Hansen HS6 Specifications, Applications, Service Instructions & Parts

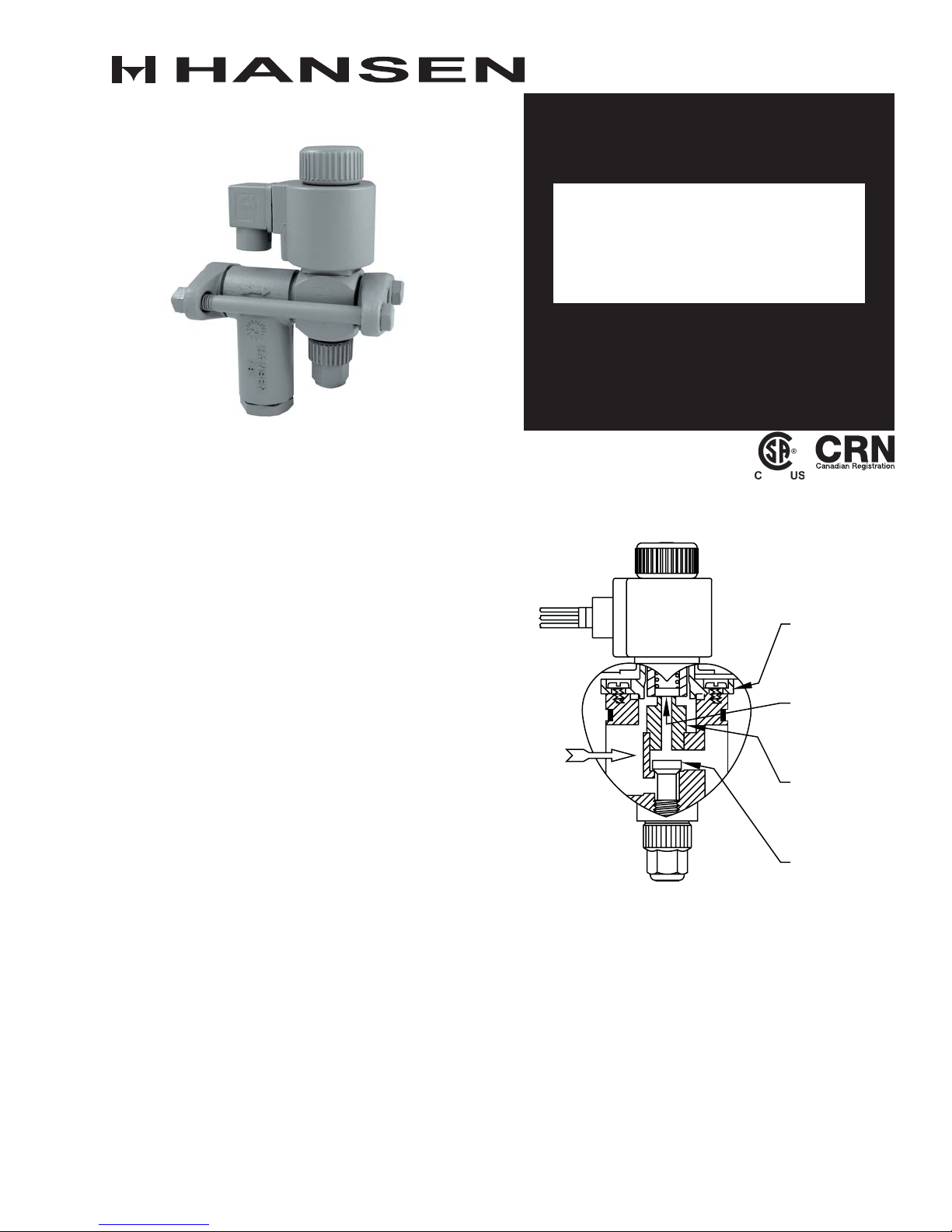

HS6 Solenoid Valve

with Close-Coupled ST050 Strainer

Bulletin S117c

MAR 2006

Specifications, Applications,

Service Instructions & Parts

HS6

SOLENOID VALVE

5/32” (4 mm) PORT

Flanged

1/4” thru 3/4”

(7 mm thru 20 mm)

for refrigerants

INTRODUCTION

This flanged, industrial refrigeration duty solenoid

valve is very simple and compact but rugged in

construction. Body is plated steel alloy with a

direct lifting stainless steel plunger that contains

a teflon seat that closes on a stainless steel

orifice. When electrically energized, seat opens

wide; when de-energized, it closes to stop flow

in the arrow direction on the valve body.

APPLICATIONS

This small, direct lifting valve is used primarily

as a pilot for various larger gas-powered or

liquid powered main valves, as a remote pilot

for back pressure regulators or other devices,

or as a liquid stop valve for expansion valves,

float valves, or as a general purpose pilot line for

ammonia, R22, R134a, CO2 and other approved

refrigerants or oil.

MAXIMUM RATINGS, AMMONIA

Liquid, Receiver Pressure: 15 Tons (52 kW)

Flow Factor: Cv=0.41 (Kv=0.35)

KEY FEATURES

REMOVABLE

SOLENOID TUBE

TEFLON DISC

STAINLESS STEEL

SEAT

MANUAL OPENING

STEM

MATERIAL SPECIFICATIONS

Body: Steel, plated

ADDITIONAL FEATURES

Encapsulated Hansen standard coil

300 psi (20 bar) MOPD

Available close-coupled strainer

Heavy-duty, direct lift

CSA Certified Status

Non-asbestos gaskets

Solenoid Tube: Stainless steel

Plunger: Stainless steel

Seat Orifice: Stainless steel

Seat: Teflon

Safe Working Pressure: 400 psig (27 bar),

600 psig (40 bar) available for CO2

Operating Temperature: -60ºF to 240ºF

(-50ºC to 115ºC)

ADVANTAGES

Power saving, low-wattage encapsulated coil; teflon

seat; stainless steel trim; spring-closing; double-seal

manual opening stem. One standard encapsulated

coil fits all Hansen valves.

INSTALLATION

Match arrow on body with system flow direction.

Protect interior of valve from dirt during installation;

normally use close-coupled inlet strainer. Allow 2.25”

(57 mm) above valve for coil removal, 1” (25 mm) below

for seal cap removal, and 3” (76 mm) below strainer

for screen removal. If a pressure reversal can occur,

as during hot gas defrost with liquid recirculation,

use a check valve on the outlet side of the HS6. For

pr o p er fla n ge gasket s e a ling, care m u s t be t a ken w hen

threading or welding to assure flanges are parallel to

each other and perpendicular to pipe. Also, gaskets

should be lightly oiled and all bolts must be tightened

evenly.

PARTS LIST

Item Description Qty Part No.

Coil Kit (115V) 1/2" Fitting w/leads 1 70-1085

Coil Kit (208/230V) 1/2" Fitting w/leads 1 70-1086

Coil Kit (24V) 1/2" Fitting w/leads 1 70-1087

Coil Kit (Other Voltages) 1 FACTORY

Above kits consist of:

1a Bare Coil, 115V 50/60 Hz w/leads 1 70-0580

1b Bare Coil, 208/230V 50/60Hz w/leads 1 70-0581

Bare Coil, 24V 50/60Hz w/leads

1c

Other Voltage Coils

1d

Coil Knob

3

Solenoid Tube/Plunger Kit

Above kit consists of:

Solenoid Tube

5

Plunger

4

6 Solenoid Tube Gasket 1 70-0301

2 O-Ring 1 75-0340

3 Coil Knob 1 70-0579

7 Screws (4) 4 70-0297

1

70-0582

1

FACTORY

1

70-0579

1 70-1059

1

70-0298

1

70-0295

ELECTRICAL

The coil draws 16 watts and will operate properly

between 85% and 110% of rated voltage (24V coil

draws 19 watts). Standard coil connection is a 1/2”

fitting (NPSM) for conduit, with two 18” wire leads and

gr ound wire. Coil s wi th DI N plu g or 1/2” NP SM qu ick

disconnect plug are available. Contact the factory.

All coils are totally encapsulated and meet NEMA 3R

(rainproof) and NEMA 4 (splashproof, approx. IP65)

requirements. The coil should only be energized

while on the solenoid tube. Otherwise, immediate coil

burnout may occur. To avoid bending the solenoid

tube, remove the coil from valve before connecting

any electrical conduit. Pilot lights are available.

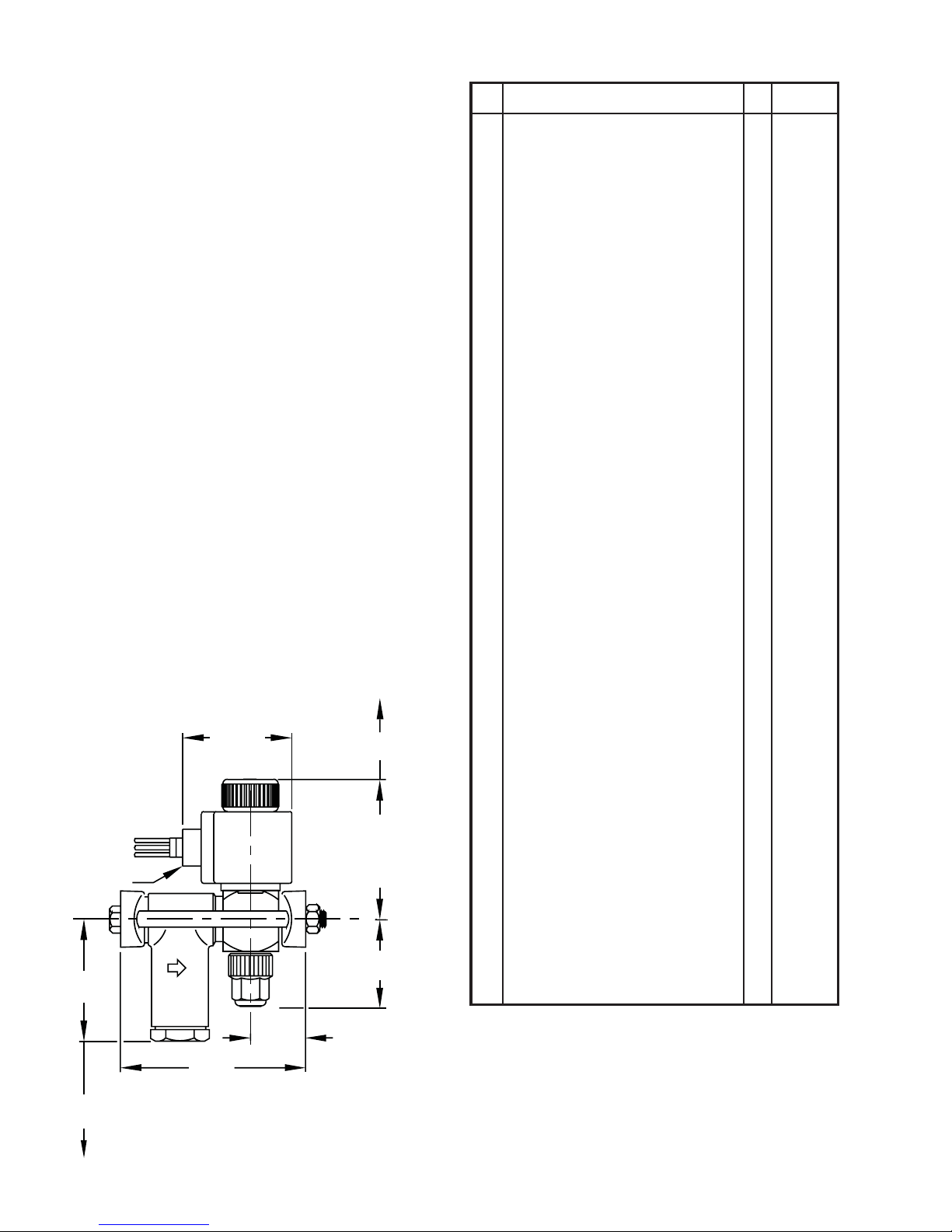

INSTALLATION DIMENSIONS

INCHES (MILLIMETERS)

2.95”

(75)

1/2” NPS M

STANDARD

ALLOW 2.25” (57)

FOR COIL REMOVAL

3.79”

(96)

4.11”

(104)

WITH PILOT LIGHT

Gasket Kit

1 70-1011

Above kit consists of:

Solenoid Tube Gasket

6

Flange Gasket

8

9 Stem O-Ring 1 70-0010

10 Stem Washer 1 70-0026

11 Stem Packing 1 70-0025

12 Packing Nut 1 70-0019

13 Pin 1 70-0150

14 Seal Cap Gasket 1 70-0011

Assembled Body Replacement Kit

15

1 70-0301

1 70-0065

1 70-1012

Complete Valve less Coil Kit

Seal Cap Kit

1 70-1075

Above kit consists of:

16 Seal Cap 1 75-0798

14 Seal Cap Gasket 1 70-0011

Strainer Screen Kit

1 78-1001

Above kit consists of:

17 Screen Assembly 1 78-0005

18 Strainer Cap Gasket 1 78-0016

Bolt and Nut Kit for HS6 less Strainer

Bolt and Nut Kit for HS6 with Strainer 1 70-1007

1 70-1006

Above kits consist of:

20 Flange Nut (7/16" - 14") 2 70-0055

21a Flange Bolt (less strainer) 3.75" 2 70-0073

21b Flange Bolt (with strainer) 5.5" 2 70-0076

Strainer Cap

19

1 78-0002

3.31”

(84)

1.5 0”

(38)

4.94”

3” (76) WITHOUT STRAINER

ALLOW 3” (76)

FOR STRAINER BASKET REMOVAL

S117c

MAR 2006

(125)

2.50”

(64)

Assembled Strainer Replacement Kit

22

Flange Kit (FPT, SW, WN, ODS)

23

1 78-1002

FACTORY

Includes (2) flanges only.

Specify style/size.

2

Loading...

Loading...