Hanyoung PX2, PX7, PX3, PX9 Instruction Manual

PX series

INSTRUCTION MANUAL

Thank you for the purchase of HANYOUNG product.

Please read this manual carefully.

Process Controller

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

Contents

2

1. SAFETY INFORMATION

2. INSTRUCTION

3. ORDERING INFORMATION

4. SPECIFICATION

5. DIMENSIONS & PANEL CUTOUT

6. TERMINAL ARRANGEMENT

7. NAME & FUNCTION

8. TABEL OF SETTING ITEMS

9. SETTING METHOD

10. CONTROL GROUP

11. INPUT GROUP SETTING

12. INPUT SIGNAL AND

MEASUREMENT RANGE

13. OUTPUT GROUP SETTING

14. SET VALUE GROUP SETTING

15. PROGRAM GROUP SETTING

16. AUTO TUNING

17. P.I.D GROUP

18. ALARM GROUP SETTING

19. ALARM TYPE AND CODE

20. RETRANSMISSION GROUP

21. COMMUNICATION

22. HEATER BREAK ALARM GROUP

23. REMOTE INPUT GROUP

P. 3

P. 5

P. 5

P. 6

P. 10

P. 11

P. 12

P. 13

P. 15

P. 16

P. 17

P. 18

P. 19

P. 20

P. 21

P. 22

P. 23

P. 24

P. 25

P. 26

P. 26

P. 27

P. 27

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

Fuzzy

Auto Tuning

Alarm Output

Retransmission Output

Multi Input Output

External Contact Input

Ramp soak function

Heating / Cooling

Zone PID

Group PID

Power supply for sensor

Output Limits

Interface (RS485 / 422)

3 Set points

Heater break alarms

(HBA1, HBA2)

IP65 Front facia

High Accuracy 0.1 class 250 ms

Features

PX Series

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

Before using, please read this (SAFETY INFORMATION) and then use this controller.

It is important that the instructions in this manual are followed when using this instrument.

Please keep this manual for future reference.

Precautions are classified in WARNING and CAUTION.

WARNING

1. Caution on wiring

Use an external protection circuit if a fault in the control loop could possibly lead to a serious

problem.

This instrument do not have a switch for power and a fuse, so please set them if it is needed.

(Fuse rating 250 V, 0.5 A)

2. Power supply

Use a rated voltage to prevent damage or trouble.

To avoid electrical shock or damage, do not turn ON the power until the wiring is completed.

3. Prohibit use in gas atmosphere

Do not use it at a place exposed to combustible or explosive gas.

4. Handling of unit

To avoid malfunction, electrical shock or fire, this unit must not be disassembled or repaired.

Do not touch the terminals to avoid electrical shock or malfunction.

5. Caution on maintenance

Turn OFF the power before mounting or removing the instrument.

To ensure continuous and safe operation of the instrument, periodical maintenance is

recommended. Some parts are limited in life.

The warranty period is 1 year only if using in the correct way.

CAUTION

1. Caution on handling

Do not install the instrument under any of the following conditions.

The ambient temperature exceeds 0 ~ 50

The ambient humidity exceeds 45 ~ 85 % RH.

A place where temperature changes suddenly or icing occurs.

A place exposed to corrosive gas or combustible gas.

Vibration or shock is likely to be transmitted to the instrument.

A place exposed to water, oil, chemicals, steam, sunlight.

A place exposed to much dust, salt or iron.

A place with much inductive disturbance, static electricity, magnetism noise.

A place where heat such as radiant heat stays.

4

WARNING

CAUTION

There is a possibility of death or heavy injury when handling in wrong way.

There is a possibility of injury or physical damage when handling in wrong way.

SAFETY INFORMATION

1

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

5

2. Installation

Attach the brackets (2 units) on the fixed halls and tighten with a screwdriver.

Fixing torque is about 147 N. cm (1.5 kg.cm)

(Care should be taken not to tighten forcedly)

3. Caution on terminal connections

To avoid induction noise to input wires seperate from the power and output wires.

Keep input wires away from output wires and use shielded wires to earth.

Use a compensating cable with thermocouple.

For R.T.D input use a cable which is a small lead wire resistance and without resistance

difference to 3 wires.

If the wiring has noise, use the following step: connect a surge absorber to the conductor coil

side if the conductors are connected to the load output, such as the relay contact output.

(EX. For 220 V AC ENC 471D-05A)

Use an insulating transformer with a noise filter when the power suppy has much noise.

(EX. TDK brand ZMB 22R5-11 noise filter)

Noise filter should be mounted on a panel which has been earthed and the wiring between the

noise filter output and the instrument power terminals should be shorten.

It is effective to use a twisted cable for power supply against noise.

The heater power supply and the instrument power supply should be connected using the

same power suppy when a heater break alarm.

Time for preparation of contact output is required at power ON. When the output signal is used

for an extenal interlock circuit, connect a delay relay.

4. For load circuit connection

Use an extra relay when the frequency of operation is rather high. SSR output type is

recommended.

Electromagnetic switch : Proportional cycle time is Min. 30 sec

SSR : Proportional cycle time is Min. 1 sec

Contact output life : Mechanical : 10 million times (no load)

Electrical : 100 thousand times (rated load)

SSR drive pulse voltage, 4 ~ 20 mA DC are not insulated with internal circuit.

Use non-grounded sensor to R.T.D and thermocouple.

5. For waterproof (Waterproof type)

The instrument has IP65. Use rubber packing when installing the instrument to panel.

Please attach the rubber in correct way.

6. Caution on key operation / trouble

If alarm function is not set correctly, alarm output can not be operated at a trouble point.

Be sure to check the alarm operation.

If the input cable is disconnected, the display shows “ ”.

When replacing the sensor, please turn OFF the power suppy.

7. Other

Do not use organic solvents such as alcohol, benzine when cleaning. (Use neutral detergent)

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

6

This instrument has process-value (PV) and set-value (SV) each 4 digits with 7 segment FND.

This instrument is available in 2 versions: Universal Type and Heating / Cooling Type. Each has

12 Setting groups (refer pages 9 & 10)

Function and feature : Group P.I.D, Multi-input (19 types), Multi-output (Relay, SSR, Current),

Local input, Remote input, External contact input, Program Control (Ramp / Soak) with 10 steps,

Auto-tuning 2 types (standard type, low PV type), Manual output, Retransmission, Communication

(RS485 /422), Power supply for sensor, 22 types of alarm, Sampling cycle 250 ms, 0.1 % FS high

accuracy.

ORDERING INFORMATION

INSTRUCTION

2

3

PX2 -

Process Controller (48

96 mm)

Universal

Heating / Cooling

0

1

Description

Suffix code

Model

PX3 -

Process Controller (96

48 mm)

Universal

Heating / Cooling

0

1

Description

Suffix code

Model

PX9 -

Process Controller (96

96 mm)

Universal

Heating / Cooling

0

1

0

1

Description

Suffix code

Model

PX7 -

Process Controller (72

72 mm)

Universal

Heating / Cooling

0

1

0

1

2

3

Description

Suffix code

Model

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

7

INPUT

Input

Sampling cycle time

Input resolution

Input impedance

Allowable signal source

resistance

Allowable wiring

resistance

Allowable input voltage

Noise ratio

Standard

Standard junction

temperature

compensation tolerance

Burn-out detection

Accuracy

Thermocouple, R.T.D, Direct voltage

( refer to the input signal and measurement range on page 18 )

250 mS

Below decimal point of range

Thermocouple / Voltage (mV) input : 1

or above

Voltage input ( V ) : Approx. 1

Thermocouple : 250 or below

Voltage input : 2

or below

R.T.D : 150

or below / 1 wire

Thermocouple, R.T.D, Direct voltage (mV) :

10 V

Direct voltage (V) :

20 V

NMRR :40 dB or above

CMRR :120 dB or above ( 50/60 Hz

1 %)

Thermocouple / R.T.D ( KS / IEC / DIN )

1.5 ( 15 ~ 35 ), 2.0 ( 15 ~ 50 )

OFF, Up / Down scale selectable

Thermocouple burn-out : Up / Down scale

R.T.D burn-out : Up scale

(TC / R.T.D burn-out detection current : Approx. 50

)

0.1 % of F.S

SPECIFICATION

4

100 - 240 V ~, 24 V

50/60 Hz

-10 % +10 %

Max. 6.0 W, 10 VA or below

27 V - 20 mA ( but, it is not available when using retransmission output )

20

min. (at 500 V DC)

Between primary terminal and secondary terminal

Between primary terminal and ground

Between ground and secondary terminal

2300 V AC 50/60 Hz for 1 minute

Between primary terminal and secondary terminal

Between primary terminal and ground

Between F.G and secondary terminal : 1500 V AC 50/60 Hz for 1 minute

Power supply voltage

Frequency

Voltage variation

Power consumption

Power supply for

sensor

Insulation resistance

Dielectric strength

POWER SUPPLY

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

8

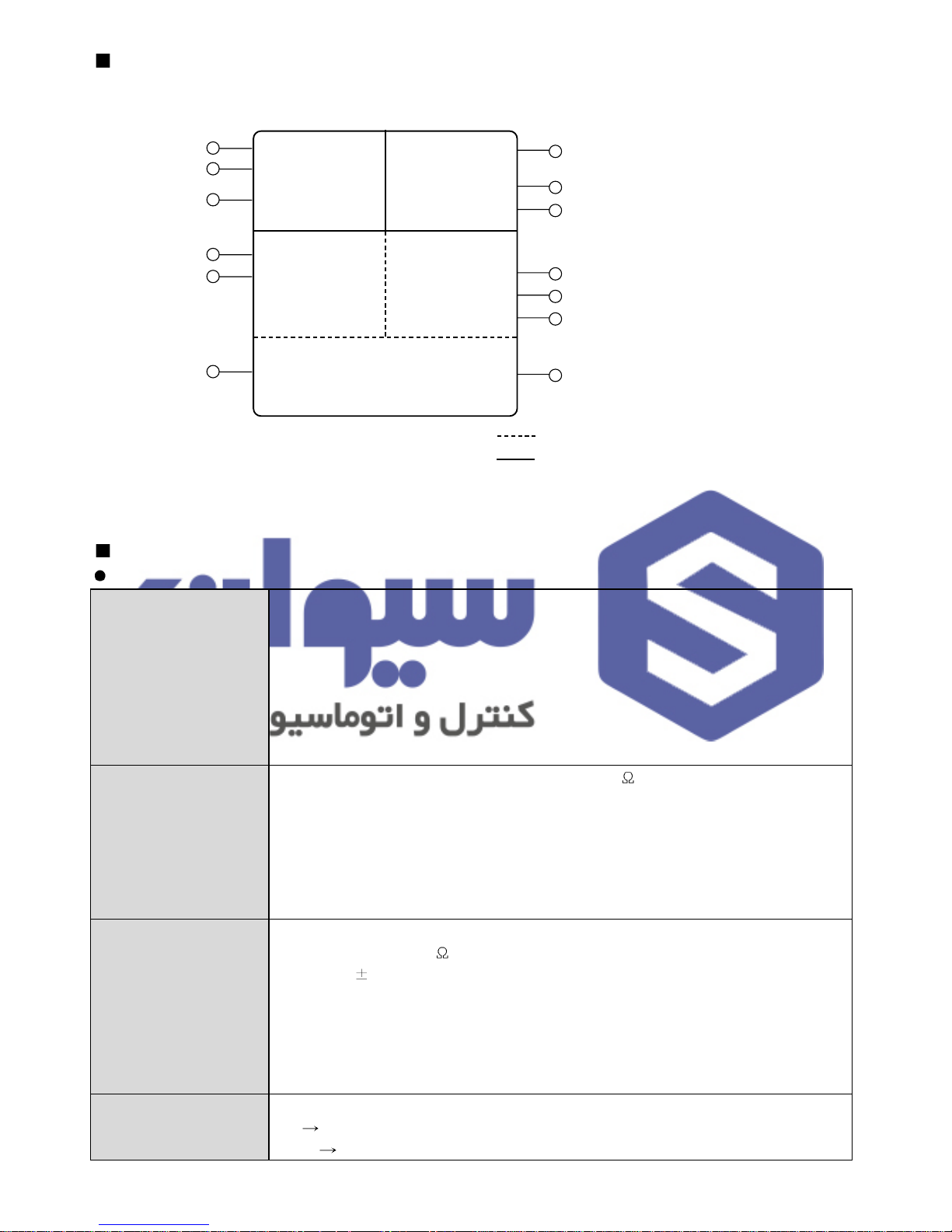

SELV

Danger Danger/Safety

SELV

SELV

MMI / F

Power supply

GND

Alarm1

Alarm2

Control output

Relay contact output

Control output 1 (SSR, SCR)

Control output 2 (SSR, SCR)

Contact input

Contact input

Communication channel

CT input

(retransmission)

Measuring

input

Divison of insulation

Functional insulation (basic insulation)

Functional insulation (double insulation)

OUTPUT

CONTROL OUTPUT

Relay

contact output

SSR output

Current output

Manual operation

Contact capacity : 240 V AC 3 A, 30 V DC 3 A ( Resistance load )

Contact structure : 1 c

Output action : Propotional or ON / OFF action

Proportion cycle time : 1 ~ 1000 sec.

Output limit : Higher (OH) or lower limit (OL) selectable within 0.0 ~ 100.0 %

range. It is also available in Auto tuning

ON / OFF hysteresis : 0 ~ 100 %

Time resolution : 0.1 % or 10 ms

ON voltage : 12 V DC min.(Resistance load: 600

min, 30 mA limit when short)

OFF voltage : 0.1 V DC max.

Output action : Proportional action

Proportion cycle time : 1 ~ 1000 sec.

Output limit : Higher (OH) or lower limit (OL) selectable within 0.0 ~ 100.0 %

range. It is also available in AT and MAN.

Time resolution : 0.1 % or 10ms (whichever is larger)

Output current range : 4 ~ 20 mA DC

Resistance load : 600

max.

Accuracy :

0.3 % of F. S ( 4 ~ 20 mA ) Resolution : Approx. 3000

Output ripple : 0.1 % of F. S ( p-p ) 150 Hz

Output update cycle time : 250 m sec.

Output action : P.I.D control

Output limit : Higher (OH) or lower limit (OL) selectable within -0.5 ~ 105.0 %

range. It is also available in AT and MAN.

It is changeable by A/M key, external contact and communication.

AT

MAN : TRACKING

MAN

AT : BUMPLESS CONVERSION

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

9

RETRANSMISSION OUTPUT

Current output

Output current range : 4 ~ 20 mA DC, Resistance load : 600

max.

Accuracy :

0.3 % of F. S (4 ~ 20 mA), Resolution : Approx. 3000

Output ripple : 0.1 % of F. S (p-p), 150 Hz

Output update cycle time : 500 msec (When remote option)

ALARM OUTPUT ( HBA COMMON )

Alarm output

Output : Relay contact, Output contact : 3 points

Contact capacity : 240 V AC 1 A , 30 V DC 1 A (Resistance load)

Contact structure : 1 a

COMMUNICATION INTERFACE

Communication

Interface

Standard : EIA RS485

Number of devices (Max.) : 31, Address setting : 1~99 range

Communication type : 2-wire or 4-wire half-duplex

Synchronization : Asynchronous

Communication order : None

Communication distance : Max. 1200 m

Communication rate : 600, 1200, 2400, 4800, 9600

Start Bit : 1Bit, Data length : 7 or 8 Bit, Parity : None, Even, Odd

Stop Bit : 1 or 2 Bit, Protocol : PC LINK

Response time : Handling time + ( RP.T

10 ms )

HEATER BREAK ALARM

Heater break alarm

Output contact : 2 points

Current measurement range : 1 ~ 50 A AC

(Resolution 0.5 A,

5 % of F.S 1 Digit)

Alarm output : AL1, 2 output

It is available to use in ON / OFF or proportional action.

(not available in current or cooling output)

Minimum detection time : 0.2 sec, Dead Band : 0 ~ 100 %

SAFETY AND EMC STANDARDS

Safety and EMC

Standards

Safety standards: IEC1010-1-1990 and EN61010-1-1992; CSA1010 CAT

(IEC1010-1); and UL508.

EMC Standards: EN55011 Class A, Group 1, for emission (EMS); and

EN50082-2-1995 for immunity(EMI).

The indicator continuously operates within a measuring

accuracy of

20 % of the range.

EN61000-3-2, EN61000-3-3

Ambience

Installation Conditions

(for normal operation)

Ambient temperature : 0 ~ 50

Ambient humidity : 20 ~ 90 % RH (No condensation)

Installation place : Indoors, Magnetic effect : 400 AT/m max.

Vibration : 5 ~ 14 Hz, forth width 1.2 mm max.

4 ~ 150 Hz, 4.9

(0.5 G) max.

Shock : 147

(15 G), 11 msec max., Height : 2000 m max.

Installation category :

(EN61010-1), Pollution degree : (EN61010-1)

Storage temperature : -25

~ 70 , Storage humidity : 5 ~ 95 % RH

Case : Plastic

Weight : PX2 (342 g), PX3 (340 g), PX7 (344 g), PX9 (472 g)

Including brackets (Brackets 40 g)

هرﮐ ﮓﻧﺎﯾﻧﺎھ تﻻوﺻﺣﻣ یرﺎﺻﺣﻧا هدﻧﯾﺎﻣﻧ ناوﯾﺳ تﮐرﺷ

021-33989001

www.sivancarno.com

021-33989002

Loading...

Loading...