-1-

MA0614E170926

※ HX9 is

chosen to explain

①

②

⑦

⑥ ⑤ ④ ③

█

External Contact Input (DI) Selection

3 predetermined set values (temperature values) could be changed with using

ON/OFF of the external 2 contact inputs

Model Code Description

HX ☐ - ☐ ☐ Multi-input and output digital temperature controller

Dimension

2 48(W) × 96(H) ㎜

PID Auto-tuning

3 96(W) × 48(H) ㎜

4 48(W) × 48(H) ㎜

7 72(W) × 72(H) ㎜

9 96(W) × 96(H) ㎜

Control output

0 Standard

1 Heating / Cooling (simultaneous control)

HX2/3/9 option

0 None

1 RS485 communication + Heater break alarm (HBA)

HX7 option

0 None

1 RS485 communication + DI 2 contacts (SV2, SV3)

2 RS485 communication + Heater break alarm (HBA)

HX4 option

0 None

1 RS485 communication + DI 1 contact (SV2)

2 RS485 communication + Heater break alarm (HBA)

1381-3, Juan-Dong, Nam-Gu Incheon, Korea,

TEL:(82-32)876-4697 FAX:(82-32)876-4696 http://www.hynux.com

HANYOUNGNUX CO.,LTD

HEAD OFFICE

Suffix code

Part name and function

Safety information

Alerts declared in the manual are classified to Danger, Warning and Caution by their criticality.

•Please install an appropriate protective circuit on the outside. Malfunction or an incorrect operation may be

a cause of leading to a serious accident.

•

Since this product does not have the power switch or a fuse, please install those separately on the outside. (Fuse rating : 250 V 0.5 A)

•To prevent damage or failure of this product, please supply the rated power voltage.

•To prevent electric shock or equipment failure, please do not turn on the power until completing wiring.

•

Since this is not explosion-proof structure, please do not use in a place where combustible or explosive gas is around.

•Never disassemble, modify or repair the product. There is a possibility of malfunction, electric shock or a risk of fire.

•Please turn off the power when mounting/dismounting of the product.This is a cause of electric shock, malfunction, or failure.

•

If the product is used with methods other than specified by the manufacturer, it may lead to injury or property damage.

•

Since there is a possibility of electric shock, please use the product as mounted on a panel while the power is being supplied.

•If it is used with systems, machines and equipment that could lead to a risk of life or property damage, please

implement safety devices and protections for both lives and the applications and plan for preventing accidents.

Warning

Do not touch or connect any undesirable conductive part to input-output terminal,

since there is a possibility of electric shock.

Danger

•The contents of the instruction manual are subjective to change without prior notice.

•Please make sure that the specification is the same as exactly you have ordered.

•Please make sure that the product is not damaged during shipping.

•

Please use this product in a place where the ambient operating temperature is 0 ~ 50 ℃ (40 ℃ max, closely installed)

and the ambient operating humidity is 35 ~ 85 % R.H (without condensation).

•Please use this product in a place where corrosive gas (such as harmful gas, ammonia, etc.)

and flammable gas do not exist.

•

Please use this product in a place where there is no direct vibration and a large physical impact to the product.

•Please use this product in a place where there is no water, oil, chemicals, steam, dust, salt, iron or

hazardous substances (Contamination class 1 or 2).

•Please do not wipe this product with organic solvents such as alcohol,

benzene or others. (Please use mild detergent instead)

•

Please avoid places where excessive amount of inductive interference and electrostatic or magnetic noise occurs.

•Please avoid places where heat accumulation occurs due to direct sunlight or radiant heat.

•Please use this product in a place where the elevation is below 2,000 m.

•

Please make sure to inspect the product if exposed to water, since there is a possibility of electric leakage or a risk of fire.

•

For thermocouple (TC) input, please use a prescribed compensation lead wire. (There will be a temperature error if a general lead is used.)

•

For resistance temperature detector (RTD) input, please use a small resistance of lead wire and the 3 lead wires should

have the same resistance. (There will be a temperature error if the 3 lead wires do not have the same resistance.)

•

Please keep the input signal wire away from the power lines and load lines to avoid the effect of inductive noise.

•The input signal wires and output signal wires should be separated from each other.

If it is not possible, please use shielded wires for the input signal wires.

•For thermocouple (TC), please use ungrounded sensors. (There is a possibility of

malfunction of the product by electric leakage, if a grounded sensor is used.)

•If there is a lot of noise from the power line, installing an insulated transformer or a noise filter

is recommended. The noise filter should be grounded on the panel and the wire between

the output of the noise filter and the power of the instrument should be as short as possible.

•It is effective against noise, if the power lines of the product are made twisted pair wiring.

•Please make sure the operation of the product before using, since the product may not

operate as it intends to if the alarm function is not properly set.

•While replacing the sensor, please turn off the power.

•In case of the high frequent operation, such as proportional operation, please use an auxiliary

relay since the life span of the output relay will be shortened if it connects to the load without

the rated margin. In this case, SSR output is recommended.

*For Electromagnetic switch : set cycle time : minimum 20 sec.

*For SSR : set cycle time : minimum 1 sec.

•Please do not connect anything to the unused terminals.

•Please connect wires properly after making sure the polarity of the terminals.

•Please use a switch or breaker (IEC60947-1 or IEC60947-3 approved)

when the product is mounted on a panel.

•Please install a switch or break near the operator to facilitate its operation.

•

If a switch or breaker is installed, please put a name plate that the power is off when the switch or breaker is activated.

•In order to use this product properly and safely, we recommend periodic maintenance.

•Some parts of this product have limited expected life span and aged deterioration.

•The warranty of this product (including accessories) is

1 year only when it is used for the purpose it was intended to under normal condition.

•When the power is being supplied there should be a preparation time for the contact output. Please

use a delay relay together when it is used as a signal on the outside of interlock circuit or others.

•When the user replaces with a spare unit due to product failure or other reason,

please check the compatibility since the operation can be varied by

the difference of setting parameters even though the model name and code are the same.

•Before using a temperature controller, there could be a temperature difference between

PV of the temperature controller and the actual temperature, so please operate the temperature

controller after correcting the temperature difference appropriately.

CAUTION

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

DANGER

WARNING

CAUTION

Number

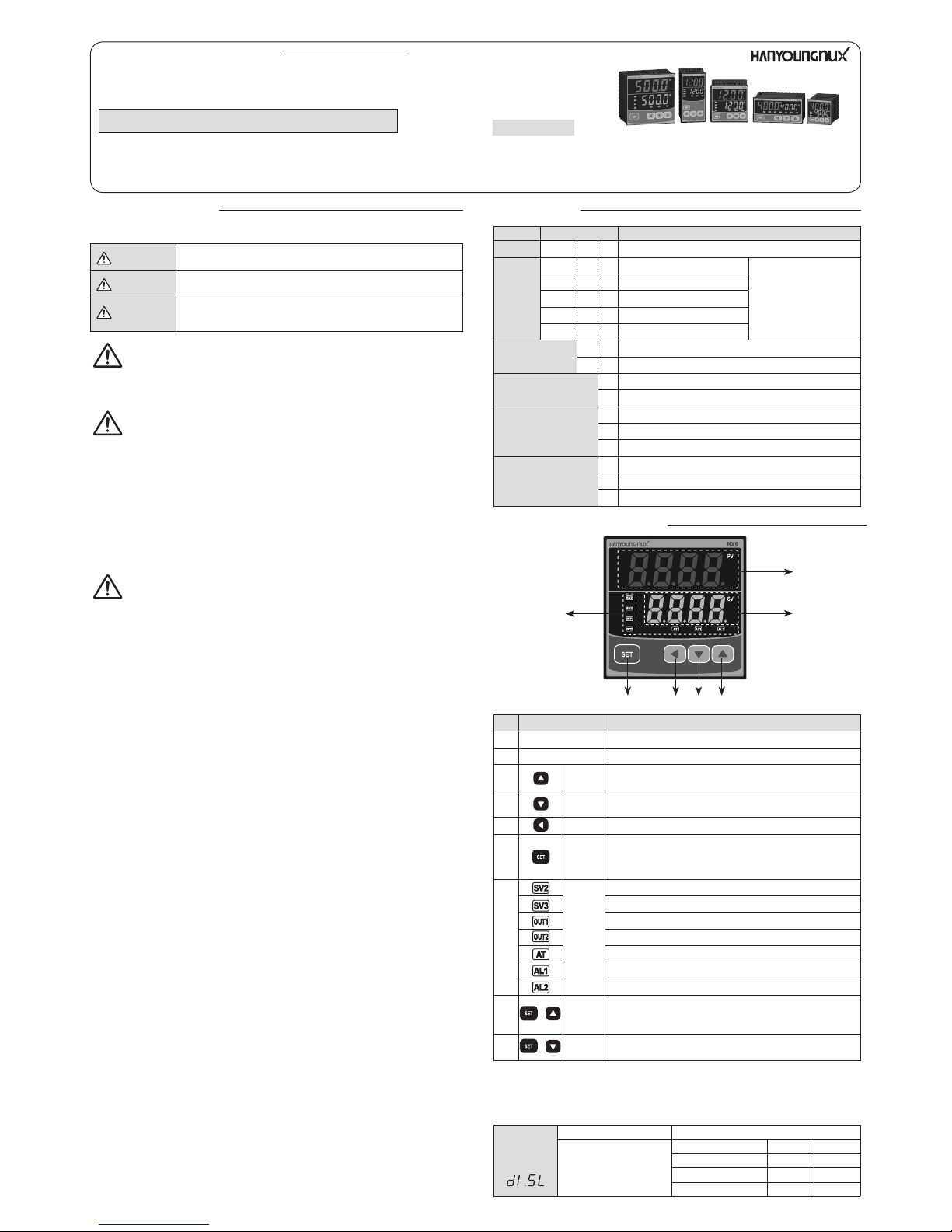

Name Description

① Process value (PV) Displays the process value in the operation mode.

② Set value (SV) Displays the set value in the operation mode.

③ Up key

Increases the set value or used to move between groups and

to change an option in a parameter in setting mode.

④

Down

key

Decreases the set value or used to move between groups and

to change an option in a parameter in setting mode.

⑤ Shift key Used to move the position of the digit.

⑥ Set key

Sets (confirm) the set value, displays the output amount, or set an

option in a parameter in setting mode and moves between the

parameters in a group. By pressing for 3 seconds, it enters the

display setting mode (setting mode) or returns to the operation mode.

⑦

Operation

Indicator

Lights when SV2 is displayed.

Lights when SV3 is displayed.

OUT1 indicator.

OUT2 indicator.

Auto-tuning indicator (blink).

Alarm 1 operation indicator.

Alarm 2 operation indicator.

⑧

+

Hot

key(run/

stop)

Hot key is designated for AT or Manual MV

configuable in the group of "G.CtL"

⑨

+

Quick

menu

Sets the value: SV1, SV2, AL1, AL2

External input

contact

selection

( )

OFF (contact input is not used)

ON (contact input is used)

No display

External contact input SV2 SV3

Set value 1 display (SV1)

OFF OFF

Set value 2 display (SV2)

ON OFF

Set value 3 display (SV3)

OFF ON

Thank you for purchasing HANYOUNG product.

Please check whether the product is exactly the same as you ordered.

Before using the product, please read this instruction manual carefully.

Please keep this manual where you can view at any time.

INSTRUCTION MANUAL

HX series

Digital Temperature Controller

-2-

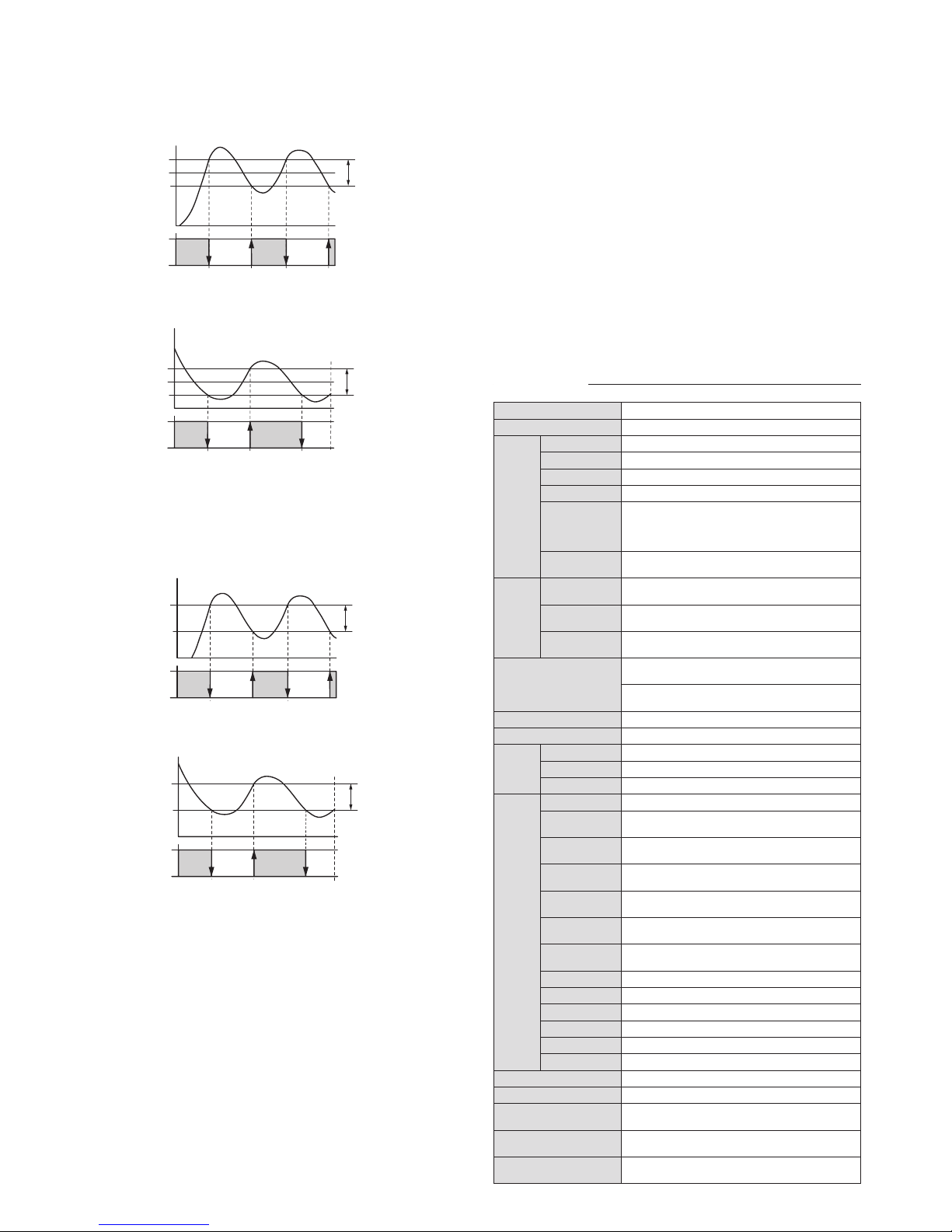

Input code for input type and range

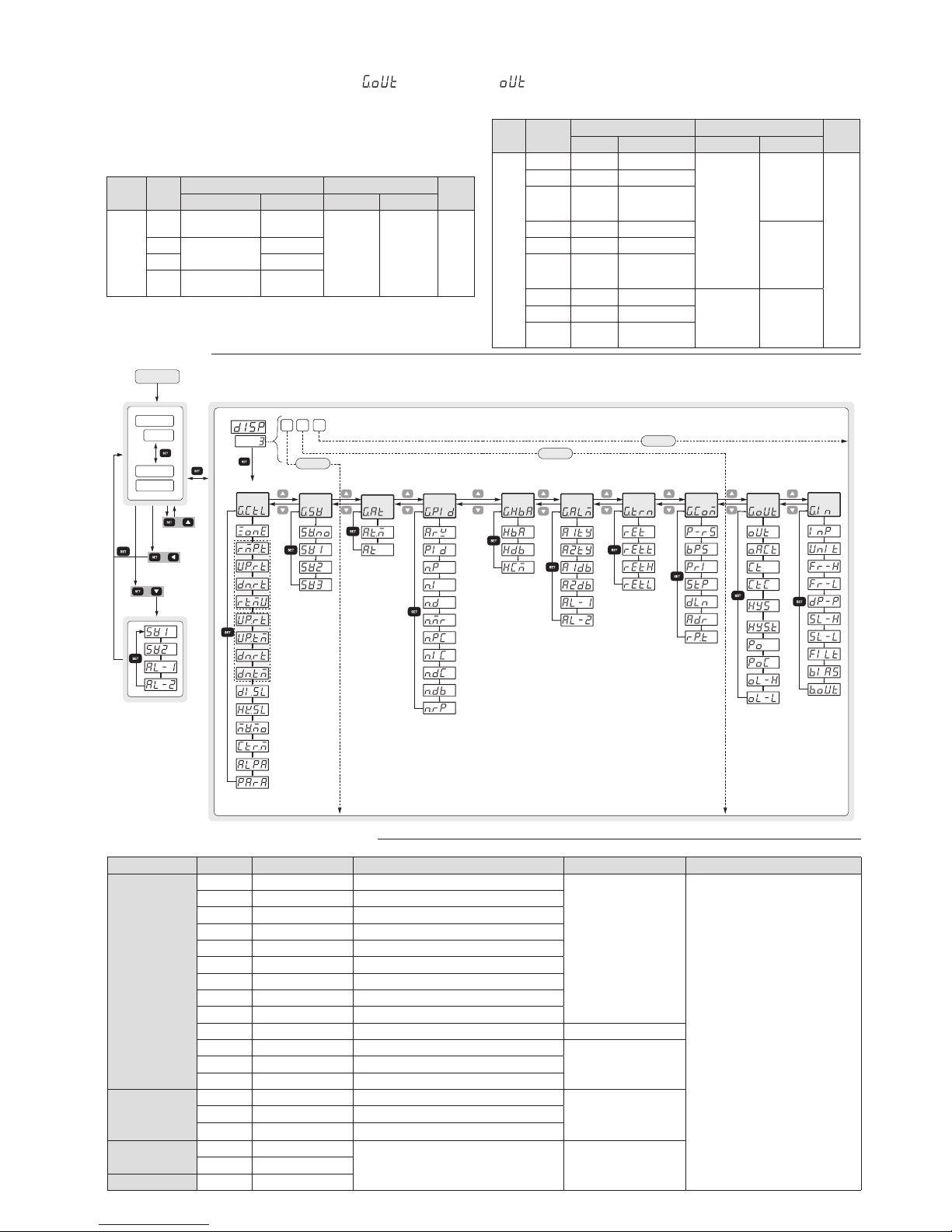

Setting Mode

56 78

9

®34

DISP 1

DISP 2

DISP 3

1 2 3

Power On

1) Operation

mode

Process value

Set value

Process value

Output amount

PV

SV

PV

SV

Control group

Auto-tuning group

Setting value group

PID group

Alarm group

RET. group

COM. group

Output group

Input group

HBA group

for 3 seconds

for 3 seconds

for 3 seconds

for 3 seconds

for

3 seconds

HOTKEY

+

Level

+

Quick menu

+

Ramp

function

type A

Ramp

function

type B

※ In the standard type, Retransmission output (RET) is only available from OUT2.

(1) Standard type

Typ e

Output

code

OUT1(Heating) OUT2

Default

Relay SSR/SCR/RET Relay

SSR/SCR/RET

Standard

Typ e

0

Control output

(ON/OFF)

AL2

(Alarm 2

output)

RET

(retransmission

output)

1

1

-

SSR

2

SCR(4 - 20 mA)

3

Control output

(PID)

-

Input signal Input signal Input type Range (℃) Accuracy Note

Thermocouple

(TC)

1 K *1 -200 ~ 1370

±0.5 % of FS ±1 Digit

•FS is the measurable range

from the maximum to the minimum

for each range.

• Digit is the minimum display value

❇1 below 0 ℃ :

±1.0 % of FS ± 1 digit

❇2 0 ~ 400℃ range :

±10 % of FS ± 1 digit

❇3 20 KPt100 Ω (C1603)

21, 22 Pt100 Ω(IEC751)

*4 In case of using Current input,

Resistor 250 Ω 0.1 % should be

installed in the input terminal.

2 K *1 -199.9 ~ 999.9

3 J *1 -100.0 ~ 999.9

4 E *1 -100.0 ~ 999.9

5 T *1 -199.9 ~ 400.0

6 R 0 ~ 1700

7 B *2 0 ~ 1800

8 S 0 ~ 1700

9 L *1 -100.0 ~ 900.0

10 N -200 ~ 1300 ±1.0 % of FS ±1 Digit

11 U *1 -199.9 ~ 400.0

±0.5 % of FS ±1 Digit12 W 0 ~ 2300

13 Platinel II 0 ~ 1390

Resistance

temperature

detector

(RTD)

20 KPt100 Ω *3 -199.9 ~ 500.0

±0.5 % of FS ±1 Digit

21 Pt100 Ω *3 -199.9 ~ 640.0

22 Pt100 Ω *3 -200 ~ 640

DC voltage

(VDC / ㎷ DC)

30 1.000 - 5.000 V DC

-1999 ~ 9999

Scaling function(SL-H/SL-L) necessary

±0.5 % of FS ±1 Digit31 0.0 - 100.0 ㎷ DC

DC current 30 4 - 20 ㎃ DC *4

█ Control Output Composition

HX series is a multi-control-output temperature controller. It can have relay ON/OFF,

SSR voltage pulse output, 4 – 20 mA current output as a control output by selecting an option in the parameter.

If the option is chosen like below in the output parameter ( ) of the output group ( ) in standard temperature controller

0 : Relay ON/OFF control is as a control output.

1 : SSR output is as a control output.

2 : 4 – 20 mA DC current output is as a control output.

3 : Relay PID control is as a control output.

(2) Heating / Cooling Type ( simultaneous control)

Typ e

Output

code

OUT1(Heating) OUT2

Default

Relay SSR/SCR/RET Relay(AL2) SSR/SCR/RET

Heating /

Cooling

type

4 - SSR

AL2

(Alarm 2

output )

SSR

4

5 - SCR(4 - 20 mA)

6

Control

output (PID)

RET

(retransmission

output)

7 - SSR

SCR

(4 - 20 mA)

8 - SCR(4 - 20 mA)

9

Control

output (PID)

RET

(retransmission

output)

10 - SSR

Control output

(PID)

RET

(

Retransmission

output

)

11 - SCR(4 - 20 mA)

12

Control

output (PID)

-

-3-

█ When turn the power ON after completing wiring

Operation Method

(1)

After the firmware version of the temperature controller appears for a short period of time, the operation

mode is running like the number ① that process value (current temperature)

and the set value are displayed.

(2) In the number ①, if button is pressed for 3 seconds, it enters

display setting mode.

It can be selected as DISP 1, DISP 2 and DISP 3 to limit displaying setting groups.

(3)

In the operation mode, if button is pressed, the output amount is displayed like the picture ⑤ - ⑥ below.

POWER ON

①

②

③

④

Output amount

display

⑤Heating Cooling type

⑥ Standard type

for 3

seconds

for 3

seconds

for 3 seconds

●

Switching between modes

How to set access levels [Level (LEVL)] and a group display [Display (dISP)]

- Setting group configuration parameters are displayed according to the group display

[Display (dISP)] setting.

- Setting group is editable depending on setting Access Level [Level (LEVL)].

Access level [Level (LEVL)]

LEVL 3 :

parameter values can be changed for all setting groups with the key of controller in front.

LEVL 2 : parameter values can not be changed for output group and input group with

the key of controller in front.

LEVL 1 :

parameter values can not be changed for Auto-tuning group(G.At), PID

group(G.PId), Alarm Group (G.ALM), retransmission group(G.trn), communication

group(G.CoM), output group(G.oUt), input group (G.In) with the key of controller in front.

Caution

In the operation mode, if and button are pressed simultaneously for 3 seconds,

it enters setting mode which prevents an operator to change parameter setting as

limiting access to the group. The default is 3rd level. The level setting mode limits the

display setting mode.

Control group

Symbol Parameter Option

Available

condition

Default

Control group Options for control mode

-

-

Zone setting OFF / ON

Control

output: PID

OFF

Ramp function type A / B

Always on

A

Ramp rising temperature

OFF/ EUS (0 ~ 100%)

Ramp

function

type A

OFF

Ramp falling temperature

OFF/ EUS (0 ~ 100%) OFF

Ramp time unit HOUR / MIN HOUR

Ramp rising temperature

OFF/ EUS (0 ~ 100%)

Ramp

function

type B

OFF

Ramp rising time 0.01 ~ 99.59(hh.mm) 0.01

Ramp falling temperature

OFF/ EUS (0 ~ 100%) OFF

Ramp falling time 0.01 ~ 99.59(hh.mm) 0.01

External contact input

OFF / ON

Always on

OFF

Hot key setting AT / A-M AT

Auto/manual setting AUTO / MAN

(1)

AUTO

Control mode

TRAD / 2DOF

TRAD

2DOF

Alpha coefficient

0 ~ 100 %

Control

mode:

2DOF

50 %

Factory reset function 0/1 [PASSWORD: 1304]

(2)

Always on 0

Set value (SV) setting group

Auto-tuning (AT) group

Symbol Parameter Option

Available

condition

Default

P.I.D group

Symbol Parameter Option

Available

condition

Default

PID group Options for PID mode - -

ANTI RESET

WIND-UP setting

Auto / 50.0 ~ 200.0 %

PID

control

100 %

PID group setting 0 / 1 ~ 3 Always on 0

n. Proportional band (P)

0.1(H/C TYPE : 0.0) ~ 999.9 %

Selecting one

of PID groups

5.0 %

n. Integral time (I)

OFF / 1 ~ 6000 s Always on 240 s

n. Derivative time (D) OFF / 1 ~ 6000 s Always on 60 s

n. Manual reset -5.0 ~ 105.0 %

Integral time:

OFF

50.0 %

n. Proportional band (PC)

for cooling

0.0(ON/OFF) / 0.1 ~ 999.9 %

heating·

cooling

5.0 %

n. Integral time (IC) for

cooling

OFF / 1 ~ 6000 s 240 s

n. Derivative time (DC) for

cooling

OFF / 1 ~ 6000 s 60 s

n. hysteresis (dead band) -100.0 ~ 50.0 % 3.0 %

n. Zone position setting

EU(0) < 1.RP < 2.RP <

EU(100 %)

PID group 1

or

PID group 2

EU

(100 %)

Heater Break Alarm (HBA) group

Alarm group

Symbol Parameter Option

Available

condition

Default

Alarm group Options for alarm mode

-

-

Alarm 1 type setting

OFF / 1 ~ 21

Refer to “Alarm type and code”

Always on

1

Alarm 2 type setting 2

Hysteresis (dead band)

of alarm 1

EUS(0 ~ 100 %)

EUS

(0.5 %)

Hysteresis (dead band)

of alarm 2

Set value of alarm 1

Absolute alarm :

EU(-100 ~ 100 %)

Deviation alarm :

EUS(-100 ~ 100 %)

EU

(100 %)

Set value of alarm 2

EU

(0 %)

Retransmission (RET) group

Symbol Parameter Option

Available

condition

초기값

RET. Group Options for RET. Group.

- -

Retransmission type

or power for sensor

Process value(PV) / set value

(SV) / output amount (MV) /

power for sensor (SPS)

RET.

option

PV

Retransmission value

4 - 20 mA / 0 – 20 mA (1) -

4-20mA

High limit of

retransmission

TC / RTD: FR-H ~ FR-L

DC voltage: SL-H ~ SL-L

( Must be RET.H > RET.L )

PV / SV

EU(100 %)

Low limit of

retransmission

EU(0 %)

(1)

If you want retransmission

0-5V

, a 250 Ω 0.1% resistor must be connected to retransmission output terminal.

If you want retransmission 0-10V, a 500 Ω 0.1% resistor must be connected to retransmission output terminal.

(1) When manual output function is selected with 'ON', 'AT indicator' lights on at the front panel.

(When auto-tuning (AT) is running, 'AT indicator' flashes at the front panel)

(2) when "1" is selected in factory reset function, PASSWORD is displayed. After input the

PASSWORD [1304], controller power turns off and on for initializing parameter values.

Auto-tuning group

Options for auto-tuning (AT) group

-

-

Auto-tuning type

setting

Standard (STD) :

Low PV (LOW) :

Control

output:

PID

STD

Auto-tuning start

setting

OFF / 1 ~ 3 / (AUTO)

OFF

Symbol Parameter Option

Available

condition

Default

Set value setting group Options for set values

-

-

Set value Number

setting

1~3 (the chosen set value is

displayed and controlled)

Always

on

1

Set value 1 (SV1) setting EU (0 ~ 100 %) EU(0 %)

Set value 2 (SV2) setting EU (0 ~ 100 %) EU(0 %)

Set value 3 (SV3) setting EU (0 ~ 100 %) EU(0 %)

Symbol Parameter Option

Available

condition

Default

Heater break alarm group

Options for HBA mode.

- -

Current setting of HBA output

OFF / 1 ~ 50 A

HBA

Option

(Refer to

“model

name and

code”

table)

OFF

Hysteresis setting of HBA

output

0 ~ 50

EUS

(0.5 %)

Current measurement value of

HBA output

Only indicates current measurement

value (0 ~ 50 A)

-4-

Output group

Please make sure to choose “input code” in “input code setting” of the input

group first and then select “output code” in “output type setting” and other

options in other groups. If “input code” is set later, the options in the other

groups will be lost.

Caution

Symbol Parameter Option

Available

condition

Default

Output group

Options for output type and

mode

-

-

Output type setting

Refer to “control output

composition”

Always on

Std : 1

HC : 4

Output operation REV: reverse, DIR: direct

Output code

0~3

REV

Cycle time

1 ~ 1000 s

relay : 20s

SSR : 2 s

Cycle time for cooling 1 ~ 1000 s

Output code

4~12

Hysteresis

Standard : EUS(0 ~ 100 %)

ON/OFF

control

EUS(0.5 %)

Heating / Cooling:

0.0 ~ 10.0 %

Heating /

Cooling

0.5%

Hysteresis type Cntr / EdGE

ON/OFF

Control

Cntr

Output amount of

OUT1 when input break

Standard

: -5.0 ~ 105.0 %

Always on

0.0 %

Heating - Cooling : 0.0~105.0 %

Output amount of

OUT2 when input break

0.0 ~ 105.0 %

Heating /

Cooling

0.0 %

High limit of output

amount

Standard : OL-L + 1Digit~ 105.0 %

PID

control

100.0 %

Heating - Cooling : 0.0 ~ 105.0 %

Low limit of output

amount

Standard : -0.5 % ~ OL-H-1Digit

0.0 %

Heating - Cooling : 0.0 ~ 105.0 %

100.0 %

Input group

Symbol Parameter Option

Available

condition

Default

Input group

Options for input type and input

mode

-

-

Input code setting

Input signal and measurable

range code

Always on

Code : 1

Temperature unit setting

℃ / ℉

TC or RTD

℃

High limit setting

Within range (refer to “input

code for input type and

range”) , FR-H > FR-L

Always on

1370

Low limit setting

-200

Decimal point position

(voltage input)

Fixed for T.C or RTD / DC

voltage: 0~3 setting for

decimal point position

Voltage input

(mV,V)

1

High limit of scale (voltage

input)

-1999 ~ 9999 but, SL-H >

SL-L decimal point according to

DP-P

100.0

Low limit of scale (voltage

input)

0.0

Process value filter

OFF / 1 ~ 120 sec

Always on

OFF

Process value bias

(compensation)

EUS(-100 ~ 100 %)

EUS(0 %)

Operation after input

break (burn-out)

OFF / UP / DOWN

UP

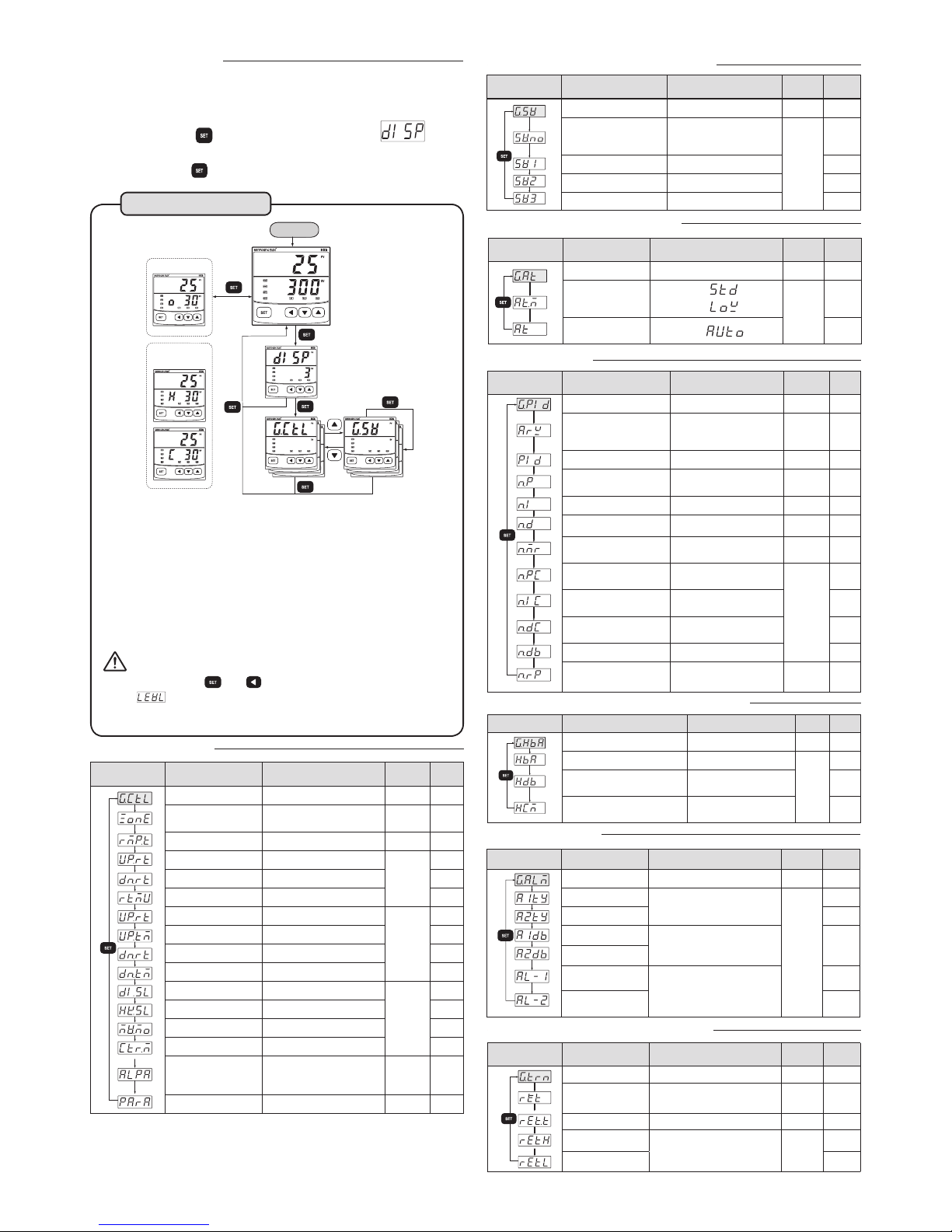

(△ : set value, -▲ : alarm set value, ▲ : alarm set value)

Hysteresis

Pay atteontion in selecting relay type. Using inverse relay ( such as use nomally closed

instead of nomally open) will not output anything even though the indicator is on.

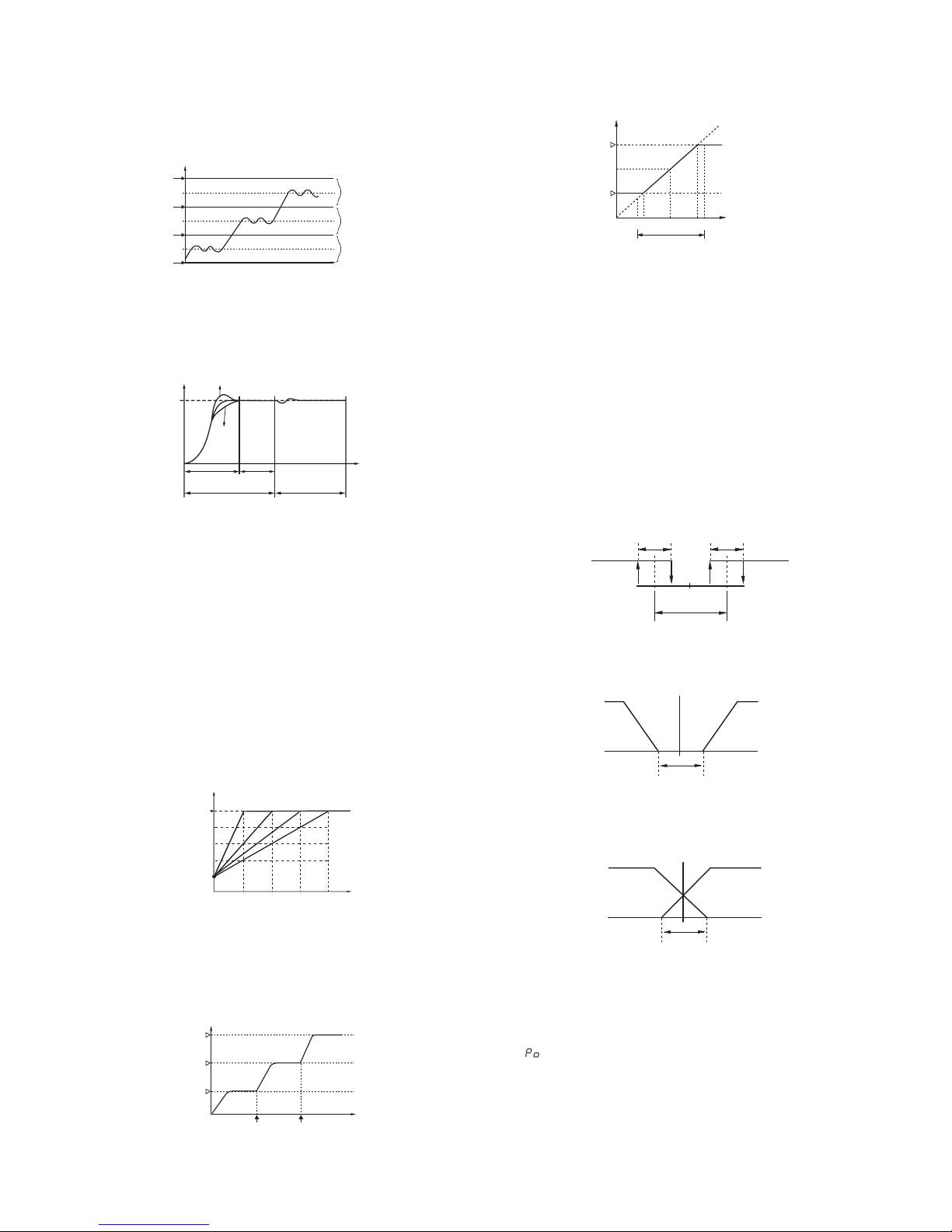

Alarm type and code

Code Alarm type Operation

1

High absolute value (NO)

2

Low absolute value (NO)

3

High deviation value (NO)

4

Low deviation value (NO)

5

High deviation value (NC)

6

Low deviation value (NC)

7

High-Low deviation value

8

High-Low deviation range

9

High absolute value (NC)

10

Low absolute value (NC)

11

High absolute (NO, Hold)

12

Low absolute (NO, Hold)

13

High deviation (NO, Hold)

14

Low deviation (NO, Hold)

15

High deviation (NC, Hold)

16

Low deviation (NC, Hold)

17

High-Low deviation value (Hold)

18

High-Low deviation range (Hold)

19

High absolute value (NC, Hold)

20

Low absolute value (NC, Hold)

21

Heater break alarm 1 (HBA1)

Meaning of auto-tuning (AT) start in auto-tuning Group(G.At) is as follows:

1 is auto-tuning for SV1.

2 is auto-tuning for SV2.

3 is auto-tuning for SV3.

- AUTO proceed with the Auto-tuning in the order of the SV1, SV2, SV3.

Function Description

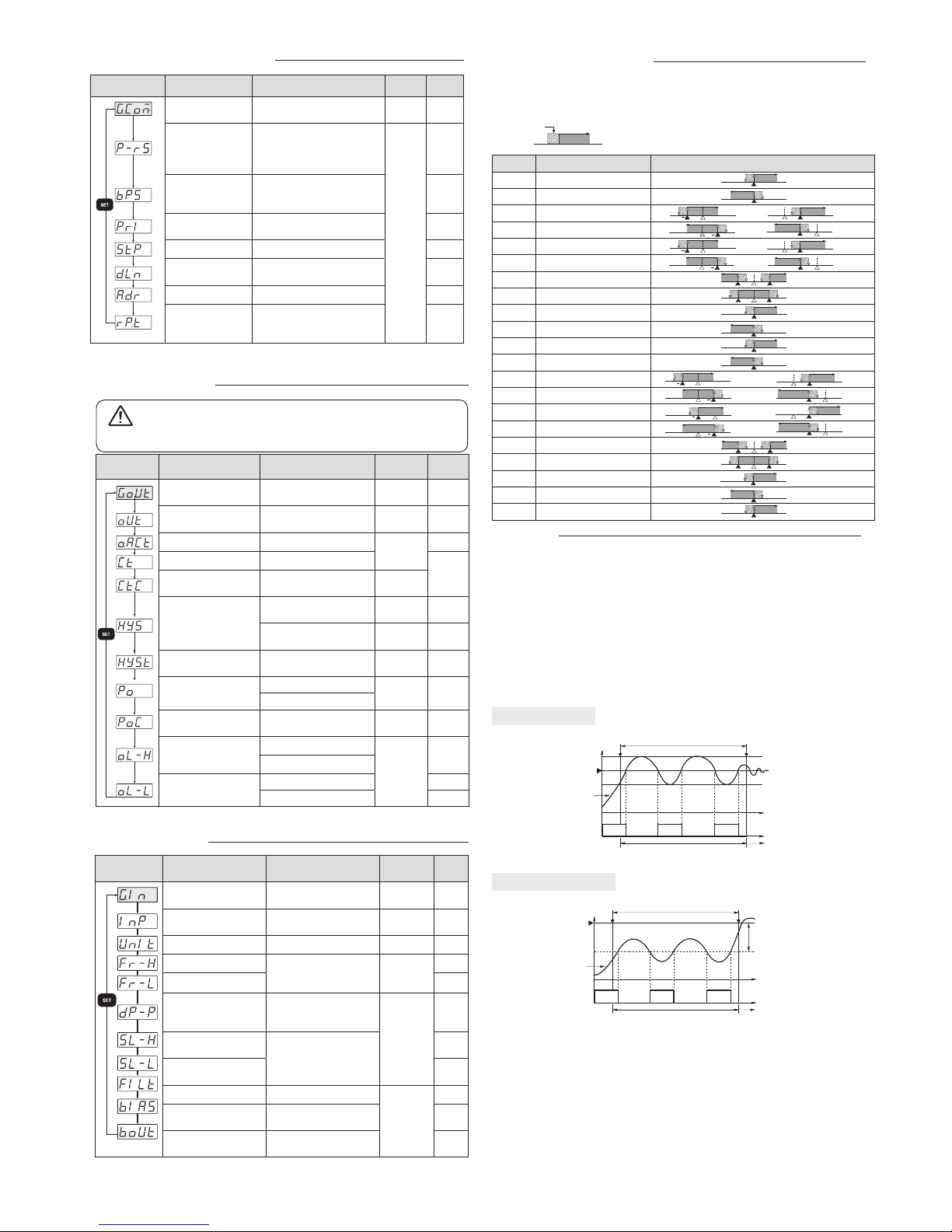

Function 1 : Auto-tuning

Auto-tuning is a function that the controller automatically measures the characteristics of

the target system and calculates the optimal values for proportional band (P), integral time

(I), and derivative time (D) and then sets the optimal values for each

PID

parameters.

During auto-tuning, the control output is changed to ON/OFF control to get response from

the target system. From the response, the most appropriate

PID

values are obtained for

the system. This is called " Limit Cycle".

HX series has two types of auto-tuning : standard type and low PV type.

① Standard auto-tuning : This auto-tuning is based on the set value (SV).

② Low PV auto-tuning : This auto-tuning is based on the value 10 % lower than the set

value (SV).

a) Standard auto-tuning

Select auto-tuning type(At.M) with standard(Std)

in auto-tuning group(G.At)

Set value (SV)

℃

Process value (PV)

Control output

ON

ON

ON

Time(t)

Time(t)

Control starts with PID values

obtained from the auto-tuning

ON/OFF operation

AT start AT end

Auto-tuning running

OFF

OFF

Select auto-tuning type with PV(LoW) in auto-tuning group (G.At)

b) Low PV auto-tuning

Set value(SV)

Process value (PV)

Control output

operation

Auto-tuning running

℃

ON

ON

ON

Time (t)

SV-10 %

Time (t)

Control starts with

P.I.D values obtained

from the auto-tuning

OFF

OFF

Function

Communication group

Symbol Parameter Option

Available

condition

Default

Communication

group

Options for

communication mode.

- -

RS485/RS422

Protocol

PC.LINK (code : 0)

PC.LINK SUM (code : 1)

MODBUS-ASCII (code : 2)

MODBUS-RTU (code : 3)

Option

0

Communication

speed (BPS)

2400(code : 2), 4800(code : 3),

9600(code : 4), 14400(code : 5),

19200(code : 6)

4

Parity Bit

NONE(code : 0),

EVEN(code : 1), ODD(code : 2)

1

Stop Bit

1bit (code : 1), 2bit (code : 2)

1

Data length

7bit (code : 7), 8bit (code : 8)

(code 8 is not available for PC LINK)

8

Address 1 ~ 99 but, max 31 units 1

Response time

0 ~ 10. Response time =

processing time +

(response time X 25 ms)

0

※ Please note that frequent communicational data recording may exceed life of EEPROM

and cause malfunction.

If you want to use the auto-tuning, there are 2 ways:

1. When you select the number for set value(SV) you want in start auto-tuning(AT)

of auto-tuning Group(G.At), auto-tuning will start.

2. After selecting auto-tuning(At) in hot-key(Hk.SL) of control group(G.At), auto-tuning will start with

pressing hot-key(SET + UP) in the operation mode of controller for 3 seconds and auto-tuning

will stop with pressing hot-key(SET+UP) for 3 seconds.

Note: When auto-tuning(AT) runs, 'AT indicator' flashes at the front panel.

(When manual output is 'ON', 'AT indicator' lights on steady at the front panel.)

AT start

AT end

*

* Std : Standard, HC : Heating / Cooling

-5-

SV3 150 ℃

℃

Time

External contact

signal SV2 : ON

External contact

signal SV3 : ON

SV2 100 ℃

SV 1 50 ℃

Function 5 : External contact input

This function is used to select one of the set values (SV1, SV2, SV3) by the external contact input

signal and it is used as the step control.

External contact input should be "ON" to use this function.

20 ㎃

Output signal

12 ㎃

4 ㎃

Output limit (%)

Setting range

Low limit

(OL-L)

High limit

(OL-H)

-5 %

50 %

105 %

Function 6 : Output limit

This function is used to set the high limit and low limit as the operating range of the control output.

The output limit (the high limit and low limit) can be set -5 ~ 105 % of the output amount.

Function 7 : Heater break alarm

① This function detects heater break and immediately turns the alarm on.

② Please use the current transformer (CT) designed by Hanyoung NUX.

③ The electric current value and alarm operating point (hysteresis) are set in “HBA group”.

④ This function cannot be used if phase control method (SCR output) is used by thyristor.

Note: If you want to use HBA, please set parameter in HBA group(G.HbA) referring to alarm type and codes.

The dead band of PID control for Heating / Cooling is shown as below.

<PID control for Heating / Cooling: Dead band of “+” set value>

DEAD BAND

Output of heating Output of cooling

Output (%)

0

100 %

0 %

100 %

0 %

If both heating and cooling are controlled by ON/OFF control,

the dead band (hysteresis) is shown as below.

<ON/OFF control for heating/cooling>

ON

OFF

ON

HYSTERESISHYSTERESIS

DEAD BAND

Heating-side output

Cooling-side output

Function 8 : Heating / Cooling control

In Heating / Cooling control, it divides the PID computation result into two control signals and outputs

to heating and cooling output terminals. The control method for each heating and cooling can be

selected either PID control or ON/OFF control. Also, it is possible to choose one of the control outputs:

relay output, SSR, and current output as the heating output and cooling output.

Also, the dead band of “-” set value and the dead band of PID control for both heating and

cooling are shown as below. At this time, there is an overlapped output from the both terminals.

<PID control for Heating / Cooling: Dead band of “-” set value>

Output of heating Output of cooling

Output (%)

0

100 %

0 %

100 %

0 %

DEAD BAND

Function 10 : Alarm hold function

If alarm hold function is not set up, low alarm is active when temperature is rising with power ON.

If you select alarm hold function, there is no limit alarm ON during the temperature rise, until set-point.

Note : If you want to use the alarm hold function, please set proper parameter referring to alarm group(G.ALM).

Function 4 : Ramp function

Ramp function Type: A

Select A in Ramp function type (rMP.t) parameters of control group(G.CtL)

The ramp refers to the gradient that reaches the set value (SV), and the setting

method is as follows:

1. Set the desired ramp temperature values in ramp-up and ramp-down temperature settings

2. Set the desired ramp hours or minutes in ramp-time unit setting.

As a result, the gradient of the ramp-up temperature set value / ramp time unit set

value (or ramp-down temperature set value / ramp time unit value) will reach the set

value (SV) from the current temperature.

Ramp function Type : B

Select B in Ramp function type(rMP.t) of control group(G.CtL)

This is similar function with Ramp function type A. except that type B sets time in detail,

0.01~99.59(hh.mm).

100

℃

Time

1 2 3 4

80

60

40

Current temperature 20 ℃

When select ON in Zone of control group(G.CtL) and set the location of temperature in n.rP

of PID group(G.PID), that distinguishes Zone 1, Zone 2, Zone 3.

Function 2 : PID auto-tuning in Zone

Within the input range, 3 different PID groups can be applied to each of the 3 zones. Since some

systems have a wide range of temperature to control and the optimal P.I.D values are different for

their temperature ranges, this function can be used to apply different optimal PID values to their

temperature ranges.

Max input range

2.rP

1.rP

Min input range

Zone 3 (PID 3)

Zone 2 (PID 2)

Zone 1 (PID 1)

Time (t)

℃

Function 3 : 2 degree of freedom PID

In order to get better response against disturbance in the steady state, there is usually

a large overshoot in the transient state. To reduce this overshoot in the transient state, 2

degrees of freedom PID control is used while obtaining good disturbance response in

the steady state. The parameter “ALPA” is used to control the amount of overshoot.

Select 2-DOF in control mode(Ctr.M) of control group(G.CtL)

If ALPA = 0%, it's same with previous PID control.

If ALPA = 100%, it may takes long to reach normal state.

ALPA :

100 %

℃

Time

ALPA : 0 %

Transition

Normal

state

Step response

Disturbance

response

SV

Function 9 : Output during emergency

When there is A/D Error or input break (Burn-out), it stops the PID control and outputs the preset

value. ( parameter in output group)

-6-

Function 12 : Manual output function

If you want to use manual output function, there are 2 ways as follows.

1. Select ON in manual output(MV.Mo) of control group(G.CtL) and current control output amount

converts manual output value. When choose OFF, manual output converts back to auto-output

control.

2. Select manual output function in hot-key(Hk.SL) of control group(G.CtL) and press

hot-key(SET+UP) for 3 seconds at the front panel for manual control output.

When press hot-key(SET+UP)again, manual output converts back to auto-output control.

Note: When auto-tuning(AT) runs, 'AT indicator' flashes at the front panel.

(When manual output is 'ON', 'AT indicator' lights on steady at the front panel.)

Output amount for manual output is adjusted by UP and DOWN key in monitor MV screen.

Function 11 : Hysteresis type

According to selection of Hysteresis type in ON/OFF control, ON/OFF turning point is as follows:

ex) HYS.t: Cntr(center)

- Hysteresis type sets center,

• In heating control, OFF point is SV + HYS/2 and ON point is SV - HYS/2.

• In cooling control, OFF point is SV - HYS/2 and ON point is SV + HYS/2.

ex) HYS.t: EdGE(edge)

- Hysteresis type sets with edge,

• In heating control, OFF point is SV and ON point is SV - HYS.

• In cooling control, OFF point is SV and ON point is SV + HYS.

105

Temperature (℃)

SV : 100 HYS : 10 ℃

95

100 %

Output signal

0 %

Time

Time

Control direction: rEV(Heating)

15

Temperature (℃)

SV : 10

HYS : 10 ℃

5

100 %

Output signal

0 %

Time

Time

Control direction: dlr(cooling)

SV : 100

Temperature (℃)

HYS : 10 ℃

100 %

Output signal

0 %

Time

Time

Control direction: rEV(Heating)

90

Function 13 : Factory reset function

This function is used for parameter values to revert to initial setting values.

1 . Select factory reset function (PArA) in control group (G.CtL).

2 . If “1” is selected, input for password will be prompt.

3 . Entering correct password [1304] will reset parameter values to initial setting values and controller

will be restarted (power OFF and ON).

4. In case of input wrong password for 3 times, display will go back to operation screen.

Function 14 : Quick menu setting

This function is for selecting frequently used parameters quickly and easily.

1 . Press SET+DOWN key for 3 sec. it will go to the quick menu setting.

2 . SV1, SV2, AL-1, AL-2 values can be set from quick set menu.

3 . Press SET key for 3 sec. to go back to operation screen.

Function 15 : HOT key

This function is for activating/deactivating most frequently used function on operation screen.

1 . Press SET+UP key for 3 sec. to activate hot-key function.

2 . Press SET+UP key for 3 sec. again to deactivate hot-key function.

One of the following two functions can be assigned as hot-key function from the hot-key

select menu (HKSL) in control group (G.CtL) .

1 . AT (Auto-tuning) : ON / OFF

2 . A-M : Automatic control / Manual control

Power supply 100 - 240 V AC (±10 %), 50/60 Hz

Power consumption 6 W max, 10 VA max

Input

Typ e Refer to input type and range

Sampling cycle 62.5 ㎳

Accuracy ±0.5 % of FS (Refer to input type and range)

Allowable voltage Within ±20 V DC (VDC), within ±10 V DC (TC, RTD)

Reference

junction

compensation

accuracy

±3.5 ℃ (0 ~ 50 ℃)

Operation after

input break

T.C: OFF, UP/DOWN RTD: UP

Control

output

Relay

NO : 5 A 250 V AC, 5 A 30 V DC (resistive load)

NC : 3 A 250 V AC, 1 A 30 V DC (resistive load)

SSR

(voltage pulse)

ON voltage : 12 V DC min, OFF voltage : 0.1 V DC max

Load resistance 600 Ω min

SCR

(current)

range : 4 – 20 mA (±5%), accuracy : ±0.2 mA

Load resistance 600 Ω max

Retransmission output

range : 4 – 20 mA (±5%), accuracy : ±0.2 mA

Load resistance 600 Ω max

range : 0 – 20 mA (±5%), accuracy : ±0.2 mA

Load resistance 600 Ω max

Alarm output 5 A 250 V a.c, 5 A 30 V DC (resistive load)

Contact input OFF resistance : 10 ㏀ min, ON resistance : 1 ㏀ max

Control

Method ON/OFF, PID control

Output operation

Reverse operation, Direct operation

Anti-reset windup Auto(A=0), 0.1 ~ 100.0 %

Interface

Standard EIA RS485

Max connection

unit

31 units (but, ADDRESS setting : 1 ~ 99)

Communication

method

2 wire half duplex

Data

transmission

asynchronous

Communication

sequence

None

Communication

distance

Within 1.2 km

Communication

Speed

2400, 4800, 9600, 14400, 19200 BPS (parameter selectable)

Start bit 1 bit

Data length 7 or 8 bit

Parity bit NONE, EVEN, ODD

Stop bit 1 or 2 bit

Protocol PC-LINK, PC-LINK SUM, MODBUS-ASCII, MODBUS-RTU

Response time Processing time in receiving + (response time x 25 ㎳)

Storage Non-volatile memory(EEPROM) writing 1,000,000 times

Insulation resistance 20 ㏁ min (primary terminal – secondary terminal)

Dielectric strength

2,300 V AC, for 1 minute

(primary terminal – secondary terminal)

Operating ambient

temperature

0 ~ 50 ℃, (without condensation)

Operating ambient

humidity

35 ~ 85 % RH (without condensation)

Specification

20

HYS : 10 ℃

100 %

Output signal

0 %

Time

Time

Control direction: dlr(cooling)

SV : 10

Temperature (℃)

-7-

HX communication - instructions about the D register address

D-register

address

Parameter

name

Parameter meaning Parameter setting

Parameter

division

0001 NPV Current present value (PV) Read only

*1

Process

0002 NSV Current set value (SV) Read only

*1

Process

0004 SSV Current set value (SV) Read only

*1

Process

0005 MVOUT

OUT1 control output value of standard type, Total

control output value of heating/cooling type.

Read only

*2

Process

0006 CH1OUT

OUT1 control output value of standard type,

OUT1 control output value of heating/

cooling type.

Read only

*2

Process

0007 CH2OUT

OUT2 control output value of heating/

cooling type.

Read only

*2

Process

0008 PIDNO

When ZONE is OFF, currentlly

applied set value (SV) and PID group

number

0001: SV1, PID group 1

0002: SV2, PID group 2

0003: SV3, PID group 3

When ZONE is OFF, currentlly

applied PID group number

0001: PID group 1

0002: PID group 2

0003: PID group 3

Read only Process

0009 ALMSTS

Current state of Alarm 1 and Alarm 2:

0000: Alarm 1 OFF, Alarm 2 OFF

0001: Alarm 1 ON, Alarm 2 OFF

0002: Alarm 1 OFF, Alarm 2 ON

0003: Alarm 1 ON, Alarm 2 ON

Read only Process

0013 OUT2_IND

When the OUT2 control output is SCR

(4-20mA) in Heating / Cooling type,

it shows the temperature controller

"OUT2 indicator" status.

Read only Process

0014 H1CM

Current measurement value of the

heater break alarm output

Read only Process

0016 ADESTS

Current situation of the AD error.

0001: AD conversion error

Read only Process

0017 ERRSTS

Current situation of the input error.

0001:Input sensor Burn-out

0002: RJC error

0004: Input range exceeded

0008: Less than input range

Read only Process

0018 AT_STS

Autotuning (AT) current state

0000: AT type

9999: AT in progress ("AT indicator" in

the temperature controller front display

blinking)

Read only Process

0102 ZONE

Zone function set (For the zone position

setting, set in RP parameter of each PID group

0: OFF, 1: ON

Control Group

0104 ARW ARW (Anti-reset windup) setting

0: AUTO, 50.0 ~ 200.0 %*2Control Group

0106 DI.SL External contact input (DI) function 0: OFF, 1: ON

Control Group

0107 ALPHA Alpha factor of 2 DOF PID 0 ~ 100 %

Control Group

0108 UP.RT Ramp-up temperature setting 0: OFF / EUS(0~100 %)*1Control Group

0109 DN.RT Ramp-down temperature setting 0: OFF / EUS(0~100 %)*1Control Group

0110 RTMU Ramp-time unit setting 0: Hour, 1: Min

Control Group

0111 UPTM Ramp-up time setting 0.01 ~ 99.59 [hh.mm]*2Control Group

0112 DNTM Ramp-down time setting 0.01 ~ 99.59 [hh.mm]*2Control Group

0113 RAMPT Ramp type selection 0: A Type, 1: B Type

Control Group

0120 MVMOD

Manual output function (when selecting

the manual output, the "AT indicator" in the

temperature controller front display is steady)

0: AUTO ,

1: MANUAL

Control Group

0121 MANMV Manual output value (Manual MV) set 0 ~ 100 %

Control Group

0122 CTRM Control mode selection

0: Traditional,

1:2 2 DOF PID (2DOF)

Control Group

0124 HKSL Hot-key selection

0: Auto-tuning (AT) function

1: Manual output function

Control Group

0300 SVNO Set value (SV) number selection 1 ~ 3

Set value setting group

0301 SV1 Set value 1 (SV) setting EU(0 ~ 100 %)

*1

Set value setting group

0302 SV2 Set value 2 (SV) setting EU(0 ~ 100 %)

*1

Set value setting group

0303 SV3 Set value 3 (SV) setting EU(0 ~ 100 %)

*1

Set value setting group

0305 AT MODE Auto-tuning (AT) type selection

0: Standard Automatic Operation

1: Low value (PV) type

automatic operation

Auto-tuning Group

0306 AT Auto-tuning (AT) 0: OFF, 1 ~ 4

Auto-tuning Group

0310 1.P PID group 1 proportional band 0.0 ~ 999.9 %

*2

PID

Group

0311 1.I PID group 1 integral time 0 ~ 6000 sec PID

Group

0312 1.D PID group 1 derivative time 0 ~ 6000 sec PID

Group

0313 1.MR PID group 1 manual reset -5.0 ~ 105.0 %

*2

PID

Group

0314 1.PC PID group 1 cooling proportional band 0.0 ~ 999.9 %

*2

PID

Group

0315 1.IC PID group 1 cooling integral time 0 ~ 6000 sec PID

Group

0316 1.DC PID group 1 cooling derivative time 0 ~ 6000 sec PID

Group

0317 1.DB

PID group 1 Heating / Cooling dead band

-100.0 ~ 50.0 %

*2

PID

Group

0318 1.RP PID group 1 zone position setting

EU(0 ~ 100 %), (1.RP < 2.RP)*1PID

Group

0320 2.P PID group 2 proportional band 0.0 ~ 999.9 %

*2

PID

Group

0321 2.I PID group 2 integral time 0 ~ 6000 sec PID

Group

0322 2.D PID group 2 derivative time 0 ~ 6000 sec PID

Group

0323 2.MR PID group 2 manual reset -5.0 ~ 105.0 %

*2

PID

Group

0324 2.PC PID group 2 cooling proportional band 0.0 ~ 999.9 %

*2

PID

Group

0325 2.IC PID group 2 cooling integral time 0 ~ 6000 sec PID

Group

0326 2.DC PID group 2 cooling derivative time 0 ~ 6000 sec PID

Group

0327 2.DB

PID group 2 Heating / Cooling dead band

-100.0 ~ 50.0 %

*2

PID

Group

0328 2.RP PID group 2 zone position setting

EU(0 ~ 100 %), (1.RP < 2.RP)*1PID

Group

0330 3.P PID group 3 proportional band 0.0 ~ 999.9 %

*2

PID

Group

0331 3.I PID group 3 integral time 0 ~ 6000 sec PID

Group

0332 3.D PID group 3 derivative time 0 ~ 6000 sec PID

Group

0333 3.MR PID group 3 manual reset -5.0 ~ 105.0 %

*2

PID

Group

D-register

address

Parameter

name

Parameter meaning Parameter setting

Parameter

division

0334 3.PC PID group 3 cooling proportional band 0.0 ~ 999.9 %

*2

PID Group

0335 3.IC PID group 3 cooling integral time 0 ~ 6000 sec PID Group

0336 3.DC PID group 3 cooling derivative time 0 ~ 6000 sec PID Group

0337 3.DB

PID group 3 Heating / Cooling dead

band

-100.0 ~ 50.0 %

*2

PID Group

0400 HBA Heater break alarm (HBA) current set 0: OFF, 1 ~ 50 A

Heater break

alarm group

0401 HDB

Heater break alarm (HBA) Hysteresis

(deadband) set.

0 ~ 50

Heater break

alarm group

0410 A1TY Alarm 1 type setting 0: OFF, 1 ~ 21 Alarm Group

0411 A2TY Alarm 2 type setting 0: OFF, 1 ~ 21 Alarm Group

0413 A1DB Hysteresis (dead band) of alarm 1 EUS(0 ~ 100 %) Alarm Group

0414 A2DB Hysteresis (dead band) of alarm 2 EUS(0 ~ 100 %) Alarm Group

0416 AL-1 Set value of alarm 1

PV alarm: EU (-100 ~ 100 %)

Deviation alarm: EUS (-100 ~ 100 %)

*1

Alarm Group

0417 AL-2 Set value of alarm 2 Alarm Group

0500 RET Retransmission output type selection

0: Indicated value

1: Set value (SV)

2: Control output value (MV)

3: Power SPS for the sensor

Retransmission

group

0501 RET.H

Retransmission output upper limit setting

-1999 ~ 9999

Retransmission

group

0502 RET.L

Retransmission output lower limit setting

-1999 ~ 9999

Retransmission

group

0503 RET.T Retransmission output form

0: 4 - 20 mA, 1: 0 - 20 mA

Retransmission

group

0600 OUT Output type selection

0~12 (refer to the number of

control output type selection)

Output group

0601 o.ACT Output operation selection

0: Reverse operation (heating),

1: Direct action (cooling)

Output group

0602 CT Cycle type (Control cycle) 1 ~ 1000 sec Output group

0603 CTC

Cooling cycle type (cooling control cycle)

1 ~ 1000 sec Output group

0604 H YS

General type. ON/OFF control hysteresis

Standard type,EUS(0~100%)

*1

Output group

Heating / Cooling type.

ON/OFF control hysteresis

Heating / Cooling type

0 ~ 10.0%

*2

0605 PO Output1 setting when input breaks -5.0~105.0%

*2

Output group

0606 POC Output2 setting when input breaks 0~105.0%

*2

Output group

0607 OL-H Output upper limit function

Standard type,

OL-L +1 digit ~ 105.0 %

Heating / Cooling type,

0.0 ~ 105.0 %

*2

Output group

0608 OL-L Output lower limit function

Standard type,

-0.5 % ~ OL-H-1 digit

Heating / Cooling type,

0.0 ~ 105.0 %

*2

Output group

0610 INP Input type selection 1~31 Input group

0611 UNIT Temperature unit selection 0: ℃, 1: ℉ Input group

0612 FR-H Upper range selection EU(0 ~ 100 %)

*1

Input group

0613 FR-L Lower range selection EU(0 ~ 100 %)

*1

Input group

0614 DP-P

Decimal point position selection

during the voltage input)

0: No decimal points

1: 1 decimal place

2: 2 decimal places

3: 3 decimal places

Input group

0615 SL-H

Scale upper limit setting

(during voltage input)

-1999 ~ 9999 Input group

0616 SL-L

Scale lower limit setting

(during voltage input)

-1999 ~ 9999 Input group

0617 FILT Measurement value filter selection 0: OFF, 1 ~ 120 sec Input group

0618 BIAS Measurement value correction setting EUS(-100 ~ 100%)

*1

Input group

0619 B.OUT Operation selection when input breaks 0: OFF, 1: UP, 2: DOWN Input group

0624 HYST Hysteresis type

0: CENTER ,

1: EDGE

Output group

*1: Please check the presence or absence of the decimal points according to the

input type and range settings

· Set value with decimal points : if you want to input an SV1 of 100.0℃ through

communication, transmit 03E8(100). (03E8 is the hex value of 1000)

· Set value without decimal points: if you want to input an SV1 of 100℃ through

communication, transmit 0064(100). (0064 is the hex value 100)

*2 : Set value with decimal places.

※ For the instructions of the protocol regarding communication, please refer to the

Hanyoung protocol instruction manual on Hanyoung Nux homepage(www.hynux.com).

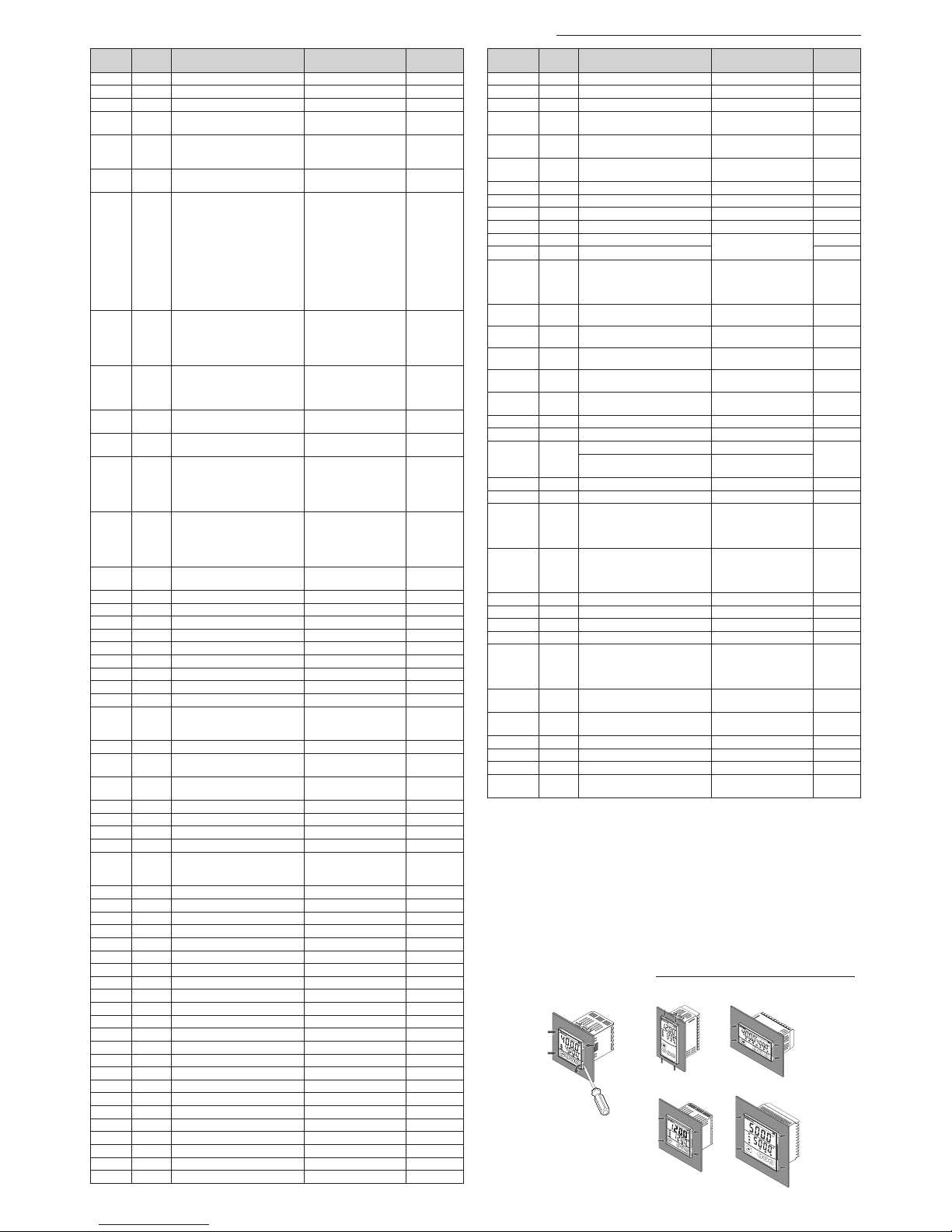

How to dismantle case

●

HX4

●

HX3

●

HX2

●

HX7

●

HX9

-8-

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

PV

SV

SET

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

PV

SV

SET

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

● Appearance

● Panel cutout

● Connection Diagram

● Connection Diagram

● Connection Diagram

●Appearance

● Panel cutout

● Appearance

● Panel cutout

HX3

HX9

HX2

HX7

HX2

OUT1

RELAY

AL1AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19 20 21

17

6

18

A

B B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

POWER

100 - 240 V~ 50/60 Hz 5.5 V

A

RTD

HX4

HX2,3

10

11

12

13

16

17

18

14

15

19

20

21

22

25

26

27

23

24

SV2

OUT2

SSR/SCR

RET

A

B

B

TC

Current

Voltage

AL1

AL2

RTX(+)

RS485

RTX(-)

SG

RTD

OUT1

RELAY

AL1

AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19

20

21

17

6

18

A

B

B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

RTD

CT

SV3

HX4

10

11

12

13

1

2

3

4

5

7

8

9

16

17

18

14

6

15

19

20

21

22

25

26

27

23

24

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

OUT1

RELAY

SV2

OUT1

SSR/SCR

RET

OUT2

SSR/SCR

RET

A

B

B

TC

Current

Voltage

AL1

AL2

RTX(+)

RS485

RTX(-)

SG

RTD

OUT1

RELAY

AL1

AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19

20

21

17

6

18

A

B

B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

RTD

CT

SV3

HX4

HX7

OUT1

RELAY

AL1

AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19

20

21

17

6

18

A

B

B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

RTD

HX4

SV2

SV3

OUT1

OUT2

SET

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

PV

SV

SET

PV

SV

SV2

AL1AT

OUT1

OUT2

AL2

SET

AL1

AL2

AT

SV2

SV3

OUT1

OUT2

PV

SV

SET

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

AT

SV2

SV3

AL2

AL1

SET

PV

SV

OUT1 OUT2

PV

SV

SET

PV

SV

SV2

AL1AT

OUT1

OUT2

AL2

SET

● Appearance

● Panel cutout

HX7

● Panel cutout

(Units : ㎜)

10

11

12

13

1

2

3

4

5

7

8

16

17

14

6

15

19

20

21

22

25

26

23

24

OUT1

RELAY

SV2

OUT1

SSR/SCR

RET

OUT2

SSR/SCR

RET

A

B

Current

AL1

AL2

RTX(+)

RS485

RTX(-)

SG

RTD

OUT1

RELAY

AL1

AL2

13

14

15

16

1

2

3

4

5

7

8

9

19

20

21

17

6

18

SV2

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

RTX(+)

RS485

RTX(-)

SG

7

8

9

10

1

2

3

4

5

11

6

12

13

14

15

16

17

18

OUT1

RTX(+)

RTX(-)

OUT1

SSR

SCR

RET

CT

SV2

OUT2

SSR

SCR

RET

POWER

100 - 240 V~

50/60 Hz

5.5 VA

A

AL1

AL2

B

B

TC

11

12

Current

Voltage

HX3

HX7

HX2

OUT1

RELAY

AL1AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19 20 21

17

6

18

A

B B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

RTD

CT

OUT1

RELAY

SV2

SV3

OUT1

SSR/SCR

RET

OUT2

SSR/SCR

RET

A

B

B

TC

Current

Voltage

AL1

AL2

RTX(+)

RS485

RTX(-)

SG

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19

20

21

17

6

18

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

RTD

10

11

12

13

1

2

3

4

5

7

8

9

16

17

18

14

6

15

19

20

21

22

25

26

27

23

24

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

OUT1

RELAY

SV2

OUT1

SSR/SCR

RET

OUT2

SSR/SCR

RET

A

B

B

TC

Current

Voltage

AL1

AL2

RTX(+)

RS485

RTX(-)

SG

RTD

OUT1

RELAY

AL1

AL2

13

14

15

16

1

2

3

4

5

7

8

10

11

12

22

23

24

9

19

20

21

17

6

18

A

B

B

SV2

TC

SV3

OUT1

SSR/SCR

RET

CT

OUT2

SSR/SCR

RET

Current

Voltage

RTX(+)

RS485

RTX(-)

SG

POWER

100 - 240 V~ 50/60 Hz 5.5 VA

RTD

7

8

9

10

11

12

A

B

11

12

CT

SV3

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

●Appearance

PV

SV

SET

AT

SV2

SV3

OUT1

OUT2

AL1 AL2

● Connection Diagram

● Connection Diagram

CT-50N

● Appearance

Bracket

Appearance, Panel cutout and Connection Diagram

Loading...

Loading...