●

Programmable Temperature and Humidity Controller

Manual

tableofcontents

before starting

1

Installation method

2

3 Setting and operating

4 Displays

5 Function setting

1.1 Checking the product5

1.2 Safety information7

.3 Quality guarantee8

1

2.1 How to install9

2.2 Suffix Code10

2.3 Dimension and panel cutout11

.4 Connection diagram14

2

2.5 Communication connection18

3.1 Initial screen20

3.2 How to input21

The name of each part on the operating screen

3.3

3.4 Fix control30

3.5 Program running32

3.6 PID Auto-tuning34

3.7 Graph display and setting35

3.8 Error indication36

4.1 Working display37

4.2 Function setting display38

4.3 System setting screen38

5.1 Operation setting41

5.2 Program setting42

5.3 Date/time reservation setting55

5.4 Graph/Save setting56

26

6 System setting

7 Simple example

8 Specification

6.1 Sensor type setting59

6.2 Control output setting63

6.3 Retransmission output setting66

6.4 Inner signal and alarm setting67

6.5 P.I.D setting71

6.6 Digital input (D.I) configuration setting74

6.7

Digital output (D.O) configuration setting

6.8 Communication setting80

6.9 Other setting81

7.1 Input related setting82

7.2 Output related setting84

7.3 Inner signal setting85

7.4 Fix control86

7.5 Program control88

8.1 Input91

8.2 Output91

8.3 Communication92

8.4 Power supply92

8.5 Functions93

8.6 Touch LCD94

8.7 Operation environment94

76

9 Accessories

(sold separately)

EM310 USB memory storage device95

3

1

Before Starting

Thank you for the purchase of HANYOUNG Temperature and Humidity Controller

(Model# TH500/TH300).

This manual contains the function of product, install method, caution information and the way of using

this controller. So please read this manual before using it. And also please make this manual to be

delivered to the final user and to be placed where can be found and seen easily

(Contents of this user manual can be edited without prior notice for improvement and modification of

the product.)

* Information in this manual may changed without prior notification.

* If you have any question or find error in this manual, please contact us

* Copying or reprinting this manual without notifying us is prohibited.

■ Service(A/S)

* Please send product to the nearest distributor, agency or head quarter for A/S.

When willing to have an on-site A/S, please call our A/S center and make an appointment.

*

* Before making an appointment for A/S, please check out our web and search for the same

problem in our FAQ.

HANYOUNG NUX

#1381-3, Juan-Dong, Nam-ku, Incheon, Korea

TEL : (+82-32) 876-4697

FAX : (+82-32) 876-4696

URL : http://www.hynux.com

E-mail : overseas@hynux.com

4

1.1 Checking the product

After purchasing the product, please check for the correct model type and check for any abnormal

parts/scratches on the outside. If it is incorrect model type or find any abnormal parts/scratches on

the outside, please contact to our nearest sales office.

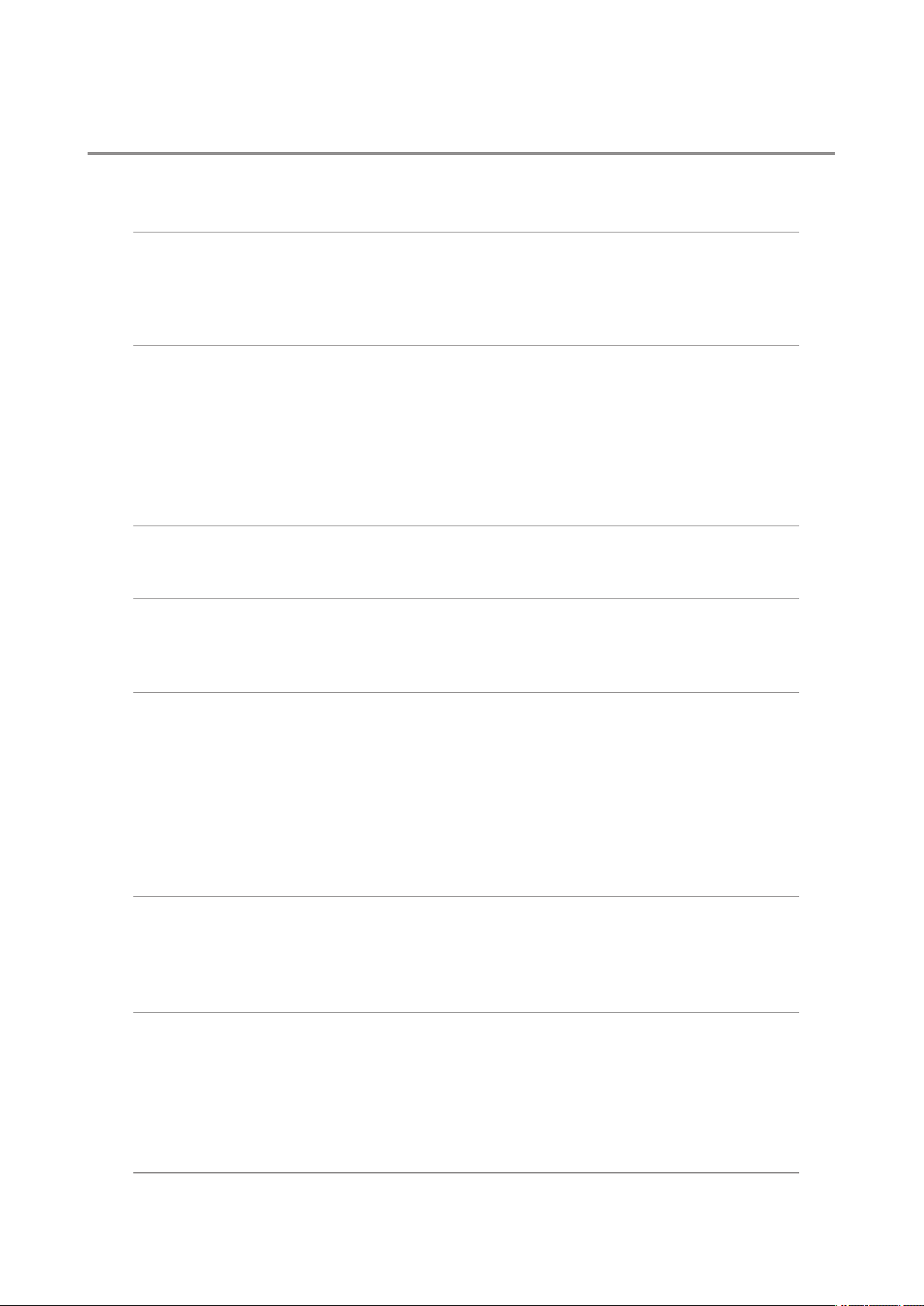

1.1.1 TH500

⦁ Standard

1)TH500-1NN

Resistance

250 Ω× 2

Standard Type

⦁ Additional

1)TH500-21N

Additional Type

Resistance

250 Ω×2

Fixing bracket

Fixing bracket

40p cable

Manual

I/O Board 1

Manual

5

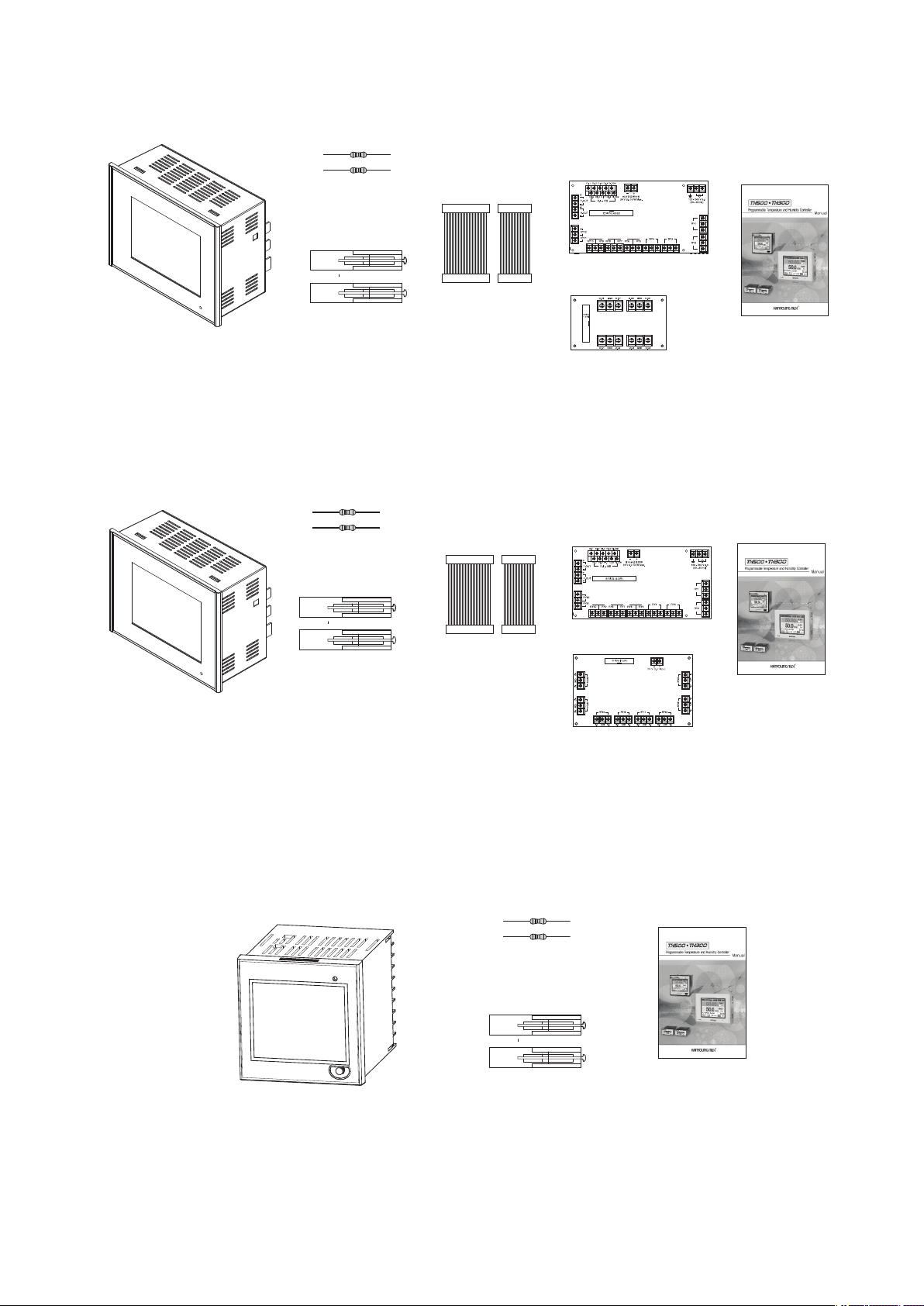

2)TH500-24N

Additional Type

3)TH500-25N

Resistance

250 Ω×2

Fixing bracket

Resistance

250 Ω×2

40p cable

20p cable

I/O Board 1

I/O Board 2

Manual

I/O Board 1

Additional Type

1.1.2 TH300

Fixing bracket

40p cable

20p cable

Resistance

250 Ω×2

Fixing bracket

I/O Board 3

Manual

Manual

6

1.2

Safety information

Alerts declared in the manual are classified to Danger, Warning and Caution by their criticality

Danger

Warning

Caution

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

AUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

C

Warning

• For safety and security of the system that is connected to the product, please read and follow

this manual carefully.

• We are not responsible for any damages and safety problems due to disregards of the manual or

lack of care of the product.

• Please install any extra safety circuitry or other safety materials outside the product for safety of

the program that is connected to the product.

• Do not disassemble, repair or reconstruct the product. It can cause electric shock, fire, and errors.

• Since this is not explosion-proof structure, please use in a place where corrosive gas

(such as harmful gas, ammonia, etc.), combustible or explosive gas does not occur.

• Do not give impact to products. It can cause of damage or malfunction.

• When you wire it, please cut out all of electric power.

• Please do not block ventilating windows. It may cause of break down.

•To avoid electric shock, please use it after installation to panel.

• Do not operate controller with wet hand, it may cause of electric shock.

• This controller is operating in 100 V - 240 Va.c, 50 - 60 Hz without additional change.

If you use other voltage, it may case of fire and electric shock.

• When you put to earth, please refer to install method. But do not it earth to gas pipes,

phone lines and lightning rods.

• When installing the product, please install a switch or a circuit break in order to separate the main

power.

Caution

•Please avoid installing the product for following places where

·People can touch terminal unconsciously

·Directly exposed to the mechanical vibration or impact.

·Exposed to the corrosive gas or combustible gas.

·It is exposed to mechanical shock or vibration

·Danger of corrosion or combustion of gas exist

·Temperature changes too frequently

·Temperature is either too high or too low

·It is exposed to direct rays

·It is exposed to electromagnetic waves too much

·Humid place

7

·It has many combustible objects

It has dusts and salinity

·

•The case of this controller is chrome-zinc plating and Bezel is made by ABS/PC

anti-combustion material but please not install it to the inflammable place.

Especially please do not put it on the inflammable products.

• Please keep it away from the machine or wires that can be cause of noise.

Especially, please have enough warn-up when you operate it under 10 Ωtemperature.

•Please install it on horizontally

• Please follow Safety Information to prevent any fire, electric shock and any damage.

• Please follow this manual for install and operation of this controller.

• Please do not turn on power until you install all of parts

• The grade of over voltage is CatalogueII and using environment is DegreeII

1.3 Quality guarantee

•Unless it is included company's conditions for warrantee, we are not responsible

for any warranties or guarantees.

• We are not responsible for any damages and indirect loss of the use or third

person due to unpredicted natural disasters.

• The warranty for this product is valid for 1 year from purchase, and we will fix any

breakdowns and faults from proper uses as it is mentioned in this manual for free.

• After the warranty period, repair will be charged according to our standard policies.

• Under following conditions, repair will be charged even during warranty period.

•Breakdowns due to user's misuses

•Breakdowns due to natural disasters

•Breakdowns due to moving the product after installation.

•Breakdowns due to modification of the product

•Breakdowns due to power troubles

• Please call our customer service for A/S due to breakdowns.

8

Panel

Insertion direction

Thickness of

panel : 1 ~ 10 ㎜

Fixing bracket

Panel

Insertion direction

Thickness of

panel : 1 ~ 10 ㎜

Fixing bracket

Fixing bracket

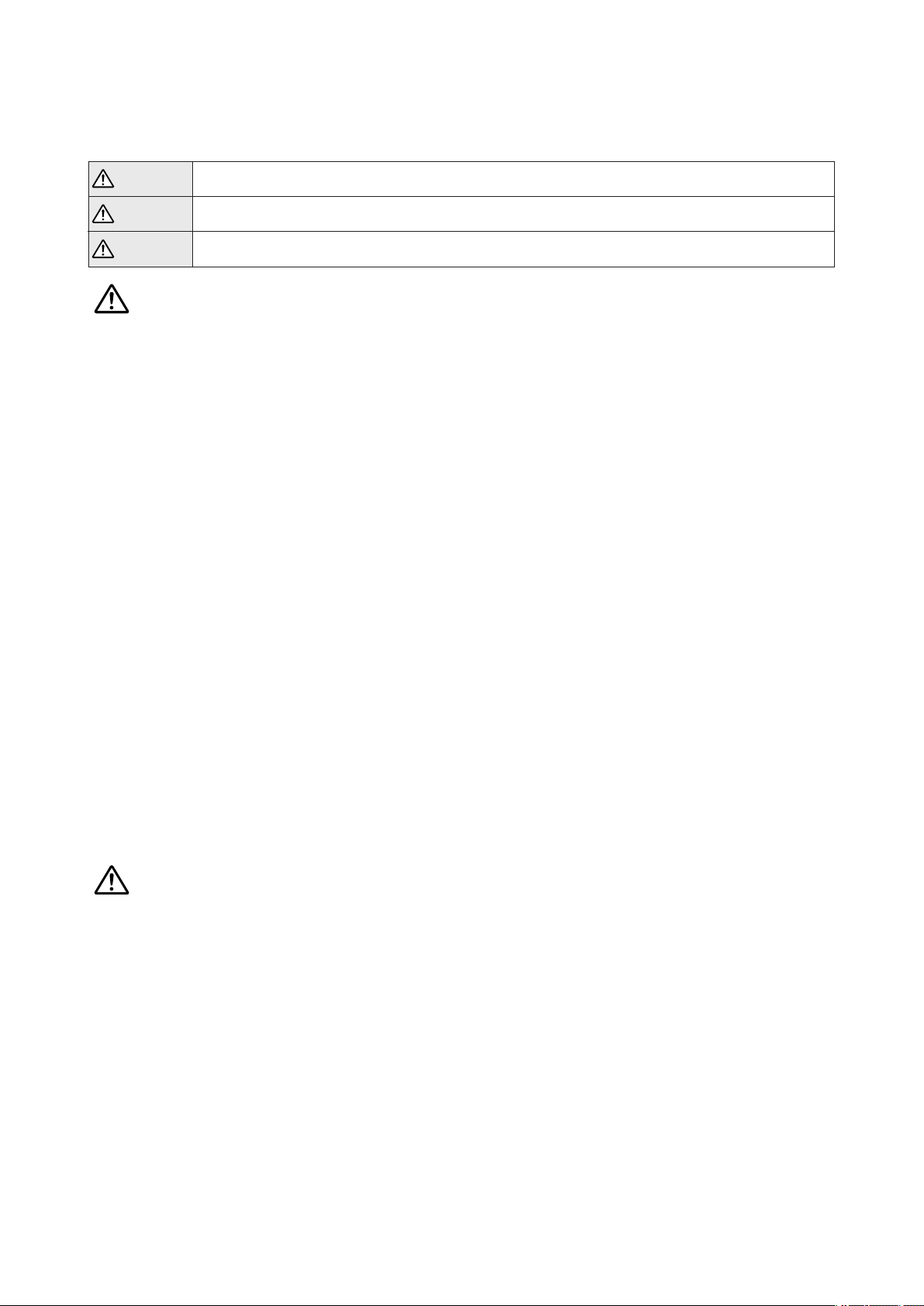

2 Installation method

This is information for installation place and method of TH300/TH500 temperature and humidity

program controller. So please ready it before installation.

2.1 How to install

(1) Use the sheet plate with thickness 1 ㎜ ~ 10 ㎜ for panel

(2) Push in the temperature/humidity controller starting at the front panel

(3) Mount the product by using the fixing bracket just like an image below.

(4) Tightening ittoostronglymay damagethefixingbracket orchangetheshapeofcase

when mounting it to the panel by using the fixing bracket.

■TH500 ■TH300

•To prevent electric shock, please check “turn off power”

•Before turn on power, please connect over the thirdclass grounding.

•During retransmission, it may cause electric shock so please do

not touch terminal.

• Please wire it after turn off main power

• Please contact around 2A fuse to main electronicpower line.

9

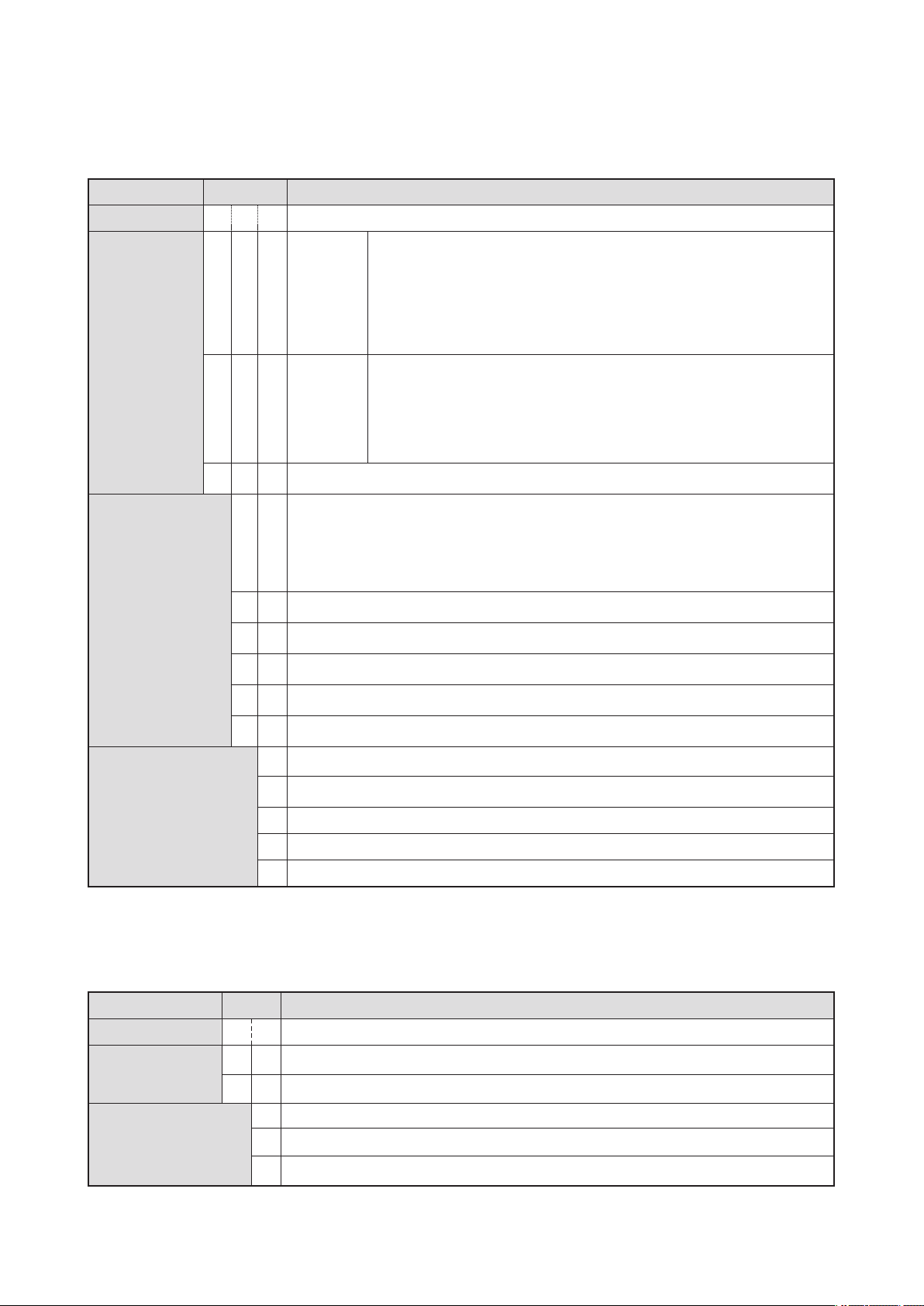

2.2 Suffix Code

2.2.1 TH500 Suffix Code

Model

TH500 -

TYPE

Separate Input ·

Output Board

Code

☐☐☐

1

2

N

1

2

Description

Programmable Temp.& Humidity Controller/ 183(W)X144(H)x103(D)

✽ Temp. & Humidity retransmission output

Standard

Type

Additional

Type

No Standard body (In case of purchasing separate I/O Board)

Input·Output Board-1 (Relay output 12 points)

Temp. & Humidity control output(SSR/SCR)

D.I : 8 points, D.O : 12 points Relay Output, SMPS : 24Vd.c18 W

Input·Output Board-2 (Open Collector 8 points external terminal board)

✽ Temp. & Humidity control output(SSR/SCR)

✽ Temp. & Humidity signal input ✽ Digital Input(D.I) : 8 points

✽ Digital Output(D.O) : Relay 12 points, Open Collector : 8 points

✽ Communication : RS232,RS485/422,USB

✽ Separate I/O Board from standard body.

✽ Temp. & Humidity retransmission output

✽ Temp. & Humidity signal input

✽ Communication : RS232,RS485/422

(Option)

3

4

5

N

Language

※ Example of Suffix Code (Standard type : TH500-1NN / Additional type : TH500-21N)

Input·Output Board-3 (Relay output 8 points output board)

Input·Output Board-1 + Output Board-2

Input·Output Board-1 + Output Board-3

No Output Board (In case of selecting standard body)

Korean / English (Standard)

N

English / Simple Chinese

2

English / Traditional Chinese

3

Korean / Simple Chinese

4

Korean / Traditional Chinese

5

2.2.2 TH300 Suffix Code

Model

TH300 -

Communication

Code

☐☐

1

2

Programmable Temp.& Humidity Controller/ 96(W)X96(H)x100(D)

RS232C

RS485/422

Description

Language

1

Korean/English

2

English/Simple Chinese

3

English/Traditional Chinese

10

186 min

147 min

186 min

147 mi n

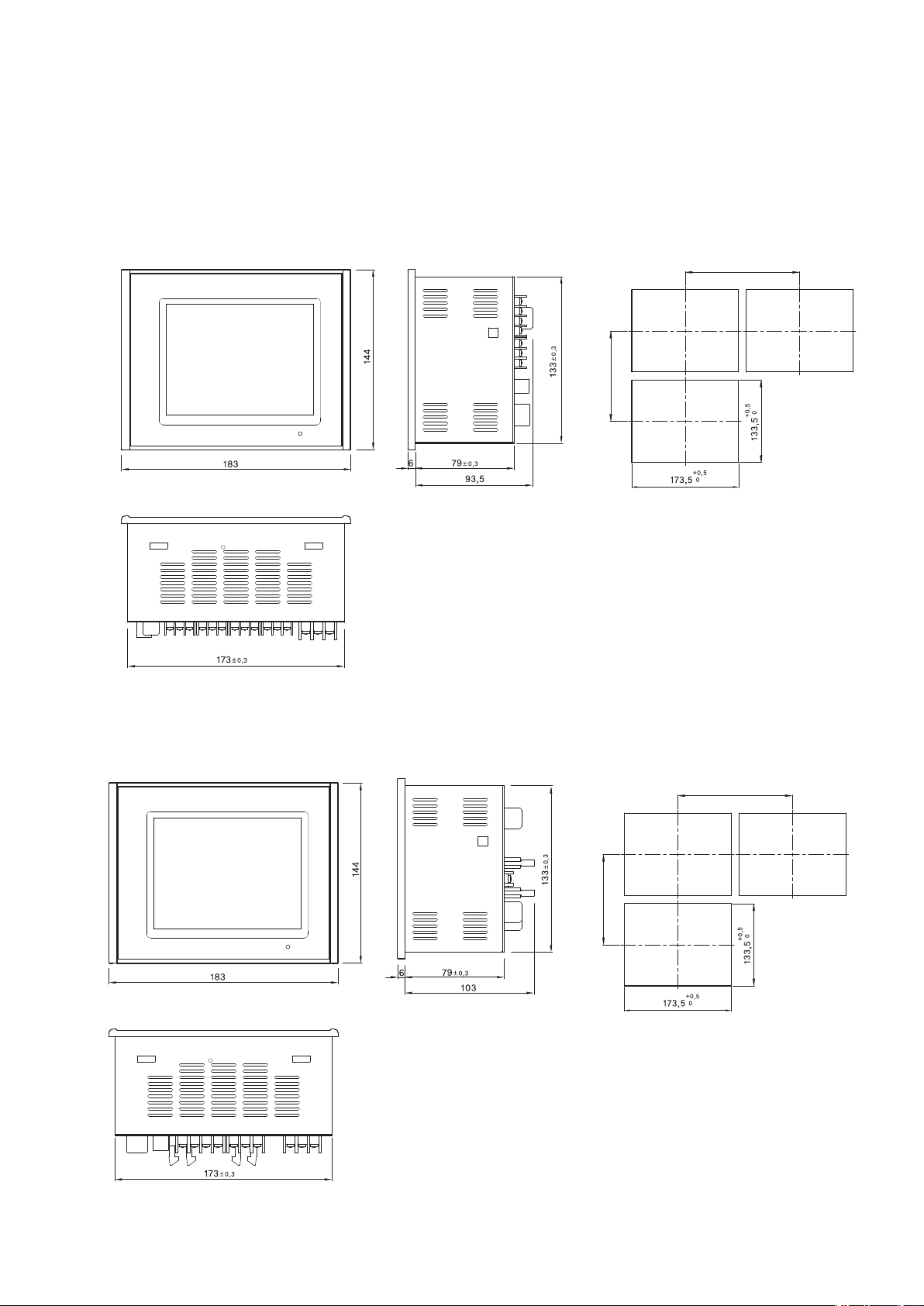

2.3 Dimension and panel cutout

2.3.1. Type

●TH500-1 (Standard)

[Unit : ㎜]

●TH500-2 (Additional )

[Unit : ㎜]

11

2.3.2 Separate body

Connector(40 Pin)

P

ower Supply for sensor

24 V d.c 18 W max.

D

.I - 8 Points

Connector(20 Pin)

● Input/Output board-1

[Unit : ㎜]

● Output board-2 (External terminal board)

[Unit : ㎜]

12

● Output board-3

Connector(20 Pin)

Unit : ㎜]

[

2.3.3 Standard type(TH300)

[Unit : ㎜]

13

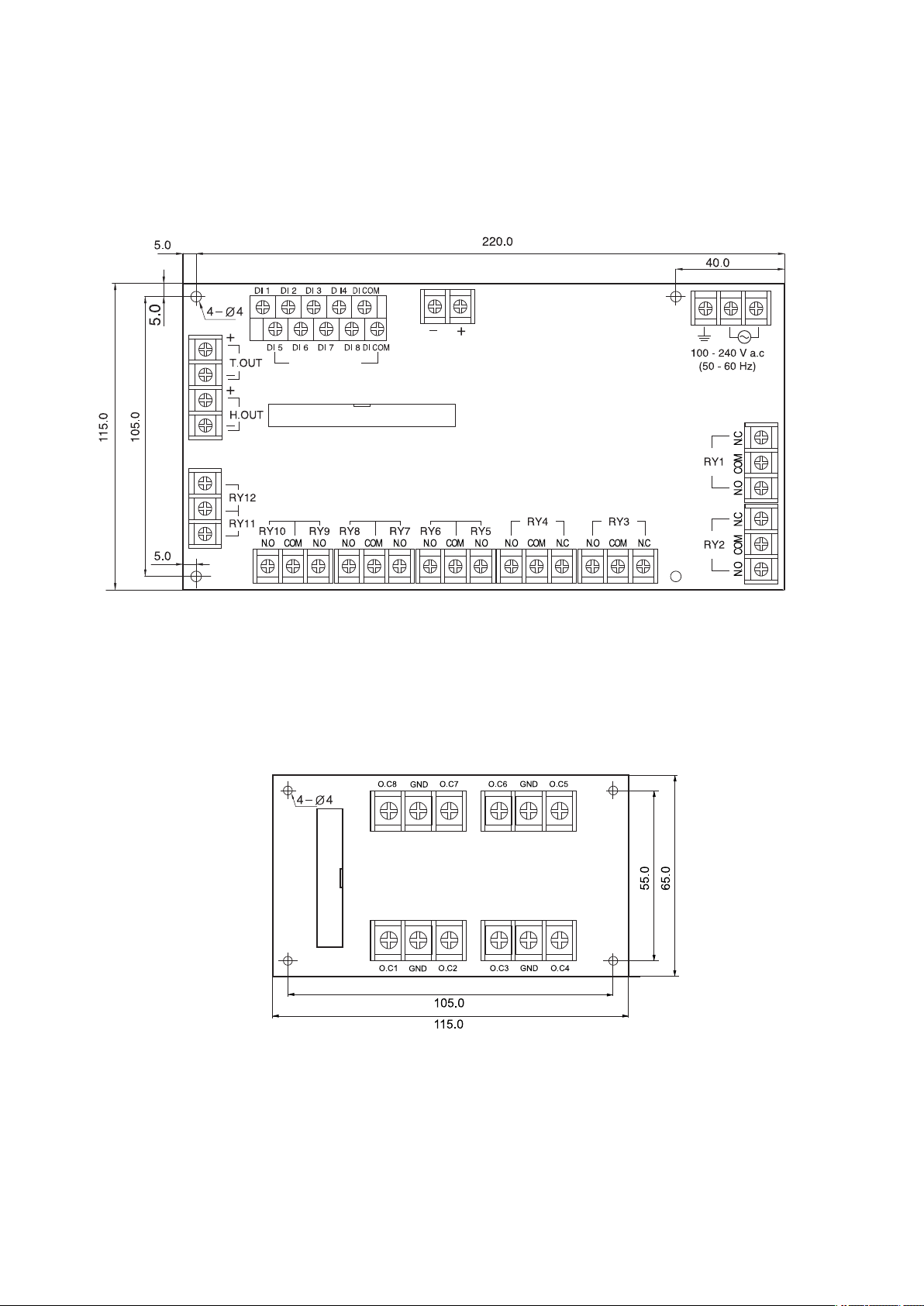

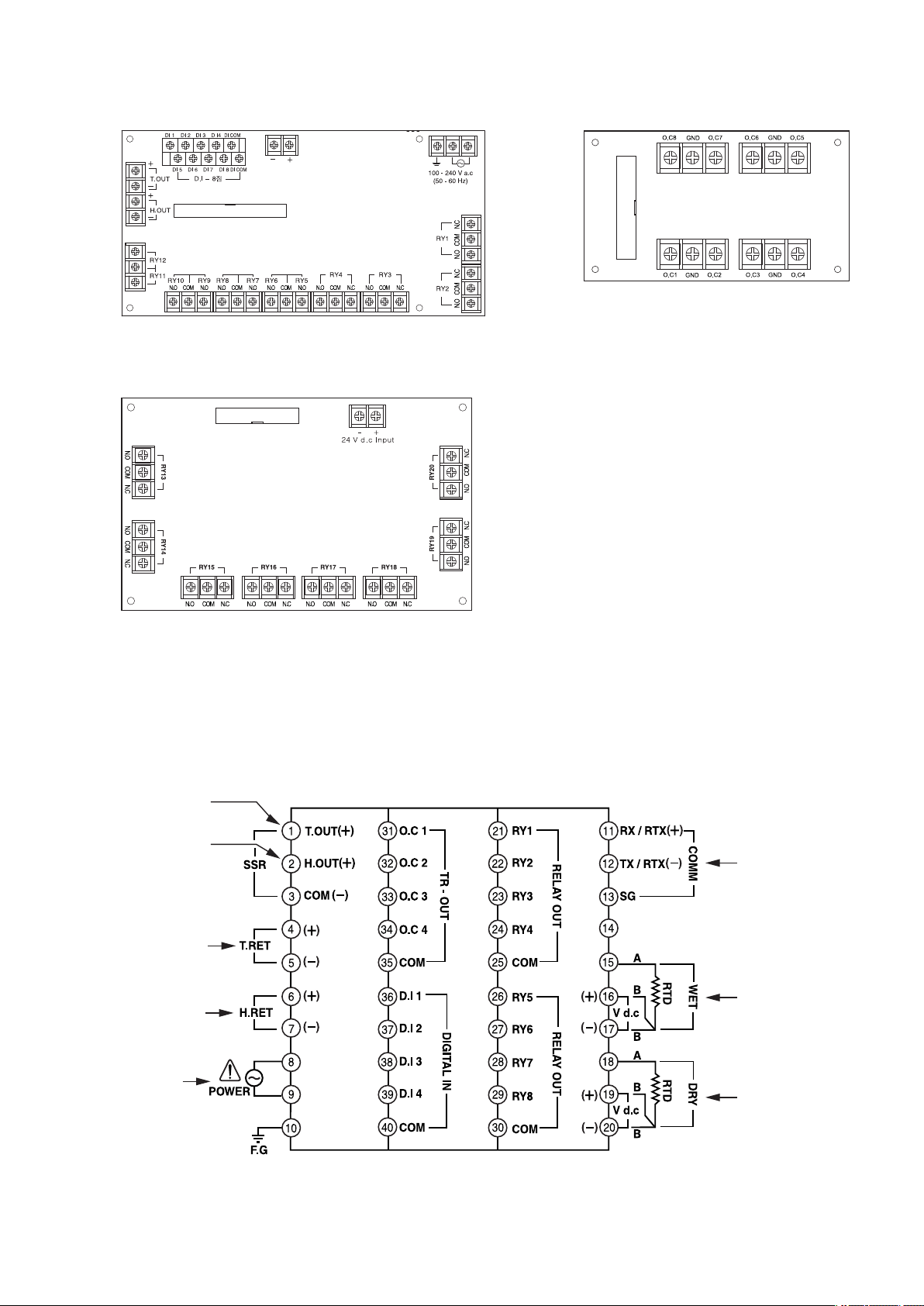

2.4 Connection Diagram

2.4.1 Model : TH500-1☐☐

2.4.2 Model : TH500-2☐☐

14

Te m p e r a t u r e

Control output

Humidity

Control output

Te m p e r a t u r e

retransmission out

Humidity

retransmission out

Power

supply voltage

Communication

terminal

Humidity

input sensor

Te m p e r a t u r e

input sensor

Connector(40 Pin)

Power Supply for sensor

24 V d.c 18 W max

Connector(20 Pin)

Connector(20 Pin)

● Input/output board-1

● Out put board-3

● Output board-2

2.4.3 Model : TH300☐☐

15

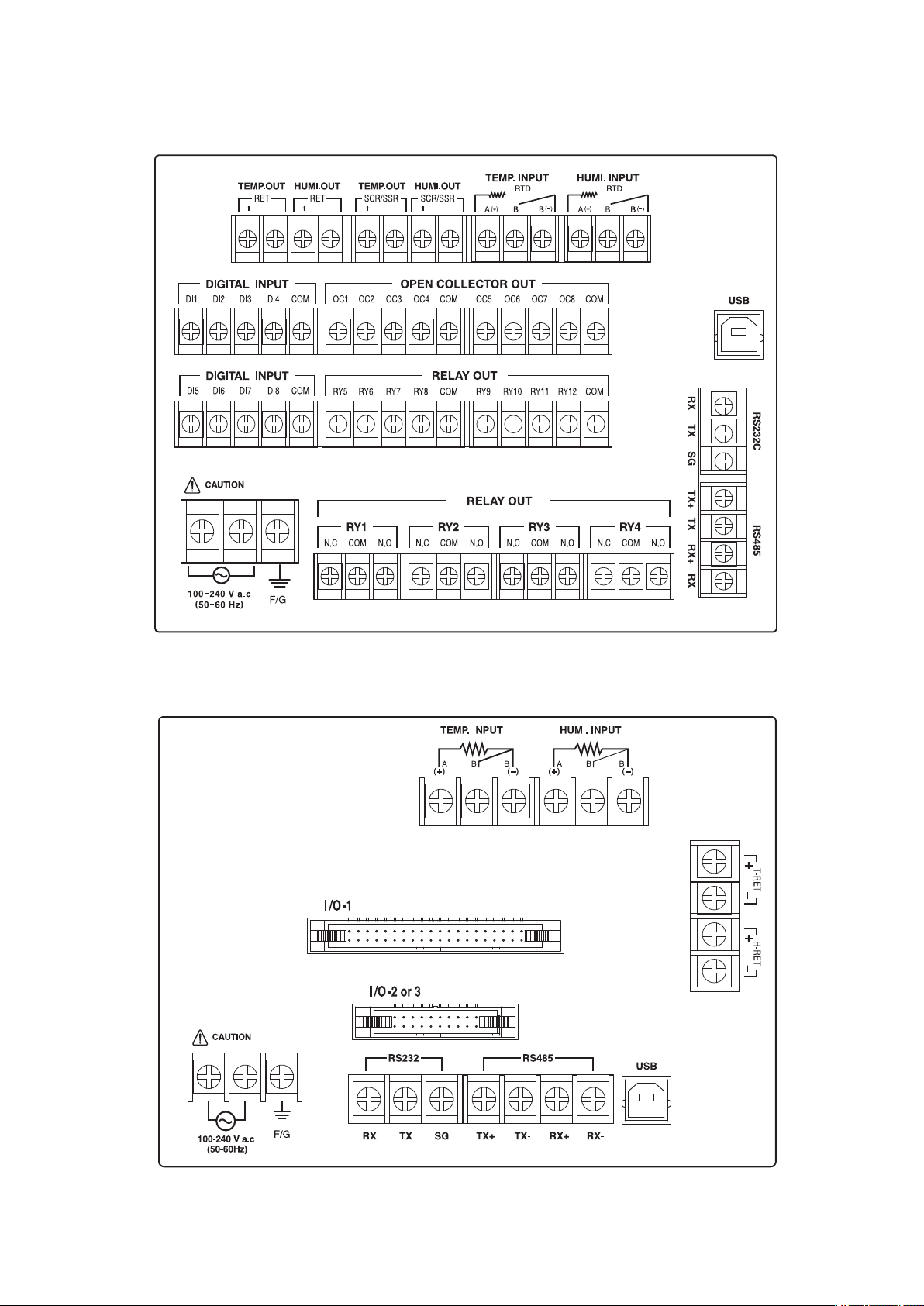

2.4.4 Connection method

SSR or SCR

r

recorder,

indicator and etc

•Grounding needs more than 2 ㎜ 2 wire at least the 3rd class grounding

connection (Grounding resistance : less than 100 Ω).

•Please use input signal wire and output wire with shield and the shield

needs to have one point grounding.

•In case of R.T.D input, please connect 3 wires without resistance difference

among three wires.

•Please connect Input, Output signal wire separately from power line.

•In case of current input, please attach resistance 250 Ω0.1 % at the end

of input terminals and use it accordingly.

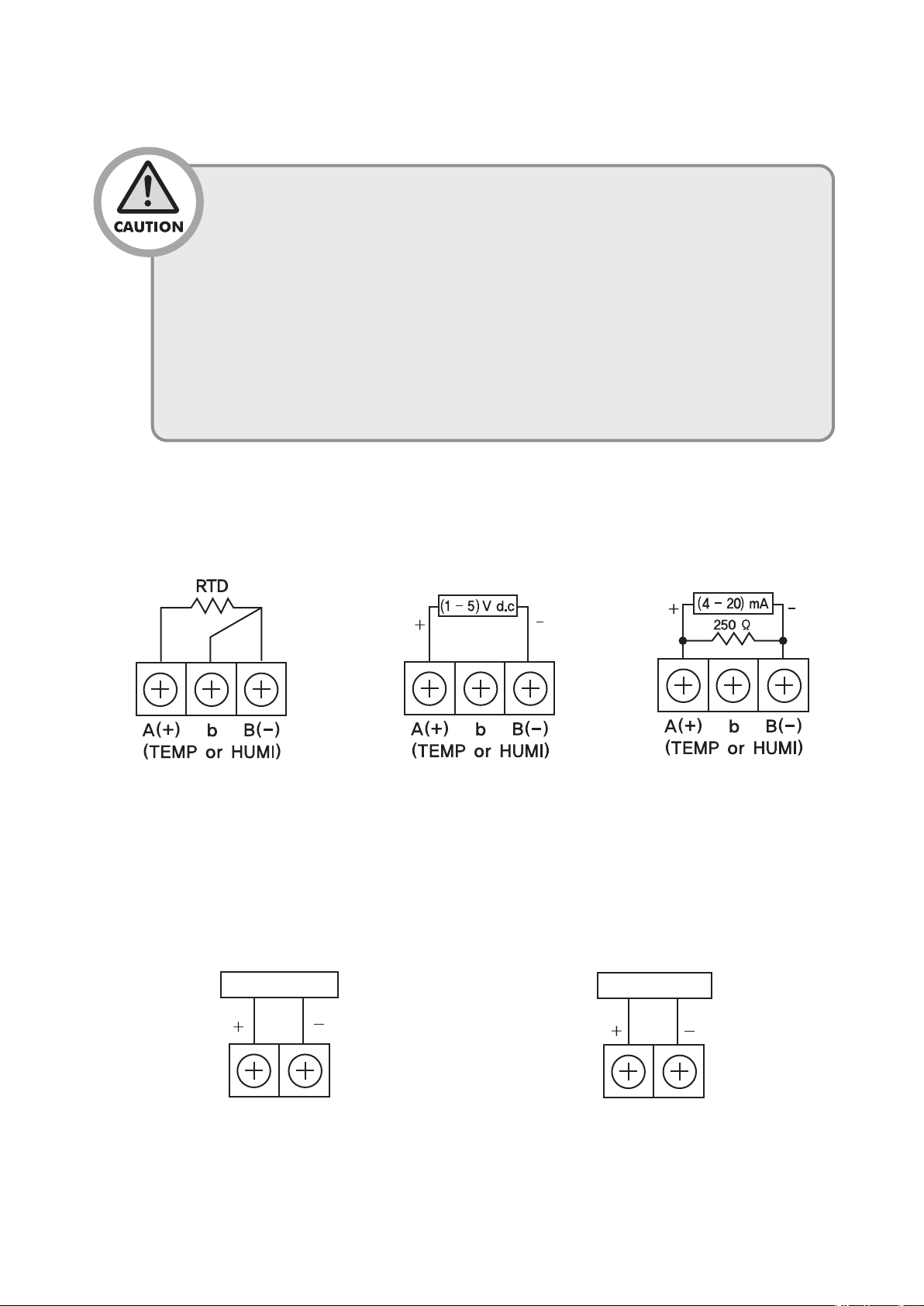

● Sensor Input

■ RTD Input

Connection of Temp / Humidity control output and retransmission output

●

■ Connection of Temp / Humidity control output■ Temp / Humidity retransmission output

■ DC voltage input■ DC current input

16

● Digital output (D.O)

■ Relay output (1c Contact) - ※ Only with TH500.

■ Relay output (1a Contact)

■

Transistor output (With TH300 D.O : 1 ~ 4)

17

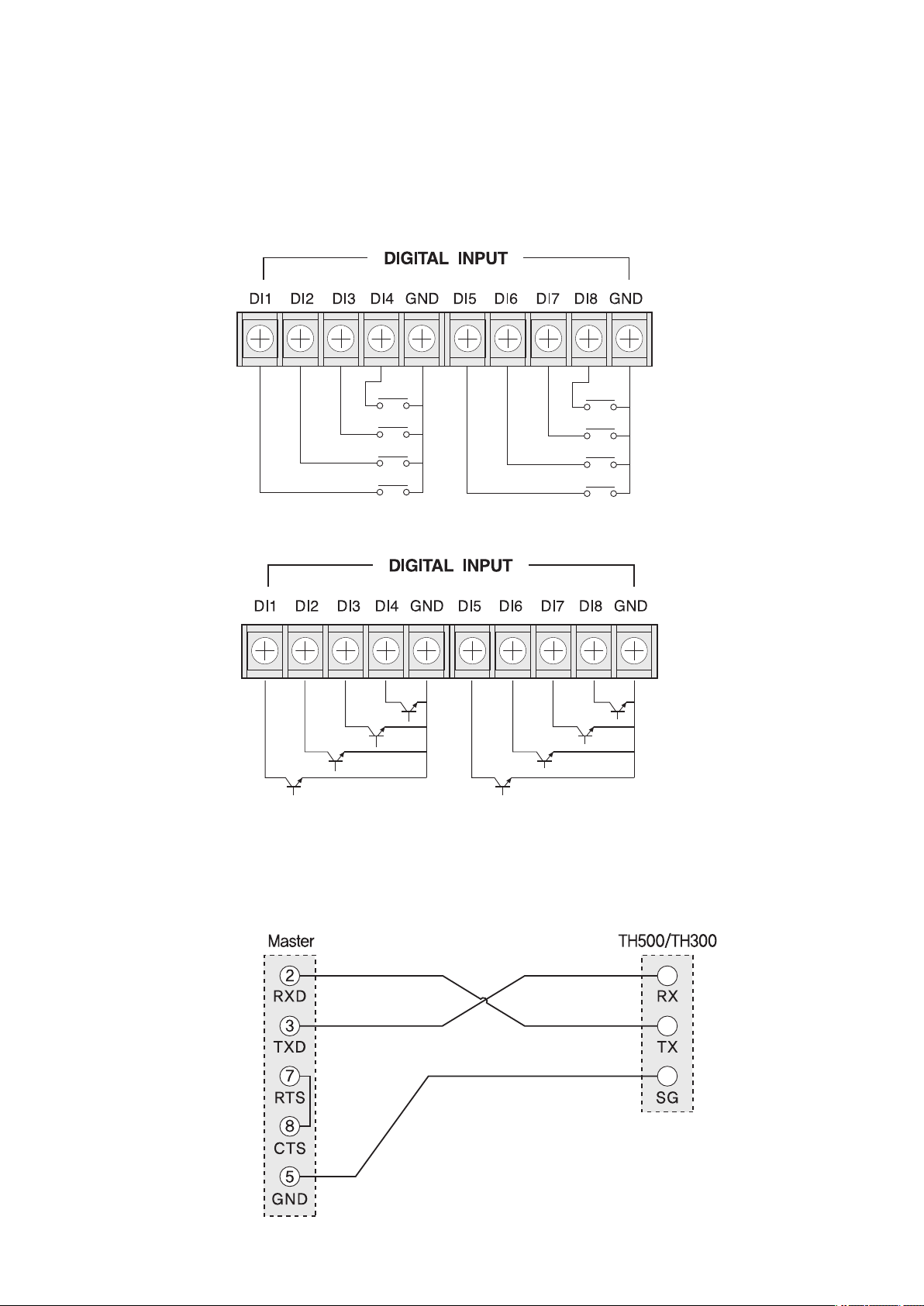

2.4.5 Digital Input (D.I)

When using open collector, please use as follows : Voltage of both ends should be below

2 V and leakage current should be below 100 ㎂.

● Relay input

● Transistor input

(D.I of TH300 D.I : 1 ~ 4)

(D.I of TH300 D.I : 1 ~ 4)

2.5 Communtcation connection

2.5.1 RS232C Connection(base on 9pin connector)

18

Te r mi na ti ng

resistance

Te r mi na ti ng

resistance

T

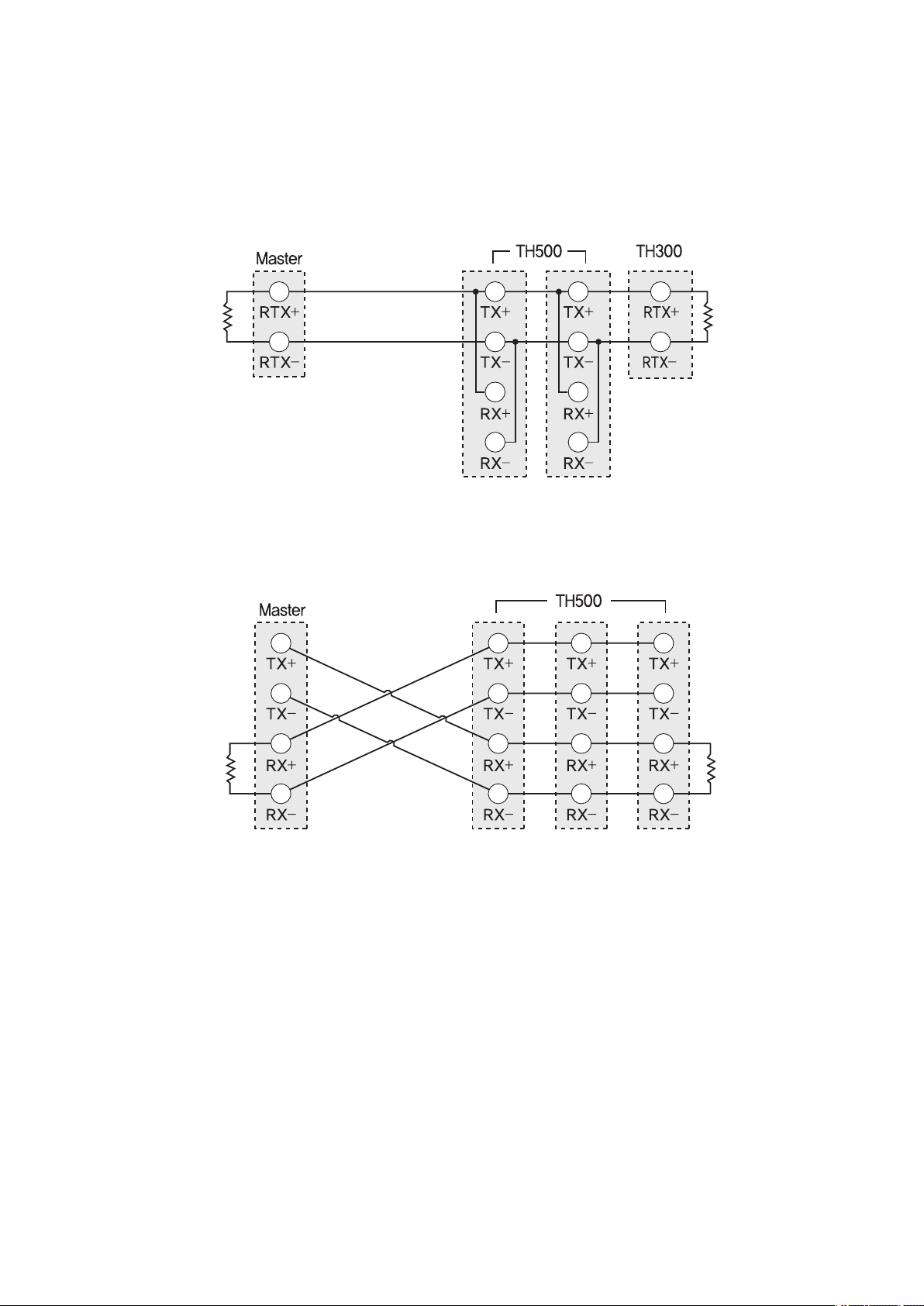

2.5.2 RS422/RS485 arrangement

Te r mi na ti ng

resistance

Te r mi na ti ng

resistance

maximum 32 machines. Please contact Terminating Resistance

100 ~ 200 Ω1/4 W) to the both of ends for retransmission lines.

(

● 2 Wire connection

● 4 Wire connection

19

3.

Setting and Operating

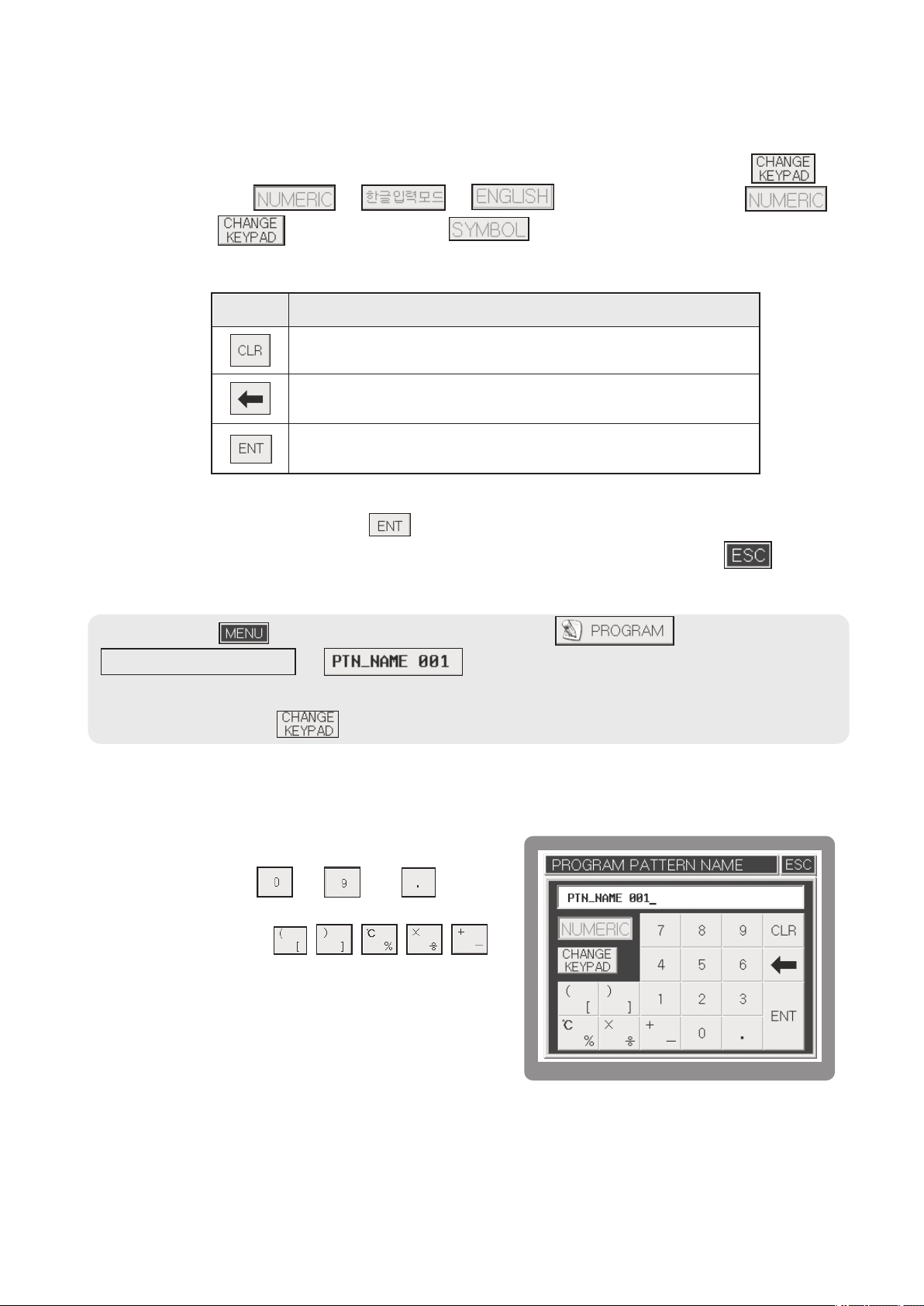

3.1 Initial screen

Whensupplyingthepowerinaftercompletingtheinstallation, operatingscreenwillbe

displayedaftertheLogodisplay[FIG.1) screenandcheck[FIG.2] screenaredisplayed

sequentially. (Users can edit the logo display screen and system check screen)

TH500TH300

[FIG.1] Logo display

TH500TH300

[FIG.2] System check

20

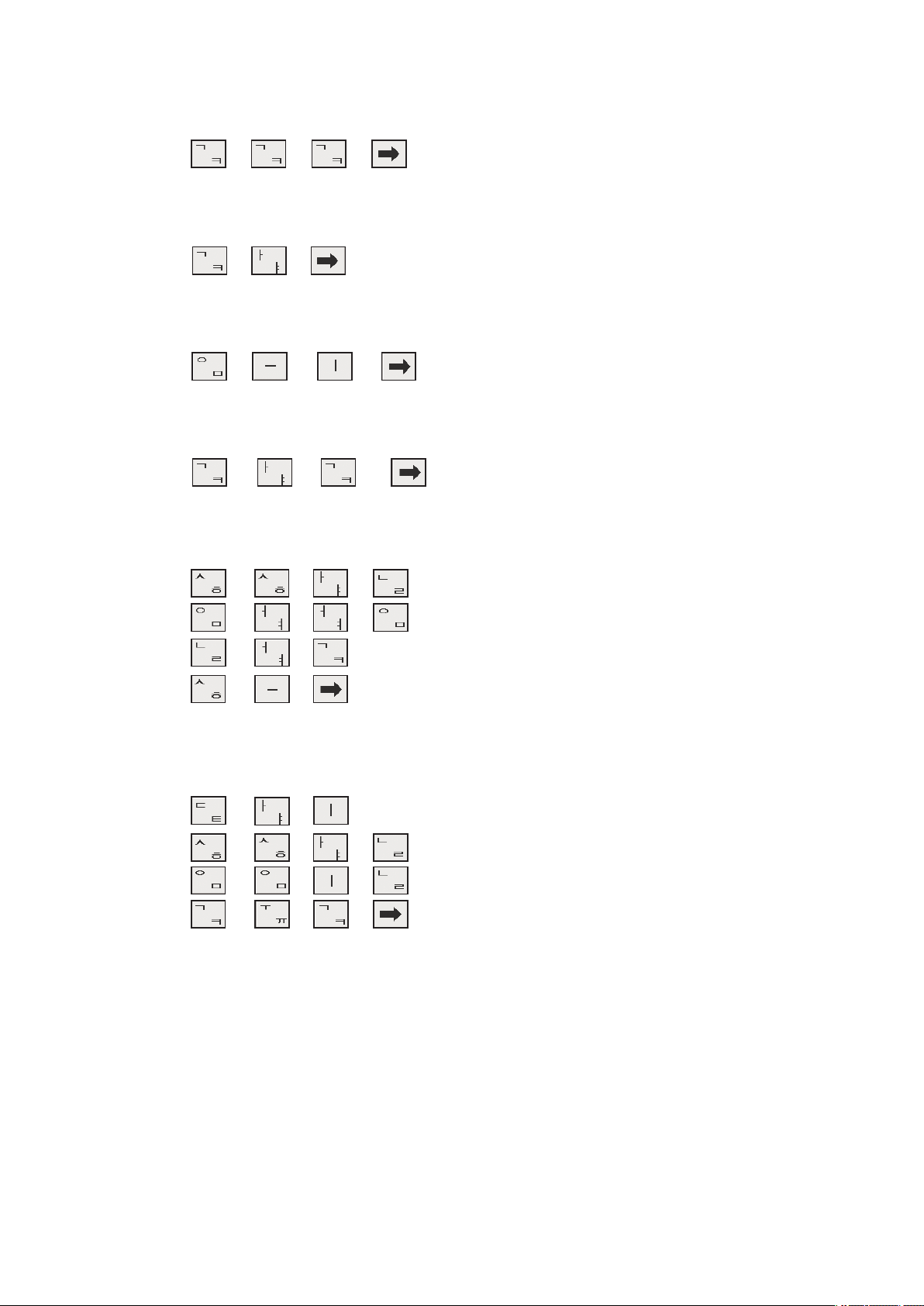

3.2 How to input

Basicsettingbuttonandinputscreenhasthefunctionas[Figure1]. Inputscreenwhichis

able to set necessary data on each screen will be displayed..

⦁ [Figure 1] Setting button and Input screen

Button

Name

Select button

Active input box

(Input vailable)

Inactive input box

(Input unavailable)

Function

Users can select this button on their demand.

If you press this button, its color will turn into another.

By releasing it back, you can select this button operation.

Users can enter various set values into this box as they

wish. When you press the box, a certain range of numbers

or the text input box [Fig.4 to Fig.7] will appear epending on

situations.Then, you have only to press the set value.

This box is inactive under current conditions or situations.

However, if you put it under certain conditions or situations, it will turn

into the active input box as shown above.

3.2.1 Screen for number input

The Fig. 3 is the basic number input box. You can enter integral numbers or real numbers

(decimal point) there. The title of an entered number and its upper and lower limits will be

indicated on the left top of the box. The current input value will be indicated at the indication

box over the figure board. The entered number will be entered completely only if you enter the

key. You can cancel the entered content by pressing the key.

[Fig.3] is the basic number input box

21

3.2.2 Number / Korean / English / sign Input

Fig. 4 to 7 shows the screen for entering the Number/Korean/English/Sign. This multi-input screen

enables you to enter the Number/Korean/English/Sign text respectively by pressing the in

turn. Its shift order is→ → → You can return to the

by pressing theThe arrangements ofNumber/Korean/English/Sign keyboards

are different from each other. However, the Function keys on the right side play the same roles as

follows.

ButtonInformation

Delete all the current texts entered.

Delete one letter ahead of the current cursor.

Savethetextindicateduptothecurrentcursorintothe

internal memory.

After typing the text based on the combination of keys and functions, you can save all

the texts completely by pressing the key. As they save completely, you will be also

escaped from the multi input screen. If you are to cancel the text, you can press thekey

on the right top side. By doing so, you can delete all the current text while escaping the input box.

When pressingin the upper part of initial screen

Program operation setting

displayed. Set up by displaying the input screen of number, Korean, English, and,

symbol with using the

→

Number input screen [Fig.4] is going to be

→→

3.2.3 Number Input Mode

The screen for number input is shown in the [Fig.4]. If

you press the number ~ and keys

once, they will be indicated on the cursor position.

Whenever you press the

keys on the left side of the keyboard, they will be

indicated in turn. When you press such duplicate keys,

the cursor will not move at all while waiting for

continuous entry. At that time, if a certain period of time

(approx. 1 second) passes, the cursor will move

automatically to the next position disabling you from

continuous entry.

22

[Fig.4] The screen for number input

Ex) If you want to indicate 1. (The _ on the bottom indicates a flickering cursor.)

Operation:

•

• Result : 1_

Ex) If you want to indicate 123.45. (The _ on the bottom indicates a flickering cursor.)

• Operation: + + + + +

• Result: 123.45_

Ex) If you want to indicate [.

• Operation: + (Press twice within one second.)

• Result: [ _ (The _ on the bottom indicates a flickering cursor.)

• Operation: One second passed after thekey is pressed once.

• Result: [) _ (The _ on the bottom indicates a flickering cursor.)

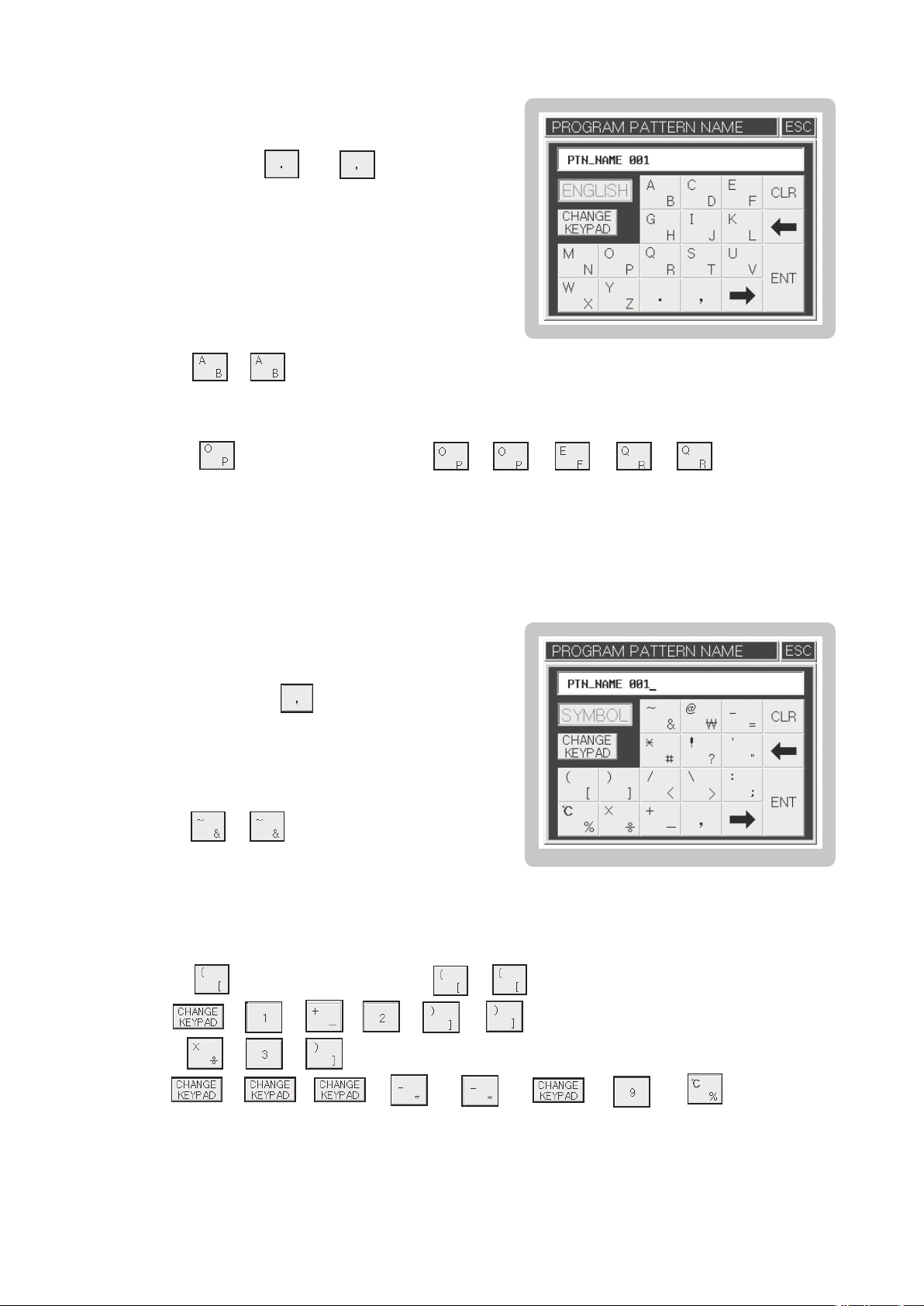

3.2.4 Korean Input Mode

The screen for Korean input is shown on the Fig.

5. All the keys except the,

, keys consist of duplicate keys. There

is also an additional function key . The

principle of using function keys is the same in

every mode. If you want to enter double

consonants such as ㄲ, ㄸ, ㅃ, ㅆ, ㅉ, you should

press the consonant three times. You should press

thekey, if you go to the next letter while

[Fig. 5] The screen for Korean input

entering letters.

Or you can also use such key when entering the blank. The Korean alphabet consists of

three elements such as an initial consonant, a medial vowel and a final consonant. This input

mode is classified into consonants and vowels, so the consonants are not divided into an

initial and final one. Therefore, you have only to enter an appropriate consonant regardless

of its initial or final position. The medial vowel consists of vowels only, so you have only to

press an appropriate vowel.

Ex) If you want to indicate “ㄱ”.

• Operation: +

• Result: ㄱ _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “ㅋ”.

• Operation: + +

• Result: ㅋ _ (The _ on the bottom indicates a flickering cursor.)

23

Ex) If you want to indicate “ㄲ”.

• Operation: + + +

• Result: ㄲ _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “가”.

• Operation: + +

• Result: 가 _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “의”.

• Operation: + + +

• Result: 의 _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “각”.

• Operation: + + +

• Result: 각 _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “한영넉스”.

• Operation: + + + +

+ +++

+ + +

+ +

• Result: 한영넉스 _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “대한민국”.

• Operation: + + +

+ + + +

+ + + +

+ + +

• Result: 대한민국 _ (The _ on the bottom indicates a flickering cursor.)

24

3.2.5 English Input Mode

he screen for English input is shown on the Fig. 6.

T

All the keys except the andkeys consist

of duplicate keys. Its basic use is the same as that

of the Korean input mode.

Ex) If you want to indicate “B”.

• Operation: +

• Result: B _ (The _ on the bottom indicates a flickering cursor.)

Ex) If you want to indicate “OPER”

• Operation: + Waif for one second + + + + +

• Result: OPER _ (The _ on the bottom indicates a flickering cursor.)

[Fig. 6] The screen for English input

3.2.6 Sign Input Mode

The screen for sign input is shown on the Fig. 7.

All the keys except the key onsist of duplicate

keys. Its basic use is the same as that of the

English input mode.

Ex) If you want to indicate “&”.

• Operation: +

• Result: & _ (The _ on the bottom indicates

a flickering cursor.)

Ex) If you want to indicate “([1+2] X 3) = 9 ℃.

• Operation: + Wait for one second + +

+ + + + + +

+ + +

[Fig. 7] The screen for sign input

+ + + + + + + +

• Result: ([1 + 2] X 3) = 9 ℃ _ (The _ on the bottom indicates a flickering cursor.)

25

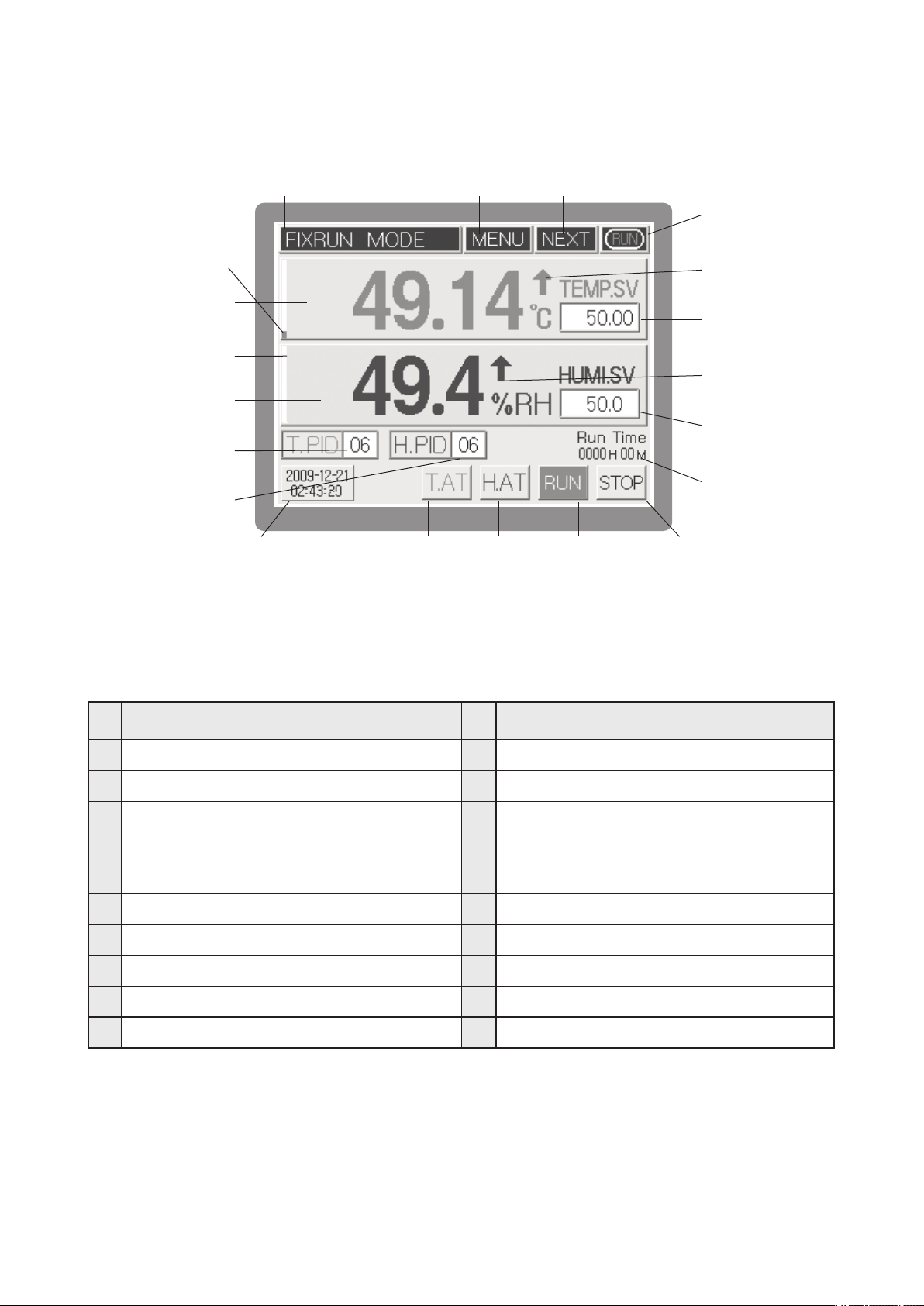

3.3 The name of each part on the operating screen

①

⑤

⑥

⑦

⑧

⑨

⑩

⑪⑰ ⑱ ⑲ ⑳

[Fig. 8] Operation screen 1 for fixed control

②

③

④

⑫

⑬

⑭

⑮

⑯

NO

Current operation status

①

Menu button

②

Operation screen 2 shift button

③

Running/Stop indication

④

Control output BAR for current temperature (MV)

⑤

Current temperature PV

⑥

Control output BAR for current humidity (MV)

⑦

Current humidity PV

⑧

⑨

Temperature PID Zone No. input box

⑩

Humidity PID Zone No. input box

NameName

NO

Current date/time

⑪

Temperature PV Up/Down indication

⑫

Temperature SV input box

⑬

Humidity PV Up/ Down indication

⑭

Humidity SV input box

⑮

Running time indication

⑯

Temperature A/T button

⑰

Humidity A/T button

⑱

⑲

Start button for Fix-Running

⑳

Stop button for Fix-Running

26

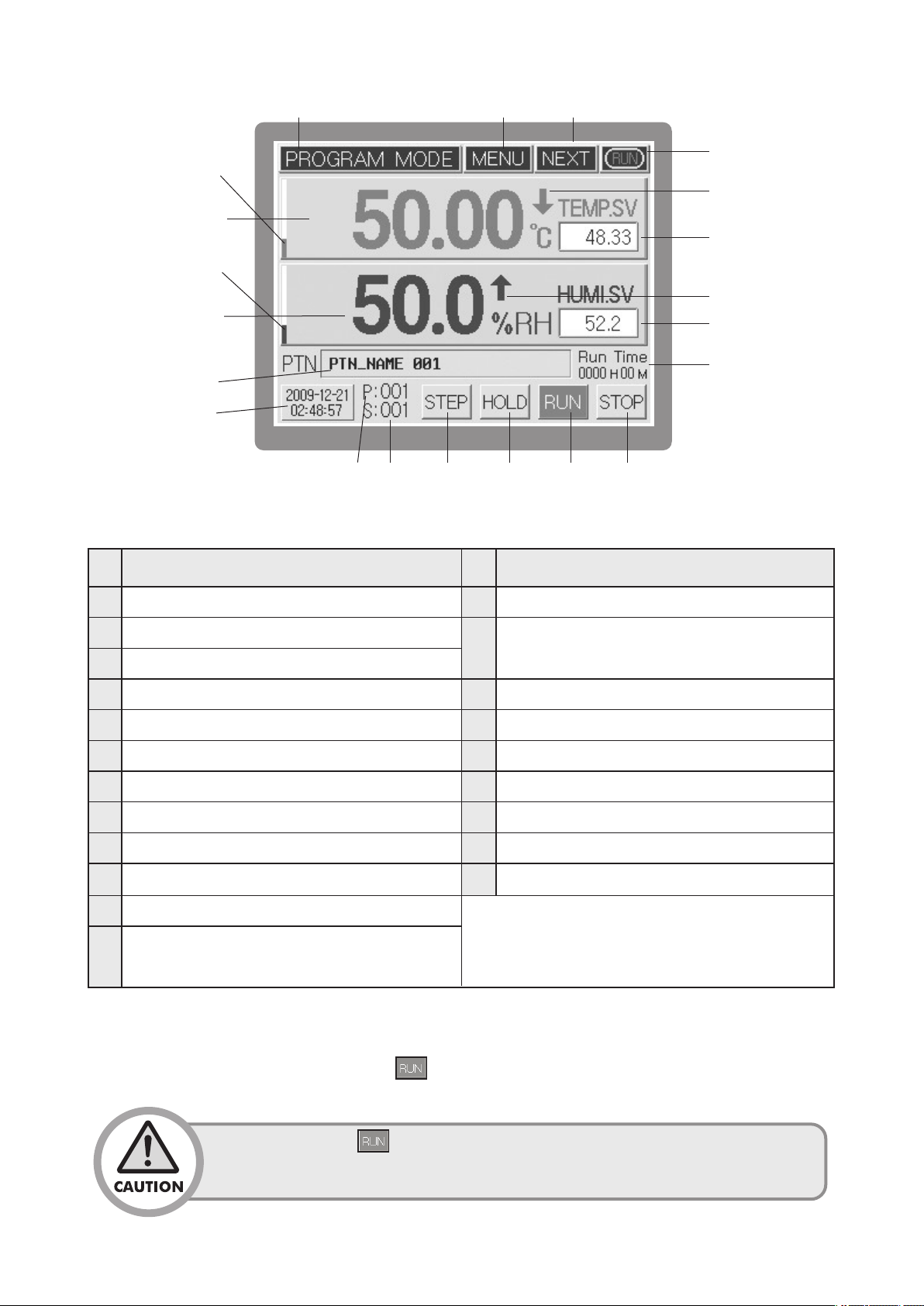

⑤

⑥

⑦

⑧

⑨

⑩

① ② ③

④

⑪

⑫

⑬

⑭

⑮

⑯ ⑰ ⑱ ⑲ ⑳ ㉑

[Fig. 9] Operation screen 1 for program control

NO

Current operation status

①

Menu button

②

NameName

NO

Humidity SV Up/Down indication

⑬

Start segment No. input box (When operation stops, it

⑭

Operation screen 2 shift button

③

Running/Stop indication

④

Control output BAR for current temperature (MV)

⑤

Current temperature PV

⑥

⑦

Control output BAR for current humidity (MV)

⑧

Current humidity PV

⑨

Operation pattern name

⑩

Current date/time

⑪

Temperature SV Up/Down indication

starts within the pattern (segment input unit))

⑮

Running time indication

⑯

Current operating pattern No.

⑰

Current operating segment No.

⑱

Program STEP button

⑲

Program HOLD button

⑳

Program operation Start button

㉑

Program operation End button

※ (16)~(19) displayed only during

Start pattern No. input box(When operation stops, it either

⑫

operation

display the pattern number or used as input unit.)

The operation screen 1 [Fig. 8, Fig. 9] is the basic screen where you can enter either temperature &

humidity setting value (SV) or start pattern/loop No. in the Fix/Program mode. After entering your

desired setting value, you can press thebutton to start controlling.

After pressing the button, you are unable to press various setting buttons

like MENU or input boxes, because they may have a serious effect on system

controlling operations.

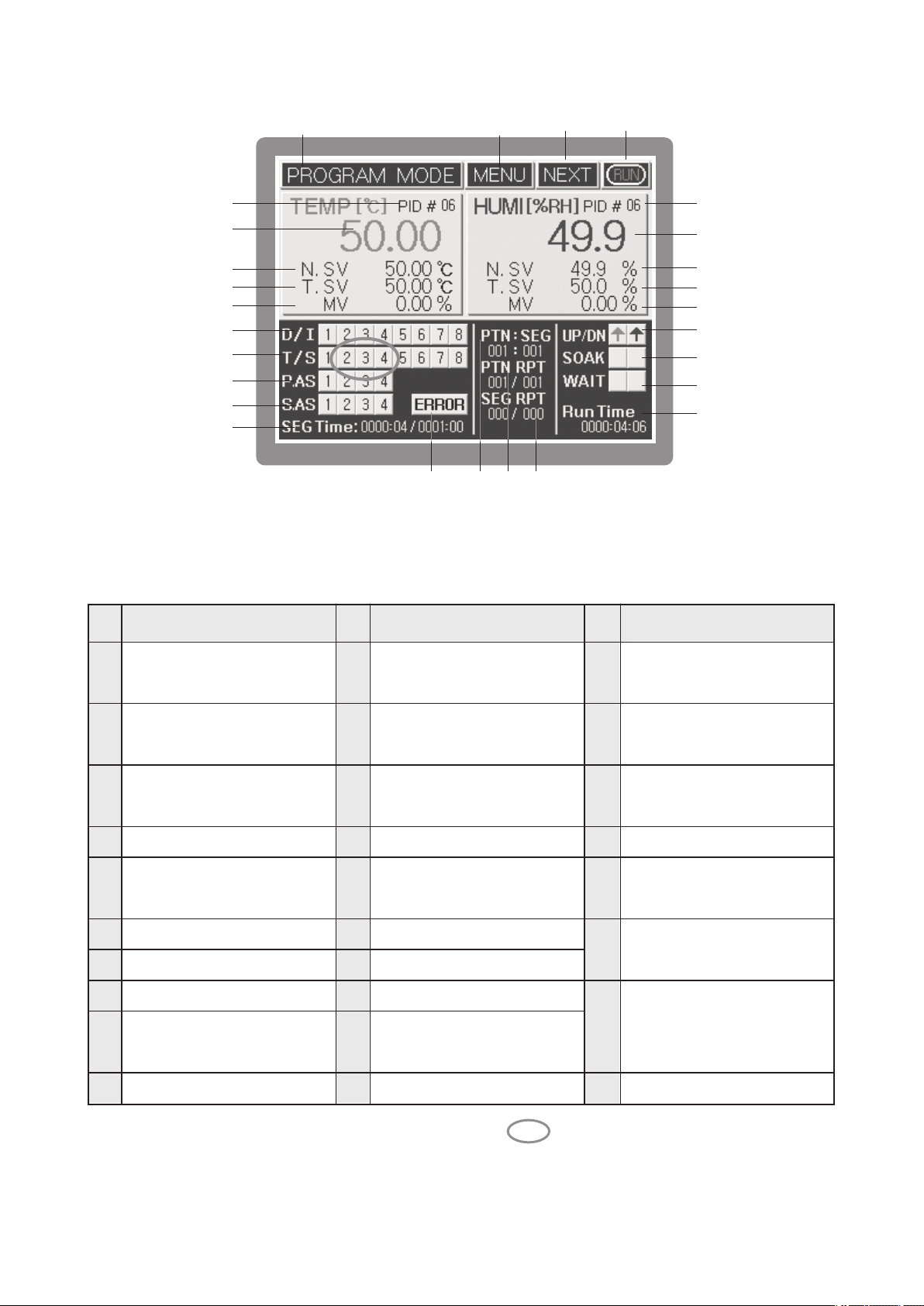

27

①

③

②

④

NO

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑯

⑰

⑱

⑲

⑳

㉑

㉒

㉓

㉔

⑭

㉕㉖㉗⑮

[Fig.10] Operation screen 2 for program control

NameNameName

NONO

①

Current operation status

②

Menu button

Operation screen 3

③

shift button 1

Running/Stop indication

④

Temperature PID ZONE

⑤

No.

Current temperature PV

⑥

Current temperature SV

⑦

Target Temperature Set Value(TSV)

⑧

Controlling output amount of

⑨

current temperature (MV)

D/I status indication

⑩

T/S status indication

⑪

I/S status indication

*

Pattern Alarm Status Indication

⑫

T.ON, H.ON status indication

*

System Alarm Status Indication

⑬

* Delay (D/S)/multiplication (DR)

signal status indication

SEG operation time indication

⑭

System error indication

⑮

button

Humidity PID zone number

⑯

Current humidity process value (PV)

⑰

Current humidity set value (SV)

⑱

Target humidity set value

⑲

(TSV)

⑳

Currenthumiditycontroloutputamount(MV)

Temperature/humidity up/down

㉑

interval indication

Temperature/humidity

㉒

maintain indication

Temperature/humidity

㉓

standby (Wait) indication

㉔

Total operation time (Run time)

Pattern number/segment

㉕

number indication

Pattern repetition indication, Number of

㉖

sequence,/Number of repetition setting

Segment repetition indication,

Number of sequence, /

㉗

Number of repetition setting

※ *Displaying items are displayed when pressing the ( ) which located on the

left-bottom of the screen.

28

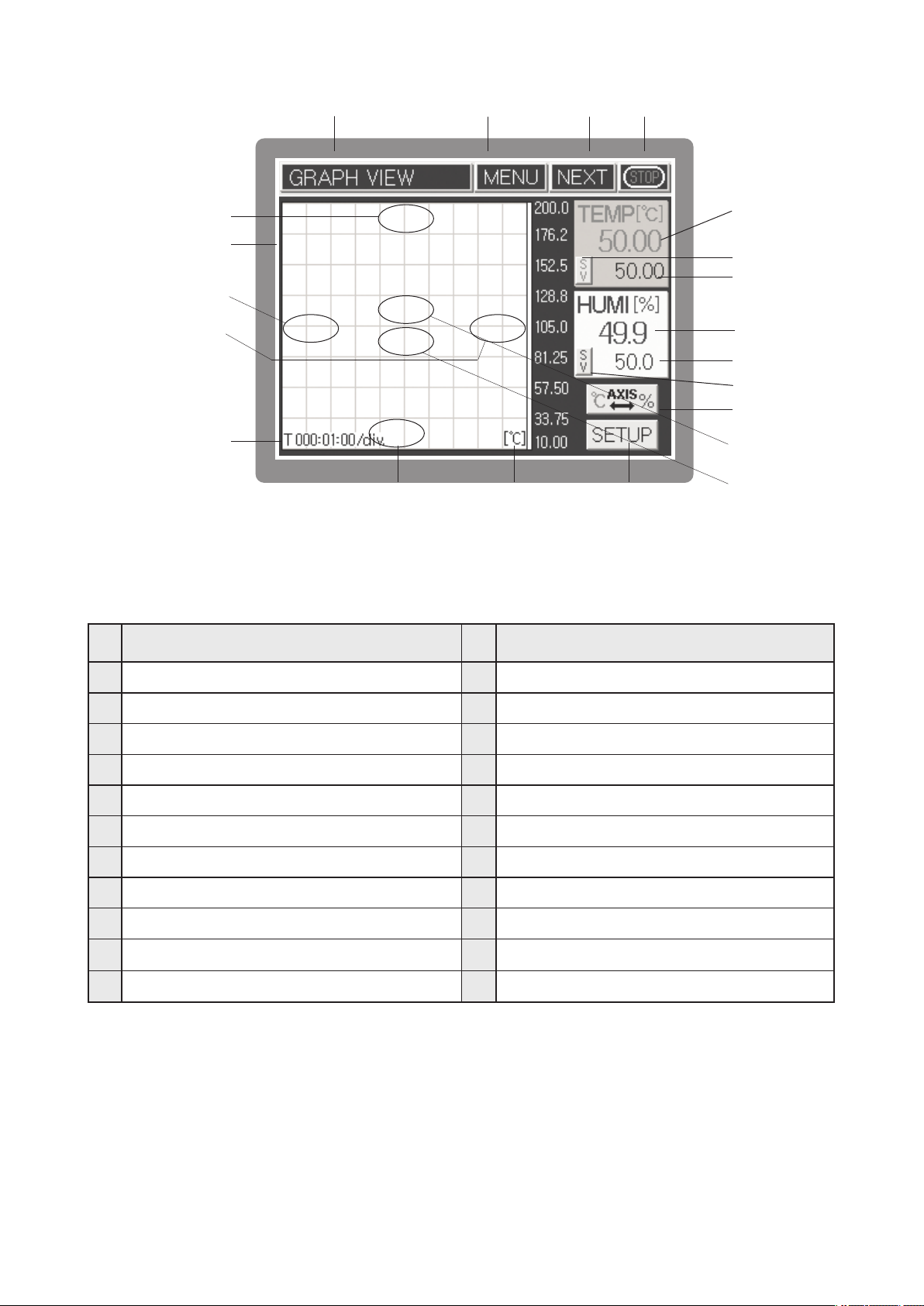

①②③

④

NO

⑤

⑥

⑦

⑧

⑨

⑩

⑲ ⑱

[Fig.11] Screen for graph indication

NameName

NO

⑪

⑫

⑬

⑭

⑮

⑯

⑰

⑳

㉑

Current operation status

①

Menu button

②

Operation screen 1 shift button

③

Running/Stop indication

④

Upside screen of Y axis

⑤

Temperature & humidity SV, PV indication

⑥

Div time increase of X axis

⑦

⑧

Div time decrease of X axis

⑨

X axis time / Div

⑩

Low part screen of Y axis

⑪

Current temperature PV indication

Current temperature MV/SV indicatorshift button

⑫

Current temperature MV or SV indication

⑬

Current humidity PV indication

⑭

Current humidity MV or SV indication

⑮

Current humidity MV/SV indicator shift button

⑯

Y axis temperature & humidity unit shift button

⑰

Y axis unit indication

⑱

Graph/Save setting button

⑲

⑳

Screen ZOOM IN

㉑

Screen ZOOM OUT

29

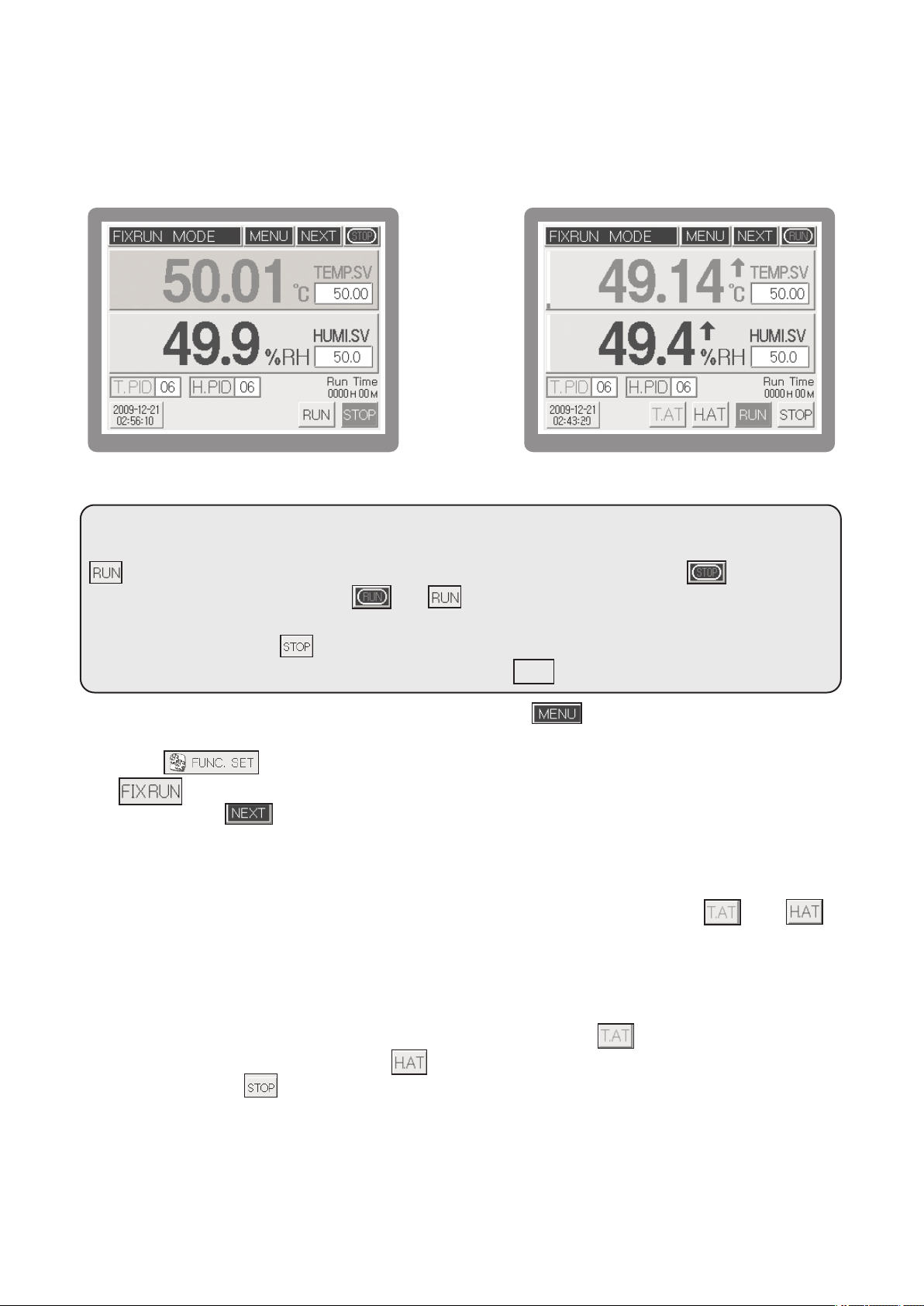

3.4 Running of Fix-control

ix-control is running a temperature and humidity by fixed set value (SV).

F

3.4.1 Running selection of Fix-control 1.

[Fig.12] Running stopped screen 1 for Fix control

Operation start: [FIG.12] Input the temperature set value (temperature SV) and humidity set value

(humidity SV) within the fix control operation stop status screen and press the

button then the fix control operation will be started just like a[FIG.13]. Here, button on the

upper right side will be changed toandbutton on the lower right side will be displayed

with the red color.

Operation stop: Press the button on the lower right side to stop the operation.

("Stop the system control" will be displayed). Here, press to stop the operation

When selecting the fix control or program control, press the button within the fix control

operation stop [FIG12] screen then function setting screen will be displayed. Within this screen,

press the button to select the operation method of function setup 1 screen. Pressing

thebutton will select the fix control. Set each of setting lists in the operation setting screen

2 by pressing the button.

While performing the fix control, changing the set value (SV) will automatically change the PID ZONE

applying number in accordance with the set value. If users want to use the specific PID zone,

please input the PID zone number after inputting the set value. During operation, if and

button appear on the lower side of fix control operation screen, each of these refers to temperature

and humidity auto tuning button. Auto-tuning is operated only in the fix control operation mode and

it runs the auto-tuning by pressing the button after inputting the temperature and humidity set value.

[Fig.13] Running screen 1 for Fix control

YES

In case where users need to stop the auto-tuning, please press the

(temperature side auto-tuning button) or (humidity auto-tuning button). Obviously pressing the

fix control button will the control operation and auto-tuning.

During auto-tuning, all of the computing values corresponding to the auto-tuning will not be saved

if users stop the auto-tuning while it is operating. Auto-tuning can be operated up to 24 hours and

elapsing the indicated hours will stop the auto-tuning.

30

• Whenitcomestotemperature, itsPVwillbealwaysdisplayedunlessthesensor

lineisdisconnected. However, asfarashumidityisconcerned, itsPVwillnot be

indicatedunlessasettingvalue(SV) isentered. Ifyouset theSV to0 andpress

thebutton, you can control the temperature only.

• It is impossible to execute A/T for temperature and humidity at the same time.

Therefore, it is desirable to try tuning humidity while maintaining a target temperature.

The button concerned will turn on and off during tuning.

Auto Tuning button : When pressingbutton in the running screen of Fixing Control, function

setting menu will be displayed. After pressingleft-top button and pressing password, System Setup

screen will be displayed, Once again if you press [Sensor Input Setup], Sensor Input Setup screen 1

will be displayed. Press button and Auto Tuning will be shown on A/T button indication in the

Sensor Input Setup 4.

Temperature Auto Tuning button (Turn on and off during running)

Humidity Auto Tuning button (Turn on and off during running)

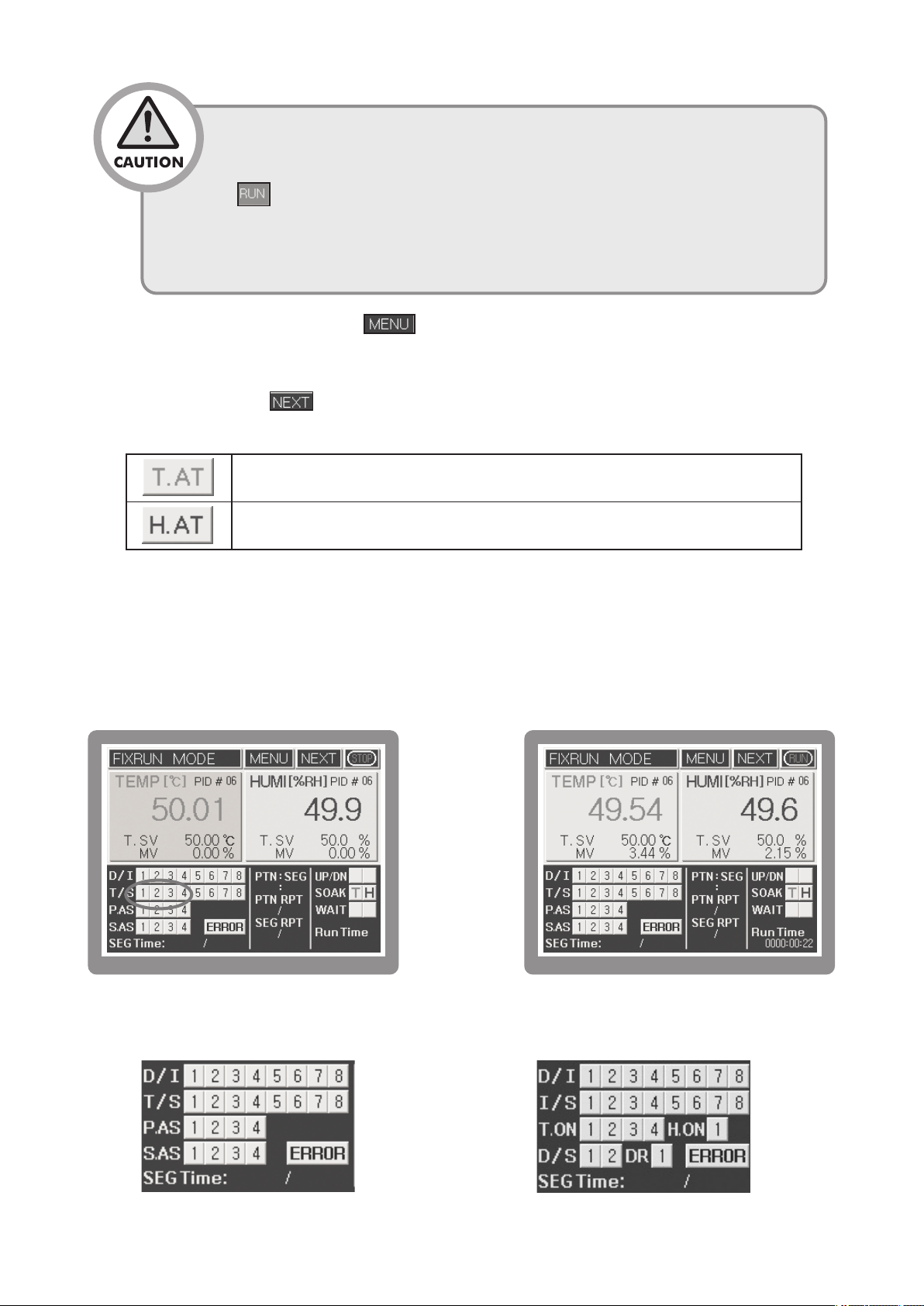

3.4.2 Running selection of Fix-control 2.

Process value and Set value of temperature and humidity is shown basically in the running screen 2

for fix control. There is shown also for Inner signal(I/S), Time signal(T/S), Digital input signal(D/I),

Alarm signal(A/S), and indicate a gradient of initial set value by form of UP/DN and SOAK.

[Fig.14] Running stopped screen 2 for Fix control.

※ Pressing the indicated circle in the [Fig.14] will change the display unit

[Fig.15] Running screen 2 for Fix control

➡

31

3.5 Running of Program control

Program control is control a Process Value (PV) by change of Set Value (SV) according to

course of time.For example, it is increase the current temperature to 30 ℃ for 10 min. and

maintain the 30 ℃ for 15 min., and then increase to 70 ℃ again for 40 min. and maintain the

70 ℃ for 1 hour. Program control is especially using widely in the test equipment for

environment like as thermostat and electric furnace.

3.5.1 Selection of Program Control Running.

[Fig.16] Running stopped screen 1 for program control.

In order to running with program control, press the button of the top on the running

stopped screen 1 for program control [Fig.16] and move to the screen for function setting

[Fig.17].

TH500TH300

[FIG.17] Function setting menu

32

Move to the screen for

“Function setup 1”

with press the

button, and select the program control as running method with press the

button. After finish to setting for function setup 1 ~ 2 with press thebutton, and move

to “Function setting menu” screen with press thebutton. And then, finish the set for

, , and move to the Program Set Screen [Fig.18]

3.5.2 Set of Program Control Pattern

Press the button in the program set screen [Fig.18] and move to the screen for program

pattern set [Fig.19]. Establish the set item for each segment of pattern in the screen for program

pattern set [Fig.19].

[Fig.18] Program Set Screen

Move to the running stopped screen 1 for program control after input for all, and input a start

segment No. in the pattern and program start pattern. And then, program control will be running if

you press the button.

[Fig.20] Running stopped screen

1 for program control.

[Fig.19] Pattern Set Screen

[Fig.21] Running screen 1 for

program control

33

Once the program operation starts, and buttons will appear newly like as running

P

ID auto-tuning interval

AT end

AT start

ON/OFF operation

PID Control interval

creen 1 for program control [Fig.21]. These buttons has function which is related to progress of

s

segment.

Button

It stops the currently processing operation of segment and runs the

next segment operation. Pressing the STOP button on the wait status

or hold status will cancel the hold function and runs the next segment

of current segment immediately.

Pressing the button while it is operating will keep the set value

(set value which had been set right before performing HOLD function)

disregarding the set time. Pressing the button on the hold

status will cancel the hold function and runs the program. While it is

in hold status, pressing the STEP button will cancel the hold status,

skip current segment and run next segment immediately.

3.6 PID Auto Tuning

Auto Tuning (hereinafter referred to as A/T) is the

automatic setting function in which the controller

Function

measures the characteristics of the control system

automatically and calculates the optimal PID values

accordingly. The A/T method measures and calculates

a cycle by producing the ON/OFF control output for the

two cycles and generating the limit cycle of controlled

targets.

You can execute A/T all the time by entering a target

setting value (SV) in the fixed control mode, pressing

thebutton, and pressing the subsequent either

orbutton. After A/T is finished normally, if

the unit is set to automatic PID ZONE reference mode,

the resulted PID value will be saved into the

appropriate PID ZONE. If this unit is set to manual PID

ZONE reference mode, the results PID value will be

saved into your designated PID ZONE.

[Fig 22] PID Auto Tuning

34

•

If A/Tstill runsin 24 hoursafterA/T execution, A/Toperationwill cometoan

end automatically. If you close theA/T operation by force during A/T process,

theoperatingvaluewillnotbesavedandmaintainedasaprevioussetting

value.

3.7 Graph display and setting

Graph's displayscreen is ascreentodisplaythesettingvalueandmeasuredvalueoftemperatureandhumidity.

Inthe graphsettingscreen, Xaxis's time andYaxis's maximumand minimum rangecanbeset upbypushing

eachofbuttonsand setupsaving operationstatusbyselecting ( ),

saveperiod (seconds), andstoringmedium( )

Inthe Yaxis's displayrange, temperature rangeorhumidityrangecanbedisplayed by selectingY button.

[Fig.23] Screen for fix control graph display

[Fig.25] Graph set screen

[Fig.24] Screen for program control graph display

35

3.8 Error Indication

Running screen 2 for program control or fix control [Fifg.26] is indicating an operating state for running.

[Fig.26] Running screen 2 for fix control

The indication of errors through sensor disconnection and external D/I is displayed withbutton

on and off in the running screen 2 for program control [Fig. 26]. If you press the button, the

error occurrence screen will appear. In this case, the error indicator for temperature & humidity

disconnection will appear, while D/I(External contact input) no. 1 to 8 will be displayed on the bottom.

You can check it by pressing the , arrow button.

Press the button to show the operating record indication screen which can check the state of

RUNNING, STOP, Sensor Disconnection and External Contact Input (D/I).

[Fig.27] Indication screen for occurrence of error

[Fig.28] Operating Rec

Whentemperatureorhumiditysensorisdisconnected, controloperation

will be stopped afterpassingsensordisconnection waiting time which was

set in the SYSTEM SETTING.

36

4 Displays

Entire displays are mainly composed of three sections which are Working display, Function setting

display(included In program installation) and System setting display.

4.1

After you finish to connect & turn on the power, Logo signal & System check display will be shown in a moment, and

then Working display will be shown. In that time, according to selecting the initial setting program or Fixed driving

method, it will be shown to Program control working display or Fixed control working display.

Operating screen

[Fig. 29]Program control the 1st working screen

[Fig. 30]Fixed control the 1st working screen

[Fig. 31]Program control the 2nd working screen[Fig. 32]Fixed control the 2nd working screen

[Fig. 33]Program control Graph screen[Fig. 34]Fixed control Graph screen

37

4.2

After you push button in working display condition, Function setting menu screenis shown.

It is composed of 6 buttons. Push each button to set up under an item.

Function setting display

[Fig. 35] Program control the 1st stop screen

TH500TH300

[Fig. 36] Function setting menu screen

4.3 System Setting screen

As pushingbutton in Working display condition, Function setting menu screen is shown.

Pushing the character of Function setting in that time, Password input display is shown. Pushing

after inputting (initial value: 0), the display of System setting function menu shows. It is

composed of 8 buttons.

38

[Fig.37] Password input screen[Fig.38] System setting menu screen

There is no need for System setting made separately by driver. Because the

Basic setting condition of this system’smodel is set up by the operator, you

should be careful especially .

39

5 Function setting

After finishing installation & connection, turn on the power. Logo display & System check display are

shown one after other. and then [Fig.39]fix control the 1st working stop screen is displayed.

[Fig.39] Fix control the 1st working stop screen

Function setting

menu botton

TH500TH300

[Fig.40] Function setting menu screen

InformationInformation

Running Screen will be

displayed.

Function setting

menu botton

Enter into Graph screen.

Running (Operation) Setting

screen will be displayed.

Program Setting(Pattern, Time Signal

setting etc.) screen will be displayed.

Enter into axis X,Y and storage

screen.

Enter into Date/Time

Reservation Setting screen.

40

5.1 Operation setting

5.1.1 Function setup 1

Pushingbutton in [Fig.40]Function setting menu screen, you should select or set

up each setting item of the function setup 1. Choose between Select Program control and Fixed

control in selecting Working method.

[Fig.41] Function setup 1 screen

RUN MODE

T.SV RATE

H.SV RATE

Fix RUN TIME

ZN. TRACKING

PROGRAM

FIX RUN

Set it up as the gradient of temperature variations [℃/m] per hour (minute) from

current temperature to setting temperature in fixed control.

Set it up as the gradient of temperature variations [℃/m] per hour (minute) from

current temperature to setting temperature in fixed control.

After executing the fixed-mode control for the time entered, the operation will stop automatically.

It prevents rapid output change when P.I.D ZONE is changed.

Select in program control

Select in fixed control

5.1.2 Function setup 2

After finishing the setting of Function setup 1, pressbutton to set up the setting item of Function setup 2.

In case outage occurs in working, it will be different with Operation condition in recovering outage by selecting

BOOT RUN of Function setup 2 screen. (only the power recovers within five seconds after outage, the same

condition as before will be kept up.

[Fig.42] Function setup 2 screen

41

FUZZY

FUNC

BOOT RUN

BEEP

t happens that measurement value is more than setting value in initial

I

ver Shoot, select Fuzzy control.

O

According to the load controlling Over shoot, the rising time can be delayed or

Under Shoot can become larger in some cases.

Program control

STOP

COLD

HOT

Turn on/off the buzzer sound to check various input and operation.

Start to operate again from the beginning

Start to operate from segment before outage

STOP

Start running in accordance with

the set value before outage.

Fixed control

STOP

TOUCH PNL.

SCREEN

P.DOWN

It is used to limit the touch panel input during system control operating. Selecting Lock, it is

impossible to input except , and/ buttons.

As it is the function to turn off the power of Back-Light after the setting time in order to

protect the LCD display, it can set up Setting time as a unit per a minute. Setting 0 when it is

not used, it is turning on all the time.

5.1.3 Function setup 3

After finishing Function Setup 2, please touch button to display Function Setup 3 screen.

You can adjust LCD brightness by, button in the Function Setup 3.

[Fig.43] Function setup 3 screen

5.2 Program setting

Press button in Function setting menu screen[Fig. 44] Program setup menu will be

shown. It is composed of 5 buttons. Push each button to set up under an item.

42

TH500TH300

[Fig.44] Function setting menu screen

[Fig.45] Program setup menu screen

5.2.1 Pattern setting

Pushing button in program setup menu screen[Fig. 45] Program pattern setup screen is indicated.

Set the agreeable segment of each pattern in this screen.

Program control will process according to the content & sequence of segment designed.

[Fig.46] Program pattern setup screen[Fig.47] Segment selection screen

43

⦁ Setting each input item of [Fig.45] in reference of the diagram below.

Name

nter the pattern number [ ] to set or select it by pressing

PTN NO.

SEG.Page

TEMP. SV

HUMI. SV

Hour/Min

Wait

T.S.(Time Signal)

ALARM

⦁ SEG. Insert/Delete

Pressing SEG number in the left side of [Fig.46], it is shown in red to segment moved & selected into

SEG. Insert/Delete display.

SEG. Page button is changed into, button in that time. Pressing this button, Segment should

E

the/ button.

Pressing the/ button, it moves each 4 segment.

Pressing the setting window, set Temperature SV of segment.

Pressing the setting window, set Humidity SV of segment.

Setting operation time of segment.

Selecting waiting operation function set in waiting operation setting display.

Selecting valid time signal in segment.

Selecting each action among 4 kinds of signal esigned in pattern signal

setting display.[Fig.47]Pattern signal selection screen

Function

-100~200 ℃ TH500

-100~500℃TH300

0 hour ~ 255 hour 59 minute

ange

R

1 ~ 100 Pattern

0.0 ~ 100.0 %

ON/OFF

1 ~ 4 each

ON/OFF

be inserted or deleted and then the next Segment will be moved.

⦁ Waiting/Pattern signal selection

Select Waiting, Pattern signal item of Program pattern

setting display to execute contents set in Waiting

Operation Setting display & Pattern Alarm Setting

display (If you press button in Program

setting display, Waiting Operation Setting display will

be indicated.)

[Fig.48]Pattern Alarmselecting screen

5.2.2 Time Signal Setting

[Fig49] and [Fig50] screen will be displayed alternately when touching button in the

Program Pattern Setting screen [Fig. 49] . Allocated Time Signal will be shown as blue color.

When touching T/S button ( ) on the Program Pattern Setting screen [Fig. 49] or Time Signal

number on the Program Pattern Setting 2 screen [Fig. 50] , Time Signal Setting screen [Fig.51]

will be displayed.

44

➡

[Fig.49] Program Pattern Setting screen 1[Fig.50] Program Pattern Setting screen 2

Time Signal Setting Mode is divided into 2 types according to mode : SEG On/Off Mode and Time

Setting Mode. Time Signal can be set to 8 points per each Segment.

[Fig.51] Time Signal Setting

Setting Mode

SEG On/Off Mode

TIME

(Time Setting

Mode)

⦁ Time signal segment ON/OFF setting method

[Fig.53] shows an example of using the T/S in ON/OFF mode. It performs turning on and off the T/S in

the desired segment with the name of ON/OFF mode. The ON and OFF buttons are composed

separately like [Fig.51]. Select by pressing orbutton, according to the desired Time Signal

Operation.

ON

Delay

ON Time

Set the Time Signal in ON, while segment is operating

Set the Time Signal in ON, after setting time is delayed

from the beginning of segment.

Set the Time Signal in ON, during setting time

from segment in ON.

Function

[Fig.52] Example of Time Signal Setting

Setting Range

Each segment

99 hour 59 min

99 hour 59 min

45

[Fig. 53] Example of Time Signal ON/OFF mode

Start program

operation

Finish program

operation

Time Signal

¡

Start program

operation

Finish program

operation

T

Time Signal(T.S)

T/S 1

T/S 2

T/S 3

T/S 4

T/S 5

T/S 6

T/S 7

T/S 8

SEG. 2 ON under 50℃ soak status

SEG. 4 ON under 25℃ soak status

SEG. 6 ON under 75℃ soak status

SEG. 1 and SEG.5 ON under Up section

SEG. 3 ON under Down section

SEG. 1 to SEG. 3 ON

SEG. 4 to SEG. 6 ON

SEG. 1 to SEG. 6 ON under program control running

⦁ Example of Setting the Time Signal in TIME Setting mode

Description

[Fig.54] Example of Setting the Time

Signal in TIME Operation mode

46

ime Signal

T

T/S 1

T/S 2

T/S 7

Description

At the start point of segment 1, time signal becomes ON and after elapsing 2 hours, it will become OFF.

(ON Delay : 00 h 00 m), (ON Time : 02 h 00 m)

At the start point of segment 6, time signal becomes ON and after elapsing 2 hours, it will become OFF.

(Since segment 6 is 2 hours, it only yield the output for 2 hours even if On Time is set as 3 hours)

(ON Delay : 00 h 00 m), (ON Time : 03 h 00 m)

At the start point of segment 1, time signal becomes ON after delaying 30 minutes

and becomes OFF after elapsing 2hour30minutes.

(ON Delay : 00 h 30 m), (ON Time : 02 h 30 m)

At the start point of segment 6, time signal becomes ON after delaying 30 minutes and

becomes OFF after elapsing 1hour

(ON Delay : 00 h 30 m), (ON Time : 01 h 00 m)

At the start point of segment 3, time signal becomes ON and after elapsing 4 hours, it will become OFF.

(ON Delay : 00 h 00 m), (ON Time : 04 h 00 m)

T/S 8

Time signal becomes ON in each of segment 2, 4 and 6 and after elapsing ON

time, it will become OFF.

Time Signal will be OFF once the program ends regardless of setting modes.

5.2.3 Pattern repeat/Link setting

Pressing button in [Fig.44] Function

Setting menu screen, and pressingbutton

in [Fig.45], Pattern REPEAT/LINK setup [Fig.55] is

shown. If you set Current Pattern repeat count to

Pattern repeat on the right side of the top and

Current Pattern number to connect Pattern,

Current pattern will be run in unlimited repeat

according to Segment Operation.

Program operation executes inputted segment in

sequence basically, but it comes occasionally that the

case of set segment contents in pattern should be repeated & executed. Using Section repeat in

that time, reduce Program input as much as possible.You can move among Section repeat setting

pages by using the/ arrow buttons on the right side in the order ranging from 1 to 20 in

total.

47

[Fig.55] Pattern repeat/Connect setting screen

ame

N

TN NO.

P

unction

F

nter the pattern number to set or select it by pressing the Up/Down button.

E

Range

1~100 Pattern

REPEAT

Set the repeating number of pattern.

1~999 Time

Set the pattern number for next operation (Operation of pattern number after

LINK PTN.

completing the operation of current pattern). Setting [0] will stop the

0~100 Pattern

operation without performing next operation.

This is partial repeating series number which affords total 20 partial repetitions per

No.

pattern and it runs from number 1 to 20 in consecutive order.

1~20 Number

Set the partial repeating start segment number. Setting [0] will

S.SEG

run the next partial repetition number.

0~100 SEG

Set the partial repeating end segment number. Setting [0] will

E.SEG

0~100 SEG

run the next partial repetition number.

Section

repeat

Set the number of current partial repetition. Setting [0] will run

0~255 Time

the next partial repetition number.

※ ⦁ The Segment operation sequence by Section repeat setting

If segment in pattern is set from ① to ⑧, it operates like below according to Section repeat Setting.

Section

repeat

serial

number

Section repeat setting

Start

End

Seg

Repeat

Seg

Segment operation sequence

ex1

ex2

ex3

ex4

ex5

ex6

1~20

1

1

2

1

2

1

2

1

2

0

❸

❸

❹

❷

❶

❷

❻

❺

❷

❻

❻

❺

❸

❹

❸

❼

❼

❸

0

①Seg → ②Seg → ③Seg → ④Seg → ⑤Seg → ⑥Seg → ⑦Seg → ⑧Seg

0

①→②→❸→❹→❺→❻

2

❸→❹→❺→❻→⑦→⑧

①→②→❸→❹→❺→❻

2

❸→❹→❺→❻

❹→❺

2

❹→❺→⑥→⑦→ ⑧

① →❷ →❸

2

❷ →❸

❶ →❷ →❸ →❹

2

❶ →❷ →❸ →❹→⑤ →⑥ →⑦ →⑧

① →❷ → ❸

2

❷ →❸ →❻ →❼

❻ →❼→⑧

2

① →② →③ →④ →❺ →❻ →❼

2

❺ →❻ →❼

❷ →❸

2

❷ →❸→④ →⑤ →⑥ →⑦ →⑧

※ Partial repeating per 1 pattern can be set up to 20 (partial repeating serial number)

48

Section

repeat

serial

number

ection repeat setting

S

tart

nd

S

E

Seg

Repeat

Seg

egment operation sequence

S

❻

❷

❶

❷

❸

❹

❺

❶

❼

❼

❸

❽

❼

❻

❺

❺

❽

❼

1

ex7

2

1

2

3

4

ex8

※ Partial repeating per 1 pattern can be set up to 20 (partial repeating serial number)

5

6

7

① →② →③ →④ →⑤ →❻ →❼

2

2

❶ →❷ →❸ →❹ →❺ →❻ →❼ →❽

1

1

1

1

2

❶ →❷ →❸ →❹ →❺ →❻ →❼ →❽

2

❶ →❷ →❸ →❹ →❺ →❻ →❼ →❽

2

❷ →❸

❷ →❸→④ →⑤ →⑥ → ⑦ →⑧

❷ →❸ →❹ →❺ →❻ →❼

❸ →❹ →❺ →❻

❹ →❺

❻ →❼

❺

❺

❼→⑧

❼

5.2.4 Waiting/Alarm start mode setting

Press , button in function setting menu screen to move Pattern Wait

setup screen. Waiting operation can be set by each segment of proper pattern. In case that Waiting

operation of process value(PV) comes or fails to come within Waiting range of Set value(SV), wait

process of segment during setting Waiting operation time and then go to next segment.

(Only if Waiting operation is set to 『0』, Waiting operation will not work).

[Fig.56] Pattern WAIT setup screen

49

Name

Waiting time

Waiting Range

Standby operation

becomes cancelled because PV

falls within the standby range

S

b

t

s

d

b

Standby operation starts

to on because PV did not fall

within the standby range

S

w

Start Waiting

Operation

S

SEG progress without

applying standby mode

SEG progress with

applying standby mode

S

a

a

PTN NO.

Function

nter a pattern number to be set or select it by

E

pressing the/ button.

ange

R

~100 Pattern

1

Temp. WAIT

RANGE

Humi. WAIT

RANGE

WAIT TIME

Set the deviation range about the temperature set

value which will be applied to the standby operation.

Set the deviation range about the humidity set value

which will be applied to the standby operation.

Until it satisfies the deviation range about the set

value which will be applied to the standby operation,

it sets the time that delays the process of segment.

When both of temperature and humidity standby

range are being set, both of them must fall within

standby operation range in order to cancel the

standby operation.

(0 ~ ±300) ℃(TH500)

(0 ~ ±600) ℃(TH300)

(0 ~ ±100) %

0 ~ 99 hour

59 minute

[Fig 57]

[FIG 57] generally display the standby operation. If process value (PV) does not fall within the

standby range at the changing point from SEG1 to SEG2, it will wait until process value (PV)

Common waiting operation

falls within the standby range (wait for the set standby time). Here, if standby time elapses, it

will process to the SEG 2 even if the process value (PV) did not fall within the standby range

[FIG 58].

50

[FIG.58] Standby action cancellation due to the elapse of standby time

Start the standby operation

b

ecause PV did not fall within

the set standby range Cancel the

standby operation even though PV

did not fall within the set standby range

b

ecause standby time is elapsed.

S

tandby operation starts

to on because PV did not fall

within the standby range

Set

s

tandby time

standby range

S

tandby

operation

SEG progress without

applying standby mode

SEG progress with

applying standby mode

5.2.5 Pattern Alarm Setting

Within the function setting menu [FIG 44] screen, pressbuttons

to enter into the standby operation setting [FIG 56] screen. After that, press the button

to enter into the pattern alarm setting [FIG 59] screen.

[FIG.59] Pattern alarm setup screen

51

[FIG.60] Alarm code selection

Pattern alarm setting [FIG 59] screen is the setting screen that sets the alarm 1~4 which will be used within the

pattern. The alarm value which was set within this screen can select the pattern alarm 1~4 of each segment.

larm type is same as the [Table 2] alarm type and code. Also, in order to input the target alarm code after

A

selecting the temperature and humidity, press the code display unit then alarm code setting [FIG 60] screen will

be displayed.

Display the target alarm code by pressing the , button. After that, pressing the indicated screen will

input the alarm code to the pattern alarm setting [FIG 59] screen code automatically. If users want to cancel the

set alarm code, press thebutton (located on the right middle side of alarm code setting [FIG 60] screen)

then set alarm code will be cancelled.

⦁ [Table2] Alarm Type & Code

Code

1

2

3

4

5

6

Alarm Type

Upper limit

absolute

(Tangent)

Lower limit

absolute

(Tangent)

Upper limit

deviation

(Tangent)

Lower limit

deviation

(Tangent)

Upper limit

deviation

(Reciprocal)

Lower limit

deviation

(Reciprocal)

Code

11

12

13

14

15

16

Alarm Type

Upper limit

absolute

(Tangent, Hold)

Lower limit

absolute

(Tangent, Hold)

Upper limit

deviation

(Tangent, Hold)

Lower limit

deviation

(Tangent, Hold)

Upper limit

deviation

(Reciprocal, Hold)

Lower limit

deviation

(Reciprocal, Hold)

Operation View

Upper & lower

7

limit deviation

17

Within the range of

8

upper & lower

18

limit deviations

Upper limit

absolute

9

19

(Reciprocal)

Lower limit

absolute

10

20

(Reciprocal)

△ : SV▲ : Alarm SV

Upper & lower

limit deviation

(Hold)

Within the range of

upper & lower limit

deviations (Hold)

Upper limit

absolute

(Reciprocal, Hold)

Lower limit

absolute

(Reciprocal, Hold)

52

Start program operation

S

Start program operation

5.2.6 Pattern start mode setting

The initial setting value is necessary to ascent or descent by the setting value of 1st segment when

you start to work with Program control. Select this the initial setting value between Start setting

value(S.SV) and Current measurement value(S.PV). Pressing, buttons in

Program setting menu display, Pattern alarm setting display will be shown. Pressingbutton

again In this display, it will be shown to [Fig.61] S.PV Working start setting display.

[Fig.61] S.PV Operaiton start setting display

Name

Enter the pattern number to set or select it by pressing

PTN NO.

the / button.

Start the operation based on the SV set in the

START

S.SV

temperature & humidity S.SV below.

MODE

S.PV

Start the operation based on the current

Set to the start SV upon temperature program running.

T. S.SV

Set to the start SV upon humidity program running.

H. S.SV

Function

[Fig.62] S.SV Operation start setting display

Range

1~100 Pattern

-

-

(-100~200) ℃ (TH500)

(-100~500) ℃ (TH300)

(0~100) %

[FIG.63] S.SV Operation start mode[FIG.64] S.PV Operation start mode

53

5.2.7 Program pattern name setting

[Fig.65] Program pattern name screen

When pressing pattern name in the Program Pattern Name setting screen [Fig.65], Number Input

Screen[Fig.66] will be shown. When pressing button in the function setting menu,

Program setup menu screen will be shown. Pressing leads to Program pattern name

screen. When pressing the Program pattern name you want by means of right-upper side

button, Number input screen[Fig.66] will be shown. Enter the desired pattern number by

button.

[Fig.66] Number input screen

5.2.8 Pattern/Segment management

[Fig.67] is the display for managing patterns through pattern copy, segment copy and segment

initializing. In the left side you should enter the source pattern or segment number used for pattern

management. In the right side you should enter the target pattern number of segment number to be

copied. After entering a desired value, you can copy it

by pressing, button in arrow.

button on the left center is used for

initializing all the internal segments of the pattern

entered into the input box above. Pressing ,

it will be copied to contents related with every

segment in internal pattern. Pressing [Fig.67] Segment

managementbutton, it will copy contents of

the original start/End segment copy from a copy start

segment. It is possible to copy segment into your

desired position by inserting different segment numbers of the right copy when copying segment.

(Example : the original 1~6 to the copy 7~12)

54

[Fig.67] Pattern/Segment management

•Keep in mind that it is impossible to recover the original contents of the target

after copying the pattern/segment. Once you press the button,

the original contents of the source cannot be recovered again. After copying

pattern by usingbutton, you should make sure that the related

parameter is proper setting. (Repeat, Connect, Waiting, Alarm, Start mode,

ect)

5.3 Date/Time Reservation Setting

Date/Time Reserve RUN setup [Fig.68] will be shown when pressing

After entering (Year,Month,Date,Hour,Minute) into the indication screen of [Current Time] and

pressingvalue, Date and Time will be set up. RUN(Operation) method by means of

Reservation Time Setting is same as Current Time Setting method. After Reservation Time

Setting and move to the Running screen of fixed control[Fig.69], screen will be on

and off and shown. If reservation time comes, it turns into RUN status. In order to cancel

, please press flickering "Reservation Waiting" and select .

[Fig.68] Reservation time setting screen

YES

[Fig.69] Fixed control the 1st working stop screen

•If you begin to work by pressingbutton during reservation waiting, reservation

waiting will be canceled automatically and the operation will start. Likewise, if you

start the 『RUN/STOP』 operation through Contact input(D.I), reservation waiting will

be canceled automatically

55

5.4 Graph/Save Setting

When touching in the Function setting menu screen[Fig.44] or touching

in the Graph Display Screen[Fig.71], Graph Setting screen[Fig.70] will be shown up. In the

Graph setting screen[Fig.70], the time of X axis means the time per division and as table 3, it

can be designated to min 20 seconds ~ max 216 hours according to its internal setting. If you

want to use Y axis as temperature, within -100 ℃ min ~ 200 ℃ max(TH500) and -100 ℃ min

~ 500 ℃ max (TH300), you can select at least 8 ℃. In case of displaying as humidity,

its value is fixed as 0 - 100 %.

[Fig.70] Graph Setting screen[Fig.71] Graph view screen

⦁ [Table 3] Time per X axis DIV

Division Setting Time

1

2

3

4

5

6

7

8

9

10

11

12

13

14

00M 20S

01M 00S

02M 00S

03M 00S

04M 00S

05M 00S

06M 00S

07M 00S

08M 00S

09M 00S

10M 00S

20M 00S

00H 30M

00H 40M

Entire Screen Time

00H 03M 20S

00H 10M 00S

00H 20M 00S

00H 30M 00S

00H 40M 00S

00H 50M 00S

01H 00M 00S

01H 10M 00S

01H 20M 00S

01H 30M 00S

01H 40M 00S

03H 20M 00S

05H 00M

06H 40M

Division Setting Time

15

16

17

18

19

20

21

22

23

24

25

26

27

28

00H 50M

01H 00M

02H 00M

03H 00M

04H 00M

05H 00M

06H 00M

09H 00M

12H 00M

24H 00M

48H 00M

72H 00M

144H 00M

216H 00M

Entire Screen Time

08H 20M

10H 00M

20H 00M

30H 00M

40H 00M

50H 00M

60H 00M

90H 00M

120H 00M

240H 00M

480H 00M

720H 00M

1440H 00M

2160H 00M

56

⦁ [

table 4] Selection of storage condition

utton

B

ame

N

ALWAYS ON

RUN ON

FIX-RUN ON

Program-

RUN ON

unction

F

Save always.

Save during controlling only.(Fix/Program)

Save during fixed-mode controlling only.

save during program mode controlling only.

Internal Buffer

Delete/Initialize Saved Contents in internal memory

initialize

USB

Do not use USB MEMORY STICK.

cancellation

USB selection

Record on USB MEMORY STICK.

As far as the saving operations are concerned, the total 86,400 pieces of information on temperature

& humidity (Y/M/D, temperature & humidity SV/PV/MV) under current controlling will be recorded to

the internal memory. The saving cycle can be designated as 1 to 360 seconds. Therefore, if the

saving cycle is 1 second, it can save for one day. On the other hand, if the saving cycle is

30 seconds, it can save for 30 days. Also recorded data will be stored in accordance with table

4 : Selection of storage condition.

When selecting , it will be recorded on USB MEMORY STICK. But it requires to connect

USB MEMORY STICK with our product name "EM310(Sold separately).

● Data transmission by USB connector

TH500 present USB connection function to send saved data to PC. According to Save Sequence &

Save Operation Mode set in [Fig.70] Graph Setting display, Data stored in internal memory become

mass difficult to transfer with low-speedy connection (max 115,200 BPS) interface like RS232,

RS422/485. If you send by using USB connection in that time, it is possible to send to PC within a

few second.

[Fig.72] is the display of USB Up-loader software presented by HANYOUNG NUX CO., LTD. When

USB connecter is connected, Device connecting status is indicated, “Connected” in blue and

button is activated. Pressing Send button, you can receive every Measure/control

57

[Fig.72] USB Uploader Utility

value recorded in TH500 through USB.Transferred date is stored in the folder of “C:\TH500_DATA”.

Because all saved Data file is in text mode, you can see the content of saved data file with any

editor, word-processor or Excel. It is possible to see a graph by using Graph Viewer program

presented.

•

Ifyouturnoff, allcontentswillbedeletedbecausethevalueofsaved

measurement & control is saved in Volatile Memory(SDRAM).

•

When you connect USB, you must use USB A-B connector cable.

•

The USB Plug& Play functionof some PCsmay have errorsupon PCbooting.

Therefore, it isnecessary to connectUSB connector afterPC booting. AfterPC

booting, you are free to connect USB connector.

[FIG.73] Graph viewer program

58

6 System Setting

•System setting is a pre-installed basic setting condition so you need

special attention when youchange them.

•ThereisnoneedforoperatortosetSystemsettingseparately. Becausethe

basicsettingconditionofthissystemisalreadysetupbysysteminstallation

company, operator should be careful when changing System setting.

If you push on operation screen, function setting menu screen will be displayed. And if you

push function-setting, Password screen will be displayed (initial value: 0). and then you can

enter system setup menu screen after pushing on screen.

[Fig. 74] Function setting menu screen[Fig. 75] System setup menu screen

6.1 Sensor type setting

Our temperature and humidity controller (Model # TH500/TH300) support various outputs and inputs

so you need to set output and input information before using this controller.

On the operation screen, push screen as following, When touching button in the Operation

screen, Function Setup screen will be shown up. This time, if you touch left-top corner, Password

confirmation screen will be displayed (Initial value : 0). After touching password and then touching

, System Setup menu screen will be shown up. When touching Sensor Input Setup button,

Temperature sensor setting screen[Fig.76] will be displayed and it is consisted of total 4 screens

(Sensor Input Setting 1~4)

6.1.1 Sensor Input Setting 1 & 2

It is possible to set sensor type(RTD/VDC), Input range, Scale(Measurable range setting),

Sensor Bias, Filtering time on the Temperature sensor setting screen[Fig.76]. The contents of

Humidity sensor setting screen[Fig.77] is the same as temperature sensor setting. But, if you

select sensor type as, Temperature only display [Fig 78] will be set up.

59

[Fig. 76] Temperature sensor setting screen

(1) Sensor type

Select by the input sensor type. When performing the relative humidity measurement by using the

wet/dry method and when sensor for dry and wet is RTD (Pt100 Ω), please select as the

for sensor type in "temperature sensor related setting" and "humidity sensor related setting." If

electrical type humidity sensor (model:EE99) is used then temperature sensor will be considered

as RTD (Pt100 Ω) so select the sensor type aswithin the "temperature sensor related

setting" and select the sensor type asd.c voltage for "humidity sensor related setting"

mA

because output for humidity sensor is 4 -20

connect the resistance (less than 250 Ω1 %) on the external input terminal in parallel.)

Lastly, please select OFF for the humidity sensor type when using as the temperature only mode.

(2) Input range

Regarding sensor input range, you can use initial value. The initial setting for temperature value is

. (But, in case of current output sensor, please

[Fig. 77] Humidity sensor setting screen

Temperature

only display

screen

In case of using Temperature only display mode, please select humidity sensor type

as OFF on the Sensor Input Screen 2 [Fig.77]. This time operation screen will be

displayed as Temperature only screen.

[Fig.78] Temperature only display

60

-100 ~ 200 ℃ and humidity value is 0 ~ 100 % R.H. If you use electronic humidity sensor

Model # EE99), please set up input range to - Vd.cand contact resistance

(

1.00

5

.00

(250 ℃ 1 % below) to the both of input terminals.

(3) Scale setting

In case of selecting sensor type as, scale setting screen is not activated. That is to

say, RTD(Pt 100) is not related to scale setting. In case of, please input proper scale

setting value. The setting range is - V. Scale setting range of temperature

0.00

5.00

sensor setting screen – TH500 : -100 ~ 200℃, TH300 : -100 ~ 500℃ / Scale setting

range of humidity sensor setting screen : 0.0 ~ 100.0 %

(4) Sensor Bias(Input Bias)

Sensor Bias screen will be displayed when touching Sensor .

Sensor Bias has two methods : OFF-set bias and Section bias.

[Fig.79] Temperature Bias[Fig.80] Humidity Bias

Sensor Bias(Input Bias) corrects deviations caused by many reasons. Horizontal axis means standard

temperature or humidity and vertical axis means measured temperature or humidity. Also each value

could be changed to any value by touching number. OFF-set bias removes deviations by selecting

desired value when measured temperature or humidity value has overall deviations compared to

standard value. For example, if measured temperature is 10℃ lower than standard temperature,

touch Off-set and change 0.00 to. In this case, measured value will be compensated

0.00

10

by 10℃ Section bias is used when compensating deviations per section. In case of standard

temperature 80℃ and measured temperature 70℃, 10℃compensation of measured temperature is

necessary. This time please touch 80℃ and enter 70 in the number plate. After touching

, compensation is finished.

•Partial biascanbe selectedbysetting eachsection in accordancewith itsuse

because partial bias aims to change the slope of section.

61

(5) Filter setting

Filtersettingsetsthesuitabletimewhenprocessvaluevariesduetotheflowofhighnoise

hrough out the input sensor line.

t

6.1.2 Sensor Input Setting 3

[Fig 81] Set Dry bulb temperature range and Wet/Dry Input Bias to control humidity.

Humi.C.RNG.

Dry Temp.

Wet Temp.

Rel. Humidity

D/W Adjust

Adjust mode

[FIG.81] Sensor Input Setting 3

It sets Wet bulb Temperature range. (Initial value : 0 ~ 100 ℃)

Measured humidity value will not be displayed in case it is beyond its

range (----), control output will be OFF.

Displays Dry bulb temperature

Displays Wet bulb temperature (Gauze have to be removed)

Displays relative humidity (% RH)

Pressand it shows the temperature difference between

dir bulb and web bulb. It very important to correct Dry/Web bulb because

relative humidity measurement is based on the temperature difference

between two sensors.

If you push setting, correction will be started

D/W ADJ.

•Please removegauze inthe webbulb sensorbefore correction. And alsostart

correctionafterstabilizationoftheprocessvalue. Pleaserecovergauzeafter

correction

62

6.1.3 Sensor Input Setting 4

ithin the [FIG 82] sensor input setting 4 screen, itsetsthe temperature setting range, humidity

W

settingrange, temperatureresolvingpower(decimalpointsindication), sensorbreakdetection

and operation delay time.

[FIG.82] Sensor Input Setting 4

Setting item

In order to prevent mistake of user mistake, the Temperature SV range can

Explanation

T.SV range

be restrictive as much as wanted range.

In order to prevent mistake of user mistake, the humidity SV range can be

H.SV range

Temp. Res.

Burnout wait time

A/T Button

restrictive as much as wanted range.

Temperature process value and SV can select 0.01 ℃ or 0.1℃

After detecting disconnection of sensor, select delayed operation

time.

It shows or hides Auto Tuning button in operation screen.

6.2 Control output setting

ControlOutputSettingscreenisconsistedoftotal4 screens: Temperaturecontroloutput,

Humiditycontroloutput, TemperatureRetransmissionoutput, HumidityRetransmissionoutput.

Move to each screen by touching button.

6.2.1 Control output setting 1

Temperatureoutputtype, OutputperiodofSSR, Outputdirection(Reverse/Forward), Output

range could be set up on the Control Output Setting 1 [Fig.83]

63

TH500TH300

[Fig. 83] Control output setting 1

6.2.2 Control output setting 2

Humidity output type, Output period of SSR, Output direction(Reverse/Forward),

Output range could be set up on the Conntrol Output Setting 2 [Fig.84]

TH500TH300

[Fig. 84] Control output setting 2

64

● Control Output Setting 1 is the same as Control Output Setting 2

min value of

output range=-5 %

max range of

output range=105 %

T.Out type

T.SSR out period

T.Out direct

T.Out range

Select and use S.S.R or S.C.R (4 - 20 ㎃ d.c). Select according to the

equipment (Initial value : S.S.R)

You can set up when you select S.S.R output. Output cycle means On/Off

working time in the proportional band.

(Initial Value : 1 seconds)

Select cooling control (direct movement) or heating control

(inverse movement) (Initial Value : Inverse movement)

You can control output and selection range : -5 %(3.2 ㎃ d.c) ···