Operating Instructions CS 2000

English Edition

09/99 - 1 of 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

CONTENTS Page

Important Note 3

Safety-technical Remarks

- Regulations 3

Product Safety 4

- Electrical Safety 4

- Mechanical Safety 4

- Crush Zones 4

- Radiation Safety 5

- Explosion Protection 6

- Electromagnetic Interference, EMI 6

- Classification per IEC 601-1-1 6

- EC Conformity 6

- Environmental Conditions for Operation 6

- Disposal 6

Design Features

- Design 7

General

- Brief Description 8

- Area of Applicability 9

- Important Note 9

Setup

- Space Requirement 10

- Room Height 10

- Connection 10

- Line Power 10

- Al Equivalency Value 10

Control Elements

- Location 11

- Explanation of Symbols/Function 12

- Setting the Exposure Position/Exposure 14

- Accessories 16

Maintenance

- Important Note 18

- Testing by the Operator 18

- Testing by Customer Service 18

- Cleaning 18

- Disinfection 19

- EEC Guideline 93/42 Regarding Medical Products 19

Placement of Model Labels

- Labeling 20

0125 7321 - 2 of 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

IMPORTANT NOTE

Proper use of this product by operating personnel requires knowledge of these

OPERATING INSTRUCTIONS; these must be studied prior to starting up the equipment.

This radiographic equipment may be operated only by personnel who possess the required

specialized knowledge of radiation safety or who are familiar with radiation safety and who

have been instructed in the operation of the radiographic equipment.

The operator is always responsible for maintaining the regulations that apply for operation

of the radiographic equipment.

SAFETY-TECHNICAL REMARKS

Regulations

If there are legally specified regulations regarding the operation of radiographic equipment,

it is the responsibility of the operator to observe them.

In the interest of safety for patient, operating personnel as well as for third parties, tests

which assure the operating reliability and functionality of the product must be performed in

accordance with the Maintenance Instructions in intervals of 12 months.

We request that you contact your customer service department regarding performance of

these tests.

If tests are required in shorter intervals in order to comply with national specifications or

regulations, it is absolutely necessary to observe them.

Modifications and additions made to the product must be in accordance with legal

regulations as well as with generally accepted rules of the technology.

As the manufacturer of the radiographic equipment, we can assume responsibility for the

safety-technical features of the product only if:

any maintenance, repair and modification on it is carried out only by us or by facilities that

have been authorized by us for this purpose, and if there is a failure of parts which affect

the safety of the product, such parts are replaced with original spare parts.

When performing this work, we recommend that written confirmation regarding the nature

and extent of work be requested from the person performing the work, and if applicable,

include any changes made in nominal values or to the operating range. In addition, the

company performing the work, the date and a signature should be included.

Prior to daily use, the user must assure himself that all devices provided for safety are

functional and that the product is operational.

If the operator of the radiographic equipment wishes to combine it with other products,

components or assemblies, and this capability is not clear from the technical data, he must

assure that the safety of patients as well as of operating personnel is not adversely affected

by the intended combination by contacting us as the manufacturer of the equipment or by

contacting someone who has specialized knowledge of the equipment.

09/99 - 3 of 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

PRODUCT SAFETY

Electrical Safety

Only specially trained maintenance personnel may remove the covers and panels on the

radiographic equipment.

This radiographic product may be operated only in medical rooms that meet the

requirements of VDE 0107.

It is designed for a permanent connection with universal isolation from the power source

(IEC 601, Chap. 57.1).

Mechanical Safety

Please make sure that neither the patient nor you can reach into the movement path of the

radiographic equipment or that parts of clothing can be caught by it.

Make sure that all objects within the movement range of the radiographic equipment have

been removed.

Crush Zones

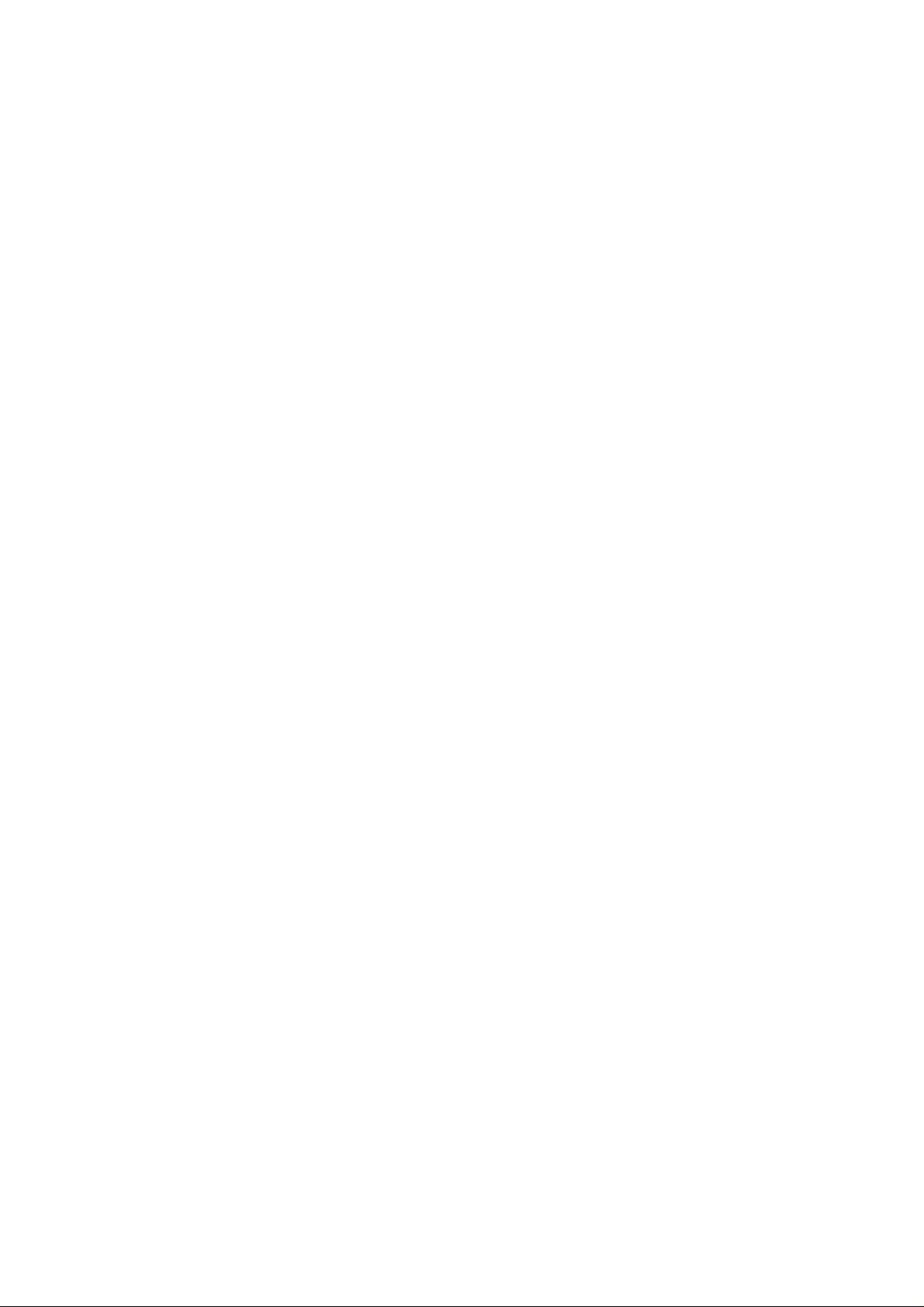

The highlighted locations in the following sketch represent the danger zones in which the

patient or operator can be injured by crushing or striking.

See following page

0125 7321 - 4 of 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Radiation Safety

The equipment does not have any control elements with which radiation can be triggered.

Triggering of exposure is made from the generator radiation-protected location.

The general regulations regarding radiation safety must be observed.

We also recommend:

1. Keep the tube current as low as possible.

2. Keep the radiation field as small as possible.

3. Maintain the max. possible distance.

4. Do not forget to provide radiation protection for the patient.

09/99 - 5 of 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Explosion Protection

This product is not intended for use in areas where there is a risk of explosion.

Only those household cleaning products whose gas-air mixture is inflammable may be

used.

Electromagnetic Interference (EMI)

The product meets EMI specifications as defined in EEC Guideline 89/336.

The limit values for measurement of interference per EN 55011, Group 1, Class B and the

requirements for immunity to interference per EN 50082-1, Degrees 2 and 5 are maintained.

Classification per IEC 601-1-1

Depending on the type of protection against electrical shock, the equipment corresponds to

Safety Class 1 and, depending on the degree of protection, Type B.

EC Conformity

This radiographic equipment meets the basic requirements as defined by EEC

Guideline 93/42 of the Committee for Medical Products, per Article 11, Paragr. 3 and the

procedure listed in Appendix II.

The CE symbol is valid only for the product without the radiographic components.

Further information can be obtained upon request from:

Hans Pausch

Röntgengerätebau

Qualitätssicherung

Postfach 28 60

D-91016 Erlangen

Fax: ..49 9131 99 24 22

Environmental Conditions for Operation

Ambient temperature range 10° C to 40° C

Relative humidity in the range 20% to 80%

Ambient pressure in the range 700 hPa to 1100 hPa

Disposal

Legal disposal regulations may exist for this product. To avoid environmental and human

damage, we request that you contact your customer service department before the product

is taken permanently out of operation.

0125 7321 - 6 of 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Design Features

- Design

A Tabletop, floating, moved manually, scratch-resistant

B Profile rail, covered, smooth, for attachment of accessories

C Table upper frame

D Adjustable Bucky, moveable

E Table base, stabile, vibration-free

F Rail assembly for column stand

G Footswitch bar

H Vertical carriage with X-ray tube unit support arm

I Column stand, can be pivoted

K X-ray tube unit

L Command arm

M Angle indicator

09/99 - 7 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

General

Brief Description

The equipment system is comprised of a patient table with the Koordinat tabletop and

adjustable Bucky device, as well as a floor-mounted, guided stand column for the X-ray

tube unit, collimator and command arm.

The stabile, vibration-free table base and the rail assembly for the column stand comprise a

single unit.

The large-area, 220 cm-long tabletop is float-mounted, can be moved manually and is

electromagnetically braked. The tabletop is designed for a maximum patient load of 136 kg.

Its wide movement range (60 cm to the left, 50 cm to the right, ± 12 cm transversely) and its

easy movement permit quick, effortless positioning of the patient.

The tabletop has smooth T-slot profile rails on the side which can accept accessories. The

scratch-resistance surface (Resopal) and the covered, smooth rails make the tabletop

especially convenient for the patient and easy to care for.

The adjustable Bucky - suitable for installation of adjustable Buckys from all well-known

manufacturers - can be moved manually in the longitudinal direction under the tabletop and

is braked electromagnetically. The smallest achievable film-skin distance of 70 mm assures

the best geometric illustration relationships. The tabletop, which is only minimally radiationabsorbent (Al attenuation equivalency value below 0.7 mm) thus has only a minimal effect

on dose. The brake for the adjustable Bucky is released by pressing a push-button on the

control grip.

There is a mechanical coupling as an accessory for automatic connection of the adjustable

Bucky and column stand.

The footswitch bar, close to the floor and mounting along the table base permits release of

the tabletop electromagnetic brakes.

The column stand for the X-ray tube unit support arm and the X-ray tube unit is guided in

the rail assembly, parallel to the table longitudinal axis.

The X-ray tube unit with collimator and command arm for the column stand is mounted on a

rigid transverse arm (tube unit support arm) of the vertical carriage. It can be moved

vertically and rotated around the longitudinal axis of the transverse arm. This way, the beam

path can be set vertically, horizontally or obliquely. Each position is locked in place

electromagnetically.

The X-ray tube unit can be pivoted around the vertical column axis with the column stand

and always mechanically engages at 0° (basic position), and at ± 90° (for lateral

exposures).

The standard model of the X-ray tube mount is designed for support flange mounting per

DIN 6836, Form C. The max. weight of the X-ray tube unit with collimator may be 40 kg (88

lbs).

0125 7321 - 8 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Area of Application

The equipment system is a universal radiographic workstation - for use in private practice,

but also for use in a hospital - for Bucky exposures of excellent quality, primarily on a

reclining patient. Due to the wide range of movement of the tabletop and easy operation, it

is work-saving and patient-friendly. A special cassette holder is available for lateral

exposures. In combination with a Bucky wall stand or with a cassette stand, exposures on a

standing or sitting patient are also possible. The movement of the column stand for the Xray tube unit for a total of ±90° also makes exposures on patient lying on a gurney or in bed

possible.

Because it is not mounted either to the wall or ceiling, the location of the equipment system

can be changed without problem.

Important Note

Proper use of this product requires that operating personnel be familiar with the operating

instructions. They should be carefully studied prior to starting up the equipment. The section

entitled, "Safety-technical Information", should be given particular attention.

Important Note for Operation

The drop brake engages immediately if movement against the end on the column stops at

the top and bottom is too hard.

09/99 - 9 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Setup

Space Requirement

The unit is designed for stationary operation.

The space required for this is approx. 330 cm x 152 cm.

In addition, a minimum spacing of 20 cm between the column stand and the wall must be

maintained.

Room Height

The height of the column stand is 234 cm. The ceiling height required for installation should

be at least 245 cm. The tabletop of the equipment system has a working height of 75 cm

above the floor.

Connection

The unit is designed for single phase AC current with fixed installation and, depending on

the ordering information, is available in two versions.

The unit is intended only for fixed connection with universal isolation from the power net

(IEC 60 l, Chap. 57.1).

It can be connected to the following nominal line voltage without a pretransformer:

Nominal voltage: 115/230 V AC

Nominal connection current: 2/1 A

Nominal frequency: 50/60 Hz

Nominal connection load: 220 VA

Line Power

Power must be led in over a 30 mA current fault interrupter installed in-house. The room

installation must comply with VDE 0107.

In all countries outside the Federal Republic of Germany, the legally specified national

regulations take priority and must be maintained.

Al Equivalency Value

The attenuation equivalency value of the tabletop (patient table) is ≤ 0.7 mm.

Measured in accordance with:

DIN EN 60601-1-3 at 100 kV and a half-value layer of 3.7 mm Al

and FDA 21 CFR § 1020.30 (n) at 100 kV and a half-value layer of 2.7 mm Al.

0125 7321 - 10 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Control Elements

Location

1 Green LED goes on when the stand is coupled in the adjustable Bucky

movement range

2 Green LED goes on when tube unit rotation is engaged

3 Green LED goes on when the default SID is reached

4 Button for longitudinal movement

5 Button for vertical movement

6 Button for turning movement

7 Button to release all stand brakes

8 Command arm with handgrips

9 Angle indicator

10 Pivot movement of the column stand by a strong motion in the direction of the

pivot on the command arm

11 Pushbutton for adjustable Bucky

12 Control grip for the cassette tray

13 Footswitch strip

09/99 - 11 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Explanation of Symbols/Function

Footswitch bar 13

to release the brakes for the floating tabletop. The tabletop

can be moved manually in the longitudinal and transverse

directions while the footswitch bar is held down completely.

The tabletop is engaged in its new working position by

releasing the footswitch bar.

Button 6

to release the brake for rotation movement of the X-ray tube

unit. The X-ray tube unit is engaged in its new working

position by releasing the button.

Button 4

to release the brake for longitudinal movement of the

column stand with the X-ray tube unit. The X-ray tube unit is

engaged in its new working position by releasing the button.

Button 5

to release the brake for vertical movement of the X-ray tube

unit. The X-ray tube unit is engaged in its new working

position by releasing the button.

Button 7

to release all stand brakes. All movements are braked in

their new working position by releasing the button.

0125 7321 - 12 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Angle indicator 9

displays the tilt angle of the X-ray tube unit to the exposure

subject.

Pilot light, green 1

when lit, indicates when the column stand with X-ray tube

unit is coupled with the adjustable Bucky in the movement

range. When leaving the movement range, the pilot lamp

goes out.

Pivoting the X-ray tube unit 10

The column stand with X-ray tube unit can be pivoted 90° to

the left or right around its longitudinal axis with a strong pull

on both command arm handgrips. It engages in place at

both the 0° and ±90° positions.

Startup

The unit system is immediately operational when it is

switched on.

Emergency Off

When the emergency off switch is installed in the

examination room, the red button of the emergency off

switch must be pressed immediately if there is any danger

for the patient, operating personnel or equipment. The

system may be put back into operation only when the

danger has been clearly eliminated. To do this, turn the red

button on the emergency off switch clockwise.

09/99 - 13 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Setting the Exposure Position/Exposure

Patient positioning/centering the adjustable Bucky, object, X-ray tube unit

Positioning the patient on the tabletop.

Note

Prior to positioning the patient, move the column stand with

the X-ray tube unit so that the patient cannot injure himself

when he sits or lays down on the tabletop!

Centering the adjustable Bucky

The adjustable Bucky can also be moved to center or

readjust in the exposure area.

Note

This readjustment is necessary when the green lamp for the

automatic stand-adjustable Bucky coupling does not go on.

Centering the exposure subject

Position the exposure subject in the central beam of the Xray tube unit by moving the tabletop. To do this, step down

completely on the footswitch bar 13. The brakes for the

floating tabletop are released. Move the tabletop, release

the footswitch bar; the tabletop is locked in position.

Centering the radiation field

Optimally limit the radiation field (light field!) using the

radiation limiting device in the collimator (collimator

operating instructions).

0125 7321 - 14 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Preparing an exposure

Insert the cassette. Set the SID. Set the exposure data at

the control console. Check readiness to make an exposure.

Instruct the patient: Please take a breath and hold it! Trigger

the exposure.

Note

Do not forget radiation protective measures for the patient,

lead-rubber apron (gonad protector, etc.)!

Oblique exposure

Appropriately move the column stand out over the coupling

area of the automatic stand-adjustable Bucky coupling.

Position the adjustable Bucky under the exposure subject.

Turn the X-ray tube unit and with the light pointer in the

collimator switched on, center to the middle of the

adjustable Bucky.

Exposure using the Bucky wall stand

Move the tabletop in opposite direction of the wall stand.

Move the column stand in the longitudinal direction to the

wall stand. Rotate the X-ray tube unit 90° (angle indicator!),

switch on the light localizer, move the X-ray tube unit or

adjustable Bucky in the wall stand appropriately in the

vertical direction to center or adjust to the exposure subject.

Lateral exposure

For lateral exposures using the lateral cassette holder (see

also Page 16, Accessories), pivot the column stand 90°,

rotate the X-ray tube unit 90° (angle indicator!). All other

positioning measures have already been described.

09/99 - 15 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Accessories

Compression band/cassette holder/head rest/handgrips

Compression band

Install

Insert take-up roll B into the wall-side profile rail in the

tabletop. Secure it in the working position using the knob on

the opposite side.

Insert tensioner A into the front rail. Secure the tensioner in

the working position opposite the take-up B with knob C.

Press the release latch F. Unroll the band and stretch it

across the patient.

Wrap the stretch band once around the shaft of the take-up

roll. Insert bow D into the slot of shaft G. Turn knob E and

roll up/tension the compression band.

To release the band

Press release latch F.

0125 7321 - 16 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Lateral cassette holder

A lateral cassette holder permits exposures using a lateral

beam path. The cassette holder is inserted into the side

profile rails of the table.

Handscrew A: Secures the holder on the tabletop

Handscrew B: Holder pivoting device

Handscrew C: Lateral adjustment of cassette tension

grip (cassette size)

Head stabilizer

The head stabilizer is inserted into the side profile rails of

the table. The stabilizer can be fixed in any desired working

position. Padded supports on the adjustable arms

immobilize the patient's head in the required exposure

position.

Handscrew A: Secures the stabilizer on the tabletop

Handscrew B: Secures the support arm

Handgrips

The handgrips are inserted into the side profile rails of the

tabletop. They can be secured in any desired position and

provide the patient with a secure hold.

Gripscrew A: Secures the working position

Important: The reclining patient may only use the handgrips

provided as a grip. Under no circumstances may be hold on

to the sides of the tabletop.

Automatic Stand-Adjustable Bucky Coupling

The automatic coupling automatically links the adjustable

Bucky with the column stand in its movement range. It

assures automatic centering of the X-ray tube unit to the

center of the film. When this position is left, the green pilot

lamp in the command arm goes off. When moving back into

the movement range of the adjustable Bucky, the green

pilot lamp goes on and coupling or uncoupling takes place

automatically.

09/99 - 17 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

MAINTENANCE

Important Note

As with every piece of technical equipment, this radiographic unit requires regular

maintenance and upkeep to assure the operating reliability of the unit.

Operator Testing

The operator must test the radiographic unit as described below.

If there are malfunctions or other differences from normal operating behavior, switch off the

unit immediately and inform customer service.

The unit may be put back into operation again only after all malfunctions have been

corrected.

Daily Checks

Indicator lamps, operating elements, labels and warning labels.

Weekly Checks

All cables and their connections,

Checks by Customer Service

To achieve problem-free operation of the CS 2000, as well as to achieve safety for patients

and for operating personnel, technical maintenance must be performed by customer service

in intervals of 12 months.

See ”Technical Maintenance" in the installation instructions.

As part of this, it is required that the steel cable in the stand be replaced every 3 years.

Caution

If there are parts failures which affect the safety of the unit, original replacement parts must

be used.

We recommend that when this work is performed, written confirmation be obtained about

the type and extent of the work, and if applicable, with a statement about any changes that

have been made to nominal data or about the working range, as well as with the date,

name of the company performing the work and a signature.

CLEANING

Switch off the system prior to cleaning it.

Plastic surfaces may be cleaned only with a solution of soapy water because other agents

(e.g. with high alcohol content) can dull or cause cracking of the surface.

No caustic, solvent or scouring cleansers or polishes may be used. Water or other liquids

may not get into the unit to avoid short-circuits in the electrical installation and corrosion of

parts.

0125 7321 - 18 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Painted parts and aluminum surfaces may be moistened only with a damp cloth and a mild

cleaning agent and wiped down with a soft cloth. Chromed parts may only be wiped down

with a soft, dry cloth.

DISINFECTION

Switch off the system prior to disinfecting it. Only those disinfection methods that meet the

applicable regulations and guidelines as well as explosion safety may be used. No caustic,

solvent or gaseous disinfectants may be used. Spray disinfection is not recommended

because if it is, disinfectants can get into the radiographic unit.

EEC Guideline 93/42 Regarding Medical Products

Article 12

Special Procedure for Systems and Treatment Equipment

Differing from Article 11, this article applies for systems and treatment equipment.

(2) Every natural or legal person who assembles products which bear the CE symbol, with

the intention of putting them into use in the form of a system or as treatment equipment

corresponding to their specified purpose and within their intended defined application, must

provide a statement of content that

a) in mutual agreement, they have tested the products in accordance with the

manufacturer's instructions and have performed the work steps in accordance with these

instructions;

b) they have packaged the system or treatment equipment and have provided specific user

instructions, including detailed manufacturer instructions;

c) the entire procedure was internally monitored and checked in an appropriate manner.

If the conditions as stated in Paragraph 2 have not been met, as would be the case when

the system or the treatment equipment includes products which do not bear the CE symbol,

or when the selected combination of products no longer corresponds to its original intended

purpose, the system or treatment equipment shall be considered a separate product and,

as such, is subject to the detailed specifications of Article 11.

The operator is responsible for maintenance of and compliance with national differences in

EC countries!

09/99 - 19 von 20 - 0125 7321

Rev. 03 1999 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Placement of Model Labels

Datum

89

Labeling

Röntgengerätebau

D-91065 Erlangen

Graf-Zeppelin-Str. 1

Type

Fabr. Nr.

Spanng.

Frequenz

Strom

Made in Germany

Volt

Hertz

Ampére

01

25

We reserve the right to make changes resulting from continuing technical developments.

TV/Ru

0125 7321 - 20 von 20 - 09/99

Rev. 03 1999 Hans Pausch Röntgengeräte Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Loading...

Loading...