Hansen AUTO-PURGER M, APM, APMF Service Instructions Manual

Specifications, Applications,

Service Instructions & Parts

Compact, Non-condensible

For Models APM & APMF

Model APM

SECTION 1 MOUNTING & PIPING INSTALLATION

Bulletin APM-001e

AUG 2015

AUTO-PURGER® M

“Energy Saver”

Gas (Air) Purger

INTRODUCTION

The AUTO-PURGER® M is a compact and totally automatic,

electronically-controlled, noncondensible gas refrigerant

purger for reducing condensing pressure, and thereby

saving electrical energy used by the refrigeration system.

This deluxe purger is preassembled, prewired, tested,

insulated, and includes an automatic water bubbler.

Installation requires piping the foul gas line, liquid line,

suction line, water line, drain line, and wiring the power

connection and the remote ½" (13 mm) port purge point

solenoid valves, which must be purchased separately. Up

to four (4) purge points can be controlled by this purger.

The AUTO-PURGER® M (APM) features welded piping

and watertight electrical construction. The APM meets

the requirements of the Canadian Standards Association

(CSA certified).

A typical APM installed in a plant with normal-entering

noncondensible loads will handle up to a 200 ton (700 kW )

system. Each purge point will be active between 10 and 30

minutes, depending on the noncondensible gas presence

(mostly air) and the purger mode of operation.

Model APMF AUTO-PURGERS are for use in halocarbon

refrigeration systems. The installation and operation of

these AUTO-PURGERS are similar to that of an ammonia

AUTO-PURGER M. See page 13 for additional details.

MOUNTING INSTRUCTIONS

Mount the APM straight and securely on a wall or sturdy

steel channels capable of supporting 350 lbs (160 Kg). Eight

mounting holes in the frame are provided to support the

purger (See Figure 1). The APM should be located in an

accessible area, but away from the movement of equipment

that could accidentally damage the purger. Elevation with

respect to condensers or high-pressure receivers is not

critical, however, purge point solenoid valves must be

above the purger.

An APM is usually installed in the compressor room where

it can be monitored, but also may be installed outdoors

where temperatures below freezing are not anticipated.

The APM comes standard with a watertight NEMA 13 (IP65,

Category 2) control cabinet enclosure with sealed conduit

wiring. Any unused electrical entrances to the enclosure

must be sealed to protect electronics from moisture. A

NEMA 4 cabinet enclosure is available.

An optional valve package (VPM) for purger isolation is

available from Hansen. This consists of three welded

assemblies which include shut-off valves, gauge valves,

and mating flanges. An illustration detailing this optional

valve package is on page 12 (Figure 13).

FOUL GAS PIPING

Purging at several points, up to four with the APM, on the

high-pressure side of the system is the best method for

removing foul gas. Foul gas is refrigerant gas containing

some air or other noncondensibles. Several points should

be used because it is nearly impossible to predict where

noncondensible gas will accumulate in a system.

Even for multipoint purging, only one purge point should be

purged at a time. Connecting two purge points from two

condensers or receivers may result in gas flowing from one

condenser to another. This is due to an unequal pressure

drop, even though the differences in pressure drop are

very small, for example ¼ psig (0.02 bar). The result would

be that, even in the best of circumstances, only one point

is effectively purged. The best practice is to purge each

condenser and receiver circuit separately.

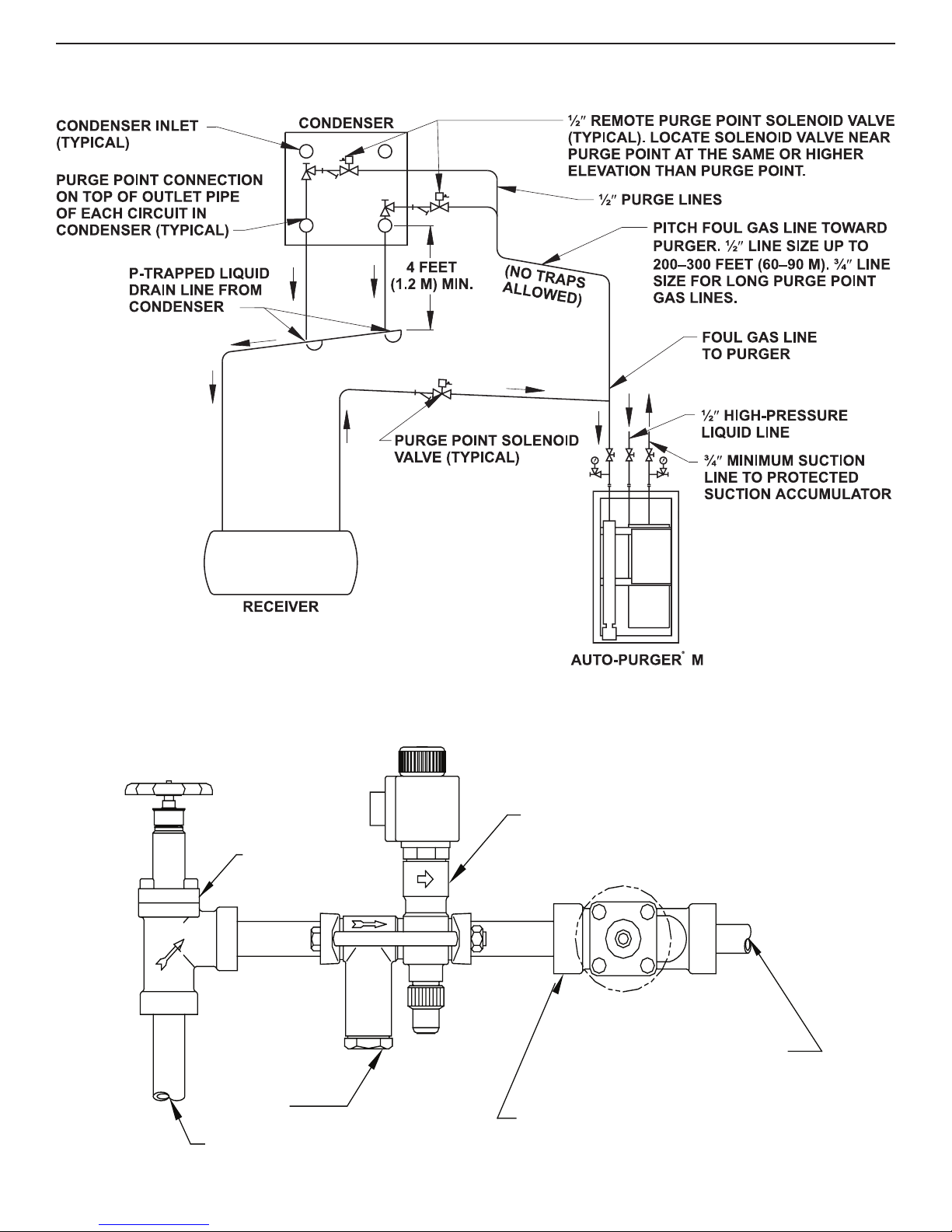

When utilizing multipoint purging, the purge point solenoid

valves can be manifolded into one foul gas line to the

purger. A ½" (13 mm) size line is the minimum and should

be pitched toward the purger to drain any condensed

liquid. Also, no liquid traps are allowed either before or

after the purge point solenoid valves (See Figure 2). The

foul gas line should not pass through cold areas where

ACTIVE PURGE POINT

1234

ENERGY SAVER

R

HANSEN TECHNOLOGIES

CORPORATION

(25)

(298)

ON HIGH PRESSURE CONDENSERS AND RECIEVERS

PROTECTED SUCTION ACCUMULATOR

(24)

(86)

(192)

TYPICAL

(16)

(508)(813)

(152)

FOR POWER CONNECTION

FOR REMOTE PURGE POINT

SOLENOID VALVE CONNECTIONS

(86)

(359)

(49)

(457)

OIL DRAIN CONNECTION (3/8" FPT)

OIL DRAIN CONNECTION (3/8" FPT)

TYPICAL

(16)

(14)

MOUNTING HOLE

8 PLACES

(59)

(130)

(178)

SHUT-OFF VALVE CONNECTION

PRESSURE RELIEF VALVE

(406)

(464)

CONNECTION

1" PVC DRAIN

WALL OR COLUMN

18.25"

BUBBLER

CONTROL CABINET

1/2" CONNECTION FOR OPTIONAL

1/2" FPT WATER LINE

7.00"

3/4" SUCTION LINE

5.11"

0.53" DIA

0.62"

18.00"

HIGH PRESSURE SEPARATOR

LOW PRESSURE SEPARATOR

1.93"

14.13"

3/4" CONDUIT KNOCK OUT

1/2" CONDUIT KNOCK OUT

6.00"

32.00"

20.00"

0.62"

3/4" SUCTION LINE CONNECTION TO

1/2" HIGH PRESSURE LIQUID LINE CONNECTION

1/2" FOUL GAS'' LINE CONNECTION FROM PURGE POINTS

''

3.38"

16.00"

2.31"

1.00"

0.94"

3.38"

7.56"

11.75"

1.63" (41 MM)

FROM FOUL GAS SOURCE

CLOSE-COUPLED

ISOLATION

TO PURGER

1/2" (13 MM) PORT

SHUT-OFF VALVE

REMOTE PURGE POINT

SOLENOID VALVE

ISOLATION SHUT-OFF VALVE

STRAINER

(GLOBE VALVE STEM HORIZONTAL

IS PREFERRED)

LEVEL OR

PITCH DOWN

SECTION 1 MOUNTING & PIPING INSTALLATION

further condensing of the saturated gas can occur. If this

cannot be avoided, the line must be insulated because

flooded purge point lines result in flooding the APM with

liquid, causing a temporary halt of noncondensibles

being removed. If flooding can not be avoided, additional

condensate drainage may be necessar y.

It is important that all purge points be located above any

liquid surfaces to avoid drawing liquid refrigerant, rather

than vapor, into the APM.

EVAPORATIVE CONDENSER PIPING

Typically, evaporative condenser outlet liquid drain lines

on each circuit must drop a minimum of 4 feet (1.2 m) for

ammonia from the centerline of the evaporative condenser

outlet to the centerline of highest elevation of the liquid

line manifold to receiver. Preferably, each circuit should

INSTALLATION DIMENSIONS (MM)

Figure 1

have a P trap to balance variations in pressure drop in each

circuit to prevent liquid from backing up into one or more

condensers, and thereby flooding the purge point. Most air

from the system will normally be trapped between the

condenser and the P trap. Also, a properly-sized equalizer

line from the receiver will help drain condenser circuits

into the receiver. Refer to ASHRAE GUIDELINES or IIAR

Papers on condenser piping design. Hansen Technologies

can provide copies of these articles. Also, consult the

condenser manufacturers’ installation instructions for

additional piping and sizing information.

On evaporative condensers, avoid using one purge point

solenoid valve to purge two circuits. This practice negates

the P-trap on the condenser drain line because of the

purge connections of the two circuits and may back liquid

up into one circuit.

APM-001e

AUG 2015

2

FROM FOUL GAS SOURCE

CLOSE-COUPLED

ISOLATION

TO PURGER

1/2" (13 MM) PORT

SHUT-OFF VALVE

REMOTE PURGE POINT

SOLENOID VALVE

ISOLATION SHUT-OFF VALVE

STRAINER

(GLOBE VALVE STEM HORIZONTAL

IS PREFERRED)

LEVEL OR

PITCH DOWN

SECTION 1 MOUNTING & PIPING INSTALLATION

TYPICAL APPLICATION

Figure 2

PURGE POINT VALVE (TYPICAL)

Figure 3

3

APM-001e

AUG 2015

SECTION 1 MOUNTING & PIPING INSTALLATION

PURGE POINT CONNECTIONS

Foul gas lines from condensers should be purged at points

recommended by the condenser manufacturer. Usually, this

is at the top of each circuit’s outlet header which drains

down through a P-trap to the receiver. In some cases, a

small high pressure auxiliary receiver is located at the

outlet of one or more condensers. This receiver should

have a purge point at the top, preferably at a “dead” area

away from condenser drain pipes. Below is a typical valve

arrangement for a purge point (Figure 3). Regardless of

the purge point location, it is absolutely necessary to

ensure that liquid is not drawn into the foul gas line.

Where a high-pressure float regulator is used to drain one

or more condensers, the top of the float valve chamber

should also be a purge point.

Horizontal shell and tube water-cooled condensers, and

heat exchangers should be purged at the top, usually at

the point(s) fur thest from the compressor discharge main

inlet.

Vertical condensers should be purged near the top of the

vessel if possible.

For certain types of oil separators where very low velocities

may exist near the top of the vessel, purging may be

advisable from a top fitting.

It is normally not advisable to purge controlled pressure

receivers, high-pressure thermosyphon vessels, or vessels

located on the low side of the system.

SUCTION LINE

The ¾” suction line from the purger should be connected

to a protected main suction line or a suction accumulator.

Install a suction line isolation shut-off valve near purger.

Excess amounts of liquid from the purger evaporator may

occasionally be transmitted through the suction line. The

suction temperature must be 40°F (4.4°C) or less to satisfy

the APM temperature sensor before purging will occur.

LIQUID LINE

A high-pressure ½” liquid line is required for the APM. The

connection to the high-pressure liquid source should be

a location where oil will not be directed into the purger.

Install liquid line shut-off valve near the purger. The liquid

line supplies refrigerant during start-up and feeds makeup liquid as required. The only requirement is the liquid

supply pressure must be sufficiently above the purger

evaporator pressure, usually greater than 60 psi (4.1 bar).

During operation, only 5% of the liquid refrigerant required

for cooling comes from the liquid line. The remainder of

the refrigerant is condensate from the foul gas line, which

is collected in the drain, condensed in the coil, and into

the evaporator.

WATER LINE

The APM has an automatic water bubbler to eliminate any

water bottle attention. Connect the water supply to the

purger water shut-off valve (See Figure 1). Water pressure

should be between 30 and 80 psig (2 and 5 bar). The

factory-installed flow controller limits the amount of water

going into the bubbler.

The transparent tube of the water bubbler may become

coated with mineral deposits after a period of time. These

deposits can be removed by adding a cup of vinegar to the

water in the bubbler and cleaning the clear tube through

the top plastic fitting with the brush supplied. A water

conditioning filter cartridge and housing are available for

abnormally hard water.

DRAIN LINE

A 1” PVC socket water drain connection is located at the

bottom of the bubbler (an alternate 1” FPT threaded adapter

is also supplied). The water should flow to a suitable drain.

Initially, fill the water bubbler with water via the threaded

plug located at the top of the bubbler. Keep the plug

lubricated and hand tight. A circular, thin, plastic “stickon” acts as a bubbler relief device in case of water drain

plugging. The drain line should be supported to prevent

undue stress on the water bubbler.

OIL DRAINS

There are two 3/8” valve oil drain connections near the

bottom of purger (see Figure 1) from which oil can be

drained. These valves are fitted with 5/16” (8 mm) hex

socket plugs. Before draining oil, first close the liquid and

foul gas lines to prevent additional liquid from entering the

purger. Wait approximately one half hour and then turn

the purger off. Allow the purger to pump out, then close

the suction line shut-off valve. Use normal refrigerant oil

draining precautions to prevent human or property damage.

In general, oil will not be a problem unless the liquid line

is connected to a vessel or line where oil can enter the

purger. See also the Caution section on page 14. Escaping

refrigerant may cause personal injury, particularly to the

eyes and lungs.

LEAK TEST

Use standard refrigeration procedures to check the APM

for leaks before placing it into service. See also the

Caution section on page 14. Manually open one purge

point solenoid valve. Open the foul gas line shut-off valve

and wait a few moments for the flooded evaporator to

pressurize through the metering orifice. Allow pressure to

build to condensing pressure, as shown on the high side

pressure gauge. Close the foul gas line shut-off valve and

check the purger for leaks.

APM-001e

AUG 2015

4

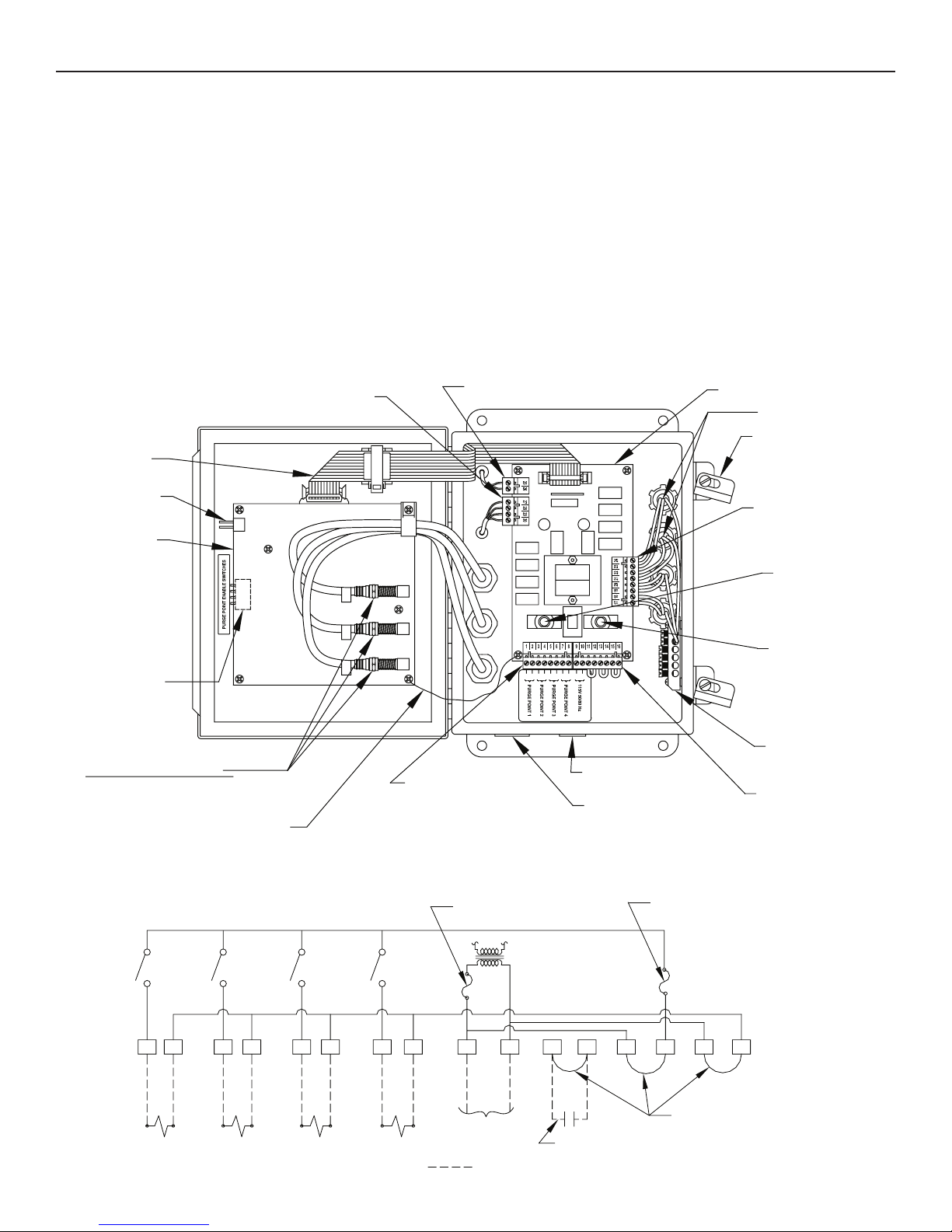

SECTION 2 ELECTRICAL INSTALLATION & OPERATION

PRESSURE TRANSDUCER

P

P

CONTROL BOAR

TEMPERATURE SENSOR

PURGE POIN

CABL

S

POWER BOARD

REMOTE PURGE POINT SOLENOID

ELECTRICAL CONNECTIONS

The standard electrical requirement for the APM is 115V

50/60 Hz. Also available is 230V 50/60 Hz. Main supply

voltage fluctuations should not to exceed ± 10% on nominal

voltage. Connect APM to a dual pole external switch or

circuit breaker suitable for full disconnection. Locate this

switch or circuit breaker nearby. The control cabinet has

a bottom ½” knockout for power connection and bottom

3/4” knockout for individual purge point solenoid valves

(See Figure 4). Any additional knockouts, if necessary,

should be made on the bottom of the control cabinet. A

grounding block inside the control cabinet is provided for 3

CONTROL CABINET (INSIDE VIEW)

Figure 4

PLUG-IN CONNECTOR

E

RESET PINS

CONTROL BOARD

AND SHIELD

D

1

wire purge point solenoid coils. Carefully study the wiring

diagram below (Figure 5) to avoid electrical short circuits.

Connect electrical wiring from each purge point solenoid to

the remote purge point solenoid plug-in connector screw

terminals (1 through 8) plus the grounding block. Normally,

the voltage of the remote purge point solenoid valves is the

same as the purger. However, if the purge point solenoid

valve coil voltage is different, simply remove and discard

the factory installed jumpers between terminals 13 & 14 and

15 & 16. Bring the purge point solenoid line (L1) connection

to terminal 14 and neutral (L2) to terminal 16.

PLUG-IN CONNECTOR

F6A

F6B

POWER BOARD

RTV SILICONE SEALANT

CONTROL BOX LATCH

PURGER SOLENOID

PLUG-IN CONNECTOR

REMOTE PURGE

POINT SOLENOID

REPLACEABLE 3 AM

FUSE (P/N 20-1698)

ENABLE SWITCHES

T

COAXIAL CONNECTORS

1-DRAINER LEVEL SENSOR

2-LOW SIDE LEVEL SENSOR

3-HIGH SIDE LEVEL SENSOR

GROUNDING WIRE

#1 #2 #3 #4

#1

PURGE POINT SOLENOID VALVES

#2 #3 #4

2

POWER BOARD

REPLACEABLE 3 AM

3

REMOTE PURGE

POINT SOLENOID

PLUG-IN CONNECTOR

NLLLN NNLLN

1/2'' KNOCKOUT

3/4'' KNOCKOUT

FUSE (P/N 20-1698)

GROUNDING BLOCK

POWER / INTERLOCK

PLUG-IN CONNECTOR

WIRING DIAGRAM

Figure 5

POWER BOARD REPLACEABLE

3 AMP TYPE F FUSE (P/N 20-1698)

LINE

NEUTRAL

LINE VOLTAGE

OPTIONAL INTERLOCK

(REMOVE JUMPER IF USED)

FIELD INSTALLED WIRING

5

REPLACEABLE 3 AMP TYPE F FUSE

(P/N 20-1698)

16151413121110987654321

FACTORY-INSTALLED JUMPER

APM-001e

AUG 2015

Loading...

Loading...