Mounting Instructions COORDINATUS-2

0125

English Edition

08/98 - 1 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

TABLE OF CONTENTS Page

1. Specification

1.1 General safety notes 3

1.2 Compatibility 3

1.3 Climatic conditions 3

1.4 Dimensions and weights 3

1.5 Component Designation 4

1.6 Dimensional Drawings 5

1.7 Dimensional Drawings/Floor Mounting 6

1.8 Installation of high tension cables 7

1.9 Constructional preparations 7

1.10 Necessary measuring means 7

1.11 Necessary special tools 7

1.12 Power supply data 7

1.13 Schematics 8

1.14 Component Numbers and Designation 11

2. Mounting of Unit

2.1 Unpack equipment parts 12

2.2 Mounting of the table 13

2.3 Mounting of Bucky 14

2.4 Mounting of the table top 14

2.5 Mounting of the table top in small rooms 15

2.6 Function control 15

2.7 Mounting of covers 15

3. Adjustments

3.1 Adjustment of Bucky in transverse direction of table 16

4.0 Technical Maintenance

4.1 Mechanical and electrical tests 16

4.2 Spare Parts Table 19

4.3 Spare Parts List 20

4.4 Maintenance Documentation 21

4.5 Name Plate Location 22

0632 7221 - 2 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1. Technical data

1.1 General safety notes

In the Federal Republic of Germany, the electrical installation of rooms for medical

purposes must conform to the provisions VDE Standard 0107. In all other countries

the national requirements have to be observed.

Check the installation layout plan.

During the installation it is important to check that all protective ground wire

connections provided by the manufacturer are properly made before the equipment is

started up.

The protective ground wires between the individual system components and the

power supply have to be connected as shown in the wiring diagram.

Regulation of professional associations concerning safety and accident prevention

has to be observed. No work may be performed on parts carrying a voltage higher

than 42 V. If it is necessary to turn on the power for execution of movements of the

equipment in the course of installation procedure, it must be shut down immediately

after completion of these movements.

1.2 Compatibility

This mounting instruction is valid for COORDINATUS-2 and all versions of them.

The table carries all customary in trade Bucky units.

A Bucky Wall stand can be installed on the right or left side of the table depending on

the user side.

1.3 Climatic conditions

During regular work:

Temperature: 10° C to 40° C

Humidity: 20% to 80%

Air pressure: 700 hPA to 1100 hPa

During transport:

Temperature: -25° C to 70° C

Humidity: 5% to 95%

Air pressure: 600 hPA to 100 h PA

1.4 Dimensions and weights

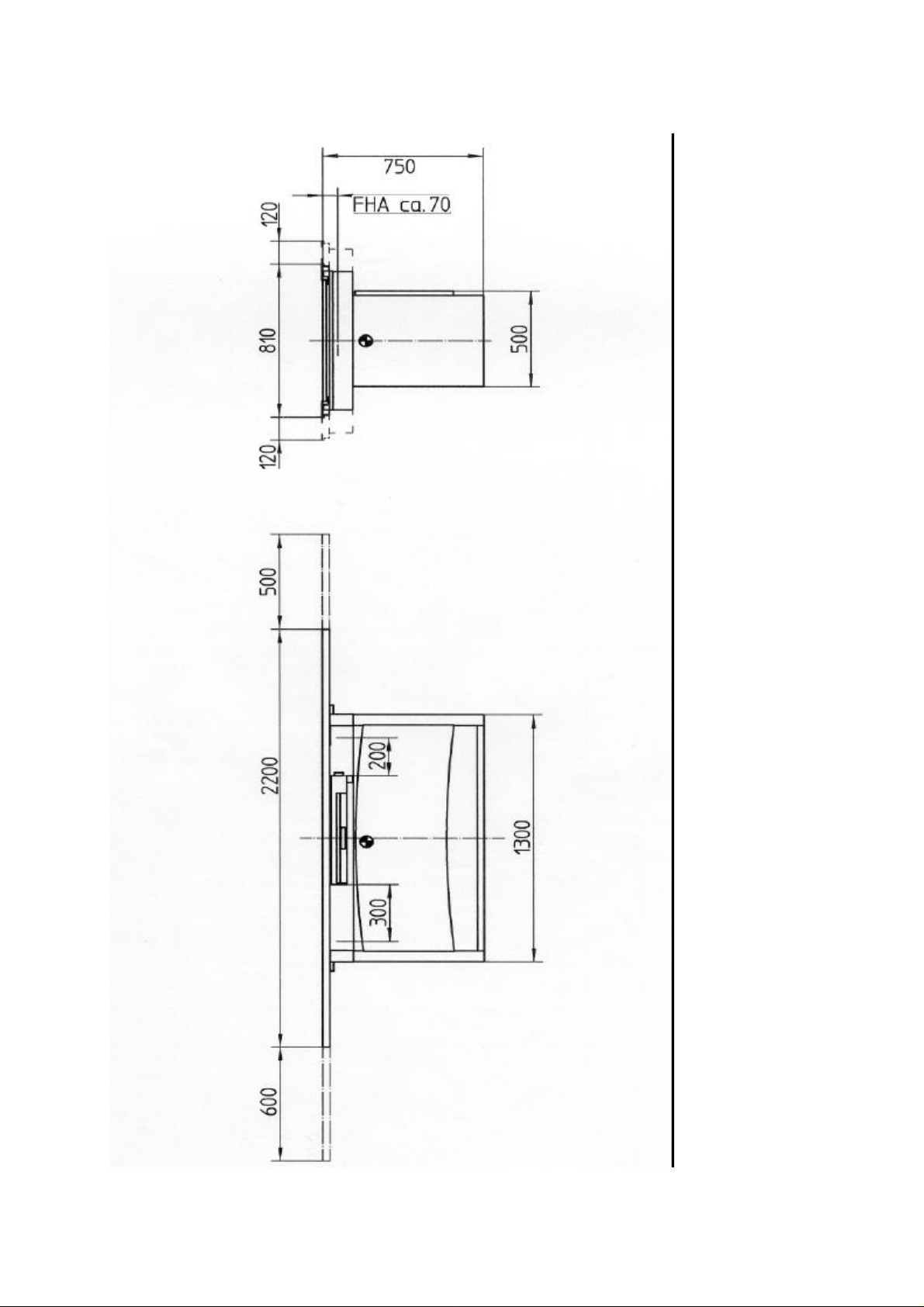

of components Dimensions of components Weights

Table 1400x770x750 mm 110 kg

Table top 2200x810x 40 mm 35 kg

of collies Dimensions of collies Weights

Table 1530x860x960 mm 165 kg

Table top 2320x930x200 mm 56 kg

08/98 - 3 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

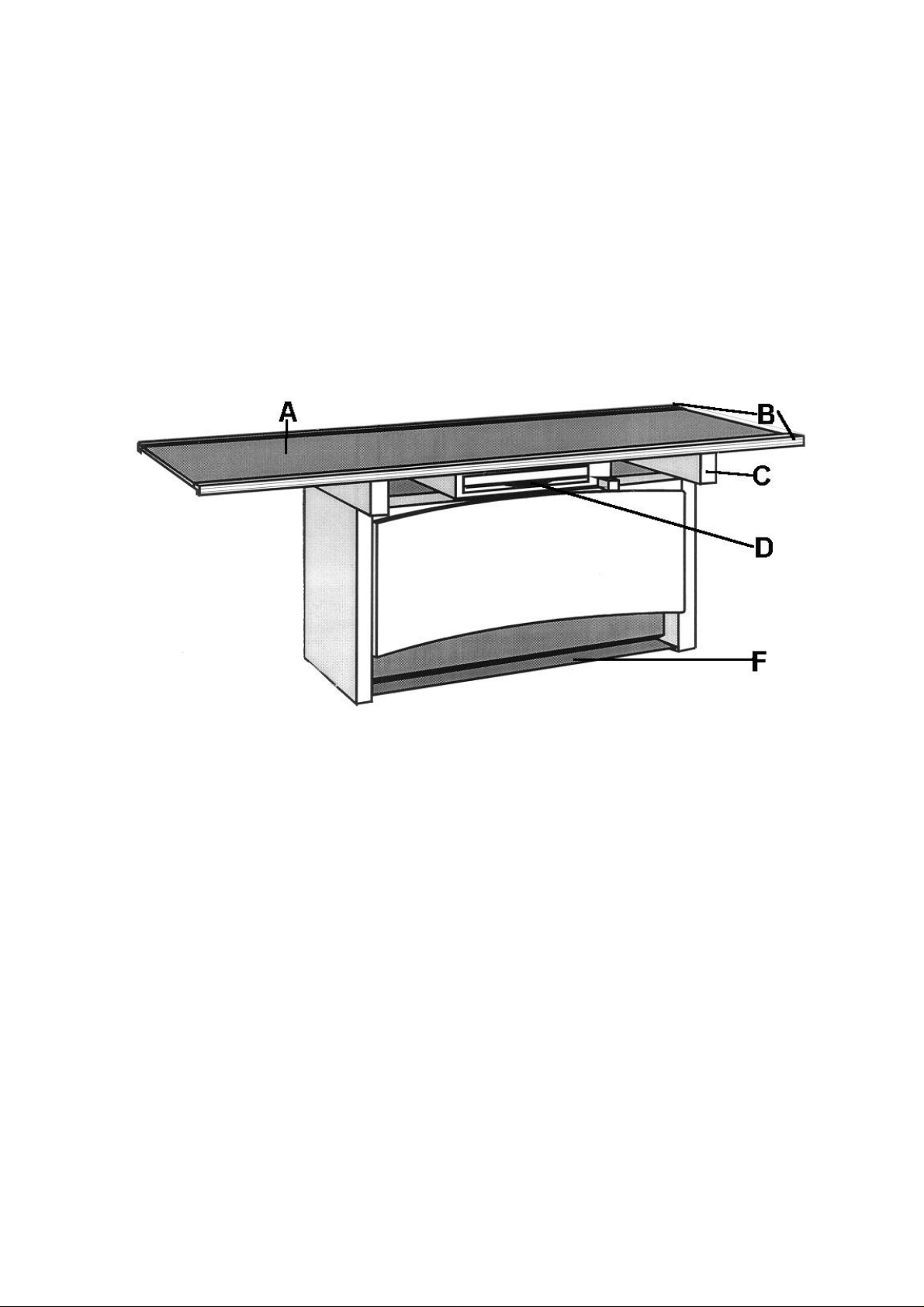

1.5 Component Designation

A Table top, floating, manually movable, scratch-proof

B Profile rail with trim cover, smooth, accepts accessories

C Upper table frame

D Bucky unit, movable

E Table base, solid, vibration-free

F Guide rails for tube stand

G Foot treadle

0632 7221 - 4 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.6 Dimensional Drawings

08/98 - 5 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

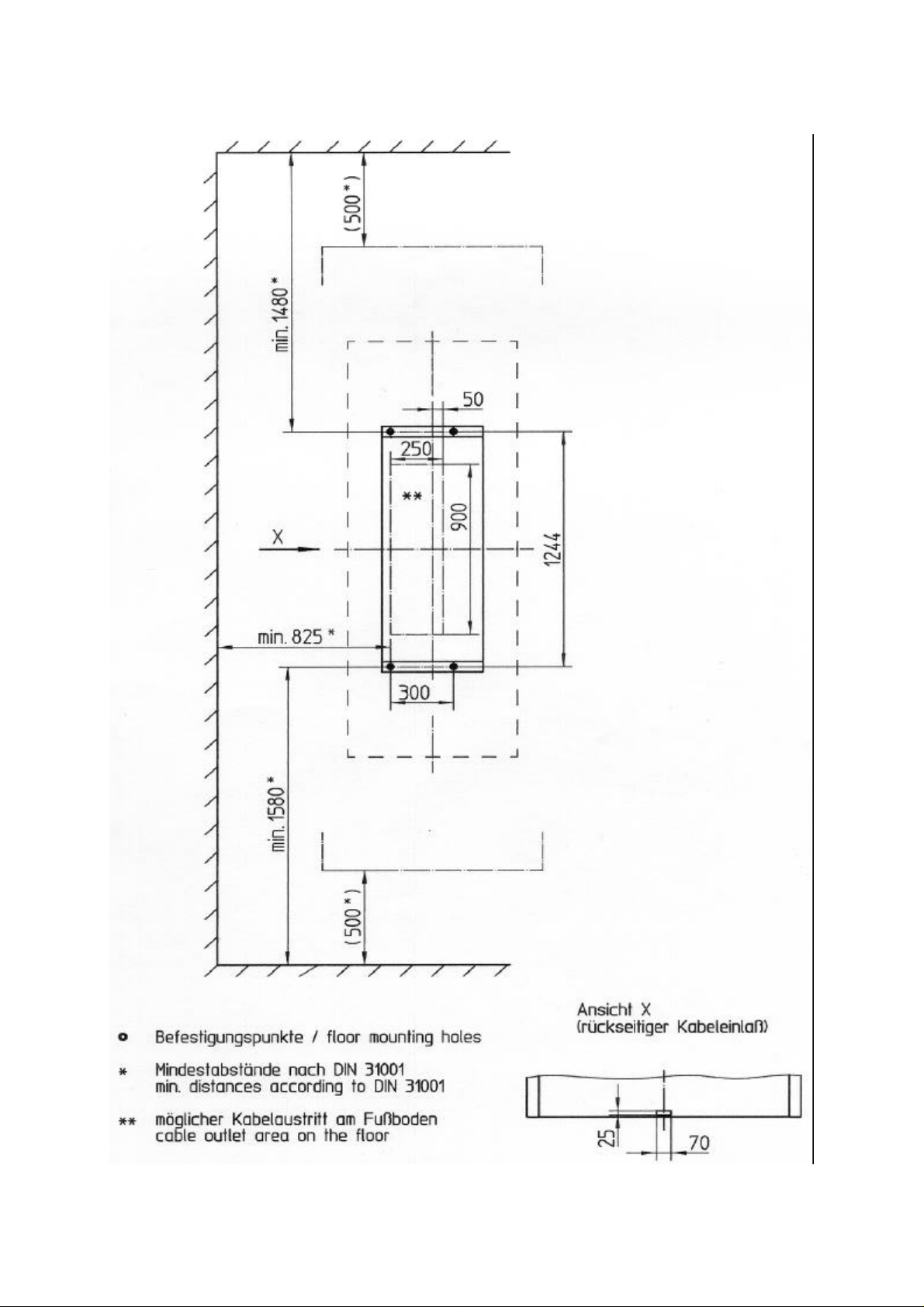

1.7 Dimensional Drawings/Floor Mounting

0632 7221 - 6 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.8 Installation of high tension cables

1.9 Constructional preparations

The electrical connection data have to correspond with the of the equipment supply

voltage.

For the COORDINATUS-2 is only a supply voltage of 115/230 V required and a

corresponding ground connection transmission. The mounting points of the

COORDINATUS-2 have to support a tractive power of 2500 N at each mounting point

(concrete floor? B 150 DIN 1045 when using the included fastening material).

Prepare on the floor fastening bore-holes of 12 mm according to drawing 1.6., under

consideration of the construction.

The connection cable of the COORDINATUS-2, the Bucky and the detector has to be

placed constructional depending on the version until the terminal box in the table base

or until the Bucky according to the installation plan.

The optional ceiling- wall- terminal box can be mounted if required to the wall or

ceiling.

1.10 Necessary measuring means

Machine air level

1.11 Necessary special tools

Percussion bore machine

Rock drill 12 mm

1.12 Power supply data

Power supply: 115/230 V

Frequency: 50 / 60 Hz

Rated current: 2/1 A

Rated power supply voltage: 220 VA

08/98 - 7 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.13 Schematics sheet 1

1.13.1 Description at Schematics

....... Schematics sheet 2

= AX control panel

= Unit, Indication

...... Schematics sheet 3

= AX control panel

= Unit, Indication

1.13.1 Table of contents at Schematics

Sheet 2 Schematics =AA

Sheet 3 Wiring diagram =AA

0632 7221 - 8 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.13 Schematics sheet 2

08/98 - 9 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.13 Wiring Diagram sheet 3

0632 7221 - 10 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

1.14 Description of components for circuit diagram

=AA- Table

=AA-C1 By-pass condenser 24V DC

=AA-F1 Curcuit fuse

=AA-F2 Fuse 24V DC

=AA-F3 Fuse 20VAC

=AA-PE1 Main earthing bolt

=AA-S1 Foot control brake release table top

=AA-S2 Foot control for collimator light

=AA-S3 Switch release Bucky brake

=AA-T1 Mains transformer

=AA-V1 Uncoupling diode

=AA-X1 Terminal strip

=AA-X2 Plug in connection power pack

=AA-X3 Plug in connection brake solenoid table top

=AA-X4 Plug in connection foot control

=AA-X5 Plug in connection Column

=AA-X6 Plug in connection Tomo

=AA-X7 Plug in connection Bucky brake

=AA-Y1 Brake solenoid table top longitudinal

=AA-Y2 Brake solenoid table top longitudinal

=AA-Y3 Brake solenoid table top transverse left

=AA-Y4 Brake solenoid table top transverse right

=AA-Y5 Brake solenoid for Bucky brake

08/98 - 11 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

2. Mounting

2.1 Unpack equipment parts

In addition:

Remove both artificial caps (Fig. 1 Pos. 1) and loosen beneath the socket head cap screw.

Tilt front plate „above“ (Pos. 2) carefully to the outside and then take out from underneath.

Take out accessory box from the table.

Fig. 1 Fig. 2

Dismount the below placed table cover (Fig. 2/Pos. 3) with both screws (Pos. 4). Loosen

both transport screws (Fig. 2/Pos. 5) from the palette and push to the bottom.

Push the table to the back from the palette (Fig. 3). Tilt table to the back, pull out palette to

the front and take off the table carefully.

Fig. 3 Fig. 4

0632 7221 - 12 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

2.2 Mounting of the table

Take the table to assembly area. Push the table at the assembly place over the fastening

bore-holes. Respectively align the table at the assembly place, mark the 4 fastening boreholes and bore

Fig. 5 Fig. 6

Insert the included set pin (Fig. 4), screws and washers. Align table with air level (Fig. 5

Pos. 1, 2 and Fig. 6/Pos. 3). If necessary, align with washers (Fig. 7/Pos. 4). Fasten all

screws tightly.

Fig. 7 Fig. 8

08/98 - 13 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

2.3 Mounting of Bucky

Remark: Buckys of different manufacturers can be installed. The equipment will be

prepared according to the order and necessary fastening materials will be included to the

shipment. Insert the Bucky (opening of cassette to the front) in the Bucky carriage (Fig.

8/Pos.1).

Bucky P

Fastening with 2 screws each (Fig. 14/Pos. 3) left and right lateral. Put at the top the cover

angle with the longer side (Fig. 8/Pos. 4) to user- and back side and fasten in front with 3

screws each and washers.

Philips

Fastening with 2 screws each (Fig. 8/Pos. 3) left and right lateral. Put at the top the cover

angle with the longer side (Fig. 8/Pos. 4) to user- and back side and fasten above with 3

screws each.

Siemens

Fastening with 2 screws each (Fig. 8/Pos. 3) left and right lateral.

Connect the power cable and ION Chamber cable according to the instructions of the

manufacturer.

2.4 Mounting of the table top

Remark:

If there are less than 2900 mm from the mid of table to a wall available, please mount the

table plate according to section 2.5.1.

Remove table plate out of packing. Dismount on one grinding the limit stop (Fig. 9/Pos.1)

and push the table top (Fig. 10/Pos.2) on the transverse carriage.

Fig. 9 Fig. 10

0632 7221 - 14 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Fig. 11 Fig. 12

Attention: Pay attention to the brake magnets (Fig. 11/Pos. 1) while inserting the table top.

Remount limit stops (Fig. 9/Pos. 1).

Put the included pasteboard of the table top packing on the table top during assembly to

avoid any damages.

2.5 Mounting of the table top in small rooms

Dismount on both grindings the limit stops (Fig. 9/Pos. 1). Dismount the bearings (Fig.

12/Pos. 1 and 2) which are in the front.

Put the table top on the table frame and lift the table top on the user side about 45°. Put

meanwhile the table top rail from behind over the Polyamid roll and bearings. Lower the

table top carefully. Move the table top longitudinal and remount the dismounted bearings

(Fig. 12/Pos. 1 and 2). Readjust the regulations of the eccentric. Remount the limit stops

(Fig. 9/Pos.1 ).

Put the included pasteboard of the table top packing on the table top during assembly to

avoid any damages.

2.6 Function control

Switch-on the X-ray generator and control all functions. If necessary adjust corrections

according to section 3. Adjustment.

2.7 Mounting of covers

Remount both front covers (Fig. 2/Pos. 3 and Fig. 1/Pos. 2).

08/98 - 15 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

3. Adjustment

3.1 Adjustment of Bucky in transverse direction of table

Remove screws (Fig. 8/Pos. 3) on the four fixing plates, adjust the Bucky transversely and

tighten afterwards the four screws.

4. Technical Maintenance

4.1 Mechanical and electrical control

The maintenance schedule described below is to be accomplished at 12-months intervals. If

functional tests require power, switch off power immediately afterwards.

Defective parts must be replaced by genuine spare parts according to spare part lists. Use

only non-acid grease for maintenance. Do not grease or oil ball bearings with sealing

washers.

Prelimentary work: Check Coordinatus-2 of damages or missing parts.

Check all cable upon damage especially on the fastening points. If

necessary replace or repair as far as possible after consultation with

the customer.

Check cable loop of sufficient length.

Check all covers. If necessary replace damaged parts respectively

arrange exchange.

Check range of equipment movement on blocked objects. When

collision danger appears inform the user of all risks.

Tools: Usual assembly tools, standing ladder, torque balance key, air level,

spring balance, feeler, cleansing agent, grease.

Preparations: Switch off equipment.

Dismount bumper and stop (Fig. 20/Pos. 1+2) at either

end of the table top from profile rails (lateral).

Take out table top and lay aside securely.

Dismount front cover (Fig. 21/Pos. 1+2).

0632 7221 - 16 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Fig. 20 Fig. 21

Floor mounting: Check firmness of dowel bolts. Tighten if loose. Torque wrench 50 Nm

(5.0 mkp).

Bucky: Check on smooth running over total travel range. Running noise ?

Determine defective bearings. Replace if necessary.

Clean guide rail and bearings and grease lightly.

Check and if necessary adjust eccentric bearing (Fig. 23/Pos. 1).

Correct adjustment: The bearings can still be rotated by hand.

Check bumpers (Fig. 24/Pos. 2) on firmness and damage.

Fig. 22 Fig. 23

Switch-on equipment. Check brake (Fig. 23/Pos. 3) and adjust if

necessary.

08/98 - 17 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Table frame: Clean left and right guide shafts (Fig. 25/Pos. 1) and grease lightly.

Switch-on equipment. Check performance brakes (Fig. 25/Pos. 2) for

transverse movement. Adjust if necessary.

Check bumpers on both sides (Fig. 25/Pos. 4) on firmness and

damage.

Fig. 25 Fig. 26

Remount the caps on the left and right side (Fig. 47/Pos. 1).

Table top: Check plastic rollers (Fig. 25/Pos. 5) for trace of wear. Replace and

grease if necessary.

Clean and check all ball bearings for table top movements on smooth

running and damage. Replace and grease if necessary.

Clean guide profiles of the table top.

Insert table top. Move over total travel range.

Running noise ? Smooth running ? Adjust bearings with eccentric

(Fig. 25/Pos. 6) if necessary.

Switch-on equipment. Check performance brake (Fig. 25/Pos.7).

Replace brake magnet if necessary.

Remount bumper and stop (Fig. 20/Pos. 1+2) at either end of the

table

top to profile rails (lateral).

Foot treadle: Check on smooth operation and contact point. Adjust switch

(Fig. 26/Pos. 1) if necessary.

Check connections of the switches.

Grease lightly both spring axis and bearing axis.

0632 7221 - 18 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

4.2 Spare Parts Table

08/98 - 19 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

4.3 Spare Parts List

Description / Order No.

Note:

Defective parts must only be replaced by genuine spare parts as listed below. When

ordering please always specify the serial number of the unit and the full order number of the

part.

Parts or part assemblies may only be replaced by the manufacturer or parties expressly

authorised. See also chapter on „Safety Procedures“.

Pos. Description Order-No.

1 Power supply 0006 0449

2 Condenser 3110 0028

3 Switch 0006 0184

4

5

6 Bridge plug 0632 0306

7

8

9 Fuse 1,6A 0006 0308b

10 Fuse 3,2A 0006 0308g

11 Fuse 10A 0006 0308k

12 Laminated spring 0632 0418

13 Brake magnet 0006 0603

14 Guide pulley 0632 0420

15 Eccentric 0632 0421

16

17 Bottom 0006 0720a

18 Brake magnet 0006 0603

19 Laminated spring 0105 0153

20 Bumper 0005 0108

21 Buffer support 0622 0620

22 Bearing with bushing 0622 0555

23

24 Bearing with bushing 0622 0556

25 Guide pulley 0632 0422

26 Baring 0005 0191a

27 Eccentric 0632 0659

28 Bearing 0632 0657

29 Bearing block 0622 0085a

30

31 Table top complete 0622 0540a

32 Table top 0622 0548

33 Table top frame 0622 0541

34 Profile rail 0622 0549

35 Stop 0622 0550a

36 Stop 0622 0550b

37

38 Trough complete 0632 0160

39 Pedal 0632 0125

40

0632 7221 - 20 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Name Plate Location:

08/98 - 21 of 22- 0632 7221

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

4.5 Maintenance Certificate

The maintenance according to the attached maintenance instructions has been carried

out. Any parts replaced were original spare parts as shown on the list.

Replaced parts (List item no. only)

------------------------------------------------------------------------------------------------- Date Name of company Signature

Replaced parts (List item no. only)

------------------------------------------------------------------------------------------------ Date Name of company Signature

Replaced parts (List item no. only)

----------------------------------------------------------------------------------------------- Date Name of company Signature

Replaced parts (List item no. only)

---------------------------------------------------------------------------------------------- Date Name of company Signature

Replaced parts (List item no. only)

---------------------------------------------------------------------------------------------- Date Name of company Signature

Subject to technical alterations TV/Ru

0632 7221 - 22 of 22 - 08/98

Revision 02 © 1998 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Loading...

Loading...