Page 1

Hantek2000 Series Handheld Scopemeter

User Manual

V1.1

Page 2

Copyright Declaration

All rights reserved; no part of this document may be reproduced or transmitted in any form

or by any means, electronic or mechanical, without prior written permission from Hantek

Technologies Co., Ltd (hereinafter referred to as „Hantek‟).

Hantek reserves all rights to modify this document without prior notice. Please contact

Hantek for the latest version of this document before placing an order.

Hantek has made every effort to ensure the accuracy of this document but does not

guarantee the absence of errors. Moreover, Hantek assumes no responsibility in obtaining

permission and authorization of any third party patent, copyright or product involved in

relation to the use of this document.

Page 3

General Safety Summary

Read the following safety precautions to avoid injury and prevent damage to this product

or any products connected to it. To evade potential hazards, use this product only as

specified.

Only qualified personnel should perform maintenance.

Avoid fire or personal injury.

Use suitable power cord. Use only the power cord specified for this product and certified

for the country of use.

Connect and disconnect properly. Connect a probe with the oscilloscope before it is

connected to measured circuits; disconnect the probe from the oscilloscope after it is

disconnected from measured circuits.

Ground the product. This product is grounded through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the product, ensure

that the product is properly grounded.

Connect the probe in a right way. The probe ground lead is at ground potential. Do not

connect the ground lead to an elevated voltage.

Check all terminal ratings. To avoid fire or shock hazard, check all ratings and markings

on the product. Refer to the product manual for detailed information about ratings before

making connections to the product.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Avoid exposed circuitry. Do not touch exposed connections and components when power

is present.

Do not operate with suspected failures. If you suspect there is damage to this product,

have it inspected by qualified service personnel.

Assure good ventilation.

Do not operate in wet/damp environments.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Page 4

Safety Terms and Symbols

Terms on the product. The following terms may appear on the product:

Danger It represents that harms may be caused to you at once

if you perform the operation.

Warning It represents that latent harms may be caused to you if

you perform the operation.

Notice It represents the damage possibly caused to the product

or other properties if you perform the operation.

Characters on the product. The following characters may appear on the product:

Product Scrapping

Device Recycling

We need extract and utilize natural resources to produce this device. If you do not reclaim

the device in a proper way, some substances it contains may become harmful or

poisonous to environments or human bodies. To avoid them being released outside and to

minimize the waste of natural resources, we suggest you reasonably call back this device

to ensure proper recovery and recycling of most materials within it.

Notice

Please read

the manual

Protective

ground terminal

Measuring

ground terminal

Chassis

ground terminal

Page 5

Brief Introduction

This series Scopemeter is compact, portable, and flexible operation; Using color TFTLCD

and pop-up menus to display; to achieve its ease of use, greatly improving the user

productivity.

In addition, this product has superior performance and it is powerful, affordable, high cost.

The real-time sampling rate can be as high as 250MSa/S,can meet the market demand of

complex signals and capture speed; Support for USB storage devices, users can upgrade

via USB, the maximum to meet customer needs.

Model

Channel

Bandwidth

Sampling Rate

GEN

DMM

Hantek2C72

2

70MHz

250MSa/S

N

Y

Hantek2C42

2

40MHz

250MSa/S

N

Y

Hantek2D72

2

70MHz

250MSa/S

Y

Y

Hantek2D42

2

40MHz

250MSa/S

Y

Y

Product features:

New exterior design, small size, light weight, more convenient to carry

Color TFT LCD, 320×240 pixels resolution

Maximum real-time sampling rate: 250MSa/s

With edge triggering function, it can be automatically detected

Backlight luminance can be adjusted

User selectable fast offset calibration

Pop-up menu makes it easy to read and easy to use

Selectable bandwidth limit: 20MHz

Page 6

Content

Copyright Declaration ........................................................................................................ 2

General Safety Summary ........................................................................................... 3

Safety Terms and Symbols ........................................................................................ 4

Product Scrapping ..................................................................................................... 4

Brief Introduction ............................................................................................................... 5

Content ............................................................................................................................. 6

Getting Started .................................................................................................................. 7

Front Panel ................................................................................................................ 8

The user interface ...................................................................................................... 9

General Inspection ..................................................................................................... 9

Functional Check ..................................................................................................... 10

Probe Check ............................................................................................................ 10

Function Introduction ....................................................................................................... 12

Menu and Control Keys ........................................................................................... 13

Connectors .............................................................................................................. 14

Automatically set ...................................................................................................... 14

Default Setting ......................................................................................................... 15

Horizontal System .................................................................................................... 16

Vertical System ........................................................................................................ 17

Trigger System ......................................................................................................... 17

Save Waveform ....................................................................................................... 18

Reference Waveform ............................................................................................... 19

Measurement ........................................................................................................... 19

Utility ........................................................................................................................ 21

DMM ............................................................................................................................... 23

Interface ................................................................................................................... 23

Measurement ........................................................................................................... 23

Generator ........................................................................................................................ 26

Interface ................................................................................................................... 26

Operation description ............................................................................................... 26

Troubleshooting .............................................................................................................. 29

General Care and Cleaning ............................................................................................ 30

Appendix A: Technical Specifications .............................................................................. 31

Appendix B: Accessories ................................................................................................. 35

Page 7

Getting Started

This oscilloscope is a small, lightweight portable instrument,to provide users with a

convenient and easy to operate front panel, you can perform basic tests.

Front Panel

The user interface

General Inspection

Functional Check

Probe Check

Page 8

Front Panel

The following diagram briefly describes the front panel of this series oscilloscope, so that

you can be familiar with it in the shortest possible time.

Page 9

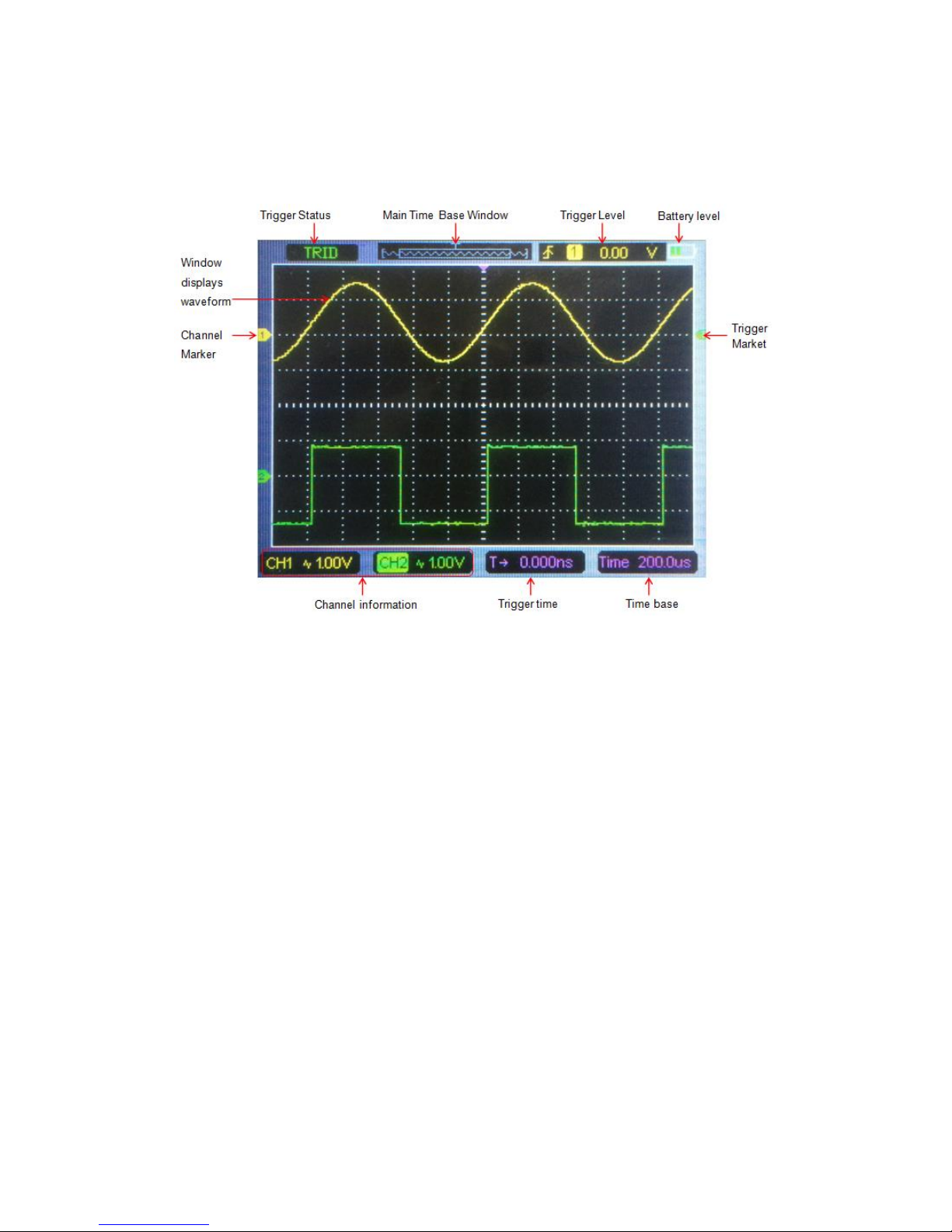

The user interface

General Inspection

Please check the instrument as following steps after receiving an oscilloscope:

Check the shipping container for damage:

Keep the damaged shipping container or cushioning material until the contents of the

shipment have been checked for completeness and the instrument has been checked

mechanically and electrically.

Check the accessories:

Accessories supplied with the instrument are listed in "Accessories" in this manual. If

the contents are incomplete or damaged, please notify the franchiser.

Check the instrument:

In case there is any mechanical damage or defect, or the instrument does not operate

properly or fails performance tests, please notify the franchiser.

Page 10

Functional Check

Follow the steps below to perform a quick functional check to your oscilloscope.

1. Power

Press the power key and the device starts. Press the power key again, and the device

will shut down. Before start it, please confirm that the battery has enough power.

The oscilloscope is equipped with a power adapter and the interface is Type-C. The

input AC power supply is 100~240V, 50~60Hz. The output is 5V@2A. The power

adapter can be used to supply the oscilloscope or charge the battery.

When connect the power adapter to the oscilloscope, if the battery is not installed

inside the oscilloscope, the power key backlight is red and flash; if the battery is

installed inside the oscilloscope and the battery power is not filled, the power key

backlight is red; if the battery is installed inside the oscilloscope and the battery power

is full, the backlight of the source key is extinguishes.

2. Observe the waveform

1) Set the switch on the probe to 1X and connect the probe to Channel 1 on the

oscilloscope. First, align the slot in the probe connector with the protuberance on the

CH1 BNC and push to connect; then, turn to right to lock the probe in place;

2)Connect the probe tip and reference lead to the generator output connector.

Recommended input ~2V@1KHz peak-peak square wave.

3)Press the [Auto] button and you should see within a few seconds a square wave of

about 2V peak-to-peak at 1KHz in the display. Repeat the steps to observe CH2.

Probe Check

Safety

When using the probe, keep your fingers behind the guard on the probe body to avoid

electric shock. Do not touch metallic portions of the probe head while it is connected to a

voltage source. Connect the probe to the oscilloscope and connect the ground terminal to

ground before you start any measurements.

Manual Probe Compensation

Upon the first connection of a probe and an input channel, you should manually perform

this adjustment to match the probe to the input channel. Uncompensated or

miscompensated probes may lead to errors or faults in measurement. To adjust the probe

compensation, follow the steps below.

1. Press Channel button to enter channel setting menu, Set the Probe option

Page 11

attenuation in the channel menu to 10X. Set the switch on the probe to 10X and

connect the probe to Channel 1 on the oscilloscope. If you use the probe hook-tip,

ensure it is firmly inserted onto the probe. Attach the probe tip to the generator output

connector (recommended input ~2V@1KHz peak-peak square wave), and connect

the reference lead to the ground of the generator. Press the [Auto] button.

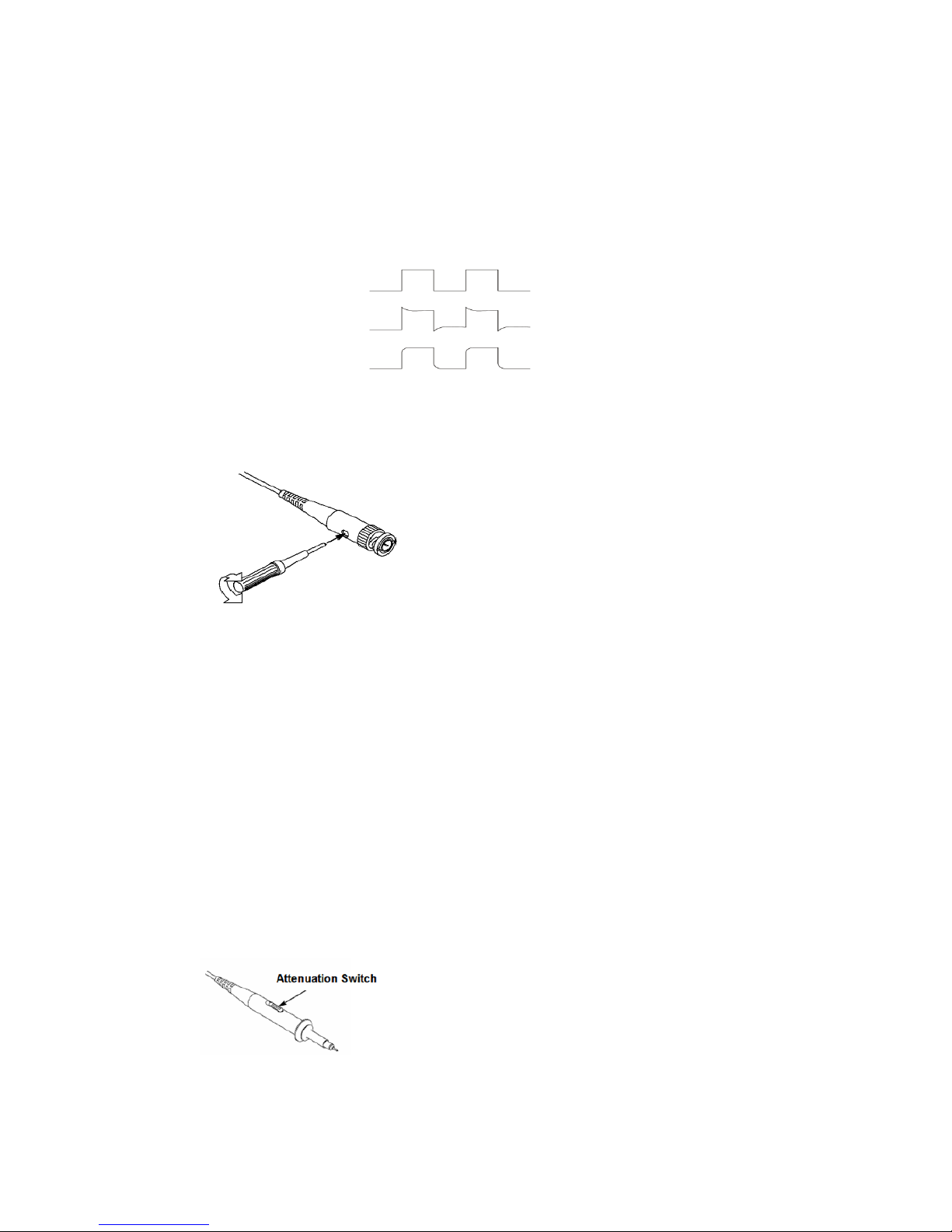

2. Check the shape of the displayed waveform.

3. If necessary, use a nonmetallic screwdriver to adjust the variable capacity of your

probe until the shape of the waveform turns to be the same as the above figure.

Repeat this step as necessary. See the figure below for the way of adjustment.

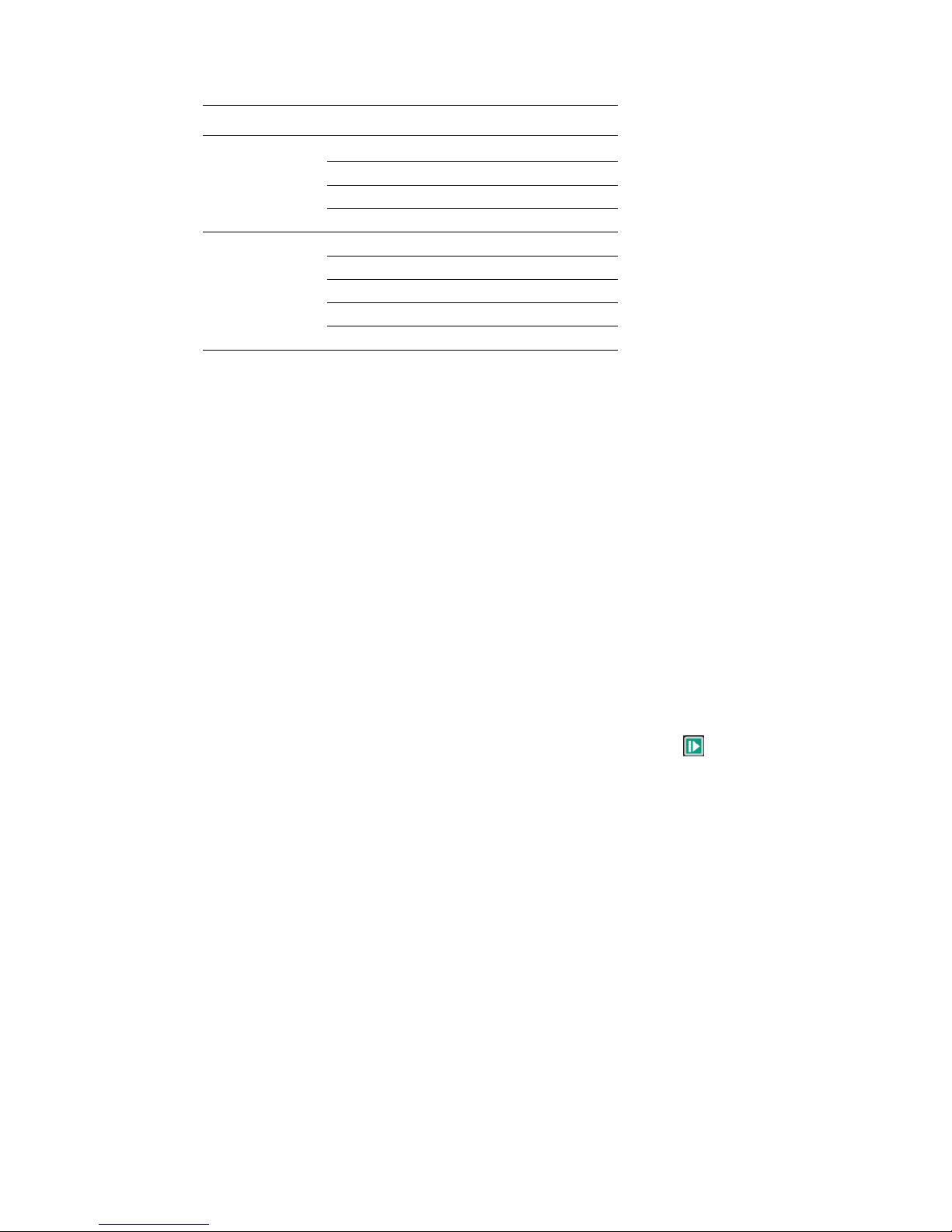

Probe Attenuation Setting

Probes are of various attenuation factors which affect the vertical scale of the signal. The

Probe Check function is used to verify if the Probe attenuation option matches the

attenuation of the probe.

You can press Channel button to enter the channel setting menu and select CH1, and

select the Probe option that matches the attenuation factor of your probe.

Make sure that the Attenuation switch on the probe matches the Probe option in the

oscilloscope. Switch settings are 1X and 10X.

When the Attenuation switch is set to 1X, the probe limits the bandwidth of the

oscilloscope to 6MHz. To use the full bandwidth of the oscilloscope, be sure to set the

switch to 10X.

Compensated correctly

Overcompensated

Undercompensated

Page 12

Function Introduction

This chapter will introduce the functions of oscilloscope in detail.

Menu and Control Keys

Connectors

Automatically set

Default setting

Horizontal System

Vertical System

Trigger System

Save Waveform

Reference Waveform

Measurement

Utility

Page 13

Menu and Control Keys

All the keys are described as follows:

Scope: Oscilloscope mode.

DMM:Multimeter mode.

AWG:Waveform generator.

Menu:Function menu.

Trig:Trigger setting menu.

Enter: In scope, save the user-defined settings of the oscilloscope;

In generator, press the button to confirm after entering the character.

Auto: It automatically adjust the horizontal and vertical scales of the oscilloscope

automatically and set the trigger coupling, type, position, slope, level and mode,

etc., to acquire a stable waveform display.

Channel: Channel setting menu.

Time: Horizontal setting menu.

Zoom and move keys:

In the trigger menu, the left and down keys push the trigger level down, and the

right and upper direction keys push the trigger level up;

In the channel menu, the upper and lower direction keys change the zero level

position of the channel, and the left and right direction keys change the volt/div of

the channel;

In the time base menu, the upper and lower direction keys change the time/div, and

the left and right direction keys change the horizontal trigger position;

In DMM, switch measurement function;

In generator, after choosing a parameter, the left and lower direction key will reduce

the parameter value, the right and up direction key will increase the parameter

value; it is also used for the digital selection of the virtual keyboard.

F1/F2/F3/F4: Multi function key, in each menu mode, is responsible for selecting

Page 14

corresponding menu items in the screen.

:

Shortcut keys. Long press this button to enter the menu, and choose

shortcut key function; After setting, press this button single time to respond

to the corresponding function.

:

In scope, stop or run the waveform acquisition;

In DMM, hold the measuring data or update data;

In generator, turn on or off the waveform output.

:

Power key.

Connectors

Automatically set

Auto set is one of the advantages digital oscilloscopes have. When you push the Auto

button, the oscilloscope will identify the type of waveform (sine or square wave) and adjust

controls according to input signals so that it can accurately display the waveform of the

CH1/CH2:Measured Signal Input

Gen Out: Waveform Generator Output

Charging and

USB Communication

Connector

DMM input connectors

Page 15

input signal.

Functions

Settings

Cursor

Off

Display Format

Set to YT

Horizontal Position

Adjusted

SEC/DIV

Adjusted

Trigger Level

Set to 50%

Trigger Mode

Auto

Trigger Source

Adjusted

Trigger Slope

Adjusted

Trigger Type

Edge

Vertical Bandwidth

Full

Vertical Coupling

DC

VOLTS/DIV

Adjusted

The Auto function examines all channels for signals and displays corresponding

waveforms. Auto determines the trigger source according to the following conditions.

If multiply channels get signals, the oscilloscope will use the channel with the lowest

frequency signal as the trigger source.

If no signals are found, the oscilloscope will use the lowest-numbered channel

displayed in Auto Scale as the trigger source.

If no signals are found and no channels are displayed, the oscilloscope will display and

use Channel 1 as the trigger source.

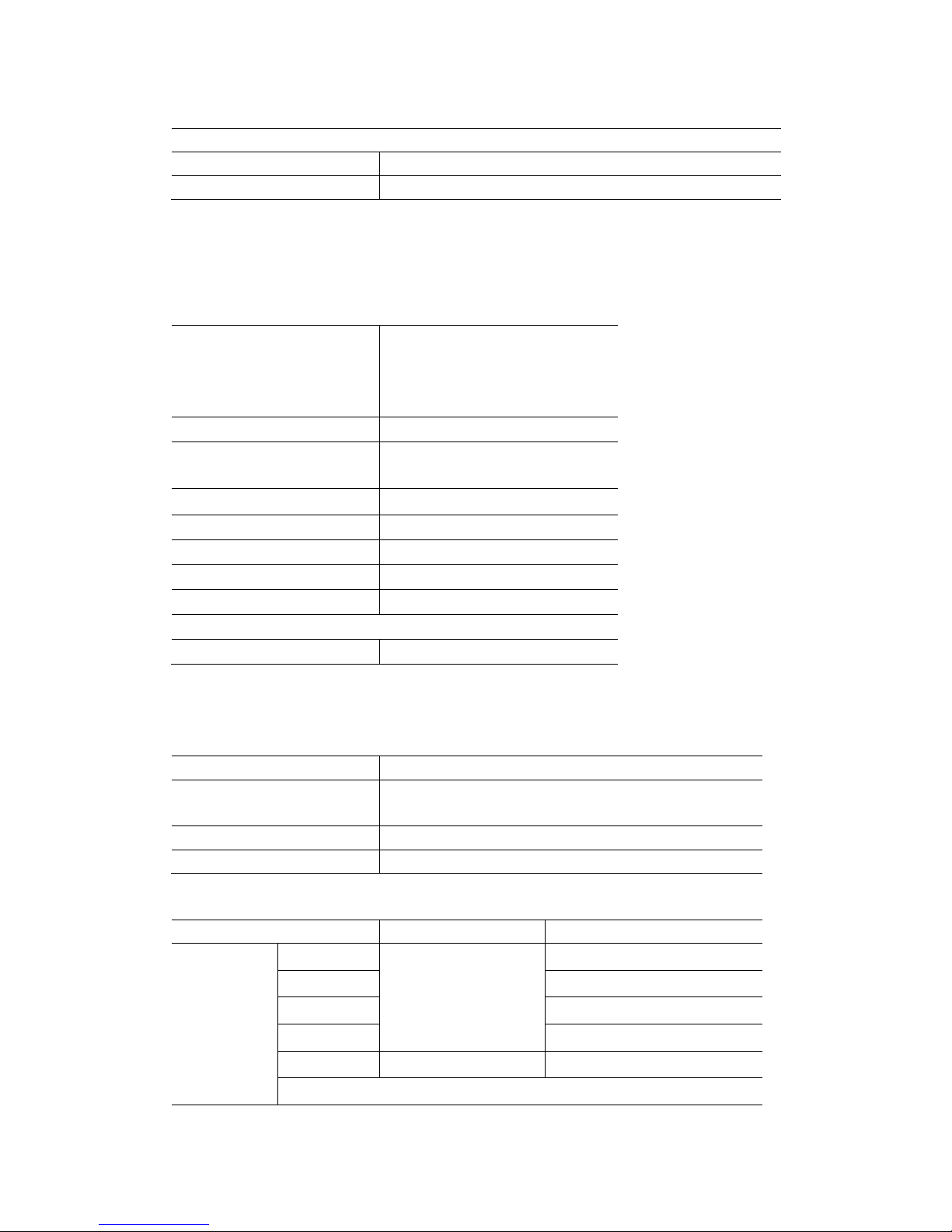

Default Setting

Long press button, enter Short key setting menu, and select Default. Press

button, pops up the prompt to recall the default settings on the screen, now press F1 to

confirm. The oscilloscope will display the CH1 waveform and remove all the others. Press

F4 to cancel. The table below gives the options, buttons and controls that change settings

at default setup.

Menu or

System

Option, Button or

Knob

Default Setting

Cursor

Type

Off

Source

CH1

Horizontal (amplitude)

±4div

Vertical (time)

±4div

Display

Format

YT

Horizontal

Position

0.00s

SEC/DIV

500μs

Page 16

Measure

On or Off

Off

Trigger (Edge)

Source

CH1

Slope

Rising

Mode

Auto

Level

0.00v

Vertical

System,

All Channels

Bandwidth Limit

Unlimited

Coupling

AC

Probe Attenuation

1X

Position

0.00div (0.00V)

VOLTS/DIV

1V

The following settings do not change when you recall default settings.

Language Option

Saved Settings

Saved waveform

Saved Reference Waveforms

Calibration Data

Horizontal System

Press Time button to enter horizontal system menu, use the direction keys to change the

horizontal scale (time base) and the horizontal trigger position. When you change the

horizontal scale, the waveform will expand or contract to the screen center.

1. SEC/DIV Knob: Used to change the horizontal time scale so as to magnify or compress

the waveform horizontally. If the waveform acquisition is stopped (by using button),

press Time button and Up or Down buttons to expand or compress the waveform.

2. Horizontal Position Knob: Used to control the trigger position against the screen

center. Press Time button and Right or Left buttons to move the waveform right or left.

The key resolution vary according to time base. Press "AUTO" key can make the

horizontal position return to zero.

3. Mode: Y-T, Roll, Scan.

Y-T: YT format shows the vertical voltage in relation to time (horizontal scale)

Roll: In Roll mode, the waveform display rolls from right to left. Trigger or horizontal offset

control of waveforms is available during Roll Mode, and it‟s only available when set to

100ms/div or slower.

Scan: In Scan Mode, the waveform display scan updates from left to right. In Scan mode,

trigger and horizontal offset control of waveforms are available during Scan Mode. This

mode is only available when set to 100ms/div or slower. Generally, used for measuring

low frequency signal. When the time/div is 100ms/div or slower, the oscilloscope

Page 17

Automatically enters the scan mode.

Vertical System

Vertical system can be used to adjust the vertical scale and location and other settings of

the channel. Each channel has a separate vertical menu, and each channel can be set

separately.

1. Vertical Position

Press Channel->F1 to select the channel, and press Up or Down direction keys to

move the vertical position of the selected channel.

2. VOLTS/DIV Settings

The range of Volt/div is 10mV/div-10V/div (1X), or 100mV/div-100V/div (10X),

1V/div-1000V/div (100X), step by 1-2-5.

Press Channel->F1 to select the channel, and press Right or Left direction keys to

change the Volt/div of the selected channel.

3. Channel Setting Menu

Options

Settings

Comments

On/Off

On

Off

Turn on the waveform display.

Turn off the waveform display.

Coupling

DC

AC

GND

DC passes both DC and AC components of the input

signal.

AC blocks the DC component of the input signal and

attenuates signals below 10Hz.

GND disconnects the input signal.

Probe

1X

10X

100X

1000X

Selects a value according to the probe attenuation

factor so as to ensure correct vertical readouts.

Reduce bandwidth to 6MHz when using a 1X probe.

BW

20MHz

On

Off

Limits the bandwidth to reduce display noise; filters the

signal to eliminate noise and other unnecessary HF

components.

Trigger System

The trigger determines when the oscilloscope begins to acquire data and display a

waveform. Once a trigger is properly set up, the oscilloscope can convert unstable

displays or blank screens to meaningful waveforms.

The triggering mode of this series oscilloscope is edge trigger.

Edge trigger distinguishes the trigger points by seeking the specified edge (rising, falling,

rising & falling) and trigger level.

Page 18

Trigger Source: Select the trigger source signal to CH1 or CH2. You can use the trigger

source options to select the signal that the oscilloscope uses as a trigger.

Trigger Mode: You can select the Auto or Normal mode to define how the oscilloscope

acquires data when it does not detect a trigger condition. Auto Mode performs the

acquisition freely in absence of valid trigger. It allows the generation of untriggered

waveforms with the time base set to 100ms/div or slower. Normal Mode updates the

displayed waveforms only when the oscilloscope detects a valid trigger condition. Before

this update, the oscilloscope still displays the old waveforms. This mode shall be used

when you want to only view the effectively triggered waveforms. In this mode, the

oscilloscope displays waveforms only after the first trigger.

Trigger Level: It sets the amplitude level the signal must cross to cause an acquisition

when using the Edge or Pulse Width trigger. Press Trig button to enter, and press Up or

Down direction keys to change the trigger level.

Force Trigger: Used to complete an acquisition regardless of an adequate trigger signal.

This button becomes useless if the acquisition is already stopped.

Save Waveform

Press Menu button to enter, and select Save to enter store waveform menu. The

waveform can be saved to the oscilloscope inside, also can be recalled to view.

The Save Menu Table

Menu

Setting

Description

Position

1,2,3,4,5,6

Select the internal storage position.

Save

Save waveform data.

Recall

Recall the waveform.

To save the waveform, follow these steps:

1. Press F1, select the storage position of the waveform.

2. Press F2 to save the waveform data to the specified position. Also users can long

press button to enter, and select F4->F2 (Data Save) as shortcut keys. Press

button one time to save the current waveform data.

3. Press F3, recall the saved waveform. The waveform can be enlarged or reduced in

the Channel or Time menu by using the direction keys.

Attention:

1. Waveform storage can not only save the waveform of the current channel, but also

save the current state settings at the same time.

Page 19

2. users can permanently store 6 waveforms in the oscilloscope memory and rewrite them

at any time.

Reference Waveform

The REF channel is used to display the reference waveform, which can compare the

actual waveforms with the reference waveforms so as to find out the differences.

Press Menu button to enter, and select Ref to enter reference Waveform menu.

REF Menu Table

Menu

Setting

Description

Position

Ref-A

Ref-B

The REF waveform is saved to the oscilloscope

Ref-A or Ref-B.

Enable

On

Off

Open the REF waveform.

Close the REF waveform.

Source

CH1

CH2

Select CH1 to save as a REF waveform.

Select CH2 to save as a REF waveform

Save

Save the REF waveform.

To save the reference waveform, follow these steps:

1. Press F1 to select the position of the reference waveform.

2. Press F2 to open the REF channel.

3. Press F3 to select the source to CH1 (or CH2), and only select the open channel.

4. Press F4 to save the current waveform to the specified location..

Measurement

Scale measurement

Graticule: This method allows you to make a quick, visual estimate and take a simple

measurement through the graticule divisions and the scale factor.

For example, you can take simple measurements by counting the major and minor

graticule divisions involved and multiplying by the scale factor. If you counted 6 major

vertical graticule divisions between the minimum and maximum values of a waveform and

knew you had a scale factor of 50mV/division, you could easily calculate your

peak-to-peak voltage as follows:

6 divisions x 50mV/division = 300mV.

Cursor measurement

The cursor measurement has two parallel lines on the screen, and move two lines to

measure the time and voltage parameters of the input signal. The result of cursor

measurement will be displayed on the second page of the cursor menu. Before use cursor

Page 20

measurement, make sure that the measured source is the signal you need to measure.

Press Menu button to enter, and select Cursor to enter cursor measurement.

Cursor Measurement Menu Table

Menu

Setting

Description

Enable

On

Off

Open the cursor measurement.

Close the cursor measurement.

Type

Voltage

Time

The horizontal line is shown to measure the voltage

parameters.

The vertical line is shown to measure the time

parameters.

Source

CH1

CH2

Select the measured source.

Cursor1

Select Cursor1 and press up, down, left and right keys to

move the Cursor1 position, and display the Cursor1 value.

Cursor2

Select Cursor2 and press up, down, left and right keys to

move the Cursor2 position, and display the Cursor2 value.

Increment

The difference between the Cursor1 and the Cursor2.

To do cursor measurement, follow these steps:

1. Press F1 to open the cursor measurement;

2. Press F2 to select a type of cursor measurement.

3. Press F3 to select the channel that needs to be measured.

4. Press F4 to enter the second page, press F1 or F2 to select Cursor1 or Cursor2, press

up, down, left and right to move Cursor1 or Cursor1;

5. The result of cursor measurement will be displayed on the cursor menu.

Automatic Measurement

The oscilloscope provides 2 kinds of automatic measurements, including frequency and

amplitude.

Press Menu button to enter, select Measure to enter automatic measurement. Press F1

to open, the measurement results will be displayed on the top left corner of the screen.

Measurement Menu Table

Menu

Description

Frequency

Measure the frequency of the signal.

Amplitude

Measure the amplitude of the signal, the low end value - the top

value.

Attention:

In the measurement result, the yellow font is the result of CH1, and the green font is the

result of CH2.

Page 21

Utility

Press Menu button to enter.

Utility Menu Table

Menu

Setting

Description

Language

中文

English

Set the menu language.

Sound

On

Off

Open the key sound.

Close the key sound.

Backlight

luminance

1~10

Set backlight brightness of the screen.

Backlight

time

30s

60s

90s

120s

Unlimited

Set the screen backlight time.

System

information

Display system information, such as software

version or PCB version.

Automatic

shutdown

5 Minute

10 Minute

20 Minute

30 Minute

Unlimited

Set automatic shutdown time.

Calibration

Start

Return

Start the self calibration.

Exit the self calibration.

Note:

1. Backlight time and automatic shutdown time will not be executed when the

oscilloscope is plugged in with an external charging device or connected to a

computer via a USB cable.

2. Shutdown automatically saves last setup.

Self calibration

The self calibration routine helps optimize the oscilloscope signal path for maximum

measurement accuracy. You can run the routine at any time but should always run it if the

ambient temperature changes by 5℃ or more. For a more accurate calibration, please

power on the oscilloscope and wait for 20 minutes until it has adequately warmed up.

To do self calibration, follow these steps:

1. Ensure that no input signal is input, otherwise it may damage the instrument.

2. Press Menu button to select the self calibration function.

Update

Connect the oscilloscope to the computer with USB cable. Press the F1 button and the

Page 22

boot button at the same time. The backlight of the button will jump between red and green,

that is, enter the upgrade mode. Using the Dfu download tool to download the program,

the oscilloscope power off, and then re-energize.

Shortcut key

Long press button to enter shortcut key settings menu, and choose shortcut key

function; After setting, press this button single time to respond to the corresponding

function.

Default settings: Long press button to enter, and select F1 (Default) as the

shortcut key, then press button one time and select F1 TO confirm to recall the

default settings

Custom settings: Long press button to enter, and select F2 or F3 (custom 1 or 2)

as shortcut keys. Now press Enter button and click F1 to confirm to save the current

settings to custom settings. Press button one time and click F1 to confirm to recall

the custom settings.

Save data: Long press button to enter, and select F4->F1 (Data Save) as shortcut

keys. Press Menu -> Save to enter the save menu, select a location, press

button one time to save the current waveform data.

Page 23

DMM

This chapter introduces the multimeter function.

Interface

The measuring types include DC voltage (V, mV), AC voltage, DC current (A, mA), AC

current (A, mA), resistance, capacitance, diode, and on-off test.

Measurement

1. DC and AC voltage measurement

a) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

b) Press the up, down, left and right direction keys or F1, F2, F3, F4 multi-function

keys to select "DC V", "DC mV" or "AC V";

c) Insert the black pen into the input port of the COM banana socket, and insert the

red pen into the input port of the V/Ω/C banana port;

d) Connect the red and black forms to the measured point. The voltage value of the

measured point will be displayed on the screen.

2. DC and AC current measurement

Page 24

a) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

b) To measure the DC current greater than 200mA, press the up, down, left and right

keys or F1, F2, F3, F4 multi function keys to select "DC A" or "AC A", and insert the

black pen to the input end of the COM banana socket, and insert the red pen into

the input port of the “A” banana socket;

c) To measure the DC current less than 200mA, press the up, down, left and right

keys or F1, F2, F3, F4 multi function keys to select "DC mA" or "AC mA", and insert

the black pen to the input end of the COM banana socket, and insert the red pen

into the input port of the “mA” banana socket.;

d) Connect the red and black forms to the measured point. The current value of the

measured point will be displayed on the screen.

3. Resistance measurement

a) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

b) Press the up, down, left and right direction keys or F1, F2, F3, F4 multi-function

keys to select "Ω";

c) Insert the black pen into the input port of the COM banana socket, and insert the

red pen into the input port of the V/Ω/C banana port;

d) Connect the red and black forms to the measured point. The resistance value of

the measured point will be displayed on the screen.

4. Capacitance measurement

e) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

f) Press the up, down, left and right direction keys or F1, F2, F3, F4 multi-function

keys to select " ";

g) Insert the black pen into the input port of the COM banana socket, and insert the

red pen into the input port of the V/Ω/C banana port;

h) Connect the red and black forms to the measured point. The capacitance value of

the measured point will be displayed on the screen.

5. Diode measurement

i) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

j) Press the up, down, left and right direction keys or F1, F2, F3, F4 multi-function

keys to select " ";

k) Insert the black pen into the input port of the COM banana socket, and insert the

red pen into the input port of the V/Ω/C banana port;

l) Connect the red and black forms to the measured point. The diode value of the

measured point will be displayed on the screen.

6. On-Off measurement

Page 25

m) Press the power button to turn on, then press the "DMM" button to enter to the

multimeter function interface;

n) Press the up, down, left and right direction keys or F1, F2, F3, F4 multi-function

keys to select " ";

o) Insert the black pen into the input port of the COM banana socket, and insert the

red pen into the input port of the V/Ω/C banana port;

p) Connect the red and black forms to the measured point. If the resistance of the

measured point is less than 50 ohms, the instrument will emit "drop" sound.

7. Data retention function

Press the button on the instrument, and the displayed data will remain on the

display, even if the input signal changes or eliminates, the value will not change.

Note: Please select the required measuring gear correctly and then measure again.

Page 26

Generator

This chapter introduces the function of waveform generator.

Interface

Operation description

Press the power button to turn on, then press the "AWG" button to enter the waveform

generator function interface.

1. Set type

Press F1 button to select the desired signal waveform, the optional waveform type

includes square, triangle, sine, trapezoidal and four arbitrary.

2. Set frequency

Press F2 button to select Frequency, then use the up, down, left and right direction

keys to adjust the frequency, press F2 button to open the digital keyboard again, use

the up, down, left, right direction keys and "Enter" key to set frequency parameter,

select "OK" and press "Enter" button to confirm.

3. Set amplitude

Press F3 button to select Amplitude, then use the up, down, left and right direction

keys to adjust the frequency, press F3 button to open the digital keyboard again, use

the up, down, left, right direction keys and "Enter" key to set frequency parameter,

Page 27

select "OK" and press "Enter" button to confirm.

4. Set offset

Press F4 button to enter the second page. Press F2 to select Offset, then use the up,

down, left and right direction keys to adjust the frequency, press F2 button to open the

digital keyboard again, use the up, down, left, right direction keys and "Enter" key to

set frequency parameter, select "OK" and press "Enter" button to confirm.

5. Set duty cycle

enter the second page. Press F3 to select Duty, then use the up, down, left and right

direction keys to adjust the frequency, press F3 button to open the digital keyboard

again, use the up, down, left, right direction keys and "Enter" key to set frequency

parameter, select "OK" and press "Enter" button to confirm.

6. Generate an arbitrary waveform

It is necessary to edit the arbitrary waveform in connection with the software and

download it into the machine. There are 4 arbitrary wave positions, and each position

can permanently store an arbitrary wave.

7. After setting the waveform parameters, press the button to turn on or off the

signal output. The output waveform of the signal generator can be observed through

an oscilloscope.

For example, set a sine waveform with 2Vpp@10KHz to output as follows:

Page 28

The waveform observed by an oscilloscope is as follows:

Page 29

Troubleshooting

1. If the oscilloscope does not start up at power on, follow these steps:

1) Check whether the battery is installed and confirm whether the battery level is enough.

2) If the battery level is not enough, use the power adapter to charge.

3) Restart the instrument after the battery level is enough.

4) Contact your local HANTEK distributor or directly keep touch with HANTEK Technical

Support department if the oscilloscope still can not be turned on normally.

2. If there is no display of waveforms on the screen when the oscilloscope is

turned on, follow these steps:

1) Check the probe to assure its proper connection to the input BNC;

2) Check the channel switch (Channel button) to make sure it has been turned on;

3) Check the input signal to verify it has been connected to the probe correctly;

4) Affirm that all measured circuits have signals to output;

5) Turn up the magnitude for DC signals with large magnitude;

6) In addition, you may press the Auto button to perform an automatic detection of

signals at first.

7) Contact HANTEK Technical Support department in time if there is still no display of

waveforms.

3. If the waveform of the input signal is distorted seriously, follow these steps:

1) Check the probe to assure its proper connection to the channel BNC;

2) Check the probe to assure its good connection to the measured object;

3) Check the probe to verify it has been well calibrated. Otherwise, refer to the content

about calibration described in this manual.

4. If the waveform is rolling continuously on the screen but can not be triggered,

follow these steps:

1) Check the trigger source to make sure it consistent with the input channel;

2) Check the trigger level to assure its correct adjustment. You may press TRIGGER

button to enter trigger menu, and use Up, Down, Right, Left direction keys to adjust

trigger level to return to signal.

Page 30

General Care and Cleaning

General Care

Do not put or leave the device in a place where the LCD display will be exposed to direct

sunlight for long periods of time.

Note: To avoid damage to the oscilloscope or probes, do not expose them to sprays,

liquids, or solvents.

Cleaning

Examine the oscilloscope and probes as often as operating conditions require. To clean

the exterior surface, perform the following steps:

1) Use a lint-free cloth to remove floating dust on the outside of the oscilloscope and

probes. Take care to avoid scratching the glabrous display filter.

2) Use a soft cloth dampened with water to clean the oscilloscope. For more efficient

cleaning, you may use an aqueous solution of 75% isopropyl alcohol.

Note: To avoid damage to the surface of the oscilloscope or probes, do not use any

corrosive or chemical cleaning agents.

Page 31

Appendix A: Technical Specifications

All specifications herein mentioned apply to the series oscilloscopes. Before checking an

oscilloscope to see if it complies with these specifications, make sure it meets the

following conditions:

The oscilloscope must have been operating continuously for twenty minutes under

the specified operating temperature.

The Do Self Cal operation must be performed through the Utility menu if the operating

temperature changes by more than 5℃.

The oscilloscope must be within the factory calibration interval.

All specifications are guaranteed unless noted „typical‟.

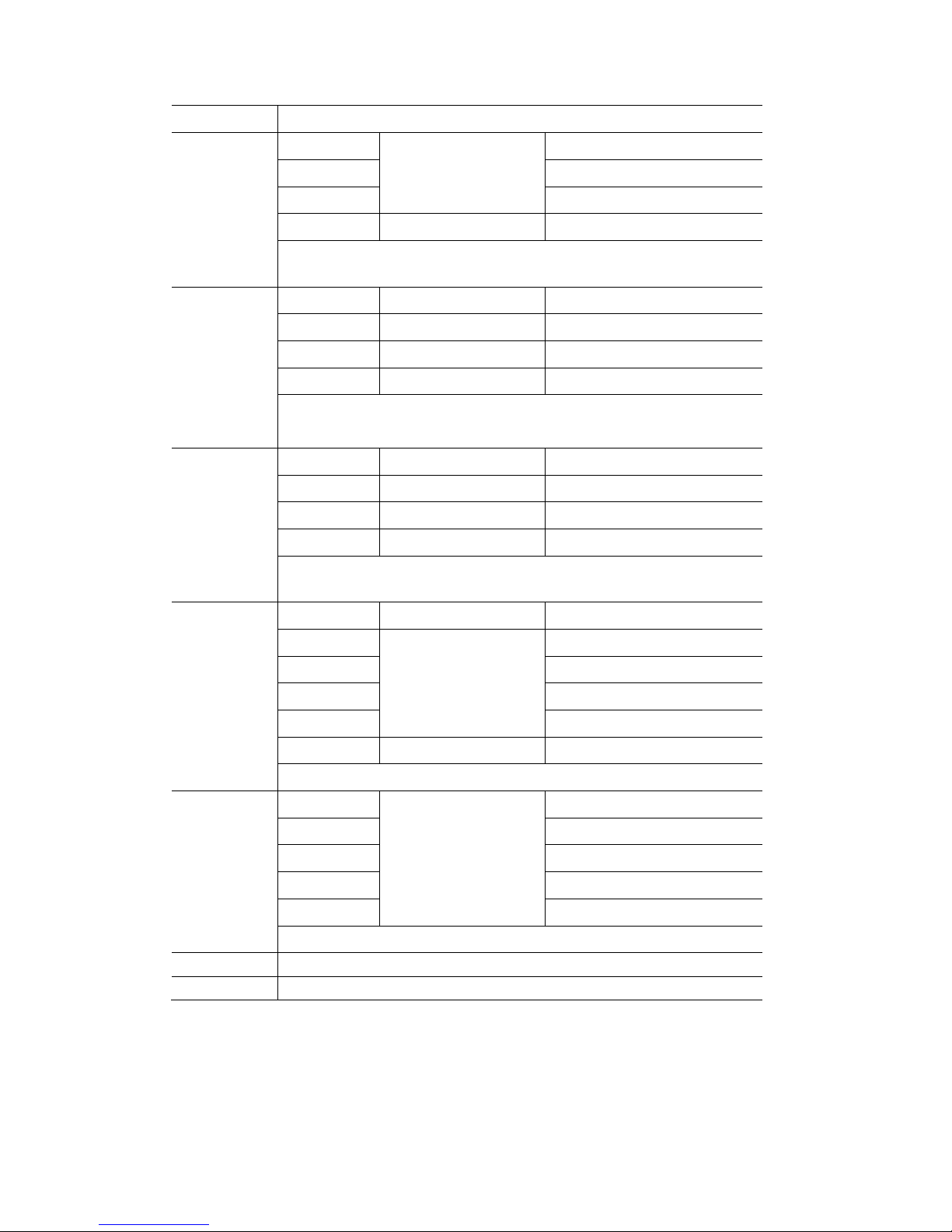

Oscilloscope Specifications

Horizontal

Model

Hantek2C72/Hantek2D72

Hantek2C42/Hantek2D42

Band Width

70MHz

40MHz

Rising time

≤5ns

≤8.75ns

Sample Rate Range

250MSa/s(Single-channel), 125MSa/s(Dual-channel)

Waveform Interpolation

(sin x)/x

Record Length

Max. 6K samples for single-channel,

3K samples per dual-channel

SEC/DIV Range

5ns/div~500s/div 1, 2, 5 sequence

Vertical

A/D Converter

8-bit resolution, each channel sampled simultaneously

VOLTS/DIV Range

10mV/div~10V/divat input BNC

Selectable Analog

Bandwidth Limit, typical

20MHz

Low Frequency Response

(-3db)

≤10Hz at BNC

Rise Time at BNC, typical

≤5ns

DC Gain Accuracy

±3% for Normal or Average acquisition mode, 10V/div to 10mV/div

Note: Bandwidth reduced to 6MHz when using a 1X probe.

Acquisition

Acquisition Modes

Normal

Trigger

Type

Edge

Page 32

Mode

Auto, Normal, single

Level

±4 divisions from center of screen

Trigger Level Accuracy

0.2div × volts/div within ±4 divisions from center of screen

Slope

Rising, Falling, Rising & Falling

Source

CH1, CH2

Input

Coupling

DC, AC or GND

Input Impedance,

DC coupled

25pF±3 pF,1MΩ±2%

Probe Attenuation

1X, 10X

Supported Probe

Attenuation Factors

1X, 10X, 100X, 1000X

Maximum Input Voltage

150V

RMS

Measurement

Cursor

Voltage difference between cursors: △V

Time difference between cursors: △T

Automatic Measurements

Frequency, Amplitude

General Specifications

Display

Display Type

2.8 inch 64K color TFT

Display Resolution

320 horizontal by 240 vertical pixels

Display Contrast

Adjustable

Power Supply

Supply Voltage

100V-240VAC, 50Hz-60Hz; DC INPUT: 5VDC, 2A

Power Consumption

<2.5W

Fuse

T, 3A

Battery

2600mAh*2

Environmental

Operating Temperature

0℃ to 50℃

Storage Temperature

-20℃ to 60℃

Humidity

≤+104℉(≤+40°C): ≤90% relative humidity

106℉~122℉ (+41°C ~50°C): ≤60% relative humidity

Cooling Method

Convection

Altitude

Operating and

Nonoperating

3,000m (10,000 feet)

Random Vibration

0.31g

RMS

from 50Hz to 500Hz,

10 minutes on each axis

Nonoperating

2.46g

RMS

from 5Hz to 500Hz, 10

minutes on each axis

Mechanical Shock

Operating

50g, 11ms, half sine

Page 33

Mechanical

Dimension

199 x 98x 40mm (L x W x H)

Weight

624g

Arbitrary Waveform Generator (Hantek2D72/Hantek2D42)

Waveform Frequency

Sine: 1Hz~25MHz

Square: 1Hz~10MHz

Ramp: 1Hz~1MHz

EXP: 1Hz~5MHz

Sampling

250MSa/s

Amplitude

2.5Vpp(50Ω)

5Vpp(High impedance)

Frequency Resolution

0.10%

Channel

1CH waveform output

Waveform Depth

512Sa

Vertical Resolution

12 bit

Output Impedance

50 Ω

Square Characteristics

Pulse width accuracy

±10ns

DMM

Maximum Resolution

4000 Counts

DMM Testing Modes

Voltage, Current, Resistance, Capacitance, Diode &

On-Off

Maximum Input Voltage

AC : 600V DC : 600V

Maximum Input Current

AC : 10A DC : 10A

Range

Accuracy

Resolution

DC Voltage

400.00mV

±(0.8% + 5)

100uV

4.000V

1mV

40.00V

10mV

400.0V

100mV

600.0V

±(1% + 2)

1V

Overload protection:

Page 34

400mV: 250V, other: 600Vrms.

AC Voltage

4.000V

±(1.2% + 5)

1mV

40.00V

10mV

400.0V

100mV

600.0V

±(1.5% + 5)

1V

Frequency: 40Hz~400Hz;

Frequency of 400V and 600V: 40Hz~100Hz

DC Current

40.00mA

±(1% + 2)

10uA

200.0mA

±(1.5% + 2)

100uA

4.000A

±(1.8% + 2)

1mA

10.00A

±(3% + 2)

10mA

Overload protection:

self restoring fuse: 200mA/250V, 4A and 10A range no fuse.

AC Current

40.00mA

±(1.3% + 2)

10uA

400.0mA

±(1.8% + 2)

100uA

4.000A

±(2% + 3)

1mA

10.00A

±(3% + 5)

10mA

Frequency: 40Hz~400Hz;

self restoring fuse: 200mA/250V, 4A and 10A range no fuse.

Resistance

400.0Ω

±(1% + 3)

0.1Ω

4.000KΩ

±(1.2% + 5)

1Ω

60.00KΩ

10Ω

400.0KΩ

100Ω

4.000MΩ

1KΩ

40.00MΩ

±(1.5%±3)

10KΩ

Overload protection: 220Vrms

Capacitance

40.00nF

±(3% + 5)

10pF

400.0nF

100pF

4.000uF

1nF

40.00uF

10nF

100.0uF

100nF

Overload protection: 220Vrms

Diode

0V~2.0V

On-Off

<50Ω

Page 35

Appendix B: Accessories

All the following accessories are available by contacting your local HANTEK distributor.

Standard Accessories

• Probe×1 (1.5m), 1:1, (10:1) Passive Probes

• A Power adapter

• A USB Line

• Crocodile clip line *1 (For Hantek2C42/Hantek2C72)

• Crocodile clip line *2 (For Hantek2D42/Hantek2D72)

• A Multimeter Probe

• A PC software CD of the oscilloscope

• Warranty Card

• Manufacturer Certificate

Loading...

Loading...