Hantech 4619277, 4619278, 4619275, 4619276 Operating Instructions Manual

OPERATING INSTRUCTIONS

BEDIENUNGSANLEITUNGEN

Artikelnummer:4619278(DE)

4619277(CH)

EN

1

Content

I.Attention Matters.................................................................................2

II.Featuresand Components.................................................................5

III.Control Setting.................................................................................6

IV.Protection function............................................................................8

V.Installation and adjustment..................................................................9

VI.Drainage Instructions..........................................................................11

VII.Maintenance.....................................................................................12

VIII.Out-of-seasonsave.........................................................................13

IX.Troubleshooting.................................................................................21

X.Addendum.........................................................................................23

The refrigerant used in mobile air conditioners is the environmentally friendly

hydrocarbon R290.This refrigerant is odorless, and compared to the alternative

refrigerant, the R290 is an ozone-free refrigerant, and its effect is very low.

Please read the instructions before use and repair.

The drawings provided in this manual may not be the same as the physical objects.

Please refer to the physical objects.

EN

2

I.Attention Matters

Warning matters:

1. Do not use means to accelerate the defrosting process or to clean,

other than those recommended by the manufacturer.

2. The appliance shall be stored in a room without continuously

operating ignition sources (for example: open flames, an operating gas

appliance or an operating electric heater.)

3. Do not pierce or burn.

4. Be aware that refrigerants may not contain an odour.

5. Appliance shall be installed, operated and stored in a room with a

floor area larger than 12 m

2

6. Keep any required ventilation openings clear of obstruction;

7. Servicing shall be performed only as recommended by the

manufacturer.

8. The appliance shall be stored in a well-ventilated area where the

room size corresponds to the room area as specified for operation.

9. Any person who is involved with working on or breaking into a

refrigerant circuit should hold a current valid certificate from an

industry-accredited assessment authority, which authorises their

competence to handle refrigerants safely in accordance with an industry

recognised assessment specification.

10. Servicing shall only be performed as recommended by the

equipment manufacturer.

Maintenance and repair requiring the assistance of other skilled

personnel shall be carried out under the supervision of the person

competent in the use of flammable refrigerants.

11. All working procedure that affects safety means shall only be carried

by competent persons.

EN

3

Notes:

*The air conditioning is only suitable for indoor use, and is not suitable

for other applications.

*Follow local grid interconnection rules while installing the air

conditioning and ensure that it is properly grounded. If you have any

question on electrical installation, follow the instructions of the

manufacturer, and if necessary, ask a professional electrician to install

it.

*Place the machine in a flat and dry place and keep a distance of above

50cm between the machine and the surrounding objects or walls.

*After the air conditioning is installed, ensure that the power plug is

intact and firmly plugged into the power outlet, and place the power cord

orderly to prevent someone from being tripped or pulling out the plug.

*Do not put any object into the air inlet and outlet of the air conditioning.

Keep the air inlet and outlet free from obstructions.

*When drainage pipes are installed, ensure that the drainage pipes are

properly connected, and are not distorted or bended.

* While adjusting the upper and lower wind-guide strips of the air outlet,

pluck it with hands gently to avoid damaging wind-guide strips.

*When moving the machine, make sure that it is in an upright position.

*The machine should stay away from gasoline, flammable gas, stoves

and other heat sources.

* Don't disassemble, overhaul and modify the machine arbitrarily,

otherwise it will cause a machine malfunction or even bring harm to

persons and properties. To avoid danger, if a machine failure occurs,

ask the manufacturer or professionals to repair it.

* Do not install and use the air conditioning in the bathroom or other

humid environments.

* Do not pull the plug to turn off the machine.

* Do not place cups or other objects on the body to prevent water or

other liquids from spilling into the air conditioning.

*Do not use insecticide sprays or other flammable substances near the

air conditioning.

* Do not wipe or wash the air conditioning with chemical solvents such

EN

4

as gasoline and alcohol. When you need to clean the air conditioning,

you must disconnect the power supply, and clean it with a half-wet soft

cloth. If the machine is really dirty, scrub with a mild detergent.

* The appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities if

they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and maintenance shall not

be made by children without supervision.

If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a

hazard.

The appliance shall be installed in accordance with national wiring

regulations.

Do not operate your air conditioner in a wet room such as a bathroom or

laundry room.

Transportation, marking and storage for units

1. Transport of equipment containing flammable refrigerants

Compliance with the transport regulations

2. Marking of equipment using signsCompliance with local regulations

3. Disposal of equipment using flammable refrigerants Compliance with

national regulations

4. Storage of equipment/appliances The storage of equipment should

be in accordance with the manufacturer’s instructions.

5. Storage of packed (unsold) equipment Storage package protection

should be constructed such that mechanical damage to the

equipment inside the package will not cause a leak of the refrigerant

charge.

The maximum number of pieces of equipment permitted to be stored

together will be determined by local regulations.

EN

5

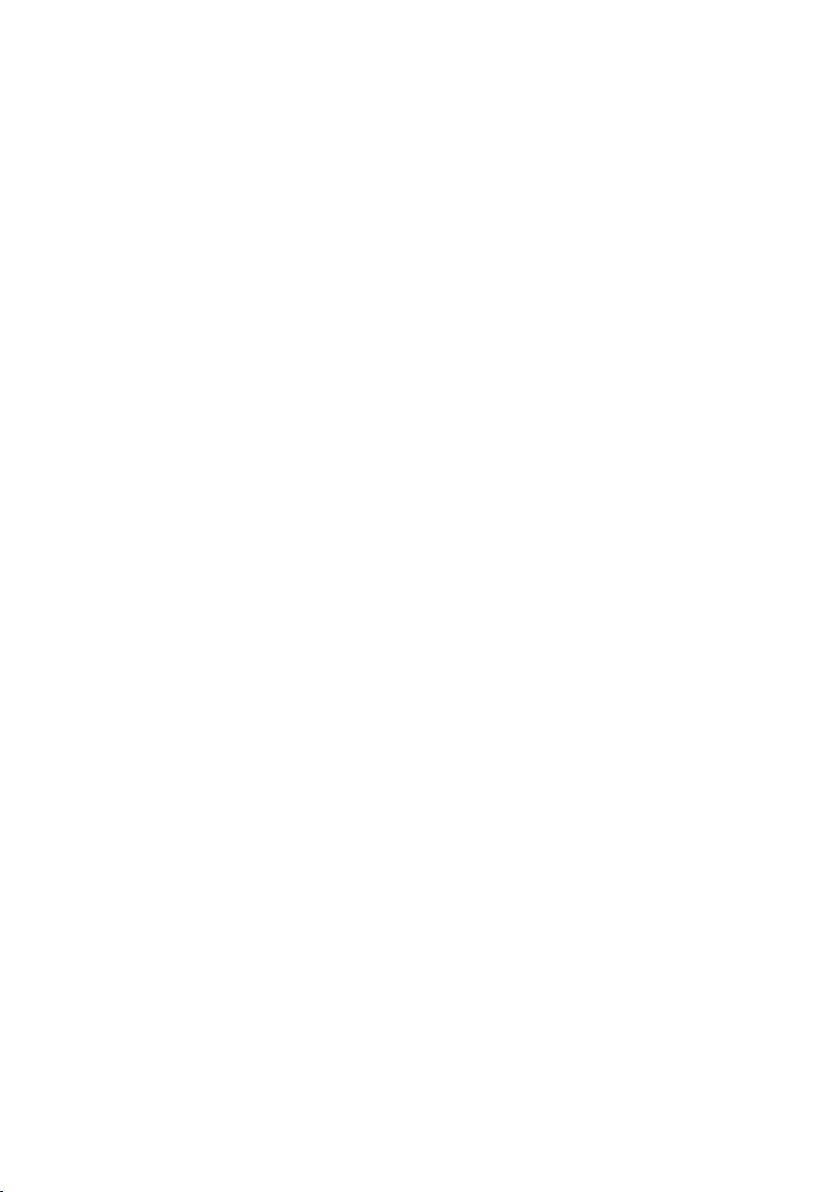

II.Features and Components

1、Features

*Brand new appearance, compact structure, smooth line, simple and generous shape.

*Functions of refrigeration, dehumidification, air supply and continuous drainage

*Outdoor interface is set high to facility assembly and keep the smooth flow of the heat

pipe.

*LED displays the control panel, beautiful and fashionable, with high-quality remote

control.It adopts a user-friendly remote control design.

*Air filtration capability.

*Timing switch function.

*Protection function of automatically restarting the compressor after three minutes, a

variety of other protection functions.

The Max operation temperature for the air conditioner Cooling: 35/24 ℃ ; heating:20/12

℃; Temperature

operation range: 7-35℃.

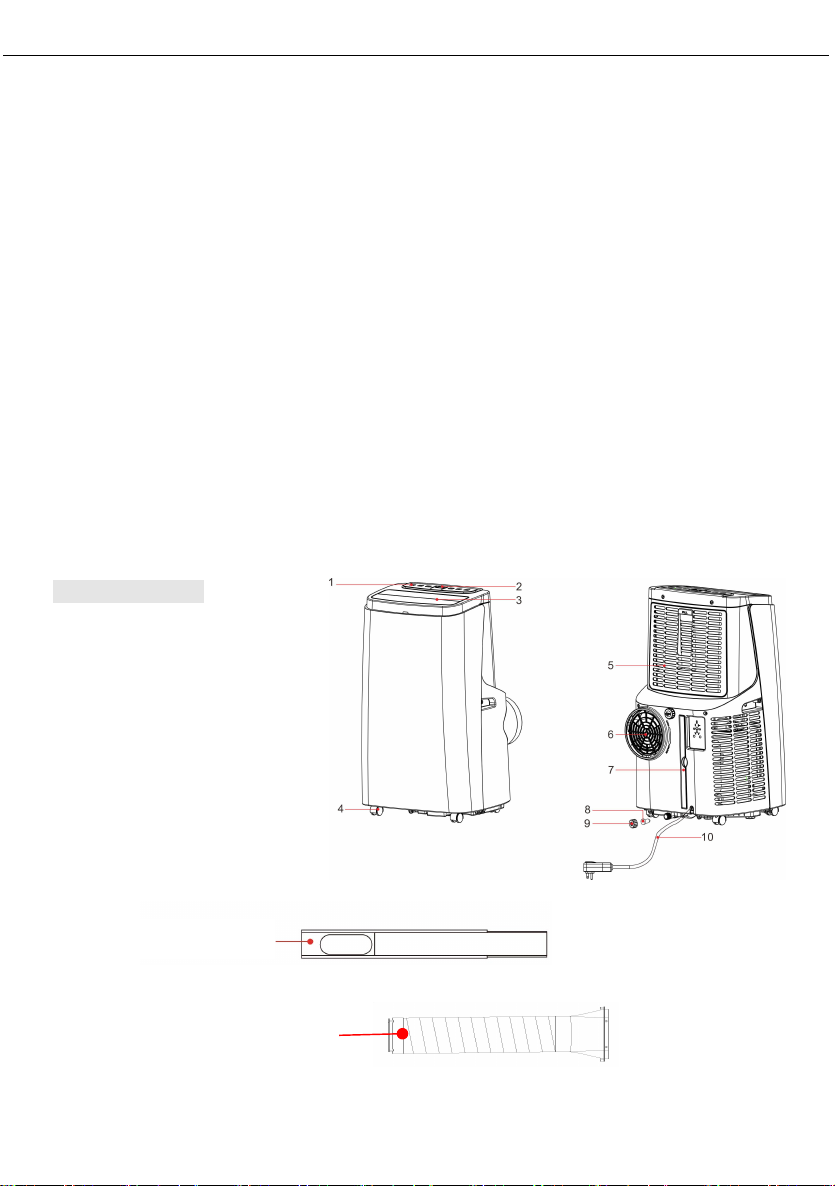

2、 Component

EN

6

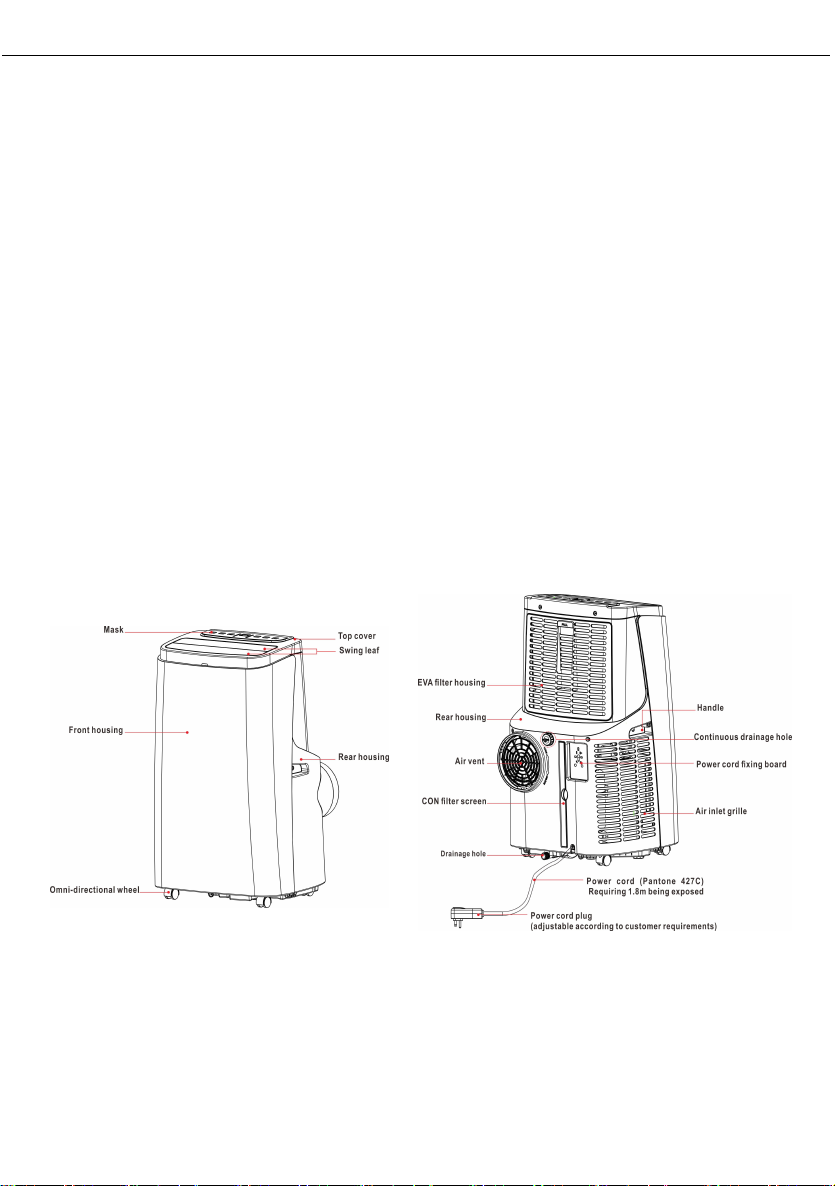

III. Control Setting

1.Control panel operation instructions

1)operation interface:

Exhaust Pipe Assembly

Window Sealing Plate Assembly

1: When the machine is powered on for the first time, the buzzer will play power-on

music, and then the machine will get into standby status.

2: Power Key: press the key to turn on and turn off the machine. In the case of power

on, press the key to turn off the machine; in the case of power off, press the key to

turn on the machine.

3: Mode Selection Key: In the case of power on, press the key to switch between

cooling → fan → dehumidifying mode.

4: Up Key and Down Key: press the two keys to change the setting temperature or

setting time, operate as follows:

While setting temperature, press up key or down key to select the required

temperature (not available in fan or dehumidifying mode).

While setting time, press up key or down key to select the required time.

5: Wind Speed Selection Key:

EN

7

1)In cooling and fan mode, press the key to select high,low wind speed operation.

But limited by

anti-cold conditions, under certain conditions, it may not run according to the set

wind speed.

2)In dehumidifying mode, pressing the key is invalid, and the fan will forcibly choose

low wind speed operation.

6: Timing Key:

In the case of power on, press the key to close timing; in the case of power off, press

the key to open timing.

Press the key, when the timing symbol flashes, press up and down key to select the

required timing value.

Timing values can be set in 1-24 hours and the timing value is adjusted up or down by

one hour.

7: Sleep Mode:

In the cooling Mode,Press the UP and Fan Key to turn on the sleep mode,then the unit

will work on Energy-Saving and quiet type.

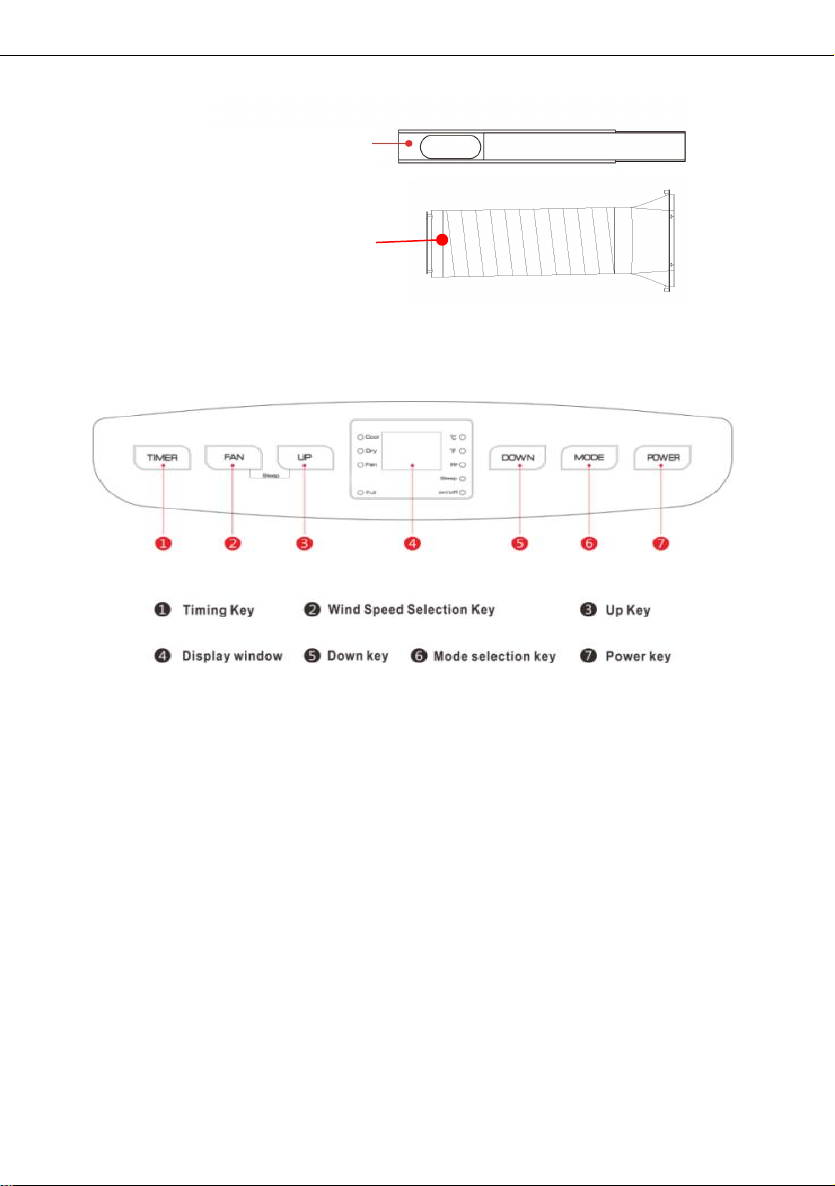

2.operation instructions of remote control

1) The remote control Panel is as follows:

3

1

2

8

7

5

4

6

9

EN

8

IV. Protection function

3.1、Frost Protection Function:

In cooling, dehumidifying or economic power saving mode, if the temperature of

the exhaust pipe is too low, the machine will automatically enter protection status;

if the temperature of the exhaust pipe rises to a certain temperature, it can

automatically revert to normal operation.

3.2、Overflow Protection Function:

When water in the water pan exceeds the warning level, the machine will

automatically sound an alarm, and the "FULL" indicator light will flash. At this

point, you need to move the drainage pipe connecting the machine or the water

outlet to sewer or other drainage area to empty the water (details see

Drainage

Instruction

s at the end of this chapter). After the water is emptied, the machine

will automatically return to the original state.

3.3 Automatic Defrosting (cooling models have this function): The machine has

automatic defrosting function.Defrosting can be achieved through four - way

valve reversing.

3.4、Protection Function of the Compressor

To increase the service life of the compressor, it has a 3-minute delay booting

protection function after the compressor is turned off.

Instructions of key operation of the high-quality remote control are as follows:

1.Power: Press the key to turn on or turn off the machine.

2.Timer: press the key to set timing.

3. Down: press - the key to reduce temperature and timing set value.

4. Mode: press the key to switch between cooling, fan, dehumidifying mode.

5. Up: press + the key to increase temperature and timing set value.

6. Fan: press the key to select high, low wind speed.

7. Sleep Mode: Press the key to turn on the sleep mode.

8. Swing: Press the louver will swing up and down(optional).

9.℃&℉Change:Press to change ℃ and ℉ display .

EN

9

Figure 1

V.Installation and adjustment

Installation:

1.

Warning: before using the mobile air conditioning, keep it upright for at least two hours.

The air conditioning can be easily moved in the room. In the moving process, ensure that the

air conditioning is in the upright position and the air conditioning should be placed on a flat

surface. Do not install and use the air conditioning in the bathroom or other humid

environments.

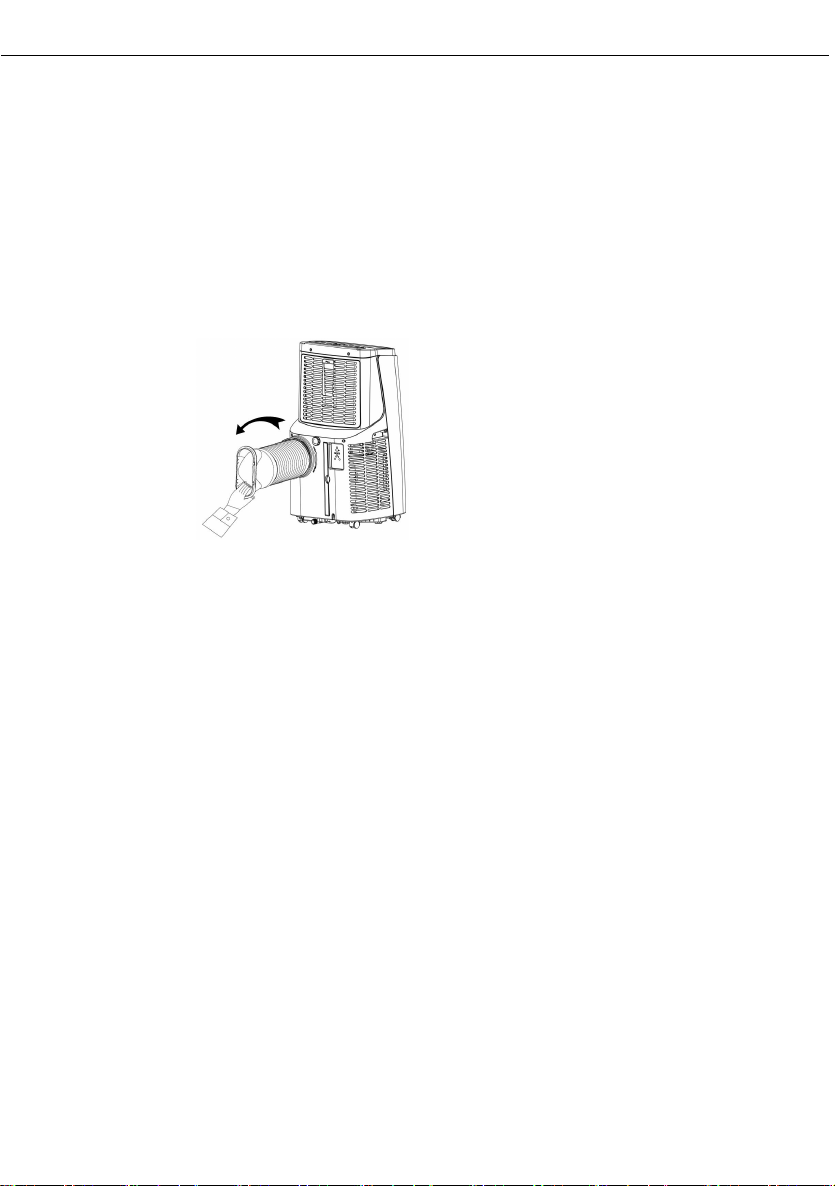

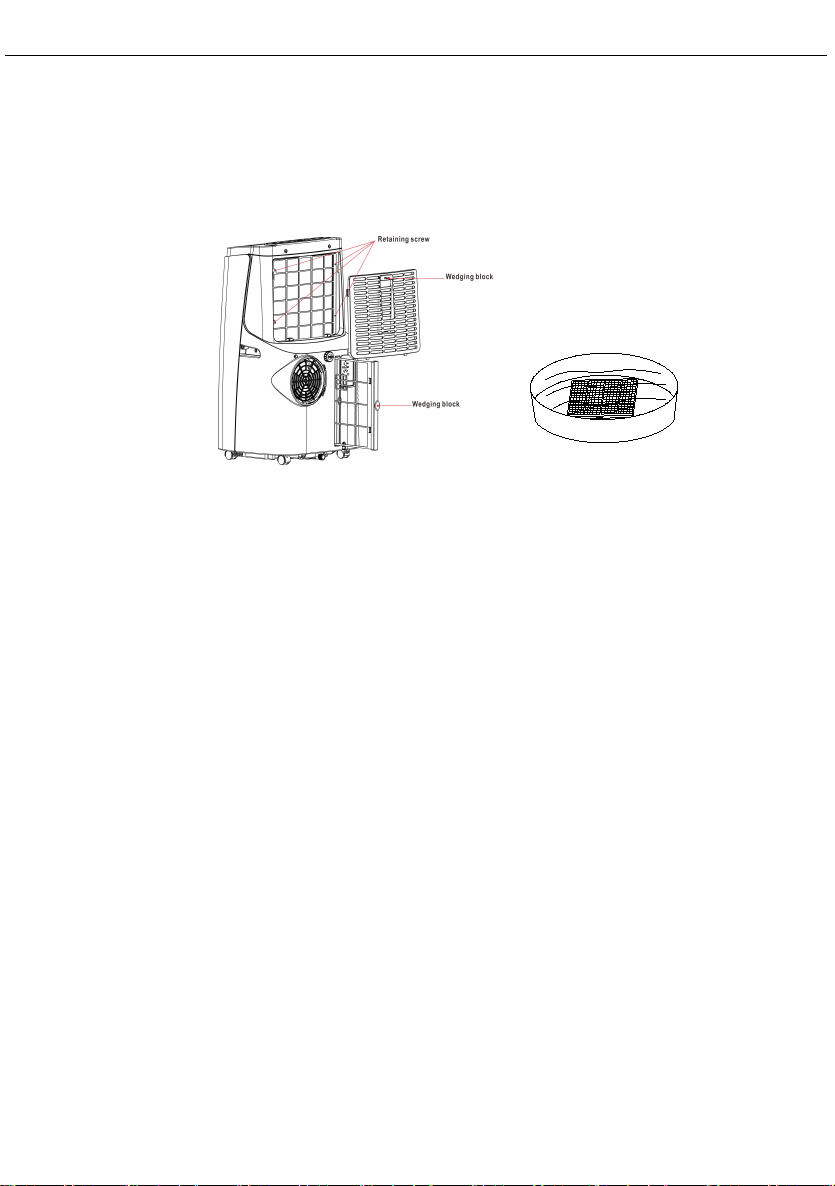

1.1 Install the heat pipe assembly (as shown in Fig.1)

1 ) take out the outer connector assembly and the exhaust pipe assembly, and

remove the plastic bags;

2) insert the heat pipe assembly (the end of the exhaust joint) into the back panel

vent slot (push to the

left) and complete the assembly (as shown in figure 1).

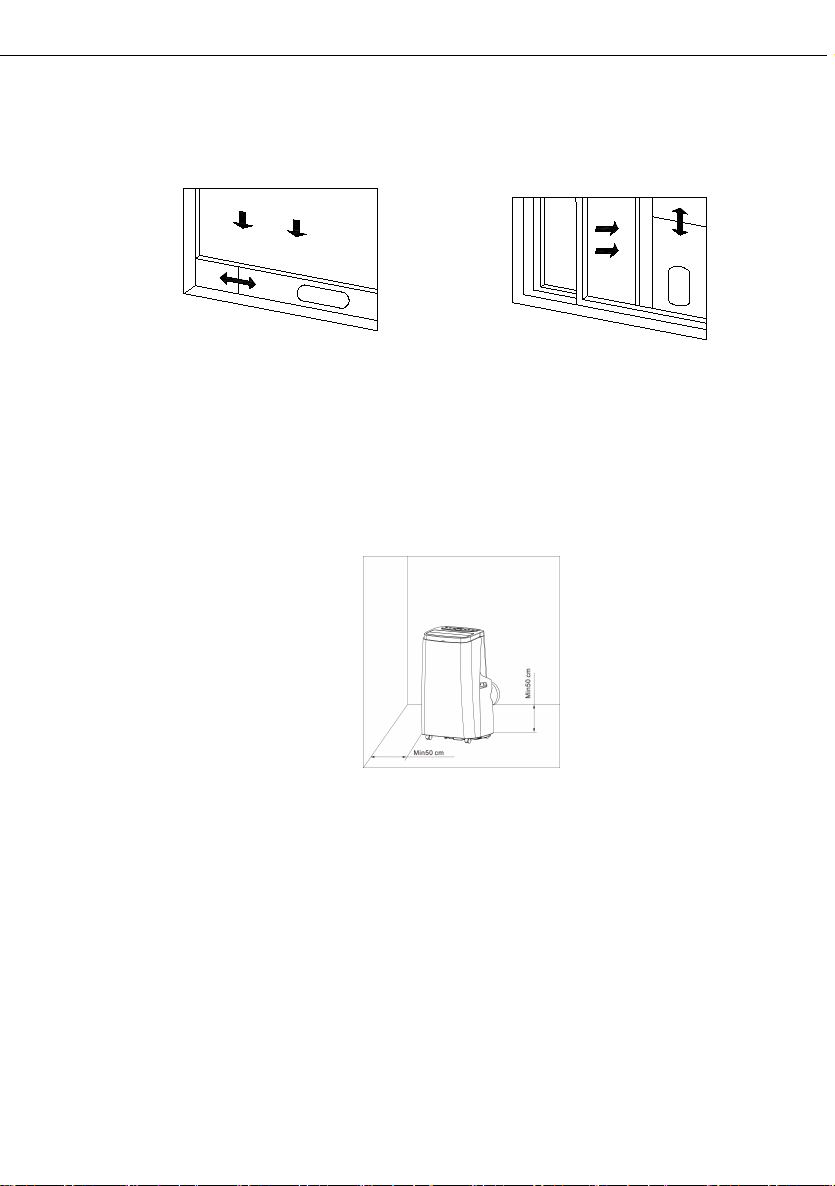

1.2 Installation of window sealing plate components

1)Half open the window,and mount the window sealing plate assembly to the window (as

shown in Fig.2 and

Fig.3).Components can be placed in horizontal and vertical direction.

2)Pull various components of the window sealing plate assembly open, adjust their

opening distance to bring

both ends of the assembly into contact with the window frame, and fix various

components of the

assembly.1.2 Install the window sealing plate assembly

EN

10

Notes:1)the flat end of the exhaust pipe joints must be snapped into place.

2)The pipe cannot be distorted nor has substantial turning (greater than 45 ° ). Keep

the ventilation of the exhaust pipe not blocked.

Figure

1.3 Install the body

Move the machine with installed heat pipe and fittings before the window, and the

1)

distance between the body

and walls or other objects shall be least 50 cm (as shown in Fig.4).

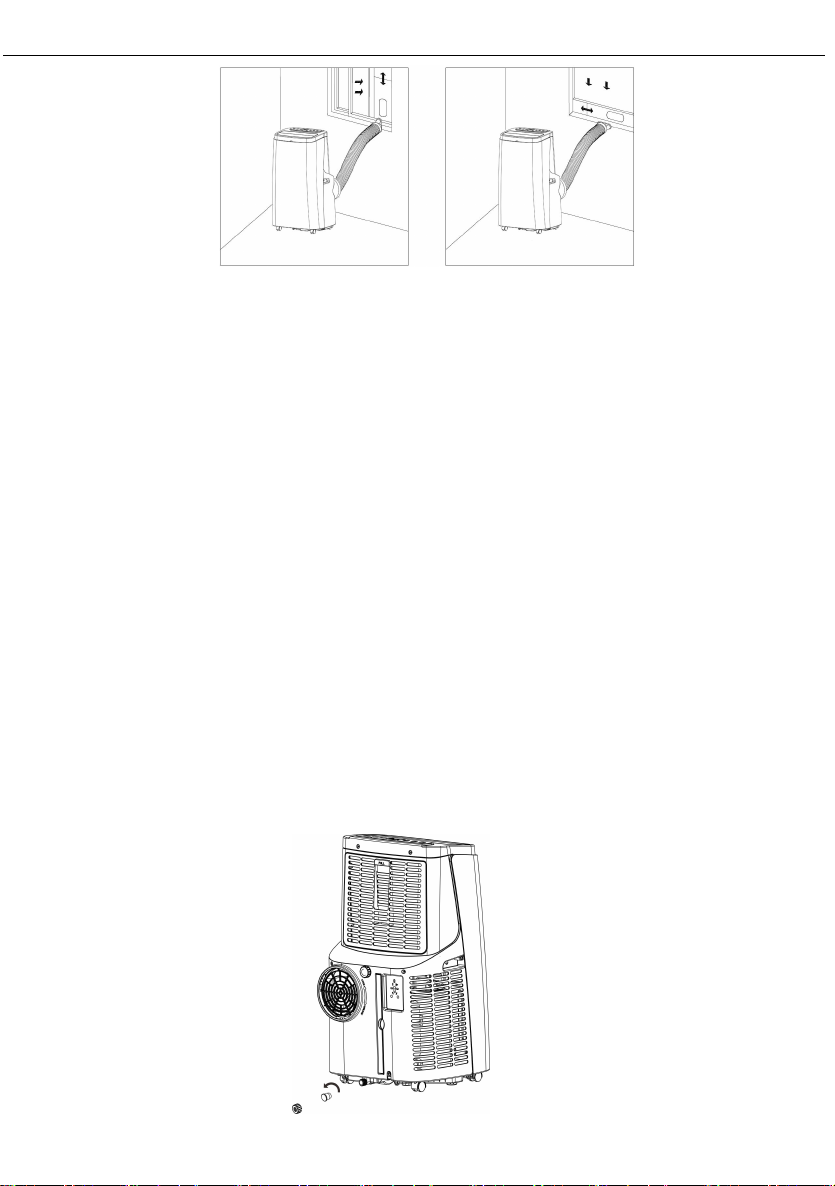

3)Elongate the exhaust pipe and snap the flat end of the exhaust pipe joints into the hole

of the window sealing

plate assembly (as shown in Fig.5 and Fig.6) .

2

Figure

4

Figure

3

Notes:1、the flat end of the exhaust pipe joints must be snapped into place.

3、 The pipe cannot be distorted nor has substantial turning (greater than 45 °). Keep the

ventilation of the exhaust pipe not blocked.

EN

Figure 5 Figure 6

Important Notice:

The length of the exhaust hose shall be 280~1,500mm, and this length is based on the

specifications of the air conditioning. Do not use extension tubes or replace it with other different

hoses, or this may cause a malfunction. Exhaust host must be not blocked; otherwise it may

cause overheating.

VI.Drainage Instructions

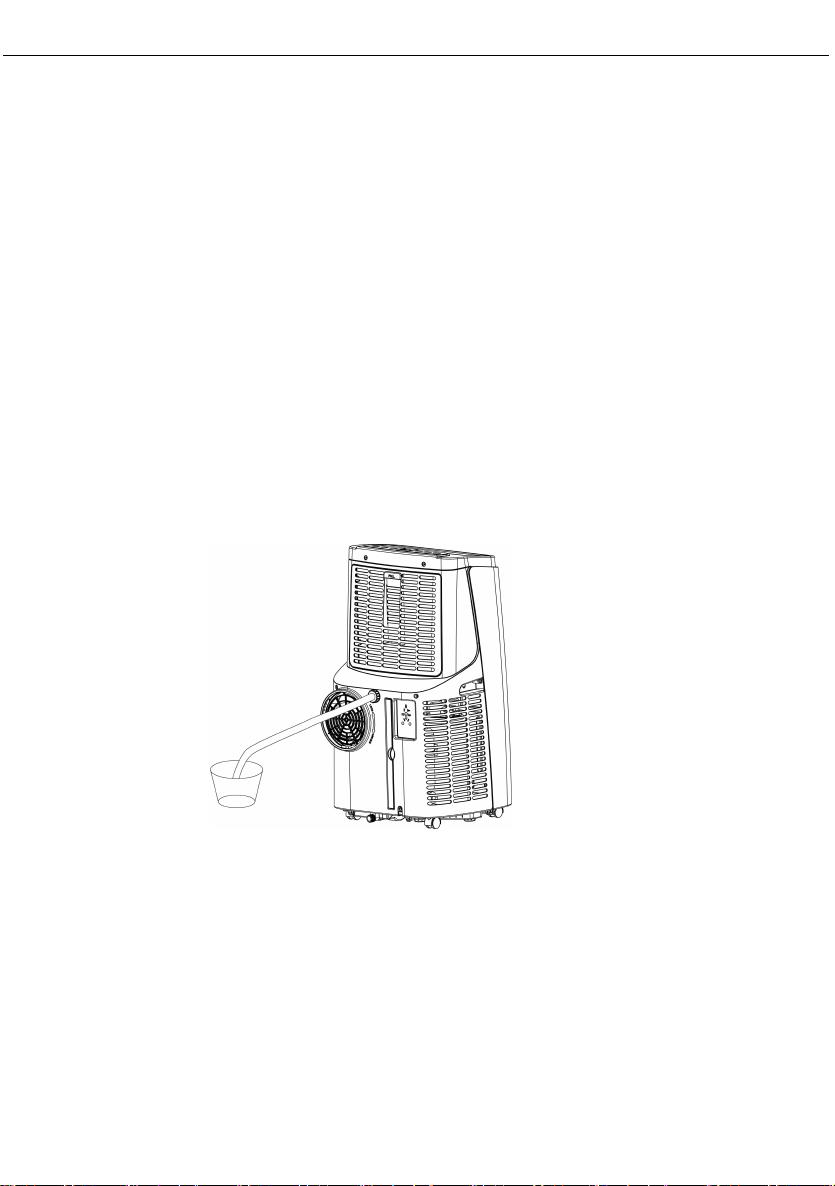

This machine has two drainage methods: manual drainage and continuous drainage.

1.Manual drainage:

1) When the machine stops after the water is full, turn off the machine power and unplug

the power plug.

Notes:Please move the machine carefully, so as not to spill the water in the water

pan at the bottom of the

body.

2) Place the water container below the side water outlet behind the body.

3) Unscrew the drainage cover and unplug the water plug, the water will automatically

flow into the water container.

11

EN

12

VII. Maintenance

Cleaning: before cleaning and maintenance, turn off the machine and unplug the plug.

1.Clean the surface

Clean with surface of machine with a wet soft cloth. Don't use chemicals, such as

benzene, alcohol, gasoline, etc; otherwise, the surface of the air conditioning will be

Notes:1)Keep the drainage cover and the water plug properly.

2)During drainage, the body can be tilted slightly backwards.

3)If the water container cannot hold all the water, before the water container is

full, stuff the water outlet

with the water plug as soon as possible to prevent water from flowing to the

floor or the carpet.

4)When the water is discharged, stuff the water plug, and tighten the drainage

cover

2.Continuous drainage (Optional) (only applicable to dehumidifying mode), as shown in

figure:

1) Unscrew the drainage cover, and unplug the water plug.

2) Set the drainage pipe into the water outlet.

3) Connect the drainage pipe to the bucket.

EN

13

damaged or even the whole machine will bedamaged.

2.Clean the filter screen

If the filter screen is clogged with dust, and the effectiveness of the air conditioning is

reduced, be sure to clean the filter screen once every two weeks.

3.Clean the upper filter screen frame

1)Unscrew one screw fixed by EVA filter net and back shell with screwdriver, and take out EVA

filter net.

2)Put the EVA filter screen into warm water with neutral detergent (about 40℃ / 104℉) and

dry it in the shade after rinsing clean.

VIII.Unit Storage:

1:Unscrew the drainage cover, unplug the water plug, and discharge the water in the water pan

into other water containers or directly tilt the body to discharge the water into other containers.

2:Turn on the machine, adjust it to low-wind ventilation mode, and maintain this state until the

drainage pipe becomes dry, so as to keep the inside of the body in a dry state and prevent it

from mildewing.

3:Turn off the machine, unplug the power plug, and wrap the power cord around the wrapping

post; install the water plug and the drainage cover.

4:Remove the exhaust pipe and keep it properly.

5:Cover the air conditioning with a plastic bag. Put the air conditioning in a dry place, keep it out

EN

14

of the reach of children, and take dust control measures.

6:Remove batteries of the remote control and keep them properly.

Note: ensure that the body is placed in a dry place and keep all machine components properly.

IX.Troubleshooting

1. Information on servicing

1) Checks to the area

Prior to beginning work on systems containing flammable refrigerants, safety checks are

necessary to ensure that the risk of ignition is minimised. For repair to the refrigerating

system, the following precautions shall be complied with prior to conducting work on the

system.

2) Work procedure Work shall be undertaken under a controlled procedure so as to minimise

the risk of a flammable gas or vapour being present while the work is being performed.

3) General work area All maintenance staff and others working in the local area shall be

instructed on the nature of work being carried out. Work in confined spaces shall be avoided.

The area

around the workspace shall be sectioned off. Ensure that the conditions within the area

have been made safe by control of flammable material.

4) Checking for presence of refrigerant The area shall be checked with an appropriate

refrigerant detector prior to and during work, to ensure the technician is aware of potentially

flammable atmospheres. Ensure that the leak detection equipment being used is suitable for

use with flammable refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

5) Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration equipment or any associated parts,

appropriate fire extinguishing equipment shall be available to hand. Have a dry powder or

CO2 fire extinguisher adjacent to the charging area.

6) No ignition sources

No person carrying out work in relation to a refrigeration system which involves exposing

any pipe work that contains or has contained flammable refrigerant shall use any sources

of ignition in such a manner that it may lead to the risk of fire or explosion. All possible

ignition sources, including cigarette smoking, should be kept sufficiently far away from the

EN

15

site of installation, repairing, removing and disposal, during which flammable refrigerant

can possibly be released to the surrounding space. Prior to work taking place, the area

around the equipment is to be surveyed to make sure that there are no flammable

hazards or ignition risks. “No Smoking” signs shall be displayed.

7) Ventilated area

Ensure that the area is in the open or that it is adequately ventilated before breaking into

the system or conducting any hot work. A degree of ventilation shall continue during the

period that the work is carried out. The ventilation should safely disperse any released

refrigerant and preferably expel it externally into the atmosphere.

8) Checks to the refrigeration equipment

Where electrical components are being changed, they shall be fit for the purpose and to

the correct specification. At all times the manufacturer’s maintenance and service

guidelines shall be followed. If in doubt consult the manufacturer’s technical department

for assistance.

The following checks shall be applied to installations using flammable refrigerants:

– The charge size is in accordance with the room size within which the refrigerant

containing parts are installed;

– The ventilation machinery and outlets are operating adequately and are not obstructed;

– If an indirect refrigerating circuit is being used, the secondary circuit shall be checked

for the presence of refrigerant;

– Marking to the equipment continues to be visible and legible. Markings and signs that

are illegible shall be corrected;

– Refrigeration pipe or components are installed in a position where they are unlikely to

be exposed to any substance which may corrode refrigerant containing components,

unless the components are constructed of materials which are inherently resistant to

being corroded or are suitably protected against being so corroded.

9) Checks to electrical devices

Repair and maintenance to electrical components shall include initial safety checks and

component inspection procedures. If a fault exists that could compromise safety, then no

electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If the

fault cannot be corrected immediately but it is necessary to continue operation, an

adequate temporary solution shall be used. This shall be reported to the owner of the

equipment so all parties are advised.

EN

16

Initial safety checks shall include:

• That capacitors are discharged: this shall be done in a safe manner to avoid possibility

of sparking;

• That there no live electrical components and wiring are exposed while charging,

recovering or purging the system;

• That there is continuity of earth bonding.

Repairs to sealed components

2.

1) During repairs to sealed components, all electrical supplies shall be disconnected from

the equipment being worked upon prior to any removal of sealed covers, etc. If it isabsolutely

necessary to have an electrical supply to equipment during servicing, then a permanently

operating form of leak detection shall be located at the most critical point to warn of a

potentially hazardous situation.

2) Particular attention shall be paid to the following to ensure that by working on electrical

components, the casing is not altered in such a way that the level of protection is affected.

This shall include damage to cables, excessive number of connections, terminals not made to

original specification, damage to seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the

purpose of preventing the ingress of flammable atmospheres. Replacement parts shall be in

accordance with the manufacturer’s specifications.

NOTE: The use of silicon sealant may inhibit the effectiveness of some types of leak

detection equipment. Intrinsically safe components do not have to be isolated prior to working

on them.

3. Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring

that this will not exceed the permissible voltage and current permitted for the equipment

in use.

Intrinsically safe components are the only types that can be worked on while live in the

presence of a flammable atmosphere. The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Other parts may

result in the ignition of refrigerant in the atmosphere from a leak.

EN

17

4. Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration,

sharp edges or any other adverse environmental effects. The check shall also take into

account the effects of aging or continual vibration from sources such as compressors or

fans.

5. Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching for or

detection of refrigerant leaks. A halide torch (or any other detector using a naked flame)

shall not be used.

6. Leak detection methods

The following leak detection methods are deemed acceptable for systems containing

flammable refrigerants.

Electronic leak detectors shall be used to detect flammable refrigerants, but the

sensitivity may not be adequate, or may need re-calibration. (Detection equipment shall

be calibrated in a refrigerant-free area.) Ensure that the detector is not a potential source

of ignition and is suitable for the refrigerant used. Leak detection equipment shall be set

at a percentage of the LFL of the refrigerant and shall be calibrated to the refrigerant

employed and the appropriate percentage of gas (25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use

of detergents containing chlorine shall be avoided as the chlorine may react with the

refrigerant and corrode the copper pipe-work.

If a leak is suspected, all naked flames shall be removed/ extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be

recovered from the system, or isolated (by means of shut off valves) in a part of the

system remote from the leak. Oxygen free nitrogen (OFN) shall then be purged through

the system both before and during the brazing process.

7. Removal and evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose –

conventional procedures shall be used. However, it is important that best practice is

followed since flammability is a consideration. The following procedure shall be adhered

EN

18

to:

• Remove refrigerant;

• Purge the circuit with inert gas;

• Evacuate;

• Purge again with inert gas;

• Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. The system

shall be “flushed” with OFN to render the unit safe. This process may need to be

repeated several times. Compressed air or oxygen shall not be used for this task.

Flushing shall be achieved by breaking the vacuum in the system with OFN and

continuing to fill until the working pressure is achieved, then venting to atmosphere, and

finally pulling down to a vacuum. This process shall be repeated until no refrigerant is

within the system. When the final OFN charge is used, the system shall be vented down

to atmospheric pressure to enable work to take place. This operation is absolutely vital if

brazing operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and there

is ventilation available.

8. Charging procedures

In addition to conventional charging procedures, the following requirements shall be

followed.

– Ensure that contamination of different refrigerants does not occur when using charging

equipment. Hoses or lines shall be as short as possible to minimise the amount of

refrigerant contained in them.

– Cylinders shall be kept upright.

– Ensure that the refrigeration system is earthed prior to charging the system with

refrigerant.

– Label the system when charging is complete (if not already).

– Extreme care shall be taken not to overfill the refrigeration system.

Prior to recharging the system it shall be pressure tested with OFN. The system shall be

leak tested on completion of charging but prior to commissioning. A follow up leak test

shall be carried out prior to leaving the site.

EN

19

9. Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar

with the equipment and all its detail. It is recommended good practice that all refrigerants

are recovered safely. Prior to the task being carried out, an oil and refrigerant sample

shall be taken in case analysis is required prior to re-use of reclaimed refrigerant. It is

essential that electrical power is available before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure ensure that:

• Mechanical handling equipment is available, if required, for handling

refrigerant cylinders;

• All personal protective equipment is available and being used correctly;

• The recovery process is supervised at all times by a competent person;

• Recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from

various parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with manufacturer's instructions.

h) Do not overfill cylinders. (No more than 80 % volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been filled correctly and the process completed, make sure

that the cylinders and the equipment are removed from site promptly and all isolation

valves on the equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system unless it

has been cleaned and checked.

1

0. Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of

refrigerant. The label shall be dated and signed. Ensure that there are labels on the

equipment stating the equipment contains flammable refrigerant.

EN

20

11. Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is

recommended good practice that all refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant

recovery cylinders are employed. Ensure that the correct number of cylinders for holding

the total system charge is available. All cylinders to be used are designated for the

recovered refrigerant and labelled for that refrigerant (i.e. special cylinders for the

recovery of refrigerant). Cylinders shall be complete with pressure relief valve and

associated shut-off valves in good working order. Empty recovery cylinders are

evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions

concerning the equipment that is at hand and shall be suitable for the recovery of

flammable refrigerants. In addition, a set of calibrated weighing scales shall be available

and in good working order. Hoses shall be complete with leak-free disconnect couplings

and in good condition. Before using the recovery machine, check that it is in satisfactory

working order, has been properly maintained and that any associated electrical

components are sealed to prevent ignition in the event of a refrigerant release. Consult

manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct

recovery cylinder, and the relevant Waste Transfer Note arranged. Do not mix

refrigerants in recovery units and especially not in cylinders.

If compressors or compressor oils are to be removed, ensure that they have been

evacuated to an acceptable level to make certain that flammable refrigerant does not

remain within the lubricant. The evacuation process shall be carried out prior to returning

the compressor to the suppliers. Only electric heating to the compressor body shall be

employed to accelerate this process. When oil is drained from a system, it shall be

carried out safely.

Fuse parameters of the machine

Type: 5ET or SMT Voltage: 250V Current: 3.15 A

A. Unit Storage:

1:Unscrew the drainage cover, unplug the water plug, and discharge the water in the water

pan into other water

containers or directly tilt the body to discharge the water into other containers.

EN

21

it out of the reach of children, and take dust control measures.

6:Remove batteries of the remote control and keep them properly.

2:Turn on the machine, adjust it to low-wind ventilation mode, and maintain this state until the

drainage pipe becomes

dry, so as to keep the inside of the body in a dry state and prevent it from mildewing.

3:Turn off the machine, unplug the power plug, and wrap the power cord around the wrapping

post; install the water

plug and the drainage cover.

4:Remove the exhaust pipe and keep it properly.

5:Cover the air conditioning with a plastic bag. Put the air conditioning in a dry place, keep

Note: ensure that the body is placed in a dry place and keep all machine components properly.

IX.Troubleshooting

Do not repair or disassemble the air conditioning by yourself. Unqualified repair will lead

to failure of the

Problems Reasons Solutions

The air

conditioning

does not work.

warranty card, and may cause damage to users or their properties.

There is no electricity.

The overflow indicator displays

"FL".

The ambient temperature is too

low or too high

In cooling mode, the room

temperature is lower than the set

temperature; in heating mode, the

room temperature is higher than

the set temperature.

In dehumidification mode, the

ambient temperature is low.

There is direct sunlight. Pull the Curtain.

Turn it on after connecting it to a socket

with electricity.

Discharge the water inside.

Recommend to use the machine in at

the temperature of 7-35 ℃ (44-95 ℉).

Change the set temperature.

The machine is placed in a room with an

ambient temperature of greater than 17

℃ (62 ℉).

EN

22

The cooling

effect is not

good

Big Noise

compressor

does not work.

The remote

control does

not work.

Displays 'E1'.

Displays 'E2' The room temperature sensor is

Doors or windows are open; there

are a lot of people; or in cooling

mode, there are other sources of

heat.

The filter screen is dirty. Clean or replace the filter screen.

The air inlet or outlet is blocked. Clear obstructions.

The air conditioning is not placed

on a flat surface.

Overheat protection starts.

The distance between the

machine and the remote control is

too far.

The remote control is not aligned

with the direction of the remote

control receiver.

Batteries are dead. Replace batteries.

The pipe temperature sensor is

abnormal.

abnormal.

Close doors and windows, and add new

air conditioning.

Put the air conditioning on a flat and

hard place (to reduce noise).

Wait for 3 minutes until the temperature

is lowered, and then restart the

machine.

Let the remote control get close to the

air conditioning, and make sure that the

remote control directly faces to the

direction of the remote control receiver.

Check the pipe temperature sensor and

related circuitry.

Check the room temperature sensor and

related circuitry.

please contact the

Note: If problems not listed in the table occur or recommended solutions do not work,

professional service organization.

EN

23

Treatment: Don't put the abandoned machine with other unsorted waste together.

Such waste shall be placed separately for other special use.

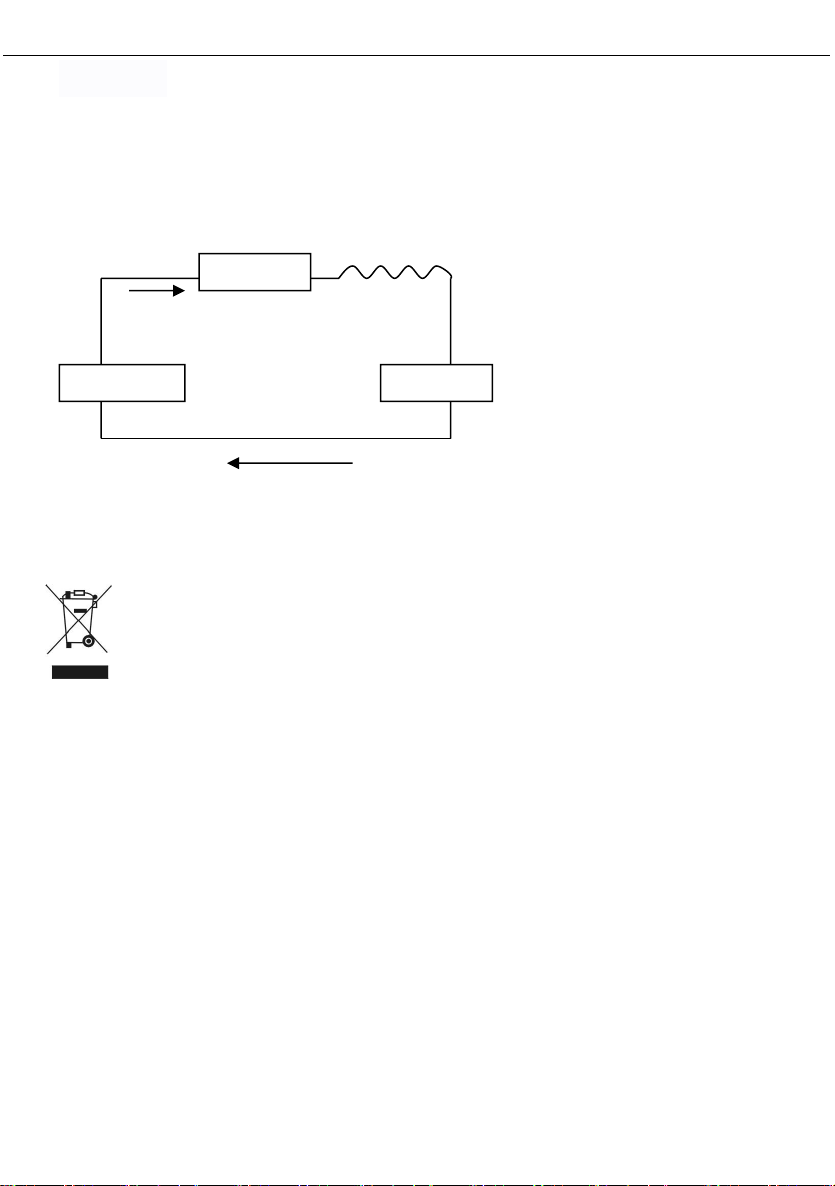

X.Addendum

Schematic diagram for air conditioning

(The specific technical parameters of the machine shall be subject to the

nameplate on the product)

Capillar

Conden

Compres

Evapora

DE

24

Inhalt

I. Zu Beachten........................................................................................25

II. Eigenschaften und Komponenten........................................................28

III. Kontrolleinstellungen.............................................................................29

IV. Schutzfunktionen...................................................................................31

V. Installation und Einstellung....................................................................31

VI. Anweisungen zum Ablaufen..................................................................34

VII. Wartung..................................................................................................35

VIII. Lagerung des Gerätes:............................................................................36

IX. Problembehebung...................................................................................42

X. Anhang....................................................................................................44

Das in dieser mobilen Klimaanlagen verwendete Kältemittel ist der

umweltfreundliche Kohlenwasserstoff R290, der geruchlos ist und im Vergleich zu

alternativen Kältemitteln ozonfrei und mit sehr geringer Wirkung ist.Bitte lesen Sie

die Gebrauchsanweisung vor Gebrauch und Reparatur sorgfältig durch.

Die Zeichnungen in diesem Handbuch stimmen möglicherweise nicht mit den

tatsächlichen physischen Objekten überein. Bitte beachten Sie die physischen

Objekte.

DE

25

I. Zu Beachten

Warnungshinweise:

1. Keine Gegenstände, außer den vom Hersteller erlaubten, zur

Beschleunigung des Abtauprozesses verwenden.

2. Das Gerät sollte nur in Räumen ohne dauernde Zündquellen (z.

B. offene Flammen, ein eingeschaltetes Gasgerät oder einen

Elektroheizer) aufbewahrt werden.

3. Nicht anbohren oder anbrennen.

4. Denken Sie daran, dass Kältemittel geruchlos sind

5. Das Gerät darf nur in Räumen betrieben werden, die größer

als 12 m² sind.

6. Halten Sie alle erforderlichen Lüftungsöffnungen frei von

Hindernissen;

7. Die Wartung darf nur gemäß den Hinweisen des Herstellers

durchgeführt werden.

8. Das Gerät ist in einem gut belüfteten Raum zu lagern, in dem

die Raumgröße der für den Betrieb vorgesehenen Raumfläche

entspricht.

9. Jede Person, die an einen Kältemittelkreislauf arbeitet oder in

diesen eindringt, sollte über ein aktuell gültiges Zertifikat einer von der

Industrie akkreditierten Bewertungsbehörde verfügen, das ihre

Kompetenz zum sicheren Umgang mit Kältemitteln gemäß einer von

der Industrie anerkannten Bewertungsspezifikation bestätigt.

10. Die Wartung darf nur gemäß den Anweisungen des

Geräteherstellers durchgeführt werden. Wartungs- und

Reparaturarbeiten, die die Hilfe anderer Fachkräfte erfordern, müssen

unter der Aufsicht der für den Umgang mit brennbaren Kältemitteln

zuständigen Person durchgeführt werden.

11. Alle Arbeitsvorgänge, die die Sicherheit betreffen, dürfen nur

von beähigten Personen durchgeführt werden.

DE

26

Hinweise:

*Die Klimaanlage ist nur für den Innenbereich und nicht für andere

Anwendungen geeignet.

*Beachten Sie bei der Installation der Klimaanlage die Regeln der

örtlichen Netzanbindung und vergewissern Sie sich, dass diese

ordnungsgemäß geerdet ist. Wenn Sie Fragen zur elektrischen

Installation haben, befolgen Sie die Anweisungen des Herstellers und

lassen Sie das Gerät gegebenenfalls von einem Elektrofachmann

installieren.

*Stellen Sie das Gerät an einem flachen und trockenen Ort auf und

halten Sie einen Abstand von mehr als 50 cm zwischen dem Gerät und

den umgebenden Gegenständen oder Wänden ein.

*Vergewissern Sie sich nach der Installation der Klimaanlage, dass der

Netzstecker intakt und fest in die Steckdose eingesteckt ist, und

verlegen Sie das Netzkabel ordnungsgemäß, um zu verhindern, dass

jemand darüber stolpert oder den Stecker herauszieht.

*Stecken Sie keine Gegenstände in den Luftein- und -auslass der

Klimaanlage. Halten Sie den Luftein- und -auslass von Hindernissen.

*Bei der Verlegung von Abflussrohren ist darauf zu achten, dass die

Abflussrohre richtig angeschlossen und nicht verzogen oder gebogen

sind.

*Zupfen Sie bei der Anpassung der oberen und unteren Windleitstreifen

des Luftauslasses diese vorsichtig mit den zupfen, um eine

Beschädigung der Windleitstreifen zu vermeiden.

*Achten Sie beim Bewegen der Maschine darauf, dass sie sich in

aufrechter Position befindet.

*Das Gerät sollte von Benzin, brennbaren Gasen, Öfen und anderen

Wärmequellen ferngehalten werden.

*Demontieren, überholen und modifizieren Sie die Maschine nicht

willkürlich, da es sonst zu einer Fehlfunktion der Maschine oder gar zu

Personen- und Sachschäden kommen kann. Um Gefahren zu

vermeiden, sollten Sie bei einem Maschinenausfall den Hersteller oder

einen anderen Fachmann bitten, die Maschine zu reparieren.

*Installieren und benutzen Sie die Klimaanlage nicht im Badezimmer

oder in anderen feuchten Umgebungen.

*Ziehen Sie nicht den Stecker, um das Gerät auszuschalten.

DE

*Stellen Sie keine Tassen oder andere Gegenstände auf das Gerät, um

zu verhindern, dass Wasser oder andere Flüssigkeiten in die

Klimaanlage gelangen.

*Verwenden Sie keine Insektizidsprays oder andere brennbare

Substanzen in der Nähe der Klimaanlage.

*Wischen oder waschen Sie die Klimaanlage nicht mit chemischen

Lösungsmitteln wie Benzin und Alkohol. Wenn Sie die Klimaanlage

reinigen müssen, müssen Sie die Stromversorgung trennen und sie mit

einem halbnassen, weichen Tuch reinigen. Wenn das Gerät stark

verschmutzt ist, schrubben Sie es mit einem milden Reinigungsmittel.

*Das Gerät kann von Kindern ab 8 Jahren und Personen mit

eingeschränkter körperlicher, sensorischer oder geistiger

Leistungsfähigkeit benutzt werden, wenn sie aufmerksam beaufsichtigt

werden oder Einweisung in die Benutzung des Gerätes erhalten haben

und die damit verbundenen Gefahren verstehen. Kinder dürfen nicht mit

dem Gerät spielen. Reinigung und Wartung dürfen nicht von Kindern

ohne Aufsicht durchgeführt werden.

Ist das Netzkabel beschädigt, muss es durch den Hersteller, seinen

Kundendienst oder ähnlich qualifizierte Personen ersetzt werden, um

eine Gefährdung zu vermeiden.

Das Gerät ist gemäß den nationalen Verkabelungsvorschriften zu

installieren.

Betreiben Sie Ihre Klimaanlage nicht in einem nassen Raum wie einem

Badezimmer oder einer Waschküche.

Transport, Kennzeichnung und Lagerung von Geräten

1. Transport von Ausrüstungen, die brennbare Kältemittel enthalten

Einhaltung der Transportbestimmungen

2. Kennzeichnung der Ausrüstung unter Verwendung von Zeichen

Einhaltung der örtlichen Bestimmungen

3. Entsorgung von Geräten, die brennbare Kältemittel enthalten

Siehe nationale Bestimmungen

4. Aufbewahrung von verpackten (unverkauften) Geräten

Die Lagerung von Geräten muss in Übereinstimmung mit den

Anweisungen des Herstellers erfolgen

5. Aufbewahrung von verpackten (unverkauften) Geräten

Die Schutzverpackung zur Aufbewahrung so beschaffen sein, das seine

mechanische Beschägung an dem verpackten Gerät keine Leckage

27

DE

des kältemittelkreislaufs zur Folge hat.

Die maximale Anzahl von Geräten oder Anlagenteilen, die zusammen

aufbewahrt warden, wird von den örtlichen Bestimmungen festgelegt.

II. Eigenschaften und Komponenten

1. Eigenschaften

*Brandneues Erscheinungsbild, kompakte Struktur, glatte Linien, einfache und

großzügige Form.

*Funktionen Kühlung, Entfeuchtung, Luftzufuhr und kontinuierliche Entwässerung

*Die Outdoor-Schnittstelle ist hoch eingestellt, um die Montage der Anlage und

den glatten Abfluss der Wärmeleitung aufrecht zu erhalten.

*Ein LED-Bedienfeld, schön und modisch, mit hochwertiger Fernbedienung und

einem benutzerfreundlichen Design.

*Luftfiltrationsfähigkeit.

*Zeitschaltfunktion.

*Schutzfunktionen des automatischen Wiederanlaufs des Kompressors nach drei

Minuten, eine Vielzahl anderer Schutzfunktionen.

Die maximale Betriebstemperatur der Klimaanlage

Kühlung: 35/24℃; Heizung:20/12 ℃; Temperaturbereich: 7-35℃.

2. Komponenten:

TEILENAMEN

1. Bedientafel

2. LED Sichtfenster

3. Lufteinlass

4. Räder

Stützschale

5. Rahmen für den oberen Filter

6. Öffnung für das Abluftrohr

7. Abluftrohr

8. Gummistöpsel

9. Knopf für die Entwässerung

10.Kabel

Abluftanlage

Fensterdichtungsplatte

排 热 管

28

Loading...

Loading...