Page 1

DE Gebrauchsanleitung / Montageanleitung 2

EN Instructions for use / assembly instructions 4

Ecomax

13356000

Ecomax

13354000

Page 2

Sicherheitshinweise

Bei der Montage müssen zur Vermeidung von Quetsch-

und Schnittverletzungen Handschuhe getragen werden.

Das Produkt darf nur zu Bade-, Hygiene- und Körper-

reinigungszwecken eingesetzt werden.

Kinder, sowie Erwachsene mit körperlichen, geis-

tigen und / oder sensorischen Einschränkungen

dürfen das Produkt nicht unbeaufsichtigt benutzen.

Personen, die unter Alkohol- oder Drogeneinfluss

stehen, dürfen das Produkt nicht benutzen.

Große Druckunterschiede zwischen den Kalt- und

Warmwasseranschlüssen müssen ausgeglichen

werden.

Montagehinweise

• Vor der Montage muss das Produkt auf Transportschäden untersucht werden. Nach dem Einbau werden

keine Transport- oder Oberflächenschäden anerkannt.

• Die Leitungen und die Armatur müssen nach den gültigen Normen montiert, gespült und geprüft werden.

• Die in den Ländern jeweils gültigen Installationsrichtlinien sind einzuhalten.

Thermostat in Verbindung mit Durchlauferhitzern

• Wird eine Handbrause angeschlossen, so muss aus

dieser eine eventuell vorhandene Drossel ausgebaut

werden.

• Bei Problemen mit dem Durchlauferhitzer oder großen

Druckunterschieden muss eine optional erhältliche

Drossel (Artikelnummer 97510000) in den Kaltwasserzulauf eingesetzt werden.

Technische Daten

Betriebsdruck: max. 1 MPa

Empfohlener Betriebsdruck: 0,1 - 0,5 MPa

Prüfdruck: 1,6 MPa

(1 MPa = 10 bar = 147 PSI)

Heißwassertemperatur: max. 70°C

Empfohlene Heißwassertemperatur: 65°C

Thermische Desinfektion: max. 70°C / 4 min

Durchflussleistung Wanneneinlauf: 58 l/min 0,3 MPa

Durchflussleistung Abgang Brause: 18 l/min 0,3 MPa

• Eigensicher gegen Rückfließen

• Das Produkt ist ausschließlich für Trinkwasser konzipiert!

Deutsch

Justierung (siehe Seite 9)

Nach erfolgter Montage muss die Auslauftemperatur des Thermostaten überprüft werden. Eine Korrektur ist erforderlich wenn die

an der Entnahmestelle gemessene Temperatur von der am Thermostaten eingestellten

Temperatur abweicht.

Kein essigsäurehaltiges Silikon verwenden!

Symbolerklärung

Wartung (siehe Seite 11 )

• Rückflussverhinderer müssen gemäß DIN

EN 1717 regelmäßig in Übereinstimmung

mit nationalen oder regionalen Bestimmungen auf ihre Funktion geprüft werden

(mindestens einmal jährlich).

• Um die Leichtgängigkeit der Regeleinheit

zu gewährleisten, sollte der Thermostat

von Zeit zu Zeit auf ganz warm und ganz

kalt gestellt werden.

Safety Function (siehe Seite 10)

Dank der Safety Function lässt sich die gewünschte Höchsttemperatur von z. B. max.

42 ºC voreinstellen.

2

Page 3

Deutsch

Serviceteile (siehe Seite 14)

Bedienung (siehe Seite 12)

Maße (siehe Seite 8)

Reinigung (siehe Seite 20)

Montage (siehe Seite 6)

Störung Ursache Abhilfe

Wenig Wasser - Versorgungsdruck nicht ausreichend - Leitungsdruck prüfen

- Schmutzfangsieb der Regeleinheit

verschmutzt

- Schmutzfangsiebe vor dem Thermostat und auf der Regeleinheit

reinigen

- Siebdichtung der Brause verschmutzt

- Siebdichtung zwischen Brause und

Schlauch reinigen

Kreuzfluss, warmes Wasser wird

bei geschlossener Armatur in die

Kaltwasserleitung gedrückt oder

umgekehrt

- Rückflussverhinderer verschmutzt /

defekt

- Rückflussverhinderer reinigen ggf.

austauschen

Auslauftemperatur stimmt nicht mit

der eingestellten Temperatur überein

- Thermostat wurde nicht justiert - Thermostat justieren

- Zu niedrige Warmwassertemperatur - Warmwassertemperatur erhöhen

auf 42 ºC bis 65 ºC

Temperaturregelung nicht möglich - Regeleinheit verkalkt - Regeleinheit austauschen

Durchlauferhitzer schaltet bei Thermostatbetrieb nicht ein

- Schmutzfangsiebe verschmutzt - Schmutzfangsiebe reinigen / austauschen

- Rückflussverhinderer sitzt fest - Rückflussverhinderer austauschen

- Drossel in der Handbrause nicht

ausgebaut

- Drossel aus der Handbrause entfernen

Brause oder Auslauf tropft - Schmutz oder Ablagerungen auf

dem Dichtsitz, Absperroberteil beschädigt

- Absperroberteil reinigen bzw. austauschen

3

Prüfzeichen (siehe Seite 8)

Page 4

Safety Notes

Gloves should be worn during installation to prevent

crushing and cutting injuries.

The product may only be used for bathing, hygienic

and body cleaning purposes.

Children as well as adults with physical, mental and/

or sensoric impairments must not use this product

without proper supervision. Persons under the influence of alcohol or drugs are prohibited from using

this product.

The hot and cold supplies must be of equal pres-

sures.

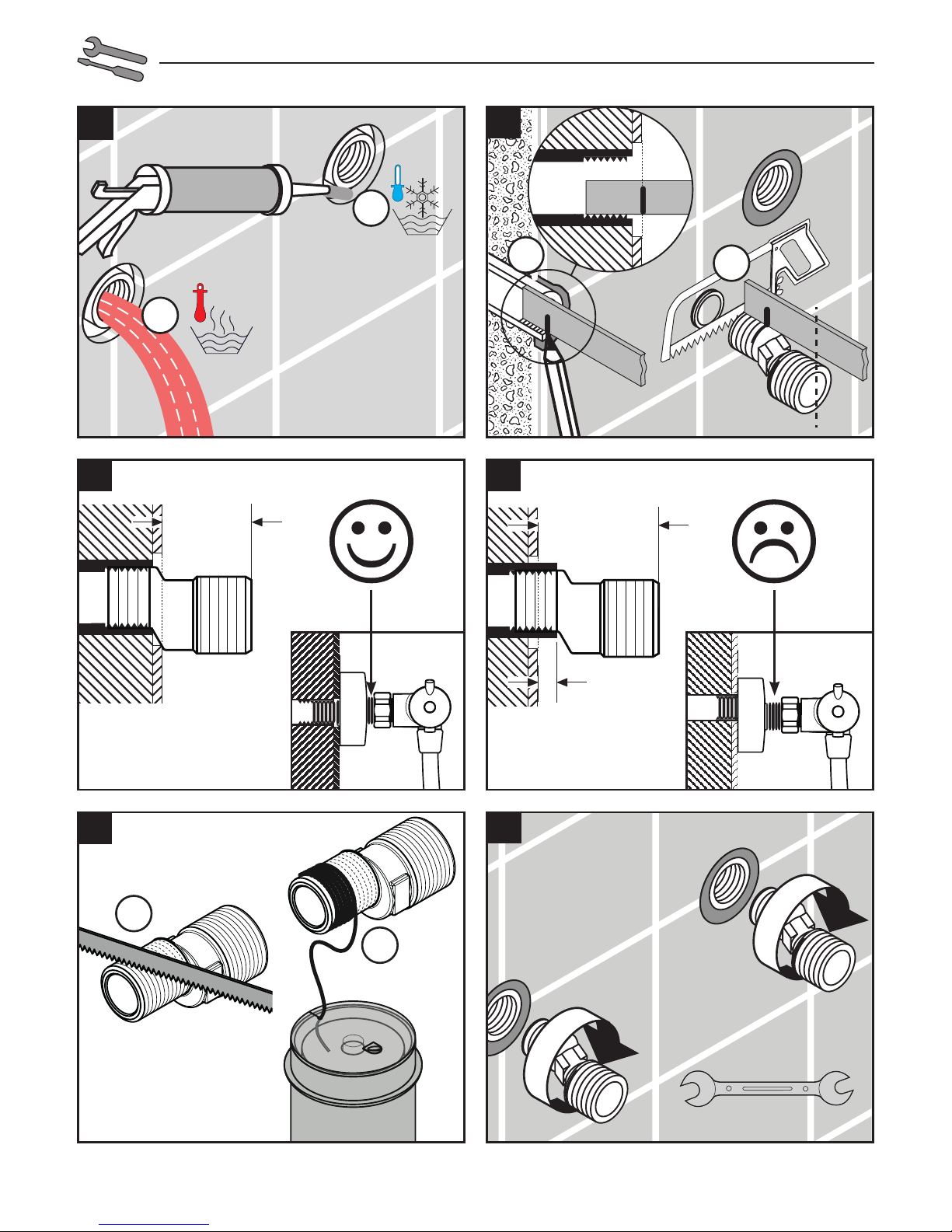

Installation Instructions

• Prior to installation, inspect the product for transport

damages. After it has been installed, no transport or

surface damage will be honoured.

• The pipes and the fixture must be installed, flushed

and tested as per the applicable standards.

• The plumbing codes applicable in the respective

countries must be observed.

Thermostatic mixer in conjunction with

combination boilers

• If fitting a hand shower remove the water limiter from

the shower.

• If the continuous water heater causes any problems,

or you have different water pressures you must

install a water limiter to the cold supply, (ordered

separately,article number 97510000).

Technical Data

Operating pressure: max. 1 MPa

Recommended operating pressure: 0,1 - 0,5 MPa

Test pressure: 1,6 MPa

(1 MPa = 10 bar = 147 PSI)

Hot water temperature: max. 70°C

Recommended hot water temp.: 65°C

Thermal disinfection: max. 70°C / 4 min

Rate of flow Bath Spout: 58 l/min 0,3 MPa

Rate of flow Shower outlet: 18 l/min 0,3 MPa

• Safety against backflow

• The product is exclusively designed for drinking water!

English

Adjustment (see page 9)

After the installation, the output temperature of the thermostat must be checked. A

correction is necessary if the temperature

measured at the output differs from the

temperature set on the thermostat.

Do not use silicone containing acetic acid!

Symbol description

Maintenance (see page 11 )

• The check valves must be checked

regularly according to DIN EN 1717 in

accordance with national or regional

regulations (at least once a year).

• To guarantee the smooth running of the

thermostat, it is necessary from time to

time to turn the thermostat from total hot

to total cold.

Safety Function (see page 10)

The desired maximum temperature for example max. 42º C can be pre-set thanks to the

safety function.

4

Page 5

English

Spare parts (see page 14)

Operation (see page 12)

Dimensions (see page 8)

Cleaning (see page 20)

Assembly (see page 6)

Fault Cause Remedy

Insufficient water - Supply pressure inadequate - Check water pressure (If a pump

has been installed check to see if

the pump is working).

- Regulator filter dirty - Clean filter in front of the mixer and

on the MTC-thermo cartridge

- Shower filter seal dirty - Clean filter seal between shower

and hose

Crossflow, hot water being forced

into cold water pipe, or vice versa,

when mixer is closed

- Backflow preventers dirty or leaking - Clean backflow preventers, exchange if necessary

Spout temperature does not correspond with temperature set

- Thermostat has not been adjusted - Adjust thermostat

- Hot water temperature too low - Increase hot water temperature to

42 ºC to 65 ºC

Temperature regulation not possible - thermo cartridge calcified - Exchange thermo cartridge

Instantaneous heater didn't work with

thermostat

- Filters are dirty - Clean the filter / exchange filter

- check valve hasn't moved back - Exchange check valves

- Flow limiter in handshower isn’t

removed

- Remove flow limiter

Shower or spout dripping - Dirt or sedimentation on valve seat,

shut-off unit damaged

- Clean or exchange shut-off unit

Special information for UK (see page 15)

5

Test certificate (see page 8)

Page 6

6

X

X + 36 mm

X 36

1

3b

2

3a

1.

2.

1.

2.

Silicone

max.

39 mm

max.

5 mm

1.

2.

5

4

36 mm

SW 24 mm

Page 7

7

6

7

8

SW 30 mm

(17 Nm)

Page 8

8

Ecomax

13354000

Ecomax

13356000

R 1/2

R 1/2

P-IX DVGW SVGW ACS WRAS ETA KIWA

13354000

X

13356000

X

Page 9

9

SW 3 mm

SW 3 mm

(2 Nm)

1

3 4

2

5 6

Page 10

10

z. B. 42° C

for example 42° C

43

1 2

5

1.

2.

SW 3mm

SW 3mm

(2 Nm)

Page 11

11

5 6

SW 30 mm

SW 30 mm

(17 Nm)

SW 12 mm

SW 12 mm

(20 Nm)

4

1.

1.

2.

2.

3

1 2

SW 24 mm

1.

2.

SW 24 mm

(20 Nm)

1.

2.

Page 12

12

1

2

3

Page 13

13

schließen / close

90°

öffnen / open

1.

2.

kalt / cold

> 40°C

warm /hot

90°

1.

2.

Page 14

14

Ecomax

13354000

94140000

96429000

98163000

(15x2)

96467000

96922000

97220000

96644000

(OV25 / DN25)

98194000

(28x2)

96157000

97210000

96466000

96225000

97163000

97738000

97211000

(25x2)

97164000

95041000

96633000

98147000

(26x2)

(34x2)

(38x2,5)

A

96264000

97162000

92929000

96264000

Ecomax

13356000

94140000

96429000

98163000

(15x2)

96157000

96467000

96922000

97220000

96644000

(OV25 / DN25)

98194000

(28x2)

97210000

97162000

92929000

96264000

98147000

(26x2)

(34x2)

(38x2,5)

A

96264000

96225000

95041000

96633000

98556000

97664000

(M5x25)

98140000

(20x1)

Page 15

15

Safety and Important Information

Hansgrohe products are safe provided they are installed,

used and maintained in accordance with these instructions

and recornrnendations.

Please read these instructions thoroughly and retain for

future use.

The plumbing installation of this thermostat mixing valvemust

comply with the requirements of UK

Water Regulations/Bylaws (Scotland), Building Regulations or any other regulations specified by the local Water

Authority and supplier.

The installation of thermostatic mixing valves must comply

with the requirements of the Water Supply (Water Fittings)

Regulations 1999.

We strongly recommend that you use a plumber registered

with or a member of an Association:

Chartered Institute of Plumbing and Heating Engineering

(CIPHE)

Water Industry Approved Plumber Scheme (WIAPS)

Dispose of plastic bags carefully

Keep children well away from the work area.

Check for hidden pipes and cables in the wall before

drilling holes.

The unit must be mounted on a finished waterproofed wall

surface (usually tiles).

If you are using power tools (e.g. to drill holes) wear safety glasses and always disconnect tools from the power

supply after use.

Do not operate the shower unit if the hand shower or spray

hose has been damaged or is blocked.

Do not block the flow of water from the hand shower, by

placing it on your hand or any other part of your body or

foreign object.

The thermostatic unit should be serviced annually by a

qualified person to ensure maximum safety during use.

The thermostatic mixing valve will be installed in such a

position that maintenance of the TMV and its valves and the

commissioning and testing of the TMV can be undertaken.

The mixer is fitted with check valves (page 14 pos.

96644000). There are filters on the thermostatic element

too (page 14 pos. A and 96922000).

The fitting of isolation valves is required (preferred location

page 17 Installation Requirements)

On the following pages 16 - 21 you can

find important information only for the

installation in UK

Technical Hotline for UK only 01372465655

E-mail for UK only Technical@hansgrohe.co.uk

(Diese Servicehotline ist nur für das Vereinigte Königreich Großbritannien, nicht z. B. für Deutschland)

Page 16

16

Technical Data

This thermostatic valve will suit supplies of:

13354000: High pressure (HP-S/ T41) / Low pressure

(LP-S)

13356000: High pressure (HP-S) / Low pressure (LP-S)

Operating pressure: max. 10 bar

Recommended operating pressure: 0.2 - 5 bar

Test pressure: 16 bar

Hot water temperature: max. 80°C

Recommended hot water temp.: 65°C

Rate of flow from bath spout: 58 l/min. @ 3 bar

Rate of flow from shower outlet: 18 l/min. @ 3 bar

Maximum outlet temperature: 43°C +/-*

Safety check: 40°C

Hot water connection: Left hand

Cold water connection: Right hand

Minimum difference between hot

water and mixed water temperature: 6 K

Hot and cold supply pressure should be balanced

Mixed water temperature

Application Mixed water temperature

(at point of discharge).

Shower 41°C max.

Washbasin 41°C max.

Bath (44°C fill) 44°C max.

Bath (46°C fill) 46°C max.

* For preset outlet temperature adjustment – See page 10.

NB. If a water supply is fed by gravity then the supply

pressure should be verified to ensure the conditions of use

are appropriate for the valve. Valves operating outside of

these supply conditions cannot be guaranteed to operate

as a TMV2 or TMV3 valve.

Recommended outlet temperatures

The BuildCert TMV scheme recommends the following

set maximum mixed water outlet temperatures for use in

all premises:

44°C for bath fill but see notes below;

41°C for showers;

41°C for washbasins.

The mixed water temperatures must never exceed 46°C.

The maximum mixed water temperature can be 2°C above

the recommended maximum set outlet temperatures.

Note: 46°C is the maximum mixed water temperature from

the bath tap. The maximum temperature takes account of the

allowable temperature tolerances inherent in thermostatic

mixing valves and temperature losses in metal baths.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5°C as

Installation Requirements

This thermostatic mixer valve must be installed in compliance with current Water Regulations. If you have any

doubts about the Water Regulation requirements contact

your local water services provider or use the services of a

professional plumber.

The thermostatic mixing valve must be installed in a position that is easily accessible for commissioning and future

servicing.

This mixer valve is suitable for use with the following water

supply systems:

Gas Combination Boiler (multi-point) 1.0 - 10 bar*

Unvented System (pressure balanced) 1.0 - 10 bar

Pumped System 1.0 - 10 bar

IMPORTANT: If you install this mixer with a gravity fed

system, there must be a minimum head (vertical distance)

from the underside of tlie cold water storage tank to the

showerhead position of at least 5 metre.

Before connecting the mixer, water should be flushed

through the system to remove all debris that might otherwise

damage the valve.

* If pressure is in excess of 3.5 bar, a pressure-reducing

valve should be fitted.

a comfortable bathing temperature for children. In premises

covered by the Care Standards Act 2000, the maximum

mixed water outlet temperature is 43°C

Supply Conditions TMV2

Operating pressure range

High

pressure

Low

pressure

Maximum static pressure - bar 10 10

Flow pressure, hot and cold - bar 1 to 5 0.2 to 1

Hot supply temperature - °C 52 to 65 52 to 65

Cold supply temperature - °C 5 to 20 5 to 20

Supply Conditions TMV3

Operating pressure range

High

pressure

Low

pressure

Maximum static pressure - bar 10 10

Flow pressure, hot and cold - bar 0.5 to 5 0.1 to 1

Hot supply temperature - °C 55 to 65 55 to 65

Cold supply temperature - °C 5 to 25 5 to 25

Page 17

17

KEY

Isolating valve

Reducing valve

Mixer Valve

Pump

Gas Combination Boiler (multi-point)

Unvented System (pressure balanced)

Pumped System

Page 18

18

peratures recorded during site tests

Application Mixed water

temperature

Shower 43°C

Washbasin 43°C

Bath (44°C fill) 46°C

Bath (46°C fill) 48°C

The mixed water temperature at terminal fitting should

never exceed 46ºC.

If there is a residual flow during the commissioning or

the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the

water seeping from the valve is no more than 2°C above

the designated maximum mixed water outlet temperature

setting of the valve.

Temperature readings should be taken at the normal flow

rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully

submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be

re-commissioned and re-tested in accordance with the

manufacturers' instructions.

Commissioning and in-service tests

Commissioning

Purpose

Since the installed supply conditions are likely to be different

from those applied in the laboratory tests it is appropriate,

at commissioning, to carry out some simple checks and tests

on each mixing valve to provide a performance reference

point for future in-service tests.

Procedure

1. Check that:

a) the designation of the thermostatic mixing valve

matches the intended application

b) the supply pressures are within the range of ope-

rating pressures for the designation of the valve

c) the supply temperatures are within the range per-

mitted for the valve and by guidance information

on the prevention of legionella etc.

2. Adjust the temperature of the mixed water in accordance with the manufacturer’s instructions (page 10)

and the requirement of the application and then carry

out the following sequence:

a) record the temperature of the hot and cold water

supplies

b) record the temperature of the mixed water at the

largest draw-off flow rate

c) record the temperature of the mixed water at

a smaller draw-off flow rate, which shall be

measured

d) isolate the cold water supply to the mixing valve

and monitor the mixed water temperature

e) record the maximum temperature achieved as a

result of (d) and the final stabilised temperature

NOTE: The final stabilised mixed water temperature

should not exceed the values in Table A.

f) record the equipment, thermometer etc. used for

the measurements

Table A: Guide to maximum stabilised tem-

Page 19

19

In-service tests

Purpose

The purpose of in-service tests is to regularly monitor and

record the performance of the thermostatic mixing valve.

Deterioration in performance can indicate the need for

service work on the valve and/ or the water supplies.

Procedure

1. Carry out the procedure 2. (a) to (e) on page 18 using

the same measuring equipment, or equipment to the

same specifications.

2. If the mixed water temperature has changed significantly from the previous test results (e.g. > 1 K), record

the change and before re-adjusting the mixed water

temperature check:

a) that any in-line or integral strainers are clean

b) any in-line or integral check valves or other anti-

backsiphonage devices are in good working order

c) any isolating valves are fully open

3. With an acceptable mixed water temperature, complete the procedure 2. (a) to (e) on page 18.

4. If at step 2. (e) on page 18 the final mixed water temperature is greater than the values in Table A and / or

the maximum temperature exceeds the corresponding

value from the previous test results by more than about

2 K, the need for service work is indicated.

NOTE: In-service tests should be carried out with a

frequency which identifies a need for service work

before an unsafe water temperature can result. In

the absence of any other instruction or guidance, the

procedure described in „Frequency of in-service tests“

may be used.

Frequency of in-service tests

TMV3*

General

In the absence of any other instruction or guidance on

the means of determining the appropriate frequency of

in-service testing, the following procedure may be used:

1. 6 to 8 weeks after commissioning carry out the tests

given in 2. on page 18.

2. 12 to 15 weeks after commissioning carry out the tests

given in 2. on page 18.

3. Depending on the results of 1. and 4. several possibilities exist:

a) If no significant changes (e.g. < 1 K) in mixed

water temperatures are recorded between commissioning and 1., or between commissioning and

4. the next in-service test can be deferred to 24 to

28 weeks after commissioning.

b) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in only one of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test can be

deferred to 24 to 28 weeks after commissioning.

c) If small changes (e.g. 1 to 2 K) in mixed water

temperatures are recorded in both of these periods, necessitating adjustment of the mixed water

temperature, then the next in-service test should be

carried out at 18 to 21 weeks after commissioning.

d) If significant changes (e.g. > 2 K) in mixed water

temperatures are recorded in either of these

periods, necessitating service work, then the next

in-service test should be carried out at 18 to 21

weeks after commissioning.

4. The general principle to be observed after the first 2

or 3 in-service tests is that the intervals of future tests

should be set to those which previous tests have shown

can be achieved with no more than a small change in

mixed water temperature.

*TMV2: The frequency of performing the in-

service tests is 1 year maximum.

Page 20

Thermostatic Adjustment

Temperature Limitation

The temperature is limited by the safety stop to 40°C. If

a higher temperature is required, it is possible to over ride

the safety stop by depressing the safety button.

NB. It is recommended that for private domestic use

the maximum mixed water temperature be set at the following factory set values:

Shower Mixer 43°C

Bath/Shower 43°C

Temperatures can be set by following the procedures on

page 9. This ensures that after correct installation the outlet

temperature of the water can never exceed 43°C.

To guarantee a smooth running of the thermostatic element,

it is necessary from time to time to turn the thermostat from

total hot to total cold. The thermostatic mixer valve should

be checked annually by a qualified person to ensure

correct operation.

The mixer is fitted with check valves (page 14 pos.

96644000) and filters (page 14 pos. A and 96922000).

If the water flow drops the filters need to be cleaned. For

that purpose please follow the steps 1 - 8 on page 10.

Calibrating Thermostat

If the temperature reading is different to the showering

temperature, follow the steps 1 - 6 on page 8.

Hansgrohe · Auestraße 5 - 9 · D-77761 Schiltach · Telefon +49 (0) 78 36/51-1282 · Telefax +49 (0) 7836/511440

E-Mail: info@hansgrohe.com · Internet: www.hansgrohe.com

07/2018

9.05016.04

20

ww

w.hansgr

ohe.com/

cleaning-recommendation

ww

w.hansgr

ohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

ww

w.hansgr

ohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

ww

w.hansgr

ohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

www.hansgrohe.com/

cleaning-recommendation

DE Reinigungsempfehlung / Garantie / Kontakt

EN Cleaning recommendation / Warranty / Contact

Loading...

Loading...