Page 1

DE Gebrauchsanleitung / Montageanleitung 2

FR

Mode d'emploi / Instructions de montage 4

EN

Instructions for use / assembly instructions 6

IT

Istruzioni per l'uso / Istruzioni per Installazione 8

ES

Modo de empleo / Instrucciones de montaje 10

NL

Gebruiksaanwijzing / Handleiding 12

DK

Brugsanvisning / Monteringsvejledning 14

PT

Instruções para uso / Manual de Instalación 16

PL

Instrukcja obsługi / Instrukcja montażu 18

CS

Návod k použití / Montážní návod 20

SK

Návod na použitie / Montážny návod 22

ZH

用户手册/组装说明 24

RU

Руководство пользователя / Инструкция по

монтажу 26

HU

Használati útmutató / Szerelési útmutató 28

FI

Käyttöohje / Asennusohje 30

SV

Bruksanvisning / Monteringsanvisning 32

LT

Vartotojo instrukcija / Montavimo instrukcijos 34

HR

Upute za uporabu / Uputstva za instalaciju 36

TR

Kullanım kılavuzu / Montaj kılavuzu 38

RO

Manual de utilizare / Instrucţiuni de montare 40

EL

Οδηγίες χρήσης / Οδηγία συναρμολόγησης 42

SL

Navodilo za uporabo / Navodila za montažo 44

ET

Kasutusjuhend / Paigaldusjuhend 46

LV

Lietošanas pamācība / Montāžas instrukcija 48

SR

Uputstvo za upotrebu / Uputstvo za montažu 50

NO

Bruksanvisning / Montasjeveiledning 52

BG

Инструкция за употреба / Ръководство

за монтаж 54

SQ

Udhëzuesi i përdorimit / Udhëzime rreth montimit 56

AR

/ 59

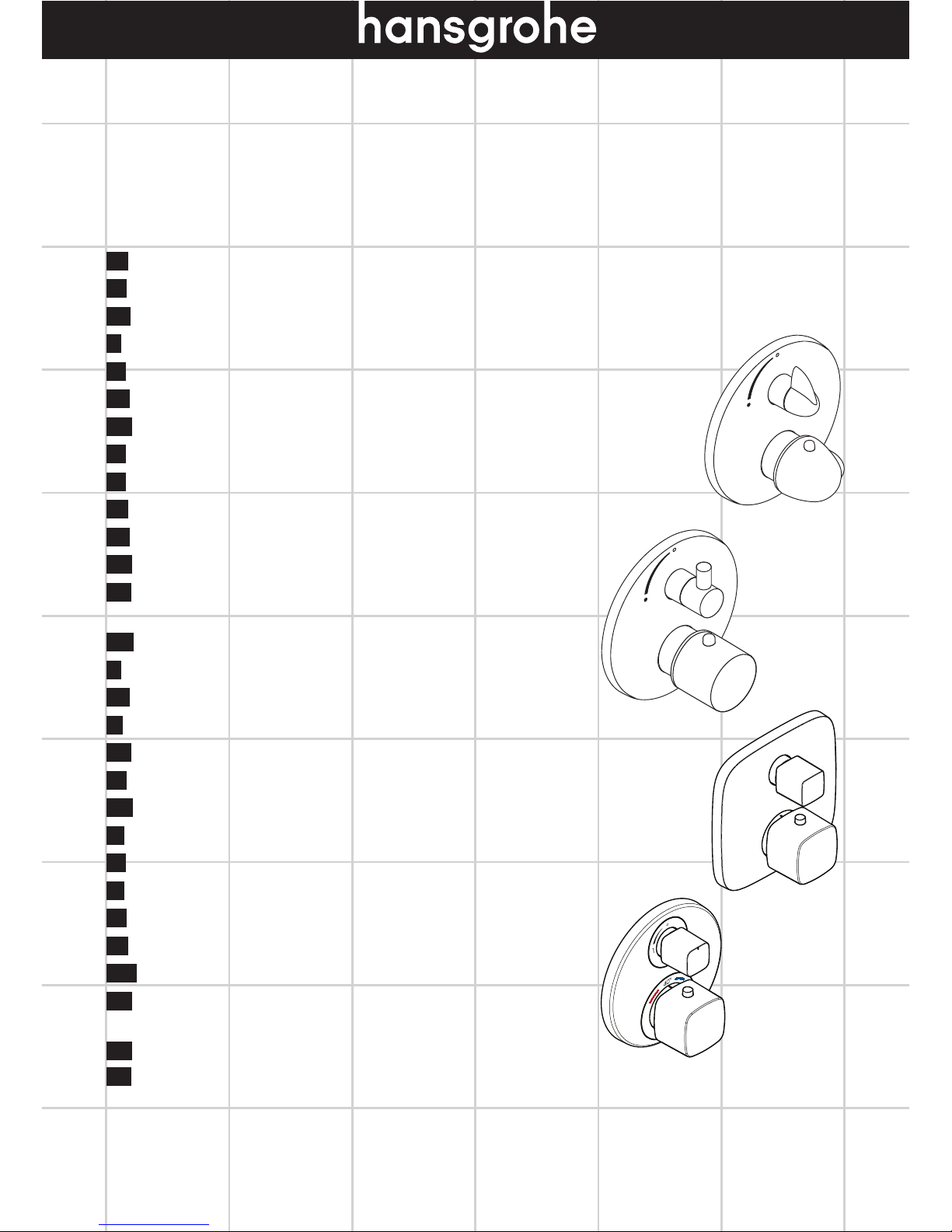

Ecostat S

15701000

Ecostat E

15700000

PuraVida

15775XXX

Metris

31572000

Page 2

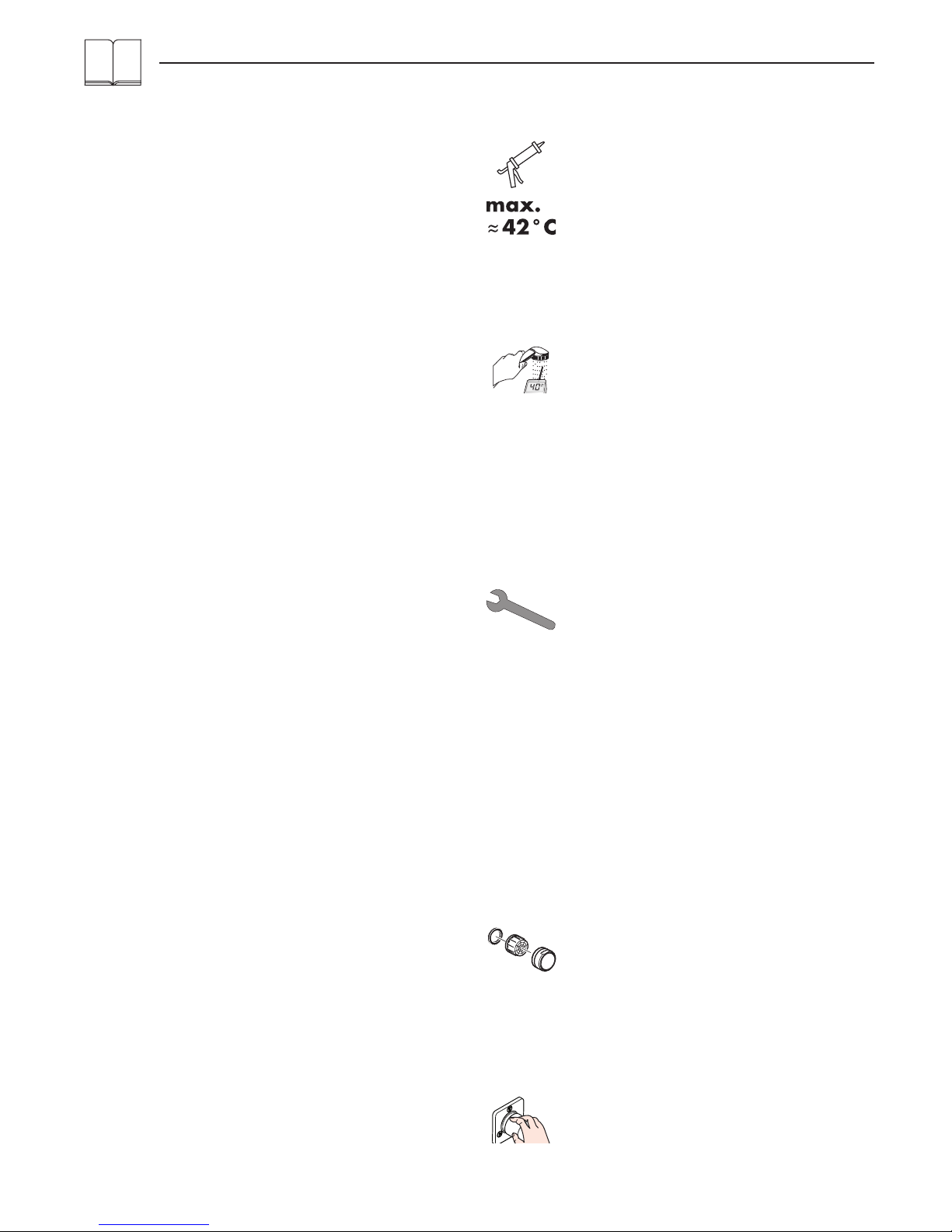

Safety Notes

Gloves should be worn during installation to prevent

crushing and cutting injuries.

The shower system may only be used for bathing,

hygienic and body cleansing purposes.

Children as well as adults with physical, mental and/

or sensoric impairments must not use this shower

system without proper supervision. Persons under

the influence of alcohol or drugs are prohibited from

using this shower system.

The hot and cold supplies must be of equal pres-

sures.

Installation Instructions

• The fitting must be installed, flushed and tested after

the valid norms!

• The plumbing codes applicable in the respective

countries must be oberserved.

• Prior to installation, inspect the product for transport

damages. After it has been installed, no transport or

surface damage will be honoured.

Technical Data

Operating pressure: max. 1 MPa

Recommended operating pressure: 0,1 - 0,5 MPa

Test pressure: 1,6 MPa

(1 MPa = 10 bar = 147 PSI)

Hot water temperature: max. 80°C

Recommended hot water temp.: max. 65°C

Thermal disinfection: max. 70°C / 4 min

Safety against backflow

The product is exclusively designed for drinking water!

English

Maintenance (see page 64)

• To guarantee the smooth running of the

thermostat, it is necessary from time to

time to turn the thermostat from total hot

to total cold.

• The mixer is equipped with check valves.

The check valves must be checked

regularly according to DIN EN 1717 in

accordance with national or regional

regulations (at least once a year).

Adjustment (see page 62)

After the installation, the output temperature of the thermostat must be checked. A

correction is necessary if the temperature

measured at the output differs from the

temperature set on the thermostat.

Safety Function (see page 62)

The desired maximum temperature for example max. 42º C can be pre-set thanks to the

safety function.

Spare parts (see page 68)

XXX = Colors

000 = chrome plated

400 = white/chrome plated

Do not use silicone containing acetic acid!

Symbol description

Operation (see page 66)

6

Page 3

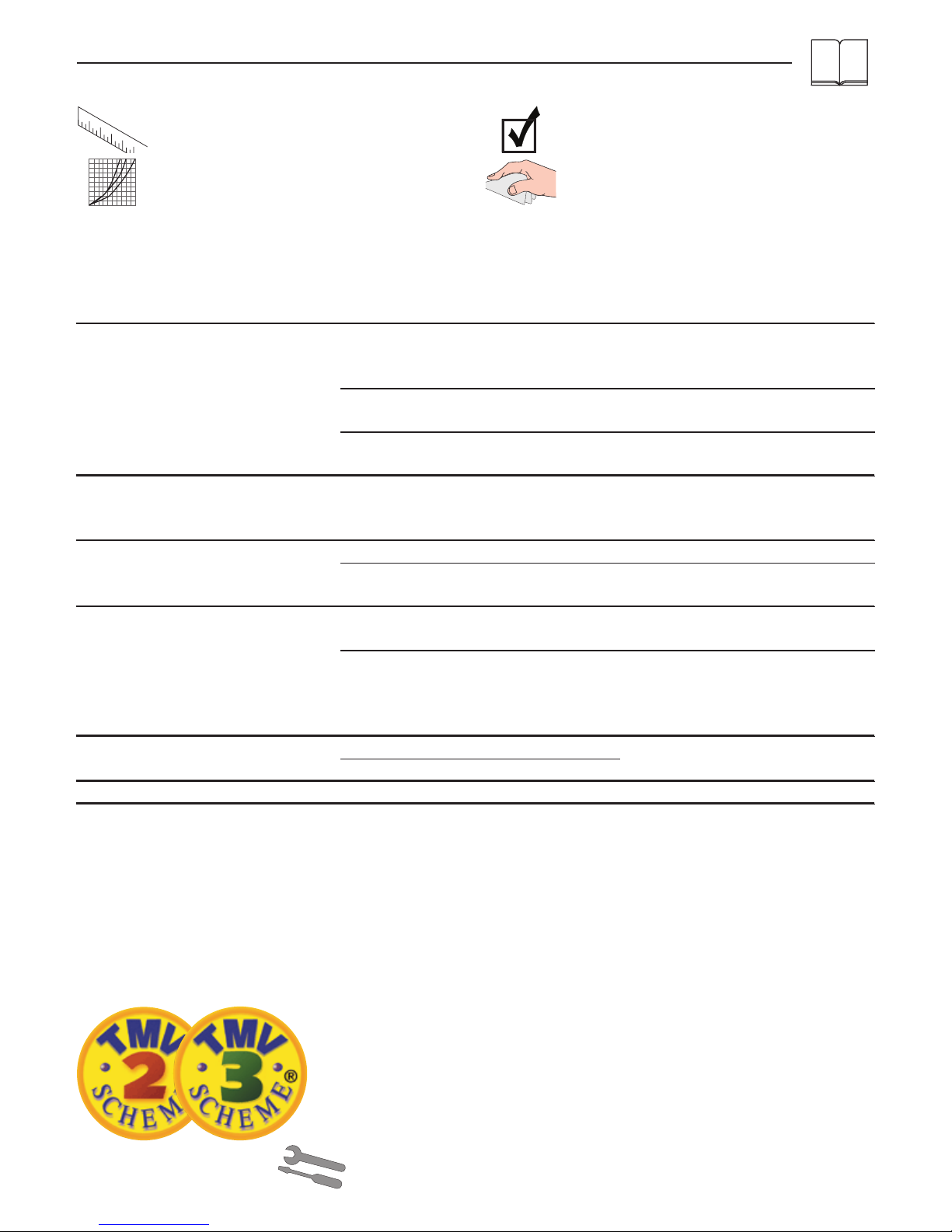

Flow diagram

(see page 67)

Test certificate (see page 66)Dimensions (see page 67)

English

Fault Cause Remedy

Insufficient water - Supply pressure inadequate - Check water pressure (If a pump

has been installed check to see if

the pump is working).

- Regulator filter dirty - Clean filter in front of the mixer

and on the MTC-thermo cartridge

- Shower filter seal dirty - Clean filter seal between shower

and hose

Crossflow, hot water being forced

into cold water pipe, or vice versa,

when mixer is closed

- Backflow preventers dirty or leaking - Clean backflow preventers, ex-

change if necessary

Spout temperature does not correspond with temperature set

- Thermostat has not been adjusted - Adjust thermostat

- Hot water temperature too low - Increase hot water temperature to

42 ºC to 65 ºC

Temperature regulation not possible - Temperature regulator dirty or calci-

fied

- Clean temperature regulator, ex-

change if necessary

- For new installations: basic body in-

correctly connected (should be: cold

right, hot left) or installed with 180º

rotation

- Install function block turned

through 180º

Safety stop button not operating - Spring defective - Clean spring and/or button, ex-

change if necessary

- push button calcified / contaminated

Valve stiff - Shut-off unit damaged - Exchange shut-off unit

Shower or spout dripping - Dirt or sedimentation on valve seat,

shut-off unit damaged

- Clean or exchange shut-off unit

Assembly see page 60

Cleaning

see enclosed brochure

Special information for UK (see page 70)

7

Page 4

60

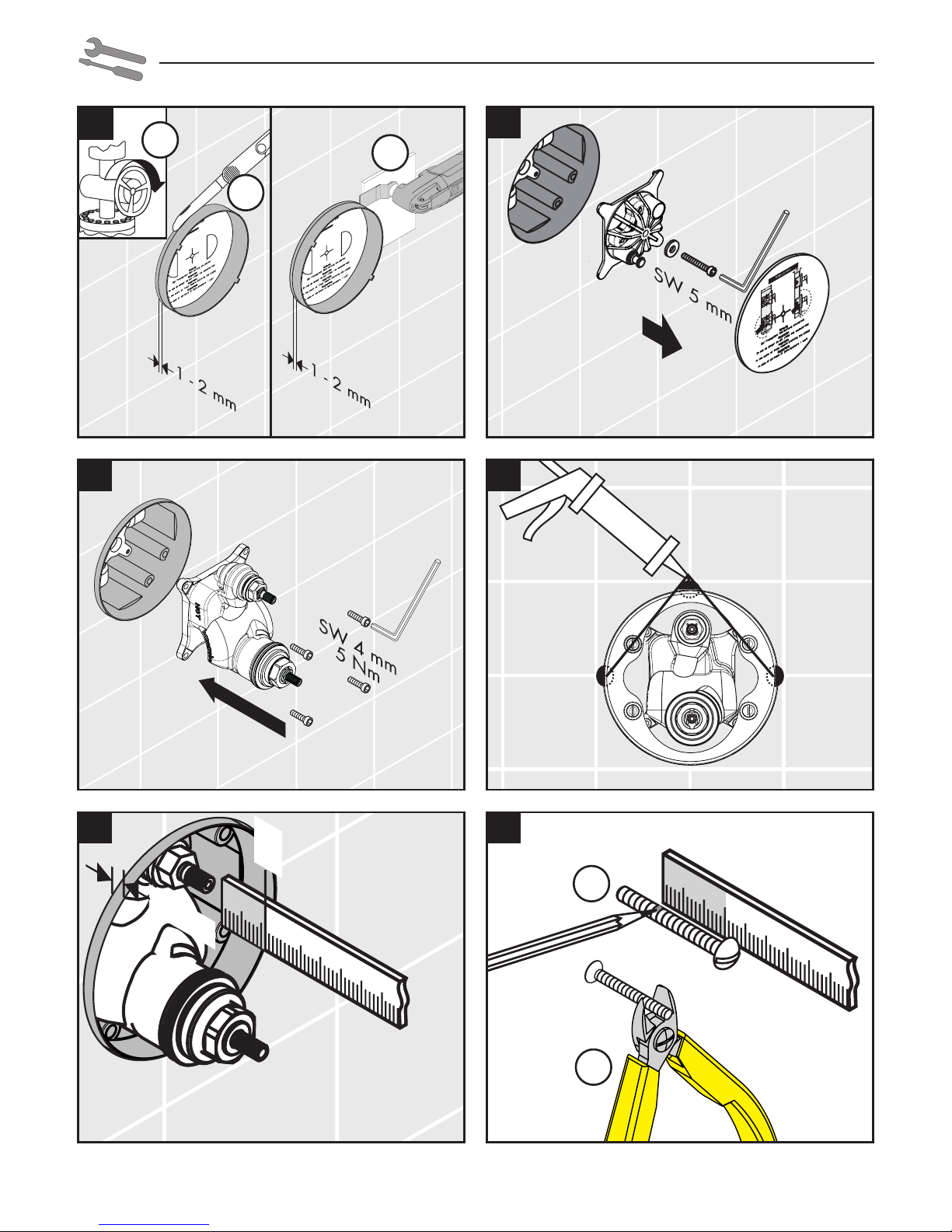

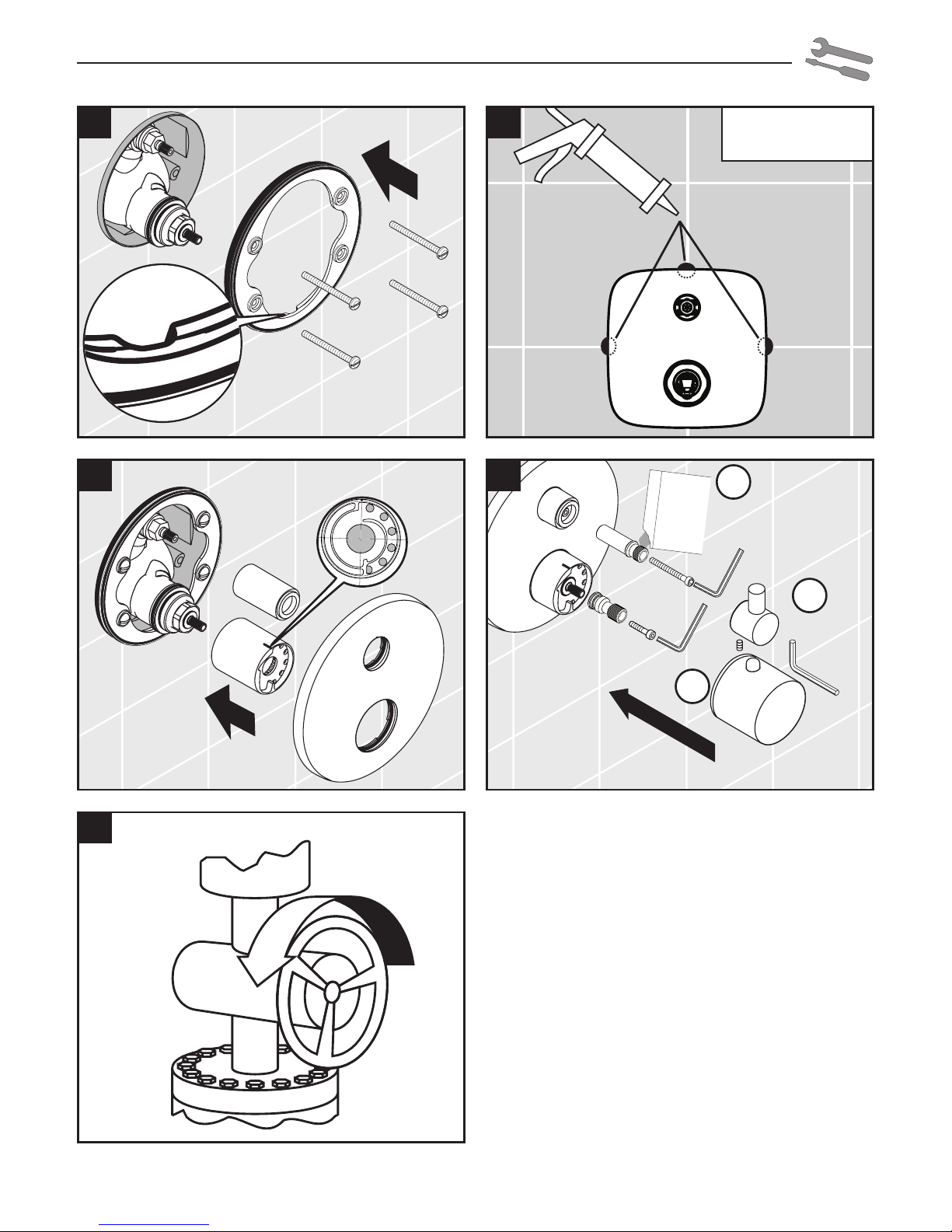

Montage

3

2

4

1

2.

1.

2.

1.

2.

6 5

X

X + 11

1 - 2 mm

Page 5

61

Montage

!

9

PuraVida

15775XXX

8

!

7

1.

2.

3.

Nr. 10476220

Armaturenfett

Grease

SW 2 mm

4 Nm

SW 3 mm

4 Nm

11

10

Page 6

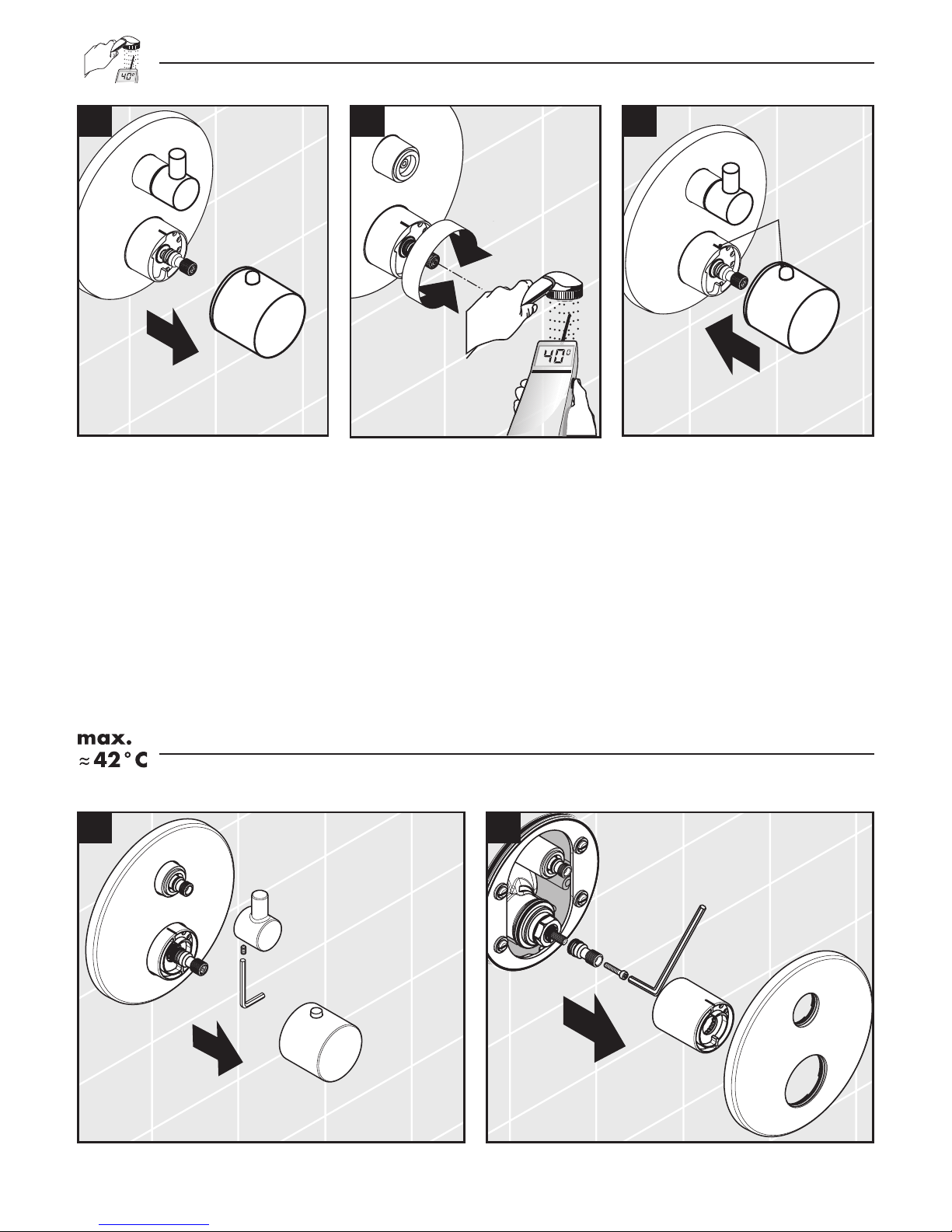

62

Safety Function

Justierung

1 2

SW 3 mm

!

1 2 3

Page 7

63

Safety Function

2.

1.

5 6

SW 3 mm

4 Nm

7

8

z. B. 42° C

for example 42° C

1.

2.

3 4

SW 2 mm

4 Nm

!

!

Page 8

64

Wartung

SW 4 mm

1. 2.

2

3 4

5 6

SW 24 mm

1.

2.

3.

1

SW 3 mm

SW 2 mm

4.

Page 9

65

Wartung

!

SW 4 mm

5 Nm

7 8

9 10

11 12

SW 24 mm

15 Nm

Nr. 10476220

Armaturenfett

Grease

SW 3 mm

4 Nm

SW 2 mm

4 Nm

!

1.

2.

3.

4.

Page 10

66

PA-IX DVGW SVGW ACS WRAS MCA ETA KIWA

15700000

PA-IX 9711/ID X X X X

1.43/18753

X

15701000

PA-IX 9711/ID X X X

1.43/18753

X

15775XXX

PA-IX 9711/ID X X

1.43/18753

X

31572000

PA-IX 9711/ID X X

1.43/18753

X

DIN 4109

PA-IX 9711/ID

Bedienung

Prüfzeichen

>40° C

1.

2.

öffnen / ouvert / open / aperto / abierto / open / åbne /

abrir / otworzyć / otevřít / otvoriť / 开 / открыть /

nyitás / avaaminen / öppna / atidaryti / Otvaranje /

açmak / deschide / ανοικτό / odpreti / avage / atvērt /

otvoriti / åpne / отваряне / hape /

ﺢﺘﻓ

schließen / fermé / close / chiudere / cerrar /sluiten /

lukke / fechar / zamknąć / zavřít / uzavrieť / 关 /

закрыть / bezárás / sulkeminen / stänga / uždaryti /

Zatvaranje / kapatmak / închide / κλειστό / zapreti /

sulgege / aizvērt / zatvori / lukke / затваряне / mbylle /

ﺢﺘﻓ

قﻼﻏإ

warm / chaud / hot / caldo / caliente / warm / varmt /

quente / ciepła / teplá / teplá / 热 / горячая / meleg /

lämmin / varmt / karštas / Vruća voda / sıcak / cald /

ζεστό / toplo / kuum / karsts / topla / varm /

топло / i ngrohtë /

ﺢﺘﻓ

ﻦﺧﺎﺳ

kalt / froid / cold / freddo / frío / koud / koldt / fria /

zimna / studená / studená / 冷 / холодная / hideg /

kylmä / kallt / šaltas / Hladno / soğuk / rece /

κρύο / mrzlo / külm / auksts / hladno / kaldt / студено /

i ftohtë /

ﺢﺘﻓ

ﺎﺑدر

Page 11

67

Ecostat E 15700000 Ecostat S 15701000

PuraVida15775XXX Metris 31572000

Maße

Durchflussdiagramm

Page 12

68

Serviceteile

13596000

(22 mm)

Ecostat E

15700000

94073000

96551000

96439000

94282000

94074000

96449000

96446000

94009000

96454000

(M5x55)

96447000

(Ø 165 mm)

95037000

96525000

(M5x20)

98133000

(16x2)

96451000

96435000

95508000

(48x3)

98371000

(29x3)

97669000

38391000

Ecostat S

15701000

97747000

13595000

(25 mm)

94073000

96551000

96439000

94282000

94074000

96449000

96446000

94009000

96454000

(M5x55)

96447000

(Ø 165 mm)

95037000

96525000

(M5x20)

98133000

(16x2)

96451000

96435000

95508000

(48x3)

98371000

(29x3)

97669000

36391000

Page 13

69

Serviceteile

13597000

Metris

22 mm

15597000

PuraVida

22 mm

Metris

31572000

PuraVida

15775XXX

97747000

13595000

(25 mm)

94073000

95663000

96439000

94282000

94074000

96446000

94009000

96454000

(M5x55)

98793000

(Ø 145 mm)

95037000

96525000

(M5x20)

98133000

(16x2)

96451000

96435000

95508000

(48x3)

98371000

(29x3)

97669000

11791XXX

95356XXX

94073000

95904000

96439000

94282000

94074000

95356000

96446000

94009000

96454000

(M5x55)

98793000

(Ø 145 mm)

95037000

96525000

(M5x20)

98133000

(16x2)

96451000

96435000

98174000

(48x5)

98153000

(30x5)

97669000

95906000

Page 14

70

Safety and Important Information

Hansgrohe products are safe provided they are installed,

used and maintained in accordance with these instructions

and recornrnendations.

Please read these instructions thoroughly and retain for

future use.

The plumbing installation of this thermostat mixing

valvemust comply with the requirements of UK

Water Regulations/Bylaws (Scotland), Building Regulations or any other regulations specified by the local Water

Authority and supplier.

The installation of thermostatic mixing valves must comply

with the requirements of the Water Supply (Water Fittings)

Regulations 1999.

We strongly recommend that you use a plumber registered

with or a member of an Association:

Chartered Institute of Plumbing and Heating Engineering

(CIPHE)

Water Industry Approved Plumber Scheme (WIAPS)

Dispose of plastic bags carefully

Keep children well away from the work area.

Check for hidden pipes and cables in the wall before

drilling holes.

The unit must be mounted on a finished waterproofed wall

surface (usually tiles).

If you are using power tools (e.g. to drill holes) wear safety glasses and always disconnect tools from the power

supply after use.

Do not operate the shower unit if the hand shower or spray

hose has been damaged or is blocked.

Do not block the flow of water from the hand shower, by

placing it on your hand or any other part of your body

or foreign object.

The thermostatic unit should be serviced annually by a

qualified person to ensure maximum safety during use.

The mixer is fitted with check valves (pages 68 and 69 pos.

94074000). There are filters on the thermostatic element

too (pages 68 and 69 pos. 94282000).

The fitting of isolation valves is required (preferred location

page 72 Installation Requirements)

On the following pages 69 - 74 you can

find important information only for the

installation in UK

Page 15

71

Technical Data

This thermostatic valve will suit supplies of:

HIGH PRESSURE (HP-S)

Operating pressure: max. 10 bar

Recommended operating pressure: 1 - 5 bar

Test pressure: 16 bar

Hot water temperature: max. 80°C

Recommended hot water temp.: 65°C

Rate of flow: 26 l/min. @ 3 bar

Maximum outlet temperature: 43°C +/-*

Safety check: 40°C

Hot water connection: Left hand

Cold water connection: Right hand

Minimum difference between hot

water and mixed water temperature: 6 K

Hot and cold supply pressure should be balanced

Mixed water temperature

Application Mixed water temperature

(at point of discharge).

Shower 41°C max.

Washbasin 41°C max.

Bath (44°C fill) 44°C max.

Bath (46°C fill) 46°C max.

* For preset outlet temperature adjustment – See page 63.

NB. If a water supply is fed by gravity then the supply

pressure should be verified to ensure the conditions of use

are appropriate for the valve. Valves operating outside of

these supply conditions cannot be guaranteed to operate

as a TMV2 or TMV3 valve.

Recommended outlet temperatures

The BuildCert TMV scheme recommends the following

set maximum mixed water outlet temperatures for use in

all premises:

44°C for bath fill but see notes below;

41°C for showers;

41°C for washbasins.

The mixed water temperatures must never exceed 46°C.

The maximum mixed water temperature can be 2°C above

the recommended maximum set outlet temperatures.

Note: 46°C is the maximum mixed water temperature

from the bath tap. The maximum temperature takes account

of the allowable temperature tolerances inherent in thermostatic mixing valves and temperature losses in metal baths.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5°C as

a comfortable bathing temperature for children. In premises

covered by the Care Standards Act 2000, the maximum

mixed water outlet temperature is 43°C

Installation Requirements

This thermostatic mixer valve must be installed in compliance with current Water Regulations. If you have any

doubts about the Water Regulation requirements contact

your local water services provider or use the services of

a professional plumber.

This mixer valve is suitable for use with the following water

supply systems:

Gas Combination Boiler (multi-point) 1.0 - 10 bar*

Unvented System (pressure balanced) 1.0 - 10 bar

Pumped System 1.0 - 10 bar

IMPORTANT: If you install this mixer with a gravity fed

system, there must be a minimum head (vertical distance)

from the underside of tlie cold water storage tank to the

showerhead position of at least 5 metre.

Before connecting the mixer, water should be flushed

through the system to remove all debris that might otherwise

damage the valve.

* If pressure is in excess of 3.5 bar, a pressure-reducing

valve should be fitted.

Operating pressure range High pressure

Maximum static pressure - bar 10

Flow pressure, hot and cold - bar 1 to 5

Hot supply temperature - °C 52 to 65

Cold supply temperature - °C 5 to 20

Supply Conditions TMV2

Supply Conditions TMV3

Operating pressure range High pressure

Maximum static pressure - bar 10

Flow pressure, hot and cold - bar 0.5 to 5

Hot supply temperature - °C 55 to 65

Cold supply temperature - °C 5 to 25

Page 16

72

KEY

Isolating valve

Reducing valve

Mixer Valve

Pump

Gas Combination Boiler (multi-point)

Unvented System (pressure balanced)

Pumped System

Page 17

73

Table A: Guide to maximum stabilised temperatures recorded during site tests

Application Mixed water

temperature

Shower 43°C

Washbasin 43°C

Bath (44°C fill) 46°C

Bath (46°C fill) 48°C

The mixed water temperature at terminal fitting should

never exceed 46ºC.

If there is a residual flow during the commissioning or

the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the

water seeping from the valve is no more than 2°C above

the designated maximum mixed water outlet temperature

setting of the valve.

Temperature readings should be taken at the normal flow

rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully

submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be

re-commissioned and re-tested in accordance with the

manufacturers' instructions.

Commissioning and in-service

tests

Commissioning

Purpose

Since the installed supply conditions are likely to be different from those applied in the laboratory tests it is appropriate, at commissioning, to carry out some simple checks

and tests on each mixing valve to provide a performance

reference point for future in-service tests.

Procedure

1. Check that:

a) the designation of the thermostatic mixing valve

matches the intended application

b) the supply pressures are within the range of ope-

rating pressures for the designation of the valve

c) the supply temperatures are within the range per-

mitted for the valve and by guidance information

on the prevention of legionella etc.

2. Adjust the temperature of the mixed water in accor-

dance with the manufacturer’s instructions (page 63)

and the requirement of the application and then carry

out the following sequence:

a) record the temperature of the hot and cold water

supplies

b) record the temperature of the mixed water at the

largest draw-off flow rate

c) record the temperature of the mixed water at a

smaller draw-off flow rate, which shall be measured

d) isolate the cold water supply to the mixing valve

and monitor the mixed water temperature

e) record the maximum temperature achieved as a

result of (d) and the final stabilised temperature

NOTE: The final stabilised mixed water temperature

should not exceed the values in Table A.

f) record the equipment, thermometer etc. used for

the measurements

Page 18

74

In-service tests

Purpose

The purpose of in-service tests is to regularly monitor and

record the performance of the thermostatic mixing valve.

Deterioration in performance can indicate the need for

service work on the valve and/ or the water supplies.

Procedure

1. Carry out the procedure 2. (a) to (e) on page 73

using the same measuring equipment, or equipment

to the same specifications.

2. If the mixed water temperature has changed signi-

ficantly from the previous test results (e.g. > 1 K),

record the change and before re-adjusting the mixed

water temperature check:

a) that any in-line or integral strainers are clean

b) any in-line or integral check valves or other

anti-backsiphonage devices are in good working

order

c) any isolating valves are fully open

3. With an acceptable mixed water temperature, com-

plete the procedure 2. (a) to (e) on page 73.

4. If at step 2. (e) on page 73 the final mixed water tem-

perature is greater than the values in Table A and / or

the maximum temperature exceeds the corresponding

value from the previous test results by more than about

2 K, the need for service work is indicated.

NOTE: In-service tests should be carried out with a

frequency which identifies a need for service work

before an unsafe water temperature can result. In

the absence of any other instruction or guidance, the

procedure described in „Frequency of in-service tests“

may be used.

Frequency of in-service tests

TMV3*

General

In the absence of any other instruction or guidance on

the means of determining the appropriate frequency of

in-service testing, the following procedure may be used:

1. 6 to 8 weeks after commissioning carry out the tests

given in 2. on page 73.

2. 12 to 15 weeks after commissioning carry out the tests

given in 2. on page 73.

3. Depending on the results of 1. and 4. several possibilities exist:

a) If no significant changes (e.g. < 1 K) in mixed

water temperatures are recorded between commissioning and 1., or between commissioning and

4. the next in-service test can be deferred to 24

to 28 weeks after commissioning.

b) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in only one of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test can be

deferred to 24 to 28 weeks after commissioning.

c) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in both of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test should be

carried out at 18 to 21 weeks after commissioning.

d) If significant changes (e.g. > 2 K) in mixed water

temperatures are recorded in either of these

periods, necessitating service work, then the next

in-service test should be carried out at 18 to 21

weeks after commissioning.

4. The general principle to be observed after the first 2 or

3 in-service tests is that the intervals of future tests should

be set to those which previous tests have shown can be

achieved with no more than a small change in mixed

water temperature.

*TMV2: The frequency of performing the in-

service tests is 1 year maximum.

Page 19

75

Thermostatic Adjustment

Temperature Limitation

The temperature is limited by the safety stop to 40°C. If

a higher temperature is required, it is possible to over ride

the safety stop by depressing the safety button.

NB. It is recommended that for private domestic

use the maximum mixed water temperature be set at the

following factory set values:

Shower Mixer 43°C

Bath/Shower 43°C

Temperatures can be set by following the procedures

on pages 62 and 63. This ensures that after correct

installation the outlet temperature of the water can never

exceed 43°C.

To guarantee a smooth running of the thermostatic element,

it is necessary from time to time to turn the thermostat from

total hot to total cold. The thermostatic mixer valve should

be checked annually by a qualified person to ensure

correct operation.

The mixer is fitted with check valves (pages 68 and

69 pos. 94074000) and filters (pages 68 and 69 pos

94282000). If the water flow drops the filters need to be

cleaned. For that purpose please follow the steps 1 - 12

on pages 64 and 65.

Calibrating Thermostat

If the temperature reading is different to the showering

temperature, follow the steps 1 - 3 on page 62.

Technical Hotline E-mail

0 870 7701975 Technical@hansgrohe.co.uk

Page 20

76

Hansgrohe · Auestraße 5 - 9 · D-77761 Schiltach · Telefon +49 (0) 78 36/51-1282 · Telefax +49 (0) 7836/511440

E-Mail: info@hansgrohe.com · Internet: www.hansgrohe.com

06/2013

9.08420.08

Loading...

Loading...