Hansen H5600A, H5600R, H5601, H5602, H5602R Specifications, Applications, Service Instructions & Parts

...

Pressure-Relief Valve

ONTAC

TPN-SNOITCENNOCDEDAERHT

BOTTOM INLET (DN) SIDE OUTLET (DN)

R0065H

1

/2T (15)PF"

3

/4T (20)PF"

A0065H

1065H

1

/2T (15)PF" PT (25)F"1

2065H

3

/4T (20)PF" PT (25)F"1R2065H

R2365H

3165H

T (25)PF1" 1

1

/4T (32)PF"

1

1

/2T (40)PF"

1

1

/4T (32)PF"

R3365H

4065H

R4365H

Bulletin K109i

AUG 2015

Specifications, Applications,

Service Instructions & Parts

REFRIGERANT

PRESSURE-RELIEF

VALVE

For Ammonia and

Halocarbon Gas Service

Safety Relief to Atmosphere

INTRODUCTION

Designed to provide emergency relief from excessive pressure

in refrigerant-containing vessels, they are built in strict

conformance with ASME Boiler and Pressure Vessel Code

requirements for safety relief devices. Each valve bears the

ASME code symbol of certification (UV ). Their capacities

are rated by the National Board of Boiler and Pressure Vessel

Inspectors. These tamper-resistant valves are accurately set

and sealed by qualified technicians at the factory.

APPLICATIONS

Hansen pressure-relief valves help meet the requirements

of ANSI/ASHRAE 15 Safety Standard for Refrigeration

Systems as well as other worldwide codes. This standard

requires pressure vessels of all refrigeration systems to

be protected by a pressure-relief device or other approved

means to safely relieve pressure in the event of fire or

other abnormal conditions. Once installed, a properly

selected Hansen pressure-relief valve is ready to vent to

atmosphere any temporary excessive overpressure inside

of a vessel. After discharge, these valves will attempt to

reseat to minimize loss of refrigerant. However, once any

relief valve has discharged, it must be replaced as soon

as possible because debris may have settled on the seat

during discharge.

Hansen pressure-relief valves should be connected to the

vapor space of refrigerant vessels, heat exchangers, oil

pots, oil stills, pilot receivers, and elsewhere as may be

required by various codes.

Where dual pressure-relief valves are required, Hansen

offers the three-way valves and other components necessary

for assembly; see page 4. Rupture disc assemblies are

required when using Hansen pressure-relief valves for

halocarbon applications because the high cost of such

refrigerants demands extreme tightness, see bulletin K209.

Also, see Bulletin K129 for information on the EZ-SRV Relief

Valves. These pressure-relief valves offer a cartridge style

design for ease of replacement without disturbing the piping.

EZ-SRV pressure-relief valves are available in pressure

ratings to 600 psi (matching the H5600 “R” series capacities

through 400 psi). Liquid relief valves are also available in

the EZ-SRV series. EZLQ relief valves are designed and

rated for liquid applications.

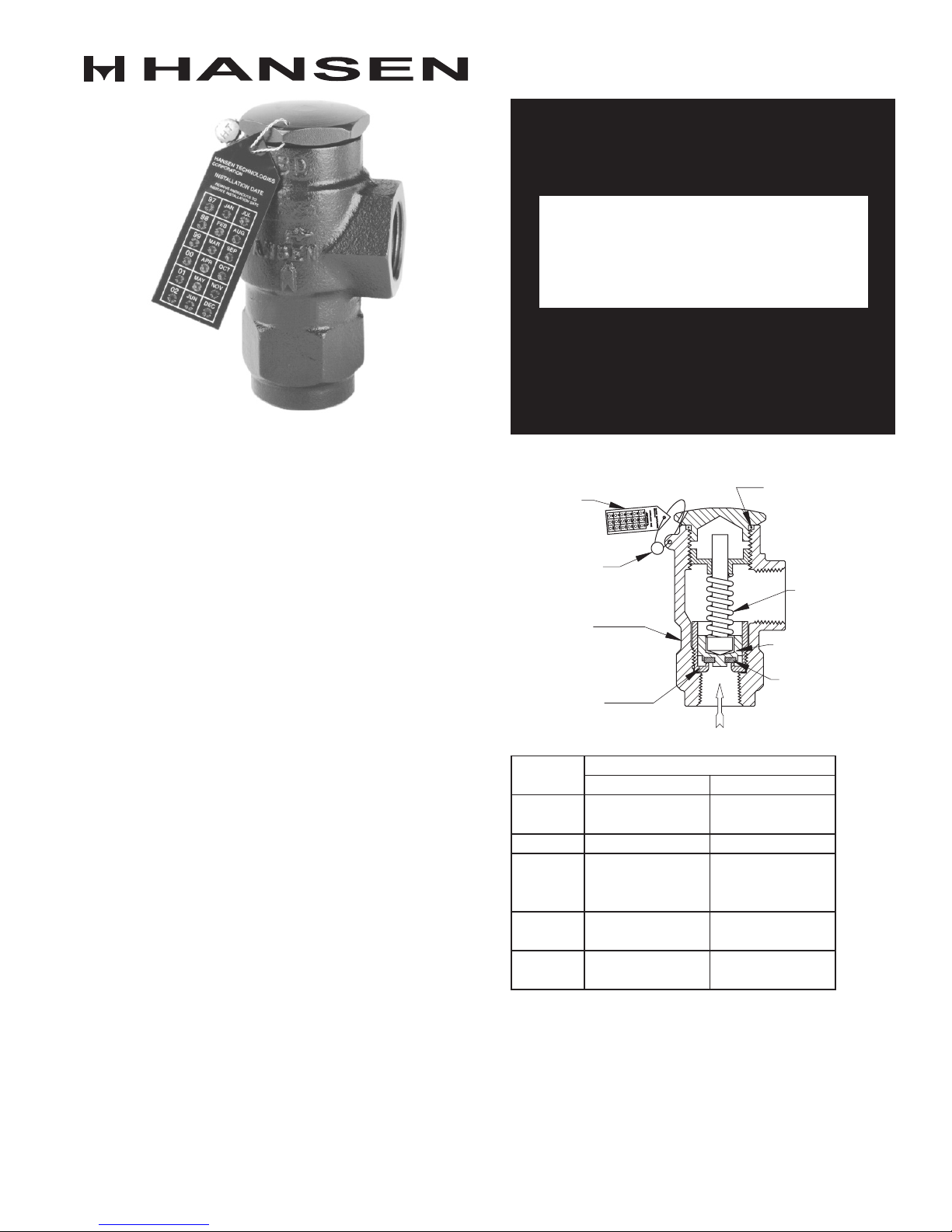

KEY FEATURES

INSTALLATION

DATE TAG

ACCURATELY

FACTORY SET

AND SEALED

DUCTILE IRON

BODY FOR ADDED

STRENGTH

STAINLESS STEEL

SEATINSERT

ORDERING INFORMATION

Specify catalog number, inlet/outlet connection size, and

pressure setting. For halocarbon applications, a rupture

disc assembly is required. See Rupture Disc Assembly

section of this bulletin. Standard pressure settings: 150*,

175, 200, 225, 250*, 275, 300*, 325, and 350 psig. (*Stock

pressure settings.) Custom pressure settings available;

may require extra delivery time. The H5600 “R” series

valves have reduced capacities, see page 2. CE marked

valves are available, add the letter “E” suffix to catalog

number (example: H5601/250E).

NEOPRENE O-RING

HELPS SEALVALVE

FROM MOISTURE

STAINLESS

STEEL SPRING

STAINLESS STEEL

PISTON

PREMIUM GRADE

VIRGIN TEFLON

SEATDISC

VALVE SIZING AND SELECTION

ONTAC

SNOITCENNOCDEDAERHT

TPN

A

(MM)B(MM)C(MM)

MOTTOB

T (DN)ELNI

EDIS

T (DN)ELTUO

A0065H

R0065H

1

/2T (15)PF"

3

/4T (20)PF"

2.13"

(54)

2.75"

(70)

1.63"

(41)

3.00"

(76)

4.13"

(105)

2.25"

(57)

1065H PT (25)F"1

2065H

R2065H

R2365H

3

/4T (20)PF" PT (25)F"1

1

3165H

R3365H

T (25)PF"1

1

/4T (32)PF"

1

1

/2T (40)PF"

4065H

R4365H

1

1

/4T (32)PF"

Step 1: Use the formula below, per ANSI/ASHRAE 15

Safety Standard for Refrigeration Systems to calculate the

minimum required discharge capacity in pounds of air per

minute. When selecting a dual pressure-relief valve system,

be aware that each individual valve must have sufficient

capacity to protect the vessel.

** This factor is not suitable when combustible materials

are within 20 feet (6.1 m) of the pressure vessel; refer to

relevant codes for corrected sizing method.

Example: To determine the minimum required capacity

of a relief valve for a vessel containing ammonia that

measures 16 feet in length and 6 feet in outside diameter,

the equation would be as follows: 0.5 x 6 x 16 = 48 lb/min.

Step 2: Determine the pressure setting needed. This

C=fDL

C = minimum required discharge capacity of

the relief device in pounds of air per minute.

f = factor for ammonia refrigerant is 0.5**,

factor for R-22 and R-134a refrigerants is 1.6**, for

other refrigerants see ANSI/ASHRAE 15 or contact

factory.

D = outside diameter of vessel in feet.

L = length of vessel in feet.

should be at or below the design pressure of the vessel.

The relief setting should also be at least 25% above the

maximum expected operating pressure to avoid “weeping”

of relief valves. The setting may be below (never above) the

design pressure of the vessel, but it is sometimes best to

match vessel design pressure and relief setting to minimize

the likelihood of a discharge.

Step 3: Refer to the Valve Capacity Ratings below and

select the valve with the required capacity (C) at the desired

pressure setting.

PRESSURE-RELIEF VALVE CAPACITY RATINGS (NATIONAL BOARD CERTIFIED)

ONTAC

R0065H

R2065H

R2365H

R3365H

R4365H

A0065H

1065H

2065H

3165H

4065H

RIA

YTICAPAC

nim/bl 5.01 2.21 8.31 4.51 0.71 6.81 2.02 8.12 5.32 7.62

mfcs 041 261 381 502 622 842 962 092 213 553

nim/bl 22 52 92 23 63 93 24 64 94 65

mfcs 292 733 283 724 274 715 165 606 156 147

nim/bl 82 33 73 14 64 05 45 95 36 27

mfcs 773 534 294 055 806 566 327 187 938 459

nim/bl 43 93 44 94 45 06 56 07 57 58

mfcs 944 815 685 556 427 397 168 039 999 6311

nim/bl 3.13 1.63 9.04 7.54 5.05 3

mfcs 714 084 445 806 276 637 997 368 729 5501

nim/bl 8.53 3.14 8.64 2.25 7.75 2.36 6.86 1.47 6.97

mfcs 674 945 226 596 867 148 319 689 9501

nim/bl 0.35 1.16 2.96 3.77 4.58 5.39 6.101 7.901 8.711 431

mfcs 407 218 029 8201 6311 3421 1531 9541 7651 2871

nim/bl 0.27 0.38 0.49 1.501 1.611 1.721 1.831 1.941 2.061 281

mfcs 859 4011 1521 7931 4451 1961 7381 4891 0312 3242

051 571 002 522 052 572 003 523 053 004

.55 1.06 9.46 7.96 3.97

)gisp(SGNITTESERUSSERPDRADNATS

Important Note: These are atmospheric relief valves. Settings equal pressure above atmosphere when outlet is connected via

proper piping to the atmosphere (outside). (scfm = Standard Cubic Feet per Minute)

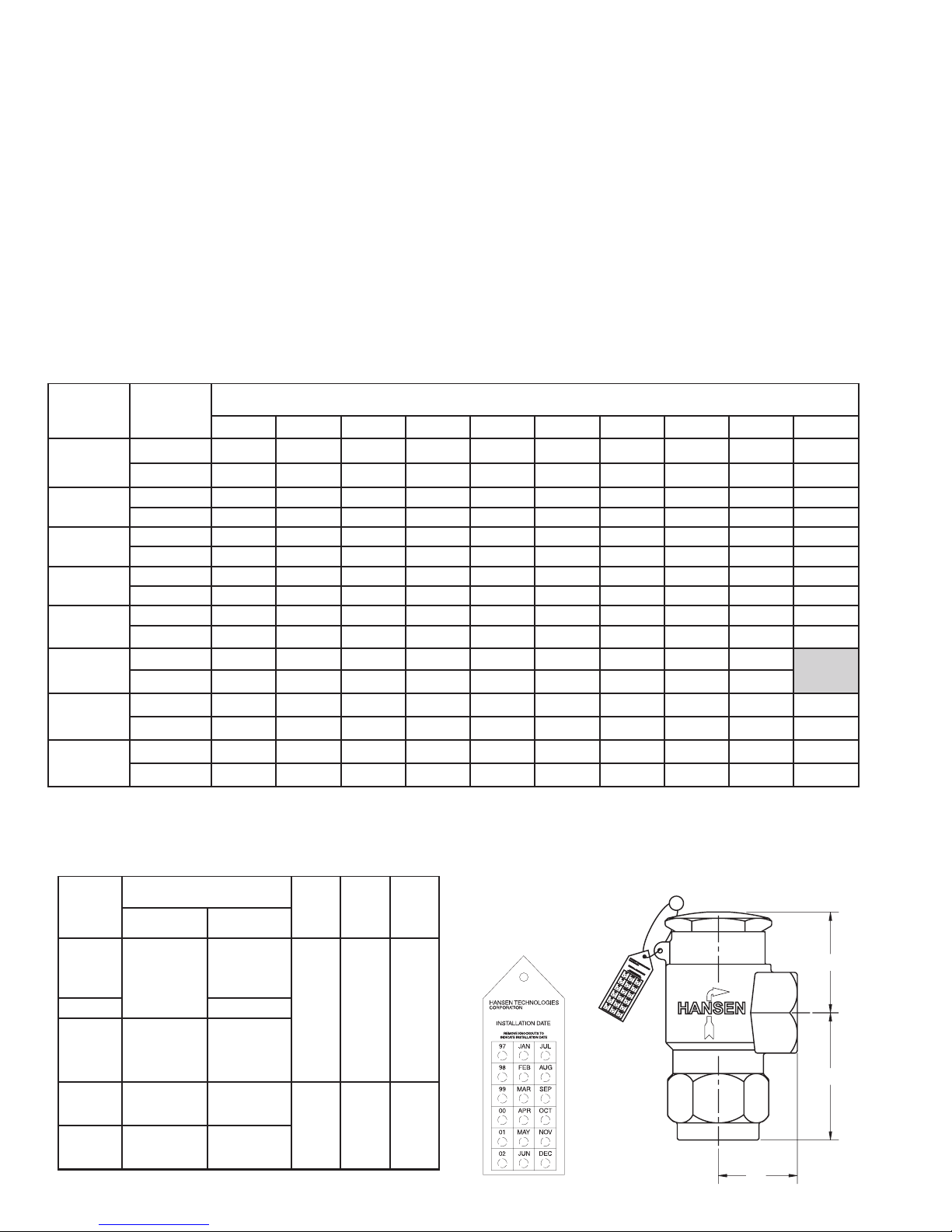

INSTALLATION DIMENSIONS

K109i

AUG 2015

H5600 “R” Series capacity valves have green installation

date tags, while all others are blue.

A

B

C

2

Loading...

Loading...