Hansen HCK4-2, HCK4-4, HCK4-3, HCK4-5, HCK4-8 Specifications, Applications, Service Instructions & Parts

...

HCK4 -4 Check Val ve

Bulletin C401e

JUL 2006

Specifications, Applications,

Service Instructions & Parts

HCK4 IN-LINE CHECK VALVES

5/8” THRU 4” PORT

(16 mm THRU 100 mm)

Flanged

3/8” thru 4”

(10 mm thru 100 mm)

FPT, SW, WN, ODS

for refrigerants

INTRODUCTION

The HC K4 series of dependable, com pac t, rugge d

in-line check valve s (disc type n on- return va lves) is

ideally suited for refr igerant flow control applications.

Valves open wide for flow in the arrow direction on the

valve bo dy. Valves close quickly a nd r eli abl y when

flow r eversals occur.

Plated b odies a nd st ainless steel sea t discs a nd

spring s enable them to withstand expec ted indus trial

refriger ation conditi ons. Fur t her mor e, these check

valves can be mounte d in any position and close-

coupled to other valves .

ADVANTAGES

These compa ct c hec k valves offer reliable op eratio n

regar dless of posit ion. Corrosion resistant stainl ess

steel seat disc. Metal-to-metal seats facilitate durable,

tight clo sing of valves .

APPLICATIONS

These i n-line c hec k valve s are designed to p rovide

refriger ant flow control to hot gas lines, liquid li nes ,

compressor discharg e line s, suction lines , an d hot

ga s heate d drain pans.

Th ese valves are n ot rec omm ende d for use with

pu l s a ting l oads s uch a s low speed c ompressor

discharge and screw compressor side port applications.

For applications suc h as the se, use Han sen HCK1

piston type check valves.

KEY FEATURES

STAIN LESS STEE L SEAT D ISC

LAPPED ME TAL SE ATI NG

CLOS IN G SPRIN G

DUAL BODY/CA RTR IDGE SE A LS

ADDITIONAL FEATURES

Mounts in a ny positio n

Less than 1 psid wide open ing pres sur e

Can be clos e-co upled

Low bubble le akage tolerance

For Amm onia, R22 , R134a , CO2 and other approved

refriger ant s

U.L. Listed

MATERIAL SPECIFICATIONS

G

H

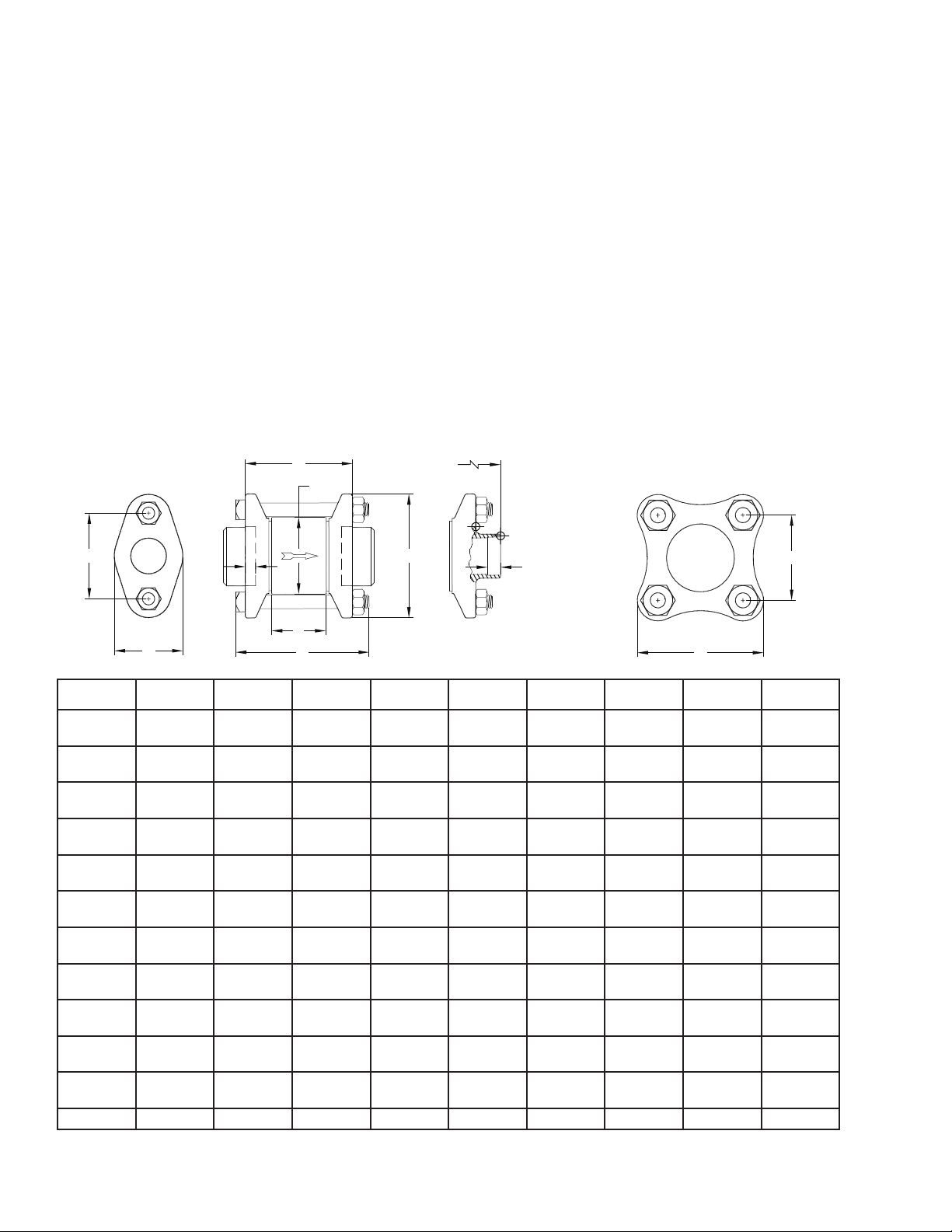

INSTALLATION DIMENSIONS

Body:

5/8” thr u 1¼”: S tee l, ASTM A108, zinc chromate

plated

1½” thru 4”: Ductile iron, ASTM A536, zinc chromate

plated

Seat Disc: St ainless steel

Seat Cartridge:

5/8” t hru 1¼”: Sta inless s teel, ASTM A582

1½” thru 4”: Steel, ASTM A108, zinc chromate

plated

Spring: Stainl ess s tee l

Safe Worki ng Pressure: 400 psig (27 bar), 6 00 psig

(40 bar) for CO2

Op eratin g Tempera tur e: -60 º F to 24 0ºF (- 50ºC to

115°C)

INSTALLATION DIMENSIONS

INSTALLATION

Val ve may be loc ated in any position. Arrow on valve

body should match direction of flow. Se cur e valve

with gaskets between flanges and tighten bolts evenly.

Do not use this valve or any component to alig n pipes

or tighten gap b etween f lan ges .

Do not install on inlet side of solenoid valves or control

valves with electric shut-off or shut-of f valves unless

a relief valve is used from therein between piping. Do

not insta ll on inl et side of outlet pressure regulators

where l iquid may become tra ppe d. In stead, c hec k

valves should be located on outlet side of these valves.

Check valves can be close- coupled to other matching

solenoi d va lves, p res sur e reg ulato rs, o r str ainers by

using a Male Adapter Ring a nd longer bolts supplied

when so specified on orde r. For pr oper flange gasket

sealing, care must be taken when threading or welding

to assure fl ang es are p arallel to each ot her and

perpendicular to pipe. Also, gaskets should be lightly

oile d and all bolts m ust be tig htened evenl y.

A

J

F

H

D

B

K

H

E

G

DI MEN S IO N

LE TT E R

A

B

C

D

E

=

F

G

H

J

K

Valve C v

(Kv)

Pipe S iz e 1/2”, 3/4 ” 3/4” 1” 1-1/4” 1-1/2 ” 2” 2-1/2 ” 3” 4”

HC K4 -2

5/ 8” PO R T

2. 50”

(6 4m m)

3.19 ”

(81mm)

3. 50”

(8 9mm)

0.38”

(10mm)

1.03”

(26m m)

1.5 0”

(3 8mm)

1.5 6”

(20m m)

2.19 ”

(56m m)

3. 26”

(8 3mm)

0.33 ”

(8 mm)

5. 8 (5 ) 8. 2 (7) 11.7 ( 10) 14.0 ( 12) 39 (33 ) 50 (4 3) 74 (63 ) 9 3 (8 0) 210 (180)

HC K4 - 3

3/4 ” PO RT

3. 25”

(8 3mm)

4.50 ”

(114mm)

4.50 ”

(114mm)

0.50 ”

(13mm)

1.2 2”

(31mm)

2. 37 ”

(6 0mm)

2. 50”

(6 4m m)

3.12”

(7 9mm)

4.00 ”

(102m m)

0.49 ”

(12mm)

C

HC K4 - 4

1” PO RT

3. 25”

(8 3mm)

4.50 ”

(114mm)

4.50 ”

(114mm)

0.50 ”

(13mm)

1.2 2”

(31mm)

2. 37 ”

(6 0mm)

2. 50”

(6 4m m)

3.12”

(7 9mm)

4.00 ”

(102m m)

0.59 ”

(15mm)

HC K4 - 5

1-1/4 ” PO RT

3. 25”

(8 3mm)

4.50 ”

(114mm)

4.50 ”

(114mm)

0.50 ”

(13mm)

1.2 2”

(31mm)

2. 37 ”

(6 0mm)

2. 50”

(6 4m m)

3.12”

(7 9mm)

4.00 ”

(102m m)

0.62 ”

(16mm)

HC K4 -7

1-1/ 2” P OR T

5.06”

(129m m)

4.56 ”

(116m m)

6. 38”

(162m m)

0.75”

(19mm)

2. 56”

(6 5mm)

3. 62 ”

(92m m)

4.56 ”

(116m m)

3.06”

(78mm)

6.06”

(154m m)

0.7 1”

(18mm)

HC K4 - 8

2” P OR T

6.06”

(154m m)

4.56 ”

(116m m)

6. 38”

(162m m)

0.75”

(19mm)

2. 56”

(6 5mm)

3. 62 ”

(92m m)

4.56 ”

(116m m)

3.06”

(78mm)

6.06”

(154m m)

0.87 ”

(22m m)

HC K4 - 9

2-1/ 2” P OR T

6.06”

(154m m)

6.00”

(152 mm)

7.50 ”

(191mm)

1.0 0”

(25m m)

2. 92”

(74mm)

4. 84”

(123m m)

6.00”

(152 mm)

4.00 ”

(102m m)

7.06 ”

(179 mm)

0.96”

(24mm)

G

HC K4 - 0

3” P OR T

6.06”

(154m m)

6.00”

(152 mm)

7.50 ”

(191mm)

1.0 0”

(25m m)

2. 92”

(74mm)

4. 84”

(123m m)

6.00”

(152 mm)

4.12”

(105m m)

7.06 ”

(179 mm)

1.08”

(27mm)

HC K4 -1

4” PO R T

6. 39”

(162m m)

7.13”

(181m m)

8.00”

(203 mm)

1.0 0”

(25m m)

3. 50”

(8 9mm)

6.06”

(154m m)

7.13”

(181m m)

5.00”

(127mm)

9.89 ”

(251mm)

1.40”

(3 6mm)

= “E” dime nsi on i s che ck v alve b ody o utsid e edge to out sid e ed ge. Flan ge gr oove d epth: nomi nal 0.12” eac h of t wo;

ga sket thic kne ss: n omina l 0.0 6” e ach of tw o.

C401 e

JUL 2006

2

Loading...

Loading...