Hans Pausch Tomo-2 User manual

OPERATING INSTRUCTIONS

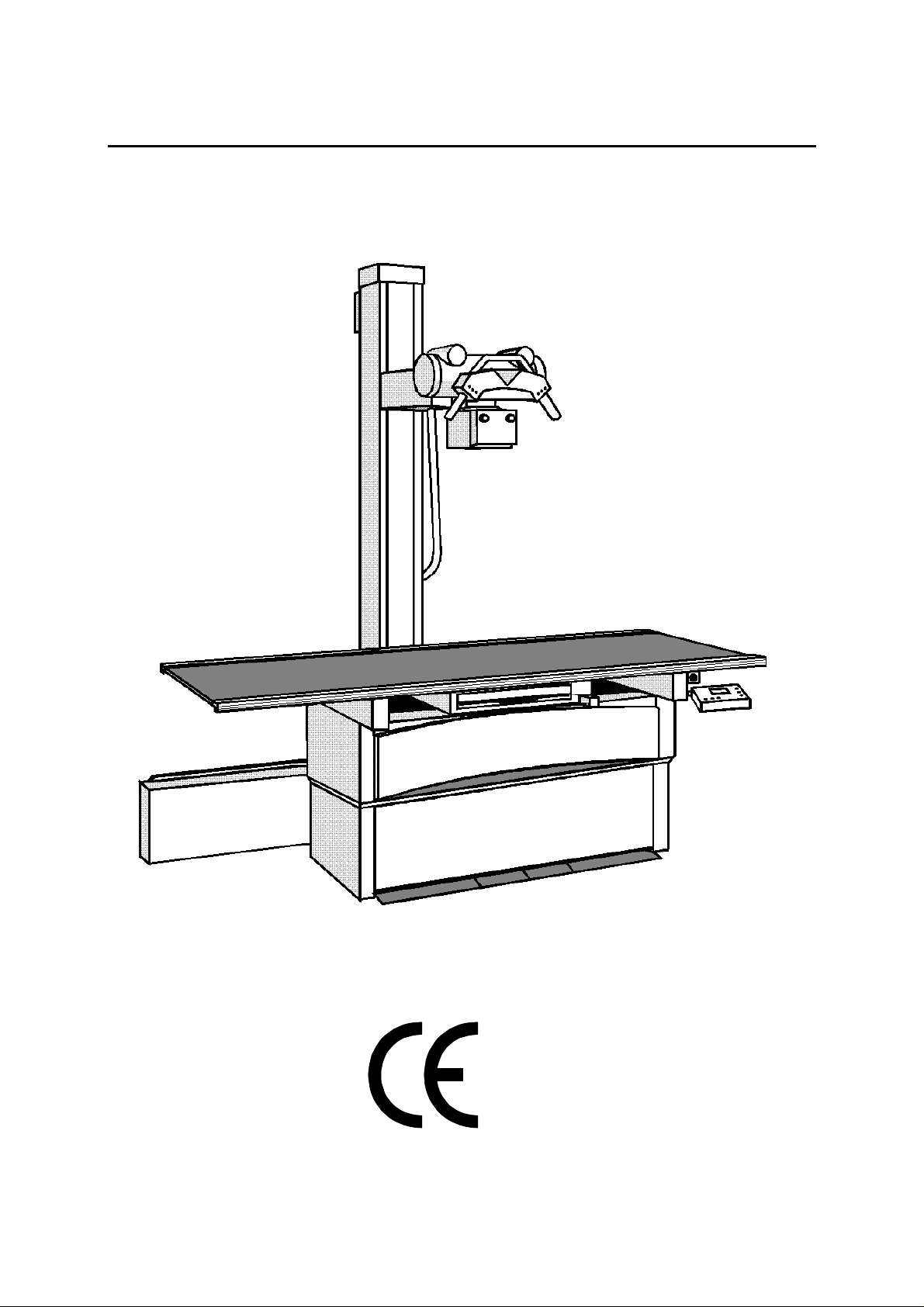

Combi Elevator Tomo-2

0125

___________________________________________________________________________________________________

English Edition

07/98 - 1 of 24- 0628 7324

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. D-91056 Erlangen ALL RIGHTS RESERVED Ru

CONTENTS Page

Technical Safety Procedures

- Regulations 3

Product Safety

- Electrical safety 4

- Mechanical safety 4

- Danger of Injury 4

- X-Ray Protection. 5

- Explosion protection 6

- Interference suppression 6

- Classification of product 6

- EC Conformity 6

- Environment condition 6

- Disposal of equipment 6

Design Features

- Conception 7

General

- Brief Description 8

- Range of Application 9

Installation

- Floor Space Required 10

- Room Height 10

- Power 10

- Mains 10

- AL- weakening equivalent 10

Operating Elements

- Arrangement 11

- Meaning of Symbols/Function 12

- Adjustment of the exposure position/exposure 17

- Tomo exposure 19

- Optional accessories 20

Maintenance

- Important note 22

- Operator`s service and maintenance 22

- Periodic maintenance 22

- Cleaning 22

- Disinfection 23

- The Council Directive 93/42EEC on Medical Devices 23

Location of Name Plate

- Labeling 24

0628 7324 - 2 of 24- 07/98

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Important Note:

To ensure proper operation of this product it is essential that the service personnel is familiar with the "Operating Instructions" which should be studied carefully

before use.

Special attention is to be given to the chapter "Safety Notes".

The equipment must be used in accordance with the safety procedures described below, and must not be used for purposes other than those for which it

was designed. The equipment may only be used by persons having recognized

qualification, including adequate training in radiation protection, authorizing them to

perform the examination or treatment carried out.

It is the responsibility of the user to ensure that the government regulations are

observed in the installation and operation of the equipment.

Technical safety note:

Regulations

If legal regulations govern the operation of the above equipment, it is the responsibility of the operator to observe them.

For the safety of patients, operators and others, as well the efficient functioning

of the equipment it is necessary to have periodic service inspections at 12-month

intervals according to the maintenance schedule. Please apply to your service organisation for inspection and maintenance.

Inspections intervals must by all means meet the requirements of the respective

legislation or government regulations.

Changes and additions to the product must comply with the relevant legislation

as well as with the accepted standards of good manufacturing practice.

As manufacturer of electromedical systems, we assume responsibility for

the safety of the equipment only if maintenance, repairs and changes are carried

out exclusively by us or third parties expressly authorised by us to do so, and if

defective parts relating to the safety of the equipment are replaced by genuine

spare parts.

We recommend that the service personnel is being asked to issue a certificate

specifying the kind and extend of things or work ranges. The certificate should

also show the date of repair, the name of the service company and the signature

of the technician.

07/98 - 3 of 24- 0628 7324

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. D-91056 Erlangen ALL RIGHTS RESERVED Ru

Before operating the equipment, the operator must check all devices concerning

the safe and efficient functioning.

Please see daily check in chapter Maintenance.

If the user of this equipment likes to combine the unit with other units, components or assemblies and this can not be made clear from the technical data, he

must question us as manufacturer or another expert to make sure that the safety

of the patients and operator is given by the planned combination.

Product Safety

Electrical safety

Only trained service personnel are permitted to remove covers and panels from

the x-ray equipment .

In the Federal Republic of Germany, the electrical installation of rooms used for

medical purposes must conform to the provisions of the VDE Standard 0107. In all

other countries, the provisions of the applicable local laws and regulations have

priority.

The unit is only prepared for solid installation with an all poled separation from the

power (IEC 601, Kap. 57.1).

Mechanical safety

It is the responsibility of the operator to ensure safety of patient while the unit is

in operation by visual check, proper patient positioning, and use of devices that

are provided.

Rest risk:

During proper operation and in case that a first mistake may accur there will be no

damage to patient and/or environment.

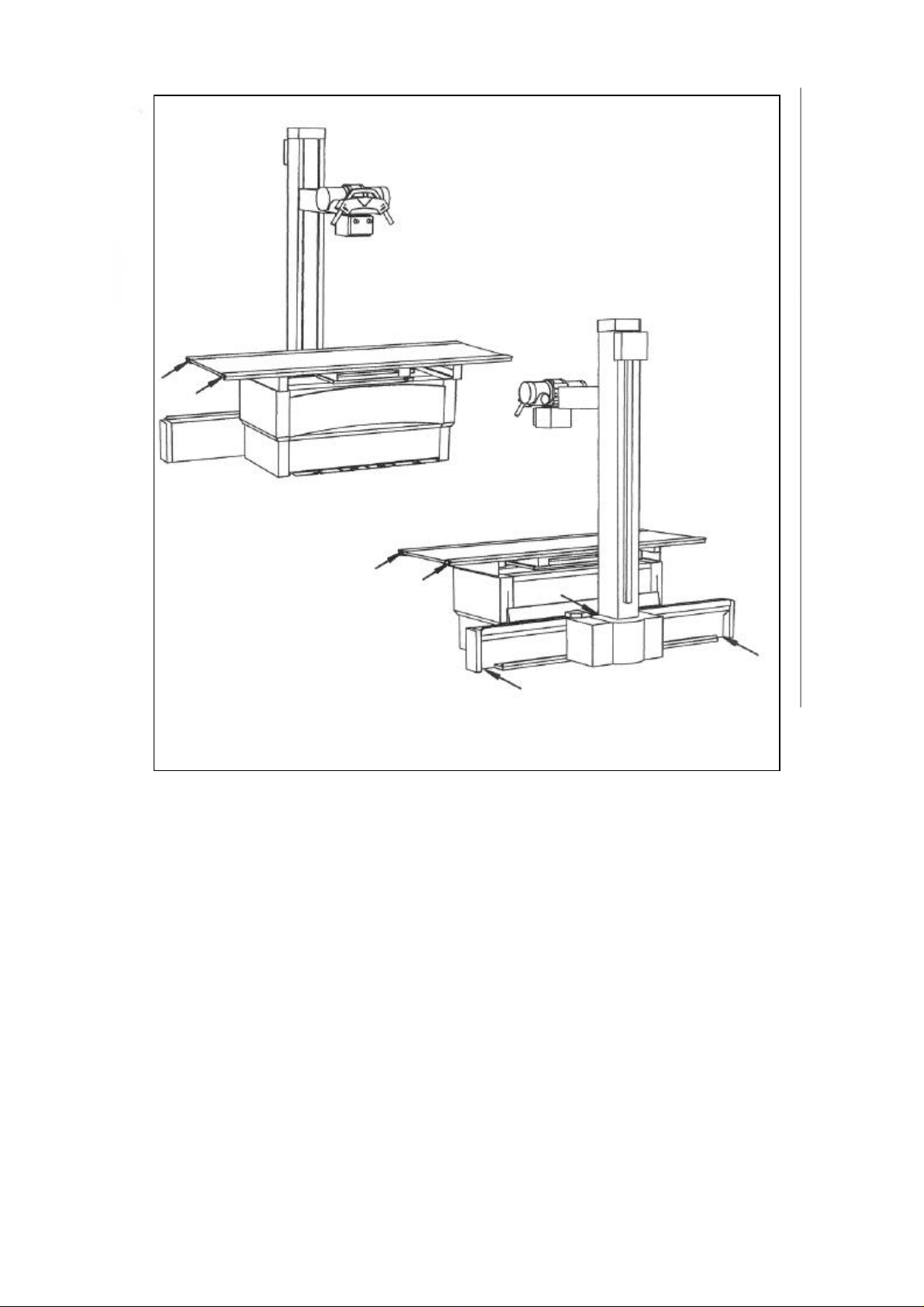

Danger of injury

The arrows in the illustration show areas which present potential Danger of Injury

to operating personnal and patient from the equipment motion.

See next page.

0628 7324 - 4 of 24- 07/98

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

X-Ray Protection.

The unit has no controls with which radiation could be triggerd.

Exposure is triggerd only from the radiation-protected location of the generator.

The general radiation-protection measures must be observed.

In addition, we recommend the following:

1 Set the tube current as low as possible .

2 Limit the radiation field to the maximum possible extent.

3 Keep as far away as possible.

4 Provide radiation protection for the patient.

07/98 - 5 of 24- 0628 7324

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. D-91056 Erlangen ALL RIGHTS RESERVED Ru

Explosion Protection

This equipment is not designed for use in areas where explosion hazard can take

place.

Only skin cleaning agents may be used which form non-explosive mixtures with air.

Interference Suppression

The equipment complies with the EMC-requirements of the guideline 89/336 EWG.

Special board International Electronic Commission (IEC). This unit complies to

EN 55011 and the reference value is according EN 55011 Group 1 Class B the international electrotechnical committee (IEC).

Classification of product

The equipment complies to the protection degree of Class 1 and for protection

against electric shock Type B.

EC Conformity

The Combi Elevator Tomo-2 to which this declaration relates fulfills the essential

requirements for safety of medical electrical equipment and follows the provisions

of Medical Device Directive 93/42 EEC part 11 para. 3 according the procedure in

annex II.

The CE-Mark is only applicable for the product without X-ray components and

Bucky.

The declaration of EC-conformity can be sent to you by request:

Write to:

Hans Pausch

Röntgengerätebau

c/o Quality Assurance Sys. Mgr.

Postfach 28 60

D-91016 Erlangen

Fax #: ..49 9131 99 24 22

Enviroment Condition

Surrounding temperatur range 10° C to 40° C

Humidity 20% to 80%

Atmospheric pressure 700 hPa to 1100 hPa

Disposal of equipment

Legal waste disposal regulations may apply to the disposal of this product. To

avoid causing damage to the environment and personal injury, we recommend

that you contact your Customer Services representative before permanently re-

moving this product from service.

0628 7324 - 6 of 24- 07/98

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

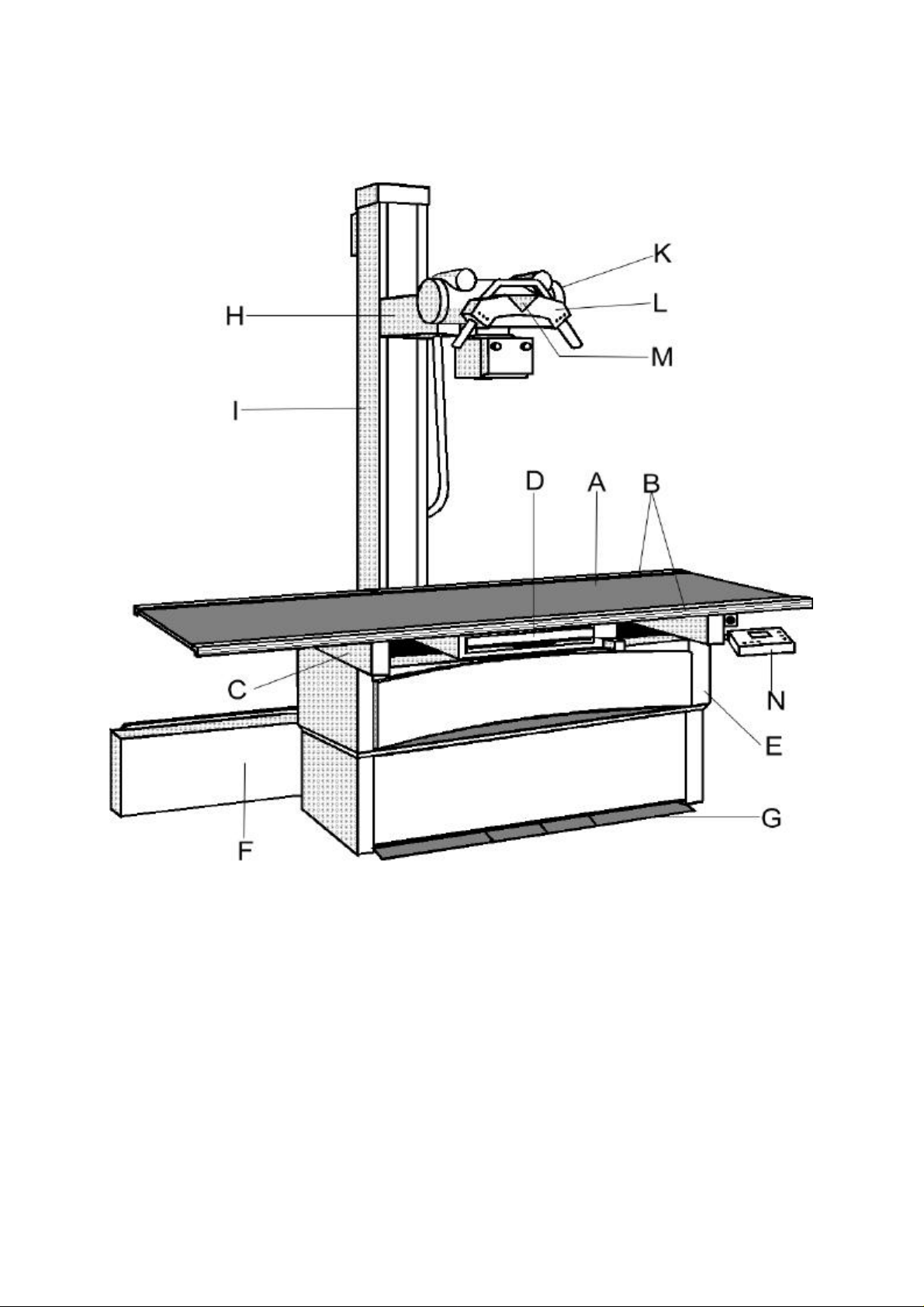

Design Features

Constructional Conception

A Table top, floating, manually movable, scratch-proof

B Profile rail with trim cover, smooth, accepts accessories

C Upper table frame

D Bucky unit, movable

E Table base, solid, vibration-free

F Guide rails for tube stand

G Foot treadle

H Vertical carriage with X-ray tube support arm

I Column, rotatable

K X-ray tube

L Control handle

M Protractor

N Control-panel for Tomo

07/98 - 7 of 24- 0628 7324

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. D-91056 Erlangen ALL RIGHTS RESERVED Ru

General

Short description

The equipment consists of a motor-driven elevating Bucky table with coordinatus table top

and Bucky carriage as well as a floor mounted column stand for X-ray tube unit, collimator

and control arm including a totally integrated tomography device for linear blurring movement without mechanical coupling.

The solid, vibration-free table base and the rail stand with column form one unit.

The large and 2.20 m long, floating table top is manually movable and locks electromagnetically. The table top is provided for a maximum patient weight of 136 kg. For fast and

easy positioning of the patient, it allows spacious lateral travel: 60 cm to the left, 50 cm to

the right and ± 12 cm transversely.

Especially for patient comfort and easy cleaning, the table top offers a scratch-proof surface

(Resopal) and trim-covered, smooth profile rails on both sides, which can accept accessories.

The Bucky carriage takes up cassette trays as supplied by any reknowned manufacturer. In

longitudinal direction, it is manually moved and electromagnetically locked. The shortest

possible OFD of 70 mm guarantees images of superior geometrical proportion. Low radiation absorption by the table top reduces the X-ray amount. The brake of the Bucky is released by a push-button on the operating handle.

The foot treadle along the table base allows the release of the elctromagnetic table top

brakes.

The tube stand for the X-ray tube support arm and tube is moved on the rail stand parallel

to the longitudinal table axis.

The X-ray tube with collimator and control handle for the tube stand is supported by a lateral arm fixed to the vertical carriage. Vertical movement and rotation of the tube around the

longitudinal axis of the lateral arm permit vertical, horizontal or oblique beam projections.

Each position is electromagnetically locked.

The X-ray tube with column stand rotates around the vertical column axis and catches mechanically at angles of 0° (basic position), ± 90° (for lateral exposures).

The standard tube support is intended for DIN 6836 flanged plate C.

The max. weight of the X-ray tube and collimator must not exceed 40 kg.

For operating there are 3 operating methods from the control panel while pushing the key

available:

Table mode - the automatic tube stand - Bucky linkage will adjust automatically the Bucky in

their travel range to the middle of the column. Exact positioning of the tube at 0° and ± 90°.

Wall mode - while pushing the key two (adjustable while mounting) SIDs will be motorized

positioned while the tube rotates in direction of wall stand. By manual movement of the column is an automaticly stop at the SID`s.

0628 7324 - 8 of 24- 07/98

Rev. 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Loading...

Loading...