Hansen EZ-SRV, EZB-BT1, EZB-BT2, EZF-BT5, EZE-BT4 Specifications, Applications, Service Instructions & Parts

...

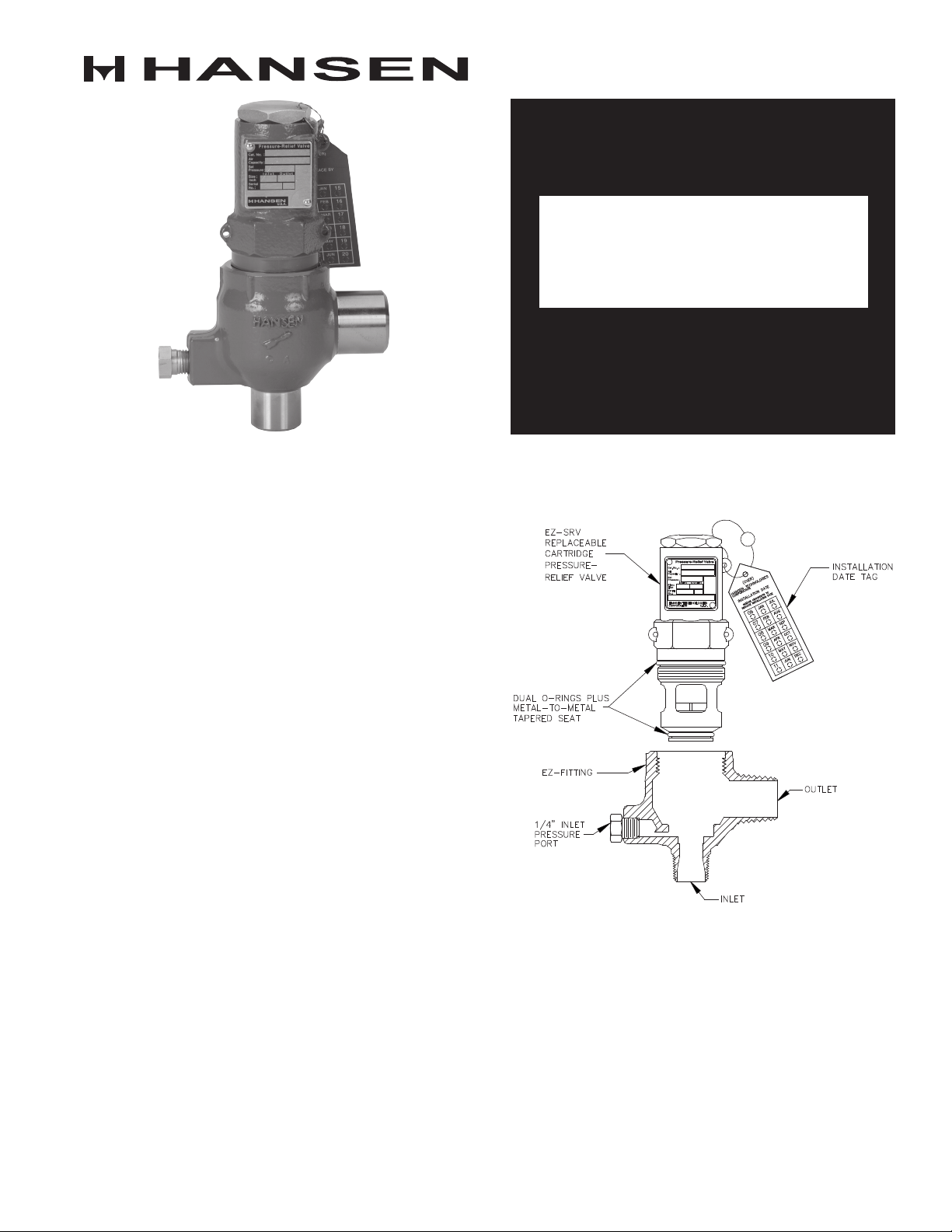

EZ-SRV™

Cartridge Pressure-Relief Valve with EZ-Fitting

Bulletin K129e

JAN 2014

Specifications, Applications,

Service Instructions & Parts

EZ-SRV™ CARTRIDGE

PRESSURE-RELIEF VALVES

For Ammonia and Halocarbon

Refrigeration Systems

INTRODUCTION

Hansen EZ-SRV™ cartridge pressure-relief valves protect

refrigeration pressure vessels and other refrigeration

system components from excessive pressure. If an

abnormally high pressure occurs, the cartridge pressurerelief valve will open to relieve the excess pressure,

preventing potential damage to equipment and injury

to personnel.

Hansen EZ-SRV™ relief valves are built in strict

conformance with both ASME Boiler and Pressure Vessel

Code requirements and ISO 4126 — Safety Devices for

Protection of Excessive Pressure. Each valve bears the

ASME code symbol of certification (UV). Valve capacities

are rated by the National Board of Boiler and Pressure

Vessel Inspectors (NB).

Refrigeration pressure-relief valves are recommended

for replacement at least every five years. However, if a

relief valve has discharged, it must be replaced as soon

as possible. Valve replacement with the Hansen EZ-SRV™

is fast and easy — saving significant time and expense

compared to traditional relief valves.

The cartridge valve can be replaced more safely than

previously available pressure-relief valves. The Hansen

EZ-Fitting has a ¼˝ NPT connection on the side of

the body. A ¼˝ gauge valve installed with a tell-tale

pressure gauge can indicate overpressure of a valve

and if pressure is present when servicing, the ¼˝ gauge

valve can also be used to safely bleed-off residual

pressure between the three-way manifold valve and

the EZ-SRV™ valve.

KEY FEATURES

Cat. No.

Air

Capacity

Set

Pressure

I n l e t

O u t l e t

Size

inch

Serial

No.

HANSEN TECHNOLOGIES

U.S.A.CORPORATION

ADDITIONAL FEATURES

Cartridge design allows quick and easy replacement.

Matched capacities to existing Hansen H5600

“R” series

Low blowdown (15% or less) for gas service

EZ-Fitting is a permanent fixture, available with

welded or threaded end connections

MPT inlet eliminates need for nipple

EZ-Adapter component available for retrofit of existing

Hansen relief valves

Liquid Rated Relief Valve (EZLQ) available

APPLICATIONS

Hansen EZ-SRV™ cartridge pressure-relief valves

typically are installed on pressure vessels to protect

from overpressure. Several design codes for refrigeration

systems require that pressure vessels have protection

from excessive pressure. For example, Hansen cartridge

pressure-relief valves comply with the requirements

of ANSI/ASHRAE Standard 15 Safety Standard for

Refrigeration Systems, and ANSI/IIAR 2 Equipment,

Design, and Installation of Closed-Circuit Ammonia

Mechanical Refrigerating Systems. Once installed,

a properly selected Hansen EZ-SRV™ cartridge

pressure-relief valve will vent to atmosphere excessive

overpressure. After discharge, these valves will quickly

reseat to minimize loss of refrigerant. After discharge,

relief valves must be replaced as soon as possible

because debris may have settled on the seat, allowing

the seat to leak out refrigerant. Hansen EZ-SRV™ valves

must be installed in the vapor space above the liquid

level of any vessel or component which contains liquid

and vapor. (Hansen offers the EZLQ, a liquid relief valve

for use with ASME rated pressure vessels and is rated

U.S. GPM.)

MATERIAL SPECIFICATIONS

EZ-Fitting Body: ASME SA105 steel

EZ-SRV™ Car tridge: ASME SA395, ductile iron

Internal Seating Components: stainless steel

Piston: stainless steel

Seat O-rings: neoprene

Spring: stainless steel

Maximum Temperature Rating: 240°F (115°C)

Safe Working Pressure: 600 psig (41 bar)

Setting Range:

Gas Service: 150 to 600 psig (10.4 to 41 bar)

Liquid Service: 50 to 100 psid (3.4 to 6.9 bar)

Reseat Pressure (blowdown):

Gas Service: within 15% below set point

Liquid Service: within 20% below set point

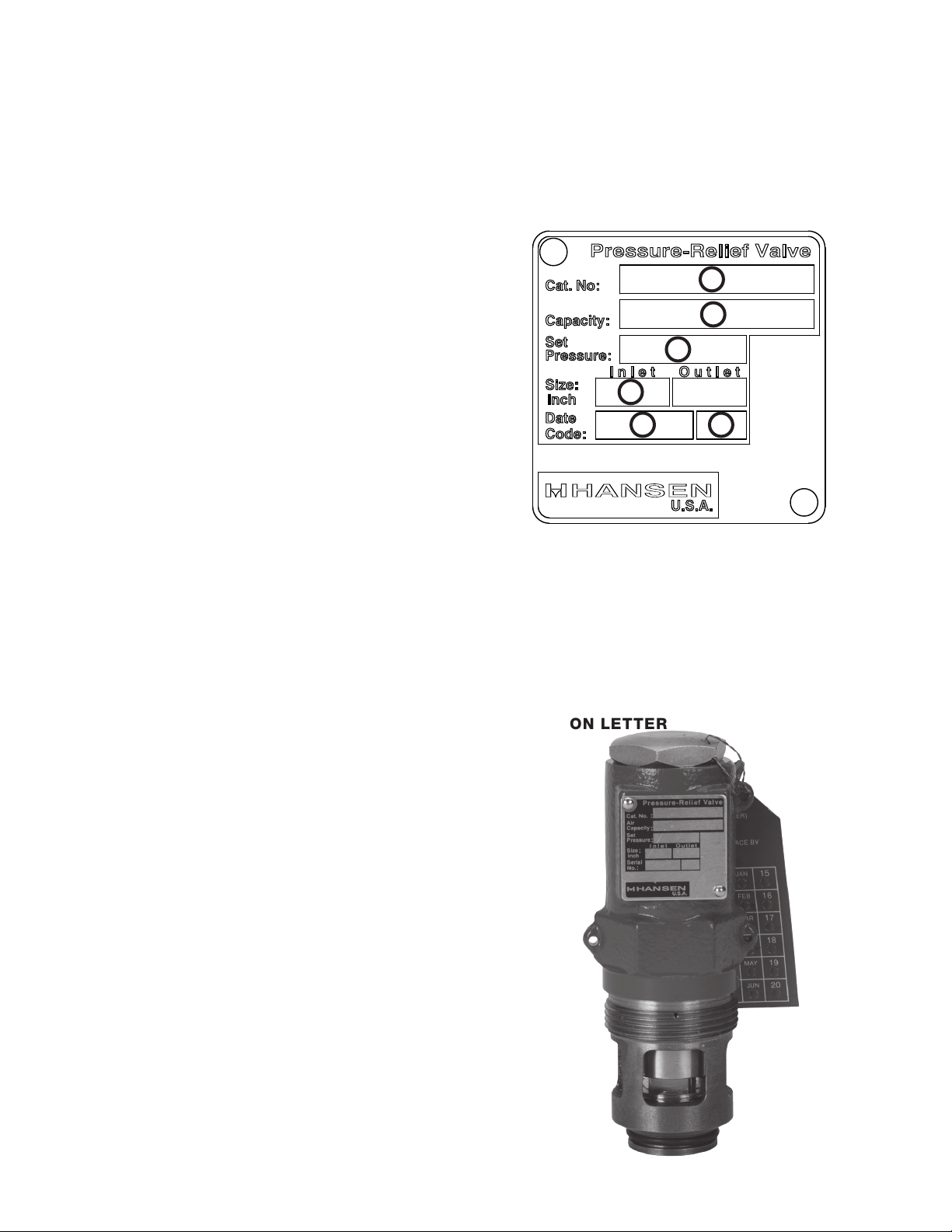

NAMEPLATE INFORMATION

The nameplate, located on the side of Hansen EZ-SRV™

cartridge pressure-relief valves, contains important

information about the valve pressure setting, capacity

and date of manufacture. The date code traces the

month and year the valve was built. Example: A valve

with Serial No. 06B 10, indicates that it was built in June

of 2010. See nameplate below for location of data and

photo of EZ-SRV replacement cartridge.

1

2

3

4

5

1. CATALOG NUMBER

2. AIR CAPACITY OR LIQUID FLOW RATE

ACCORDING TO THE SET PRESSURE

3. SET PRESSURE

4. INLET SIZE

5. MONTH AND DAY OF MANUFACTURE AND

VALVE NUMBER

6. YEAR OF MANUFACTURE AND CURRENT

REVISION LETTER

6

CODE AND STANDARD COMPLIANCE

ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1

ANSI/ASHRAE Standard 15 Safety Standard for

Refrigeration Systems

ANSI/IIAR 2 Equipment, Design, and Installation of

Closed-Circuit Ammonia Mechanical Refrigerating

Systems

ISO 4126, Safety Devices for Protection of Excessive

Pressure

PED (Pressure Equipment Directive) Categor y IV

K129e

JAN 2014

EZ-SRV Replacement Cartridge

2

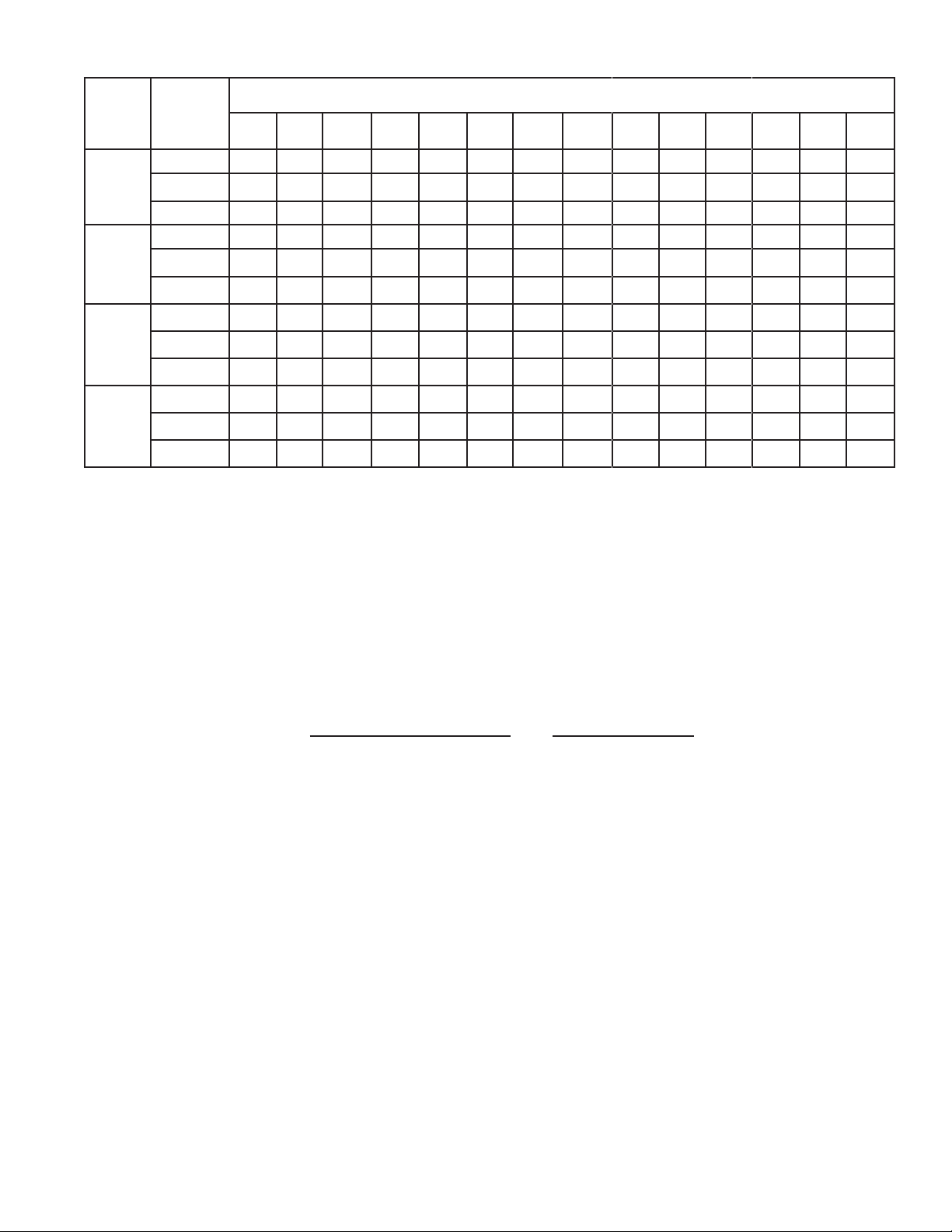

CAT NO

EZB

EZC

PRESSURE-RELIEF VALVE CAPACITY RATINGS

PRESSURE SETTING, PSIG

AIR

CAPACIT Y

lb/min 10.5 12. 2 13. 8 15.4 17.0 18.6 20.2 21.8 23.5 26.7 30 33 36 40

scfm 140 162 183 205 226 248 269 290 312 355 398 441 484 526

kg/hr 286 330 373 418 461 506 549 592 636 724 812 900 987 1075

lb/min 22 25 29 32 36 39 42 46 49 56 62 69 76 83

scfm 292 337 382 427 472 517 561 606 651 741 831 920 1010 1100

kg/hr 598 689 780 872 963 10 55 1146 123 8 132 9 1512 1695 1878 2061 2244

lb/min 28 33 37 41 46 50 54 59 63 72 – – – –

150

(10.3)

175

(12 .1)

200

(13. 8)

225

(15.5)

250

(17. 2 )

275

(19)

(BAR)

300

(20.7)

325

(22.4)

350

(24 .1 )

400

(27. 6 )

450

(31.0 )

500

(34.5)

550

(37. 9 )

600

(41. 4)

EZE

EZF

scfm 377 435 492 550 608 665 723 781 839 954 – – – –

kg/hr 770 888 1006 112 3 12 41 1359 147 7 15 95 1712 1948 – – – –

lb/min 34 39 44 49 54 60 65 70 75 85 – – – –

scfm 449 518 586 655 724 793 861 930 999 113 6 – – – –

kg/hr 916 10 56 119 6 1336 1477 16 17 1757 1897 2038 23 17 – – – –

SELECTION

Step 1: Use the formula below, per ANSI/ASHRAE Standard 15 Safety Standard for Refrigeration Systems, to calculate

the minimum required discharge capacity in pounds of air per minute (or kg/s). When selecting a dual pressure-relief

valve system, each individual valve must have sufficient capacity to protect the vessel.

C=fDL

C = minimum required discharge capacity of the relief device in pounds of air per minute (kg/s).

D = outside diameter of vessel in feet (m).

L = length of vessel in feet (m).

f = factor dependent upon type of refrigerant**

Refrigerant

ammonia (R-717)

† R-22, R-134a

† R-404A, R-410A, R-507A

CO2 ( R -74 4)

Value of f** (SI)

0.5 (0.041)

1.6 (0.131)

2.5 (0.203)

1.0 (0.082)

For other refrigerants see ANSI/ASHRAE 15 or contact factory.

** When combustible materials are used within 20 feet (6.1 m) of a pressure vessel, multiply the value of f by 2.5.

† Refer to the Rupture Disc Assemblies section of this bulletin

Example: To determine the minimum required capacity of a relief valve for a vessel containing ammonia that

measures 16 feet (4.9 m) in length and 6 feet (1.8 m) in outside diameter, the equation would be as follows:

0.5 x 6 x 16 = 48 lb/min (0.041 x 4.9 x 1.8 = 0.362 kg/s = 1302 kg/hr).

Step 2: Determine the pressure setting needed. This should be at or below the design pressure of the vessel. The

relief setting should also be at least 25% above the maximum expected operating pressure to avoid “weeping” of

relief valves. The setting may be below (never above) the design pressure of the vessel, but it is sometimes best to

match vessel design pressure and relief setting to minimize the likelihood of a discharge.

Step 3: Refer to the Pressure-Relief Valve Capacity Ratings above and select the valve with the required capacity

(C) in lb/min (kg/hr) at the desired pressure setting.

3

K129e

JAN 2014

Loading...

Loading...