REGULATED DC POWER SUPPLY

HT3003PE; HT3005PE; HT5003PE;

HT3003PF; HT3005PF;

HT3003PG; HT3005PG

INSTRUCTION MANUAL

Content

SAFETY SUMMARY .................................................................... 1

INSTRUCTIONS .......................................................................... 2

WARRANTY ................................................................................. 3

1. GENERAL ................................................................................ 4

2. PRECAUTIONS ....................................................................... 5

3. SPECIFICATIONS .................................................................... 8

4. PANEL DETAILS – SINGLE TYPE ........................................... 9

5. DESCRIPTION OF PANEL FUNCTION – SINGLE TYPE ...... 10

6. OPERATIONS PROCEDURES – SINGLE TYPE ................... 11

8. DESCRIPTION OF PANEL FUNCTION – DUAL TYPE .......... 15

9. OPERATION PROCEDURES – DUAL TYPE ......................... 17

10. NOTES ON ENVIRONMENTAL CONDITION ...................... 21

11. NOTICES .............................................................................. 22

SAFETY SUMMARY

Safety Precautions

Please take a moment to review these safety precautions.

They are provided for your protection and to prevent damage to the

power supply.

This safety information applies to all operator and service personnel.

※NOTE: If the equipment is used in a manner not specified by the

manufacture, the protection provided by the equipment may be

impaired.

Caution and Warning Statements

CAUTION: Is used to indicate correct operating or maintenance

procedures in order to prevent damage to or destruction of equipment

or other property.

WARNING: Calls attention to a potential danger that requires correct

procedures or practices in order to prevent personal injury.

SYMBOLS:

Caution (refer to accompanying documents)

Protective conductor terminal

1

INSTRUCTIONS

1. To maintain the precision and the reliability of the product, use it in

the standard settings

Operating temperature: 5 ~ +40℃℃

Operating humidity: 50% ~ 80%

Storage temperature: 0 ~ 70℃℃

Storage humidity: less than 85%

2. For quality improvement, the exterior design and specifications of

the product can be changed without notice.

2

WARRANTY

Warranty service covers one year the date of original purchase.

In case of technical failure within a year, repair service will be

provided by our service center or sales outlet free of charge.

We charge for repairs after the one-year warranty period expires.

When the failure is a result of user’s neglect, natural disaster or

accident, we charge for repairs regardless of the warranty period.

For more professional repair service, be sure to contact our service

center or sales outlet.

3

1. GENERAL

HT3000PE/PF/PG series Regulated DC Power Supply comprises

the following models:

HT3003PE: Single 0~30V, 0~3A

HT3005PE: Single 0~30V, 0~5A

HT5003PE: Single 0~50V, 0~3A

HT3003PF: Dual 0~30V, 0~3A

HT3005PF: Dual 0~30V, 0~5A

HT3003PG: Dual 0~30V, 0~3A and Fixed 5V, 3A

HT3005PG: Dual 0~30V, 0~5A and Fixed 5V, 3A

It features low ripple and high stability.

Main features for the above models are as follows:

1)

Utilizes SMT technology.

LCD display to show voltage and current.

2)

LCD display to show regulated voltage and current.

3)

Green/Amber LCD back-light selectable.

4)

5) Auto interchangeable of regulated voltage and current.

6)

Multi-turn variable device to provide high precision voltage

setting.

7)

Step-by-step current limit setting.

Auto-tracking on PARALLEL and SERIAL working condition.

8)

Extended output terminal connection.

9)

Continuously working under full loaded condition.

10)

4 5

2. PRECAUTIONS

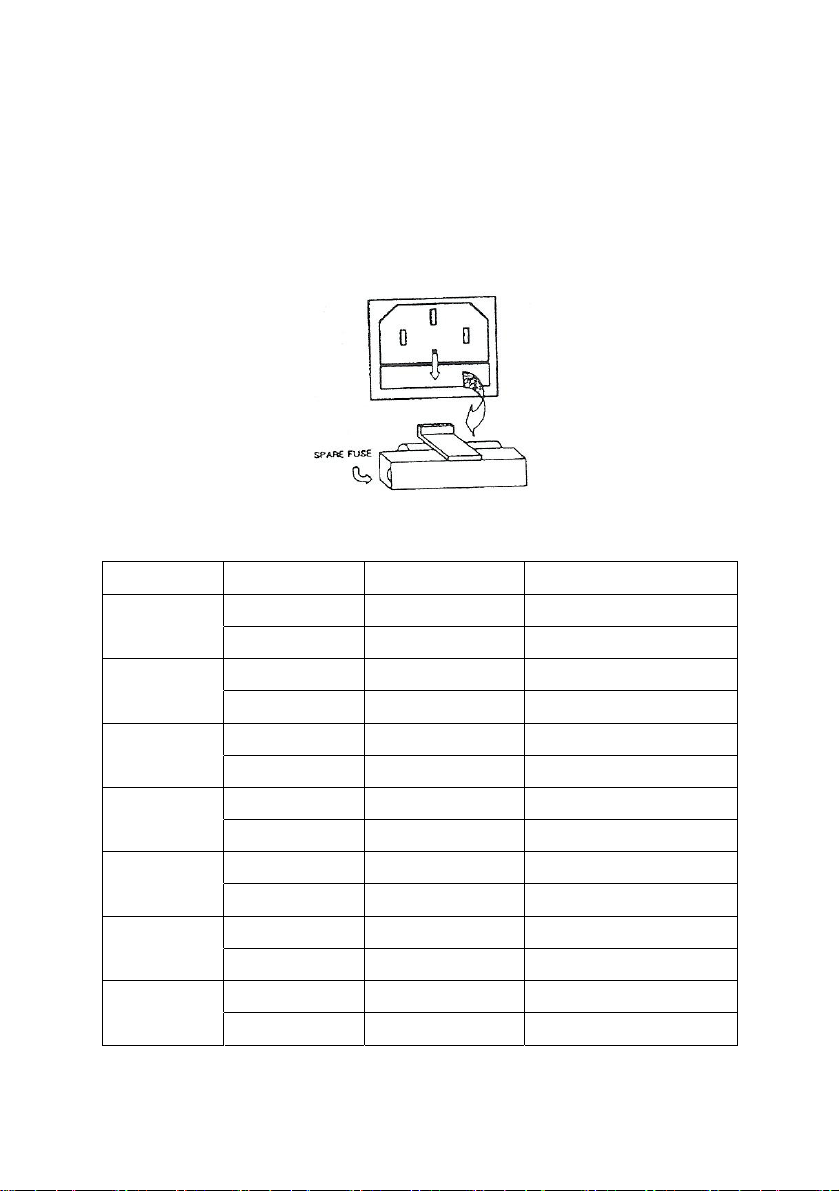

2-1. Exchange Method of fuse

If you wish to change FUSE F1, please use driver and pull it over

as per drawing.

Fig 1

Line Voltage Selection and Fuse Ratings

Model Line Voltage Mark Position Fuse Rating (250V)

HT3003PE

HT3005PE

HT5003PE

HT3003PF

HT3005PF

HT3003PG

HT3005PG

AC 220V 220V 1.6AL

AC 110V 110V 3AL

AC 220V 220V 2AL

AC 110V 110V 4AL

AC 220V 220V 2AL

AC 110V 110V 4AL

AC 220V 220V 3.15AL

AC 110V 110V 6AL

AC 220V 220V 4AL

AC 110V 110V 8AL

AC 220V 220V 3.15AL

AC 110V 110V 6AL

AC 220V 220V 4AL

AC 110V 110V 8AL

2-2. Installation and Handling Precautions

When placing the Power Supply in service at your workplace,

observe the following precautions for best instrument performance

and longest service life.

1.Avoid placing this instrument in an extremely hot or cold place.

Specifically, don’t leave this instrument in a closed car, exposed to

sunlight in midsummer, or next to a space heater.

2. Don’t use this instrument immediately after bringing it in from the

cold. Allow time for it to warm to room temperature. Similarly don’t

move it from a warm place to a very cold place, as condensation

might impair its operation.

3. Do not expose the instrument to wet or dust environments.

4. Do not place liquid-filled containers (such as coffee cups) on top

of this instrument.

A spill could seriously damage the instrument.

5. Do not use this instrument where it is subject to serve vibration,

or strong blows.

6. Do not place heavy objects on the case, or otherwise block the

ventilation holes.

7. Do not use this Power Supply in strong magnetic fields, such as

near motors.

8. Do not insert wires, tools, etc, through the ventilation holes.

9. Do not leave a hot soldering iron near the instrument.

10. Do not place this instrument face down on the ground, or damage

to the knobs may result.

11. Do not connect other power source to +.- of the output terminal.

6

2-3. Cleaning

1. To clean stained casing, lightly rub the stained area with a soft cloth

dipping a neutral detergent.

2. If the surface of the panel is dirty, use the same method to clean.

If the panel is heavily stained, rub the affected area lightly with a soft

cloth soaked in light neutral detergent or alcohol.

3. Never use highly volatile material such as benzenes or paint

thinner.

7

3. SPECIFICATIONS

Models HT

3003

PE

Input

Voltage

Output

Voltage

Current

Stepwise

Output

Current

Line

Regulation

Load

Regulation

Ripple &

Noise

Operating

Temperatur

e

Relative

Humidity

0 ~ 30V 0 ~ 50V 0~30V×2 0~30V×2, 5V

30mA±3

mA

0~3A 0~5A 0~3A 0~3A×2 0~5A×2

HT

3005

PE

50mA±

5mA

HT

5003

PE

220V / 110V ±10% 50~60Hz

30mA±

3mA

CV ≤ 0.02% + 2mV

CC ≤ 0.05% + 5mA

CV ≤ 0.02% + 2mV

CC ≤ 0.05% + 5mA

HT

3003

PF

30mA±

3mA

CV ≤ 0.5mV

CC ≤ 2mA

0~40℃

≤ 90%

HT

3005

PF

50mA±

5mA

HT

3003

PG

30mA±

3mA

0~3A×2

, 3A

HT

3005

PG

50mA±

5mA

0~5A×2

, 3A

8

4. PANEL DETAILS – SINGLE TYPE

Fig 2

9

5. DESCRIPTION OF PANEL FUNCTION – SINGLE TYPE

1. Output Voltage LCD Display.

2. Output Current LCD Display.

3. On/Off Power Switch.

4. Output terminals.

5. Extended Output Terminals.

6. Constant Voltage Display.

7. Constant Current Display.

8. Current Limit Adjustment Indicator.

9. C.V. / C.C. Selection Switch.

10. Current Limit Down Setting.

11. Current Limit Up Setting.

12. Output Voltage setting.

10

6. OPERATIONS PROCEDURES – SINGLE TYPE

6-1 Pre-operational Checking

1. Visual inspection

First, the functional elements should be visually inspected for

damages. For example, the chassis, VR knobs, output terminals.

Function buttons, fuse holders, voltmeters, current meters, switches

etc. should be checked for visible damage.

If damage is detected, the supply should not be operated.

2. Basic electrical check

1) Check that the power switch is set to OFF.

2) Turn the voltage knob to maximum CCW, that is, minimum output

voltage.

3) If no problem is found for 1)~2), connect the supply’s power cord to

the AC outlet and turn the power switch ON

4) Adjust the voltage setting knob to the desired voltage which can be

shown in the LCD display.

5) Connect the load, make sure the load current not exceeding the

maximum output current.

11

6-2 Constant Current Adjustment Method

1. Adjust by turning the voltage setting knob to desired voltage.

2. Press the CV/CC setting button down to light up the CC/CV setting

indicator.

3. Use a wire to shorten the (+) and (-) terminal at the output terminal.

4. Push the UP or DOWN button to obtain the desired current value.

5. When pushing and hold the UP or DOWN button over 0.8 sec, the

value will go up or go down continuously.

6. Release the shortend wire, connect the load to begin operation.

7. The setting of current value will be stored in the EEPROM after

power off.

The current value will be resumed by pushing the CV/CC button when

next power on.

12

7. PANEL DETAILS – DUAL TYPE

Fig 3

13

7.1 PANEL DETAILS – TRIPLE TYPE

Fig 4

14

8. DESCRIPTION OF PANEL FUNCTION – DUAL TYPE

1. Constant Voltage Display – Ch.1

2. Output Voltage Display – Ch.1

3. Constant Current Display – Ch.1

4. Output Current Display – Ch.1

5. Current Limit Adjustment Indicator – Ch.1

6. Current Limit Up Setting – Ch.1

7 .Current Limit Down Setting – Ch.1

8. C.V. / C.C. Selection Switch – Ch.1

9. Output Voltage Setting – Ch.1

10. Output Terminal – Ch.1

11. Extended Output terminals – Ch.1

12. Serial Function Select Switch

13. Serial Function Indicator

14. PARALLEL Function Indicator

15. PARALLEL Function Select Switch

16. Constant Voltage LCD Display – Ch.2

17. Output Voltage LCD Display – Ch.2

18. Constant Current Display – Ch.2

19. Output Current Display – Ch.2

20. Current Limit Adjustment Indicator – Ch.2

21. C.V. / C.C. Selection Switch – Ch.2

15

DESCRIPTION OF PANEL FUNCTION – DUAL TYPE (cont’)

1. Current Limit Down Setting – Ch.2

2. Current Limit UP Setting – Ch.2

3. Output Voltage Setting – Ch.2

4. Output Terminals – Ch.2

5. Extended Output Terminals – Ch.2

6. Output Terminals for 5V 3A

7. Power Switch

16

9. OPERATION PROCEDURES – DUAL TYPE

8.1 Constant Voltage Setting Method

1) Turn on power switch.

2) Adjust voltage setting knob to the desired voltage which can be

shown in the LCD display.

3) Connect the load, make sure the load current not exceeding the

maximum output current.

8.2 Constant Current Adjustment Method

1. Adjust by turning the voltage setting knob to desired voltage.

2. Press the CV/CC setting button down to light up the CC/CV setting

indicator.

3. Use a wire to shorten the (+) and (-) terminal at output terminal.

4. Push the UP or DOWN button to obtain the current value.

5. When pushing and hold the UP or DOWN button over 0.8 sec, the

value will go up or go down continuously.

6. Release the shortend wire, connect the load to begin operation.

7. The setting of current value will be stored in the EEPROM after off.

8. The current value will be resumed by pushing the CV/CC button

when next power on.

17

8.3 Serial Function operating method

1. Turn on the power by pressing the POWER switch.

2. Push the SERIAL button down to light up the indicator, the dual

power supply is now working under serial condition, the maximum

voltage output is from 0~60V.

3. When adjusting both the voltage setting knobs independently, the

total output voltage is the sum of 2 voltage readings from the LCD

display.

4. Push the SERIAL button down again, the indicator will be off, and

this dual power supply will work independently.

Notice: When operating at constant current condition, the constant

current value should be set at the same value.

Fig 5

18

9.4 PARALLEL function operating method

1. Turn on the power by pressing the POWER switch.

2. Under normal condition, to adjust both voltage knob to obtain same

or similar voltage value.

3. Push the PARALLEL button down to light the indicator, the unit is

now working under parallel condition, the maximum current possibly

obtained is 6A(3003II), 10A(3005XII).

4. To obtain desired voltage by fine tuning any of the voltage setting

knob.

5. Push the PARALLEL button down again, the light will be off, this

dual power supply will operate independently.

Fig 6

19

9.5 DUAL FUNCTION

With this function, you can simultaneously ground channel 1 and

channel 2 to get +30V and –30V outputs, proceed as follows :

1. First do not turn on power.

2. Short the output (+) terminal of channel 1 and channel 2 with a

short wire.

3. Turn on the power switch, push “serial” button down to light up the

indicator, and you can get negative output voltage of 0~30V from

channel 1 and positive output voltage of 0~30V from channel 2, as

shown in the diagram.

4. In order to limit the current for +/- supply, you can perform the

setting of CV/CC procedures to get the desired current output.

5. Do not forget to remove short wire of output terminals when

operating in other mode.

Fig7

20

10. NOTES ON ENVIRONMENTAL CONDITION

1. Aviod using the unit such a place where the ambient temperature

exceeds 40 o℃ r under the direct sun shines. Limit the maximum

output current when the unit is used in such a place where ventilation

is interrupted or a radiation exists from other equipments.

2. Use the instrument within 10% tolerance of the specified voltage

from the power source.

3. Environmental conditions

1) Indoor use.

2) Altitude: up to 2,000m

3) Relative humidity: 50% ~ 80%

4) Installation Category (Over voltage category) Ⅱ

5) Pollution: Degree 2

21

11. NOTICES

1. When the operation is under PARALLEL condition, when activating

the SERIAL button, the operation will be changed from PARALLEL

condition to SERIAL condition.

2. When the operation is under SERIAL condition, when activating the

PARALLEL button, the operation will be changed from SERIAL

condition to PARALLEL condition.

3. When the unit is used in inductance load (like DC electric buzzer),

install a 4,700uF ~ 2,200uF/50V electrode capacitor across the

extension terminal, connection please refer to Fig 8.

4. When the unit is used with the high frequency instruments (like

ultrasonic soldering tool), the electric power supply should be

grounded.

Fig 9

22

Loading...

Loading...