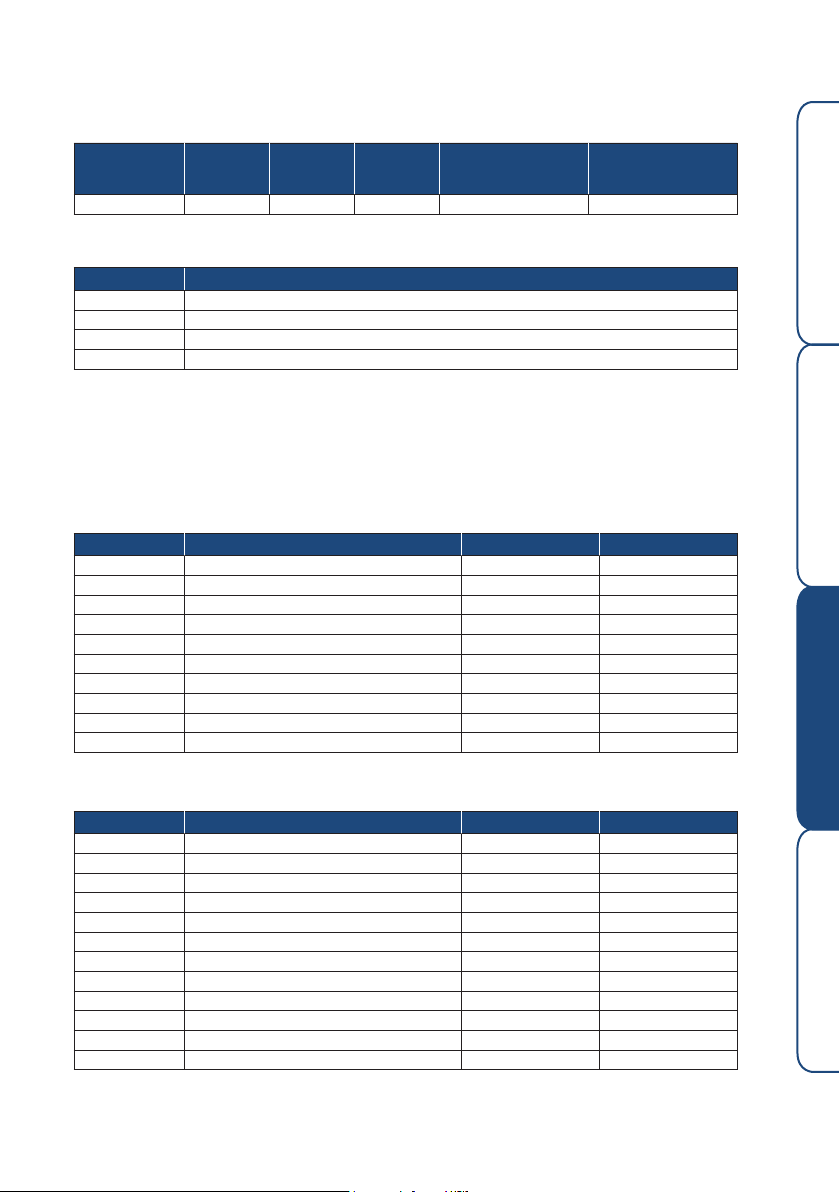

3.2. Register composition

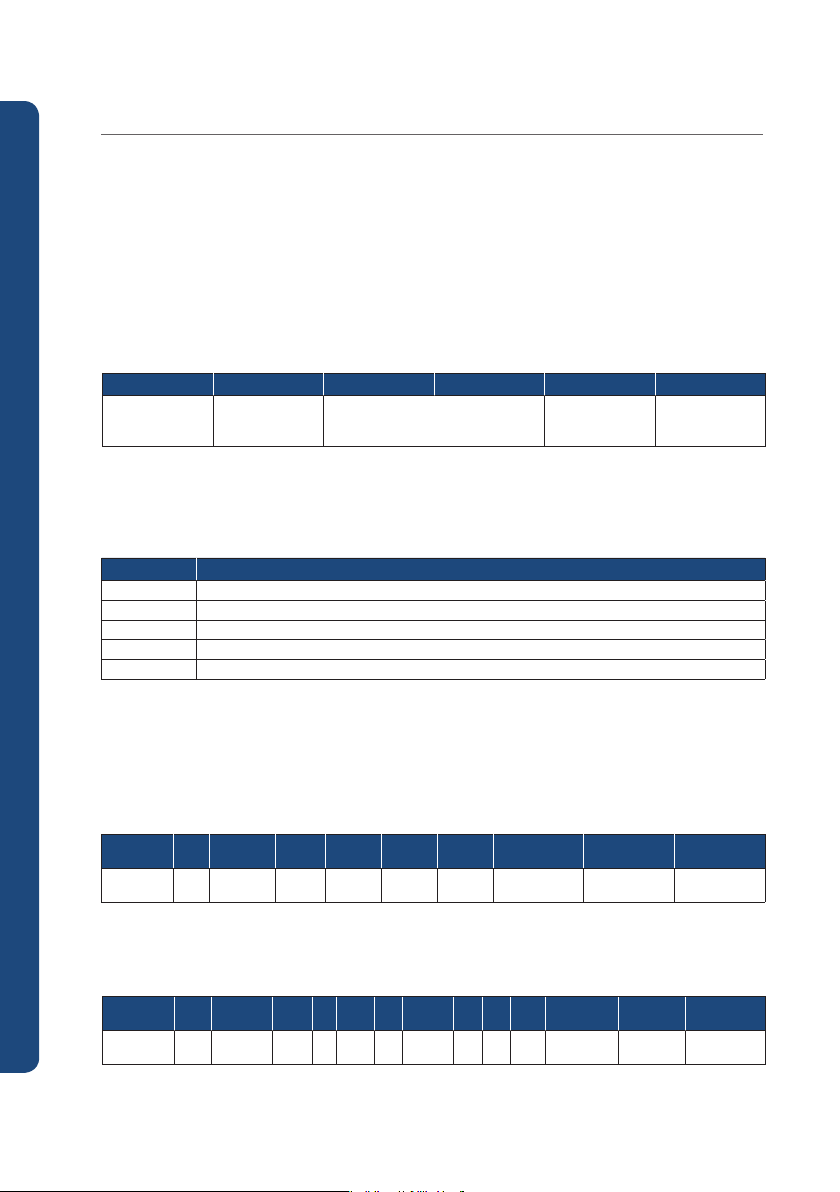

3.2.1 ML-D2H Register composition

No. 0 Description +100 +200 Description by channel

0 - - - - -

1 PV.1

2 PV.2 SV.1 SV.2 Set vlalue

3 - - MV.1 MV.2 Manipulated value

4 5

6 SV.1

7 SV.2 RJC.1 RJC.2

8 - TC.1 TC.2 sensor value

9 - INP.1 INP.2 Input type

10 - - CHMD.1 CHMD.2 Channel mode

11 MV.1 Manipulated

12 MV.2

13 - OUTS.1 OUTS.2 SSR/SCR output setting

14 15 - - - - 16 CHSTS.1

17 CHSTS.2 - - 18 - - - - 19 - - - - -

20 - - - - -

21 TSV.1

23 - - EV.1HY.1 EV.1HY.2

Multi Loop Controller

18

24 - - EV.2TY.1 EV.2TY.2

26 EVT_STS Event status EV.2HY.1 EV.2HY.2

27 EVBUS_STS Event output status EV.3TY.1 EV.3TY.2

29 - - EV.3HY.1 EV.3HY.2

30 - - EV.4TY.1 EV.4TY.2

31 LOCK Parameter setting lock EV.4VL.1 EV.4VL.2

32 COMCHK

33 PARA_SAVE

34 PARA_COPY Run parameter save EV.5VL.1 EV.5VL.2

35 - - EV.5HY.1 EV.5HY.2

36 CHMD.1

38 - - EV.6HY.1 EV.6HY.2

39 - - EV.7TY.1 EV.7TY.2

40 - - EV.7VL.1 EV.7VL.2

41 AT.1

42 AT.2 EV.8TY.1 EV.8TY.2

44 - - EV.8HY.1 EV.8HY.2

45 - - LBA.1 LBA.2 Loop break time setting

46 R/S RUN/STOP LBD.1 LBD.2 Loop break dead band setting

- - EVSTS.1 EVSTS.2 Event status

Process value

-

Set value

value

Channel status

Current trget set value

Time setting for RS485

communication

disconnection detection time

Save parameter

when communicating

Channel mode

Auto tuning

PV.1 PV.2 Process value

CHSTS.1 CHSTS.2

OUTSTS.1 OUTSTS.2 Heating control output status

AT.1 AT.2 Auto tuning

OUT.1

OUT_C_STS.1 OUT_C_STS.2

- - -

EV.1TY.1 EV.1TY.2

EV.4HY.1 EV.4HY.2

EV.5TY.1 EV.5TY.2

EV.6TY.1 EV.6TY.2

EV.7HY.1 EV.7HY.2

OUT.2 Output type

Channel status

Reference junction

compensation

Cooling control output status

Event channel 1 setting22 TSV.2 EV.1VL.1 EV.1VL.2

Event channel 2 setting25 - - EV.2VL.1 EV.2VL.2

Event channel 3 setting28 - - EV.3VL.1 EV.3VL.2

Event channel 4 setting

Event channel 5 setting

Event channel 6 setting37 CHMD.2 EV.6VL.1 EV.6VL.2

Event channel 7 setting

Event channel 8 setting43 - - EV.8VL.1 EV.8VL.2

No. 0 Description +100 +200 Description by channel

47 R/S_SAVE

48 PARA_INIT Parameter initialization HBC.1 HBC.2 Heater break current value

49 - - HBA.1 HBA.2 Heater break event current value

50 - - HB_HYS.1 HB_HYS.2 Heater break hysteresis

51

52

53 - - TD.1 TD.2

54 - - AP.1 AP.2

55 - - MR.1 MR.2 Manual reset

56 - - CT.1 CT.2 Heating control cycle

57 - - PO.1 PO.2 Heating control emergency output

58 - - HYS.1 HYS.2

59 - - RO.1 RO.2 Heating control stop / output when monitor

60 - - RUP.1 RUP.2 SV increase temperature

61 EVSTS.1

62 EVSTS.2 RMIN.1 RMIN.2 SV change time (minute)

63 - - RHRS.1 RHRS.2 SV change time (hour)

64 - DR.1 DR.2 Control output

65 - - OHL.1 OHL.2 Output high limit

66 EV.1STS

67 EV.2STS AT_HYS.1 AT_HYS.2 Auto tuning hysteresis

68 EV.3STS - - 69 EV.4STS - - 70 EV.5STS - - -

71 EV.6STS BS.1 BS.2 Input compensation

72 EV.7STS FL.1 FL.2 Input filter

73 EV.8STS SVH.1 SVH.2 SV High setting

74 - - SVL.1 SVL.2 SV low setting

75 - - FRH.1 FRH.2 Input high limit

76 EVBUS.1

77 EVBUS.2 SLH.1 SLH.2 High scale limit

78 EVBUS.3 SLL.1 SLL.2 Low scale limit

79 EVBUS.4 DOT.1 DOT.2 Set decimal point

80 EVBUS.5 - - -

81 EVBUS.6 PBC.1 PBC.2 Cooling control proportion value

82 EVBUS.7 TIC.1 TIC.2 Cooling control differential value

83 EVBUS.8 TDC.1 TDC.2 Cooling control differential value

84 - - CTC.1 CTC.2 Cooling control control cycle

85 - - POC.1 POC.2

86 PRS Communication protocol HYSC.1 HYSC.2 ON/OFF cooling control hysteresis

87 BPS Transmission speed ROC.1 ROC.2

88 PRI Parity bit 89 STP Stop bit 90 DLN Data length - - -

91 RPT Delay time HC.1 HC.2

92 - - HC_DB.1 HC_DB.2 Heating/cooling control deadband

93 - - 94 - - - - 95 ADDR Switch address - - 96 MAX_CH Number of channels - - 97 R_SYS System data - - 98 R_OPT Option date - - 99 ROMVER Version - -

Power outage recovery setting

- -

- - TI.1 TI.2

Event status by channel

Channel status by event

Event bus output setting

EVSTOP.1 EVSTOP.2 Stop Running at event occurrence

PB.1

RDN.1 RDN.2 SV decrease temperature

OLL.1 OLL.2 Auto tuning hysteresis

FRL.1 FRL.2 Input low limit

PB.2

Heating control Proportion control value

Heating control Integral control value

Heating control Differential control value

Cooling control stop. Output at monitoring situation

Heating, heating/cooling control setting

ALPH value

ON/OFF heating control hysteresis

Cooling control output at

emergency situation

-

Before staring Installation Operation Specifications

19

3.2.2 ML-D2H register description

Register range Details

4 0001(0) ~ 4 0099(63) CH1~2 PV, SV, MV, TSV, CHSTS, EVSTS and common channel setting ※ Please use address

4 0101(65) ~ 4 0199(C7) CH1 related setting

4 0201(C9) ~ 4 0299(12B) CH2 related setting

40000 for Modbus

communication

Register address

(HEX)

CH1 CH2

1(1) 2(2) PV Process value R EU(0 ~ 100%) ℃ -

6(6) 7(7) SV Set value R/W EU (0 ~ 100%) ℃ EU (0%)

11(B) 12(C) MV Manipulated Value R 0.0 ~ 100.0 % -

16(10) 17(11) CHSTS Channel status R

21(15) 22(16) TSV Target set value R EU (0 ~ 100%) ℃ EU (0%)

26(1A) EVT_STS Event status R

Symbol

n : Number

of channel

Multi Loop Controller

27(1B)

31(1F) LOCK

32(20)

33(21)

34(22)

36(24) 37(25)

41(29)

46(2E) R/S Run setting R/W

EVBUS_STS

COMCHK

PARA_SAVE

PARA_COPY

CHMD.n Set channel mode R/W

42(2A)

AT.n

20

Description

Event Bus output

status

Parameter change

lock

Time setting for

RS485 communication

disconnection detection

time

Setting of communication

used parameter save

Run parameter save R/W

Run PID auto tuning (AT)

Property

(R/W)

R/W

R/W

R/W

R/W

Setting range Unit

OR run for situation occurrence

15 Bit: Set “1” at System Data error

14 Bit: Set “1” at Calibration Data error

13 Bit: Set “1” at input circuit error

12 Bit: Set “1” at EEPROM error

11 Bit: Set “1” after 24 hours of auto toning (AT)

10 Bit: Set “1” at standard contact point correction

(RCJ) error

9 Bit: Set “1” when exceeding ±5% input range

8 Bit: Set “1” at input sensor error (B. OUT)

2 Bit: Set “1” at auto tuning (AT) running

1 Bit: Set “1” at monitor mode

0 Bit: Set “1” at run start

Indication of occurrence to all events previously set

0: no event occurred

1: event occurred

Event bus output OR run

7 Bit(128): Set “1” at event bus8 output occurrence

6 Bit(64): Set “1” at event bus 7 output occurrence

5 Bit(32): Set “1” at event bus 6 output occurrence

R

4 Bit(16): Set “1” at event bus 5 output occurrence

3 Bit(8): Set “1” at event bus 4 output occurrence

2 Bit(4): Set “1” at event bus 3 output occurrence

1 Bit(2): Set “1” at event bus 2 output occurrence

0 Bit(1): Set “1” at event bus 1 output occurrence

0: possible to edit all parameters

1: possible to edit only SV, R/S, AT, CHEN

parameters

2. impossible to edit all parameters

0 : OFF

1 ~ 3,600

0: Automatic parameter save

1: save manually using PARA_COPY

parameter

1: When PARA_SAVE “1” is set, save

parameters manually

0:Stop mode

1: Monitor mode

2: Run mode

0: PID auto tuning (AT) stop

1: PID auto tuning (AT) start

0: run stop (STOP)

1: run start (RUN)

Initial

value

ABS -

ABS -

ABS -

ABS 0

sec.

0 (OFF)

ABS 0

ABS 0

ABS 0

ABS 0

ABS 0

Register

address (HEX)

CH1 CH2

47(2F)

48(30)

61(3D) 62(3E)

66(42)

67(43) EV.2STS

68(44) EV.3STS

69(45) EV.4STS

70(46) EV.5STS

71(47) EV.6STS

72(48) EV.7STS

73(49) EV.8STS

76(4C) EVBUS.1

77(4D) EVBUS.2

78(4E) EVBUS.3

79(4F) EVBUS.4

80(50) EVBUS.5

81(51) EVBUS.6

82(52) EVBUS.7

83(53) EVBUS.8

Symbol

n : Number

of channel

R/S_SAVE

PARA_INIT

EVSTS

EV.1STS

Description

Power outage recovery

setting

Run parameter initialization

Event channel by

channel, 1~8 status

Event channel 1, channel

1~4 status

Event channel 2, channel

1~4 status

Event channel 3, channel

1~4 status

Event channel 4, channel

1~4 status

Event channel 5, channel

1~4 status

Event channel 6, channel

1~4 status

Event channel 7, channel

1~4 status

Event channel 8, channel

1~4 status

Event bus 1 output setting

Event bus 2 output setting

Event bus 3 output setting

Event bus 4 output setting

Event bus 5 output setting

Event bus 6 output setting

Event bus 7 output setting

Event bus 8 output setting

Property

(R/W)

R/W

0: NO run return

1: run return

Setting range Unit

ABS 1

R/W 1: Parameter initialization ABS 0

All events OR running

7 Bit(128): Set “1” at event channel 8 occurrence

6 Bit(64): Set “1” at event channel 7 occurrence

5 Bit(32): Set “1” at event channel 6 occurrence

R

4 Bit(16): Set “1” at event channel 5 occurrence

3 Bit(8): Set “1” at event channel 4 occurrence

2 Bit(4): Set “1” at event channel 3 occurrence

1 Bit(2): Set “1” at event channel 2 occurrence

0 Bit(1): Set “1” at event channel 1 occurrence

ABS -

R

R

R

All events OR run

R

1 Bit(2): Set “1” at CH2 event occurrence

0 Bit(1): Set “1” at CH1 event occurrence

R

ABS -

R

R

R

R/W

R/W

R/W

Set corresponding event bus output option at

R/W

event occurrence

0: output (OFF)

R/W

1: output (ON)

R/W

ABS 0

R/W

R/W

0 : PC-LINK

86(56) PRS Communication protocol R/W

1 : PC-LINK with SUM

2 : Modbus ASCII

ABS0

3 : Modbus RTU

0 : 9600 bps

1 : 19200 bps

87(57) BPS Transmission speed R/W

2 : 38400 bps

ABS0(9600

3 : 57600 bps

4 : 76800 bps

0 : NONE

88(58) PRI Parity bit R/W

1 : ODD

ABS

2 : EVEN

89(59) STP Stop bit R/W

90(5A) DLN Data length R/W

91(5B) RPT

95(5F) ADDR

Communication response

delay

Communication setup

Address

1 : 1 Bit

2 : 2 Bit

7 : 7 Bit

8 : 8 Bit

0~10 delay time= process time

R/W

(maximum 25ms) +RTP X 10ms

ABS 1 (1 Bit)

ABS 8 (8 Bit)

ABS 0

R 1 ~ 32 ABS -

96(60) MAX_CH Number of channels R 2 : 2 Channel ABS -

Initial

value

(PC-

LINK)

bps)

2

(EVEN)

Before staring Installation Operation Specifications

21

Register address

(HEX)

CH1 CH2

97(61) R_SYS System data R - ABS -

98(62) R_OPT Option data R - ABS -

99(63) ROMVER Firmware version R - ABS -

101(65) 201(C9)

102(66)

202(CA)

203(CB)

103(67)

104

(68)

105

(69)

106

(6A)

107

Multi Loop Controller

(6B)

108

(6C)

109

(6D)

110

(6E)

Symbol

n : Number of

channel

PV Process value R EU (0 ~ 100%) ℃ -

SV Set vlalue R/W EU (0 ~ 100%) ℃ EU (0%)

MV

204

CHSTS Channel R

(CC)

205

EVSTS

(CD)

206

OUTSTS Output status R

(CE)

207

(CF)

208

(D0)

209

(D1)

210

(D2)

RJC

TC

INP Set input type R/W

CHMD

Description

Manipulated

Value

Event channel

by channel 1~8

status

RJC temperature

value

Thermo couple

(TC) value

Set channel

mode

Property

(R/W)

R 0.0 ~ 100.0

All error status OR run

15 Bit: Set “1” at System Data error

14 Bit: Set “1” at Calibration Data error

13 Bit: Set “1” at input circuit error

12 Bit: Set “1” at EEPROM error

11 Bit: Set “1” after 24 hours of auto toning (AT)

10 Bit: Set “1” at RJC

9 Bit: Set “1” when exceeding ±5% input range

8 Bit: Set “1” at input sensor error (B. OUT)

2 Bit: Set “1” at auto tuning (AT) run

1 Bit: Set “1” at monitor mode

0 Bit: Set “1” at run start

All events OR run

7 Bit(128): Set “1” at event channel 8 occurrence

6 Bit(64): Set “1” at event channel 7 occurrence

5 Bit(32): Set “1” at event channel 6 occurrence

R

4 Bit(16): Set “1” at event channel 5 occurrence

3 Bit(8): Set “1” at event channel 4 occurrence

2 Bit(4): Set “1” at event channel 3 occurrence

1 Bit(2): Set “1” at event channel 2 occurrence

0 Bit(1): Set “1” at event channel 1 occurrence

0: output (OFF)

1: output (ON)

R EU (0 ~ 100%) ℃ -

R EU (0 ~ 100%) ℃ -

0~18: Thermo Couple (TC)

20~23: Resistance Temperature Detector (RTD)

30~ 32: Direct Current Voltage (DCV)

* Refer to input type

0: Stop mode

R/W

1: Monitor mode

2: Run mode

Setting range Unit

%

ABS -

ABS -

ABS -

ABS

ABS 0

Initial

value

-

1

(Thermo

couple

K Type)

22

111

(6F)

112

(70)

113

(71)

114

(72)

211

(D3)

212

(D4)

213

(D5)

214

(D6)

AT

OUT Output type R

OUTS

OUT_C_STS

Run PID auto

tuning(AT)

SSR/SCR

output setting

Cooling control

output status

0: PID auto tuning (AT) stop

R/W

1: PID auto tuning (AT) start

0 : OUT1 - RELAY, OUT2 - RELAY

1 : OUT1 - SSR/SCR, OUT2 - RELAY

2 : OUT1 - SSR/SCR, OUT2 - SSR/SCR

'0' setting for SSR, '1' setting for SCR

R/W

1 Bit(2): SSR/SCR output setting for OUT2

0 Bit(1): SSR/SCR output setting for OUT1

Output OFF

R

Output ON

ABS 0

Follow

ABS

product

specs

ABS

ABS

0

-

Register

address

(HEX)

CH1 CH2

121

(79)

(DD)

122

(7A)

(DE)

123(7B)

223(DF)

124(7C)

224(E0)

~

144(90)

244(F4)

145

(F5)

(91)

146

(92)

147

(93)

(F7)

148

248

(94)

(F8)

149

249

(95)

(F9)

150

250

(96)

(FA)

151

(97)

(FB)

152

(98)

(FC)

153

253

(99)

(FD)

154

254

(9A)

(FE)

155

255

(9B)

(FF)

156

256

(9C)

(100)

157

(9D)

(101)

158

258

(9E)

(102)

159

259

(9F)

(103)

160

260

(A0)

(104)

161

(A1)

(105)

162

262

(A2)

(106)

Symbol

n : Number of

channel

221

EV.1TY

222

EV.1VL

EV.1HY

EV.2

~

~

EV.8

245

LBA

246

LBD

(F6)

247

EVSTOP

HBC

HBA

HB_HYS

251

PB Set proportional band R/W EUS (0 ~ 100%) ℃

252

257

261

TI Set integral time R/W 1 ~ 3600 Sec. 240

TD Set differentiation time R/W 1 ~ 3600 Sec. 60

AR/AP

MR Set Manual Reset R/W 0.0 ~ 100.0 % 0.0

CT Set control cycle R/W 1 ~ 100 Sec.

PO Set emergency output R/W 0.0 ~ 100.0 % 0

HYS

RO

RUP

RDN

RMIN

Description

Set event channel 1

type

Event set value of event

channel 1

Event channel 1, event hysteresis

Set event channel

2~8 event type, set

value and hysteresis

Set loop break

event time

Set loop break event

dead band

Set stop run at event

occurrence

Heater break

current value

Heater break current

value setting

Heater break

hysteresis setting

Heating control: Set 2

DOF PID ALPHA

Heating/Cooing

control: Anti reset

windup (ARW) setting

Set hysteresis at

ON/OFF control

Set output at stop,

monitor status

Set SV increase

temperature at RAMP

control

Set SV decrease

temperature at RAMP

control

Set SV change time

(min.) at RAMP control

Property

(R/W)

None(OFF)

1:Deviation high limit

2: Deviation low limit

3. Deviation high/low limit

4: Within deviation scope

R/W

5: Deviation high limit (stand by)

6: Deviation low limit (stand by)

7. Deviation low/high limit (stand by)

8. Within deviation (stand by)

9:PV high limit

R/W EUS (0 ~ 100%) EU (0 ~ 100%) ℃ -

R/W EUS (0 ~ 10%) ℃ -

R/W Same as event channel 1

R/W 0(OFF), 1~7200 Sec. 0(OFF)

R/W EUS (0 ~ 100%) ℃

0: continuous run

R/W

1: stop run

R 1~50A A -

R/W 0(OFF), 1.0~50.0A A 0(OFF)

R/W 0.0~50.0 A 0.3

Heating control: 1~100

R/W

Heating/Cooing control: 0(AUTO), 50.0~200.0

R/W EUS (0 ~ 10%) ℃

R/W 0.0 ~ 100.0 % 0

R/W EUS (0 ~ 100%) ℃

R/W EUS (0 ~ 100%) ℃

R/W 0 ~ 1000 Min. 0

Setting range Unit

10: PV low limit

11: PV high limit (stand by)

12:PV low limit (stand by)

13: SV high limit

14: SV low limit

15: Loop break (LBA)

16: 17: Run start (RUN)

18: Run/monitor mode

(READY)

19: FAIL

Initial

value

ABS 0(OFF)

EUS

(100%)

0

(continuous

ABS

run)

EUS

(1%)

ABS 0

RELAY :

30 sec.

SSR

: 2 sec.

EUS

(0.2%)

EUS

(0%)

EUS

(0%)

Before staring Installation Operation Specifications

23

Register

address (HEX)

CH1 CH2

163

(A3)

164

(A4)

165

(A5)

166

(A6)

171

(AB)

172

(AC)

173

(AD)

174

(AE)

175

(AF)

176

(B0)

177

(B1)

178

(B2)

179

(B3)

181

Multi Loop Controller

(B5)

182

(B6)

183

(B7)

184

(B8)

185

(B9)

186

(BA)

187

(BB)

191

(BF)

192

(C0)

Symbol

n : Number

of channel

263

RHRS

(107)

264

(108)

265

(109)

266

(10A)

(10F)

272

(110)

273

(111)

(112)

275

(113)

276

(114)

277

(115)

278

(116)

279

(117)

(119)

282

(1A0)

283

(1A1)

284

(1A2)

285

(1A3)

286

(1A4)

287

(1A5)

(1A9)

292

(1AA)

DR Set control run R/W

OHL

OLL

271

BS Set input correction R/W EUS (-100 ~ 100%) ℃ EUS (0%)

FL Set input filter R/W 0 ~ 100 ABS 0

SVH Set SV high limit R/W EU (0 ~ 100%) ℃ EU (100%)

274

SVL Set SV low limit R/W EU (0 ~ 100%) ℃ EU (0%)

FRH Set PV high limit R/W EU (0 ~ 100%) ℃ EU (100%)

FRL Set PV low limit R/W EU (0 ~ 100%) ℃ EU (0%)

SLH

SLL

DOT Set decimal point R/W 0 ~ 3 :

281

PBC

TIC

TDC

CTC

POC

HYSC

ROC

291

HC

HC_DB

Description

Set SV change time

(hr.) at RAMP control

Set high limit to

Manipulated Value

Set low limit to

Manipulated Value

Set scale high limit

at DCV input setting

Set scale low limit

at DCV input setting

Cooling control

Proportional band

setting

Cooling control integral

time setting

Cooling control

derivative time setting

Cooling control control

period setting

Cooling control

Emergency output

setting

Cooling control

ON / OFF control

Hysteresis setting

Stop cooling control.

Output setting at monitor

status

Heating, heating /

cooling control settings

Heating / cooling control

dead band setting

Property

(R/W)

R/W 0 ~ 100 hour 0

R/W 0.0 ~ 100.0 % 100.0

R/W 0.0 ~ 100.0 % 0.0

R/W EU (0 ~ 100%) mV EU (100%)

R/W EU (0 ~ 100%) mV EU (0%)

R/W EUS (0 ~ 100%) ℃ EUS (2%)

R/W 1 ~ 3600 Second 240

R/W 1 ~ 3600 Second 60

R/W 1 ~ 100 Second

R/W 0.0 ~ 100.0 % 0

R/W EUS (0 ~ 10%) ℃ EUS (0.2%)

R/W 0.0 ~ 100.0 % 0

R/W

R/W -100 ~ 50 % 0

Setting range Unit Initial value

0: Reverse run (heating)

control

1: Direct run (cooling)

control

decimal point digit

0 : heating control

1 : heating/cooling control

ABS 0

ABS 0

ABS

RELAY :

30 Sec.

S.S.R :

2 Sec.

0 (heating

control)

24

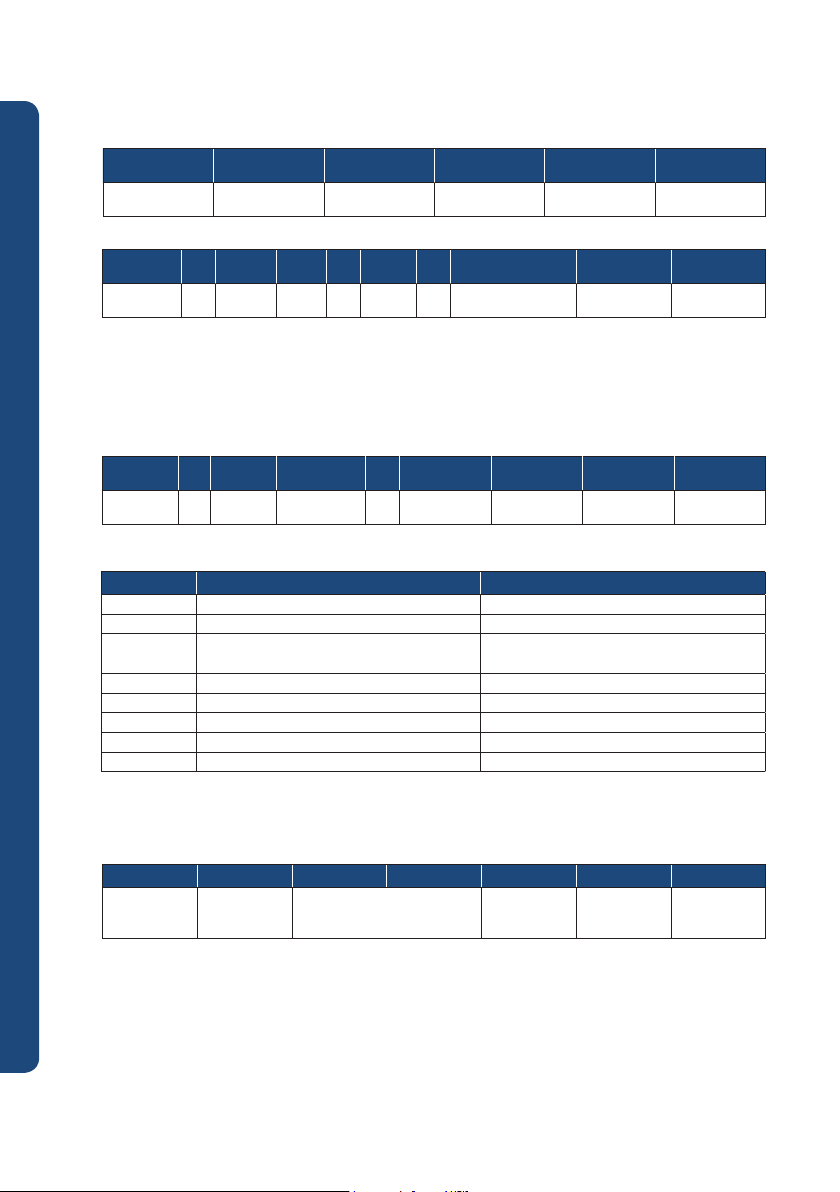

3.2.3 ML-D4 Register composition

No. 0

0 - - - - - - -

1 PV.1

2 PV.2 SV.1 SV.2 SV.3 SV.4 Set value

3 PV.3 MV.1 MV.2 MV.3 MV.4 Manipulated Value

4 PV.4

5 - - EVSTS.1 EVSTS.2 EVSTS.3 EVSTS.4 Event status

6 SV.1

7 SV.2 RJC.1 RJC.2 RJC.3 RJC.4 Temperature

8 SV.3 TC.1 TC.2 TC.3 TC.4 Sensor value

9 SV.4 INP.1 INP.2 INP.3 INP.4 Input type

10 - - CHMD.1 CHMD.2 CHMD.3 CHMD.4 Channel mode

MV.1

11

12 MV.2 OUT.1 OUT.2 OUT.3 OUT.4 Output type

13 MV.3 EV.1DLY.1 EV.1DLY.2 EV.1DLY.3 EV.1DLY.4

14 MV.4

15 - 16 CHSTS.1

17 CHSTS.2

18 CHSTS.3

19 CHSTS.4

20 - -

21 TSV.1

23 TSV.3 EV.1HY.1 EV.1HY.2 EV.1HY.3 EV.1HY.4

24 TSV.4 EV.2TY.1 EV.2TY.2 EV.2TY.3 EV.2TY.4

26 EVT_STS Event status EV.2HY.1 EV.2HY.2 EV.2HY.3 EV.2HY.4

27 EVBUS_STS Event output status EV.3TY1 EV.3TY2 EV.3TY3 EV.3TY4

29 - - EV.3HY.1 EV.3HY.2 EV.3HY.3 EV.3HY.4

30 - - EV.4TY.1 EV.4TY.2 EV.4TY.3 EV.4TY.4

31 LOCK Parameter setting lock EV.4VL.1 EV.4VL.2 EV.4VL.3 EV.4VL.4

32 COMCHK

33 PARA_SAVE

PARA_

34

COPY

35 - - EV.5HY.1 EV.5HY.2 EV.5HY.3 EV.5HY.4

36 CHMD.1

38 CHMD.3 EV.6HY.1 EV.6HY.2 EV.6HY.3 EV.6HY.4

39 CHMD.4 EV.7TY.1 EV.7TY.2 EV.7TY.3 EV.7TY.4

40 - - EV.7VL.1 EV.7VL.2 EV.7VL.3 EV.7VL.4

41 AT.1 Auto tuning EV.7HY.1 EV.7HY.2 EV.7HY.3 EV.7HY.4

42 AT.2

44 AT.4 EV.8HY.1 EV.8HY.2 EV.8HY.3 EV.8HY.4

Description

Process value

Set value

Manipulated Value

Channel status

Current target

set value

Time setting for RS485

communication

disconnection detection

time

Save parameter

when communicating

Run parameter save EV.5VL.1 EV.5VL.2 EV.5VL.3 EV.5VL.4

Channel mode

Auto tuning

+100 +200 +300 +400

PV.1 PV.2 PV.3 PV.4

CHSTS.1

OUTSTS.1 OUTSTS.2

EV.2DLY.1 EV.2DLY.2 EV.2DLY.3 EV.2DLY.4

EV.3DLY.1 EV.3DLY.2 EV.3DLY.3 EV.3DLY.4

EV.4DLY.1 EV.4DLY.2 EV.4DLY.3 EV.4DLY.4

EV.5DLY.1 EV.5DLY.2 EV.5DLY.3 EV.5DLY.4

EV.6DLY.1 EV.6DLY.2 EV.6DLY.3 EV.6DLY.4

EV.7DLY.1 EV.7DLY.2 EV.7DLY.3 EV.7DLY.4

EV.8DLY.1 EV.8DLY.2 EV.8DLY.3 EV.8DLY.4

EV.1TY.1 EV.1TY.2 EV.1TY.3 EV.1TY.4

EV.4HY.1 EV.4HY.2 EV.4HY.3 EV.4HY.4

EV.5TY.1 EV.5TY.2 EV.5TY.3 EV.5TY.4

EV.6TY.1 EV.6TY.2 EV.6TY.3 EV.6TY.4

EV.8TY.1 EV.8TY.2 EV.8TY.3 EV.8TY.4

CHSTS.2 CHSTS.3

OUTSTS.3 OUTSTS.4

AT.1 AT.2 AT.3 AT.4 Auto tuning

CHSTS.4

Description by channel

Process value

Channel status

control output status

Event 1 delay setting

Event 2 delay setting

Event 3 delay setting

Event 4 delay setting

Event 5 delay setting

Event 6 delay setting

Event 7 delay setting

Event 8 delay setting

Event 1 setting22 TSV.2 EV.1VL.1 EV.1VL.2 EV.1VL.3 EV.1VL.4

Event 2 setting25 - - EV.2VL.1 EV.2VL.2 EV.2VL.3 EV.2VL.4

Event 3 setting28 - - EV.3VL.1 EV.3VL.2 EV.3VL.3 EV.3VL.4

Event 4 setting

Event 5 setting

Event 6 setting37 CHMD.2 EV.6VL.1 EV.6VL.2 EV.6VL.3 EV.6VL.4

Event 7 setting

Event 8 setting43 AT.3 EV.8VL.1 EV.8VL.2 EV.8VL.3 EV.8VL.4

Before staring Installation Operation Specifications

25

No. 0

45 - - LBA.1 LBA.2 LBA.3 LBA.4

46 R/S RUN/STOP LBD.1 LBD.2 LBD.3 LBD.4

47 R/S_SAVE

48 PARA_INIT

49 -

50 - - - - - - -

51 - - PB.1 PB.2 PB.3 PB.4

52 - - TI.1 TI.2 TI.3 TI.4 Integral control value

53 - - TD.1 TD.2 TD.3 TD.4

54 - - AP.1 AP.2 AP.3 AP.4 ALPHA value

- - MR.1 MR.2 MR.3 MR.4

55

56 - 57 - 58 - 59 - -

60 - -

61 EVSTS.1

62 EVSTS.2

63 EVSTS.3 RHRS.1 RHRS.2 RHRS.3 RHRS.4

64 EVSTS.4 DR.1 DR.2 DR.3 DR.4 Control run

65 - - OHL.1 OHL.2 OHL.3 OHL.4

66 EV.1STS

67 EV.2STS - - - - 68 EV.3STS - - - - 69 EV.4STS - - - - 70 EV.5STS - - - - 71 EV.6STS BS.1 BS.2 BS.3 BS.4 Input compensation

Multi Loop Controller

26

72 EV.7STS FL.1 FL.2 FL.3 FL.4 Input filter

73 EV.8STS SVH.1 SVH.2 SVH.3 SVH.4 High limit to setting

74 - - SVL.1 SVL.2 SVL.3 SVL.4 Low limit to setting

75 - - FRH.1 FRH.2 FRH.3 FRH.4 High limit to input

76 EVBUS.1

77 EVBUS.2 SLH.1 SLH.2 SLH.3 SLH.4 High limit to scale

78 EVBUS.3 SLL.1 SLL.2 SLL.3 SLL.4 Low limit to scale

79 EVBUS.4 DOT.1

80 EVBUS.5 - -

81 EVBUS.6 - 82 EVBUS.7 - - - - 83 EVBUS.8 - - - - -

84 - - - - - - -

85 - - - 86 PRS

87 BPS Transmission speed - -

88 PRI Parity bit - -

89 STP Stop bit - -

90 DLN Data length

91 RPT Delay time

92 - 93 - 93 - 94 - -

Channel status by

Communication protocol

Description

Power outage

recovery setting

Parameter

initialization

-

Event status by

channel

event

Event bus output

+100 +200 +300 +400

EVSTOP.1

HYS.1 HYS.2 HYS.3 HYS.4 hysteresis

RUP.1 RUP.2 RUP.3 RUP.4

RDN.1 RDN.2 RDN.3 RDN.4

RMIN.1 RMIN.2 RMIN.3 RMIN.4

OLL.1 OLL.2 OLL.3 OLL.4

FRL.1 FRL.2 FRL.3 FRL.4 Low limit to input

EVSTOP.2 EVSTOP.3 EVSTOP.4

- -

- -

CT.1 CT.2 CT.3 CT.4

PO.1 PO.2 PO.3 PO.4 emergency output

RO.1 RO.2 RO.3 RO.4

DOT.2 DOT.3 DOT.4

- -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- -

-

- -

- -

- -

- -

- -

- -

- -

Description by channel

Loop break event time

Loop break event dead band

Stop running at event

occurrence

- -

Proportion control value

Differential control value

Manual reset

control cycle

Output at stop/monitor mode

SV increasing temperature

SV decreasing temperature

SV increase and decrease

time (minute)

SV increase and

decrease time (hour)

Manipulated Value high limit

Manipulated Value low limit

Decimal point

-

-

-

-

-

-

-

-

-

-

-

-

-

-

No.

0

93 - 94 - 95 ADDR Switch address - - - - 96 MAX_CH Number of channels - - - - 97 R_SYS System data - - - - -

R_OPT Option data - - - - -

98

99 ROMVER Version - - - - -

Description

+100 +200 +300 +400

- - - -

- - - -

Description by channel

3.2.4 ML-D4register description

Register address (HEX) Description

40001(0) ~ 4 0099(63)

40101(65) ~ 40199(C7) CH1 related setting

40201(C9) ~ 40299(12B) CH2 related setting

40301(12D) ~ 40399(18F) CH3 related setting

40401(191) ~ 40499(1F3) CH4 related setting

Register address (HEX) Symbol

CH1 CH2 CH3 CH4

1(1) 2(2) 3(3) 4(4) PV

6(6) 7(7) 8(8) 9(9) SV

11(B) 12(C) 13(D) 14(E) MV

16(10) 17(11) 18(12) 19(13) CHSTS

21(15) 22(16) 23(17) 24(18) TSV

26(1A) EVT_STS

27(1B)

31(1F) LOCK

32(20)

33(21)

CH1~4 PV, SV, MV, TSV, CHSTS, EVSTS and common channel setting

n : Number

of channel

EVBUS_STS

COMCHK

PARA_SAVE

Description

Process value

Set value

Manipulated

Value

Channel

status

Current target

set value

Event status

Event bus output

status

Parameter

setting lock

Time setting for

RS485

communication

disconnection

detection time

Save parameter

when

communication

Property

(R/W)

R EU(0 ~ 100%) ℃ -

R/W EU (0 ~ 100%) ℃ EU (0%)

R 0.0 ~ 100.0 % -

OR run for situation occurrence

15 Bit: Set “1” at System Data error

14 Bit: Set “1” at Calibration Data error

13 Bit: Set “1” at input circuit error

12 Bit: Set “1” at EEPROM error

11 Bit: Set “1” after 24 hours of auto toning (AT)

R

10 Bit: Set “1” at standard contact point

correction (RCJ) error

9 Bit: Set “1” when exceeding ±5% input range

8 Bit: Set “1” at input sensor error (B. OUT)

2 Bit: Set “1” at auto tuning (AT) run

1 Bit: Set “1” at monitor mode

0 Bit: Set “1” at run start

R EU (0 ~ 100%) ℃ EU (0%)

Indication of occurrence to all events

previously set

R

0: no event occurred

1: event occurred

Event bus output OR run

7 Bit(128): Set “1” at event bus8 output occurrence

6 Bit(64): Set “1” at event bus7 output occurrence

5 Bit(32): Set “1” at event bus6 output occurrence

R

4 Bit(16): Set “1” at event bus5 output occurrence

3 Bit(8): Set “1” at event bus4 output occurrence

2 Bit(4): Set “1” at event bus3 output occurrence

1 Bit(2): Set “1” at event bus2 output occurrence

0 Bit(1): Set “1” at event bus1 output occurrence

0: possible to edit all parameters

1: possible to edit only SV, R/S, AT, CHEN

R/W

parameters

2. impossible to edit all parameters

0: OFF

R/W

1 ~ 3,600

0: Automatic parameter save

R/W

1: save manually using PARA_COPY

parameter

Setting range Unit

※ Please use address

40000 for Modbus

communication

-

-

ABS -

ABS -

ABS -

ABS 0

second

0 (OFF)

ABS 0

Initial

value

Before staring Installation Operation Specifications

27

Register address (HEX) Symbol

CH1 CH2 CH3 CH4

34(22)

36(24) 37(25) 38(26) 39(27)

41(29)

42(2A)

43(2B)

44(2C)

46(2E) R/S Run setting R/W

47(2F)

48(30)

61

(3D)62(3E)63(3F)64(40)

66(42)

67(43)

68(44)

69(45)

Multi Loop Controller

70(46)

71(47)

72(48)

73(49) EV.8STS

76(4C) EVBUS.1

77(4D) EVBUS.2

78(4E) EVBUS.3

79(4F) EVBUS.4

80(50) EVBUS.5

81(51) EVBUS.6

82(52) EVBUS.7

83(53) EVBUS.8

n : Number

of channel

PARA_COPY

Description

Run parameter

save

Property

CHMD.n Set channel mode R/W

AT.n

R/S_

SAV E

PARA_

INIT

Run PID auto

tuning (AT)

Set power outage

return

Run parameter

initialization

Event channel

EVSTS

by channel, 1~8

status

EV.1STS

EV.2STS

EV.3STS

EV.4STS

EV.5STS

EV.6STS

EV.7STS

Event channel 1,

channel 1~4 status

Event channel 2,

channel 1~4 status

Event channel 3,

channel 1~4 status

Event channel 4,

channel 1~4 status

Event channel 5,

channel 1~4 status

Event channel 6,

channel 1~4 status

Event channel 7,

channel 1~4 status

Event channel 8,

channel 1~4 status

Event bus 1 output setting

Event bus 2 output

setting

Event bus 3 output

setting

Event bus 4 output

setting

Event bus 5 output

setting

Event bus 6 output

setting

Event bus 7 output

setting

Event bus 8 output

setting

(R/W)

1: When PARA_SAVE “1” is set, save

R/W

parameters manually

Setting range Unit

Initial

value

ABS 0

0:Stop mode

1: Monitor mode

ABS 0

2: Run mode

0: PID auto tuning (AT) stop

1: PID auto tuning (AT) start

R/W

2: P.I.D auto tuning start.

ABS 0

stop after running

0: run stop (STOP)

1: run start (RUN)

0: NO run return

R/W

1: run return

ABS 0

1 (Return to

ABS

R/W 1: Parameter initialization ABS 0

All events OR run

7 Bit(128): Set “1” at event channel 8 occurrence

6 Bit(64): Set “1” at event channel 7 occurrence

5 Bit(32): Set “1” at event channel 6 occurrence

R

4 Bit(16): Set “1” at event channel 5 occurrence

3 Bit(8): Set “1” at event channel 4 occurrence

2 Bit(4): Set “1” at event channel 3 occurrence

1 Bit(2): Set “1” at event channel 2 occurrence

0 Bit(1): Set “1” at event channel 1 occurrence

ABS -

R

R

R

All events OR run

R

3 Bit(8): Set “1” at CH4 event occurrence

2 Bit(4): Set “1” at CH3 event occurrence

1 Bit(2): Set “1” at CH2 event occurrence

R

0 Bit(1): Set “1” at CH1 event occurrence

ABS -

R

R

R

R/W

R/W

R/W

Set corresponding event bus

R/W

output option at event occurrence

0: output (OFF)

R/W

1: output (ON)

ABS

R/W

R/W

R/W

run

0

28

Register address (HEX) Symbol

CH1 CH2 CH3 CH4

86(56) PRS

87(57) BPS

88(58) PRI Parity bit R/W

89(59) STP Stop bit R/W

90(5A) DLN Data length R/W

91(5B) RPT

95(5F) ADDR

96(60) MAX_CH

97(61) R_SYS System data R - ABS -

98(62) R_OPT Option data R - ABS -

99(63) ROMVER Firmware version R - ABS -

101

201

(C9)

202

(CA)

203

(CB)

204

(CC)

205

(CD)

206

(CE)

301

(12D)

302

(12E)

303

(12F)

304

(130)

305

(131)

306

(132)

(65)

102

(66)

103

(67)

104

(68)

105

(69)

106

(6A)

n : Number

of channel

401

PV Process value R EU (0 ~ 100%) ℃ -

(191)

402

SV Set value R/W EU (0 ~ 100%) ℃ EU (0%)

(192)

403

MV Manipulated Value R 0.0 ~ 100.0 % 0

(193)

404

CHSTS Channel status R

(194)

405

EVSTS

(195)

406

OUTSTS Output status R

(196)

Description

Communication

protocol

Transmission

speed (Bit per

second)

Communication

response delay

Communication

setup Address

Number of

channels

Event channel

by channel 1~8

status

Property

(R/W)

0 : PC-LINK

1 : PC-LINK with SUM

R/W

2 : Modbus ASCII

3 : Modbus RTU

0 : 9600 bps

1 : 19200 bps

R/W

2 : 38400 bps

3 : 57600 bps

4 : 76800 bps

0 : NONE

1 : ODD

2 : EVEN

1 : 1 Bit

2 : 2 Bit

7 : 7 Bit

8 : 8 Bit

0~10 delay time= process time

R/W

(maximum 25ms) +RTP X 10ms

R 1 ~ 32 ABS -

R 4 : 4 Channel ABS -

All error status OR run

15 Bit: Set “1” at System Data error

14 Bit: Set “1” at Calibration Data error

13 Bit: Set “1” at input circuit error

12 Bit: Set “1” at EEPROM error

11 Bit: Set “1” after 24 hours of auto toning (AT)

10 Bit: Set “1” at standard contact point

correction (RCJ) error

9 Bit: Set “1” when exceeding ±5% input range

8 Bit: Set “1” at input sensor error (B. OUT)

2 Bit: Set “1” at auto tuning (AT) run

1 Bit: Set “1” at monitor mode

0 Bit: Set “1” at run start

All events OR run

7 Bit(128): Set “1” at event channel 8 occurrence

6 Bit(64): Set “1” at event channel 7 occurrence

5 Bit(32): Set “1” at event channel 6 occurrence

R

4 Bit(16): Set “1” at event channel 5 occurrence

3 Bit(8): Set “1” at event channel 4 occurrence

2 Bit(4): Set “1” at event channel 3 occurrence

1 Bit(2): Set “1” at event channel 2 occurrence

0 Bit(1): Set “1” at event channel 1 occurrence

0: output (OFF)

1: output (ON)

Setting range Unit

Initial

value

0 (PC-

ABS

LINK)

0 (9600

ABS

bps)

2

ABS

(EVEN)

ABS 1 (1 Bit)

ABS 8 (8 Bit)

ABS 0

ABS -

ABS -

ABS -

Before staring Installation Operation Specifications

29

Register address (HEX) Parameter

CH1 CH2 CH3 CH4

107

207

(CF)

208

(D0)

209

(D1)

210

(D2)

211

(D3)

212

(D4)

213(D5)

~

220(78)

221

(DD)

224(E0)

~

244(F4)

245

(F5)

246

(F6)

247

(F7)

251

(FB)

307

(133)

308

(134)

309

(135)40(199)

310

(136)

311

(137)

312

(138)

313(139)

~

320(78)

321

(141)

324(144)

~

344(158)

345

(159)

346

(15A)

347

(15B)

351

(15F)

355(163)

(6B)

108

(6C)

109

(6D)

110

(6E)

111

(6F)

112

(70)

113(71)

~

120(78)

121

(79)

122(7A) 222(DE) 322(142) 422(1A6) EV.1VL

Multi Loop Controller

123(7B) 223(DF) 323(143) 423(1A7) EV.1HY

124(7C)

~

144(90)

145

(91)

146

(92)

147

(93)

151

(97)

152(98) 252(FC) 352(160)

153(99) 253(FD) 353(161)

154(9A) 254(FE) 354(162)

155(9B) 255(FF)

407

(197)

408

(198)

410

(19A)

411

(19B)

412

(19C)

413(19D)

~

420(78)

421

(1A5)

424(1A8)

~

444(1BC)

445

(1BD)

446

(1BE)

447

(1BF)

451(1C3)

452(1C4)

453(1C5)

454(1C6)

455(1C7)

n : Number

of channel

EV.1DLY

EV.8DLY

EVSTOP

Description

Reference

RJC

TC

INP Set input type R/W

CHMD Set channel mode R/W

AT

OUT Input type R

~

EV.1TY

EV.2~

~

EV.8~

LBA

LBD

PB

TI Set integral time R/W 1 ~ 3600 Sec. 240

TD

AP

MR Set Manual Reset R/W 0.0 ~ 100.0 % 0.0

junction

compensation

temperature

value

Thermo couple

(TC) value

Run PID auto

tuning(AT)

Set event delay R/W 0 ~ 9999 Sec. 0

Set event channel 1

type

Event set value of

event channel 1

Event channel 1,

event hysteresis

Set event channel

2~8 event type, set

value and hysteresis

Set loop break

event time

Set loop break

event dead band

Set stop running at

event occurrence

Set proportional

band

Set differentiation

time

Set 2 DOF PID

ALPHA

Property

(R/W)

R EU (0 ~ 100%) ℃ -

R EU (0 ~ 100%) ℃ -

0~18: thermo couple (TC)

20~23: Resistance Temperature Detector (RTD)

30~ 32:direct current voltage (DCV)

* Refer to input type

0: Stop mode

1: Monitor mode

2: Run mode

0: PID auto tuning (AT) stop

R/W

1: PID auto tuning (AT) start

0:RELAY

1:SSR

2.SCR

None(OFF)

1:Deviation high limit

2: Deviation low limit

3. Deviation high/low limit

4: Within deviation scope

R/W

5: Deviation high limit (stand by)

6: Deviation low limit (stand by)

7. Deviation low/high limit

(stand by)

8. Within deviation (stand by

9:PV high limit

R/W EUS (0 ~ 100%) ℃

R/W EUS (0 ~ 10%) ℃

R/W Same as event channel 1

R/W 0(OFF), 1~7200 Sec. 0 (OFF)

R/W EUS (0 ~ 100%) ℃

0: continuous run

R/W

1: stop run

R/W EUS (0 ~ 100%) ℃

R/W 1 ~ 3600 Sec. 60

R/W 1 ~ 100 ABS 50

Setting range Unit

ABS

ABS

ABS 0

ABS

10: PV low limit

11: PV high limit (stand by)

12:PV low limit (stand by)

13: SV high limit

14: SV low limit

15: Loop break (LBA)

16: 17: Run start (RUN)

18: Run/monitor mode

(READY)

19: FAIL

ABS 0 (OFF)

ABS

K Type)

product

(continuous

Initial

value

1

(TC

0

(stop

mode)

Follow

specs

EUS

(0%)

EUS

(0.2%)

EUS

(100%)

0

run)

EUS

(2%)

30

Register address (HEX) Parameter

CH1 CH2 CH3 CH4

154(9A) 254(FE) 354(162)

n : Number of

454(1C6)

channel

Description

AP Set 2 DOF PID ALPHA R/W 1 ~ 100 ABS 50

Property

(R/W)

Setting range Unit Initial value

155(9B) 255(FF) 355(163)

156(9C)

256(100) 356(164) 456(1C8)

257(101)

157(9D)

158(9E) 258(102) 358(166)

159(9F) 259(103) 359(167)

260(104) 360(168)

160(A0)

161(A1) 261(105)

162(A2) 262(106)

163(A3) 263(107)

264(108)

164(A4)

165(A5)

265(109)

166(A6)

266(10A)

171(AB) 271(10F) 371(173) 471(1D7) BS Set input correction R/W EUS (-100 ~ 100%) ℃ EUS (0%)

172(AC) 272(110) 372(174) 472(1D8) FL Set input filter R/W 0 ~ 100 ABS 0

173(AD) 273(111) 373(175) 473(1D9) SVH Set SV high limit R/W EU (0 ~ 100%) ℃ EU (100%)

174(AE) 274(112) 374(176) 474(1DA) SVL Set SV low limit R/W EU (0 ~ 100%) ℃ EU (0%)

175(AF) 275(113) 375(177) 475(1DB) FRH Set PV high limit R/W EU (0 ~ 100%) ℃ EU (100%)

176(B0) 276(114) 376(178) 476(1DC) FRL Set PV low limit R/W EU (0 ~ 100%) ℃ EU (0%)

177(B1) 277(115) 377(179) 477(1DD) SLH

178(B2) 278(116) 378(17A) 478(1DE) SLL

179(B3) 279(117) 379(17B) 479(1DF) DOT Set decimal point R/W

455(1C7)

457(1C9)

357(165)

458(1CA)

459(1CB)

460(1CC)

461(1CD)

361(169)

362(16A)

462(1CE)

363(16B) 463(1CF)

464(1D0)

364(172)

365(173)

465(1D1)

366(174)

466(1D2)

MR Set Manual Reset R/W 0.0 ~ 100.0 % 0.0

RELAY

CT Set control cycle R/W 1 ~ 100 Sec.

Set emergency output

PO

Set hysteresis at ON/OFF

HYS

RO

RUP

RDN

RMIN

RHRS

DR

OHL

OLL

Set output at stop,

temperature at RAMP

temperature at RAMP

Set SV change time (min.)

Set SV change time (hr.)

Manipulated Value

Manipulated Value

Set scale high limit at

Set scale low limit at

control

monitor status

Set SV increase

control

Set SV decrease

control

at RAMP control

at RAMP control

Set control run

Set high limit to

Set low limit to

DCV input setting

DCV input setting

R/W 0.0 ~ 100.0

R/W EUS (0 ~ 10%) ℃

R/W 0.0 ~ 100.0 % 0

R/W EUS (0 ~ 100%)

EUS (0 ~ 100%)

R/W

R/W 0 ~ 1000 Minute 0

R/W 0 ~ 100 Hour 0

0: Reverse run

(heating) control

R/W

1: Forward run (cooling)

control

R/W 0.0 ~ 100.0 % 100.0

0.0 ~ 100.0 % 0.0

R/W

R/W EU (0 ~ 100%) mV EU (100%)

R/W EU (0 ~ 100%) mV EU (0%)

0 ~ 3 :

decimal point digit

: 30 Sec.

S.S.R :

2초 Sec.

% 0

(0.2%)

EUS (0%)

℃

℃ EUS (0%)

(Reverse

ABS

run (heating)

control)

ABS 0

EUS

0

Before staring Installation Operation Specifications

31

3.3. Manipulation and run

3.3.1 Input section

● Input type (INP)

It is a parameter setting input signal (sensor) type, and once this input type is set, input scope (range) and

decimal point indication or not is determined depending on the type of input. Input type can be set differently by

channel. All parameters related to PV are initialized when changing input type.

※ Set value (SV), Event Set value (EVVL), Event Hysteresis(EVHY), Event Loop break Dead Band (LBD), Set

value High/Low Limit (SVH/SVL), Reading High/Low Limit (FRH/FRL), Scale High/Low Limit Setting (SLH/SLL),

Set value Increase Temperature (RTUP), Set value decrease temperature(RTDN), input correction (BS), ON/OFF

control hysteresis (HYS),decimal point(DOT),proportional band(PB), integral time (TI), differential time (TD) 2 DOF

ALPHA value (AP) set value(SV),event set value(EVVL),event hysteresis (EVHY), event loop break alarm dead

band (LBD)

Symbol INP Input type Input scope (oC) Degree

1 K

2 K -199.9 ~ 1370.0

3 J -200 ~ 1200

4 J -199.9 ~ 1200.0

5 E -199 ~ 999

6 E -199.0 ~ 999.0

7 T -50 ~ 400

8 T -50.0 ~ 400.0

TC

Multi Loop Controller

RTD

DCV

F.S is from minimum value to maximum value of possible reading range of each input, and digit is

minimum indication value.

(Note 1) 0~400oC range: ±10% of F.S±1digit

(Note 2) Below 0oC: ±1% of F.S±1digit

(Note 3) -150.0 ~ 150.0oC range: ±1% of F.S±1digit

※ When using 4 -20mA direct current input, please select input code 31, and attach 250 Ω of electric resistance

to both input terminals.

32

9 R 0 ~ 1700

10 B (Note1) 0 ~ 1800

11 S - 0 ~ 1700

12 L

13 L -199.0 ~ 900.0

14 N - -199 ~ 1300 ±0.6 % of F.S ±1digit

15 U

16 U -50.0 ~ 400.0