HANYOUNG NUX HY-4500, HY-5000, HY-4700, HY-4500S, HY-4700S Instruction Manual

Analog Temperature Controller

HY-4500/4700/5000

MK0101KE180920

INSTRUCTION MANUAL

Thank you for purchasing HANYOUNG product.

Please check whether the product is the exactly same as you ordered.

Before using the product, please read this instruction manual carefully.

Please keep this manual where you can view at any time

Safetyinformation

Before using the product, please read the safety information thoroughly and use it properly.Alerts

declared in the manual are classified to Danger, Warning and Caution by their criticality

DANGER

WARNING

CAUTION

There is a danger of occurring electric shock in the input/output terminals so please never let

your body or conductive substance is touched.

•

If there is a concern about a serious accident caused by a malfunction or abnormality of this

product, please install an external protection circuit and devise a scheme for preventing an accident.

•This product does not contain an electric switch or fuse, so the user needs to install a

separate electric switch or fuse externally. (Fuse rating: 250 V 0.5 A)

•To prevent defection or malfunction of this product, apply a proper power voltage in

accordance with the rating.

•

To prevent electric shock or malfunction of product, do not supply the power until the wiring is completed.

•Since this product is not designed with explosion-protective structure, do not use it any place

with flammable or explosive gas.

•Do not decompose, modify, revise or repair this product. This may be a cause of malfunction,

electric shock or fire.

•

Reassemble this product while the power is OFF. Otherwise, it may be a cause of malfunction or electric shock.

•If you use the product with methods other than specified by the manufacturer, there may be

bodily injuries or property damages.

•There is a possibility of occurring electric shock so please use this product after installing it

onto a panel while it is operating.

•The contents of this manual may be changed without prior notification.

•Before using the product you purchased, make sure that it is exactly what you ordered.

•Make sure that there is no damage or abnormality of the product during the delivery.

•Use this product within the range of the operating ambient temperature, 0 ~ 50 ℃ (When it is

closely installed Max 40 ℃) and ambient humidity, 35 ~ 85 % R.H (No condensation).

•Do not use this product at any place with occurring corrosive

(especially noxious gas or ammonia) or flammable gas.

•Do not use this product at any place with direct vibration or impact.

•Do not use this product at any place with liquid, oil, medical substances, dust, salt or iron

contents.(Use at Pollution level 1 or 2)

•

Do not polish this product with substances such as alcohol or benzene. (Use neutral detergent.)

•Do not use this product at any place with a large inductive difficulty or occurring static

electricity or magnetic noise.

•

Do not use this product at any place with possible thermal accumulation due to direct sunlight or heat radiation.

•Install this product at place under 2,000m in altitude.

•

When the product gets wet, the inspection is essential because there is danger of an electric leakage or fire.

•In case of inputting thermocouple, use a compensating cable.

(If using a normal wire, there is a possibility of occurring temperature error.)

•

For R.T.D input, use a cable which is a lead wire has small resistance and resistances of three wires

shall be the same. (If the three wires have different resistances then there will be a temperature error.)

•To avoid an effect of inductive noise to input signal cables, use the product after separating

the input signal cables from power, output and load cables.

•Separate an input signal cable from an output signal cable. If separating is not possible,

please use the input signal cable after shielding it.

•Use non-earth sensor with thermocouple. (In case of using earth sensor, there is a possibility

of occurring malfunction caused by a short circuit.)

•

If there is excessive noise from the power supply, using insulating transformer and noise filter is

recommended. The noise filter must be attached to a panel which is already connected to a ground

and the wire between the filter output side and power supply terminal must be short as possible.

•If twisting the power cables closely together then it is effective against noise.

•

If the alarm functions are not properly set then it will not be output when the product is

malfunctioning. Therefore, make sure its movements are properly working before the operation.

•Turn the power OFF when replacing a sensor.

•Use an auxiliary relay in case of high frequent operation such as proportional operation or etc.

its life span will be shorter if connecting a load without permissible rating of output relay. In this

case, using SSR output type is recommended.

·Life Span of Contact Point Output :

Mechanical Life Span: above 10 million times (with no load)

Electrical Life Span: 100 thousand times (250 V a.c 3 A: with the rated load)

•Do not connect anything to the unused terminals.

•After checking the polarity of terminal, connect wires at the correct position.

•

When this product is connected onto a panel, use a circuit breaker or switch approved with IEC60947-1 or IEC60947-3.

•Install a circuit breaker or switch at near place for convenient use.

•Write down on a label that if the circuit breaker or switch is operating then the power will be

disconnected since the circuit breaker or switch is installed.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

Danger

Warning

Caution

HANYOUNGNUX CO.,LTD

HEADOFFICE

INDONESIA

FACTORY

•For the continuous and safe use of this product, the periodical maintenance is recommended.

•Some parts of this product have limited life span, and others are changed by their usage.

•The warranty period for this product including parts is one year if this product is properly used.

•When the power is on, the preparation period of contact output is required. In case of using

signals of external interlock circuit or etc., use it with a delay relay.

•In case of replacing this unit with a spare unit, make sure its compatibility because its operation

can be different by different parameter settings even though the model name is the same.

•Before using a temperature controller, there could be a temperature difference between PV of

the temperature controller and the actual temperature so please operate the temperature

controller after compensating the temperature difference appropriately.

1381-3, Juan-Dong, Nam-Gu Incheon, Korea.

TEL:(82-32)876-4697 FAX:(82-32)876-4696 http://www.hynux.net

PT. HANYOUNG ELECTRONIC INDONESIA

JL.CEMPAKA BLOK F 16 NO.02 DELTA SILICON II INDUSTRIAL PARK

LIPPO CIKARANG CICAU, CIKARANG PUSAT BEKASI 17550 INDONESIA

TEL : 62-21-8911-8120~4 FAX : 62-21-8911-8126

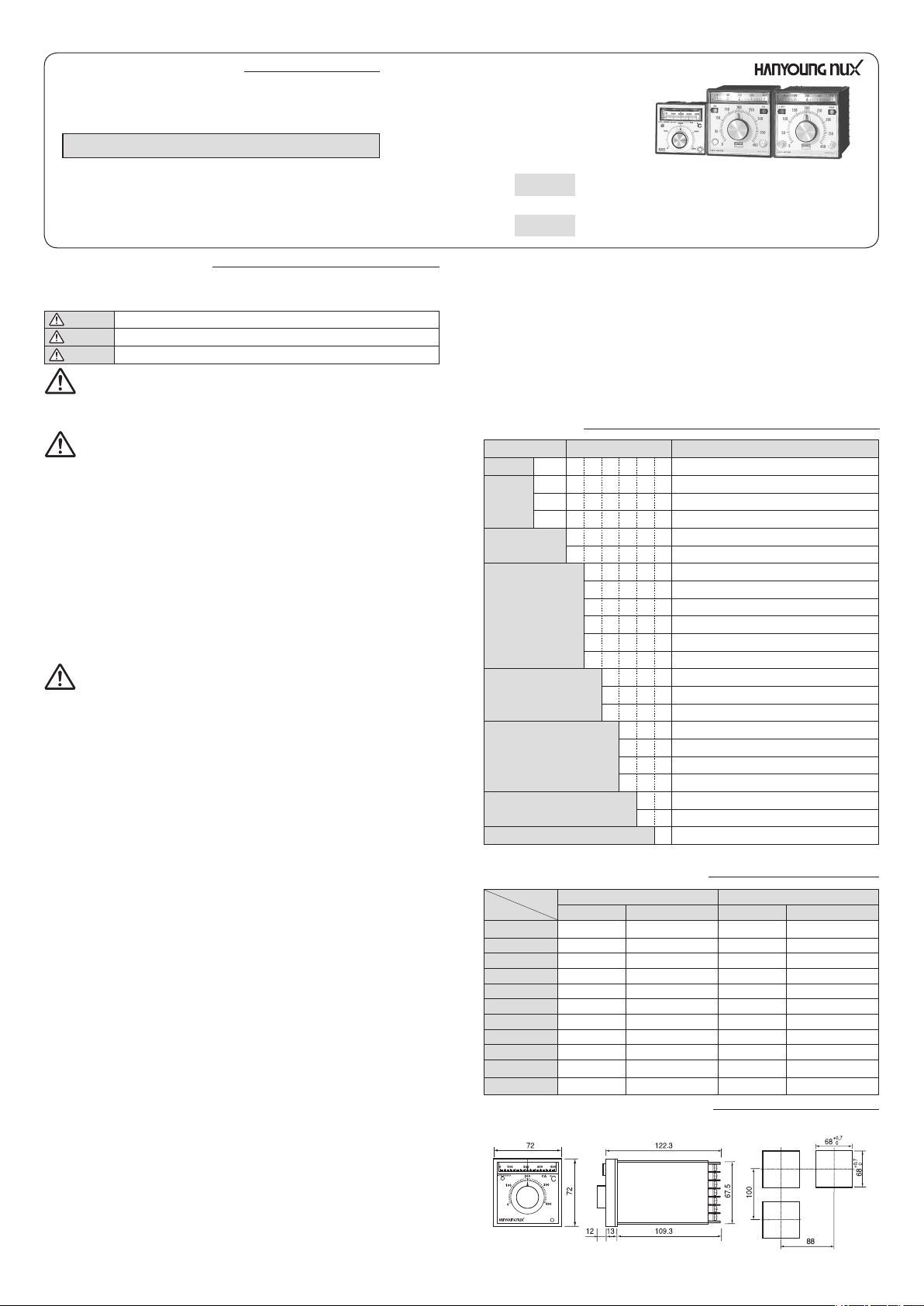

Suffixcode

Model Code Description

HY- Analog indication temperature controller

4500S 96(W) × 96(H)

Dimension

Control type

Input

Control output

Sub output (L.M)

(Apply only with the model

HY-4700)

Control operation

Range code Select the standard range code

4700S 96(W) × 96(H) (Auxiliary output : L.M)

5000S 72(W) × 72(H)

F ON/OFF control (2 position control)

P Proportional control

K K thermocouple

J J thermocouple

R R thermocouple

P RTD Pt100 Ω(IEC)

V 1 - 5 V d.c

C 4 - 20 mA d.c

M Relay

C Current output (4 - 20 mA d.c)

S S.S.R (12 V d.c Voltage pulse output)

N None

O High action

P Low action

W High·Low action

R Reverse action (Heating control)

D Direct action (Cooling control)

RangeandInputcodechart

Model

Code No

1 Pt100 Ω -50 ~ 50 Pt100 Ω -50 ~ 50

3 Pt100 Ω -50 ~ 100 Pt100 Ω 0 ~ 100

5 Pt100 Ω 0 ~ 100 K, Pt100 Ω 0 ~ 200

6

7 K, Pt100 Ω 0 ~ 200 K, Pt100 Ω 0 ~ 400

8 K, Pt100 Ω 0 ~ 300 K 0 ~ 600

9 K, J, Pt100 Ω 0 ~ 400 K 0 ~ 800

10 K 0 ~ 600 K 0 ~ 1200

11 K 0 ~ 800 - 13

14

HY-4500S, HY-4700S HY-5000

Input Range (℃) Input Range (℃)

- -

K 0 ~ 1200

R 0 ~ 1600

K, Pt100 Ω 0 ~ 300

- -

- -

DimensionandPanelcutout

█HY-5000

3

[Unit : mm]

Temperature

Temperature

Time

Time

SV

ON

OFF

SV

PB

PB

PT

PC

Over shoot Hunting Adjusting Sensitivity

Temperature

Time

SV

SV

PB

PB

PT

PC

█HY-4500S,4700S

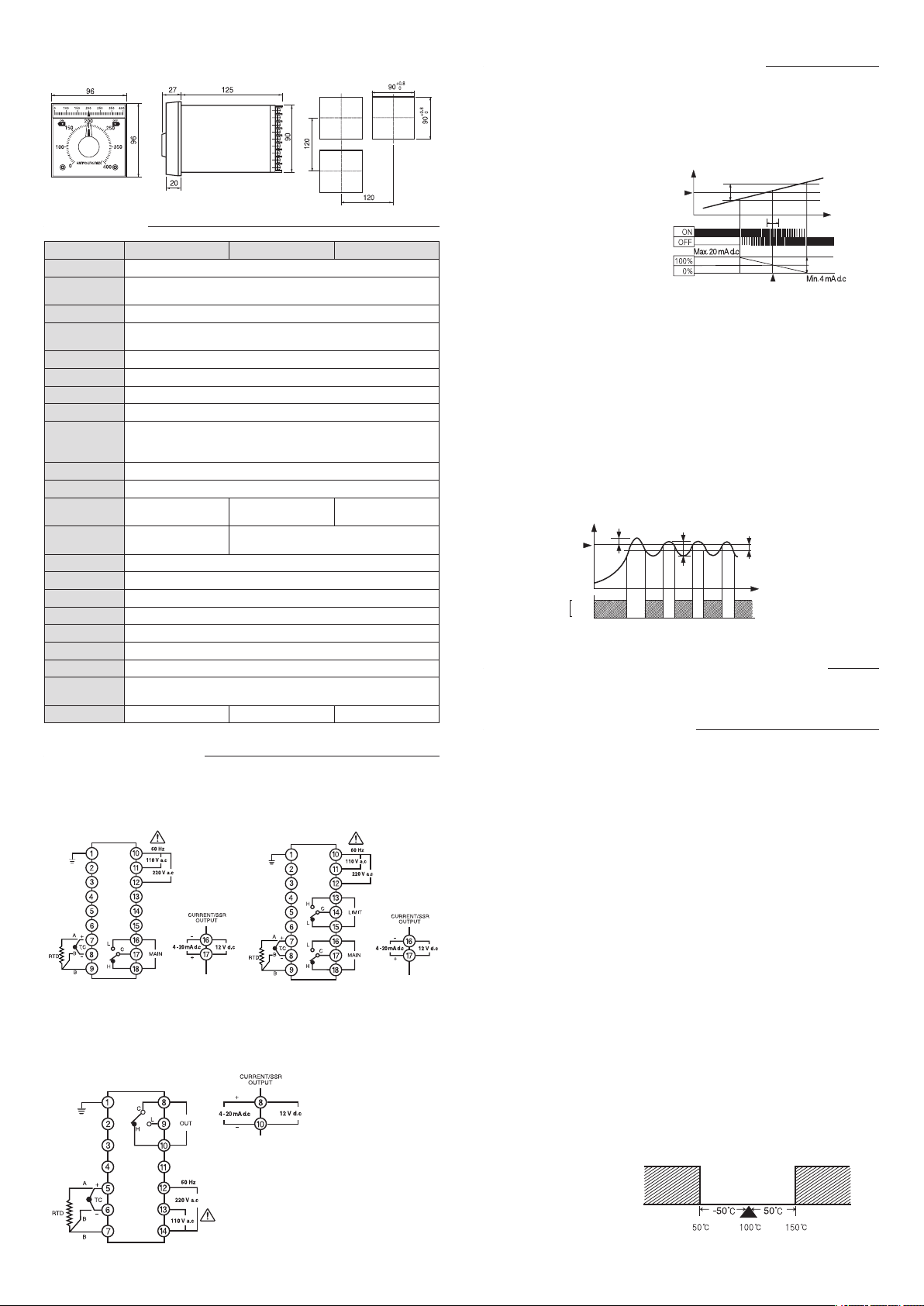

Specification

Model HY-4500S HY-4700S HY-5000

Power supply voltage

Allowable voltage

fluctuation

Power consumption

Input

Adjusting Sensitivity

Control Method Proportional Control, ON/OFF Control

Setting Method Analog Setting

Display Method Analog Display

Control Output

Setting Accuracy 2 % of max. Range

Display Accuracy ±2.0 % of F.S ±1 digit

Alarm Operation -

Proportional Band

Proportional Cycle Relay output : 20 ~ 30 sec SSR output : 2 ~ 4 sec

Insulation Resistance

Dielectric Strength 2000 V a.c, 50 - 60 Hz for 1 minute

Noise Immunity Squared wave noise (Pulse width : 1000 ㎲) ±1 KV

Vibration Resistance

Shock Resistance 300 ㎨

Relay Life Expectancy

Ambient

Temperature/Humidity

Weight

Connectiondiagram

(see Range and Input code chart)(Built-in Burnout circuit)

Relay Output : Capacity 250 V a.c 3 A (Resistive Load) contact : 1c

SSR Output : 12 V a.c (Constant Voltage Pulse) (Resistive Load : above 800 Ω)

Current Output : 4 - 20 mA d.c (Resistive Load : below 600 Ω)

1 - 10 % of max.

Range(variable)

10 - 50 Hz (cycle for 1 minute), double amplitude : 0.75 mm, each X·Y·Z direction for 1hour

Mechanical : 10 millions times, Electrical : 100 thousands times (250 V a.c, 3 A Resistive Load)

0 ~ 50 ℃ / 35 ~ 85 % R.H (without condensation)

658 g (Including brackets) 658 g (Including brackets) 358 g (Including brackets)

█HY-4500S

※Limit output: when Measuring Value > Setting Value, it is “ON”

█HY-5000

110/220 V a.c 50/60 Hz

±10 % of power supply voltage

Approx. 3 VA max

Thermocouple, RTD, DC current, DC voltage

±2.0 % (fixed) of max. Range

High action, Low action,

High·Low action

3 % of max. Range(Fixed)

20 ㏁ min ( 500 V a.c mega)

█HY-4700S

Terminology&FunctionExplanation

█ProportionalControl

Proportional Control is that an output capacity regarding a setting value (SV) is proportionally

operated by a deviation. The width which the output is varied within 0 ~ 100 % is called

Proportional Band (PB). Therefore, for Reverse Action, if PT=Present (Process) Temperature,

PB=Proportional Band

PT < PB → Output capacity 100 %

PT > PB → Output capacity 0 %

PT = PB → Output capacity 50 %

·PT : Present (Process) Temperature

·PC : Proportional Cycle

·SV : Setting Value (Temperatrue)

·PB : Proportional Band

SV

Temperature

PB

SV

PT

PC

Time

PB

█2-positionControl,ON-OFFControl

This is a control method that if PT is higher than SV then output will be OFF or if PT is less

than SV, then the output will be ON. Also, it is called 2-position control since it outputs either

0 % or 100 %. The status which the temperature is unstable and there is high/low wave

around SV is called hunting. The width between the point where its output is OFF because PT

is higher than SV and the point where its output is ON since PT is less than SV is called

adjusting sensitivity, hysteresis. If the width, hysteresis, is narrow, then high/low wave

becomes smaller but the cycle of ON-OFF gets smaller so that it may severely damage to

electromagnetic switch, electrovalve or etc.. Especially, for controlling burner which is using

freezer or electrovalve, 2-postion control is generally used.

·PT : Present (Process) Temperature

Setting

Value

Output

Temperature

Over shoot Hunting Adjusting Sensitivity

ON

OFF

Time

-

ProportionalControl/ON-OFFControlSelection

It is depending on its specification code when you are ordering.

UsageoftheFrontVolume

█ProportionalBand(PB)

•For Proportional Control :

If the proportional band (PB) is narrow, then the output’s variable width will become

smaller so that the time which the controlling temperature(PT) is approaching to SV* is

fast. Also, OFF-Set (deviation) becomes small. However, if PB* is too narrow, then there

is over shoot or hunting. PB* can be set within the max range of 1 ~ 10 %. If turn the PB

volume in clockwise then PB* gets larger.

If turn the PB volume in counterclockwise then PB gets smaller.

•For ON-OFF Control :

For the case of selecting ON-OFF Control, the adjusting sensitivity is varied within the

max range of 1 ~ 10 % by PB volume.

█ResetVolume(RST)

For Proportional Control, when the controlling temperature(PT) and SV* are the same, it

generates 50 % of output so that there is constant error (normal deviation) by heat capacity or

etc. of a controlling target.

To eliminate this matter, change the output capacity by Reset volume.

Display Value < Setting Value: Turn the volume in clockwise.

Display Value > Setting Value: Turn the volume in counterclockwise.

█AlarmVolume(ALM)

For Alarm Operation, ±0 ~ 50 ℃ of the setting value (SV) can be set and high limit, low limit or

high/low limit operation can be selected.

Ex) for case of setting Alarm (ALM) as 50 ℃

High Limit Operation : it will operate when it is 50 ℃ higher than SV*.

Low Limit Operation : it will operate when it is 50 ℃ lower than SV*.

High/Low Limit Operation : it will operate when it is 50 ℃ higher or 50 ℃ lower than SV*.

·PT* : Present (Process) Temperature

·PC* : Proportional Cycle

·SV* : Setting Value (Temperatrue)

·PB* : Proportional Band

Low Limit Operation

High Limit Operation

(Setting Value)

4

Loading...

Loading...