Page 1

Installation Instructions / Warranty

Showerpanel I

Showerpanel II

Page 2

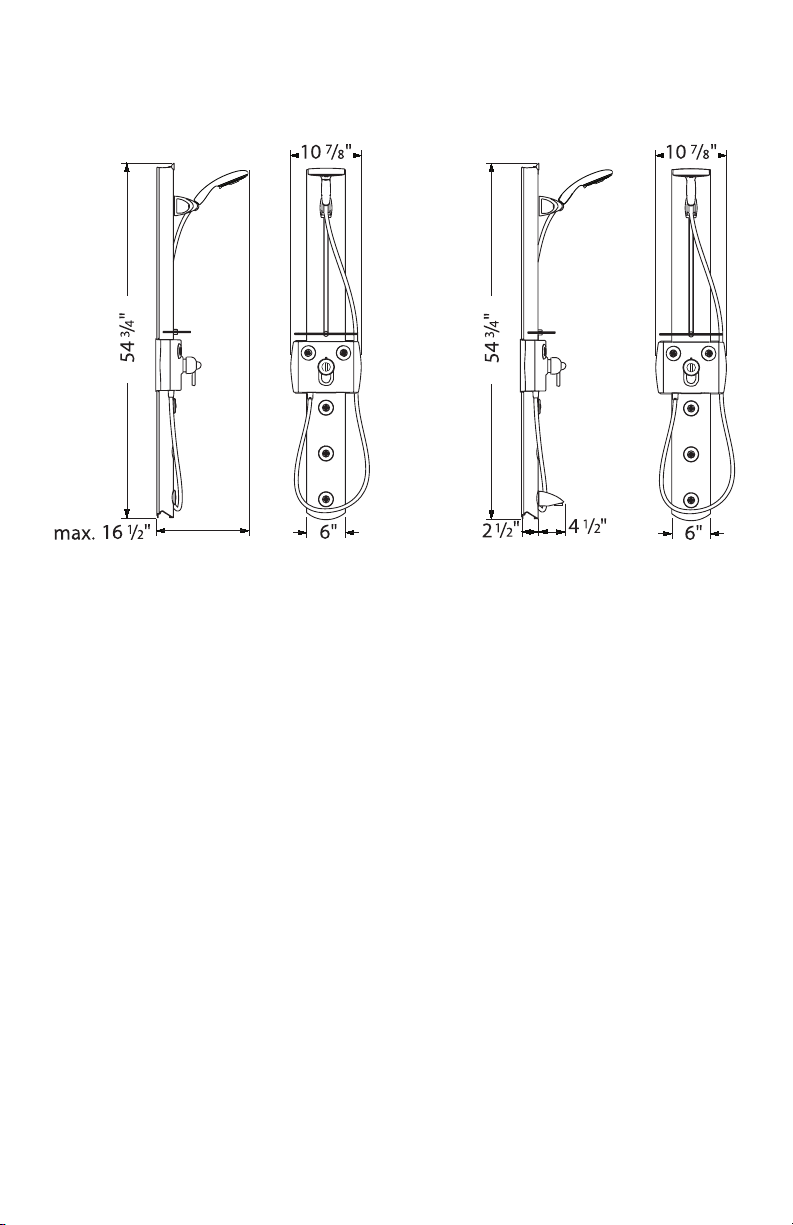

Showerpanel I

Showerpanel II

Showerpanel I Showerpanel II

handshower & bodyjets handshower, bodyjets, tub spout

Metro E 06572000 06573000

Solaris E 06549XX0 06550XX0

Stratos E 06564XX0 06565XX0

Technical information Données techniques

Recommended water pressure Pression d’eau recommandée 45 - 72.5 psi

Max. water pressure Pression d’eau maximum 147 psi

Recommended hot water temp. Température recommandée d'eau

chaude

Max. hot water temp Température maximum d'eau

chaude

Flow rate of handshower Débit de douchette 2.5 gpm

Flow rate of each bodyspray Débit de chaque jet mural <1.0 gpm

Flow rate of thermostatic mixing

valve

*Please know and follow all applicable local plumbing codes when setting the temperature on the water heater.

* Vous devez connaître et respecter tous les codes de plomberie locaux applicables pour le réglage de la température

du chauffe-eau.

2

Débit maximum du mitigeur thermostatique

120� - 140� F*

158�F*

8 gpm @ 45 psi

10 gpm @ 65 psi

Page 3

Français – voir p. 17

Installation considerations

For best results, Hansgrohe recom-

•

mends that this unit be installed by a

licensed, professional plumber.

Please read over these instructions

•

thoroughly before beginning installation. Make sure that you have all tools

and supplies needed to complete the

installation.

This product is listed by IAPMO and is

•

approved for use in Massachusetts.

Protection against backflow provided

•

by check valve in the handshower

outlet.

The high temperature limit stop on the

•

thermostatic mixing valve may be reset

to comply with local plumbing codes*

-- see page 13.

*In Massachusetts, the maximum output temperature

cannot exceed 112°F.

Tools required

The following tools are suggested for installing the showerpanel:

Tape measure

•

Level

•

Grease pencil or other marking device

•

Drill with 6 mm bit suitable for wall

•

surface

10 mm nut driver

•

10, 11 and 19 mm wrenches

•

3 mm Allen wrench

•

Philips screwdriver

•

Waterproof sealant

•

Mallet (to install anchors)

•

Teflon tape

•

English

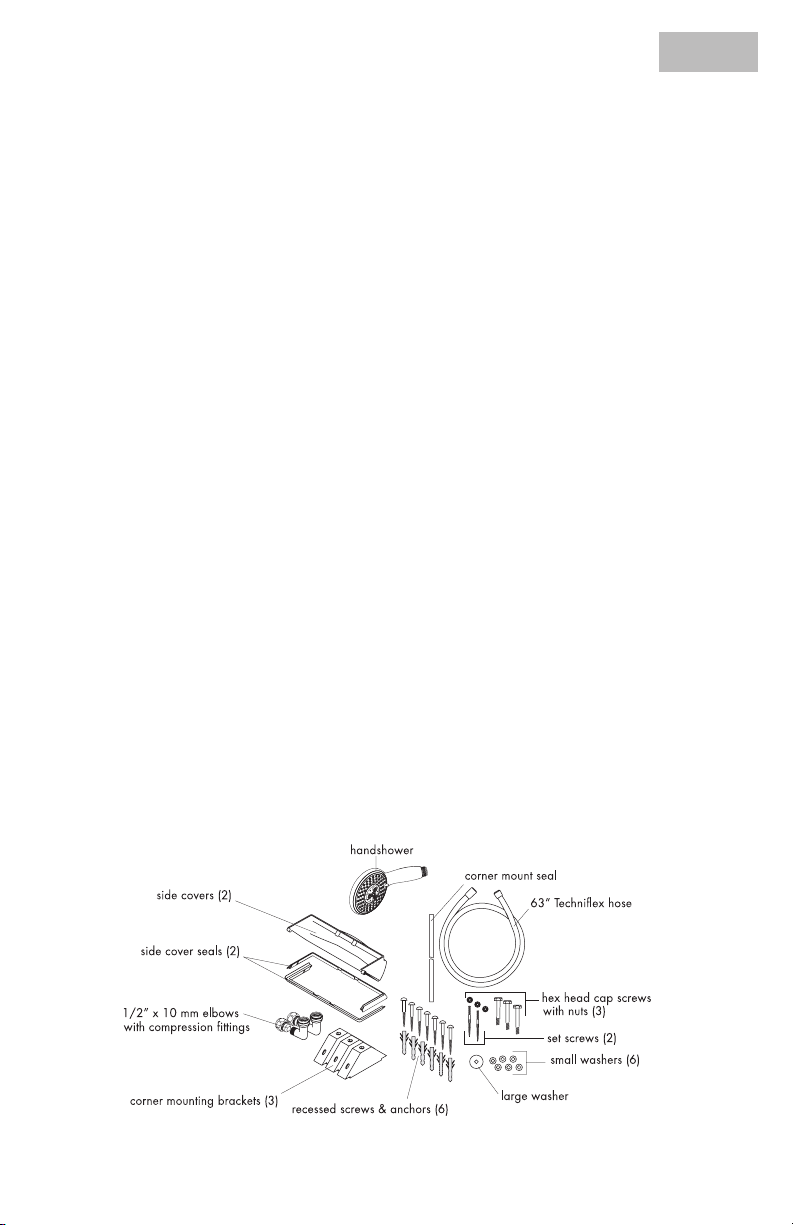

Check package contents

Before beginning installation, check the contents of this package. Make sure that all parts

are present and in good condition. If any part is missing or damaged, please contact

Hansgrohe Customer Service before proceeding.

3

Page 4

English

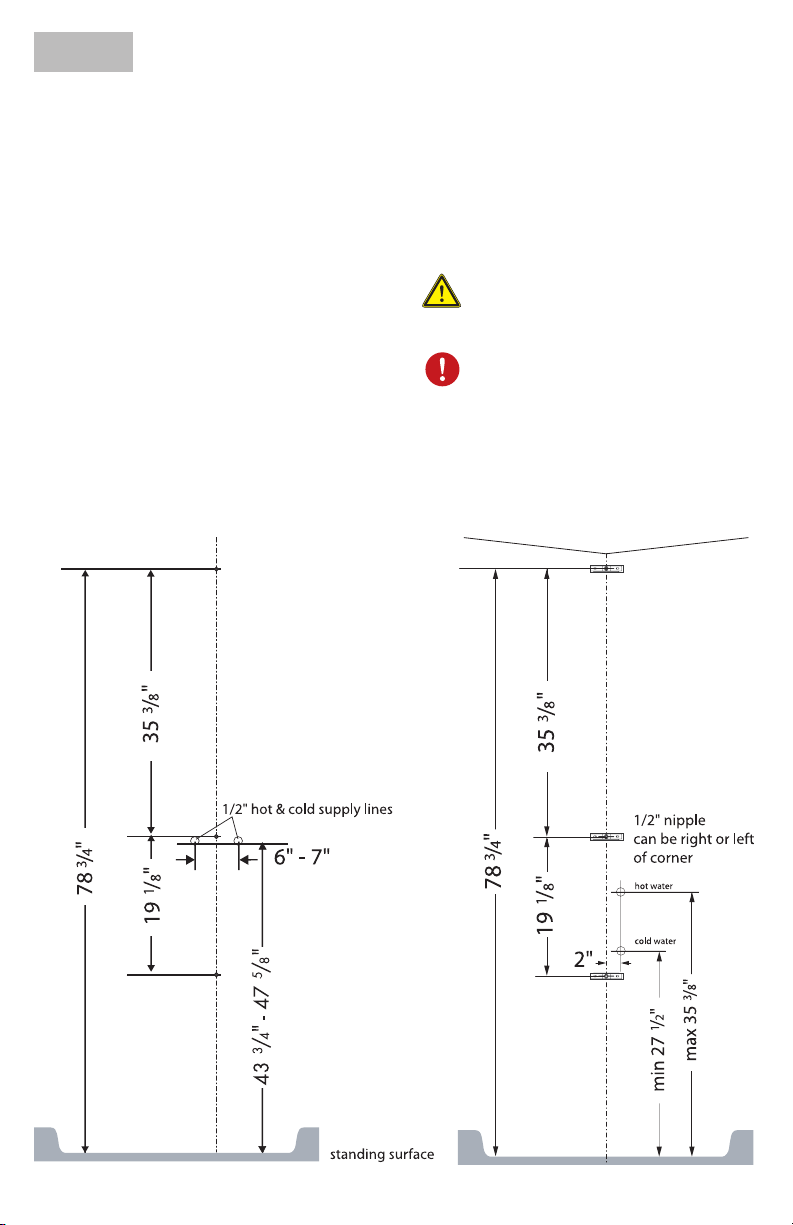

Rough-in

This unit can be installed on a flat wall or

in a 90° corner. Instructions for installation on a flat wall begin on page 5. Go

to page 8 if the panel is to be installed in

a corner.

Ensure that you have a minimum

83" ceiling height from the standing surface.

Stub out 1/2" NPT male nipples for the

hot and cold water supplies at the locations shown on the appropriate rough-in

diagram. The nipples should extend 5/8"

outside the surface of the finished wall.

Install the wall surface and make the wall

watertight before installing the panel. The

panel hangs on the finished wall.

Seal the wall around the

nipples with waterproof

sealant.

Failure to seal the wall

can lead to possible water

damage.

Installation on a flat wall Installation in 90° corner

4

Page 5

Installation � flat wall

Wrap the threads on the nipples with Teflon tape.

Install the elbows so that the outlets face upwards.

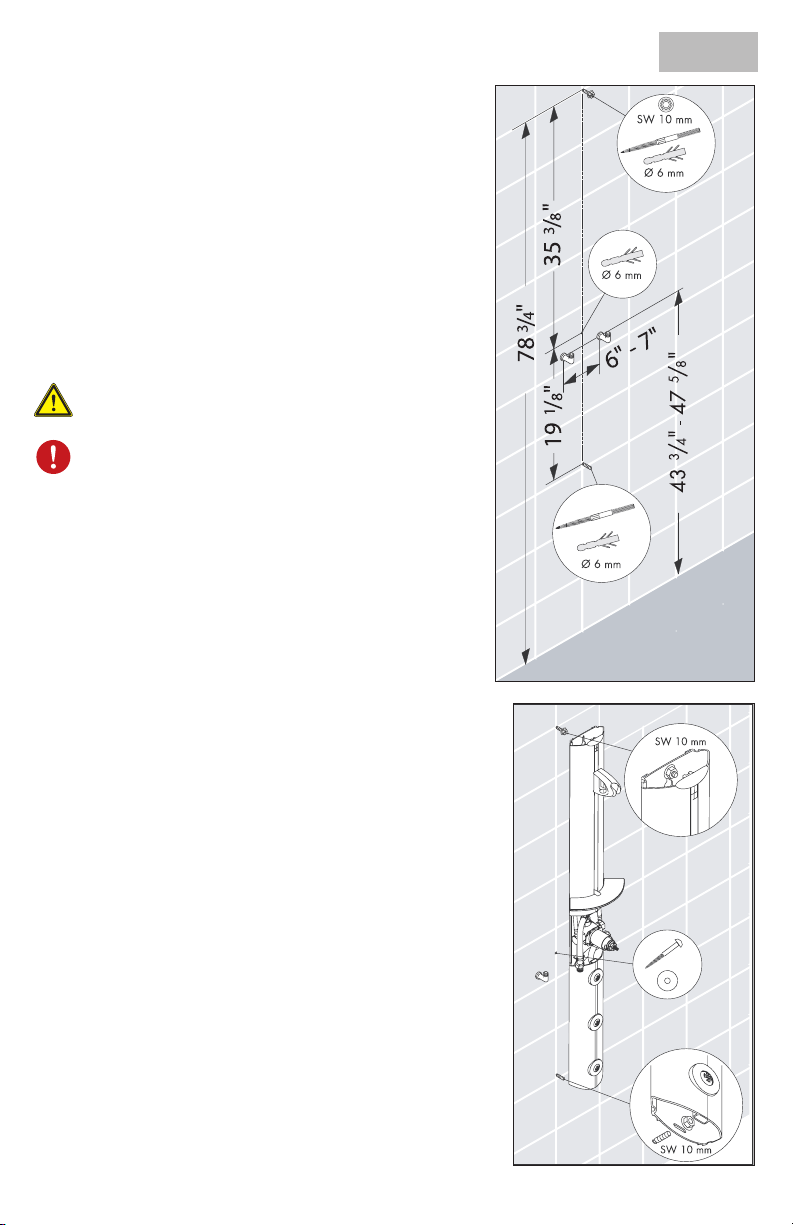

Measure up the wall 78 ¾", making sure that the line is

plumb. Mark the position for the top screw hole.

From the position of the top screw hole, measure down

35 3/8”. Mark the position for the center screw hole.

From the center screw hole, measure down 19 1/8".

Mark the position for the bottom screw hole.

Use a 6 mm bit to drill the three screw holes.

Seal the wall around the anchors

with waterproof sealant.

Failure to seal the wall can lead to

possible water damage.

Install the set screws in the top and bottom holes.

Use a 10 mm nut driver to attach a nut to the top set

screw.

English

Slide the panel over the top and bottom set screws.

Tighten the nut on the top set screw.

Install and tighten the nut on the bottom set screw.

Install one recessed head screw and the large washer

on the center hole. Tighten the screw.

5

Page 6

English

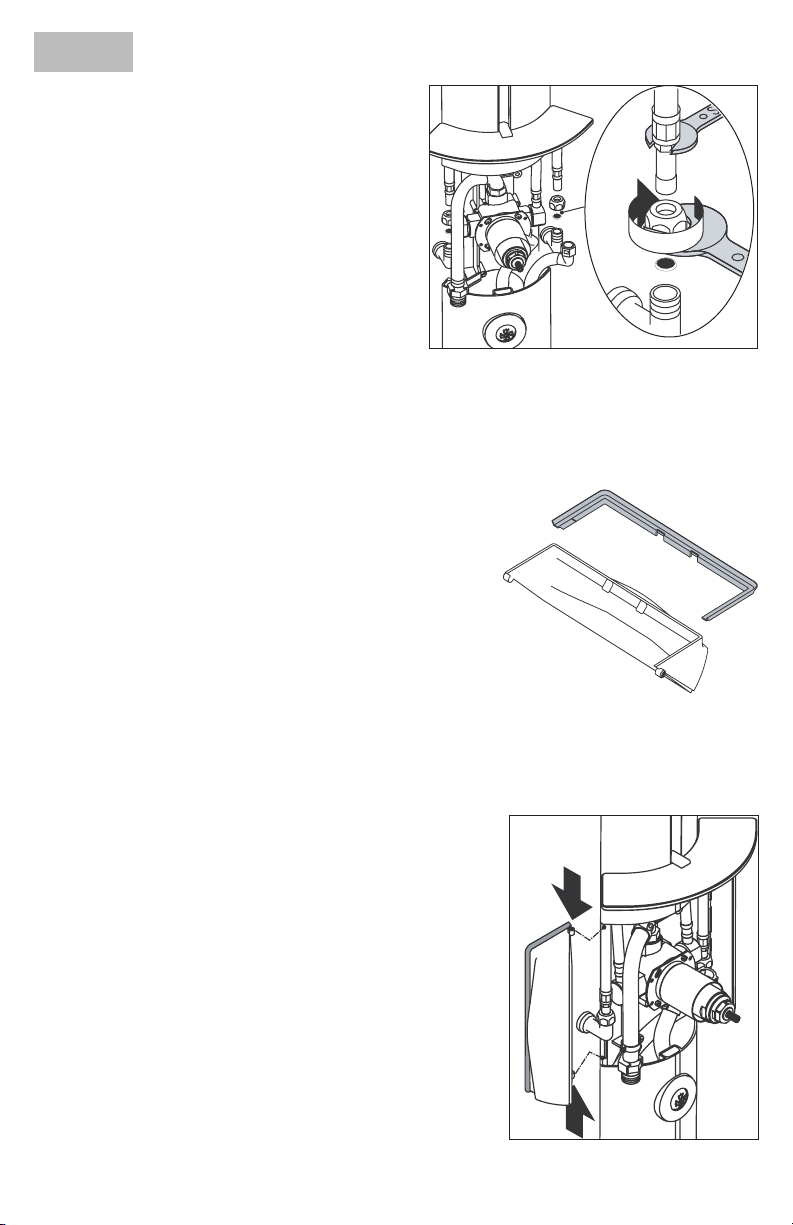

Use the compression nuts and ferrules to connect

the supply hoses on the panel to the supply

elbows.

Use two wrenches, as shown, to prevent the sup-

ply hoses from twisting.

Attach the seals to the side covers.

Install the side covers.

The pins on the covers must go into the grooves on

the sides of the panel.

6

Page 7

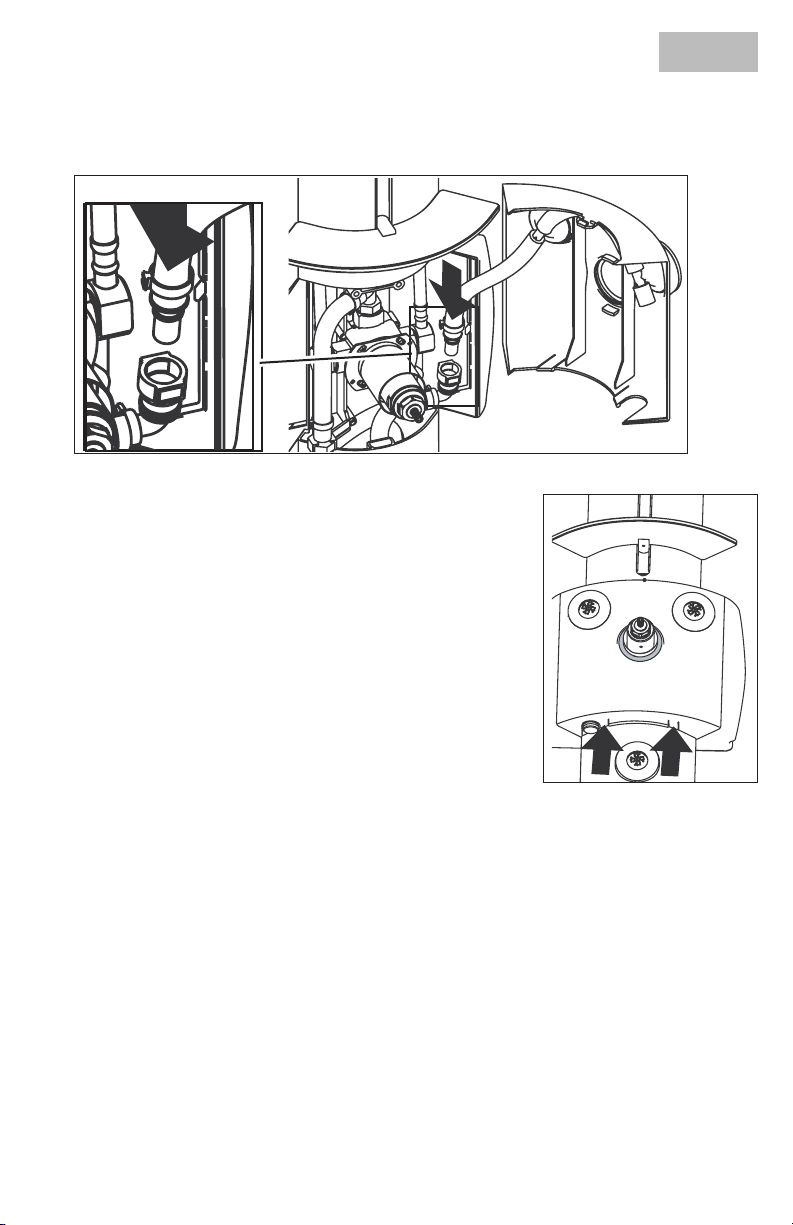

Push the bodyjet supply hose on the valve cover into the fitting on the panel.

Install the valve cover on the panel.

The pins on the cover must connect to the slots on the panel.

Turn to page 11 to continue the installation.

English

7

Page 8

English

Installation in 90° corner

Wrap the threads on the nipples with Teflon tape.

Install the elbows so that the outlets face upwards.

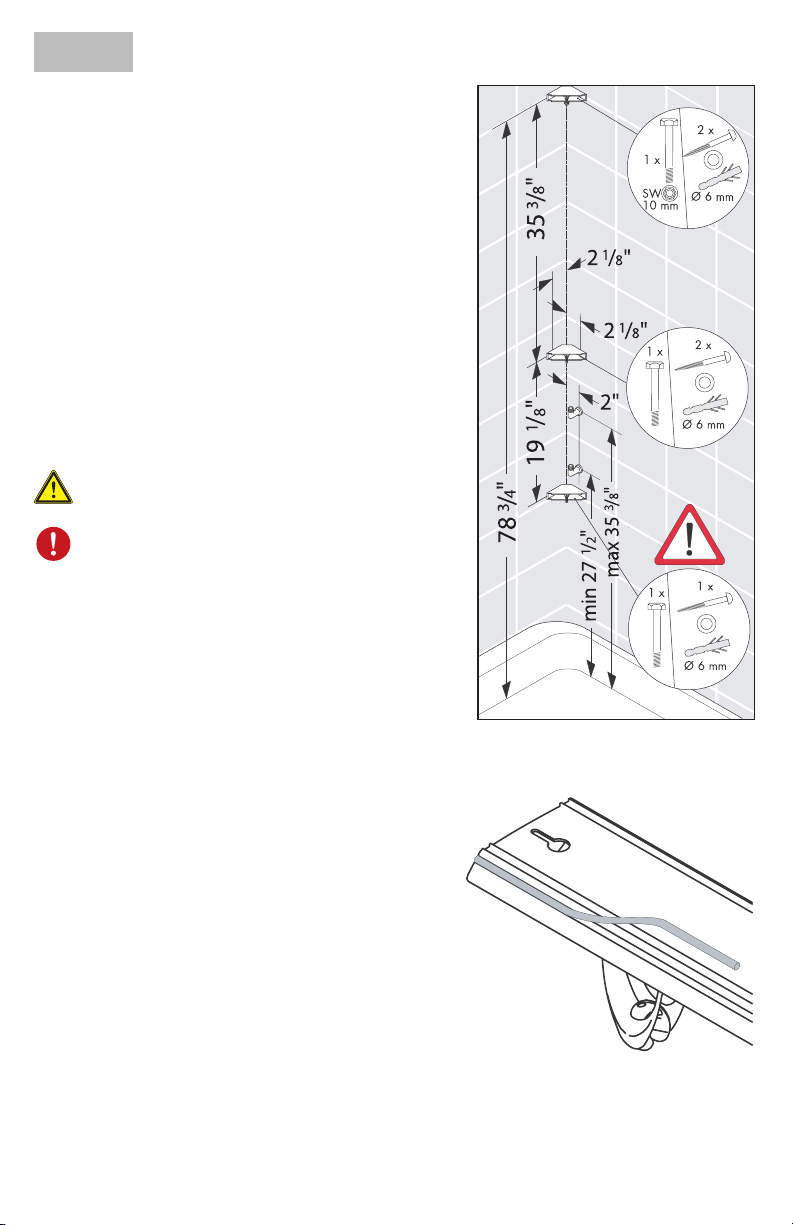

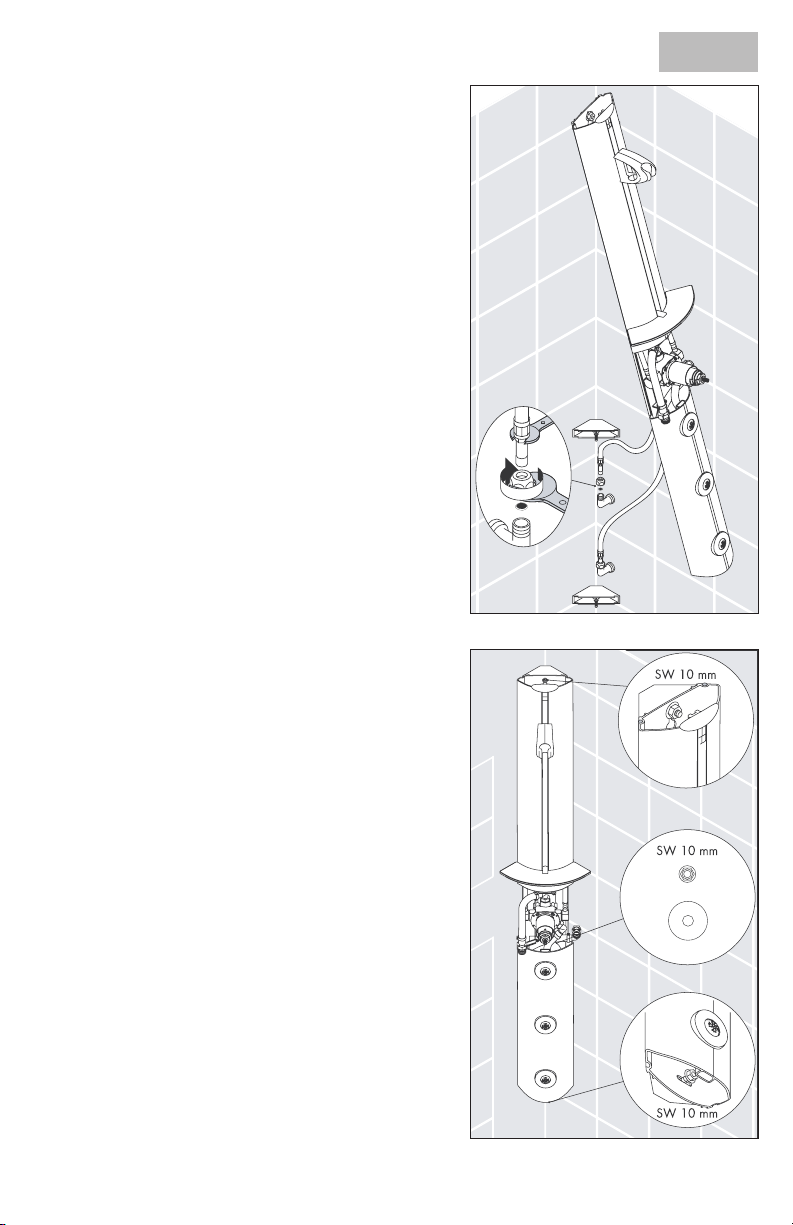

In the corner, measure up the wall 78 ¾", making

sure that the line is plumb. Mark the position for the

top mounting bracket.

From the position of the top screw hole, measure

down 35 3/8". Mark the position for the center

mounting bracket.

From the center screw hole, measure down 19 1/8".

Mark the position for the bottom mounting bracket.

Use the mounting brackets as templates to mark the

positions of the screw holes. Drill the holes with a 6

mm bit.

Seal the wall around the anchors

with waterproof sealant.

Failure to seal the wall can lead to

possible water damage.

Install the mounting brackets to the walls using five of

the recessed head screws.

Install the corner sealing gasket to the grooves on

the panel.

8

Page 9

While a helper holds the panel, attach the supply

hoses to the elbows with the compression fittings.

Use two wrenches, as shown in the diagram, to

prevent the supply hoses from twisting.

English

Tighten the hex head cap screw on the top

mounting bracket.

Install and tighten the hex head cap screw on the

bottom mounting bracket through the hole in the

panel and tighten.

Install the hex head cap screw and large washer

on the center mounting bracket through the hole

in the panel and tighten.

9

Page 10

English

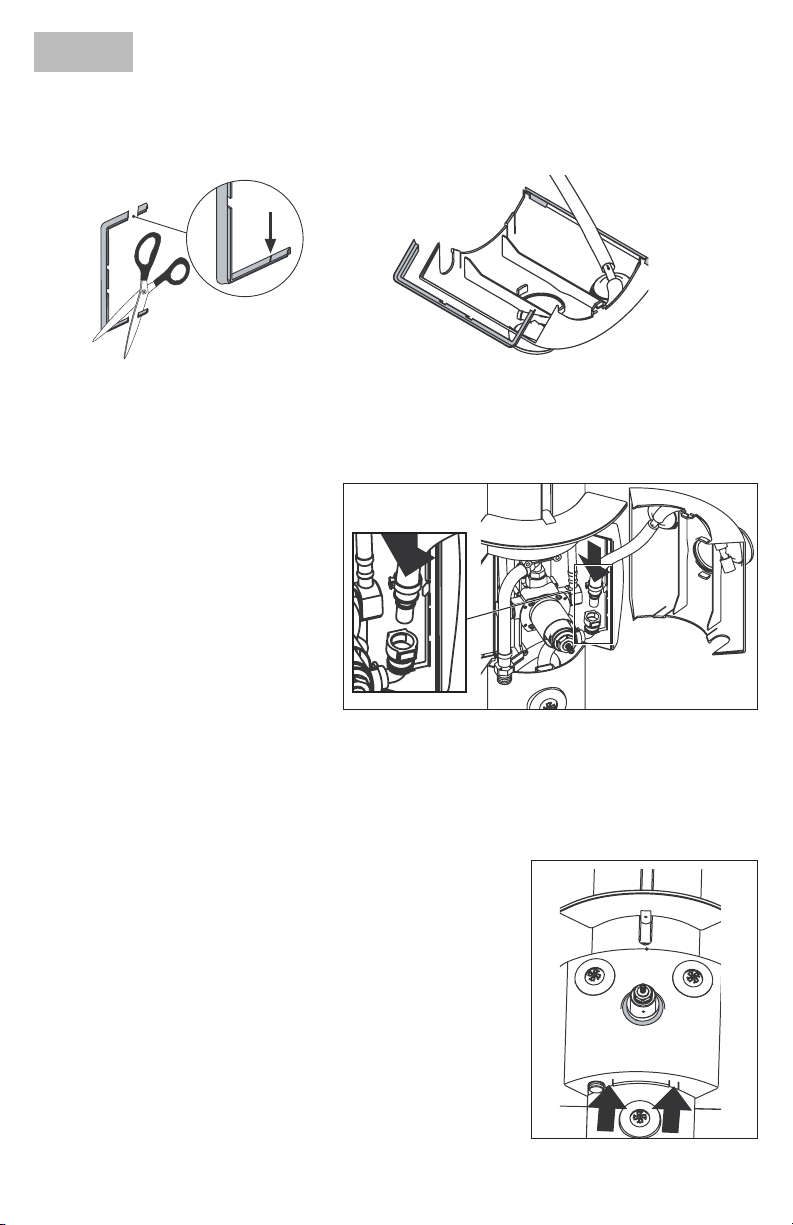

Clip the side cover seals as shown in the diagram. Attach the side cover seals to the valve

cover.

Push the bodyjet supply hose on the

valve cover into the fitting on the

panel.

Install the valve cover on the panel. The pins on the cover

must connect to the slots on the panel.

Turn to page 11 to continue the installation.

10

Page 11

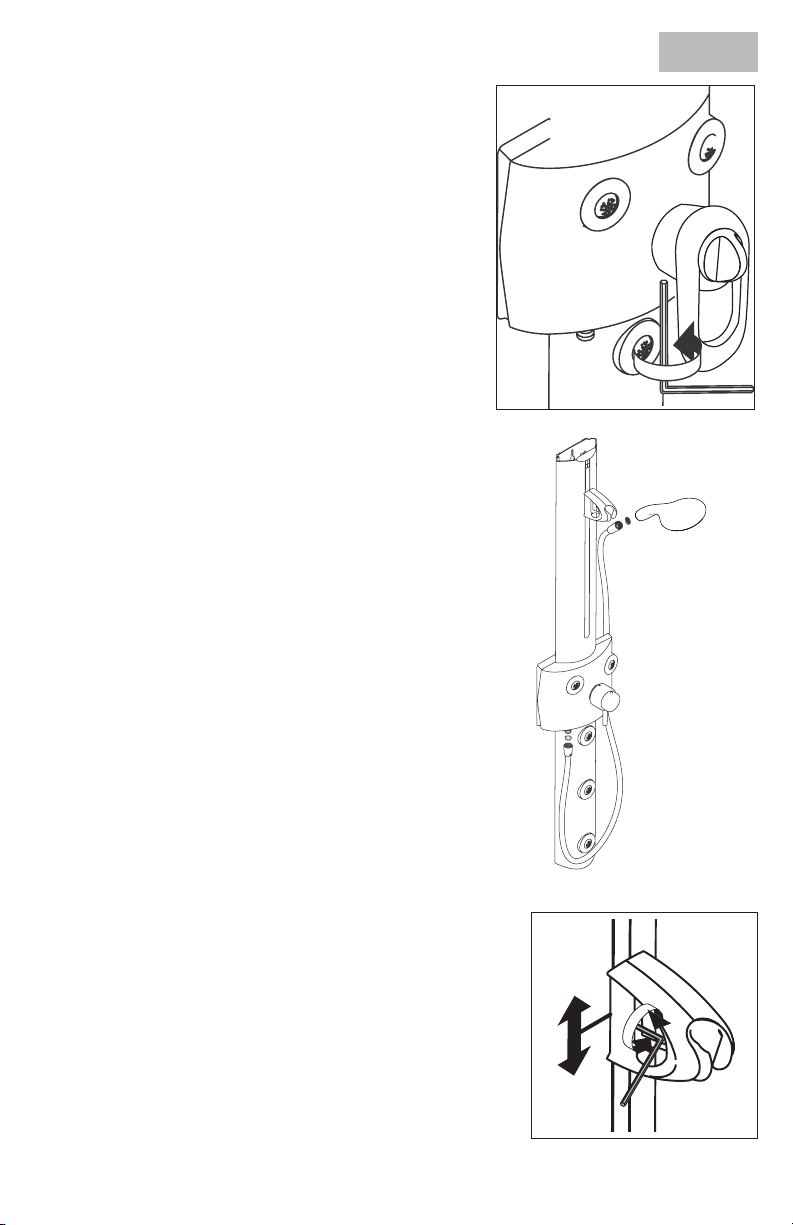

Install the handle

Push the handle over the valve stem. Tighten the handle

screw using a 3 mm Allen wrench.

The handle screw must engage the slot milled into the

cartridge.

Install the handshower

Place a black rubber washer one end of the hose. Connect

this end to the handshower outlet on the panel.

Place the screen washer in the other end of the hose.

Connect it to the handshower.

Place the handshower in the handshower holder.

English

Adjust the slider

Use a 2.5 mm Allen wrench to adjust the tension on the

slider.

Turn the screw clockwise to make the slider easier to move.

Turn the screw counter-clockwise to make the slider harder

to move.

11

Page 12

English

Justify the handle

Turn the water on to the

handshower.

Turn the temperature control

knob so that the indicator is

next to the 100º marking.

Turn the temperature control

knob until the output water is

100ºF. Turn the water off.

Install the handle. Tighten

the screw.

Remove the handle.

12

Page 13

Set the high temperature limit stop (optional)

English

Loosen the handle screw using a 3mm Allen wrench.

Grasp the cartridge stop unit

and turn it counter-clockwise

to turn on the handshower.

Remove the handle. Remove the clip and the stop

ring from the stem.

Turn the stem until the output water is the desired maximum

high temperature (usually about 110°F*).

*In Massachusetts, the maximum output temperature cannot exceed 112°F.

Turn the stop unit clockwise

to turn the water off.

Install the stop ring so that the

tooth is against the stop on the

top of the cartridge. Replace

the clip.

Install the handle. Tighten

the screw.

13

Page 14

English

User instructions - Showerpanel I

Turn the temperature control knob clockwise to make the water cooler, counter-clockwise to make it warmer. The

knob will stop at the 100°F position. If

water hotter than 100°F is desired, push

in on the knob, and continue turning it

counter-clockwise.

User instructions - Showerpanel II

From the “off” position, turn the diverter handle counter-clockwise for the

handshower.

Turn the diverter handle clockwise for

the bodysprays. Turn the handle further

clockwise for the handshower and the

bodysprays simultaneously.

off position

temperature control knob

diverter handle

Turn the temperature control knob clockwise to make the water cooler, counter-clockwise to make it warmer. The

knob will stop at the 100°F position. If

water hotter than 100°F is desired, push

in on the knob, and continue turning it

counter-clockwise.

Using the handshower

The handshower has 3 spray modes -Rain AIR, Whirl AIR, and Balance AIR.

Push the function lever until the desired

spray mode is achieved.

14

From the “off” position, turn the diverter

handle counter-clockwise for the tub spout.

Turn the diverter handle clockwise for the

handshower, then for the handshower and

bodysprays simultaneously, and finally for

the bodysprays.

function lever

Page 15

Scale removal

The Raindance Air 3-jet handshower incorporates the Quick

Clean™ cleaning system. If scale deposits are noticed in the

spray channels, turn the water on lightly and rub the spray

channels with a finger or a sponge.

If scale deposits are noticed on the spray face, pour about

3/4” of a commercial scale remover, such as Lime-Away™ or

CLR™ ,into a shallow dish. Dilute the remover according to the

label instructions.

Soak only the spray face in the solution for the amount of time

specified on the label.

English

Rinse the handshower with clear water.

Install the handshower.

Flush the handshower with clear water for at least one

minute.

15

Page 16

English

Check valve maintenance

The check valve should be removed and

inspected yearly.

If the check valve is damaged, replace it.

check valve

Clean the cartridge filters

If the water pressure decreases as the water is made

warmer, clean the cartridge filters.

Turn the water off at the main.

Remove the handle.

Hold the cartridge stop unit steady with a 36 mm

wrench.

Hold the stop unit steady while

removing or installing the thermostat cartridge.

Failure to do so may result in

damage to the stop unit.

Use a 24 mm wrench to unscrew the thermostatic

cartridge from the stop unit.

Clean the filters under running water. Use a soft tooth-

brush to remove stubborn deposits.

Lightly lubricate the cartridge o-rings with white

plumbers grease.

Install the thermostat cartridge.

Justify and install the handle.

16

filters

Page 17

Français

À prendre en considération pour l’installation

Pour de meilleurs résultats, Hansgrohe

•

recommande que ce produit soit

installé par un plombier professionnel

licencié.

Veuillez lire attentivement ces instruc-

•

tions avant de procéder à l’installation.

Assurez-vous de disposer de tous les

outils et du matériel nécessaires pour

l’installation.

Homologué par IAPMO.

•

Le clapet anti-retour de la sortie de

•

douchette protège contre les retours

d'eau.

La butée limite d'eau chaude de la

•

cartouche du mitigeur thermostatique

peur être reprogrammée pour satisfaire

aux codes de plomberie locaux -- voir

page 27.

Outils requis

Nous recommandons d’utiliser les outils suivants pour installer la colonne de douche :

Ruban à mesurer

•

Niveau

•

Crayon gras ou autre instrument de

•

marquage

Perceuse avec une mèche de 6 mm

•

convenant à la surface du mur

Tournevis à douille de 10 mm

•

Clés de 10, 11 et 19 mm

•

Clé hexagonale de 3 mm

•

Tournevis Phillips

•

Agent d’étanchéité

•

Maillet (pour installer les chevilles)

•

Ruban de plomberie Téflon

•

Vérification du contenu de l’emballage

Épargnez du temps et évitez les problèmes. Vérifiez le contenu de cet emballage avant de

commencer l’installation. Assurez-vous qu’aucune pièce ne manque et qu’elles sont toutes

en bon état. S’il manque une pièce ou si une pièce est endommagée, veuillez contacter le

Service à la clientèle Hansgrohe avant de commencer l’installation.

17

Page 18

Français

Pièce intérieure

Cet article peut être installé sur un mur à

plat ou dans un coin à angle de 90°. Les

instructions d’installation sur un mur plat

commencent à la page 19. Passez à la

page 22 si vous installez la colonne de

douche dans un coin.

Assurez-vous d’avoir une hauteur

de 83 po minimum (2,11 m), de

la surface du plancher jusqu’au

plafond.

Pour les conduites d’alimentation en eau

chaude et froide, faites sortir les mamelons

mâles NPT de ½ po aux emplacements

indiqués sur le schéma de pièce intéri-

Installation – mur plat Installation dans un coin à

eure approprié. Les mamelons devraient

dépasser de 5/8 po (1,6 cm) de la surface

du mur fini.

Installez la surface de mur et assurez-vous

de son étanchéité avant d’installer la col-

onne. La colonne se suspend au mur fini.

Scellez le mur autour du

mamelon à l’aide d’un agent

d’étanchéité.

Si le mur n’est pas scellé, l’eau

pourrait éventuellement causer

des dommages.

angle de 90°

18

Page 19

Installation – mur plat

Enveloppez les filets des mamelons de conduite avec

du ruban de plomberie Téflon.

Installez les coudes (compris) de façon à ce que les

orifices de sortie soient dirigés vers le haut.

Mesurez le mur de bas en haut sur une longueur de

78 ¾ po en vous assurant que la ligne est droite, de

niveau. Marquez la position du trou de la vis du haut.

À partir du trou de la vis du haut, mesurez une lon-

gueur de 35 3/8 po vers le bas. Marquez la position

du trou pour la vis du centre.

À partir du trou de la vis du centre, mesurez 19 1/8

po vers le bas. Marquez la position du trou pour la

vis du bas.

Utilisez une mèche de 6 mm convenant à la surface du

mur. Percez les trois trous de vis.

Installez les chevilles.

Scellez le mur autour des

chevilles à l’aide d’un agent

d’étanchéité.

Si le mur n’est pas scellé, l’eau

pourrait éventuellement causer

des dommages.

Français

Installez les vis de pression dans les trous du haut et

du bas.

Utilisez un tournevis à douille de 10 mm pour fixer un

écrou à la vis de pression du haut.

Faites glisser la colonne sur les vis de pression du haut

et du bas.

Serrez l’écrou sur la vis de pression du haut.

Installez et serrez l’écrou sur la vis de pression du

bas.

Installez une vis à tête fraisée et la grande rondelle

dans le trou du centre. Serrez la vis.

19

Page 20

Français

Utilisez les écrous à compression et les

bagues d’extrémité pour relier les tuyaux

d’alimentation de la colonne aux coudes

d’alimentation.

Utilisez deux clés, tel qu’illustré, pour éviter

que les tuyaux d’alimentation ne s’entortillent.

Fixez les joints aux plaques latérales.

Installez les plaques latérales. Les tiges des plaques

doivent s’insérer dans les rainures sur les côtés de la

colonne.

20

Page 21

Français

Poussez le conduit d’alimentation du jet mural sur le couvercle de la valve dans le raccord

de la colonne.

Installez le couvercle de la valve sur la colonne.

Les tiges du couvercle doivent se loger dans les fentes de la

colonne.

Passez à la page 25 pour continuer l’installation.

21

Page 22

Français

Installation dans un coin à angle de

90°

Enveloppez les filets des mamelons avec du ruban

de plomberie Téflon. Installez les coudes (compris) de façon à ce que les orifices de sortie soient

dirigés vers le haut. Dans le coin, mesurez le mur

de bas en haut sur une longueur de 78 ¾ po en

vous assurant que la ligne est droite, de niveau.

Marquez la position du support de montage du

haut.

À partir du trou de la vis du haut, mesurez une

longueur de 35 3/8 po vers le bas. Marquez la

position du support de montage du centre.

À partir du trou de la vis du centre, mesurez 19

1/8 po vers le bas. Marquez la position du sup-

port de montage du bas.

Servez-vous des supports de montage comme

gabarit pour marquer la positions des trous de vis.

Percez les trous au moyen d’une mèche de 6 mm

convenant à la surface du mur.

Installez les chevilles.

Scellez le mur autour des

chevilles à l’aide d’un agent

d’étanchéité.

Si le mur n’est pas scellé, l’eau

pourrait éventuellement causer

des dommages.

Installez les supports de montage aux murs à l’aide

des cinq vis à tête fraisée.

Installez le joint d’étanchéité du coin sur les rainures

de la colonne.

22

Page 23

Demandez à quelqu’un de tenir la colonne, puis

fixez les tuyaux d’alimentation aux coudes à

l’aide des raccords à compression.

Utilisez deux clés, tel qu’illustré dans le schéma,

pour éviter que les tuyaux d’alimentation ne

s’entortillent.

Français

Serrez la vis à tête hexagonale sur le support de

montage du haut.

Installez la vis à tête hexagonale dans le support

de montage du bas au travers du trou de la col-

onne et serrez-la.

Installez la vis à tête hexagonale et la grande

rondelle dans le support de montage du centre au

travers du trou de la colonne et serrez-la.

23

Page 24

Français

Taillez les joints d’étanchéité de plaque latérale tel qu’illustré dans le schéma. Fixez les

joints de plaque latérale au couvercle de valve.

Poussez la conduite d’alimentation

du jet mural sur le couvercle de

la valve dans le raccord de la

colonne.

Installez le couvercle de la valve sur la colonne. Les

tiges du couvercle doivent se loger dans les fentes de la

colonne.

Passez à la page 25 pour continuer l’installation.

24

Page 25

Installation de la poignée

Poussez la poignée sur la tige de la valve. Serrez la

vis de pression au bas de la poignée à l’aide d’une

clé hexagonale de 3 mm. La vis de compression doit

s’engager dans la fente de l’élément thermostatique.

Installation de la douchette à main

Placez une rondelle en caoutchouc noir dans le raccord

de l’extrémité courte du tuyau. Vissez le raccord de

l’extrémité courte du tuyau à la sortie de la douchette sur

la colonne.

Placez le tamis dans le raccord de l’extrémité longue du

tuyau. Serrez le raccord de l’extrémité longue du tuyau

sur la douchette.

Placez la douchette dans son support.

Français

Ajustement du curseur

Utilisez une clé hexagonale de 2,5 mm pour ajuster la

tension du curseur.

Tournez la vis dans le sens horaire pour que le curseur se

déplace facilement.

Tournez la vis dans le sens antihoraire pour que le curseur

se déplace moins facilement.

25

Page 26

Français

Réglage de la poignée

Ouvrez la valve. Placez

le thermomètre dans le jet

d’eau.

D’une main, tenez le levier

de la poignée. Tourner le

bouton de contrôle de la température jusqu’à ce qu’il soit

en position verticale et qu’il

atteigne l’arrêt de sûreté.

Tournez le bouton de

contrôle de la température

jusqu’à ce que l’eau qui

s’écoule atteigne 100° F.

Installez la poignée. Serrez

la vis.

Fermez l’eau.

À l’aide d’une clé hexago-

nale de 3mm, desserrez la

vis de la poignée. Retirez la

poignée de la valve.

26

Page 27

Réglage de la butée limite d’eau chaude (en option)

Français

À l’aide d’une clé hexago-

nale de 3mm, desserrez la

vis de la poignée.

Tournez le dispositif d’arrêt

pour utiliser la douchette

Retirez la poignée de la

valve.

Retirez l’étrier et la bague

de retenue de la tige de la

cartouche thermostatique.

Tournez la tige du mitigeur thermostatique jusqu’à ce que la

température de l’eau chaude atteigne le degré voulu – habi-

tuellement 110 °F* .

*Dans le Massachusetts, la température ne doit pas excéder 112°F.

Tournez le dispositif d'arrêt

au de la position «off».

Réinstallez la bague de

retenue de façon à ce qu’elle

s’appuie sur la butée d’arrêt.

Réinstallez l’étrier.

Réglez et réinstallez la

poignée.

27

Page 28

Français

Instructions à l’intention de l’utilisateur – Showerpanel I

Tournez le bouton de contrôle de la

température dans le sens horaire pour

que l’eau soit plus froide, et dans le sens

antihoraire pour qu’elle soit plus chaude.

Le bouton de contrôle s’arrête à la position

de 100°F). Si vous désirez que la température de l’eau excède 100° F, poussez

sur le bouton de contrôle et continuez à le

tourner dans le sens antihoraire.

Depuis la position d’arrêt (« off »), tournez

la poignée de l’inverseur dans le sens

antihoraire pour utiliser la douchette.

Pour utiliser les jets muraux, tournez la poignée de l’inverseur dans le sens horaire.

Tournez la poignée plus loin encore dans

le sens horaire pour utiliser à la fois la

douchette et les jets muraux.

«off»

bouton de contrôle

poignée de

l'inverseur

Instructions à l’intention de l’utilisateur – Showerpanel II

Tournez le bouton de contrôle de la

température dans le sens horaire pour

que l’eau soit plus froide, et dans le sens

antihoraire pour qu’elle soit plus chaude.

Le bouton de contrôle s’arrête à la position

de 100°F. Si vous désirez que la température de l’eau excède 100°F, poussez

sur le bouton de contrôle et continuez à le

tourner dans le sens antihoraire.

Depuis la position d’arrêt (« off »), tournez

la poignée de l’inverseur dans le sens antihoraire pour utiliser le bec de la baignoire.

Tournez la poignée de l’inverseur dans le

sens horaire pour utiliser la douchette, puis

un peu plus loin pour la douchette et les

jets muraux simultanément, puis plus loin

pour les jets muraux uniquement.

Utilisation de la douchette

La douchette offre 3 modes de jet – « Rain AIR

», jet de pluie, « Whirl AIR », jet massant et «

Balance AIR », combinaison des deux jets.

Poussez le levier de fonctions jusqu’à ce que

vous obteniez le mode de jet voulu.

28

levier de fonctions

Page 29

Nettoyage

La douche à main Raindance Air 3-jet comprend le sys-

tème nettoyant Quick Clean™ . Si vous remarquez que les

canaux de jet sont entartrés, ouvrez l’eau à faible débit et

frottez les canaux à l’aide d’une éponge ou avec un doigt

pour en déloger les dépôts.

En cas d’entartrage de la face des jets, versez environ

2 cm (¾ po) d’un détartrant commercial (comme Lime-

Away™ ou CLR™) dans un contenant peu profond.

Diluez le détartrant tel qu’indiqué sur les instructions de

l’étiquette.

Faites tremper seulement la face des jets dans cette solutions pour la période de temps spécifiée sur l’étiquette.

Français

Rincez la douchette à l’eau claire.

Réinstallez la douchette. Ouvrez l’eau et faites fonctionner

la douchette durant au moins une minute.

29

Page 30

Français

Entretien du clapet anti-retour

Le clapet anti-retour doit être retiré et examiné une

fois par année.

Le clapet anti-retour doit être remplacé s’il est

endommagé.

Entretien: nettoyage des tamis de

filtre

ATTENTION : Avant de commencer, fermez

l’eau à la vanne principale.

Retirez la poignée.

À l’aide d’une clé à molette, saisissez le pan de

manoeuvre sur le dispositif d’arrêt.

Tenez fermement le dispositif d’arrêt en place. À

l’aide d’une seconde clé à molette ou d’une clé à

douille longue de 17 mm, dévissez la cartouche

thermostatique et retirez-la.

ATTENTION :

pourrait être endommagé si vous ne

le retenez pas fermement en place lorsque

vous retirez ou remplacez la cartouche

thermostatique.

Le dispositif d’arrêt

Rincez les débris ou dépôts pouvant se trouver dans

les tamis de filtre. Au besoin, brossez délicatement

à l’aide d’une brosse à dent douce. Ne retirez pas

les tamis.

Lubrifiez les joints toriques avec de la graisse blanche de plomberie. Tenez fermement le dispositif

d’arrêt en place. Réinstallez et serrez la cartouche

thermostatique.

Réglez et installez la poignée.

30

Page 31

Replacement parts

15

19

1

11

18

2

7

3

6

5

4

8

12

13

7

14

10

15

19

1

11

18

2

3

17

4

10

5

9

16

20

1 slider 97024000

2 hose 28276XX0

3 shelf 25969000

4 sleeve 88520XX0

5 thermostat cartridge 94282000

6 stop unit -- panel I 25973000

7 side cover 25974880

8 valve cover, panel I 25976880

9 valve cover, panel II 25985880

10 escutcheon 25981XX0

11 handshower

Solaris E 28518XX1

Stratos E 28507XX1

Metro E 28502XX1

12 handle - Solaris E 88530XX0

13 handle - Stratos E 88547XX0

14 handle - Metro E 88548XX0

15 check valve 94074000

16 tub spout (panel II only) 88584XX0

17 cartridge (panel II only) 88500000

18 screen washer 94246000

19 hose washer 98058000

20 hardware kit 25977001

XX = finish

00 = chrome

82 = brushed nickel

31

Page 32

Cleaning Recommendation for Hansgrohe Products

Modern lavatory faucets, kitchen faucets, and showers consist of very different materials to comply with the needs of

the market with regard to design and functionality. To avoid damage and returns, it is necessary to consider certain

criteria when cleaning.

Cleaning Materials for Faucets and Showers

Acids are a necessary ingredient of cleaning materials for removing lime, however please pay attention to the following points when cleaning faucets and showers:

Only use cleaning materials which are explicitly intended for this type of application.

•

Never use cleaning materials which contain hydrochloric, formic, phosphoric, or acetic acid, as they cause

•

considerable damage.

Never mix one cleaning material with another.

•

Never use cleaning materials or appliances with an abrasive effect, such as unsuitable cleaning powders, sponge

•

pads, or micro fiber cloths.

Cleaning Instructions for Faucets and Showers

Please follow the cleaning material manufacturer’s instructions. In addition, pay attention to the following points:

Clean the faucets and showers as and when required

•

Use the amount of cleaning product and the amount of time recommended by the manufacturer. Do not leave the

•

cleaner on the fixture longer than necessary.

Regular cleaning can prevent calcification.

•

When using spray cleaners, spray first onto a soft cloth or sponge. Never spray directly onto the faucet as drop-

•

lets can enter openings and gaps and cause damage.

After cleaning, rinse thoroughly with clean water to remove any cleaner residue.

•

Important

Residues of liquid soaps, shampoos, and shower foams can also cause damage, so rinse with clean water after using.

Please note: if the surface is already damaged, the effect of cleaning materials will cause further damage.

Components with damaged surfaces must be replaced or injury could result.

Damage caused by improper treatment is not covered under the warranty.

Recommandations pour le nettoyage des produits Hansgrohe

Les robinetteries modernes de lavabo, de cuisine et de douche utilisent des matériaux très différents pour répondre aux

besoins du marché en termes de conception et de fonctionnalité. Certaines règles de base doivent être respectées lors

du nettoyage de ces produits afin d’éviter de les endommager ou d’avoir à les retourner.

Produits de nettoyage pour robinetteries et douches

Les acides sont une partie intégrante nécessaire de tous les produits de détartrage; il faut cependant prendre les

précautions suivantes lors du nettoyage des robinets et des douches :

N’utilisez que des produits/articles de nettoyage conçus spécifiquement pour les articles de robinetterie et de

•

douche.

N’utilisez jamais de produits/articles de nettoyage contenant de l’acide chlorhydrique, formique, phosphorique

•

ou acétique car ils pourraient causer des dommages considérables.

Ne mélangez jamais deux produits de nettoyage.

•

N’utilisez jamais de produits/articles de nettoyage de nature abrasive tels que poudres de nettoyage, tampons-

•

éponge ou chiffons microfibre non appropriés.

32

Page 33

Instructions de nettoyage pour robinetteries et douches

Veuillez suivre les instructions du fabricant de produits/articles de nettoyage. De plus, tenez compte des conseils

suivants :

Nettoyez vos produits de robinetterie et de douche aussi souvent que nécessaire.

Utilisez la quantité de produit nettoyant et respectez la durée recommandée par le fabricant. Ne laissez pas le

•

produit sur les articles de robinetterie plus longtemps que nécessaire.

Un nettoyage régulier peut prévenir la formation de dépôts calcaires.

•

Si vous utilisez des nettoyants en vaporisateur, vaporisez d’abord sur une éponge ou un chiffon. Ne vaporisez

•

jamais directement sur un robinet : des gouttelettes pourraient s’infiltrer dans les ouvertures et les interstices et

endommager celui-ci.

Après le nettoyage, rincez abondamment avec de l’eau propre pour éliminer tout résidu de produit nettoyant.

•

Important

Les résidus de savon liquide, de shampoing et de mousse pour la douche peuvent également endommager la robinette-

rie; rincez donc avec de l’eau propre après utilisation de ces produits.

Veuillez noter :

Les composants dont la surface est endommagée devraient être remplacés sous peine d’entraîner

des blessures.

Les dommages dus à un mauvais traitement ne sont pas couverts par la garantie.

si la surface est déjà endommagée, les produits de nettoyage l’endommageront encore plus.

Limited Lifetime Consumer Warranty

This product has been manufactured and tested to the highest quality standards by Hansgrohe, Inc. (“Hansgrohe”).

This warranty is limited to Hansgrohe products which are purchased by a consumer in the United States after March 1,

1996, and installed in either the United States or Canada.

WHO IS COVERED BY THE WARRANTY

This warranty extends to the original consumer purchaser only. This warranty is non-transferable.

WHAT IS COVERED BY THE WARRANTY

This warranty covers only your Hansgrohe manufactured product. Hansgrohe warrants this product against defects in

material or workmanship as follows: Hansgrohe will repair at no charge for parts only or, at its option, replace any

product or part of the product that proves defective because of improper workmanship and/or material, under normal

installation, use, service and maintenance. If Hansgrohe is unable to provide a replacement and repair is not practical

or cannot be timely made, Hansgrohe may elect to refund the purchase price in exchange for the return of the product.

LENGTH OF WARRANTY

Replacement or repaired parts of products will be covered for the term of this warranty as stated in the following two

sentences. If you are a consumer who purchased the product for use primarily for personal, family, or household

purposes, this warranty extends for as long as you own the product and the home in which the product is originally

installed. If you purchased the product for use primarily for any other purpose, including, without limitation, a commercial purpose, this warranty extends only (i) for 1 year, with respect to Hansgrohe and Commercial products, and (ii) for

5 years, with respect to AXOR products.

THIS WARRANTY DOES NOT COVER, AND HANSGROHE WILL NOT PAY FOR:

A. Conditions, malfunctions or damage not resulting from defects in material or workmanship.

B. Conditions, malfunctions or damage resulting from (1) normal wear and tear, improper installation, improper

maintenance, misuse, abuse, negligence, accident or alteration, or (2) the use of abrasive or caustic cleaning

agents or “no-rinse” cleaning products, or the use of the product in any manner contrary to the product instruc-

tions. (3) Conditions in the home such as excessive water pressure or corrosion.

33

Page 34

C. Labor or other expenses for the disconnection, deinstallation, or return of the product for warranty service, or for

installation or reinstallation of the product (including but not limited to proper packaging and shipping costs), or

for installation or reinstallation of the product.

D. Accessories, connected materials and products, or related products not manufactured by Hansgrohe.

TO OBTAIN WARRANTY PARTS OR INFORMATION

Contact your Hansgrohe retailer, or contact Technical Service at:

Hansgrohe Inc.

1492 Bluegrass Lakes Parkway

Alpharetta GA 30004

Toll-free (800) 334-0455.

In requesting warranty service, you will need to provide

1. The sales receipt or other evidence of the date and place of purchase.

2. A description of the problem.

3. Delivery of the product or the defective part, postage prepaid and carefully packed and insured, to Hansgrohe

Inc. 1492 Bluegrass Lakes Parkway, Alpharetta, Georgia 30004, Attention: Technical Service, if required by

Hansgrohe.

When warranty service is completed, any repaired or replacement product or part will be returned to you postage

prepaid.

EXCLUSIONS AND LIMITATIONS

REPAIR OR REPLACEMENT (OR, IN LIMITED CIRCUMSTANCES, REFUND OF THE PURCHASE PRICE) AS PROVIDED

UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. HANSGROHE NEITHER ASSUMES

NOR AUTHORIZES ANY PERSON TO CREATE FOR IT ANY OBLIGATION OR LIABILITY IN CONNECTION WITH

THIS PRODUCT.

HANSGROHE SHALL NOT BE LIABLE TO PURCHASER OR ANY PERSON FOR ANY INCIDENTAL, SPECIAL, OR

CONSEQUENTIAL DAMAGES, ARISING OUT OF BREACH OF THIS WARRANTY OR ANY IMPLIED WARRANTY

(INCLUDING MERCHANTABILITY).

Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you. This warranty gives you specific legal rights, and you may have other rights which

vary from State to State. You may be required by law to give us a reasonable opportunity to correct or cure any failure

to comply before you can bring any action in court against us under the Magnuson-Moss Warranty Act.

PRODUCT INSTRUCTIONS AND QUESTIONS

Upon purchase or prior to installation, please carefully inspect your Hansgrohe product for any damage or visible

defect. Prior to installing, always carefully study the enclosed instructions on the proper installation and the care and

maintenance of the product. If you have questions at any time about the use, installation, or performance of your

Hansgrohe product, or this warranty, please call or write to us or call us toll-free at 800 334 0455.

34

Page 35

35

Page 36

Hansgrohe, Inc. • 1490 Bluegrass Lakes Parkway • Alpharetta, GA 30004

Tel. 770-360-9880 • Fax 770-360-9887

www.hansgrohe-usa.com

US - Installation Instructions • Part No. 90972801-04 • Revised 7/2008

Loading...

Loading...