Page 1

INSTALLATION INSTRUCTIONS Uromat 3000

________________________________________________________________________

________________________________________________________________________

English Version

06/00 - 1 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 2

CONTENTS Page

1. Technical Data

1.1 General Safety Information 4

1.2 Component Weights 4

1.3 Component Dimensions 4

1.4 Packaging Dimensions and Weights 4

1.5 Component Designations 5

1.6 Dimensional Drawing 6

1.7 Cable Lengths of the High Voltage, Collimator,

Adjustable Bucky and Image lntensifier Cables 10

1.8 Power Line Connection Data 11

1.9 Required Special Tools 11

1.10 Required Test Equipment 11

1.11 Environmental Conditions 11

1.12 Operating Conditions 11

1.13 Circuit Diagram Overview 12

1.14 Component Designations for the Circuit Diagram 27

1.15 Function Description of the Controller 31

2. Installation

2.1 Preparations for Installation 35

2.2 Unpacking the Unit Parts 35

2.3 Taking the Unit Off the Pallet 36

2.4 Installing the Unit 37

2.5 Aligning the Unit 38

2.6 Temporarily Connecting Line Power 39

2.7 Installing the Tube Unit Support Arm 39

2.8 Preinstallation of the Tube Unit - Collimator 40

2.9 Installing the Tube Unit - Collimator on the Tube

Unit Support Arm 40

2.10 Installing the Image Intensifier (I.I.) 41

2.11 Laying the Collimator Cables 41

2.12 Laying the High Voltage Cables 42

2.13 Laying the I.I. Cables 44

2.14 Connecting the Power Supply via the Generator 44

2.15 Installing the Measuring Chamber 45

2.16 Installing the Grid 46

2.17 Installing the Tilt Angle Indicator - Error Display 46

2.18 Installing the Cover Panels 47

2.19 Installing the Monitor Support Arm 47

2.20 Installing the Holder for the Flush Bowl 47

2.21 Sealing the Table Frame Cover Panel 48

0116 7201 -2 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 3

3. Adjustments

3.1 Installing the Tube Unit Support Arm 48

3.2 Central Beam to Center of Bucky 50

3.3 Central Beam to Center of I.I. 50

3.4 Tabletop, Longitudinal Movement Path Potentiometer 51

3.5 Tabletop, Transverse Movement Path Potentiometer 52

3.6 Bucky Movement Path Potentiometer 52

3.7 I.I. Carriage Movement Path Potentiometer 52

3.8 Table Tilt Movement Path Potentiometer 1 53

3.9 Table Tilt Movement Path Potentiometer 2 53

3.10 Table, Longitudinal Safety Switches 54

3.11 Tabletop, Transverse Safety Switches not configured 54

3.12 Tabletop, Longitudinal Safety Switches 55

3.13 I.I. Carriage Movement Path Safety Switches 55

3.14 Table Tilt Up Movement Path Switch Strike Plate 55

3.15 Table Tilt Down Movement Path Switch Strike Plate 55

3.16 +88° Tilt Movement Safety Switches 56

3.17 -20° Tilt Movement Safety Switches 56

3.18 Spindle Nut Safety Switches 56

3.19 Accessory Sensor Switches 57

3.20 Longitudinal Tabletop Belt Tension 57

3.21 Raise - Lower Table Belt Tension 57

3.22 Cassette Carriage Drive Belt Tension 58

3.23 Operation in the Service Mode 59

3.24 Startup 61

3.25 Collimator Basic Setting 62

3.26 Collimation to Cassette and I.I. Formats 63

3.27 Saving the Parameters in the PC 64

3.28 Setting Parameters - Electronics 65

4. Technical Maintenance

4.1 Mechanical and Electrical Checks 67

4.2 Function Test 70

4.3 Spare Parts - Overall View 72

4.4 List of Spare Parts 79

5. Troubleshooting 84

6. Replacing Boards 86

7. Version Updates 86

8. Maintenance Verification 87

9. Location of Identification Labels 88

06/00 - 3 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 4

1. TECHNICAL DATA

1.1 General Safety Information

Maintenance and repair may be performed only by an office that is authorized by the

manufacturer.

In the Federal Republic of Germany, electrical installation of medically used rooms must

conform to VDE Regulation 0107. In all other countries, the particular applicable national

regulations take precedence and must be observed. These can be found in the system

project plan.

During installation, it must be assured that all ground wire connections provided by the

manufacturer must be connected prior to starting up the unit.

The ground wire between the individual components and the power supply must be

connected as shown in the Wiring Diagram.

The regulations provided by the trade unions for occupational safety and prevention of

accidents must be observed.

No work may be performed on parts that are under power (above 42 V).

This condition applies for both measurement and adjustment work steps. However, special

care is required when performing these worksteps.

If the operating instructions call for voltage to be switched on for unit movements, the system

must be shut down immediately following such tests.

The radiation regulations must be observed while making settings and checks that must be

performed under X-radiation; radiation protective clothing must be worn.

1.2 Component Weights

Unit column approx. 320 kg

Table approx. 230 kg

Tube unit support arm approx. 50 kg

Footswitch approx. 5 kg

Total weight, incl. tube unit, collimator,

adjustable Bucky and I.I.: approx. 730 kg

1.3 Component Dimensions

Unit column with table and tube unit support arm on the pallet.

2050 mm x 1015 x 1800 mm

1.4 Packaging Dimensions and Weights

Unit column with table, incl. accessories 2050 mm x 1015 mm x 1890 mm

approx. 900 kg

Transport carriage 1800 mm x 200 mm x 200 mm

approx. 85 kg

0116 7201 -4 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 5

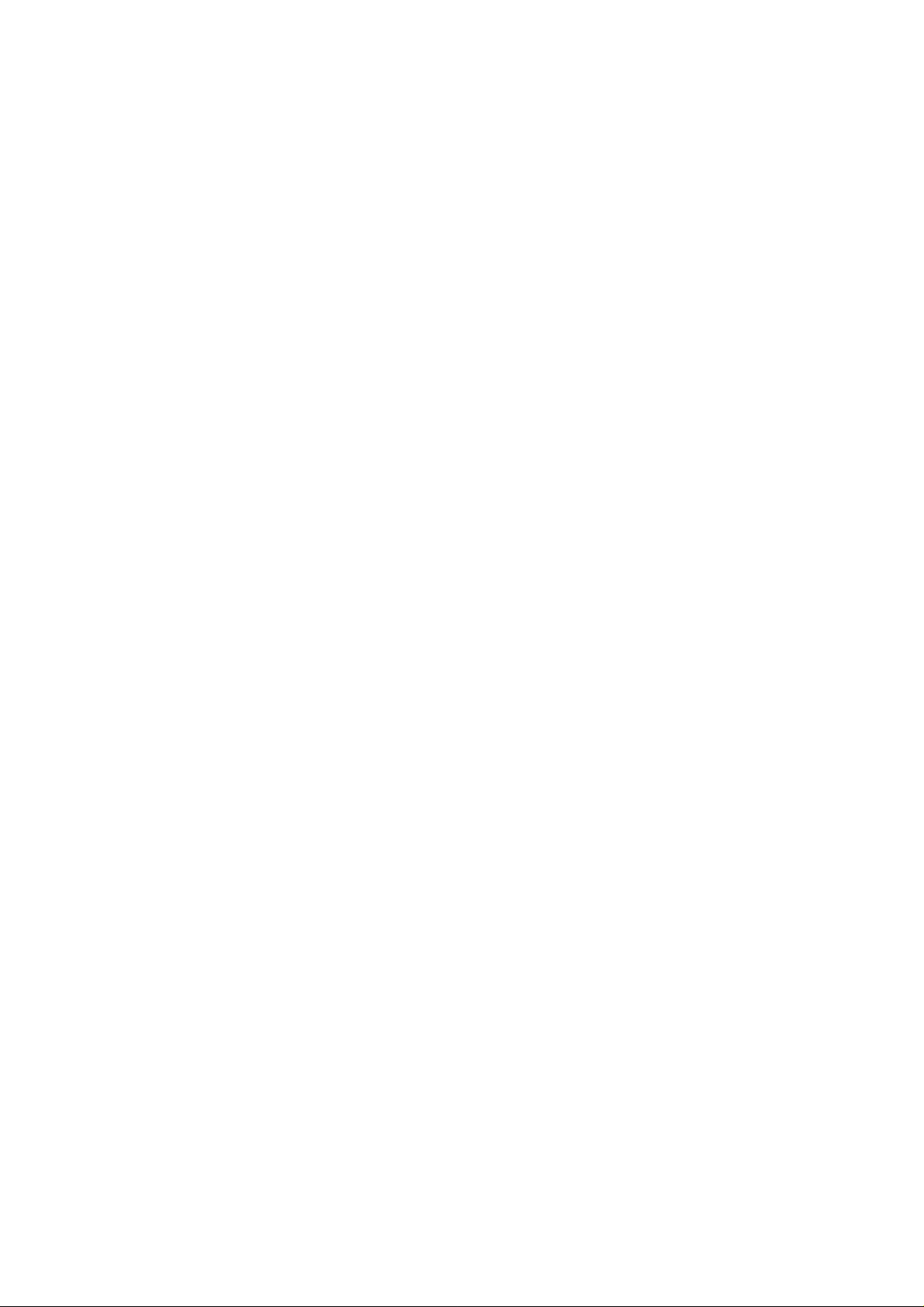

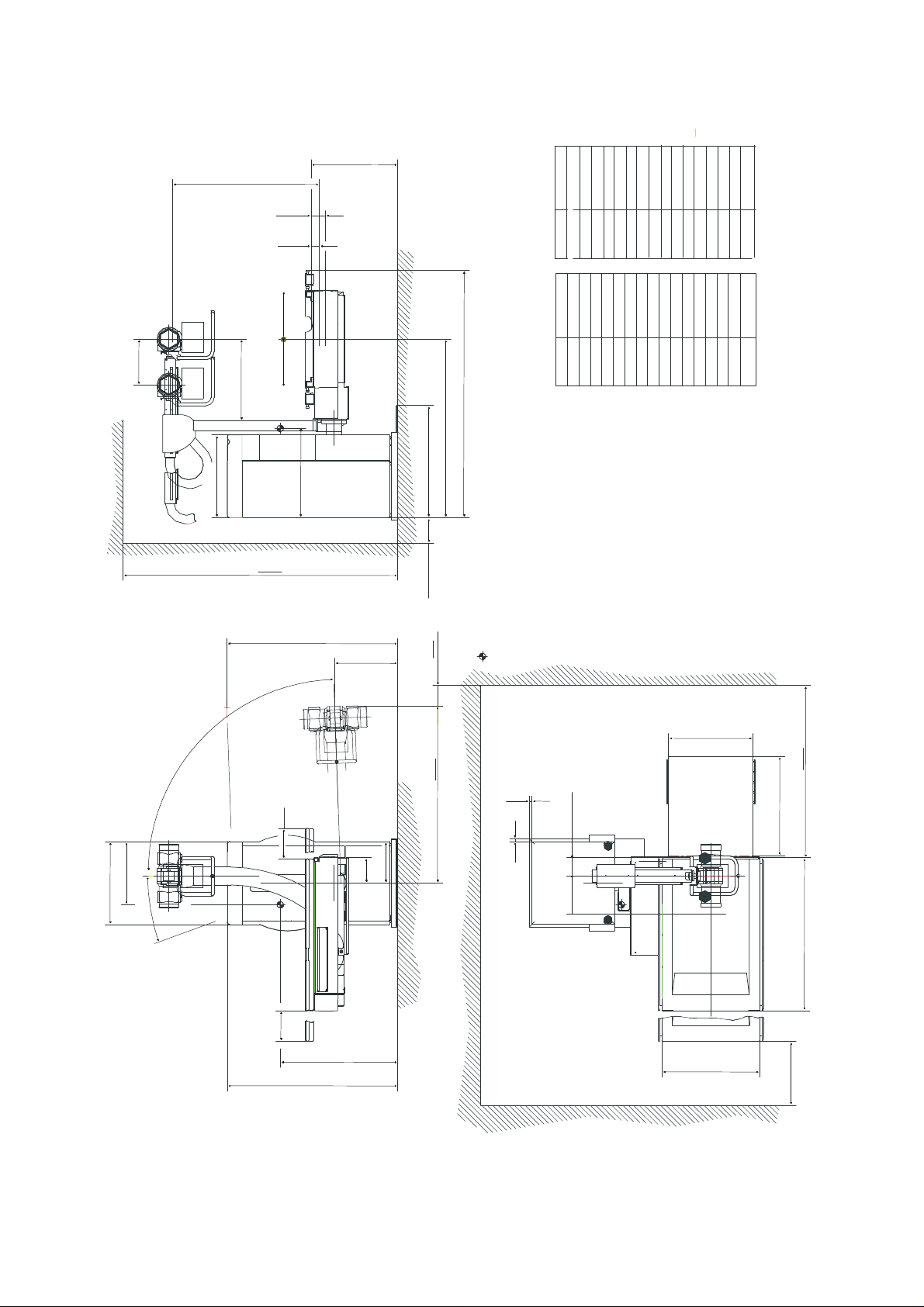

1.5 Component Designations

(the illustration shows the right-handed version, the left-handed version is the mirror

image)

A X-ray tube unit - collimator

B Tube unit support arm, adjustable

C Unit table with four-way table movement

D Unit column

E Manual control unit

F Leg supports

G Elbow supports

H Flush bowl and rinse bag holder

J Table extension

K Footrest for table extension

L Cassette shaft cover

M Micturation seat

N Emergency stop switch

O Head cushion with holder

P Paper roll with holder

R Patient handgrips

S Footswitch for exposure and fluoroscopy

T Multi-function footswitch

U Grip handle

V Tilt angle display / position memory display / error display

06/00 - 5 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 6

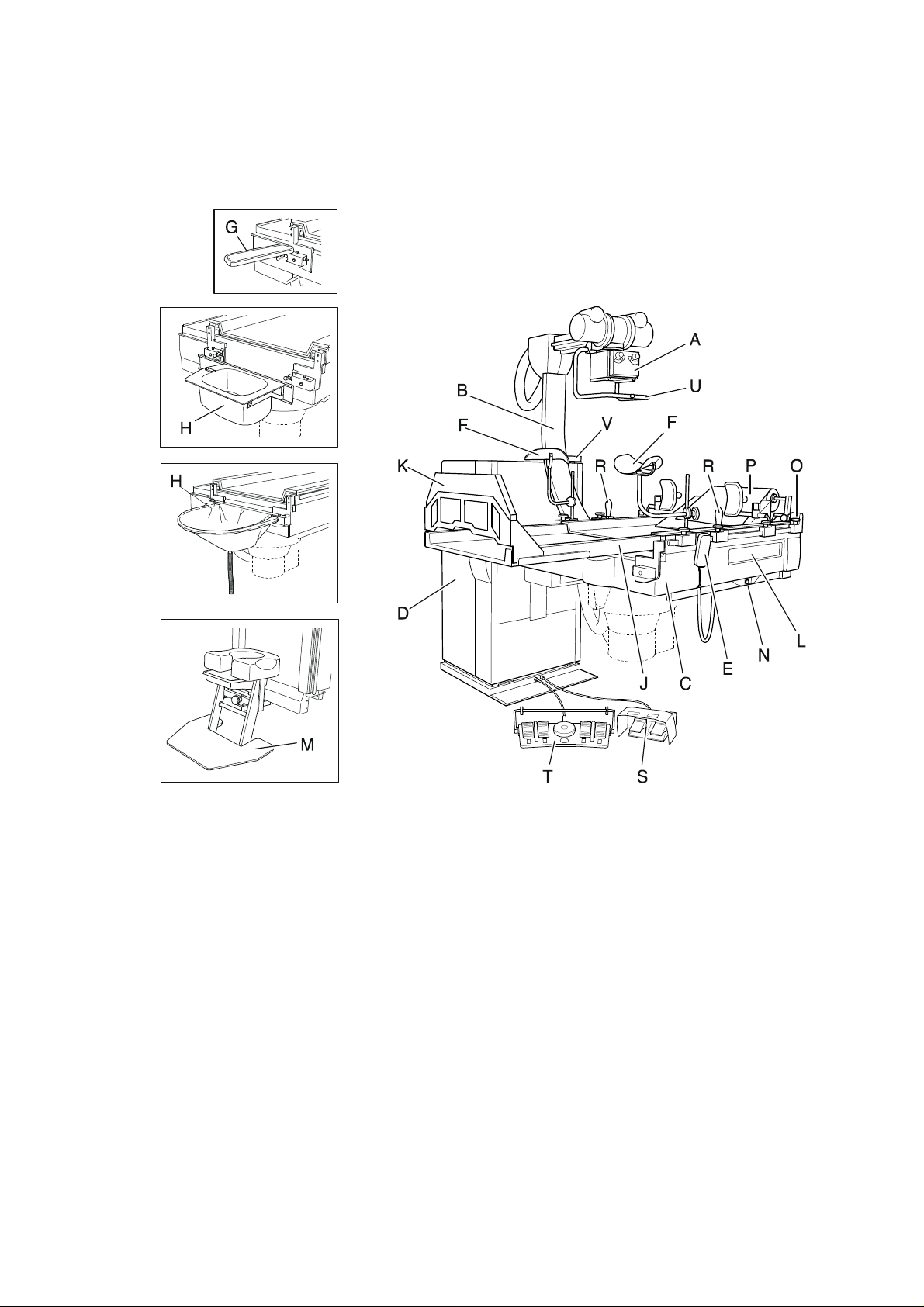

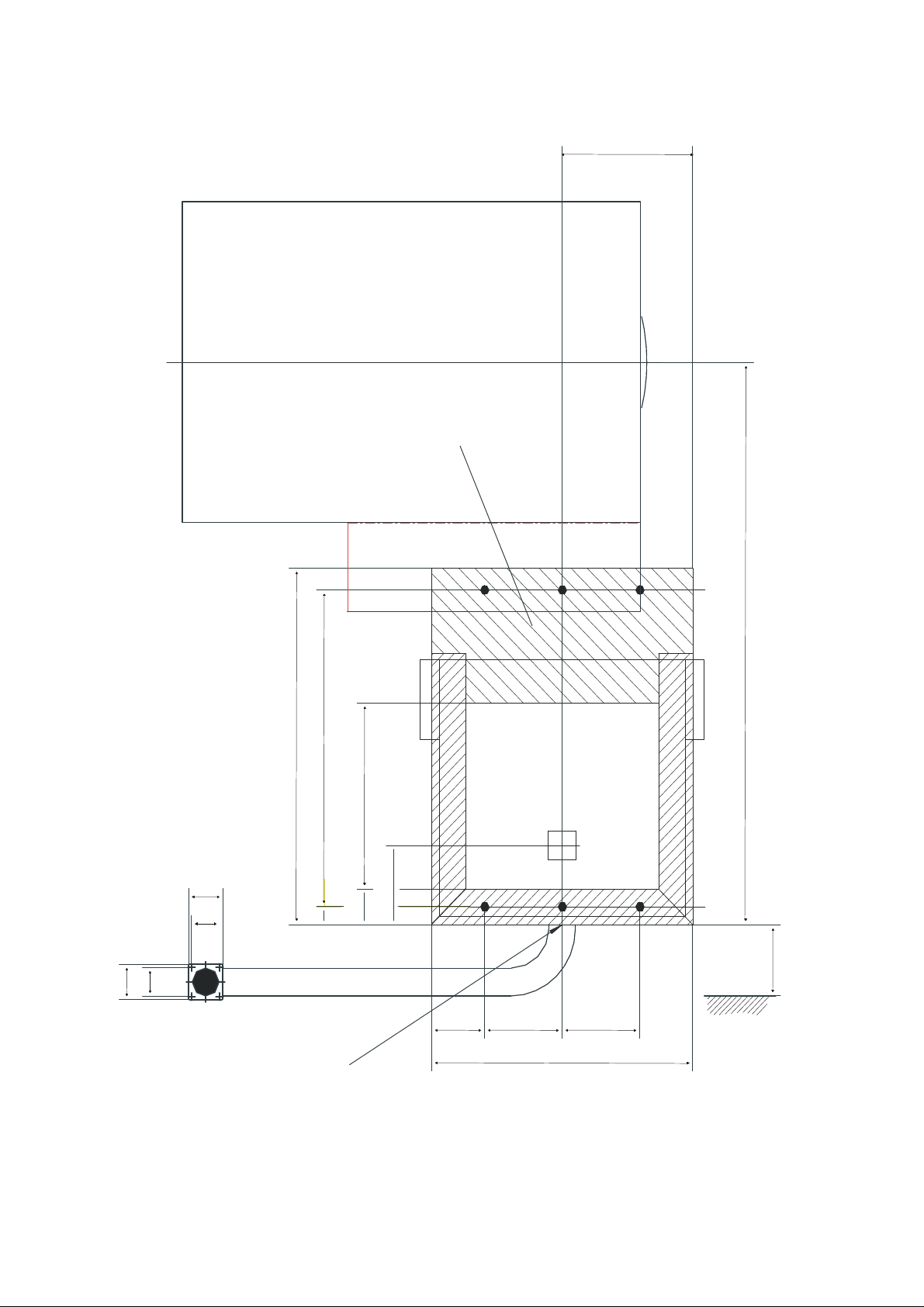

1.6 Dimensional Drawing, Right-handed Version

min.

650

1750min.

1200

The mentioned centre of gravity applies

without X-ray components and accessories.

Table horizontal in highest position,

tube support arm at the head end.

* gemÌB DIN EN 349

according to DIN EN 349

min.680 - max.1225

1150FFA

113

BV

65

Film

360

650

640

130 130

1940max.

1400

880

700

inchmm

inchmm

26,772

27,559700

680

0,787

2,559

65

20

30,709

29,921

780

760

5,118

4,449

113

130

34,646

36,220

880

920

5,709

7,087

180

145

45,276

47,244

1150

1200

7,874

9,449

240

200

48,228

52,559

1335

1225

11,811

12,795

300

325

55,118

52,756

1400

1340

14,173

19,488

495

360

57,087

68,898

1450

1750

19,685

25,197

640

500

76,378

102,362

1940

2600

26,063

25,591

650

662

2600min.

200min.

Der angegebene Schwerpunkt gilt

ohne RÎntgenkomponenten und ZubehÎr.

Tisch horizontal in oberster Stellung,

RÎhrentragarm auf der Kopfseite.

Gewicht ca. 670 kg

weight approx. 670 kg

1335

920

760

500min. *

240

495

20°

88°

240

200

325

1450max. ca.

300max.

20

20

145min.

TischverlÌngerung

+ FuBbank table extension

+ foot rest

780

662

*

495min. ca.

500

1340max. ca.

0116 7201 -6 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 7

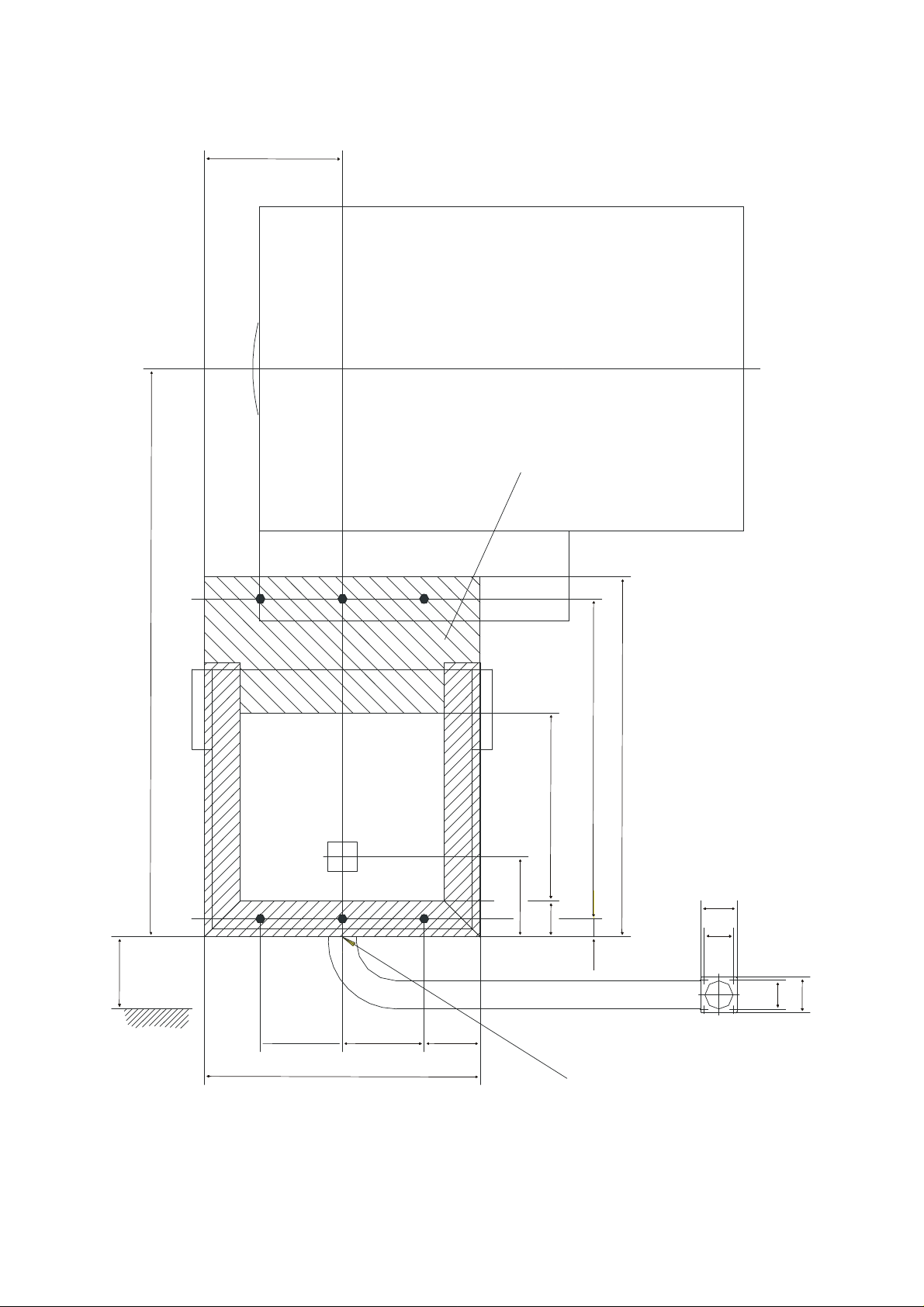

1.6.1 Dimensional Drawing, Left-handed Version

1200

1750min.

650

min.680 - max.1225

1150FFA

113

BV

65

Film

130130

360

650

640

700

1940max.

1400

880

mm inch

mm inch

27,559

26,772

700

680

0,787

2,559

65

20

30,709

29,921

780

760

5,118130

4,449

113

36,220

34,646

920

880

5,709

7,087

145

180

47,244

45,276

1150

1200

9,449

7,874

200

240

52,559

48,228

1225

1335

11,811

12,795

300

325

55,118

52,756

1340

1400

19,488

14,173

360

495

68,898

57,087

1750

1450

25,197

19,685

500

640

76,378

102,362

2600

1940

26,063

25,591

650

662

495

20°

88°

2600min.

1340max. ca.

495min. ca.

200min.

500min. *

Der angegebene Schwerpunkt gilt

ohne RÎntgenkomponenten und ZubehÎr.

Tisch horizontal in oberster Stellung,

RÎhrentragarm auf der Kopfseite.

The mentioned centre of gravity applies

without X-ray components and accessories.

Table horizontal in highest position,

tube support arm at the head end.

Gewicht ca. 670 kg

weight approx. 670 kg

* gemÌB DIN EN 349

according to DIN EN 349

662

1450max. ca.

240

200

325

20

20

145min.

TischverlÌngerung

+ FuBbank table extension

+ foot rest

780

300max.

240

920

760

1335

06/00 - 7 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

500min. *

Page 8

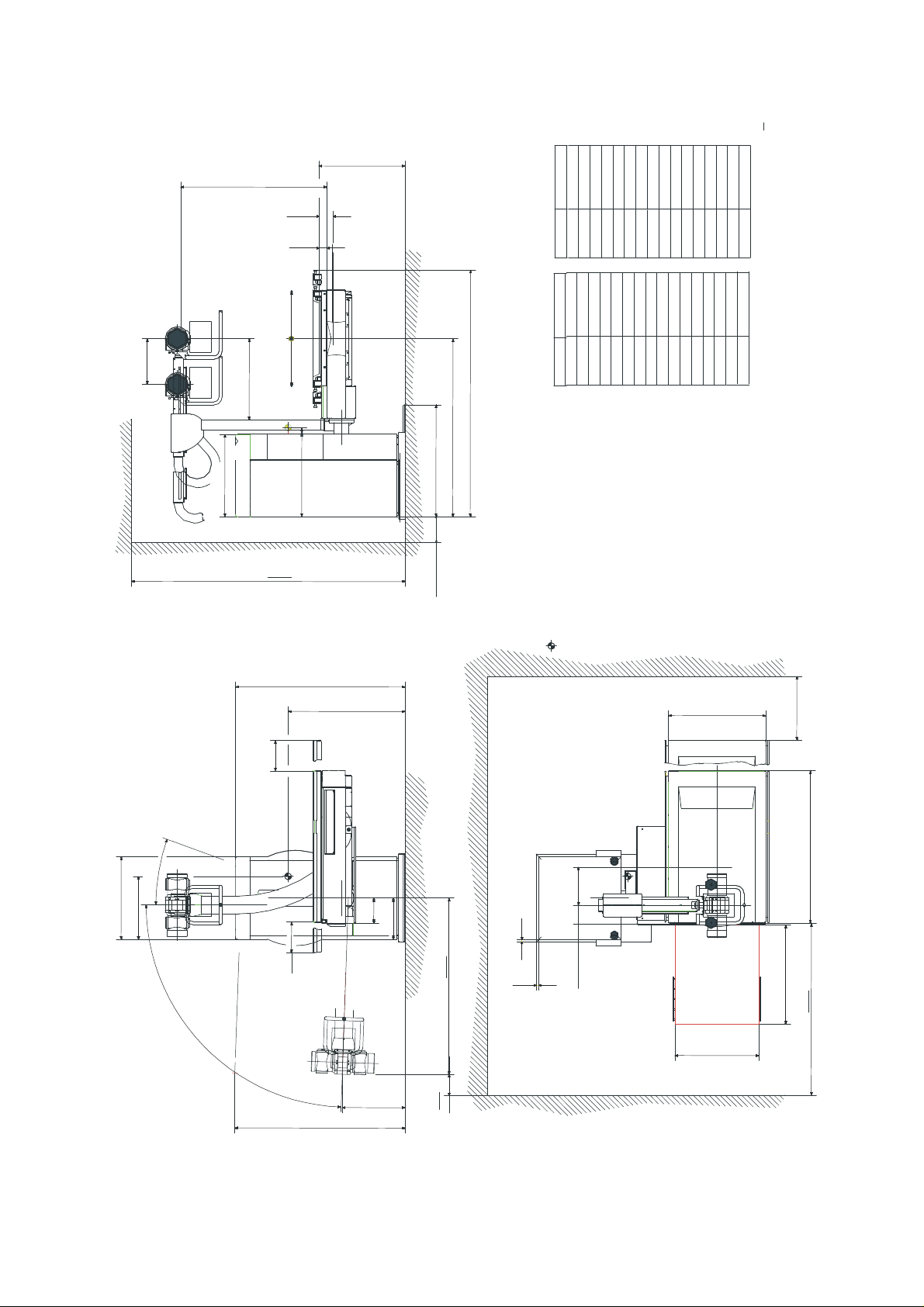

1.6.2 Dimensional Drawing for Floor Mounting, Right-handed Version

450 mm über dem Boden

345

90

min. Wandabstand

Drehachse

Fußauflagfläche

1420

74

90

74

**

900

45 800

90 470

P1

*

200

P2

180

140 205205

* Cable intake through the floor

** End of flexible hose for wall connection of 2000 mm flexible hose length

0116 7201 -8 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Kabelanschluß

690

mit Rillenschlauch

Page 9

1.6.3 Dimensional Drawing for Floor Mounting, Left-handed Version

450 mm über dem Boden

345

180

min. Wandabstand

Drehachse

Fußauflagefläche

P1

1420

P2

900

*

200

90 470

90

74

45 800

74

140205 205

**

* Cable intake through the floor

** End of flexible hose for wall connection of 2000 mm flexible hose length

06/00 - 9 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

690

Kabelanschluß

mit Rillenschlauch

Page 10

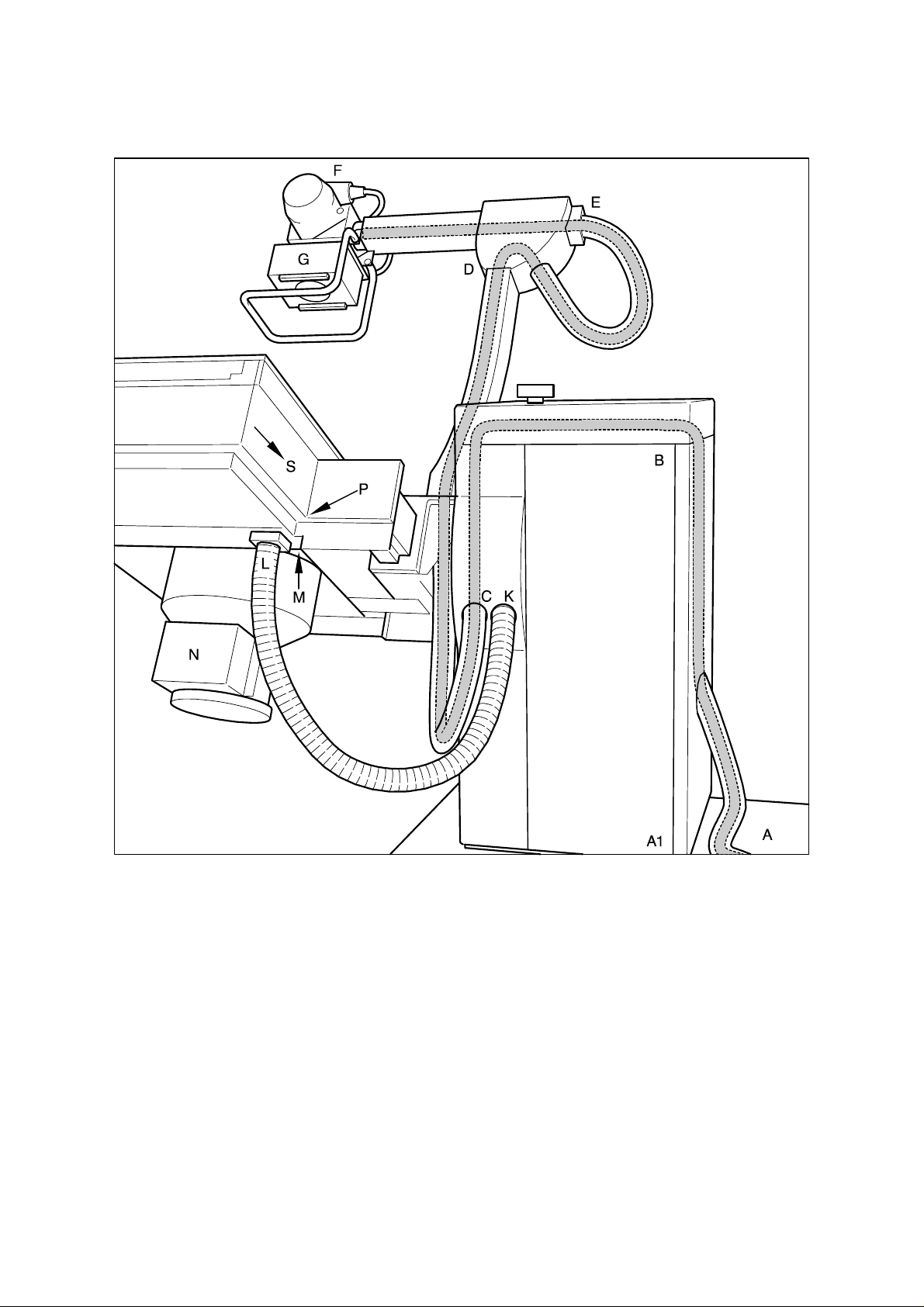

1.7 Cable Lengths of the High Voltage, Collimator, Bucky and Image

Intensifier Cables

High voltage cables A, C, D, E, F, 700 cm

Collimator cables B, C, D, E, G, 650 cm

Bucky, measuring chamber A, K, L, M, P, S, 490 cm

Image intensifier cables A, K, L, M, N, 630 cm

0116 7201 -10 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 11

1.8 Power Line Connection Data

Power lead-in must be routed over a 30 mA fault current interrupter that is provided by the

customer. The room installation must comply with VDE 0107.

In all other countries outside the Federal Republic Germany, the legally specified country

regulations take precedence and must be maintained.

Prerequisite:

The unit is designed for single-phase DC current with a fixed installation and for a fixed

connection using an all-pole separator from the Network (IEC 601, Chapter 57.1).

During installation, it must be possible to adapt the power line voltage and frequency to

correspond to the order.

Power connection: 1 N 115 /200/208/ 230/240 V AC

Frequency: 50 / 60 Hz

Nominal current (fuse): 13/7.5/7.2/6.5/6.25 A

Nominal line power: 1500 VA

Heat dissipation: 240 W

1.9 Required Special Tools

Torque wrench 50 Nm (5 mkp)

Masonry drill bit 12 mm dia.

Sista sanitary caulking F 101

Special grease - Tunap Tungrease BS Pa. Nr.: 9026 0001

1.10 Required Test Equipment

PC or laptop with color display (black/white is also sufficient, but operation is made more difficult);

min. 486 processor; 16 MB RAM; with a 3 ½" diskette drive and hard drive.

Windows 3.x ; Win 95 operating system (Windows NT can cause difficulties with the Com interface).

Serial connection cable (9-pole, Sub-D connector to 9-pole Sub-D socket, 1-1 connection), length > 1m.

Spirit level

Tape measure

Multimeter test instrument

1.11 Conditions for Transport and Storage

Ambient temperature range -25 C to 70 C

Relative humidity in the range 5% to 95%

Air pressure in the range 700 hPa to 1100 hPa

1.12 Operating Conditions

Ambient temperature range 10 C to 40 C

Relative humidity in the range 20% to 80%

Air pressure in the range 700 hPa to 1100 hPa

06/00 - 11 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 12

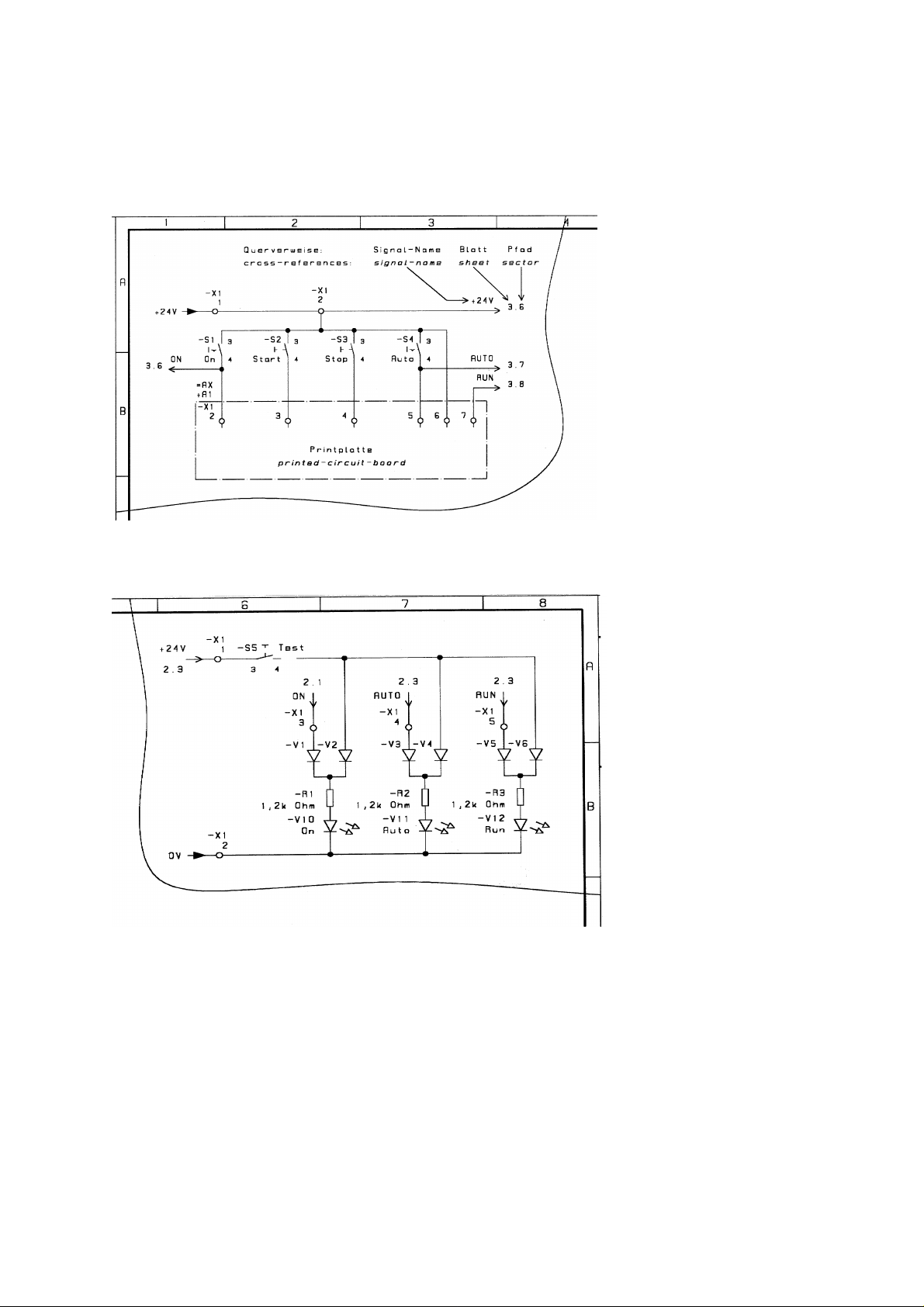

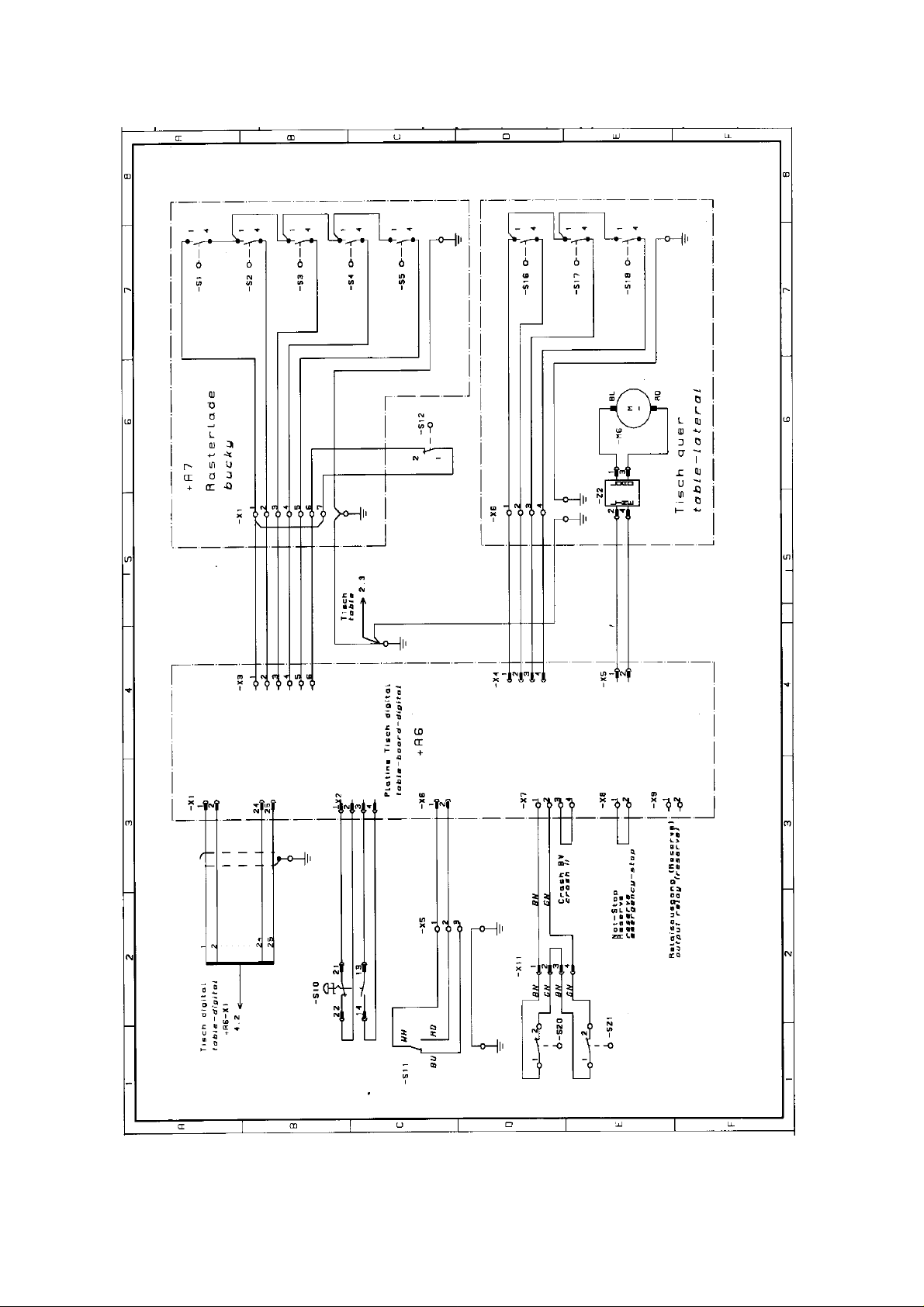

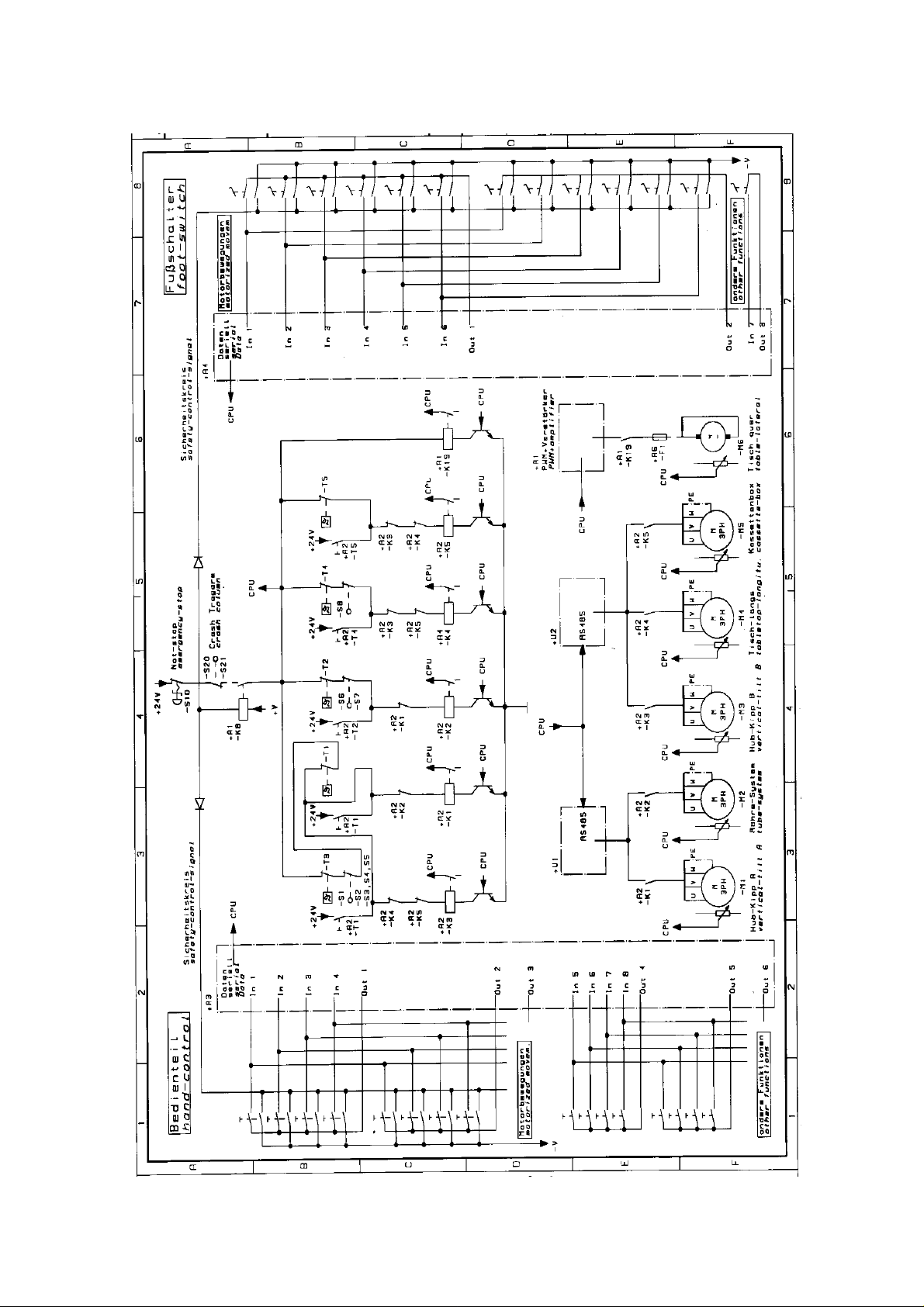

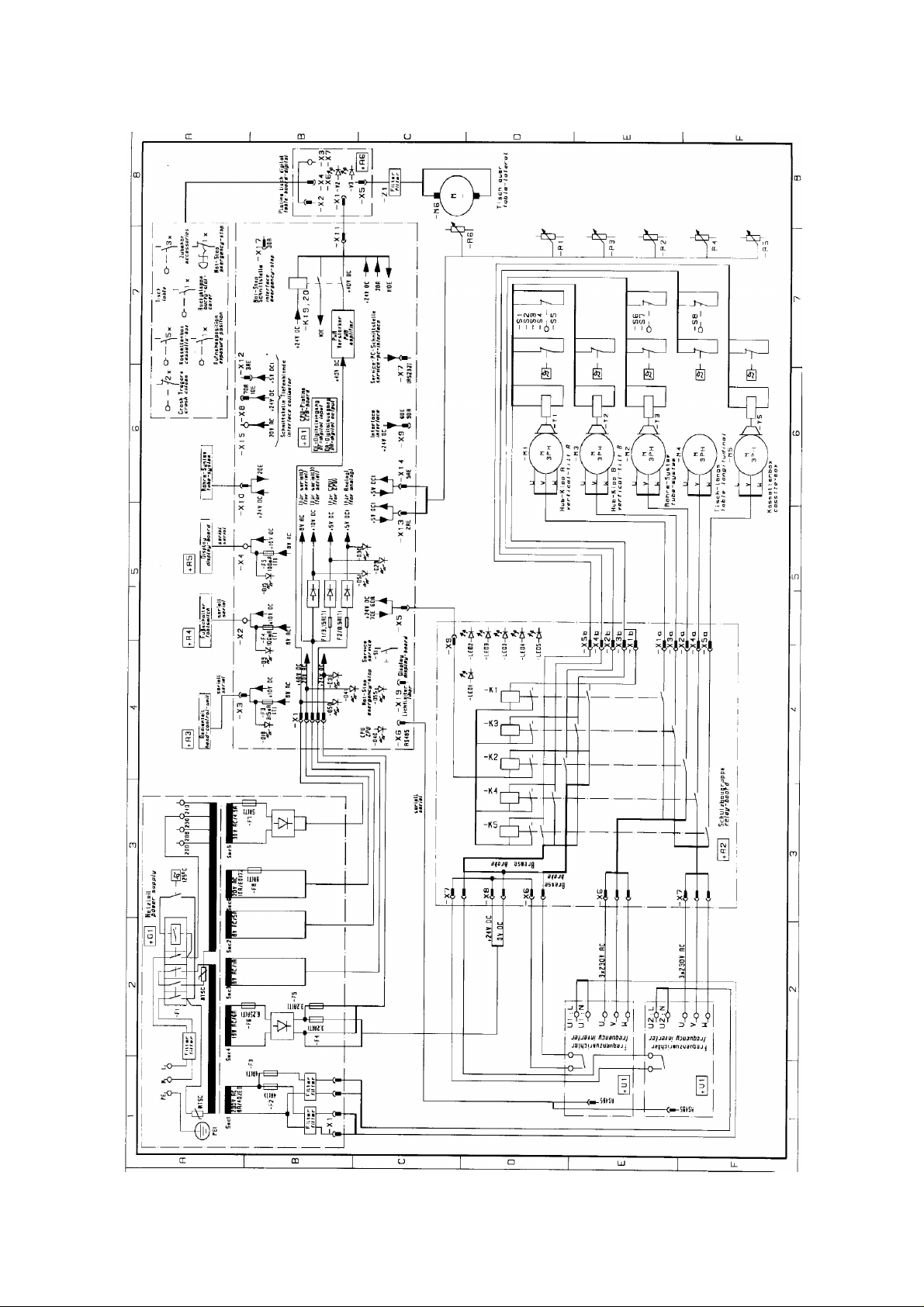

1.13 Circuit Diagram, Page 1

1.13.1 Description of Circuit Diagram

....... Circuit Diagram, Page 2

= AX Control unit

= system, designation

...... Circuit Diagram, Page 3

= AX + A2 Display unit

= system, + location, designation

1.13.2 Contents of Circuit Diagram

1.13 Circuit Diagram, Page 2 Page 13

1.13 Circuit Diagram, Page 3 Page 14

1.13 Circuit Diagram, Page 4 Page 15

1.13 Circuit Diagram, Page 5 Page 16

1.13 Circuit Diagram, Page 6 Page 17

1.13 Circuit Diagram, Page 7 Page 18

1.13 Circuit Diagram, Page 8 Page 19

1.13 Circuit Diagram, Page 9 Page 20

1.13 Circuit Diagram, Page 10 Page 21

1.13 Circuit Diagram, Page 11 Page 22

1.13 Circuit Diagram, Page 12 Page 23

1.13 Circuit Diagram, Page 13 Page 24

1.13 Circuit Diagram, Page 14 Page 25

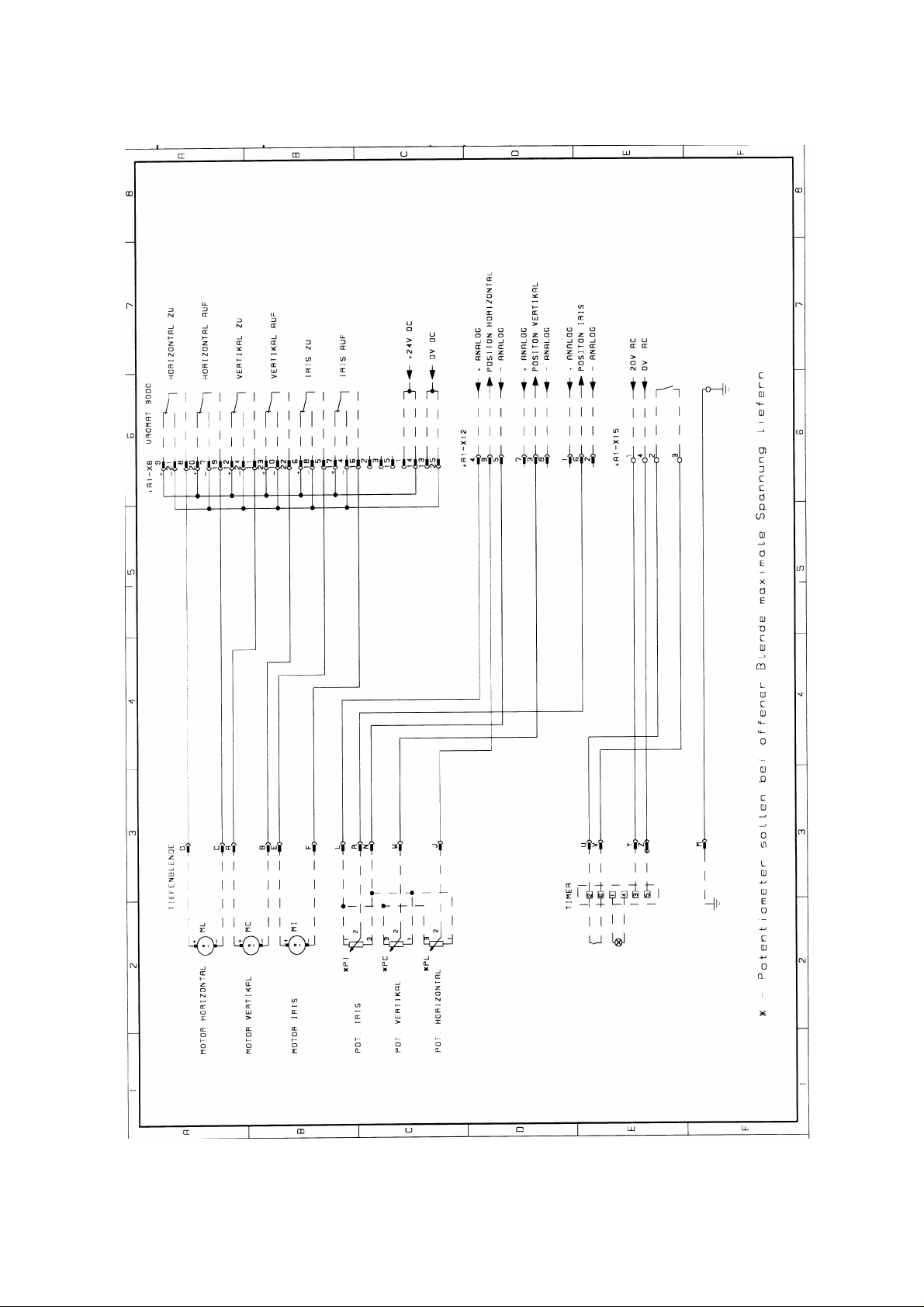

1.13 Circuit Diagram, Page 15 Collimator Page 26

0116 7201 -12 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 13

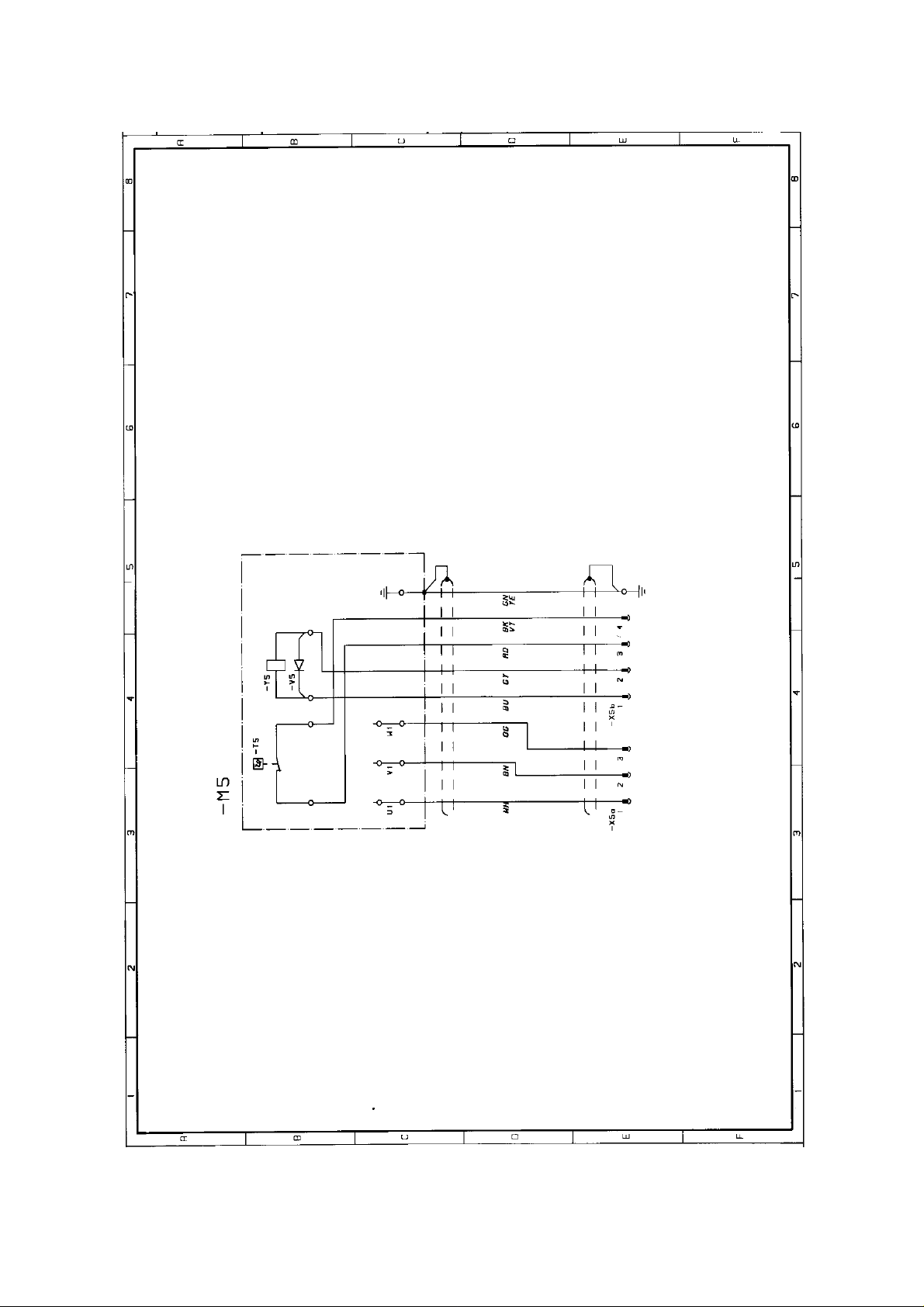

1.13 Circuit Diagram, Page 2

06/00 - 13 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 14

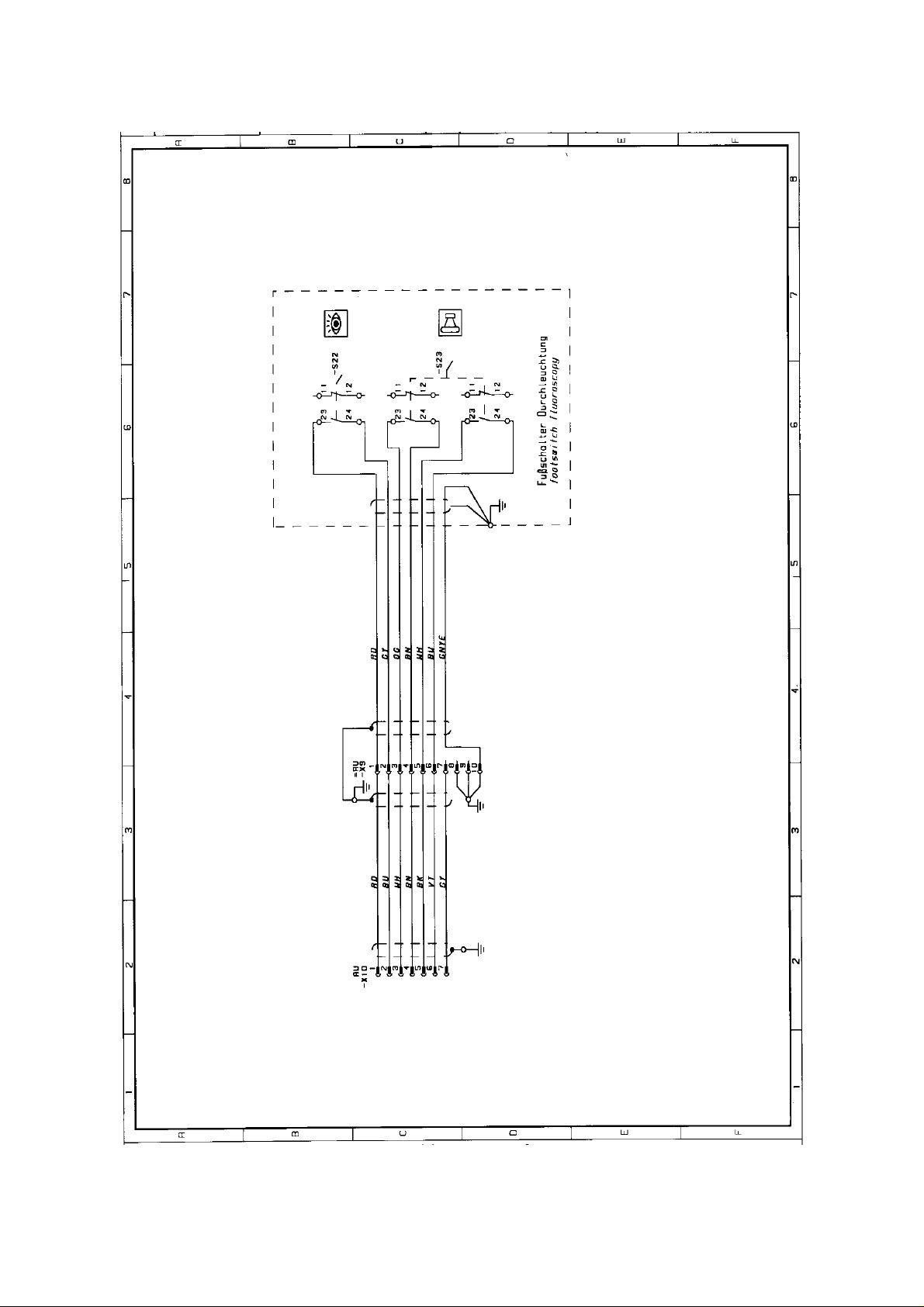

1.13 Circuit Diagram, Page 3

0116 7201 -14 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 15

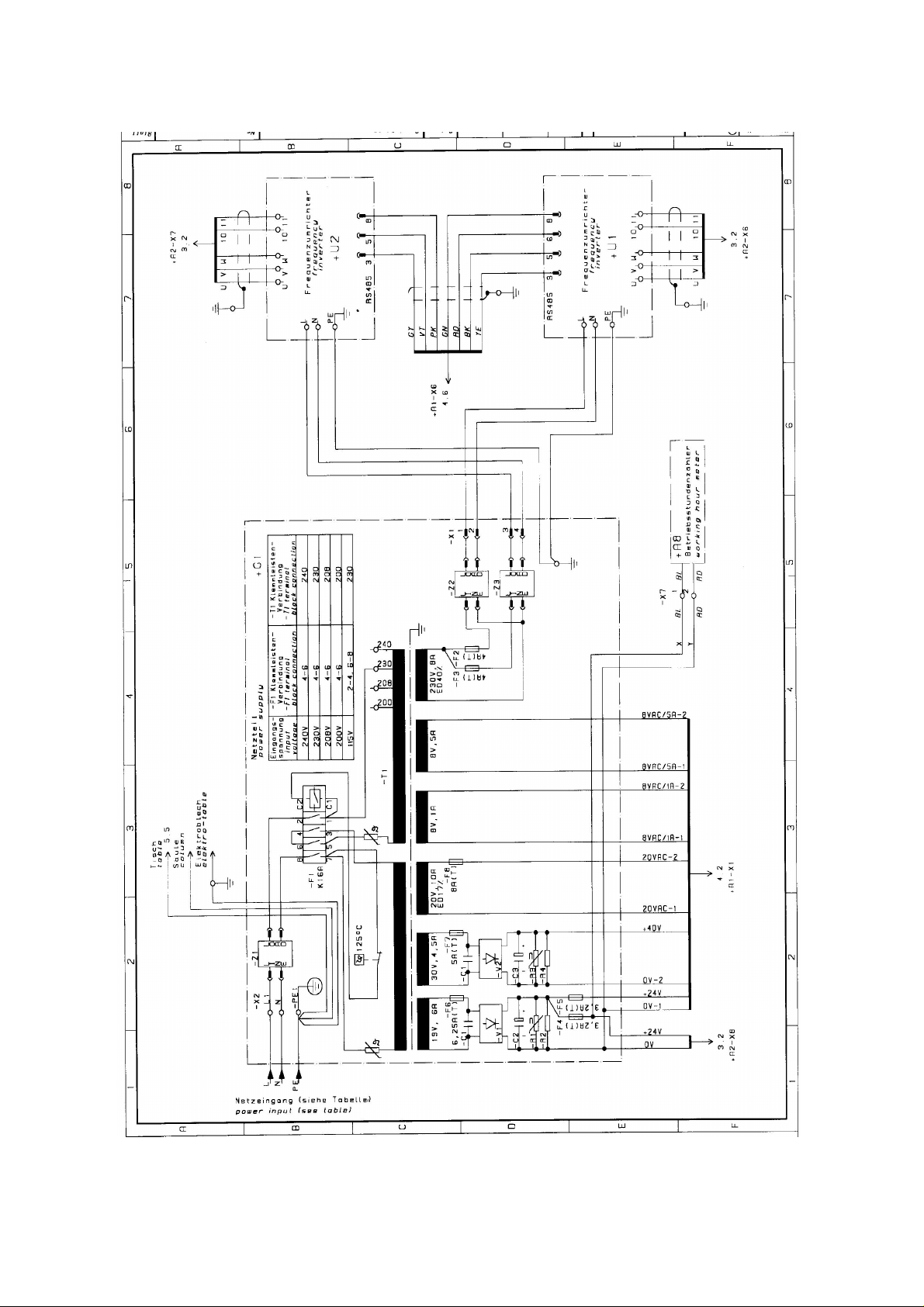

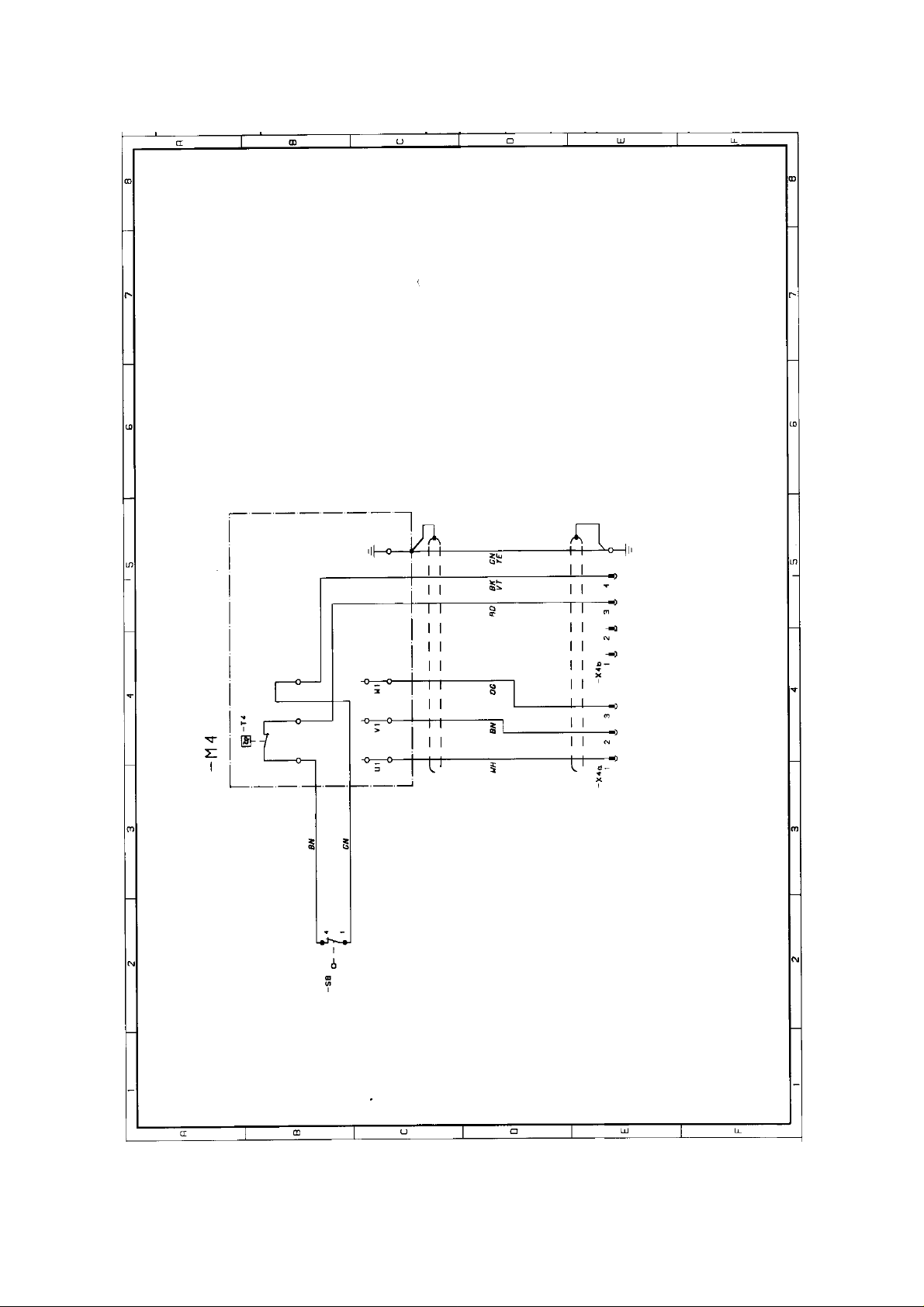

1.13 Circuit Diagram, Page 4

06/00 - 15 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 16

1.13 Circuit Diagram, Page 5

0116 7201 -16 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 17

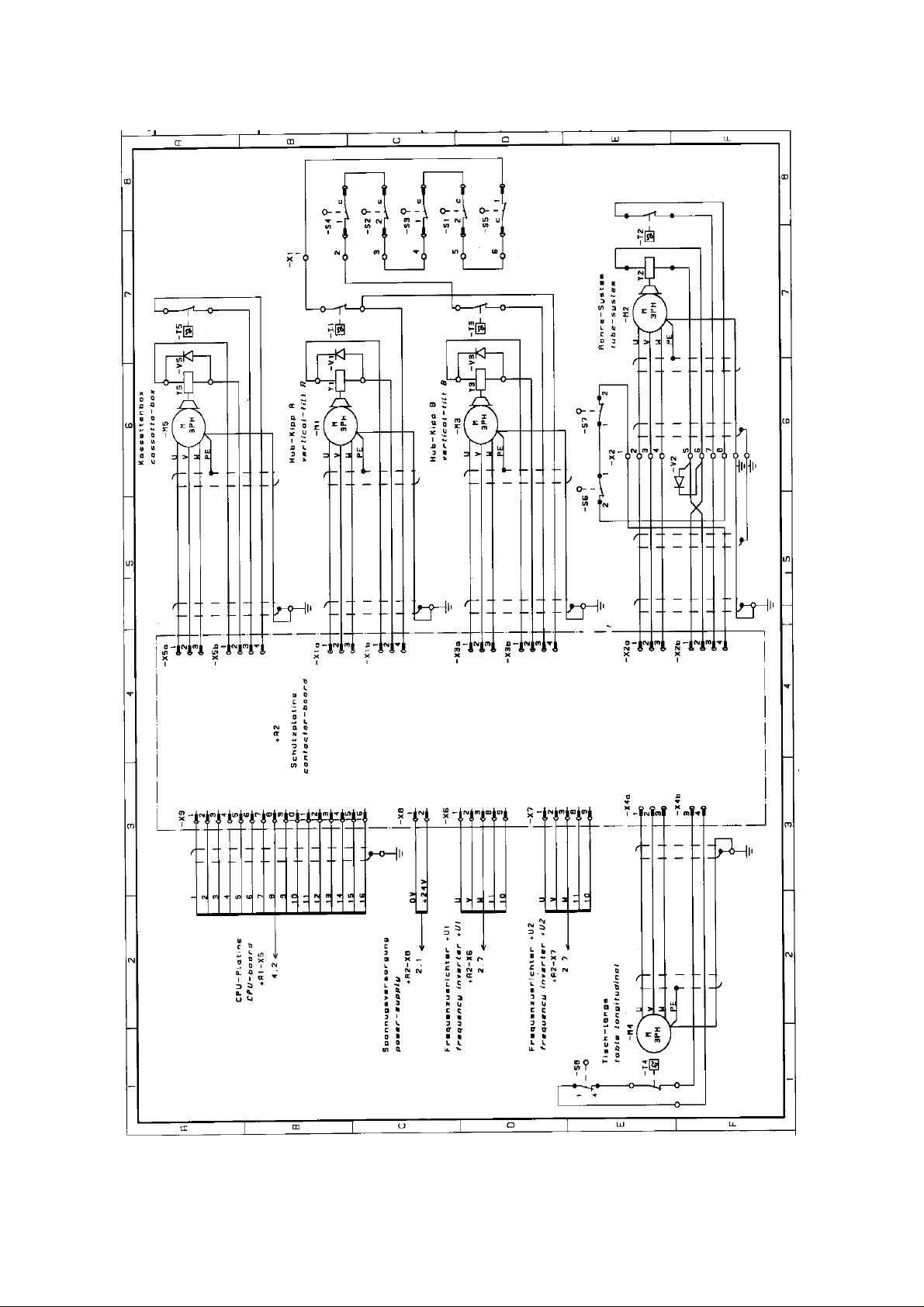

1.13 Circuit Diagram, Page 6

06/00 - 17 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 18

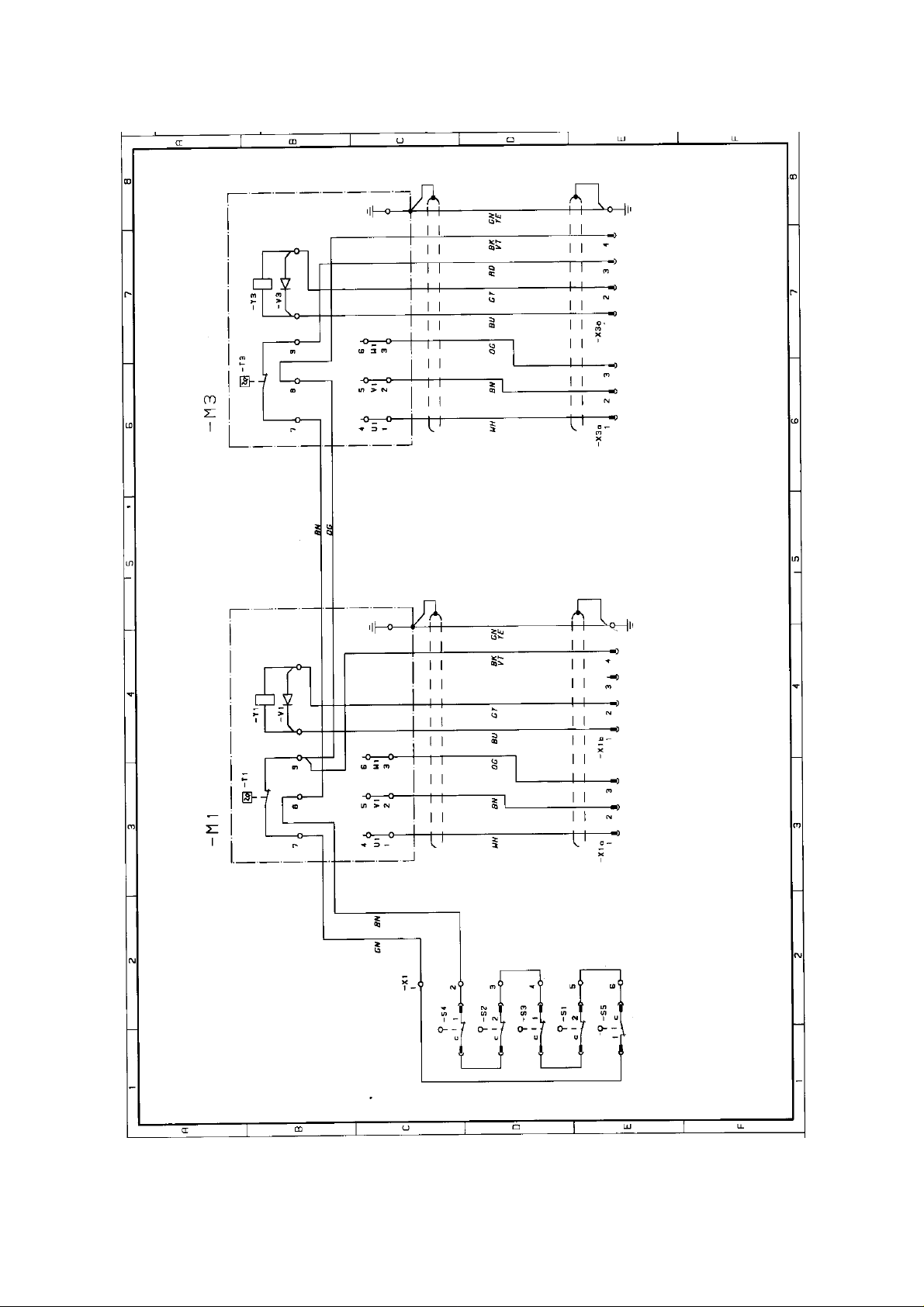

1.13 Circuit Diagram, Page 7

0116 7201 -18 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 19

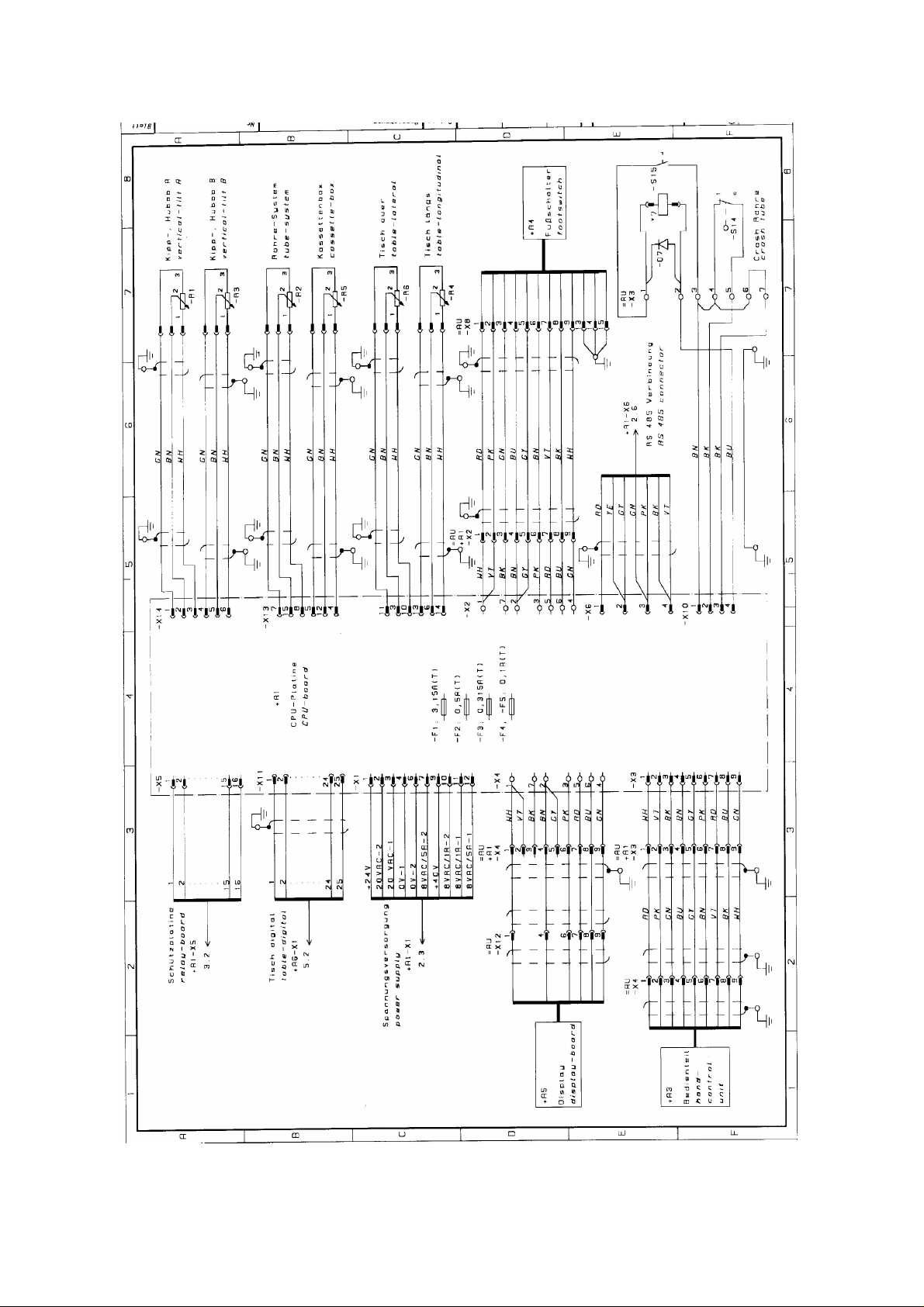

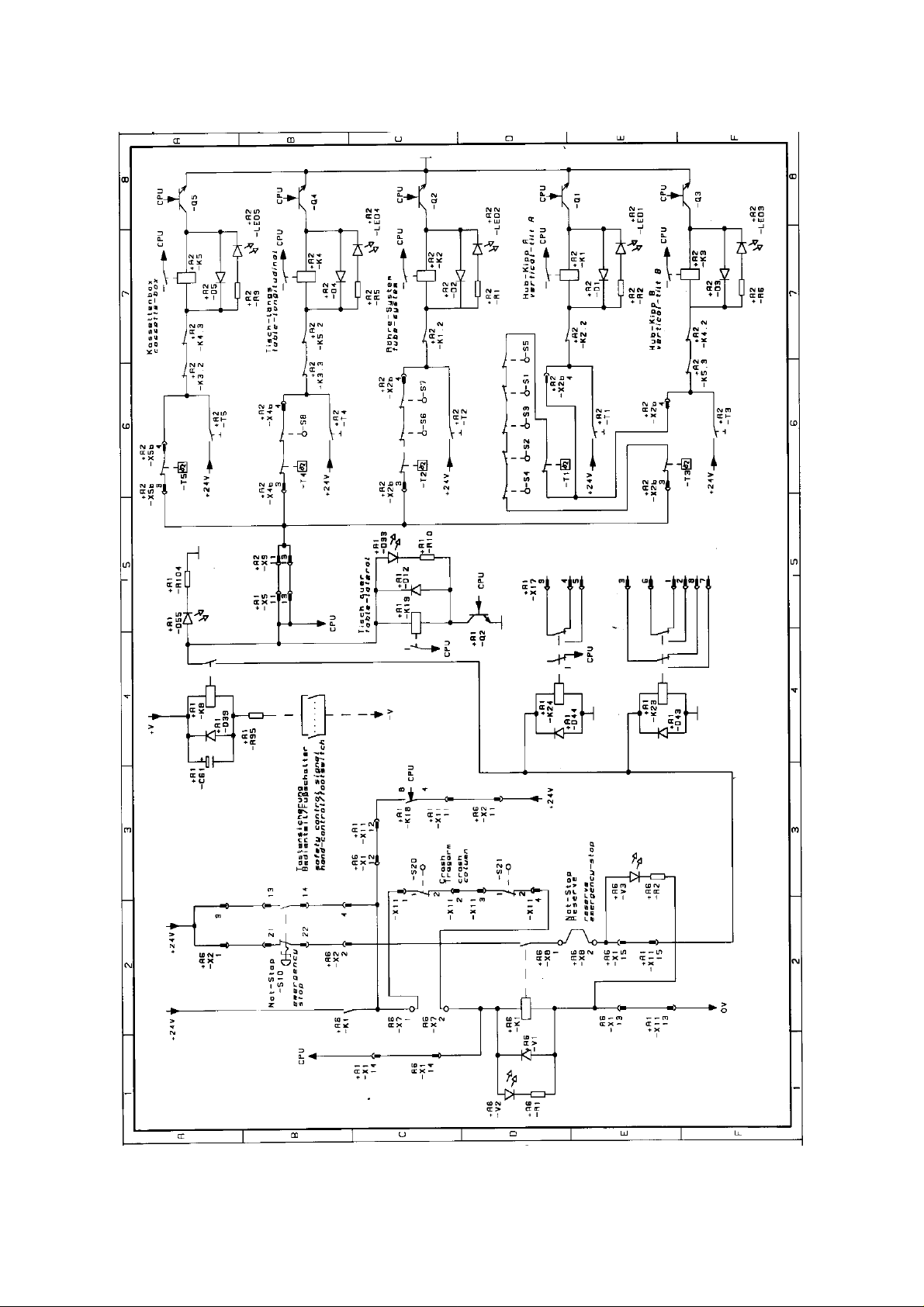

1.13 Circuit Diagram, Page 8

06/00 - 19 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 20

1.13 Circuit Diagram, Page 9

0116 7201 -20 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 21

1.13 Circuit Diagram, Page 10

06/00 - 21 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 22

1.13 Circuit Diagram, Page 11

0116 7201 -22 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 23

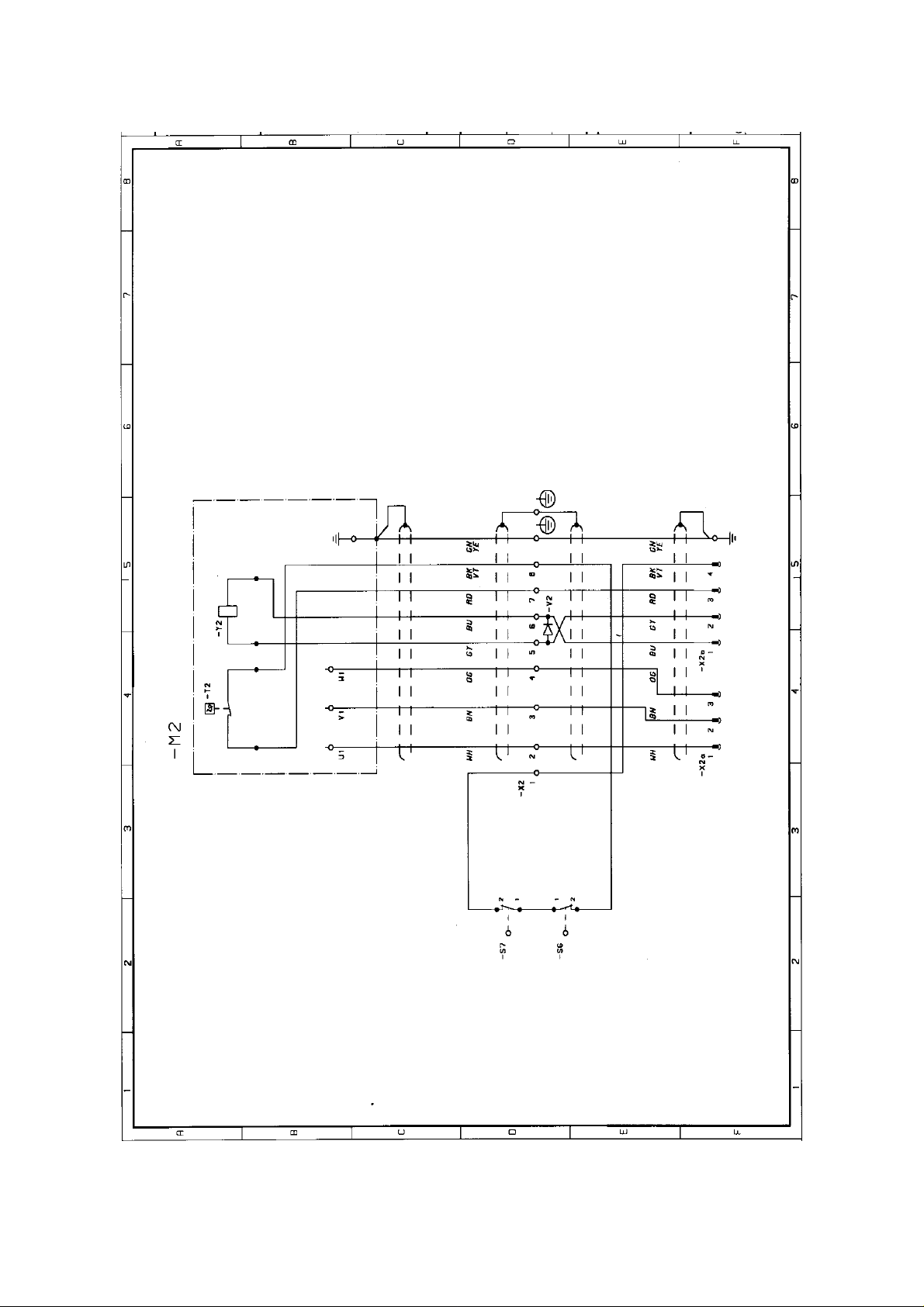

1.13 Circuit Diagram, Page 12

06/00 - 23 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 24

1.13 Circuit Diagram, Page 13

0116 7201 -24 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 25

1.13 Circuit Diagram, Page 14

06/00 - 25 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 26

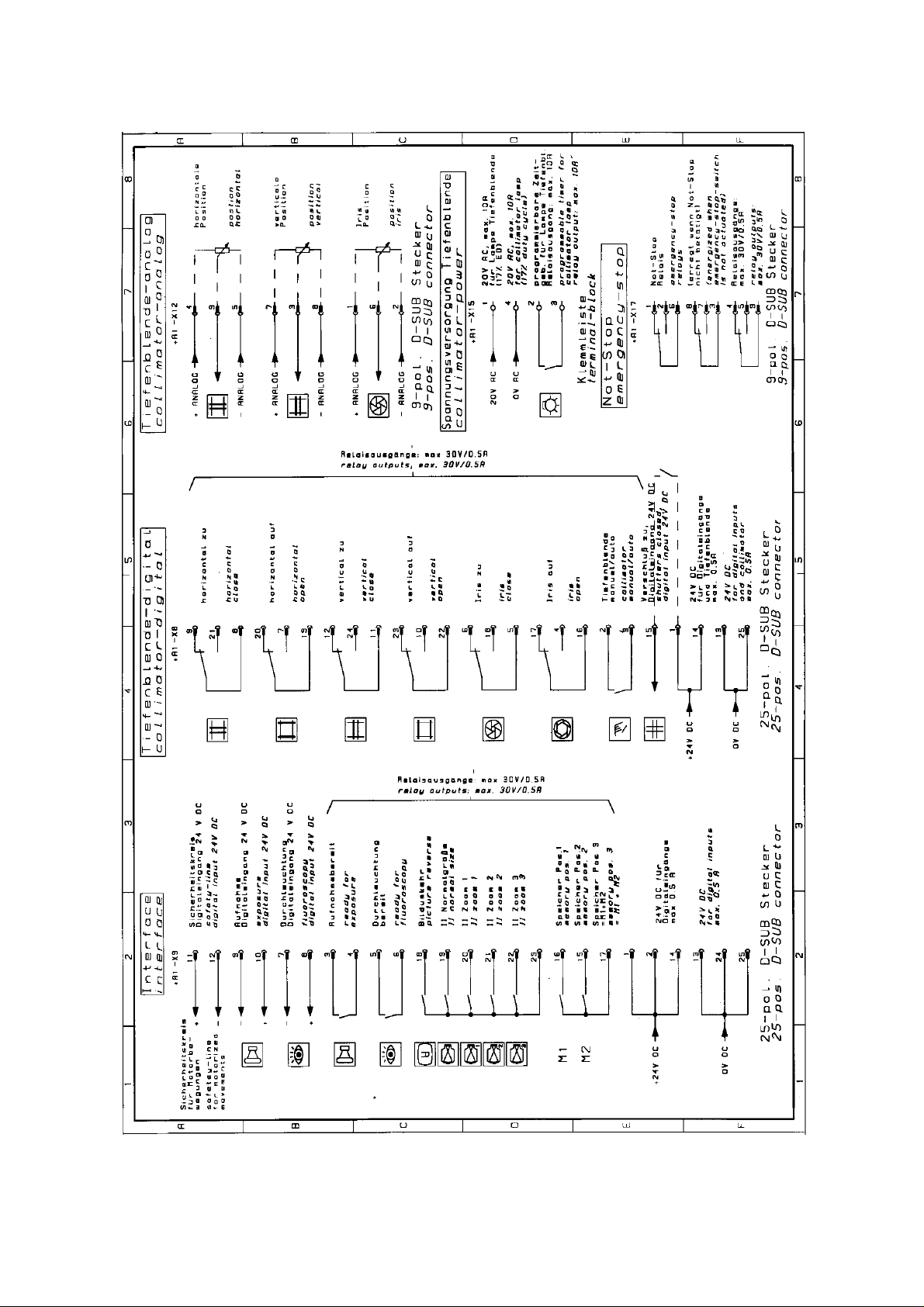

1.13 Circuit Diagram, Page 15 Collimator connection

0116 7201 -26 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 27

1.14 Component Designations for the Circuit Diagram

System Location Component Function

=AU Uromat 3000

=AU +A1 CPU board

=AU +A1 -D9 LED, footswitch power supply

=AU +A1 -D15 LED, display power supply

=AU +A1 -D18 LED, control console power supply

=AU +A1 -D29 LED, CPU power supply

=AU +A1 -D30 LED, Analog power supply

=AU +A1 -D31 LED, + 24 V power supply

=AU +A1 -D33 LED, K19 relay activated

=AU +A1 -D40 LED, CPU status

=AU +A1 -D41 LED, 20VAC power supply

=AU +A1 -D50 LED, +24V DC power supply

=AU +A1 -D51 LED, +10V DC power s

=AU +A1 -D55 LED, emergency stop

=AU +A1 -F1 Fuse, CPU power supply

=AU +A1 -F2 Fuse, analog power supply

=AU +A1 -F3 Fuse, control console power supply

=AU +A1 -F4 Fuse, footswitch power supply

=AU +A1 -F5 Fuse, display power supply

=AU +A1 -K8 Button fuse relay

=AU +A1 -K19 Enable table transverse movement relay

=AU +A1 -K20 Table, transverse, left, right movement relay

=AU +A1 -K23 Emergency stop interface relay

=AU +A1 -K24 Emergency stop interface relay

=AU +A1 -Q2 Transistor for K19 pull-in relay

=AU +A1 -S1 Service switch

=AU +A1 -X1 Power supply plug-in connector

=AU +A1 -X2 Footswitch plug-in connector

=AU +A1 -X3 Control console plug-in connector

=AU +A1 -X4 Display connector strip

=AU +A1 -X5 Display connector strip

=AU +A1 -X6 RS 485 plug-in connector

=AU +A1 -X7 Service PC plug-in connector

=AU +A1 -X8 Collimator plug-in connector

=AU +A1 -X9 Interface plug-in connector

=AU +A1 -X10 Tube unit system plug-in connector

=AU +A1 -X11 Digital table plug-in connector

=AU +A1 -X12 Collimator plug-in connector

=AU +A1 -X13 Analog table plug-in connector

=AU +A1 -X14 Analog column plug-in connector

=AU +A1 -X15 Power supply terminal strip

=AU +A1 -X17 Emergency stop plug-in connector

=AU +A1 -X19 Display fiber-optic cable plug-in connector

06/00 - 27 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 28

System Location Component Function

=AU +A2 Breaker board

=AU +A2 -K1 Motor breaker for M1 motor

=AU +A2 -K2 Motor breaker for M2 motor

=AU +A2 -K3 Motor breaker for M3 motor

=AU +A2 -K4 Motor breaker for M4 motor

=AU +A2 -K5 Motor breaker for M5 motor

=AU +A2 -LED1 Motor breaker LED - K1 energized

=AU +A2 -LED2 Motor breaker LED - K2 energized

=AU +A2 -LED3 Motor breaker LED - K3 energized

=AU +A2 -LED4 Motor breaker LED - K4 energized

=AU +A2 -LED5 Motor breaker LED - K5 energized

=AU +A2 -LED6 +24V power supply LED

=AU +A2 -Q1 Transistor for K1 breaker

=AU +A2 -Q2 Transistor for K2 breaker

=AU +A2 -Q3 Transistor for K3 breaker

=AU +A2 -Q4 Transistor for K4 breaker

=AU +A2 -Q5 Transistor for K5 breaker

=AU +A2 -T1 M1 safety circuit override button

=AU +A2 -T2 M2 safety circuit override button

=AU +A2 -T3 M3 safety circuit override button

=AU +A2 -T4 M4 safety circuit override button

=AU +A2 -T5 M5 safety circuit override button

=AU +A2 -X1a M1 power supply plug-in connector

=AU +A2 -X1b M1 brake safety switch plug-in connector

=AU +A2 -X2a M2 power supply plug-in connector

=AU +A2 -X2b M2 brake safety switch plug-in connector

=AU +A2 -X3a M3 power supply plug-in connector

=AU +A2 -X3b M3 brake safety switch plug-in connector

=AU +A2 -X4a M4 brake safety switch plug-in connector

=AU +A2 -X4b M4 brake safety switch plug-in connector

=AU +A2 -X5a M5 power supply plug-in connector

=AU +A2 -X5b M5 brake safety switch plug-in connector

=AU +A2 -X6 +U1 frequency converter plug-in connector

=AU +A2 -X7 +U2 frequency converter plug-in connector

=AU +A2 -X8 +24V DC power supply plug-in connector

=AU +A2 -X9 CPU board plug-in connector

=AU +A3 Control unit

=AU +A4 Footswitch

=AU +A5 Display

=AU +A6 Digital table board

=AU +A6 -V2 LED, K1 relay energized

=AU +A6 -V3 LED, emergency stop not pressed and K1 energized

=AU +A6 -X1 CPU board cable plug-in connector

=AU +A6 -X2 Emergency stop switch plug-in connector

0116 7201 -28 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 29

System Location Component Function

=AU +A6 -X3 Terminal strip for Bucky

=AU +A6 -X4 Plug-in connectors for accessories

=AU +A6 -X5 Table, transverse motor plug-in connector

=AU +A6 -X6 Bucky shaft cover plug-in connector

=AU +A6 -X7 Support arm collision, I.I. collision terminal strip

=AU +A6 -X8 Spare emergency stop plug-in connector

=AU +A7 Bucky

=AU +A7 -S1 Cassette inserted switch

=AU +A7 -S2 24x43 cassette switch

=AU +A7 -S3 30x43 cassette switch

=AU +A7 -S4 24x30 cassette switch

=AU +A7 -S5 18x43 cassette switch

=AU +A8 Operating hours counter

=AU +G1 Power supply

=AU +G1 -F1 Trip breaker

=AU +G1 -F2 +U1 frequency converter fuse

=AU +G1 -F3 +U2 frequency converter fuse

=AU +G1 -F4 Fuse for breaker, motor brake

=AU +G1 -F5 Fuse for inputs/outputs

=AU +G1 -F6 +24V power supply fuse

=AU +G1 -F7 Table transverse power supply fuse

=AU +G1 -F8 Collimator power supply fuse

=AU +G1 -PE1 Main grounding stud

=AU +G1 -T1 Isolation transformer

=AU +G1 -X1 Frequency converter plug-in connector

=AU +G1 -X2 Power supply terminal strip

=AU +G1 -Z1 Power input filter

=AU +G1 -Z2 +U2 frequency converter filter

=AU +G1 -Z3 +U1 frequency converter filter

=AU +U1 Frequency converter

=AU +U2 Frequency converter

=AU -M1 Lift motor tilt A

=AU -M2 Tube unit system motor

=AU -M3 Lift motor tilt B

=AU -M4 Table longitudinal motor

=AU -M5 Cassette box motor

=AU -M6 Table transverse motor

=AU -R1 Lift motor tilt A potentiometer

=AU -R2 Tube unit system motor potentiometer

=AU -R3 Lift motor tilt B potentiometer

=AU -R4 Table longitudinal motor potentiometer

06/00 - 29 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 30

System Location Component Function

=AU -R5 Cassette box motor potentiometer

=AU -R6 Table transverse motor potentiometer

=AU -S1 M1 spindle nut safety switch

=AU -S2 M3 spindle nut safety switch

=AU -S3 M1 counterweight safety switch

=AU -S4 M3 counterweight safety switch

=AU -S5 Vertical movement safety switch

=AU -S6 Tube unit system safety switch, foot end

=AU -S7 Tube unit system safety switch, head end

=AU -S8 Table longitudinal safety switch

=AU -S10 Emergency switch

=AU -S11 Bucky shaft cover switch

=AU -S12 System cassette exposure position switch

=AU -S14 Tube unit support arm exposure position switch

=AU -S15 Tube unit support arm movement switch

=AU -S16 Accessory switch

=AU - S17 Accessory switch

=AU - S18 Accessory switch

=AU - S20 Support arm collision switch

=AU - S21 Support arm collision switch

=AU - S22 Fluoroscopy switch

=AU - S23 Exposure switch

=AU - T1 Lift motor tilt A thermoswitch

=AU - T2 Tube unit system motor thermoswitch

=AU - T3 Lift motor tilt B thermoswitch

=AU - T4 Table longitudinal motor thermoswitch

=AU - T5 Tube unit system motor thermoswitch

=AU - T6 Table transverse motor thermoswitch

=AU - X1 Lift, tilt movement safety circuit connector strip

=AU - X2 Tube unit system motor connector strip

=AU - X3 Tube unit support arm connector strip

=AU - X4 Control unit plug-in connector

=AU - X5 Bucky shaft cover connector strip

=AU - X6 Accessories connector strip

=AU - X7 Operating hours counter connector strip

=AU - X8 Footswitch plug-in connector

=AU - X9 Fluoro plug-in connector (table)

=AU - X10 Fluoro connector (electronics panel)

=AU - X11 Support arm collision plug-in connector

=AU - X12 Display plug-in connector

=AU - Y1 M1 motor brake

=AU - Y2 M2 motor brake

=AU - Y3 M3 motor brake

=AU - Y5 M5 motor brake

=AU - Y7 Tube unit support arm lift magnet

=AU - Z1 Table transverse motor filter

0116 7201 -30 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 31

1.15 Function Description of the Controller

wire bit bus

a. System Overview

The electronic controller for the UROMAT 3000 is comprised of a max. of 5 units that are

connected to each other via a bus.

UNIT FUNCTION LOCATION REMARK

CPU board

Central unit for the

entire controller with

all interfaces.

Breaker board

Board with 5 breakers

for the 5 AC motors.

Footswitch

Operation using

pedals, equivalent to

control unit, but does

Control unit

not have all functions.

Portable manual

control unit with all

functions.

Display unit

Display of the tilt

angle and of various

statuses.

Additional peripheral equipment can be connected via the USS interface.

All interfaces are located on the CPU board:

INTERFACE FUNCTION MODE REMARK

MOTRON bus Connection of the

CPU in the star

configuration to the

display unit, control

unit and footswitch.

USS bus Connection to the

frequency converters.

Fiber optic Connection to status

display (customer

request)

Behind the cover

panel, top.

Behind the cover

panel, below the CPU

board.

Metal housing on the

floor, connected to

the CPU board via

cables.

External, connected

by a spiral cable to

the CPU.

Permanently mounted

on the housing.

Connected to the

CPU by cable.

Serial, two-wire bit

bus via optocoupler

with full duplex

connection.

Serial twovia RS485 with

full duplex connection

with USS protocol.

Optical serial bus with

USS protocol.

All connectors on the

CPU board are

labeled.

If there is a foot-

switch, not absolutely

necessary for

operation.

If there is a foot-

switch, not absolutely

necessary for

operation.

Not absolutely

necessary for

operation.

1 direction only:

write!

06/00 - 31 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 32

b. Boards

Emergency off Digital Interface

Interface

to frequency

converter

Potentiometer

Fiber optic monitoring

Service LED

Potentiometer

Service switch for adjustment of

the stopping

force of the DCConnector to PC motor

Eprom with URO connector

Software DC Motor

power supply

Plug-in

Processor

Module

Interface for Interface for

display multi-function

footswitch-

Interface for

manual controller

CPU Board

0116 7201 -32 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 33

5 buttons with

LED

to freely move

out of the limit

positions

5 Switch

breakers

for -

the 5

motors

Breaker Board

06/00 - 33 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 34

Interface for CPU board

Key connections

Footswitch Board

Control Unit

Interface for CPU board

Display Board

0116 7201 -34 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 35

2. Installation

2.1 Preparations for Mounting

Prepare the unit location according to the dimensional drawing, Page 6 or 7 or Page 8 or 9.

Caution: The minimum distances listed in the dimensional drawings must be maintained to

assure that all movements of the system are possible.

The floor must be capable of bearing a load of 10,450 N on the front mounting points

according to Dimensional Drawing, Pages 8 and 9.

The P2 mounting points on the back of the unit must each be capable of assuming 1020 N

pull.

Example: Liebig S12/40 or S12/65 expansion bolts with an image quality of 2 with a

concrete quality of B 25, DIN 1045. The minimum drill hole depth may be 80 or 105 mm.

With a vinyl tile floor, the floor covering must be cut out in the area of the unit base.

2.2 Unpacking the Unit

Open the crate and remove the protective film (Fig. 01 /Pos. 1). Only open the cartons (Pos.

2,3+4) and place them to one side until it is time to use them.

Check the items included in the shipment or the parts for completeness and for good

condition.

Unit on pallet

Fig. 01 Fig. 02

Remove the securing screws on the unit base cover panel (Fig. 02/Pos.1). The left cover

panel (Fig.03/Pos. 2) and right cover panel (Fig.02/Pos. 3) after removing the mounting

screws closest to the floor.

Remove the narrow left (Fig.03/Pos. 4) and narrow right cover panel (Fig.02/Pos. 5).

06/00 - 35 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 36

Fig. 03 Fig. 04

Take off the back wall (Fig. 04/Pos. 7).

Notice:

The tube unit support arm (Fig. 05/Pos. 1) is hooked onto the opening of the base with the

mounting bracket (painted red) (Pos. 2) and secured on the floor plate. The tube unit support

arm is unhooked from its holder only after it is installed.

7

8

6

Fig. 05 Fig. 06

2.3 Removing the Unit from the Pallet

Remove the transport safety devices (Fig. 05/Pos. 6, 7 + 8 ).

Install the two support struts of the installation frame (Fig. 06/Pos. 1+2) on both sides of the

unit column and the connector piece (Pos. 3) between the two support struts.

0116 7201 -36 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 37

Install a spindle cross piece (Pos. 5+6) on each end of both support struts.

Remove the mounting screws (Fig. 07/Pos. 1+ Fig.06/Pos. 8) of the unit column from the

pallet and press it down onto the pallet.

Use the 4 lift spindles (Fig. 06/Pos. 7) to evenly raise the unit until the transport pallet

(Pos.9) is free and then slide it out from under the unit.

Install the 4 castors (Fig. 08/Pos. 3+4) (transport castors) for transport on the support studs

(Pos. 1+2). Use the 4 lift spindles to lower the unit (with narrow transport pathways, remove

the spindle cross pieces, Pos. 5+6) and move the unit to its installation location.

At the installation location, use the spindles to raise the unit until the castors are off the floor.

Remove the castors and evenly lower the unit.

Caution:

The two support struts on the installation frame (Fig. 06/Pos. 1+2) may be removed

only when the unit is secured to the floor.

Fig. 07 Fig. 08

2.4 Installing the Unit Column

Remove the lower transport bracket (Fig. 05/Pos. 2) on the tube unit support arm.

While observing the tensile strength data that is listed on them, use the 6 heavy-duty load

expansion bolts (for example, Liebig S12/40 or S12/65 expansion bolts) (Fig. 07/Pos. 1 and

Fig. 09/Pos. 2).

Remove the transport frame (Fig. 06/Pos. 1+2).

Disengage the tube unit support arm (Fig. 03/Pos. 3) towards the top out of the unit base

and carefully place it down on the floor next to the unit.

Disconnect the plug-in connector for the display.

Remove the cover panel on the unit base (Fig. 02/Pos. 1).

06/00 - 37 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 38

Fig.09 Fig. 10

2.5 Aligning the Unit Column

Check the unit column (Fig. 10/Pos. 1) in both directions using a spirit level that has been

placed on the guide rail (Fig. 10/Pos. 3+4).

Compensate for the differences using shims (Fig. 11/Pos. 1+2) from the items included in

the shipment.

Caution: The unit column may not be under tension in any direction.

Fig. 11 Fig. 12

0116 7201 -38 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 39

2.6 Temporarily Connecting Line Power

Caution:

If the unit is connected to a different line power than that listed on the order, the setting must

be changed to the one that corresponds to the local line power as specified by the Wiring

Diagram to the power line transformer (Fig. 12/Pos. 1).

Provide the unit with power by connecting a temporary connection cable (plug-in cable) to

move the table for individual installation steps.

Connect the multi-function footswitch on the bottom of the table.

Fig. 13 Fig. 14

2.7 Installing the Tube Unit Support Arm

Tilt the tabletop all the way down into the horizontal position and move it towards the front,

transversely to the user, until it is in the end position. Move the tube unit carriage (system

carriage) max. to the head end.

Remove the drain panel (Fig. 13/Pos. 1) after loosening the 5 mounting screws (Pos. 2,3+4).

Place the tube unit support arm (Fig. 14/Pos. 1) on the longitudinal carriage (Pos. 2) and

secure it in place with the 6 screws (Pos. 3+4).

Remove the red transport bracket (Fig. 05/Pos. 1) (hooking device).

Reinstall the drain panel (Fig. 13/Pos. 1).

06/00 - 39 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 40

2.8 Preinstalling the Tube Unit – Collimator Combination

Assemble the tube unit – Collimator combination according to the description in the

manufacturer's installation instructions. See Fig. 15

Fig. 15 Fig. 16

2.9 Installing the Tube Unit – Collimator on the Tube Unit Support Arm

Tilt the tabletop until it is vertical and move the tube unit carriage towards the foot-end.

Remove the cover (Fig. 18/Pos. 6) on the tube unit support arm. Remove the support studs

(Fig. 16/Pos. 1) from the tube unit support arm (Pos. 2). Place the preinstalled tube unit –

collimator combination (Fig. 17/Pos. 1) down on its side and move the command arm (Pos.

2) between the support studs (Pos. 3) and the tube unit housing (Pos. 1) and secure them in

place with the 4 screws (Pos. 5).

Fig. 17 Fig. 18

0116 7201 -40 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 41

Place the assembled tube unit – collimator combination (Fig. 17/Pos. 1) on the tube unit

support arm (Fig. 18/Pos. 2) using the support studs (Pos. 3), insert the shims (Fig. 16/ Pos.

5) and secure it in place using the 4 screws (Pos. 6).

2.10 Installing the Image Intensifier

Remove the I.I. adapter plate (Fig. 20/Pos. 1) from the I.I. carriage (Pos. 2). Secure the I.I.

adapter plate (Fig. 19/Pos. 1) in position on the I.I. housing (Pos. 2) with the screws. Install

the I.I. unit on the I.I. carriage (Fig. 20/Pos. 2) using the two strips (Pos. 4+5) the 8 washers

and the 8 nuts (Pos. 7). Max. torque: 20 Nm.

Fig. 19 Fig. 20

2.11 Laying the Collimator Cables

The cable for the collimator is laid in the unit base parallel to the high voltage cables. The

cable for the collimator is laid parallel from the unit controller in the unit base to the high

voltage cables.

Clamp, or plug in, the cable (Fig. 12/Pos. 2) on the unit controller (Pos. 3),at the connection

points provided.

Lay the cables later in Section 2.12, Section 2.12.

06/00 - 41 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 42

Fig.21 Fig. 22

2.12 Laying the High Voltage Cables

Preparations:

Remove the cover (Fig. 18/Pos. 6), the flexible hose holder (Fig. 23/Pos. 1), the flexible hose

mount (Pos. 3) and the flexible hose holder (Pos. 5).

Remove the lift magnet (Fig. 22/Pos. 1), the latching stud (Pos. 2) and the cable deflector

(Pos. 3).

Take the two safety limit switches (Fig. 21/Pos. 1+2) out of the tube unit support arm after

removing the screws (Pos. 8).

Lay the high voltage cables and the stator cable coming from the generator up to the wall or

to the floor outlet.

To lay cables in the unit, 7 meters are required.

The high voltage cable coming from the wall and the stator cable must first be laid through

the flexible hose (Fig. 23/Pos. 9), through the back wall (Pos. 10), or if it is coming directly

from the floor, then lay it directly to the cable channel (Pos. 11) and up into the unit base.

Lay the cable for the collimator, the high voltage cable and the stator cable parallel to the

cables for the unit controller to the cable outlet (to the side of the unit table) (Fig. 23/Pos.

14).

Gather the cables together so that they are slightly staggered, pass them through the flexible

hose (Pos. 16) while being careful of the flexible hose mounting, and then pull them through

the hose mounting and through the support arm (Pos. 17), in the direction of the tube unit

(Pos. 20).

0116 7201 -42 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 43

Fig. 23

Lay the cables through the support arm towards the back, through the flexible hose (Pos. 22)

and through the carriage (Pos. 23) to the tube and to the collimator.

Guide the cable for the control handle (Pos. 24) to the connector strip (Pos. 25) in the

support arm and clamp it in place.

Secure the cables in place with the cable ties provided.

Reinstall the cable deflector (Fig. 22/Pos. 1) the latching studs (Pos. 2) and reinstall the lift

magnet (Pos. 3).

Reinstall the two safety switches (Fig. 21/Pos. 1+2) for the tube unit support arm and secure

them in place with the screws (Pos. 8).

Reinstall the flexible hose holder (Fig. 23/Pos. 1), the flexible hose mount (Pos. 3) and the

flexible hose holder (Pos. 5). Reinstall the cover panel (Fig. 18/Pos. 6).

06/00 - 43 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 44

Fig.25 Fig. 26

2.13 Laying the I.I. Cable

First lay the I.I. cable coming from the wall through the flexible hose (Fig. 23/ Pos. 9),

through the back wall (Pos. 10) and then – if it is coming directly through the floor – to the

cable channel (Fig. 23/Pos. 11) and up into the unit base.

Lay the I.I. cable parallel to the cables for the unit controller to the cable outlet (on the side of

the unit base) (Fig. 25/Pos. 4).

Remove the flexible hose (Fig. 26/Pos. 1). Pull the I.I. cable through the flexible hose to the

table, place it in the flexible plastic link chain (Pos. 2) and lay it to the I.I. connector (Pos. 3).

2.14 Making the Power Connection through the Generator

Remove the temporary power connection and connect the power via the generator.

0116 7201 -44 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 45

Fig. 27 Fig. 28

2.15 Installing the Measuring Chamber

Lift up the tabletop (CFC panel) (Fig. 27/Pos. 1), it will be held by the gas spring.

Move the tabletop towards the back and remove the front Nirosta panel. Move the tabletop

towards the front and remove the rear Nirosta panel. Remove the left (Fig. 27/Pos. 3) and

right (Pos. 4) cover panels. Remove the screws for the spiral cable guide panel and remove

the cable guide panel. Move the tabletop longitudinally, remove the 6 mounting screws in the

polycarbonate panel (Pos. 2) and remove the polycarbonate panel towards the front.

Switch the unit into the service mode, the green LED on the controller goes on and stays on.

Press the Store and Reset buttons on the control unit simultaneously, the three memory

LED`s on the control unit will blink green and the LED on the controller will blink very rapidly.

The cassette Bucky can be moved slowly forward and backward using the Recall and Reset

buttons.

Move the Bucky into the exposure position using the Recall button. Remove the grid frame

(Fig. 28/Pos. 1) after removing the two screws (Pos. 3). Insert the measuring chamber into

the holder (take note of the measuring chamber orientation) and secure it in place.

First lay the measuring chamber cable coming out of the wall through the corrugated hose

(Fig. 23/ Pos. 9), through the back wall (Pos. 10), or the cable coming directly out of the

floor, to the cable channel (Pos. 11) up and into the unit base.

Lay the measuring chamber cable parallel to the cables for the unit controller to the cable

outlet (on the side of the unit base) (Fig. 25/Pos. 4).

Remove the corrugated hose holder (Fig. 26/Pos. 1). Pull the measuring chamber cable

through the corrugated hose to the table. Insert the measuring chamber cable through the

side frame box into the flexible plastic chain of the Bucky and bring it to the measuring

chamber connector.

Caution:

The cable must be laid so that the cassette drive belt does not touch the cable.

Then reinstall the grid frame. Reinstall the polycarbonate panel (Pos. 2).

06/00 - 45 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 46

2.16 Installing the Grid – Replacing the Grid

Lift up the tabletop (CFC panel) (Fig. 27/Pos. 1), it will be held by the gas spring.

Move the tabletop towards the back and remove the front Nirosta panel. Move the tabletop

towards the front and remove the rear Nirosta panel. Remove the left (Fig. 27/Pos. 3) and

right (Pos. 4) cover panels. Remove the screws for the spiral cable guide panel and remove

the cable guide panel. Move the tabletop longitudinally, remove the 6 mounting screws in the

polycarbonate panel (Pos. 2) and remove the polycarbonate panel towards the front.

Switch the unit to the service mode, the green LED on the controller will go on and stay on.

Press the Store and Reset buttons on the controller simultaneously, the three memory LED’s

on the controller will blink green and the LED on the controller will blink very rapidly.

The cassette Bucky can now be moved slowly forward and backward using the Recall and

Reset buttons.

Move the Bucky into the exposure position using the Recall button. Remove the mounting

brackets (Fig. 28/ Pos. 2). Insert the grid with the focus mark facing up and secure it in place

with the mounting brackets. Reinstall the polycarbonate panel (Fig. 27Pos. 2).

2.17 Installing the Tilt Angle Display- Error Display

Place the unit base cover panel (Fig. 29/Pos. 1) on the unit base. Guide the cable (Pos. 2)

into the conduit (Pos. 3), install the tilt angle display (Pos. 4) and plug in the connector.

Secure the plug-in connector with cable ties.

Fig. 29 Fig. 30

0116 7201 -46 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 47

2. 18 Installing the Cover Panels

Caution: Before the cover panels are installed, it is best to carry out the adjustment as

described in Section 3.

Tube unit support arm:

Place the two halves of the cover panel (Fig. 30/Pos. 1) over the support arm (Pos. 2) while

paying attention to the two safety switches (Fig. 21/Pos. 1+2) and secure them in place with

the roll pins (Pos. 4). Place the two head cover panels (Pos. 5) over the support arm and

secure them in place with the paneling screws (Pos. 6).

Unit base:

Reinstall the narrow left (Fig. 31/Pos. 4) and the narrow right cover panel (Pos. 5).

Reinstall the unit base cover panel (Fig. 29/Pos.1), the left (Pos. 2) and right cover panels

(Pos. 3).

Reinstall the cover panel bracket for the floor panel (Pos. 6) and the back wall (Pos. 7).

Monitor support arm

Fig. 31 Fig. 32

2.19 Installing the Monitor Support Arm (Option)

Insert the monitor support arm (Fig. 32/Pos. 1) into the tube (Pos. 3).

06/00 - 47 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 48

Fig. 33 Fig. 34

2.20 Installing the Mount for the Flush Bowl

Lift up the tabletop (CFC panel) (Fig. 34/Pos. 1), it will be held in place by the gas spring.

Remove the two covers on the tube frame. Insert the left and right mounts (Fig. 33/ Pos.

2+3) into the opening of the tube frame and secure them with 2 screws for each.

2.21 Sealing the Table Frame Cover Panel

Seal the table frame cover panel (Fig. 34/Pos. 2) along the table frame using the Sista F 101

sanitary caulking.

0116 7201 -48 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 49

3. Adjustment

Caution: If changes are made to the movement paths, the software must

afterward be corrected.

3.1 Tube Unit Support Arm

Check the tube unit support arm (Fig. 51/Pos. 1) with the spirit level (Pos. 2) and loosen the

nuts (Fig. 51a/Pos. 5) and the mounting screws (Fig. 51b/Pos. 6). Correct any differences

with the screws (Pos. 8). Retighten the mounting screws and nuts.

Fig.51 Fig.51a

Fig.51b Fig.52

06/00 - 49 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 50

3.2 Central Beam - Center of Bucky

Determine the deviation of the central beam.

Transverse to the tabletop, for this:

Caution:

Risk of an accident exists here because the tube unit must be loosened.

Remove the cover panel (Fig. 52/Pos. 6). Remove the mounting screws (Fig. 52/Pos. 1),

remove the shims (Pos. 2) for the tube unit and insert them to compensate for any difference

in the central beam. Reinstall the mounting screws (Pos. 1).

Lengthwise to the tabletop, for this:

Remove the cover panel (Fig. 53/Pos. 1). Correct the exposure position of the system using

the software and the switch strike plate (Fig. 54/ Pos. 2) by the amount of the difference.

Reinstall the cover panel (Fig. 53/Pos. 1).

Fig.53 Fig.54

3.3 Central Beam – Center of I.I.

Determine the deviation of the central beam.

Loosen the screws (Fig. 54/Pos. 1), correct the connector brackets (Pos. 3) by the amount of

the difference and retighten the screws.

0116 7201 -50 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 51

Fig.55 Fig.56

3.4 Movement Path Potentiometer, Tabletop longitudinal

Lift up the tabletop (Fig. 55/Pos. 2) (it will be held in place by the gas spring) and

remove the cover panel (Fig. 55/Pos. 1). Move potentiometer =AU -R4 (Fig. 56/Pos.

1) away from the pinion rack, move the tabletop into the centered position. Turn the

potentiometer to the middle position, mesh it back into the pinion rack and align the

pinion on the rack. Check the function over the entire movement path and reinstall

the cover panel.

Fig.57 Fig.58

06/00 - 51 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 52

3.5 Movement Path Potentiometer, Tabletop transverse

Remove the cover panel (Fig. 57/Pos. 1). Move the tabletop transversely into the

centered position, lift up potentiometer =AU -R6 (Fig. 58/Pos. 1) (the view in Fig. 58

is visible only when the cover is removed Fig. 55/Pos. 3, however, the potentiometer

can be reached from behind through the slot Pos.2) and set it to the middle position.

Mesh the pinion and align it to the rack. Move through the entire movement path and

while doing this, check the function.

Fig.59 Fig.60

3.6 Bucky - Cassette Tray Movement Path Potentiometer

Move the cassette carriage into the park position and turn the potentiometer =AU -R5

(Fig. 59/Pos. 1) until it is one half turn before the mechanical end position, while

doing this, take note of the direction of the turn. Adjust the potentiometer pinion (Pos.

2) to the opposing pinion (Pos. 3).

3.7 I.I. Carriage System Potentiometer

Move the support arm until it is at the mechanical end stop at the foot end. Turn the

potentiometer =AU -R2 (Fig. 60/Pos. 2) until it is half a turn in front of the mechanical

end position; while doing this, take note of the direction of the turn.

Move the system toward the head end until it is 7 mm in front of the stop and save

the software limit for the head-end limit position.

Move the system toward the head end until it is 7 mm in front of the stop and save

the software limit for the foot-end limit position.

0116 7201 -52 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 53

Fig.61 Fig.62

3.8 Potentiometer 1 – Table Tilt Movement Path

Take off the potentiometer belt (Fig. 61/Pos. 2). Move the vertical carriage into the

top position and tilt the tabletop so that the potentiometer moves into the highest

possible position, e.g. -20° position. Turn potentiometer =AU -R1 (Pos. 1) until it is

half a turn in front of the mechanical end position; while doing this, take note of the

direction of the turn. Place the potentiometer belt back on without turning the

potentiometer and secure it in position.

3.9 Potentiometer 2 – Table Tilt Movement Path

Take off the potentiometer belt (Fig. 62/Pos. 2). Move the vertical carriage into the

top position and tilt the tabletop so that potentiometer =AU -R3 (Pos. 1) moves into

the highest possible position, e.g. +88° position. Turn the potentiometer until it is half

a turn in front of the mechanical end position; while doing this, take note of the

direction of the turn. Place the potentiometer belt back on without turning the

potentiometer and secure it in position.

06/00 - 53 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 54

Fig.63 Fig.64

3.10 Tabletop Longitudinal Safety Switch

Lift up the tabletop (it will be held in place by the gas spring) and remove the cover

panel (Fig. 63/Pos. 1). Set the software end positions to 240+/- 5 mm in each

direction. Adjust the limit switch (Fig. 64/Pos. 2) so that it switches off approx. 3 - 5

mm behind each end position. To do this, either the limit switch or the switch strike

place can be adjusted. Check the function over the entire movement path and

reinstall the cover panel.

3.11 Tabletop Transverse Safety Switch not configured

Fig.65 Fig.66

0116 7201 -54 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 55

3.12 Bucky Movement Path Safety Switch

Move the Bucky to the foot end to the mechanical stop, move the system carriage

into the exposure position. Adjust the S12 switch (Fig. 66/Pos. 1) so that it positively

switches.

3.13 I.I. Carriage Movement Path Safety Switch

Remove the cover panel (Fig. 65/Pos. 1). Move the system carriage to the head end until

there is 3 mm distance and adjust the switch strike plate (Fig. 67/ Pos. 1) so that it just

actuates the S6 switch. Move the system carriage to the foot end until there is 3 mm

distance and adjust the switch strike plate (Fig. 67/Pos. 2) so that it just actuates the S7

switch.

Fig.67 Fig.68

3.14 Table Up Movement Path Switch Strike Plate

Raise the table to max. 1225+/-10 mm position.

When the software limit is set, the top switch strike plate (Fig. 68 / Pos. 1) can be

adjusted so that the limit switch (Pos. 3) actuates approx. 2 - 5 mm behind the

maximum height.

3.15 Table Down Movement Path Switch Strike Plate

Lower the table to the min. 680+/-10 mm position.

When the software limit is set, the bottom switch strike plate (Fig. 68/ Pos. 2) can be

adjusted so that the limit switch actuates approx. 2 - 5 mm behind the minimum

height.

06/00 - 55 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 56

Fig.69 Fig.70

3.16 -20° Tilt Movement Safety Switch

Tilt the tabletop into the -20° end position.

The top of the two switches is the limit switch and the floating switch (bronze) is also

the switch strike plate, respectively.

The floating switch (Fig. 69/Pos. 1) should actuate the microswitch approx. 2 mm

after the end position (Pos. 2).

3.17 +88° Tilt Movement Safety Switch

Tilt the tabletop into the +88° end position.

The top o the two switches is the limit switch for tilt movement and the floating switch

(bronze) is also the switch strike plate, respectively.

The floating switch (Fig. 69/Pos. 1) should actuate the microswitch (not shown in Fig.

69) approx. 2 mm after the end position.

3.18 Spindle Nut Safety Limit Switch

The safety nut (Fig. 70/Pos. 1) must be installed centered in the bottom half between

the two steel plates (Pos. 2+3).

The switch strike plate in the microswitch with the roller must be up against the safety

nut and actuated; when the safety nut moves up, the microswitch responds and the

switch circuit is interrupted.

0116 7201 -56 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 57

Fig.71 Fig.72

3.19 Accessory Sensor Switches

Securely and audibly insert the table extension or the micturation seat into the

opening.

The corresponding microswitch is for sensing of the S17 table extension (Fig. 71/

Pos. 1) and S18 is for the micturation seat (Pos. 2). The switch strike plate must be

adjusted so that it is on the tip of the nib so that any play will trigger a positive

response of the S16 microswitch (Pos. 3).

3.20 Tabletop longitudinal Belt Tension

Belt tension should be determined as follows:

The spring balance should be placed centered between the belt return wheel (Fig. 72/Pos. 2)

and the belt tension roller (Pos. 3) to achieve a deflection of 1 cm when a force of 35 N is

applied. Adjustment can be made by means of the tension screw (Pos. 4) after loosening the

two mounting screws (Pos. 5+6).

3.21 Raise-Lower Tabletop Belt Tension

Belt tension should be determined as follows:

The spring balance should be placed centered between the drive wheel (on motor side) and

the belt wheel for the spindle (Fig. 73/Pos. 2) to achieve a deflection of 1 cm when a force of

80 N is applied. Adjustment can be made by means of the tension screw (Pos. 4) after

loosening the two mounting screws (Pos. 5+6).

06/00 - 57 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 58

Fig.73 Fig. 74

3.22 Cassette Carriage Drive Belt Tension

Move the tabletop max. forward and take off the cover panel (Fig. 74/Pos. 1) after removing

the 5 mounting screws.

Belt tension should be determined as follows:

The spring balance should be placed centered between the motor-side drive pulley (Fig.

75/Pos. 3) and the belt return pulley (Pos. 2) to achieve a deflection of 1 cm when a force of

25 N is applied. Adjustment can be made by means of the tension screw (Pos. 4) after

loosening the 4 mounting screws (Pos. 5).

Fig.75 Fig. 76

0116 7201 -58 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 59

3.23 Operation in the Service Mode

a. Connection of a Laptop

To establish a connection with the URO controller, a PC/laptop is required.

Equipment:

⇒ PC or laptop with color display (black/white is also sufficient, but makes operation more

difficult)

⇒ 486 processor, 16 MB RAM

⇒ Windows 3.x Win 95 operating system (Windows NT can cause difficulties with the Com

interface)

⇒ Hard drive

⇒ Serial connection cable (9-pole, Sub-D connector to a 9-pole, Sub-D socket, connected

1 - 1), length > 1m.

⇒ Current version of the "hp-Service" software

b. Procedure

• Switch off the URO

• Connect the PC and the URO CPU board using the connection cable

• Switch on the URO

• After approx. 1 s, the service LED will begin to blink

• Switch on the PC

• Start the PC software

• Set the PC software to monitor. The terminal screen will appear

• Set the service switch on the CPU board to the up "Service" position

• After approx. 1 s, the service LED will switch to continuously on

• The start message of the service menu will appear on the screen.

U U RRRR OOO 333 000 000 000

U U R R O O 3 0 00 0 00 0 00

U U RRRR O O 33 0 0 0 0 0 0 0 0 0

U U R R O O 3 00 0 00 0 00 0

UUU R R OOO 333 000 000 000

Service mode

(1) Input test

(2) Analog test

(3) Handcontrol and footswitch test

(4) Axis calibration

(5) Versioncheck

Select testmode

06/00 - 59 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 60

The service technician can now start the desired adjustment. The above-listed sequence

does not have to be followed when making the connection. However, it should be noted that

the cable connection may not be plugged in while power is switched on!

c. Setting Parameters

A critical and often-used routine is setting the table parameters to adapt speeds or limits.

Procedure:

Once the URO controller has been set to the service mode (see above), the PC software is

not switched to the monitor mode, but to the parameter mode after clicking on the

"Parameters" button. (We also refer you to the Online Help of the PC software, which can be

selected by pressing the F1 key).

A file window open with which the supplied adjustment file named "*.HPP" can be opened.

Using data from this file, a complete parameter table is described. Please enter your name.

Data can be viewed, changed or saved this way in the usual manner.

Changing the parameters in the URO controller is performed as follows:

⇒ Read out the URO with "Read CPU".

⇒ Save these data under a new name as xxx.HPP as a backup.

⇒ Change the parameters as desired.

⇒ Write them into the URO with "Write CPU".

⇒ Test the new parameters.

⇒ If ok, save these new parameters in the URO with "EEPROM"

d. Self Test

All boards in the controller, with the exception of the breaker board, have a software self test,

which is performed after switching on power. To the extent possible, this test can be viewed.

e. CPU Self Test

After switching on power, the CPU reads all inputs. This takes approx. 1 - 2 s. If this is

correct, the service LED does into the blink mode.

If this does not happen, there is a malfunction.

If a peripheral unit is not connected or the bus traffic is malfunctioning, this is signaled on the

display as an error code. If the display cannot be addressed, the error message can be read

on the service laptop.

If an error occurs in the footswitch or in the control unit, the URO can still be operated using

the other unit.

0116 7201 -60 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 61

f. Display Self Test

After switching on power, all segments in the tilt display and the large round LED’s are

tested individually. If this does not happen, there is a malfunction.

Seven-segment display: visible by a circular sequence of the active segments. All segments

must light up. If a segment does not go on, there is a malfunction.

LED’s: All three LED’s light up cyclically in the three colors: red, green and yellow. If one

color does not appear, there is a malfunction.

g. Footswitch Self Test

This test cannot be viewed. However, correct function is signaled via the bus.

h. Control Unit Self Test

After switching on power, all LED’s are individually tested by blinking, the multi-colored

LED’s also blink in the three colors. If this does not happen, there is a malfunction.

3.24 Startup

Adjusting the Axes

If a PC is not available, proceed as described below:

Switch the unit with the switch (Fig. 76/Pos. 1) into the service mode, the green LED (Pos. 2)

on the controller goes on and stays on.

Press the Store and Reset buttons on the control unit at the same time, the three memory

LED`s on the control unit blink green and the LED on the controller blinks very quickly.

Each axis can now be moved normally. Exception: the cassette can be moved slowly forward

and backward by pressing the Recall and Reset buttons.

To save a new software limit, Store must be pressed and held (M1 LED blinks red) and the

corresponding direction button for the desired movement must also be pressed.

If the controller has recognized this correctly, the M1 LED blinks red, and the position has

been accepted and the keys can be released again. The M1 LED then blinks green again.

To save a centered position, the Store button must again be pressed and held and then the

two buttons for the corresponding axis must either be pressed and held, or pressed in

sequence.

To move past an incorrectly set software limit, the ZOOM button must be held down and the

corresponding direction button must also be held. The software limit is now set to the

maximum AD value.

If an axis is completely adjusted, the new limits should be saved in the EEprom. To do this,

the Store and Reset buttons must be pressed at the same time. During the save routine

(approx. 5 sec) all three memory LED’s will blink red.

When the save routine is completed, the memory LED`s will again blink green.

06/00 - 61 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 62

3.25 Collimator Basic Setting

Switch the unit into the service mode using the switch (Fig. 77/Pos. 1), the green LED (Pos.

2) on the controller will go on and stay on.

Simultaneously press the Store (Fig. 78/Pos. 54) and Reset (Pos. 56) buttons on the control

unit, the three memory LED`s (Pos. 51-53) on the control unit will blink green and the LED

on the control unit (Fig. 77/Pos. 2) will blink very rapidly.

Fig. 77 Fig. 78

The movement paths must be moved manually to the mechanical end stops using the

direction buttons (the collimator plate will not move any further because the motor has a slip

clutch).

Save the position that is established this way for each of the 6 end positions by holding the

Store button (Fig. 78/Pos. 54) (M1 LED (Pos. 52) blinks red) and pressing the

corresponding direction button for the movement at the same.

If the controller has correctly detected this position, the M1 LED (Pos. 52) goes on red. The

position has been accepted and buttons can be released again. The M1 LED (Pos. 52) then

blinks again green.

To move past an incorrectly set software limit, the Zoom (Pos. 54) must be pressed and

held and the corresponding direction button (Pos. 31, 32, 37, 35, 36, 38) must be pressed at

the same time. The software limit is now set to the maximum AD value and the axis can now

be moved to a new position and stored again by pressing the Store (Pos. 54) and directional

buttons (Pos. 31, 32, 37, 35, 36, 38) again.

To determine the tracking path of the motors, the collimator must be closed using the button

(Pos. 34) and auto tuning started. All three collimator motors will then be started

automatically 5 times and stopped again to save the tracking time that has been determined.

0116 7201 -62 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 63

3.26 Setting the Collimator to the Cassette and I.I. Format

Cassette Format:

To adjust the collimator to the 4 possible film formats, the corresponding cassette must be

inserted.

Use the button (Fig. 78/Pos. 33) to switch on the collimator light field and center the cassette

template included in the shipment so it is centered on the tabletop.

With the light field switched on, move the collimator plates using the buttons (Fig. 78/Pos.

31, 32, 35, 37) horizontal open, horizontal closed, vertical open, vertical closed to the

position of the cassette template and save the position with the Store (Pos. 54) and Light

(Pos. 33) buttons.

Then as a control, make a radiographic exposure and, if needed, correct the collimator plate

adjustment.

Caution:

During exposure, radiation protective measures must be observed.

Perform this routine with all 4 cassettes.

A format that has been saved previously can be overwritten by repeating the save routine.

I.I. Format:

The unit can store 3 Zoom steps.

LED`s Z-N (Pos. 41) = I.I. size, LED`s Z-1 (Pos. 42) = Zoom step 1, LED`s Z-2 (Pos. 43) =

Zoom step 2, LED`s Z-1 + Z-2 (Pos. 41 + 42) = Zoom step 3.

The Zoom step is changed by pressing the Zoom button (Pos. 44).

Use the button (Fig. 78/Pos. 33) to switch on the collimator light field and center the cassette

template included in the shipment on the tabletop.

Move the iris diaphragm to the desired position with the keys Iris open (Fig. 78/Pos. 38) or

Iris closed (Pos. 36).

To save the currently selected zoom step, press and hold the Store button (Pos. 54) on the

manual controller and then, both iris buttons (Pos. 36 and 38) should be pressed either

together or in sequence.

Then the adjustment should be checked, and if needed, corrected under fluoroscopy.

Caution:

During radiographic fluoroscopy, radiation safety regulations must be observed.

Since the position of the horizontal and vertical collimator plates also need to be saved for

improved radiation safety, they must be moved as exactly as possible to the limit of the iris

diaphragm without them being visible in the radiation field.

Save the position of the collimator plates with the Store (Fig. 78/Pos. 54) and Light (Pos. 33)

buttons.

Perform this routine for all zoom steps.

The values can be resaved as often as wished, the old settings will be overwritten when this

is done.

After completing adjustment work, all parameters must be saved in the EEprom by pressing

the Reset button (Pos. 56).

The switch the unit into the normal mode with the switch (Fig. 77/Pos. 1), the green LED

(Pos. 2) on the controller blinks.

06/00 - 63 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 64

3.27 Saving the Parameters in the PC

Switch off the unit. Connect the PC and the unit using the connection cable included in the

shipment.

Switch the unit into the service mode with the switch (Fig. 77/Pos. 1), the green LED (Pos. 2)

controller goes on continuously.

Start the URO service tool. See 3.23

Open the parameter file included in the shipment and read the parameters from the Uromat

and save them (do not overwrite the original file).

0116 7201 -64 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 65

3.28 Electronic Adjustment Parameters

Min Max Wert

40

70

40

70

40

70

25

0

Setup Parameters

lf. Nr.: Name

1 Tilt MAX 0

2 Tilt MIN 0

3 Tilt Null-Grad 0

4 Tilt V1 [Hz] 0

5 Tilt ACC V1 [s/10] 0

7 Tilt V2 [Hz] 0

8 Tilt ACC V2 [s/10] 0

9 Tilt DEC [s/10] 0

10 Tilt DNS 0

11 Vertical MAX 0

12 Vertical MIN 0

13 Vertical V1 [Hz] 0

14 Vertical ACC V1 [s/10] 0

15 Vertical V2 [Hz] 0

16 Vertical ACC V2 [s/10] 0

17 Vertical DEC [s/10] 0

18 Vertical DNS 0

19 System MAX 0

20 System MIN 0

21 System X-ray position 0

22 System V1 [Hz] 0

23 System ACC V1 [s/10] 0

24 System V2 [Hz] 0

25 System ACC V2 [s/10] 0

26 System DEC [s/10] 0

27 System DNS 0

28 Tabletop long. MAX 0

29 Tabletop long. MIN 0

30 Tabletop long. NULL 0

31 Tabletop long. V1 [Hz] 0

32 Tabletop long. ACC V1 [s/10] 0

33 Tabletop long. V2 [Hz] 0

34 Tabletop long. ACC V2 [s/10] 0

35 Tabletop long. DEC [s/10] 0

36 Tabletop long. DNS 0

37 Tabletop lateral MAX 0

38 Tabletop lateral MIN 0

39 Tabletop lateral NULL 0

40 Tabletop lateral V1 [PWM%] 0

41 Tabletop lateral ACC V1 [s/10] 0

42 Tabletop lateral V2 [PWM%] 0

43 Tabletop lateral ACC V2 [s/10] 0

44 Tabletop lateral DEC [s/10] 0

45 Tabletop lateral DNS 0

46 Cassette MAX 0

47 Cassette MIN 0

48 Cassette V1 [Hz] 0

49 Cassette V2 [Hz] 0

50 Cassette ACC V1 [s/10] 0

51 Cassette DEC [s/10] 0

52 Cassette DNS 0

53 Cassette V X-ray [Hz] 0

54 ***** Colimator-Axisdata ***** 0

55 Col horizontal MAX 0

56 Col horizontal MIN 0

57 Col horizontal Format 1 0

1023

1023

1023

100

255

100

255

255

255

1023

1023

255

255

255

255

1023

1023

1023

255

255

255

255

1023

1023

1023

255

255

255

255

1023

1023

1023

150

255

255

255

255

255

1023

1023

255

255

255

255

255

1023

1023

1023

06/00 - 65 of 90 - 0116 7201

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 66

0

0

4

0

1

0

0

1

1

1

1

1

1

1

1

0

1

1

58 Col horizontal Format 2 0

59 Col horizontal Format 3 0

60 Col horizontal Format 4 0

61 Col horizontal delay 0

62 Col vertical MAX 0

63 Col vertical MIN 0

64 Col vertical Format 1 0

65 Col vertical Format 2 0

66 Col vertical Format 3 0

67 Col vertical Format 4 0

68 Col vertical delay 0

69 Iris MAX 0

70 Iris MIN 0

71 Iris Zoom-normal 0

72 Iris Zoom-1 0

73 Iris Zoom-2 0

74 Iris Zoom-3 0

75 Iris delay 0

76 ***** Colimator-Zoom ***** 0

77 Col horizontal Zoom-normal 0

78 Col horizontal Zoom-1 0

79 Col horizontal Zoom-2 0

80 Col horizontal Zoom-3 0

81 Col vertical Zoom-normal 0

82 Col vertical Zoom-1 0

83 Col vertical Zoom-2 0

84 Col vertical Zoom-3 0

85 ******** Colimator ******** 0

86 Lightvisor timer [s] 0

87 II Magnification [1..4] 1

88 Colimator-Typ [0=none] 0

89 Iris shut analog/digital [1/0] 0

90 Film cassette Detector/yes/no [2/1/0] 0

91 ***** Image Intensifier ***** 0

92 II depth [mm] 0

93 II width-foot [mm] 0

94 II width-head [mm] 0

95 Distance II-center - footend [mm] 0

96 ***** Axis Positionmemory ***** 0

97 Vertical store yes/no [1/0] 0

98 Tilt store yes/no [1/0] 0

99 System store yes/no [1/0] 0

100 Tabletop long. Store yes/no [1/0] 0

101 Tabletop lateral store yes/no [1/0] 0

102 Col horizontal store yes/no [1/0] 0

103 Col vertical store yes/no [1/0] 0

104 Iris store yes/no [1/0] 0

105 ***** Table configuration ***** 0

106 Slow motion [s/10] 0

107 Isocentric yes/no [1/0] 0

108 V1 isocentric [Hz] 0

109 V2 isocentric [Hz] 0

110 Uro-type right/left [1/0] 0

111 Tableextension [mm] 0

112 Micturitionseat [mm] 0

113 Ellbowrests [mm] 0

114 Saftydistance first [mm] 0

115 Saftydistance end [mm] 0

1023

1023

1023

255

1023

1023

1023

1023

1023

1023

255

1023

1023

1023

1023

1023

1023

255

1023

1023

1023

1023

1023

1023

1023

1023

255

255

1000

1000

1000

1023

255

255

255

1000

1000

1000

1000

1000

0116 7201 -66 of 90 - 06/00

Rev. 00 © 2000 Hans Pausch Röntgengerätebau Graf-Zeppelin-Str. 1 D-91056 Erlangen ALL RIGHTS RESERVED Ru

Page 67

4. Technical Maintenance

NOTE:

The maintenance described below must be performed every12 months.

If unit components need to be moved using the motor during maintenance, or if functions