Page 1

EN Instructions for use / assembly instructions

Ecomax

Bath / Shower

14242000

Page 2

Contents

Safety and Important Information 3

Pack Contents 4

Dimensions 4

Technical Data 5

Supply Conditions TMV2 5

Installation Requirements 6-7

Installation

Thermostat 8-9

Commissioning and in-service tests

Commissioning 10

In-service tests 11

Frequency of in-service tests 11

Thermostatic Adjustement

Temperature Limitation 12

Callibrating Thermostat 12 -13

Operating your Thermostat 14

Assembling and Operating the Diverter Fixing Device 15

Cleaning 16

Spare Parts 17

Test Certificate 17

Trouble Shooting 18

Warranty 19

If there are any queries regarding this product or its

installation, please contact the Hansgrohe technical

hotline: 01372465655

The Ecomax Bath / Shower 14242000 meets the

requirements of the TMV2 Scheme.

2

Page 3

3

Safety and Important Information

Hansgrohe products are safe provided they are

installed, used and maintained in accordance with these

instructions and recornrnendations.

Please read these instructions thoroughly and retain for

future use.

The plumbing installation of this thermostat mixing

valvemust comply with the requirements of UK

Water Regulations/Bylaws (Scotland), Building

Regulations or any other regulations specified by the

local Water Authority and supplier.

The installation of thermostatic mixing valves must

comply with the requirements of the Water Supply

(Water Fittings) Regulations 1999.

We strongly recommend that you use a plumber

registered with or a member of an Association:

Chartered Institute of Plumbing and Heating Engineering

(CIPHE)

Water Industry Approved Plumber Scheme (WIAPS)

Dispose of plastic bags carefully

Keep children well away from the work area.

Check for hidden pipes and cables in the wall before

drilling holes.

The unit must be mounted on a finished waterproofed

wall surface (usually tiles).

If you are using power tools (e.g. to drill holes) wear

safety glasses and always disconnect tools from the

power supply after use.

Do not operate the shower unit if the hand shower or

spray hose has been damaged or is blocked.

Do not block the flow of water from the hand shower, by

placing it on your hand or any other part of your body

or foreign object.

The thermostatic unit should be serviced annually by a

qualified person to ensure maximum safety during use.

The thermostatic mixing valve will be installed in such

a position that maintenance of the TMV and its valves

and the commissioning and testing of the TMV can be

undertaken.

The mixer is fitted with check valves (page 17

#94074000). There are filters on the thermostatic

element too (page 17 #94282000).

The fitting of isolation valves is required (preferred

location page 6 and 7 Installation Requirements)

Page 4

4

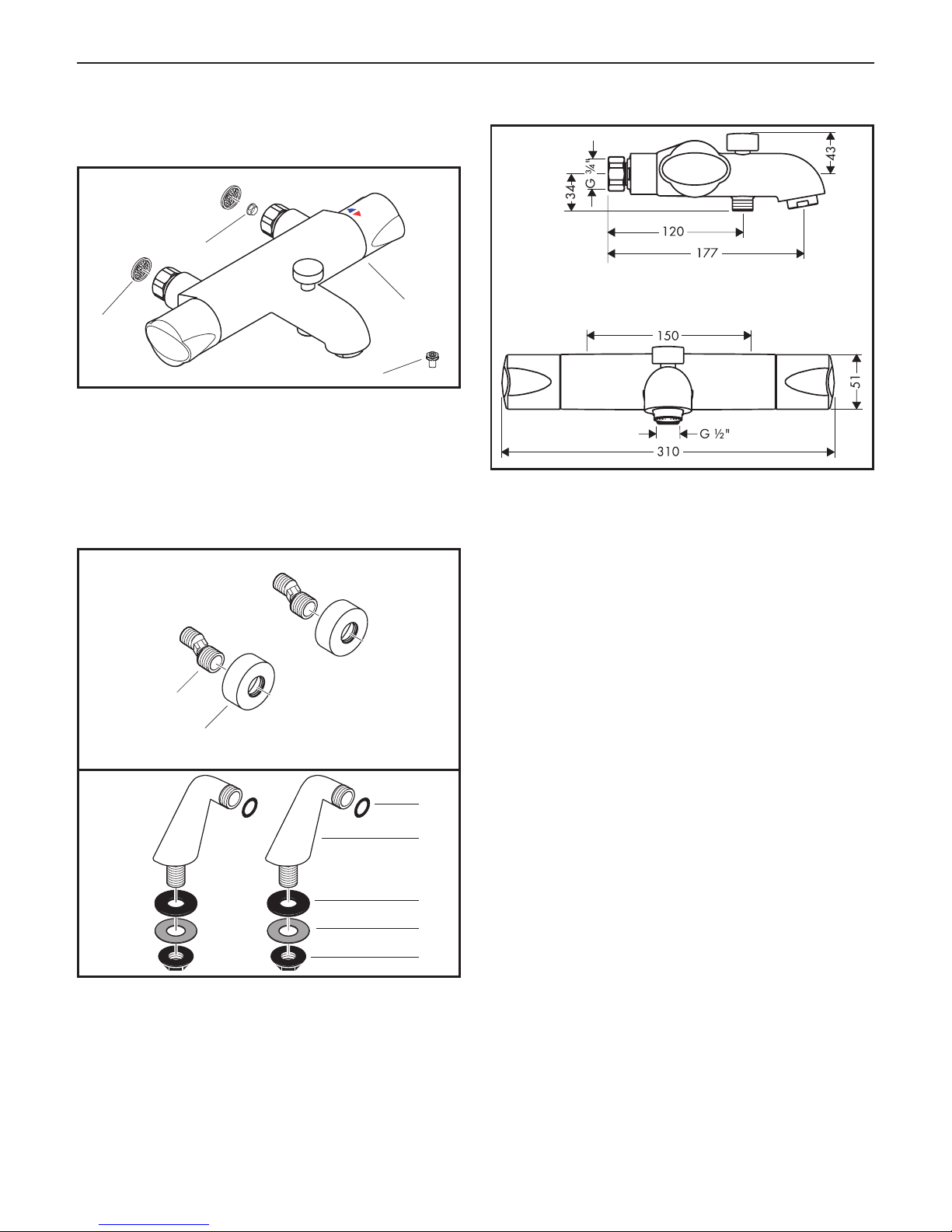

Pack Contents

Please check that you have been supplied with the

following:

Thermostat Bath / Shower

1 Ecomax Bath/Shower

2 Mesh washers

3 Flow limiter (when assembling the flow limiter, the

TMV2 certificate is invalid)

4 Diverter fixing device

Optional accessories

5 Escutcheons

6 S-unions

7 Pillar unions

8 Small seals

9 Large seals

10 Fixing nuts

11 Fibre washers

1

2

5

6

7

8

9

11

10

Dimensions

3

4

Page 5

5

Technical Data

This thermostatic valve will suit supplies of:

HIGH PRESSURE (HP-S-T)

Operating pressure: max. 10 bar

Recommended operating pressure: 1 - 5 bar

Test pressure: 16 bar

Hot water temperature: max. 70°C

Recommended hot water temp.: 65°C

Rate of flow: 36 l/min. @ 3 bar

Maximum outlet temperature: 43°C +/-*

Safety check: 40°C

Hot water connection: Left hand

Cold water connection: Right hand

Minimum difference between hot

water and mixed water temperature: 6 K

Hot and cold supply pressure should be balanced

Mixed water temperature

Application Mixed water temperature

(at point of discharge).

Bidet 38°C max.

Shower 41°C max.

Washbasin 41°C max.

Bath (44°C fill) 44°C max.

Bath (46°C fill) 46°C max.

* For preset outlet temperature adjustment – See page

14 „Commisioning“.

NB. If a water supply is fed by gravity then the supply

pressure should be verified to ensure the conditions of use

are appropriate for the valve. Valves operating outside of

these supply conditions cannot be guaranteed to operate

as a TMV2 valve.

Recommended outlet temperatures

The BuildCert TMV scheme recommends the following

set maximum mixed water outlet temperatures for use in

all premises:

44°C for bath fill but see notes below;

41°C for showers;

41°C for washbasins,

38°C for bidets.

The mixed water temperatures must never exceed 46°C.

The maximum mixed water temperature can be 2°C above

the recommended maximum set outlet temperatures.

Note: 46°C is the maximum mixed water temperature

from the bath tap. The maximum temperature takes account

of the allowable temperature tolerances inherent in thermostatic mixing valves and temperature losses in metal baths.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5°C

as a comfortable bathing temperature for children. In

premises covered by the Care Standards Act 2000, the

maximum mixed water outlet temperature is 43°C

Supply Conditions TMV2

Operating pressure range High pressure

Maximum static pressure - bar 10

Flow pressure, hot and cold - bar 0.5 to 5

Hot supply temperature - °C 55 to 65

Cold supply temperature - °C 5 to 25

Operating pressure range Low pressure

Maximum static pressure - bar 10

Flow pressure, hot and cold - bar 0.1 to 1

Hot supply temperature - °C 55 to 65

Cold supply temperature - °C 5 to 25

Page 6

6

Installation Requirements

This thermostatic mixer valve must be installed in

compliance with current Water Regulations. If you have

any doubts about the Water Regulation requirements

contact your local water services provider or use the

services of a professional plumber.

This mixer valve is suitable for use with the following

water supply systems:

Gas Combination Boiler (multi-point) 1.0 - 10 bar*

Unvented System (pressure balanced) 1.0 - 10 bar

Pumped System 1.0 - 10 bar

IMPORTANT: If you install this mixer with a gravity

fed system, there must be a minimum head (vertical

distance) from the underside of tlie cold water storage

tank to the showerhead position of at least 5 metre.

Before connecting the mixer, water should be flushed

through the system to remove all debris that might

otherwise damage the valve.

* If pressure is in excess of 3.5 bar, a pressure-reducing

valve should be fitted.

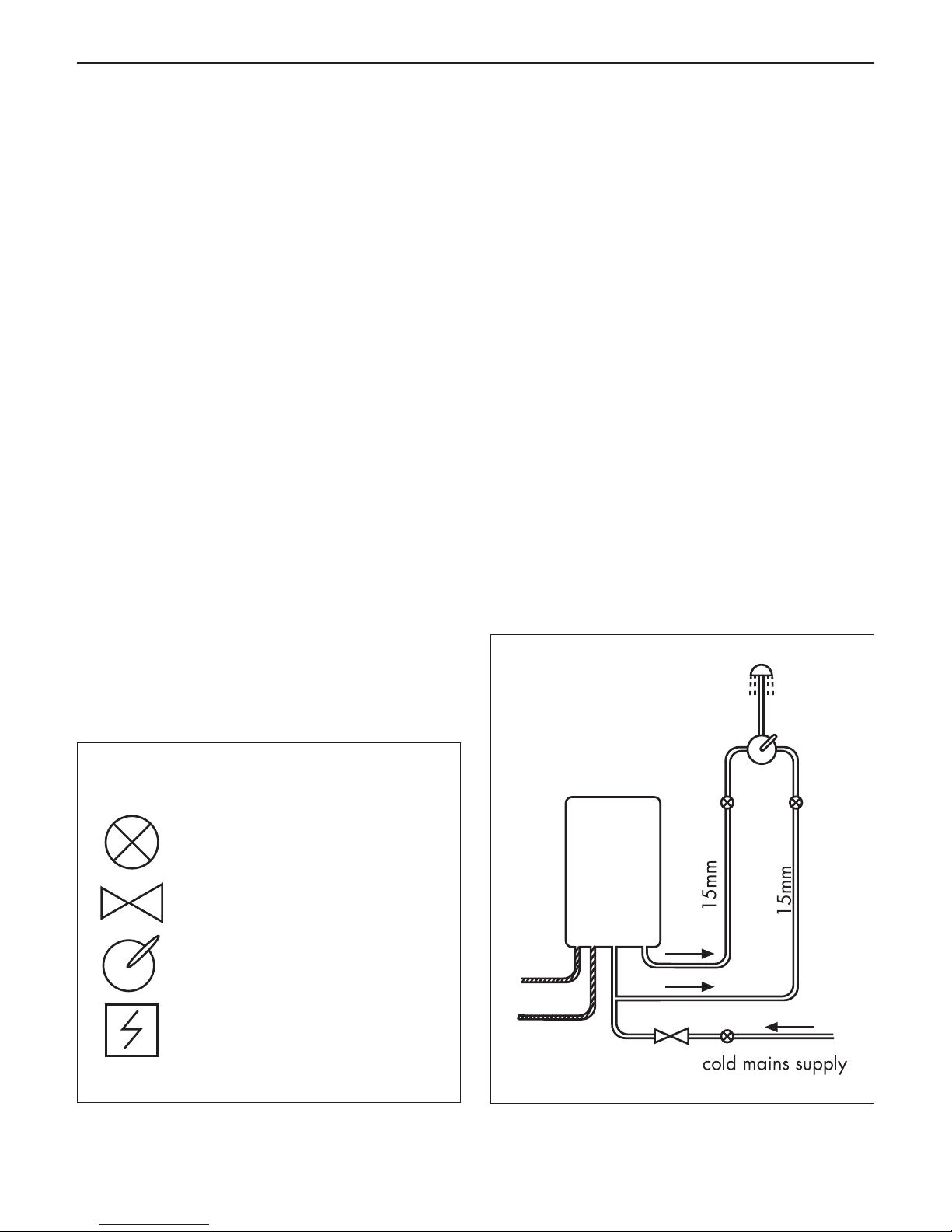

KEY

Isolating valve

Reducing valve

Mixer Valve

Pump

Gas Combination Boiler (multi-point)

Page 7

7

Unvented System (pressure balanced)

Pumped System

Page 8

8

Bath/Shower Thermostat

180 mm

Installation

36 - 39

mm

Seal

Shower Thermostat

PTFE

tape

150 mm

HOT

COLD

1 2

3

4

Page 9

9

Bath / Shower Thermostat (positioned over a bath)

The thermostatic mixing valve must be installed in a

position that is easily accessible for commissioning and

future servicing.

1. The hot and cold water outlets should be 150 mm

apart (plus or minus 12mm). Hot on the left and cold

on the right (fig. 1). The recommended plumbing

fittings are ½“ back plate elbows (not supplied).

2. Flush through the hot and cold water supplies.

3. Wrap PTFE tape round the S-unions and screw into the

backplate elbows. The S-unions must protrude beyond

the tiled surface between 32 and 41mm (figs.2-3).

4. Seal the gap between the S-unions and the tiles (fig.3).

5. Screw the escutcheons onto the S-unions.

6. Fasten the thermostatic mixer onto the S-unions using

the union nuts. Align the unit and tighten the nuts (be

careful not to damage the chrome finish). The S-unions

allow inaccuracies to be compensated for.

Bath/Shower Thermostat (Fitting to the bath using

pillar unions).

The thermostatic mixing valve must be installed in a

position that is easily accessible for commissioning and

future servicing.

1. The pillar unions are designed to fit tap holes on a

bath 180 mm apart with hot on the left and cold on

the right (fig.4).

2. Flush through the hot and cold water supplies.

3. Place fibre washers into the holes of the chrome union

nuts. (DO NOT USE FILTERS WHEN USING PILLAR

UNIONS!)

From under the bath fit a large seal washer over the

thread then fix with the nuts.

4. Fasten the mixer onto the union pillars using the union

nuts (be careful not to damage the chrome finish).

Page 10

10

f) record the equipment, thermometer etc. used for

the measurements

Table A: Guide to maximum stabilised tem-

peratures recorded during site tests

Application Mixed water

temperature

Shower 43°C

Washbasin 43°C

Bath (44°C fill) 46°C

Bath (46°C fill) 48°C

The mixed water temperature at terminal fitting should

never exceed 46ºC.

If there is a residual flow during the commissioning or

the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of

the water seeping from the valve is no more than 2°C

above the designated maximum mixed water outlet

temperature setting of the valve.

Temperature readings should be taken at the normal

flow rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully

submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be

re-commissioned and re-tested in accordance with the

manufacturers' instructions.

Commissioning and in-service

tests

Commissioning

Purpose

Since the installed supply conditions are likely to be

different from those applied in the laboratory tests it is

appropriate, at commissioning, to carry out some simple

checks and tests on each mixing valve to provide a

performance reference point for future in-service tests.

Procedure

1. Check that:

a) the designation of the thermostatic mixing valve

matches the intended application

b) the supply pressures are within the range of ope-

rating pressures for the designation of the valve

c) the supply temperatures are within the range per-

mitted for the valve and by guidance information

on the prevention of legionella etc.

2. Adjust the temperature of the mixed water in accor-

dance with the manufacturer’s instructions and the

requirement of the application and then carry out the

following sequence:

a) record the temperature of the hot and cold water

supplies

b) record the temperature of the mixed water at the

largest draw-off flow rate

c) record the temperature of the mixed water at a

smaller draw-off flow rate, which shall be measured

d) isolate the cold water supply to the mixing valve

and monitor the mixed water temperature

e) record the maximum temperature achieved as a

result of (d) and the final stabilised temperature

NOTE: The final stabilised mixed water temperature

should not exceed the values in Table A.

Page 11

11

In-service tests

Purpose

The purpose of in-service tests is to regularly monitor

and record the performance of the thermostatic mixing

valve. Deterioration in performance can indicate the

need for service work on the valve and/ or the water

supplies.

Procedure

1. Carry out the procedure 2. (a) to (e) on page 72

using the same measuring equipment, or equipment

to the same specifications.

2. If the mixed water temperature has changed signi-

ficantly from the previous test results (e.g. > 1 K),

record the change and before re-adjusting the mixed

water temperature check:

a) that any in-line or integral strainers are clean

b) any in-line or integral check valves or other

anti-backsiphonage devices are in good working

order

c) any isolating valves are fully open

3. With an acceptable mixed water temperature, complete the procedure 2. (a) to (c) on page 10.

4. If at step 2. (e) on page 10 the final mixed water tem-

perature is greater than the values in Table A and / or

the maximum temperature exceeds the corresponding

value from the previous test results by more than about

2 K, the need for service work is indicated.

NOTE: In-service tests should be carried out with a

frequency which identifies a need for service work

before an unsafe water temperature can result. In

the absence of any other instruction or guidance, the

procedure described in „Frequency of in-service tests“

may be used.

Frequency of in-service tests TMV2

The frequency of performing the in-service

tests is 1 year maximum.

General

In the absence of any other instruction or guidance on

the means of determining the appropriate frequency of

in-service testing, the following procedure may be used:

1. 6 to 8 weeks after commissioning carry out the tests

given in 2. on page 10.

2. 12 to 15 weeks after commissioning carry out the tests

given in 2. on page 10.

3. Depending on the results of 1. and 4. several possibilities exist:

a) If no significant changes (e.g. < 1 K) in mixed

water temperatures are recorded between commissioning and 1., or between commissioning and

4. the next in-service test can be deferred to 24

to 28 weeks after commissioning.

b) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in only one of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test can be

deferred to 24 to 28 weeks after commissioning.

c) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in both of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test should be

carried out at 18 to 21 weeks after commissioning.

d) If significant changes (e.g. > 2 K) in mixed water

temperatures are recorded in either of these

periods, necessitating service work, then the next

in-service test should be carried out at 18 to 21

weeks after commissioning.

4. The general principle to be observed after the first 2 or

3 in-service tests is that the intervals of future tests should

be set to those which previous tests have shown can be

achieved with no more than a small change in mixed

water temperature.

Page 12

12

SW 3 mm

1

2

3

Thermostatic Adjustment

Temperature Limitation

The temperature is limited by the safety stop to 40°C.

If a higher temperature is required, it is possible to over

ride the safety stop by depressing the safety button.

NB. It is recommended that for private domestic

use the maximum mixed water temperature be set at the

following factory set values:

Shower Mixer 43°C

Bath/Shower 46°C

Bath/Shower Mixer when installed as type 3 valve the

maximum mixed water temperature shall be set at 43°C

for both outlets (bath & shower)

Temperatures can be set by following the procedures

under „Setting thermostat to a maximum tem-

perature“. This ensures that after correct installation

the outlet temperature of the water can never exceed

43°C.

To guarantee a smooth running of the thermostatic

element, it is necessary from time to time to turn the thermostat from total hot to total cold. The thermostatic mixer

valve should be checked annually by a qualified person

to ensure correct operation.

The mixer is fitted with check valves (page 17

#96644000) and filters (page 17 #96922000). If the

water flow drops the filters need to be cleaned. For that

purpose the mixer has to be removed from the wall.

Calibrating Thermostat

1. If the temperature reading is different to the

showering temperature, turn the thermostat

handle until a 40°C reading is shown on your thermometer.

2. Remove the handle end cap, undo the screw (fig. 1).

3. Pull off the handle (fig. 2).

4. Remove the circlip from the spindle and slide off the

locking ring (fig. 3).

Page 13

13

SW 3 mm

(2 Nm)

4

5

6

5. Turn the spindle until the required maximum temperature is reached (40°C). You will need to use a

thermometer (fig. 4).

6. Replace the locking ring back onto the spindle as

shown. Refit the circlip (fig. 5).

7. Replace the handle, screw and end cap

(fig. 6).

Page 14

14

Operating your Thermostat

Flow ON/OFF Control

Turn the flow control handle (fig.1a) anti-clockwise to

turn the water on and to increase the flow. Turn it clockwise to decrease the flow and turn off.

Temperature Control

Turn the temperature control handle (fig. 1b) anti-clockwise to increase the water temperature and clockwise to

decrease the water temperature.

Thermostat

The valve automatically adjusts for changes in flow

supply and maintains the outlet set water temperature.

Using Bath / Shower Diverter

When first turned on, the water flow automatically

comes from the bath tap.

To divert the water flow to the hand shower, pull up the

diverter knob (fig. 2).

To divert the water flow to the bath tap, push down on

the diverter knob (fig. 3).

a

b

1

2

3

Page 15

15

Assembling and Operating the

Diverter Fixing Device

If the Bath / Shower Diverter does not work perfect, please

assemble the diverter fixing device.

To remove the diverter knob, fix the diverter from below

with a screw driver and screw off the diverter knob (fig. 1).

Assemble the diverter fixing device (fig. 2).

Assemble the diverter knob (fig. 3).

To divert the water flow to the hand shower, pull up the

diverter knob and turn 90° clockwise (fig. 4).

To divert the water flow to the bath tap, turn the diverter

knob 90° counter clockwise and push down (fig. 5).

1

2 3

90°

1.

2.

90°

4

5

Page 16

16

Cleaning

Cleaning Recommendation for Hansgrohe

Products

Today, modern sanitary and kitchen tapware, showers,

accessories, washstands, sinks, tubs and radiators consist

of very different materials to comply with the needs of

the market with regard to design and functionality.

To avoid damage and reclamations, it is necessary to

consider certain criteria when cleaning.

With regard to caring for the Hansgrohe

products, the following must in principle be

heeded:

• Only use cleaning material which is explicitly provided

for this type of application.

• Never use cleaning materials, which contain

hydrochloric acid, formic acid, concentrated caustic

soda, chlorine pale lye or acetic acid, as they cause

considerable damage.

• Phosphorus acidic cleaners are only conditionally

applicable.

• Mixing cleaning agents is not permitted, generally.

• Never use cleaning materials or appliances with an

abrasive effect, such as unsuitable cleaning powders,

sponge pads or micro fibre cloths.

• The instructions of the cleaning agent manufacturers

have to be followed absolutely.

• Cleaning has to be carried out with a specified

cleaner dosage, contact time, object-related and

adapted to the needs.

• The building up of calcifications has to be removed by

cleaning regulary.

• When using spray cleaners, spray the cleaning

solution onto a soft cloth or sponge, never directly

onto the Hansgrohe products, as the atomised spray

could enter openings and gaps in the Hansgrohe

products and cause damage.

• After cleaning rinse thoroughly with clean water to

remove any cleaner residue.

• The use of steam cleaners is not permitted. The high

temperatures can damage the products.

Important

Residues of toiletries such as liquid soaps, shampoos and

shower gels, hair dyes, perfumes, aftershave and nail

varnish can also cause damage.

Here too: Carefully rinse with water after use to remove

residues.

Likewise, do not store any cleaning agents or chemicals

under the products, for example in a vanity unit, as the

vapours may damage the products.

The damage of already damaged surfaces will

deteriorate under the effect of the cleansers.

Components with damaged surfaces must be

exchanged, otherwise there could be an injury

danger.

Page 17

17

Spare Parts

Ecomax

Bath / Shower

14242000

96633000

92929000

97469000

97335000

97163000

96488000

97164000

97210000

96922000

97211000

96644000

97510000

98163000

(15x2)

98421000

(28x1,5)

Test Certificate

WRAS

14242000

X

Page 18

18

Fault Cause Remedy

Insufficient water - Supply pressure inadequate - Check water pressure (If a pump

has been installed check to see if

the pump is working).

- Shower filter seal dirty - Clean filter insert between shower

and hose

- Filters are dirty #96922000 - Clean the filter / exchange filter

Crossflow, hot water being forced

into cold water pipe, or vice versa,

when mixer is closed

- Backflow preventers dirty or leaking - Clean backflow preventers,

exchange if necessary

Spout temperature does not

correspond with temperature set

- Thermostat has not been adjusted - Adjust thermostat

- Hot water temperature too low - Increase hot water temperature to

42 ºC to 65 ºC

Temperature regulation not possible - thermo cartridge calcified - Exchange cartridge

Shower or spout dripping - Dirt or sedimentation on valve seat,

shut-off unit damaged

- Clean or exchange shut-off unit

Trouble Shooting

Page 19

19

Warranty

Hansgrohe guarantees to the consumer that this product is free of production faults. If nevertheless any defect is

detected within 5 years from date of purchase, Hansgrohe will remedy this defect free of charge. You will find the

conditions and details of this guarantee at www.hansgrohe-int.com/guarantee. Please contact your contracting party

to claim your rights under this guarantee. This guarantee does not affect the customer‘s rights under the respective

national legislation.

Technical Hotline E-mail

01372465655 Technical@hansgrohe.co.uk

Page 20

20

Hansgrohe · Units D1 & D2 Sandown Park · Park Trading Estate, Royal Mills · Esher Surrey KT10 8BL · Technical Hotline 01372465655

E-Mail: technical@hansgrohe.co.uk · Internet: www.hansgrohe.co.uk

07/2018

9.05577.04

Loading...

Loading...