Page 1

Instruction Manual

HI 9914

Wall mounted

Fertigation

Controller

Manufacturers since 1978

1

These Instruments are in

Compliance with the CE

Directives

Page 2

Dear Customer,

Thank you for choosing a Hanna Product. Please read this instruction

manual carefully before using the instrument.

This manual will provide you with the necessary information for a correct

use of the instrument, as well as a precise idea of its versatility.

If you need more technical information, do not hesitate to e-mail us at

tech@hannainst.com.

These instruments are in compliance with CE directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ......................................................... 3

GENERAL DESCRIPTION ................................................................. 3

MECHANICAL LAYOUT ................................................................... 5

FUNCTIONAL DESCRIPTION ........................................................... 6

SPECIFICATIONS........................................................................... 8

INSTALLATION ...........................................................................10

TANK ASSEMBLY SETUP .............................................................. 10

CONNECTIONS AND WIRING........................................................ 12

CONTROLLER START-UP .............................................................. 18

NORMAL OPERATION .................................................................19

ALARM CONDITIONS .................................................................. 22

CONTROLLER SETTINGS............................................................... 23

CALIBRATION ............................................................................. 26

pH ELECTRODE CONDITIONING & MAINTENANCE ........................... 29

CONDUCTIVITY PROBE MAINTENANCE ........................................... 31

ACCESSORIES ............................................................................. 32

APPENDIX .................................................................................. 33

A-pH VALUES AT VARIOUS TEMPERATURES ............................. 33

B-NUTRIENT SOLUTION - TABLES ........................................... 34

C-INSTALLATION EXAMPLES.................................................... 36

WARRANTY ................................................................................ 38

CE DECLARATION OF CONFORMITY ............................................... 39

2

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has occurred during shipping. If there

is any noticeable damage, notify your Dealer.

Note: Save all packing materials until you are sure that the instrument

functions correctly. Any defective item must be returned in the

original packaging, together with the supplied accessories.

• Read carefully the instructions before using the instrument.

• Never install the controller outdoors, in a wet or humid area or under

direct sun light. Nor install the controller where liquids may be

sprayed or poured on it.

• The instrument has to be connected to a mains socket.

• The instrument’s mains power line is protected by a 400mA fuse. Use

only a 400mA fuse for replacement.

• The instrument’s dosage, water nozzle, feeding pump, circulation

pump and alarm terminals are protected by separate 2A fuses. Use

only 2A fuses for replacement.

GENERAL DESCRIPTION

HI 9914 Wall Mounted Fertigation Controller is designed to meet specific

process control requirements in agricultural, horticultural and hydroponics applications.

The controller is provided with two measuring channels, one for pH and

one for Conductivity. The actual values of pH and Conductivity are

displayed separately on two large LCDs with backlight feature for a best

easy reading.

The EC probe is designed with a built-in temperature sensor which allows

the controller to automatically compensate for the temperature effect.

The matching pin prevents potential grounding problems and thus

ensure longer life to the pH electrode.

The controller includes two regulators for pH and Conductivity, each of

them can be adjusted from the front panel and the setpoint values will

be displayed.

The conductivity regulator adds fertilizer in order to increase the conduc-

3

Page 4

tivity of the irrigation water, while the pH regulator can be set for high

or low pH correction.

For a better result, the Conductivity and pH controls are time separated

and a timed operation mode avoids overdosing of fertilizer or acid.

The controller is designed with relay outputs for pH and Conductivity

control (2A/240V), each one corresponding to a status LED for visual

check.

Three level sensors are used to offer the best control of water level, alarm

conditions and irrigation sequences.

The beginning of the irrigation can be triggered through an external

signal, while an additional input allows to restart the cycle at any time.

The good water composition is signaled on the front panel and with an

external signal for remote operating purposes.

The controller is equipped with an alarm system activated when an

unusual working condition occurs.

A humidity detector can be used to stop the controller if any leakage is

detected.

Water nozzle, Circulation pump, Feeding pump and Alarm are equipped

with 2A (240V) relays.

Two models of HI9914 controller are available, according to the required

power supply: 220/240V or 110/115V, at 50/60Hz.

4

Page 5

MECHANICAL LAYOUT

Front view

The molded mounting holes in the 4 corners provide for quick and secure

installation. No additional tool is needed. All the electrical connections

and control are located on the front panels so that adjustments can be

made without removing the unit.

Bottom view

The modular design isolates the control circuitry from the contacts, making possible to wire the connections and then close the compartment.

Adjustments can be made through the “control area” (left panel),

without open the connection compartment (right panel).

5

Page 6

FUNCTIONAL DESCRIPTION

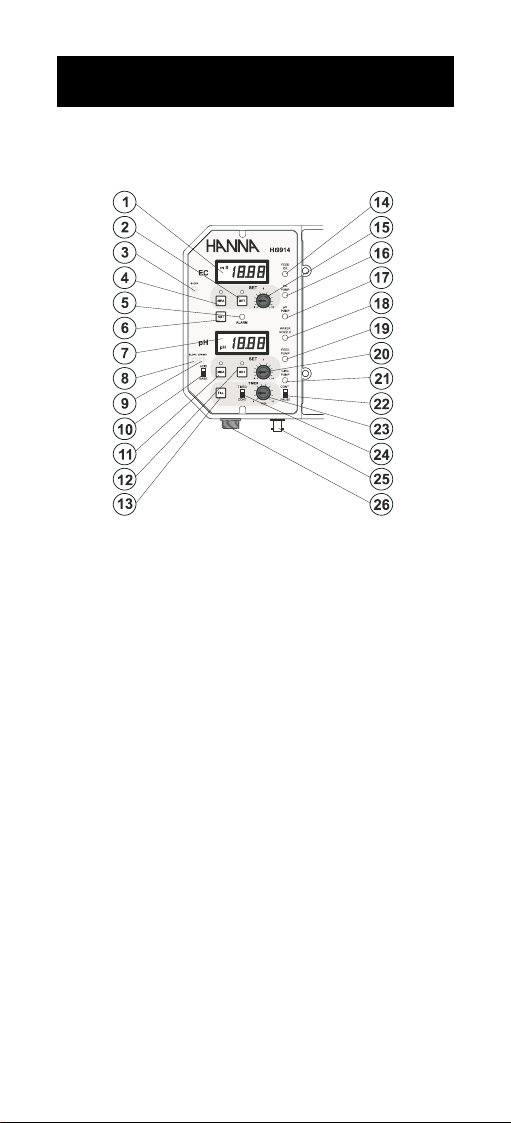

LEFT PANEL

1. LCD for Conductivity readings

2. EC SET button

3. EC slope adjustment trimmer

4. EC MEAsure button

5. Alarm LED

6. Reset button

7. LCD for pH readings

8. pH slope adjustment trimmer

9. pH offset adjustment trimmer

10. Acid / Base selector switch

11. pH MEAsure button

12. pH SET button

13. FILL button

14. Feed OK LED

15. EC setpoint knob

16. EC pump LED

17. pH pump LED

18. Water nozzle LED

19. Feed pump LED

20. pH setpoint knob

21. Circulation pump LED

22. RUN/STOP switch for Circulation pump

23. Timer knob

24. Timer mode selection switch

25. BNC connector for pH electrode

26. DIN connector for EC probe

6

Page 7

RIGHT PANEL

1. Connections for matching pin

2. EC analog output

3. pH analog output

4. Level sensors input

5. Mains power fuse

6. Fuse for pH and EC correction dosing pumps

7. Fuse for Water nozzle relay

8. Fuse for Feeding pump

9. Fuse for Circulation pump

10. Fuse for Alarm relay

11. Feed OK output

12. Connections for external fill switch

13. Irrigation start

14. Mains power transformer

15. Humidity sensor input

16. Power input

17. pH and EC pumps output

18. Water nozzle output

19. Feeding pump output

20. Circulation pump output

21. Alarm output

7

Page 8

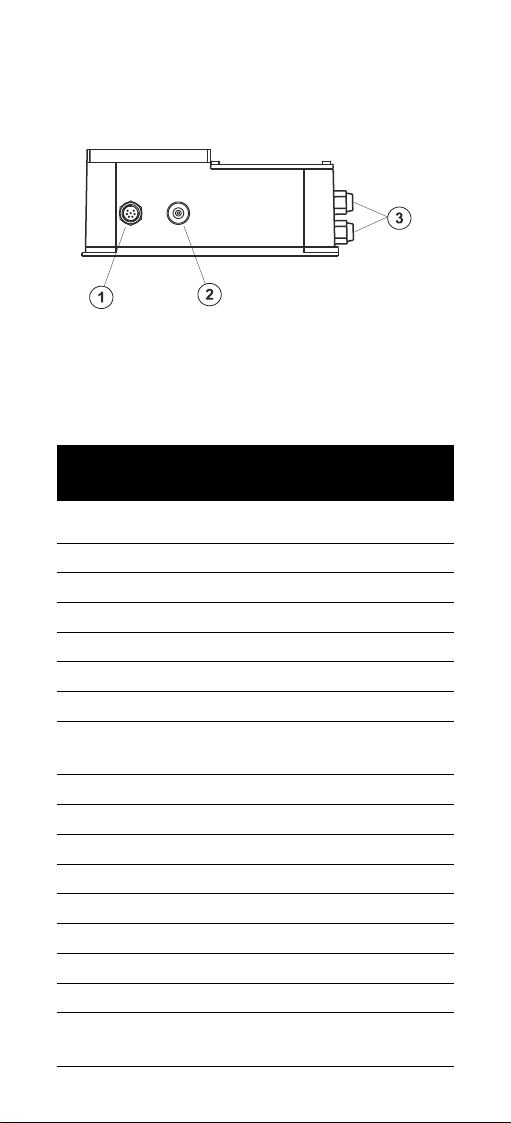

Bottom view

1. DIN connector for EC probe

2. BNC connector for pH electrode

3. Wiring access ports

SPECIFICATIONS

Conductivity

Range 0.00 to 10.00 mS/cm

Resolution 0.01 mS/cm

Accuracy (@20ºC/68ºF) ±5% Full Scale

Typical EMC deviation ±2% Full Scale

Setpoint Adjustable, from 0.50 to 10.00 mS/cm

Temp.Compensation Automatic from 0 to 50°C

Calibration Manual, through slope (80-120%) trimmer

on the front panel

Analog output 0-5V ±5% (0.5V / mS)

Controller output 2A, 220V relay

pH

Range 0.00 to 14.00 pH

Resolution 0.01 pH

Accuracy (@20ºC/68ºF) ±0.02 pH

Typical EMC deviation ±0.1 pH

Setpoint Adjustable, from 0.5 to 14.0 pH

Calibration Manual through offset (±2 pH) and slope

(80 to 120%) trimmers on the front panel

8

Page 9

Analog output 0-7V ±5% (0.5V / pH)

Controller Output 2A, 220V relay

other features

Timer Adjustable, from 1 to 10 min within a

15-minutes-time frame

Feed OK output 12V, 15 mA current source

Humidity sensor Active when resistivity is below 220 KΩ

Water nozzle output 2A, 220V relay

Circulation pump output 2A, 220V relay

Feeding pump output 2A, 220V relay

Alarm output 2A, 220V relay

Water level inputs Contact type water level sensors

User input Contact type switch

External FILL button Contact type push-button

Power supply 220/240V or 110/115V; 50/60Hz

Environment -10 to 50°C (14 to 122°F);

RH 95% max. non-condensing

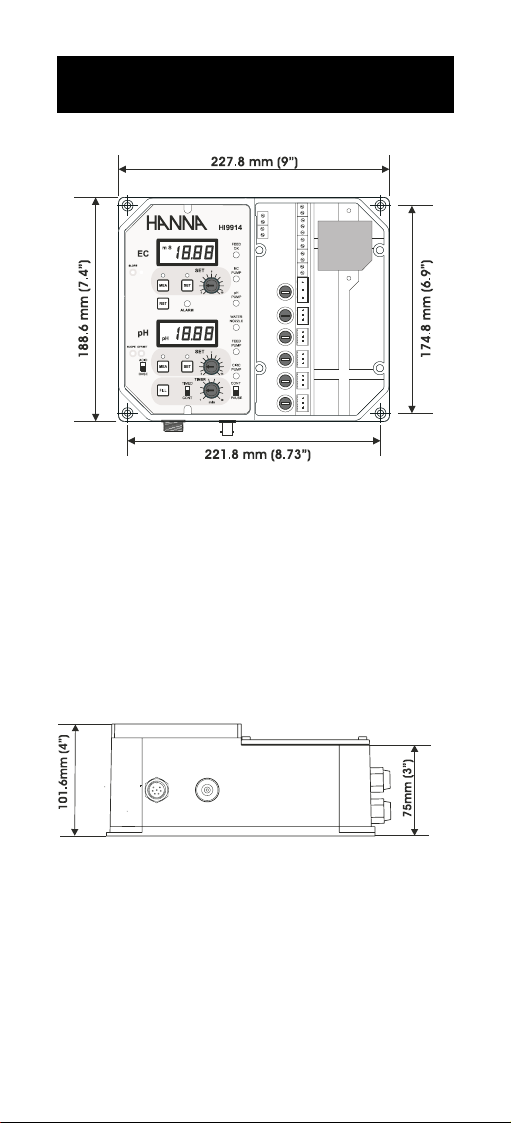

Dimensions 189 x 228 x 102 mm (7.4 x 9 x 4”)

Weight 1.75 Kg (3.85 lb.)

9

Page 10

INSTALLATION

Install the HI 9914 controller on a wall, indoors, in a dry area and not

under direct sun light. Assure that liquids can not be sprayed or poured

on it. Fix the controller at a proper height to easily reach the front panels

and fix the 4 screws at the 4 corners.

Install the controller near the tank to keep short the cables of pH

electrode and Conductivity probe.

Assure the proper working voltage.

TANK ASSEMBLY SETUP

HI 9914 can work with different tank volumes and with various complexity of tank assembly. For proper operation of the controller, the tank

assemblies must be set minding the following:

- the pH electrode and EC probe should rapidly detect any modifications

in the water characteristics;

- it is recommended to use a circulation pump to mix water with fertilizer

and acid;

- fertilizer and acid should be added to the water at distance from sensors

to assure good mixing before the measuring point is reached;

- make sure that the pH electrode is always wet;

- the level sensors must be in the correct order, bottom to top: low level,

normal level and high (alarm) level;

- place the sensors in the area with the minimum waves amplitude;

- when a level is reached, the corresponding level sensor will close the

contact;

- the humidity detector must be placed outside the tank, where water

leakage can be detected;

- the inlets for the circulation and the feeding pumps must be under the

minimum water level (low level sensor);

- the normal level sensor must be used in all tank arrangements;

- if the high (alarm) level sensor is not used, leave the pin unconnected;

- if the low-level sensor is not used, connect the corresponding pin to the

common;

- if the humidity sensor is not used, leave the pin unconnected;

- for activate external refill, press the corresponding push-button.

10

Page 11

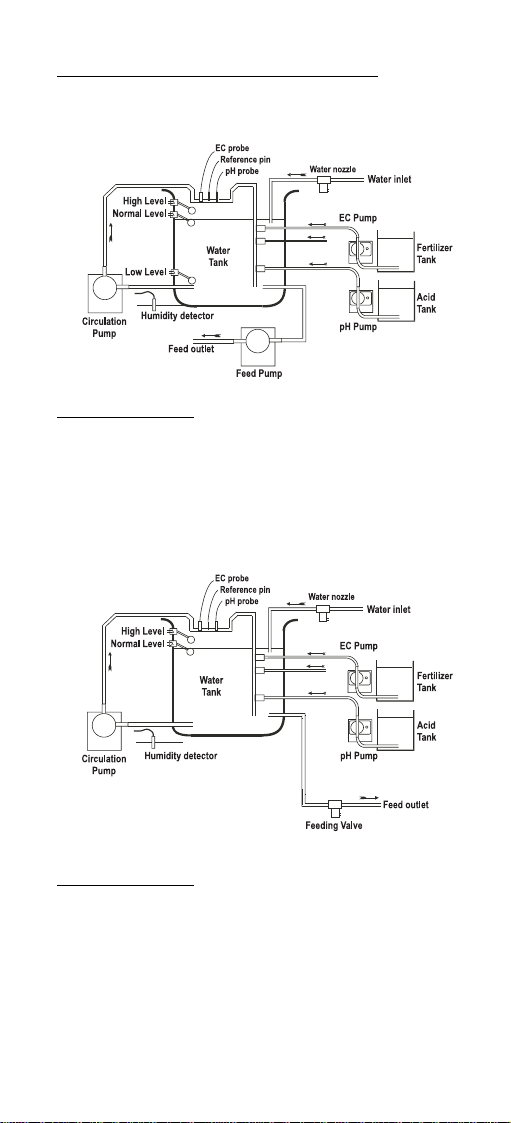

Typical arrangements for the Tank assembly

Complete tank assembly: all the sensors and pumps are mounted; the

best control of water composition and irrigation sequence is assured. The

inlet and outlet of the circulation pump are below the Low Level to avoid

that the pH electrode remains dry.

Simplified tank assembly: the low level detector is not used; the controller

does not react if the water level is too low.

Note: If a feed pump is used, provide a little water volume to keep

always the level in the tank above the circulation pump inlet.

Note: The inlet of the circulation pump must be below its outlet to avoid

damages to the pump itself.

11

Page 12

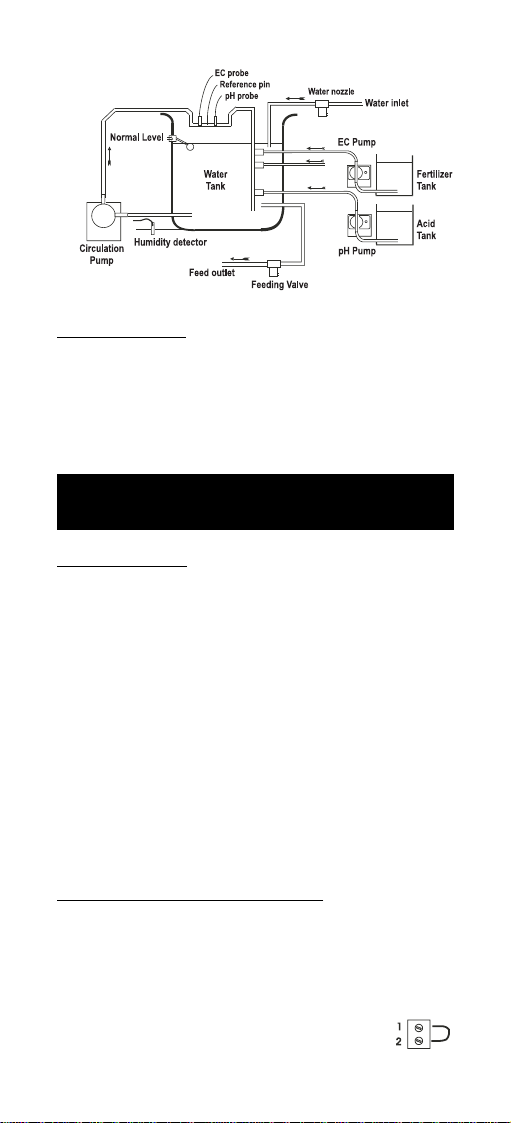

Minimal tank assembly: only the normal level sensor is used, the irrigation is made manually, regardless of the water composition or level. The

controller will refill the tank if the water goes under normal level for about

15 minutes or if the fill button is pressed.

Note: The inlet of the circulation pump must be below its outlet to avoid

damages to the pump itself.

CONNECTIONS AND WIRING

Wiring the controller

• Make sure the power supply is disconnected.

• Make sure all the auxiliary power sources are off.

• Unscrew the 4 screws from the right hand panel and remove the lid

and the gasket.

• Thread the wires through the access port on the right hand side of the

controller.

• Before connecting the controller to the mains, wire it completely,

connect the pumps, valves, alarm, probes, level sensors and user

input.

• Replace the lid. Connect the controller to mains line.

• Turn on all the auxiliary sources.

pH electrode and ground probe connections

• Attach the in-line pH electrode (for example HI 1001) to the BNC

socket on the bottom of the controller.

• Use the matching pin (differential input) to prevent potential grounding problems and thus ensure longer life to the electrode.

• If the matching pin is not used, short pin 1 and pin

2 of the external connector located in the right panel.

12

Page 13

• If the matching pin is used, connect

the matching pin terminal to the connector pin 2 located on the right panel.

• Immerse the matching pin near the pH electrode.

Conductivity probe connection

• Attach the conductivity probe (HI7632/D or HI3003/D) to the DIN

socket located on the bottom of the controller. Align the guide on the

connector with the socket, push-in the connector and tighten the

retainer ring.

• The probe is provided with a built-in temperature sensor, which allows

automatic temperature compensation of the readings.

Level inputs connections

All level sensors must have a contact type output.

If the water level is above the sensor position, the corresponding contact

is closed. If the water is below the sensor, the contact is open.

Each sensor will be connected between the INPUT COMMON (pin 9) and

the corresponding input pin (LOW LEVEL, NORM LEVEL, HIGH/ALARM

LEVEL).

13

Page 14

• Place the low-level sensor to indicate the minimum water level for the

correct function of both the circulation and feeding pumps.

• Connect the sensor between INPUT COMMON and LOW LEVEL pins.

• Place the normal-level sensor to indicate the filling level when the tank

is full.

• Connect the sensor between INPUT COMMON and NORMAL LEVEL pins.

• Place the alarm-level sensor to limit the highest water level.

• Connect the sensor between INPUT COMMON and HIGH (ALARM) LEVEL

pins.

Note: The level sensors act correctly if the sensor switch is closed when the

water is above the corresponding level

Irrigation start connection

Connect the irrigation-start switch

between INPUT COMMON and IR-

RIGATION START pins.

Irrigation can be controlled by:

• using a switch connected between the INPUT COMMON and IRRIGA-

TION START: the irrigation is started by closing the switch, and lasts

until the contact is open.

• using a 5V-logic signal, connected to the IRRIGATION START and

referred to INPUT COMMON: the irrigation starts at level “0” (0V)

and stops at level “1” (5V).

• using a level sensor that will be open when the desired level is

reached: the controller will irrigate until the desired level is reached,

and the irrigation will restart if the water falls below this level.

14

Page 15

External fill button connection

• Connect the button

between FILL and IN-

PUT COMMON pins.

• The tank will be immediately filled with

water if the external

fill button is pressed

and the water level is

below the normal level

float.

External FEED OK connection

This output is a current source from the FEED OK pin.

• Connect a LED, buzzer or other

device between FEED OK and IN-

PUT COMMON pins.

• When the water composition is good

for irrigation, the FEED OK will

source about 15mA and activate

the device.

Analog output connections

• Connect an external device between the

EC+ and EC- (for Conductivity signal) or

pH+ and pH- (for pH signal) pins.

• The output voltage is related to the value displayed on LCD. For EC the

output will be 0V for 0.00 on LCD and 5V for 10.00 on LCD; for pH the

output will be 0V for 0.00 on LCD and 7V for 14.00 on LCD.

Note: Never connect “EC” with “pH”. Make sure there is no galvanic

connection between the EC and the pH analog outputs, otherwise

the measured values will be not reliable and probes can be

damaged.

Relay connections

The controller is provided with six relay outputs (2A, 220V) protected by

2A fuses.

When a relay is off the COMMON pin is connected with the NC pin; when

is on the COMMON pin is connected with the NO pin.

The NC pin is not accessible for the pH and EC pumps and the COMMON

15

Page 16

pin is the same, so that the voltage of the power source has to match the

working voltage of the selected device and both the pH and EC correction

pumps have to work at the same voltage.

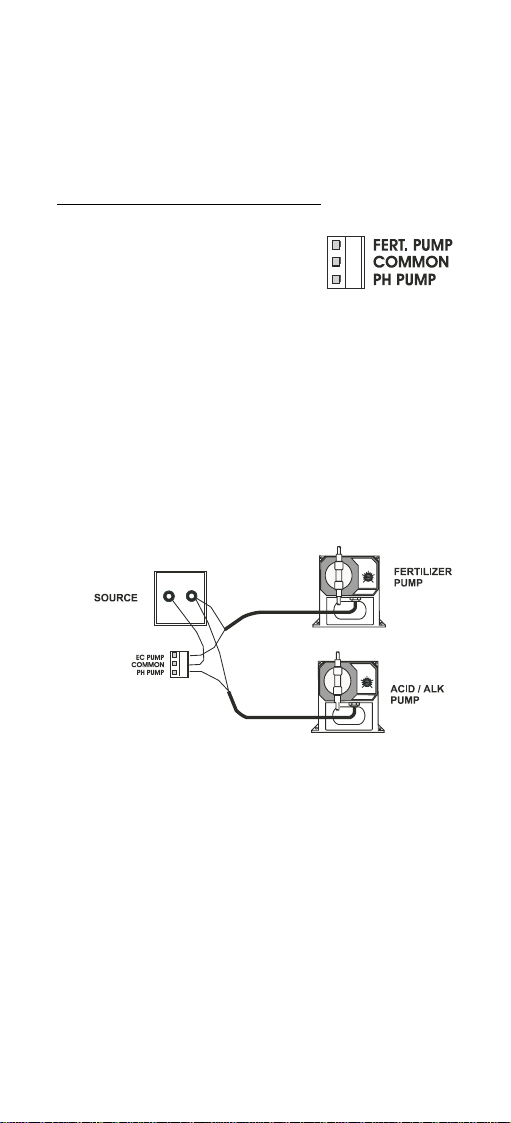

Acid and fertilizer dosing pump connection

The pH and EC correction relays (2A, 240V)

have a common pin: if the pH correction

pump is on, the COMMON pin is connected

to the pH PUMP pin; if the EC pump is

activated, the COMMON pin is connected to

the FERT. PUMP pin.

• Connect one pin of the source to the COMMON pin.

• Connect the pH correction pump between the pH PUMP pin and the

remaining pin of the source.

• Connect the EC correction pump between the FERT PUMP pin and the

remaining pin of the source.

Note: Both pH and EC correction pumps must have the same operating

voltage. The rated power of the pumps can be different.

16

Page 17

Water nozzle, Circulation and Feeding pump connection

The Water nozzle, Circulation pump and Feeding pump outputs are

relay type (2A, 240V). Both the NO (normally open) and NC (normally

closed) contacts are available to the user. If the device is off, the COM-

MON pin is connected to corresponding NC pin. If the device is on, the

COMMON pin is connected to the NO pin.

• Connect one pin of the source to the COMMON pin.

• Connect the device between the NO pin and the remaining source pin.

Alarm connection

The Alarm output is relay type (2A, 240V). Both the NO (normally open)

and NC (normally closed) contacts are available to the user. If the alarm

is off, the COMMON pin is connected to the NC pin. If the alarm is off, the

COMMON pin is connected to the NO pin.

• Connect one pin of the source to the COMMON pin of the alarm

output.

• Connect the alarm device between the NO output pin and the

remaining source pin.

17

Page 18

Main power supply connection

Before connecting the unit to the mains, make sure the controller is

completely wired and all the connections for pumps, alarm, probes, etc.

have been done.

• Connect the mains power wires to the power

supply input pins.

• Replace the right panel lid and tighten the four

provided screws.

• Connect the controller to the mains.

CONTROLLER START-UP

Before starting-up make sure the controller has been properly calibrated,

and the pH and conductivity setpoints have been adjusted (see the

following pages).

The pH electrode, conductivity probe and any reference pin must be

properly connected and wired to the controller (see the section above).

The EC probe must be immersed in the solution above the air-vent holes

on the external sleeve, and installed in such a way to minimize the

presence of air bubbles (see probe installation tips at the end of the

manual).

Remove the protective cap from the pH electrode and immerse the

electrode (at least 4cm/1.5") into the solution to be tested. Install the

electrode in such a way that it permanently lies in the solution.

The level sensors, user input, external fill button and humidity sensor

must be connected accordingly with the chosen tank assembly.

If some of the inputs are not used, they must be connected as explained

in the TANK ASSEMBLY section.

The pumps, water nozzle and alarm must be wired as described above.

Turn on the water supply and start the controller by connecting it to the

mains power supply.

The HI 9914 controls different status and gives visual information through

various LED:

- When the dosing pumps are active, the corresponding EC and pH pump

LEDs are on.

- When the circulation or the feeding pump is running, the corresponding

LED is ON.

- When the water nozzle is open, the water nozzle LED is ON.

18

Page 19

- When the water is good for irrigation, the Feed OK LED is ON.

- If any alarm condition occurs (see pag.22), the ALARM LED turns ON.

The controller can be restarted by pressing the

RESET button.

If the alarm condition is still present, the controller goes back in alarm

status.

When the controller is powered, the actual pH and conductivity values

are displayed on the two LCDs in pH and mS/cm units respectively.

NORMAL OPERATION

When the HI 9914 controller is turned on, the meter performs a status

check of the level sensors and provides the commands depending on the

input status.

All the inputs have a delay of about 1 second in order to avoid wrong

commutations caused by the waves.

Step 1:

At start-up the controller checks the normal level and low-level sensors.

• If the tank is empty, both sensors are open and the controller goes

to step 2.

• If the low-level sensor is closed and the normal level sensor is open (the

water level is between low and normal level), the controller goes to

step 3.

Step 2:

The water nozzle is activated (open) and the tank is filled with water.

When the low level is reached, the controller goes to step 3.

• If the controller remains in this status for more than 30 seconds, an

alarm condition occurs.

Step 3:

The water nozzle is open, the circulation pump is running and the tank

is filled with water.

When the normal level is reached (the normal level sensor is closed) the

controller goes to step 4.

19

Page 20

Step 4:

The water nozzle is closed, circulation pump is running and the Conductivity & pH controls are activated. The Conductivity control has the

priority over the pH control.

• If the timer feature is activated, the control is on for a selected period

(1-10 minutes) and off for the remaining period until 15 minutes.

• If both the conductivity and pH values are good for at least 30

seconds, the controller goes to step 5.

• If the normal level sensor remains open for about 15 minutes, the

controller goes back to step 3.

Step 5:

The Conductivity & pH values are good. The Circulation pump is running

and the controller waits for user input. This state is signaled on the front

panel by FEED OK LED and externally through a 15mA current between

the FEED OK and INPUT COMMON pins.

• If the water composition is not good, the controller goes back to step 4.

• If the normal level sensor remains open for about 15 minutes, the

controller goes back to step 3.

• If the FILL button (or the external fill button connected between FILL

and INPUT COMMON) is pressed while the NORMAL LEVEL sensor is

open, then the controller goes back to step 3.

• If the user input command is active (the contact is closed between the

USER INPUT and INPUT COMMON pins), the controller goes to step 6.

Step 6:

The Feeding pump is activated. The control of Conductivity and pH is

inhibited.

• If the user input becomes inactive (the contact between the USER

INPUT and INPUT COMMON pins is open), the controller goes back

to step 3.

• If the low level is reached (the low-level sensor contact is open), the

controller goes back to step 3.

• If the water remains under normal level for about 15 minutes (the

normal level contact is open), the controller goes back to step 3.

The tank can also be filled by pressing the FILL button on the front panel

(or the external fill button connected between FILL and INPUT COMMON

pins) when the irrigation is completed.

20

Page 21

If the CONT/PAUSE switch of the Circulation pump is in

CONT position, the circulation pump will act as described

above.

If the CONT/PAUSE switch of the Circulation pump is in

PAUSE position, the circulation pump will not run the step 5.

When the low-level sensor is not used, the low-level condition is not sensed

by the controller. The user must take care to stop the user input command before the water in the tank goes below the low level.

When the high (alarm) level sensor is not used and

the normal level sensor does not work properly, the

controller is unable to detect when the water reaches

the high (alarm) level. In order to stop the controller, the humidity sensor must be placed where it can

sense if the water pours down from the tank.

If the tank assembly is minimal, the irrigation takes place without using

the user input command. Only the normal level and humidity sensors are

used. The controller fills the tank at normal level and begins the Conductivity & pH correction. The user can add water at any time or wait until

a good water composition is signaled.

21

Page 22

ALARM CONDITIONS

When an alarm condition is reached, the ALARM LED turns ON and the

alarm relay contact is closed (short between the COMMON and NO pins).

All the pumps and the water nozzle are off. The Conductivity and pH

measuring channels display the EC and pH values.

An alarm condition occurs when:

• the water remains below the low level (the sensor contact is open) for

about 30 seconds;

• the high (alarm) level is reached (the sensor contact is closed);

• the humidity sensor detects water leakage;

• an impossible condition is detected, for example when the low level is

not reached and the normal level is reached.

Reset button

To return to normal function, it is necessary that:

• the water level in the tank decreases

below the high (alarm) level sensor;

• the level sensors operate correctly;

• the humidity sensor is dry;

• the RESET button is pressed.

22

Page 23

CONTROLLER SETTINGS

SETTING THE pH CONTROL

To adjust the pH setpoint:

• Press the SET button close to the pH display to read the setpoint value.

• Turn the SET knob until the display shows the desired value.

• Return to measurement mode by pressing the MEA button.

To select the dosing direction:

• Select the desired solution for pH correction by setting the ACID/BASE

switch.

• If the switch is in the ACID position, the pH pump is activated when

the pH value exceeds the setpoint. The controller will dose

acidic solution to reduce the pH until the user-selected

setpoint is reached.

• If the switch is in the BASE position, the pH pump is

activated when the pH value falls below the setpoint.

The controller will dose alkaline solution to increase the

pH until the user-selected setpoint is reached.

SETTING THE EC CONTROL

To adjust the Conductivity setpoint:

• Push the SET button close to EC display to read the setpoint value.

23

Page 24

• Turn the SET knob until the display shows the desired value.

•Turn back in measurement mode by pressing the MEA button.

Note: The internal pH and EC regulators have a small hysteresis to

prevent oscillations of the relay output that can damage the

pumps. As a result, the selected pH and EC values are equal to

the set value ± hysteresis value.

SETTING EC AND pH CONTROL TIMERS

The Timer feature is provided to avoid overdosing in a system with a long

response time. The running time of the dosing pumps is set through the

TIMER knob. The total time frame is 15 minutes. For example, if the

TIMER is set to 3 minutes, the EC or pH correction pumps will be active for

3 minutes and off for 12 minutes (3+12=15 minutes).

Setting the timer:

• In order to activate the timed dosing feature put the TIMED/CONT

switch to the TIMED position.

• To set the duty cycle of the dosing

pumps, turn the TIMER knob to the

desired position, from 1 to 10 minutes,

depending on the tank volume.

When the TIMED/CONT switch is at the CONT position, the EC and pH

correction pumps will run continuously.

24

Page 25

SETTING THE CIRCULATION PUMP WORKING REGIME

• Set the CONT/PAUSE switch to CONT to enable a continuous running

of the Circulation pump (if no ALARM condition is present).

• Set the CONT/PAUSE switch to PAUSE to stop the Circulation pump

after the good water composition is reached (do not run the Step 5).

The pump will start again when an adjustment of water composition

is needed or the irrigation takes place.

25

Page 26

CALIBRATION

Disconnect the pumps, the water nozzle and the alarm or assure that the

start of one of them will cause no damage.

ON, OFF or blinking LEDs have no effect on the measurement and

calibration of pH and EC.

pH CALIBRATION

To calibrate the controller, first set it in measurement mode by pressing

the MEA button (MEA LED is on).

Make sure the pH electrode and matching pin have been properly

connected and wired to the controller, and the meter is plugged to the

mains.

The calibration should be performed at a temperature similar to that of

the liquid to be monitored. Use the Hanna Checktemp (or other accurate thermometer) as reference.

Remove the protective cap from the electrode.

During calibration, move the electrode and the ground probe (if in use)

together from one buffer to the next.

Offset adjustment

• Rinse the tip of the electrode with pH7.01

solution (HI 7007), dip the bottom 4 cm

(1.5") of the electrode and ground probe in

the pH7.01 buffer.

• Place also the Checktemp thermometer in

the solution.

• Wait for the reading to stabilize and adjust

the OFFSET trimmer to display the correct

pH value at the measured solution temperature; e.g. 7.01 at 25°C (77°F). See the

“pH VALUES AT DIFFERENT TEMPERATURES”

section.

26

Page 27

Slope adjustment

• Rinse the electrode and the ground probe

thoroughly with water and immerse the

bottom 4 cm (1.5") in a pH10.01 (HI 7010)

or a pH4.01 (HI 7004) buffer solution.

• Stir the electrode and wait for the reading

to stabilize before adjusting the SLOPE trimmer to display the correct pH value at the

measured solution temperature; e.g. 4.01

(or 10.01) at 25°C (77°F). See the “pH

VALUES AT DIFFERENT TEMPERATURES” section.

The pH calibration is now complete.

CONDUCTIVITY CALIBRATION

To calibrate the controller, first set it in measurement mode by pressing

the MEA button (the MEA LED lights up).

Make sure the conductivity probe has been properly connected and wired

to the controller and the meter is plugged to the mains.

The calibration should be performed at a temperature similar to that of

the liquid to be monitored.

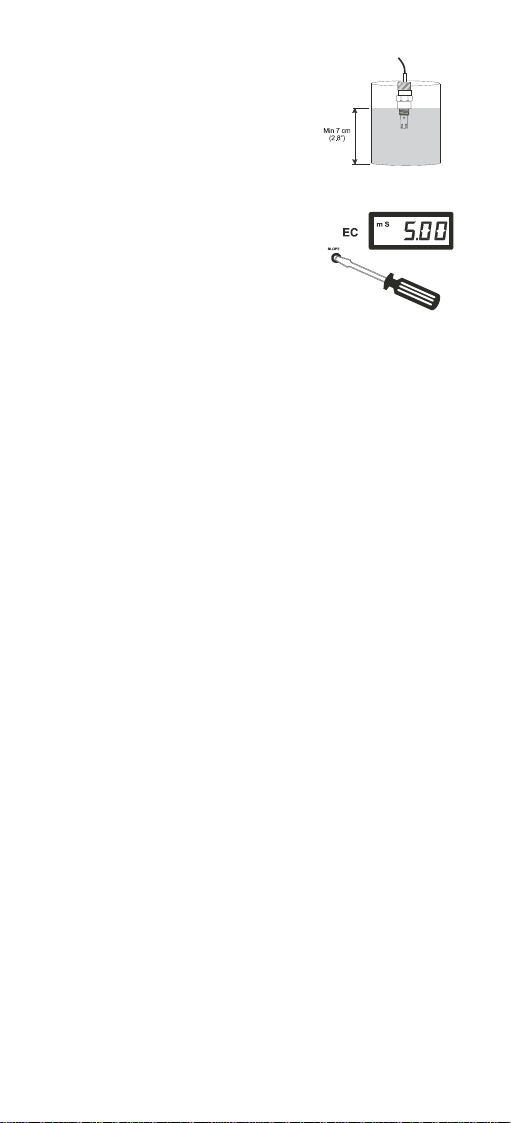

Slope adjustment

• Pour in a beaker a solution of known conductivity value, which should

be close to the sample stream to be monitored. For example, if

measurements are in the 1.2 to 2.5 EC range, choose HI 7031 (1.41

mS/cm @25°C). Similarly, if measurements are in the 4 to 6 mS/cm

range utilize HI 7031 or HI 7039 (5.00 mS/cm @25°C).

• Immerse the probe in the beaker ensuring that the holes on the probe

sleeve are completely covered.

27

Page 28

• Stir the probe and tap it gently to the

bottom of the beaker to ensure that

any air bubbles trapped inside it.

For best results, do not put the probe

close to the walls of the beaker or lying

on the bottom.

• Wait for the reading to stabilize. Adjust

the SLOPE trimmer to display the same

value as the calibration solution

@25°C. For example, with HI 7039

buffer solution, adjust the trimmer to

display “5.00”.

Note: Once the controller has been calibrated by referring to the value

@25°C of the calibration solution, all the subsequent measurements are temperature compensated to 25°C. Temperature compensation to a different temperature reference point can be obtained by calibrating the meter to that value. For example, the

conductivity value of HI 7031 @20°C is 1.28 mS/cm. By adjusting the trimmer to display this values, all the subsequent measurements will be compensated to a temperature of 20°C.

The conductivity calibration is now complete.

28

Page 29

pH ELECTRODE CONDITIONING

& MAINTENANCE

Preparation

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DEPOSITS ARE PRESENT. This is

normal with pH electrodes and they will disappear when rinsed with

water.

During transportation tiny air bubbles may have formed inside the glass

bulb (membrane). Shake down the electrode, as you would do with a

glass thermometer to remove the bubbles.

If the bulb and/or junction are dry, soak the electrode overnight in HI

70300 Storage Solution.

Storage

To minimize noise and assure a quick response time, the glass bulb and

the junction should be kept moist at any time and not allowed to dry out.

This can be achieved by installing the electrode in such a way that it is

constantly in a well filled with the sample.

When not in use, pour a few drops of HI 70300 Storage Solution or HI

7007 pH 7.01 Buffer Solution in the protective cap and place it on the

electrode.

NEVER USE DISTILLED OR DEIONIZED WATER FOR STORING PURPOSES.

Periodic maintenance

Rinse off any salt deposits with water.

Inspect the electrode and the cable. The electrode connection cable must

be intact. There must be no points of broken insulation on the cable or

cracks on the electrode stem or bulb. If any scratches or cracks are

present, replace the electrode.

The connector must be perfectly clean and dry.

Cleaning procedure

Soak the electrode in HI 7061 General Cleaning Solution for approximately half an hour.

For a more specific cleaning procedure, refer to the electrode’s instruction

manual.

Note: After performing a cleaning procedure, rinse the electrode thor-

oughly with distilled water and recalibrate the controller.

29

Page 30

Troubleshooting

Evaluate the electrode performance based on the following:

• Noise (readings fluctuate up and down) could be due to clogged/dirty

junction:

- Dry Membrane/Junction: soak in HI 70300 Storage Solution overnight.

Check that the installation has been done to create a well to maintain

the electrode bulb constantly moist.

• Low Slope:

- Check the electrode for cracks in the glass stem or bulb (replace the

electrode if cracks are found).

- Make sure that cable and connections are neither damaged nor lying

in a pool of water or solution.

• Slow Response/Excessive Drift:

- Soak the tip in HI 7061 Solution for 30 minutes, rinse thoroughly with

distilled water and then recalibrate the meter.

Note: It is always recommended to keep at least one spare electrode

handy. When anomalies are not resolved with a simple maintenance, change the electrode (and recalibrate the controller) to see

if the problem is solved.

30

Page 31

CONDUCTIVITY PROBE MAINTENANCE

Preparation

Make sure that the protective sleeve is on the probe shaft and is intact.

Storage

Conductivity probes should be stored dry. If they are not to be used for a

while, clean and dry them thoroughly before storing them in a dry place.

Periodic maintenance

Inspect the probe and the cable. The cable used for the connection to the

controller must be intact. There must be no points of broken insulation on

the cable or cracks on the probe sleeve. If any cracks are present, replace

the probe and cable.

The connector must be clean and dry.

Cleaning procedure

Soak the probe in HI 7061 General Cleaning Solution for 1 hour.

If the probe has been left in highly concentrated fertilizer solution and

does not seem to have become clean, repeat the cleaning procedure. The

pins can also be cleaned with a cloth. The cloth has to be made of a soft

and nonabrasive material and does not scratch the pins.

Note: After performing a the cleaning procedure, rinse the probe thor-

oughly with distilled or tap water. Dry the probe and recalibrate

the controller.

Troubleshooting

• If the controller does not respond properly or constantly reads zero or

a value close to it:

- Check the probe and cable for cracks and replace it if needed.

• If the controller display shows 1. :

- The cable may be shorted or the probe broken. Replace it if needed.

• If the response seems sluggish:

- Follow the above cleaning procedure.

• If there are anomalies such as fluctuating numbers:

- Ensure that the probe has been properly mounted and constantly lies

in a well filled with solution.

31

Page 32

- Air bubbles also disturb measurements and the probe should be

installed in such a way as to minimize them.

Note: It is always recommended to keep at least one spare probe

handy. When anomalies are not resolved with a simple maintenance, change the electrode (and recalibrate the controller) to see

if the problem is alleviated.

Note: Ensure that the probe is installed in such a way that it perma-

nently lies in the solution whether in the tank or the circulation

pipe.

ACCESSORIES

pH electrodes

HI 1001 pH electrode for continuous flow-through monitoring

HI 1002 pH electrode for continuous flow-through monitoring

HI 1003 pH electrode with matching pin

EC probes

HI 7632/D Conductivity probe, ATC, 1/2” thread, with DIN

connector and 2m (6.6’) cable, for continuous flowthrough monitoring up to 3 atm pressure

HI 3003/D Conductivity probe, ATC, Pt-ring, Kynar® body,

1/2” thread, with DIN connector and 2m (6.6’)

cable, for continuous flow-through monitoring up to

6 atm pressure

pH calibration solutions

HI 7004L pH 4.01 buffer solution, 460ml bottle

HI 7007L pH 7.01 buffer solution, 460ml bottle

HI 7010L pH 10.01 buffer solution, 460ml bottle

pH electrode storage solution

HI 70300L Storage solution, 460ml bottle

EC calibration solutions

HI 7031L 1.41 mS/cm EC calibration solution, 460ml bottle

HI 7039L 5.00 mS/cm EC calibration solution, 460ml bottle

Electrode & probe cleaning solution

HI 7061L General cleaning solution, 460ml bottle

Other accessories

BL1.5, BL3, BL5, BL7, BL10, BL15, BL20

Dosing pumps with flow rate from 1.5 to 18.3 lph

(0.4 to 4.8 gph)

32

Page 33

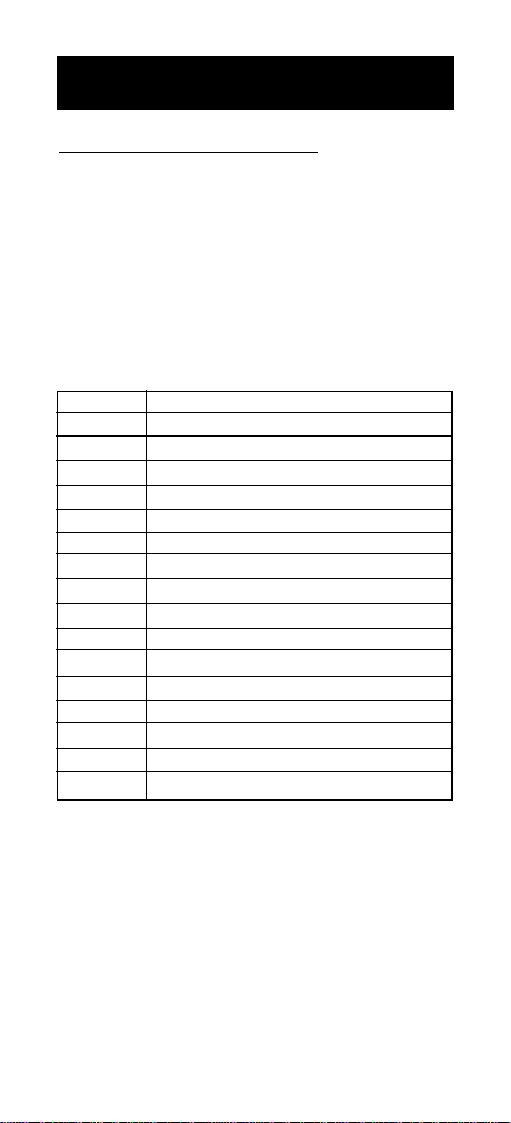

APPENDIX - A

pH VALUES AT VARIOUS TEMPERATURES.

The temperature directly affects the pH value.

For example, if the buffer’s temperature is 25°C (77°F), calibrate the

meter to read 7.01, 4.01 or 10.01; if the temperature is 20°C, calibrate

the meter to 7.03, 4.00 or 10.06; if the temperature is 50°C, calibrate

the meter to 6.98, 4.06 or 9.82; etc.

Please refer to the following chart for a more accurate pH calibration.

TEMP pH VALUES

°C °F 4.01 6.86 7.01 9.18 10.01

0

32

4.01

6.98

7.13

9.46

10.32

5

41

4.00

6.95

7.10

9.39

10.24

10

50

4.00

6.92

7.07

9.33

10.18

15

59

4.00

6.90

7.04

9.27

10.12

20

68

4.00

6.88

7.03

9.22

10.06

25

77

4.01

6.86

7.01

9.18

10.01

30

86

4.02

6.85

7.00

9.14

9.96

35

95

4.03

6.84

6.99

9.10

9.92

40

104

4.04

6.84

6.98

9.07

9.88

45

113

4.05

6.83

6.98

9.04

9.85

50

122

4.06

6.83

6.98

9.01

9.82

55

131

4.07

6.84

6.98

8.99

9.79

60

140

4.09

6.84

6.98

8.97

9.77

65

149

4.11

6.85

6.99

8.95

9.76

70

158

4.12

6.85

6.99

8.93

9.75

33

Page 34

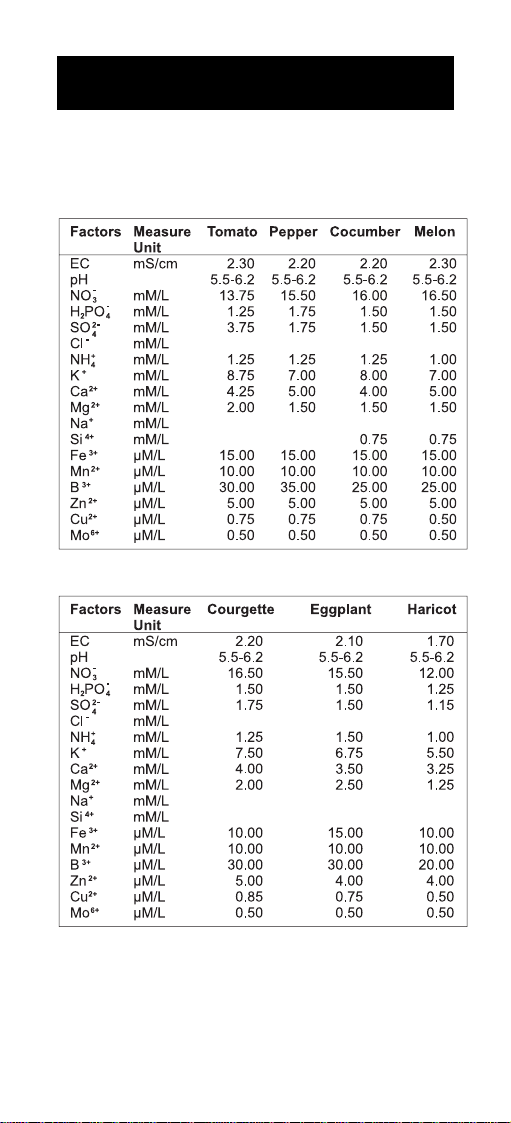

APPENDIX - B

Composition of nutrient solution for several plants growth in hydroponic

system utilized in nursery and cutting plants cultivation.

34

Page 35

Reference:

“Principi tecnico-agronomici della fertirrigazione e del fuori suolo”, pag.115,

published by “Veneto Agricoltura-Centro Sperimentale Ortofloricolo Po di

Tramontana”, coordinator Prof. F.Pimpini, Agricultural Faculty, University of Padova - Oct. 2001

35

Page 36

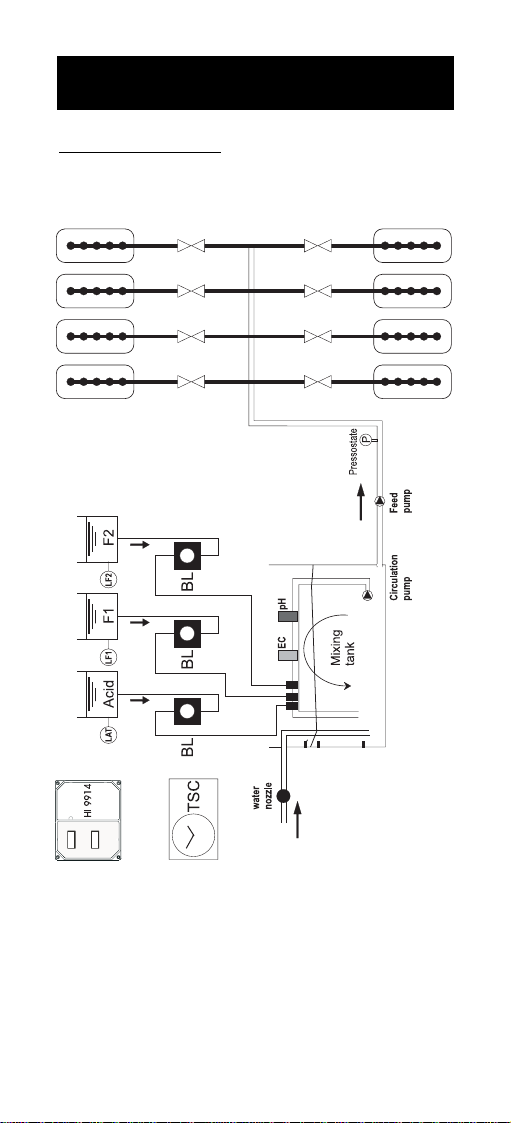

APPENDIX - C

INSTALLATION EXAMPLES

Block diagram for a typical installation of an irrigation system, with

HI9914 controller.

36

Page 37

Block diagram for an irrigation system with recirculation circuit.

37

Page 38

WARRANTY

All Hanna controllers are warranted for two years against defects in

workmanship and materials when used for their intended purpose and

maintained according to instructions. Electrodes and probes are war-

ranted for a period of six months.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered. This warranty is limited to free of charge or

replacement of the meter only, if any malfunctioning is due to manufacturing defects.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase, serial number and the nature of failure. If the repair is not covered

by the warranty, you will be notified of the charges incurred. If the

instrument is to be returned to Hanna Instruments, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping

any instrument, make sure it is properly packaged for complete protection.

All rights are reserved. Reproduction in whole or in part is prohibited without the written

consent of the copyright owner, Hanna Instruments Inc, 584 Park East Drive, Woonsocket,

Rhode Island, 02895, USA

Hanna Instruments reserves the right to modify the design, construction and

appearance of its products without advance notice.

38

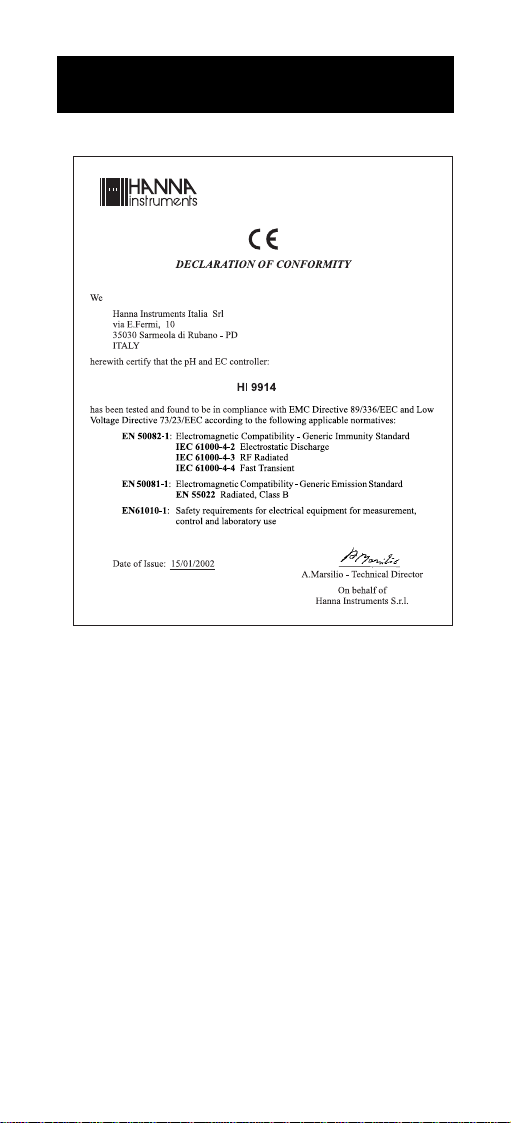

Page 39

CE DECLARATION OF CONFORMITY

Recommendations for Users:

Before using this product, make sure that it is entirely suitable for the environment in

which it is used.

Operation of this instrument in residential area could cause unacceptable interferences

to radio and TV equipment.

Any variation introduced by the user to the supplied equipment may degrade the

instrument’s EMC performance.

Unplug the instrument from the power supply before replacing the fuse or making any

electrical connections.

39

Page 40

07/02

www.hannainst.com

40

MAN9914

Loading...

Loading...