Page 1

Instruction Manual

HI 9910 - HI 9911

HI 9920

Wall Mounted

pH & ORP

Controllers

H

I 9

pH

O

F

F

S

E

T

O

N

A

L

A

R

M

O

F

F

3

0

2

4

0

0

5

1

0

0

0

6

0

-

1

7

0

8

1

0

.5

1

.

0

p

2

H

P

R

O

P

O

R

9

AC

ID

S

E

T

C

O

A

R

S

E

F

I

N

E

S

L

O

P

E

A

L

K

A

L

I

N

E

S

E

T

S

E

T

AC

ID

AC

ID

R

F

E

E

A

E

D

D

A

L

K

A

L

M

0

0

5

.

0

T

I

O

N

K

T

5

C

2

.5

A

L

°

C

A

K

7

.

5

1

4

5

1

0

5

2

AC

.

5

I

D

7

0

L

S

.5

S

E

C

9

O

0

N

D

S

1

E

T

T

I

N

G

S

M

IN

U

1

0

T

E

S

T

IM

E

R

http://www.hannainst.com

p

H

A

L

A

R

M

1

0

2

T

E

M

P

.C

O

M

M

P

.

T

C

AT

C

4

/

2

0

0

/

2

0

m

A

O

U

T

P

U

T

A

L

A

R

M

S

E

T

A

C

ID

S

E

T

A

L

K

L

I

N

E

Compliance with the CE Directives

These Instruments are in

Page 2

Dear Customer,

Thank you for choosing a Hanna Product.

Please read this instruction manual carefully before using the

instrument. This manual will provide you with the necessary

information for a correct use of the instrument, as well as a more

precise idea of its versatility. If you need more technical information, do not hesitate to e-mail us at tech@hannainst.com.

These instruments are in compliance with the directives

EN 50081-1, 50082-1 and 61010-1.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PRELIMINARY EXAMINATION .....................................................3

GENERAL DESCRIPTION.............................................................3

MECHANICAL LAYOUTS ............................................................. 4

FUNCTIONAL DIAGRAM HI 9910 ............................................... 6

FUNCTIONAL DIAGRAM HI 9911 ............................................... 9

FUNCTIONAL DIAGRAM HI 9920 ............................................. 12

CONNECTIONS & WIRING ....................................................... 14

NORMAL OPERATION & MEASUREMENT ................................... 19

pH CALIBRATION ................................................................... 20

ORP CALIBRATION ................................................................. 22

ADJUSTEMENT OF SETPOINT(S) ............................................... 23

PROPORTIONAL CONTROL ...................................................... 26

OVERDOSAGE TIMER............................................................... 29

pH VALUES AT VARIOUS TEMPERATURES................................. 30

REDOX MEASUREMENT (HI 9920)............................................ 31

ELECTRODE CONDITIONING & MAINTENANCE............................. 33

SUGGESTED INSTALLATIONS FOR pH/ORP ELECTRODES.............. 34

ACCESSORIES......................................................................... 35

WARRANTY ............................................................................ 37

OTHER PRODUCTS FROM HANNA ............................................ 38

CE DECLARATION OF CONFORMITY ........................................... 39

ISO 9000 Certified

Company since 1992

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occurred during shipping.

If there is any noticeable damage, notify your Dealer.

Note: Save all packing materials until you are sure that the

instrument functions correctly. Any defective item must be

returned in the original packaging together with the supplied

accessories.

IMPORTANT:

1. Read the instructions before using the instrument.

2. The instrument should be connected to a mains socket.

3. Never install the controller outdoors, in a wet or humid area or

under direct sun light. Nor install the controller where liquids may

be sprayed or poured on it.

4. The instrument’s main power line as well as the dosage and

alarm terminals are protected by separate 2A fuses. Use only 2A

fuses for replacement.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

Hanna's wall-mounted pH and ORP controllers

control are designed to meet a variety of process control requirements.

The electrodes can be installed quickly and easily. Simply plug the

universal BNC connector into the socket and twist it into a secured

position. Accurate measurements are displayed on a large LCD.

The controllers come equipped with relays operating at a maximum of

2A (240V).

The Hanna controllers incorporate a triple contact alarm system.

When activated, the alarm contacts will open or close, triggering the

mechanism of your choice, whether a buzzer, light or any other

electrical device.

The recorder output terminals are isolated from the controller circuitry

to avoid any interference and are user-switchable between 0 to 20

mA or 4 to 20 mA.

In order to avoid electrical noise and interference all models provide

for a ground probe (differential input).

These controllers are housed in a rugged, modular, fiber-reinforced

ABS housing.

3

with proportional

Page 4

All models can be wired to work with 110/115V or 220/240V

50/60 Hz power supplies.

The models covered in this manual are:

HI 9910 a single setpoint pH controller

HI 9911 a dual setpoint pH controller, specifically designed for

all those applications in which the pH value intends to

oscillate both up and down

HI 9920 ORP controller, designed for numerous industrial

applications, but in particular for swimming pools and

drinking water sanitation

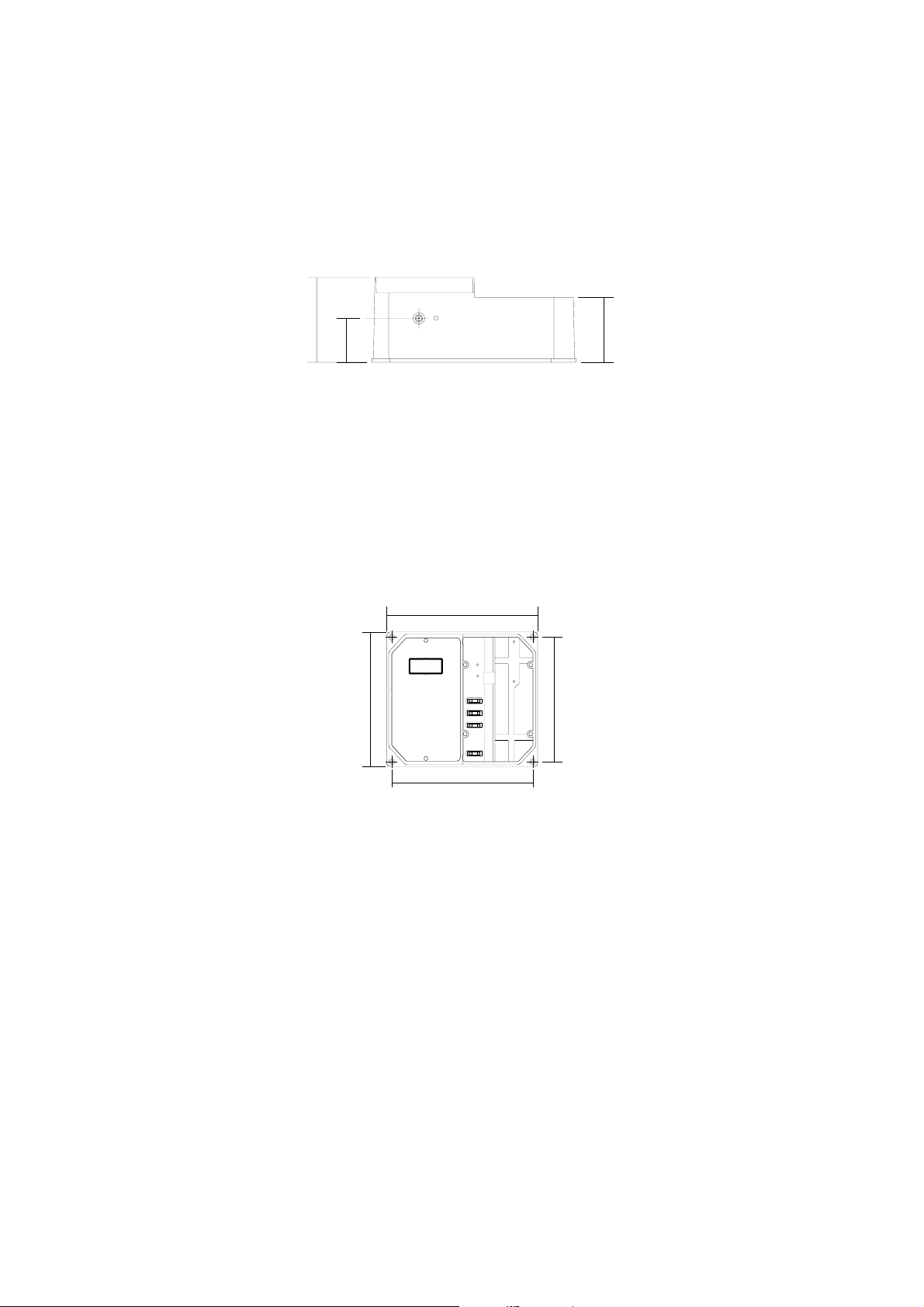

MECHANICAL LAYOUTSMECHANICAL LAYOUTS

MECHANICAL LAYOUTS

MECHANICAL LAYOUTSMECHANICAL LAYOUTS

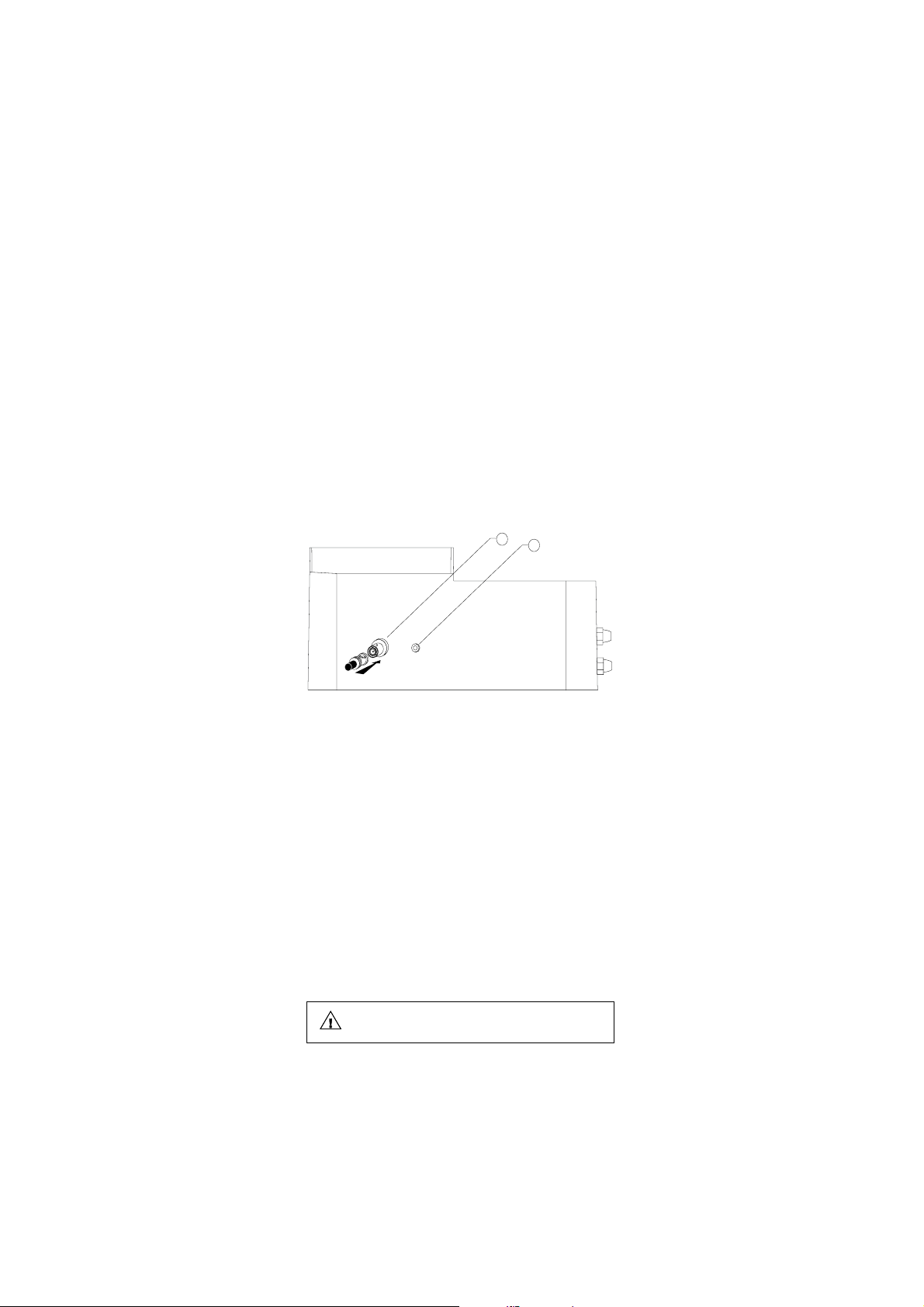

BNC CONNECTOR FOR ELECTRODE

4 mm BANANA SOCKET

FOR GROUND PROBE

WIRING ACCESS

PORTS

Fig. 1

Figure 1: displays the connector for electrode and the wiring access

ports.

LCD DISPLAY

CALIBRATION

TRIMMERS

CONTROL KNOBS

AND SWICHES

pH

ALARM

30

20

10

0

-10

0.511.5

0pH2.0

COARSE

ON

ACID

OFF

ALK

40

50

60

MTC

70

80

PROPORTIONAL SETTINGS

SET POINT

°C

45

090

SECONDS

FINE SLOPEOFFSET

SET

READ

HI 9910

2.557.5

1

MINUTES

ALARM DOSINGTIME

pH

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

ALARM

SET pH

DOSING

10

LINE

OUTPUT CONTACTS

TEMP.COMPENSATION

SWITCH

ALARM CONTACTS

DOSING TERMINALS

POWER SUPPLY

TERMINALS

Fig. 2

Figure 2 illustrates the controls and terminals on the HI 9910 pH

controller. Layouts vary from model to model based on their features

and capabilities.

4

Page 5

3.8“

96.9 mm

1“

25 mm

75 mm

Fig. 3

Figure 3 is a dimensioned, bottom view of the wall mounted

controllers. The modular design isolates the control circuitry from the

contacts making it possible to make the connections and then close

the compartment. Adjustments can then be made only in the control

area, without having to open the contacts compartment.

227.8 mm

9“

3“

7.4“

188.6 mm

221.8 mm

8.7“

6.9“

174.8 mm

Fig. 4

Figure 4 is a dimensioned front view of the wall mounted controllers.

The molded, mounting holes in the corners provide for quick and

secure installation. No additional hardware is needed for mounting.

All electrical connections and controls are located on the front of the

instrument so that adjustment can be made without having to

remove the unit.

5

Page 6

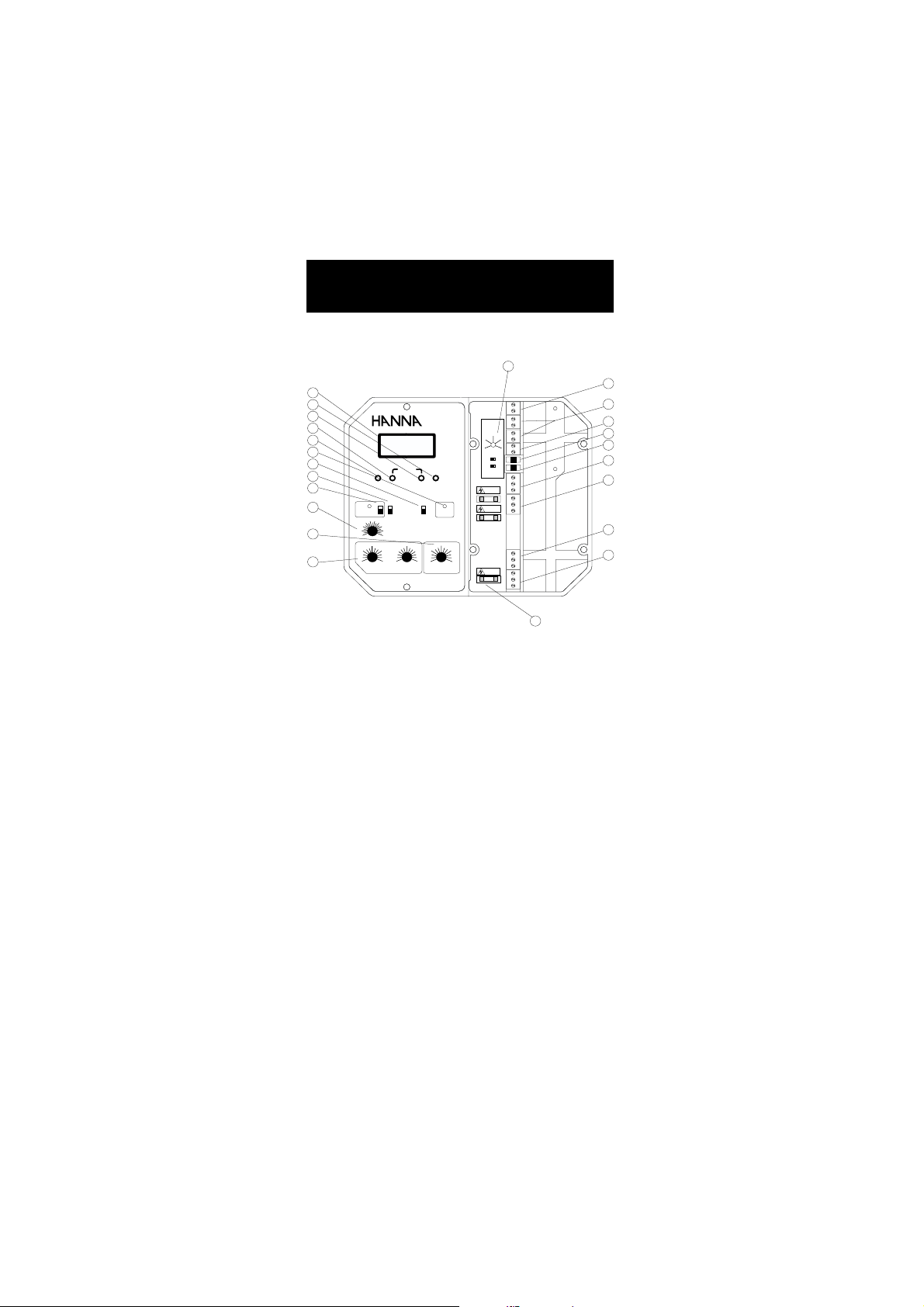

FUNCTIONAL DIAGRAM HI 9910FUNCTIONAL DIAGRAM HI 9910

FUNCTIONAL DIAGRAM HI 9910

FUNCTIONAL DIAGRAM HI 9910FUNCTIONAL DIAGRAM HI 9910

SINGLE SETPOINT, SINGLE SETPOINT,

SINGLE SETPOINT,

SINGLE SETPOINT, SINGLE SETPOINT,

pp

H CONTROLLERH CONTROLLER

p

H CONTROLLER

pp

H CONTROLLERH CONTROLLER

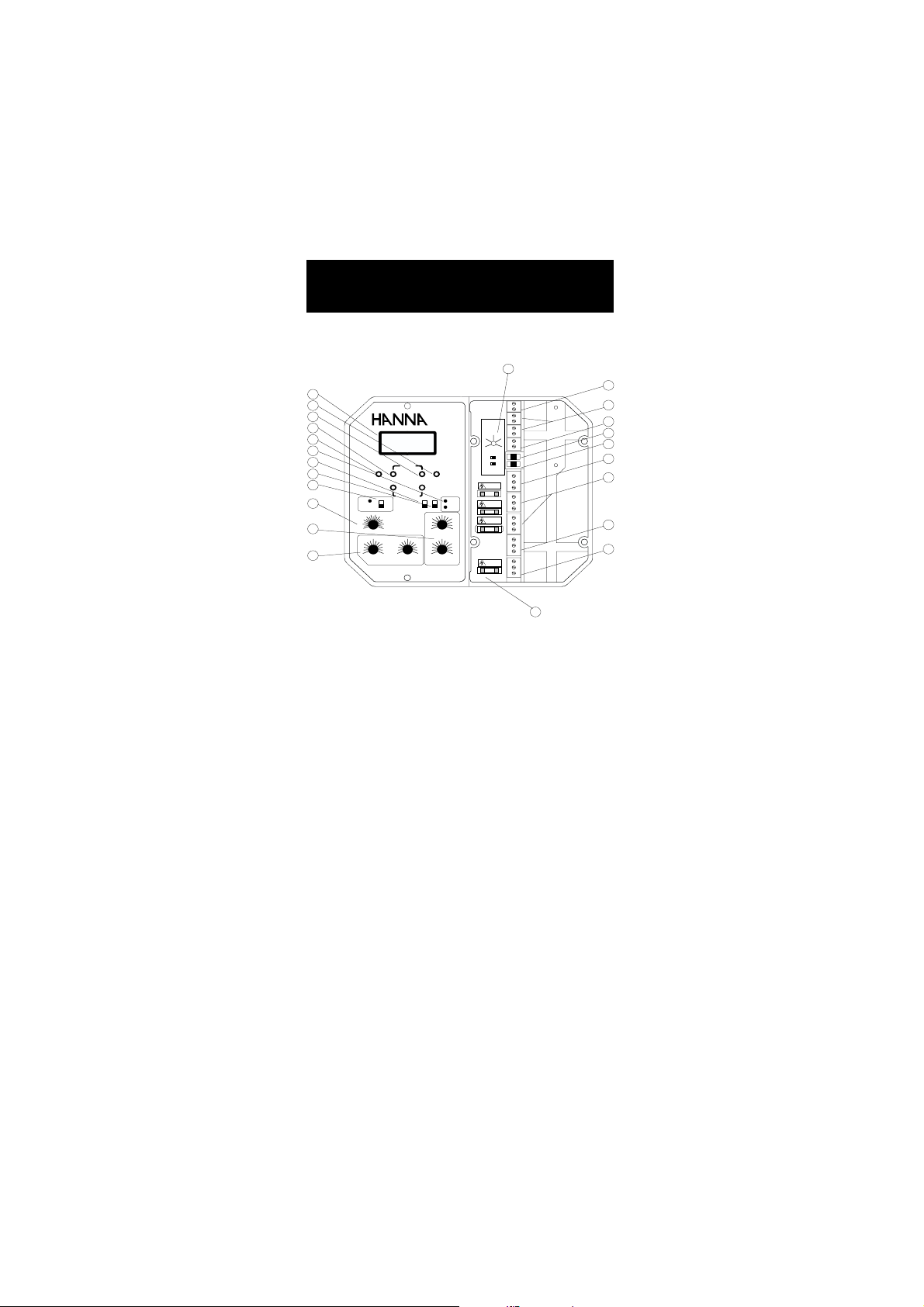

FRONT PANEL

13

1

2

3

4

5

6

7

8

9

10

11

12

pH

ALARM

30

40

20

10

0

-10

0.511.5

0pH2.0

PROPORTIONAL SETTINGS

ON

OFF

50

SET POINT

COARSE

ACID

ALK

60

MTC

70

°C

80

45

090

SECONDS

HI 9910

FINE SLOPEOFFSET

SET

READ

2.557.5

ALARM DOSINGTIME

DOSING

1

MINUTES

pH

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

ALARM

SET pH

10

LINE

23

Left panel

1. Liquid Crystal Display

2. Slope calibration trimmer

3. Fine setpoint trimmer

4. Coarse setpoint trimmer

5. Offset calibration trimmer

6. Dosing LED visual signal

7. READ for actual measurement and SET for setpoint

adjustment

8. Acid or Alkaline Dosage selection

9. Alarm LED and switch to disable the alarm

10. Graded dial for Manual Temperature Compensation

11. Overdosage timer

12. Proportional pH band and time cycle settings

14

15

16

17

18

19

20

21

22

Right panel

13. pH alarm setting from 0 to 2 pH

14. Short the terminals if a ground probe is not in use, or

connect the ground probe wire to the Matching Pin terminal

15. Three-wire Pt 100 plus a shield protection

6

Page 7

16. Recorder output contacts

17. Automatic or Manual Temperature Compensation switch

18. 0 to 20 or 4 to 20 mA isolated output switch

19. Triple contact alarm in a Normally Closed (NC) or a Normally

Open (NO) position.

20. Powered dosage terminals (Relay)

21. 110/115V or 220/240V power configuration

22. Incoming power terminals

23. Fuses

BOTTOM VIEW

24

25

24. Female BNC socket for combination pH electrode

25. 4-mm Banana socket for ground probe

Unplug the instrument from the power supply before

wiring and replacing the fuses.

7

Page 8

Specifications HI 9910

RANGE 0.00 to 14.00 pH

RESOLUTION 0.01 pH

ACCURACY ±0.02 pH

(@20°C/68°F)

TYPICAL EMC ±0.1 pH

DEVIATION

mA OUTPUT User-selectable 0 to 20 mA or 4 to 20 mA

CALIBRATION Through "OFFSET" and "SLOPE" trimmers

TEMPERATURE

COMPENSATION

SETPOINT From 0.00 to 14.00 pH with "COARSE" and "FINE"

RANGE trimmers with "ACID" or "ALK" (alkaline) selection

PROPORTIONAL pH is user adjustable from 0.0 to 2.0 and

CONTROL time cycle from 0 to 90 seconds

ALARM

CONTACT

DOSING TERMINALS Relay terminals (115 to 240V, Max.2A,1,000,000

strokes) are activated when pH exceeds the setpoint with

“ACID” dosage or falls below the setpoint with “ALK”

selection (Alkaline dosage)

POWER SUPPLY 220/240V or110/115V at 50/60Hz

ENVIRONMENT -10 to 50 °C (14 to 122 °F)

WEIGHT 1.6 Kg (3.5 lb.)

ENCLOSURE 181 x 221 x 142mm (7.1 x 8.7 x 5.6")

CASE MATERIAL Fiber-reinforced, self-extinguishing ABS

over the 0-14 pH range with isolated output

(Max. ±1.5 pH for offset and 80% to 110% for slope)

Manual from -10 to 80 °C (14 to 176 °F) or

automatic with a 3-wire Pt 100 probe from 0 to 50

°C (32 to 122 °F)

Terminals can be configured as normally open or

normally closed (isolated output Max. 2A, Max. 240V,

resistive load, 1,000,000 strokes). The alarm is

activated if pH varies by more than user-selectable

interval (0 to 2 pH) from setpoint or due to overdosage

max. 95% RH non-condensing

8

Page 9

FUNCTIONAL DIAGRAM HI 9911FUNCTIONAL DIAGRAM HI 9911

FUNCTIONAL DIAGRAM HI 9911

FUNCTIONAL DIAGRAM HI 9911FUNCTIONAL DIAGRAM HI 9911

DUAL SETPOINT, DUAL SETPOINT,

DUAL SETPOINT,

DUAL SETPOINT, DUAL SETPOINT,

pHpH

CONTROLLER CONTROLLER

pH

CONTROLLER

pHpH

CONTROLLER CONTROLLER

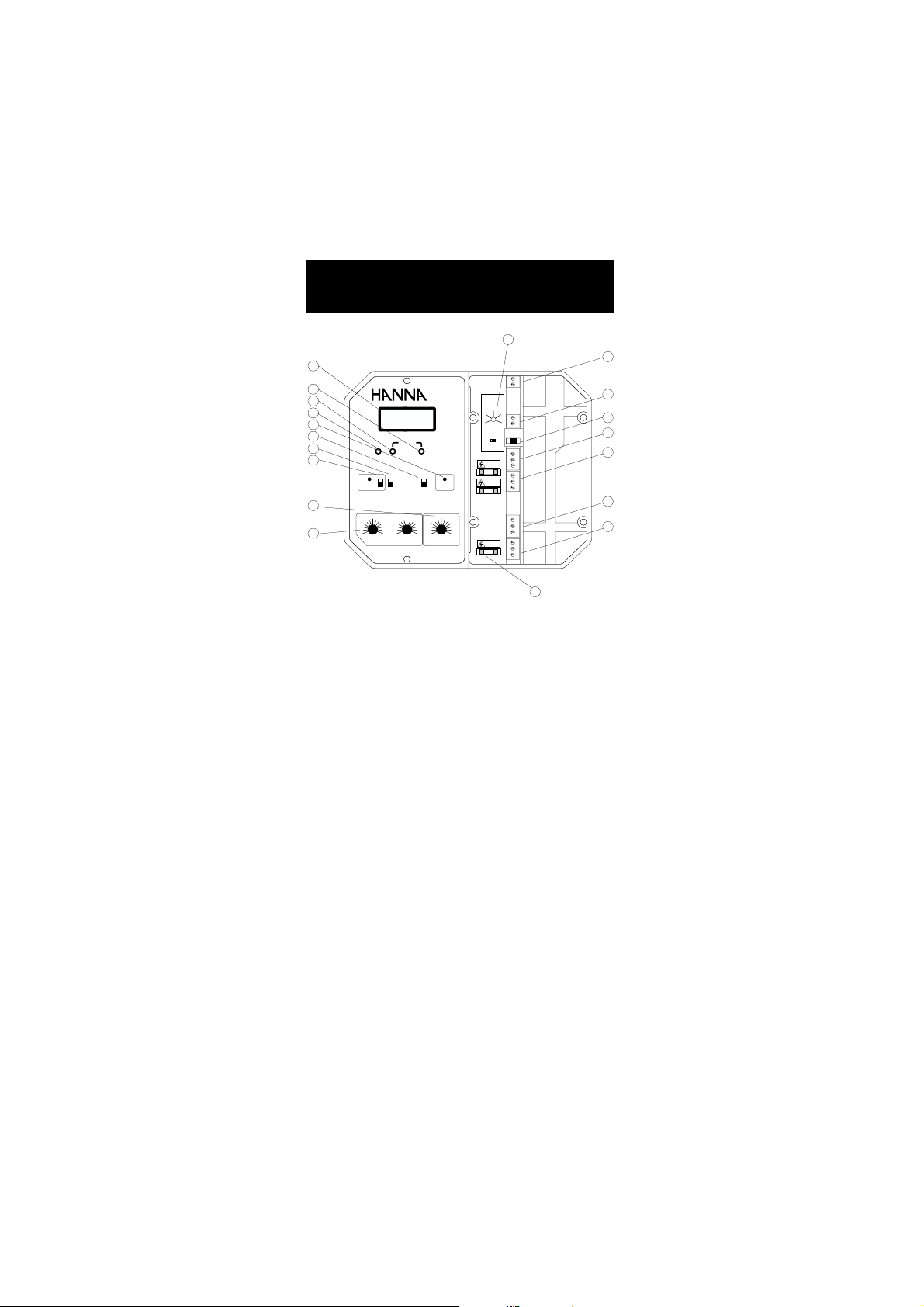

FRONT PANEL

13

1

2

3

4

5

6

7

8

9

10

11

12

pH

ALARM

30

20

10

0

-10 80

1

0.5

0

pH

PROPORTIONAL SETTINGS

ON

OFF

40

50

60

70

1.5

2.0 0

HI 9911

ACID SET

COARSE FINE SLOPEOFFSET

ALKALINE SET

SET

ACID

READ

ALK

2.557.5

MTC

°C

1

45

2.557.5

90

1

SECONDS

MINUTES

TIMER

pH

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

ALARM

ACID

SET ACID

FEED

ALK

ALK

SET ALK

10

ACID

10

LINE

23

Left panel

1. Liquid Crystal Display

2. Slope calibration trimmer

3. Fine setpoint trimmers for acid and alkaline feed

4. Coarse setpoint trimmers for acid and alkaline feed

5. Offset calibration trimmer

6. Dosing LED signals for acid and alkaline feed

7. READ for actual measurement and SET for setpoint

adjustment

8. Acid or Alkaline selection for setpoint

9. Alarm LED and switch to disable the alarm

10. Graded dial for Manual Temperature Compensation

11. Two independent overdosage timers

12. Proportional pH band and time cycle settings

14

15

16

17

18

19

20

21

22

Right panel

13. pH alarm setting from 0 to 2 pH

14. Short the terminals if a ground probe is not in use, or

connect the ground probe wire to the Matching Pin terminal

15. Three-wire Pt 100 plus a shield protection

16. Recorder output contacts

17. Automatic or Manual Temperature Compensation switch

9

Page 10

18. 0 to 20 or 4 to 20 mA isolated output switch

19. Triple contact alarm in a Normally Closed (NC) or a Normally

Open (NO) position.

20. Powered dosage terminals (Relays)

21. 110/115V or 220/240V power configuration

22. Incoming power terminals

23. Fuses

BOTTOM CONNECTION

24

25

24. Female BNC socket for combination pH electrode

25. 4-mm Banana socket for ground probe

Unplug the instrument from the power supply before

wiring and replacing the fuses.

10

Page 11

Specifications HI 9911

RANGE 0.00 to 14.00 pH

RESOLUTION 0.01 pH

ACCURACY ±0.02 pH

(@20°C/68°F)

TYPICAL EMC ±0.1 pH

DEVIATION

mA OUTPUT User-selectable 0 to 20 mA or 4 to 20 mA

CALIBRATION Through "OFFSET" and "SLOPE" trimmers

TEMPERATURE

COMPENSATION

SETPOINT

RANGE

PROPORTIONAL pH is user adjustable from 0.0 to 2.0 and

CONTROL time cycle from 0 to 90 seconds

ALARM

CONTACT

DOSING TERMINALS Two sets of independent relay terminals (115 to 240V,

Max.2A, 1,000,000 strokes) are activated whenever pH

exceeds the “ACID” setpoint or falls below the “ALK”

setpoint (Alkaline dosage)

POWER SUPPLY 220/240V or110/115V at 50/60Hz

ENVIRONMENT -10 to 50 °C (14 to 122 °F)

WEIGHT 1.6 Kg (3.5 lb.)

ENCLOSURE 181 x 221 x 142mm (7.1 x 8.7 x 5.6")

CASE MATERIAL Fiber-reinforced, self-extinguishing ABS

over the 0-14 pH range with isolated output

(Max. ±1.5 pH for offset and 80% to 110% for slope)

Manual from -10 to 80 °C (14 to 176 °F) or automatic

with 3-wire Pt 100 probe from 0 to 50 °C (32 to 122 °F)

From 0.00 to 14.00 pH with 2 trimmers: "COARSE"

for approx. regulation, "FINE" for fine tuning.

Terminals can be configured as normally open or

normally closed (isolated output Max. 2A, Max.

240V, resistive load, 1,000,000 strokes). The alarm

is activated if pH varies by more than user-selectable

interval (0 to 2 pH) from setpoint or due to

overdosage

max. 95% RH non-condensing

11

Page 12

FUNCTIONAL DIAGRAM HI 9920FUNCTIONAL DIAGRAM HI 9920

FUNCTIONAL DIAGRAM HI 9920

FUNCTIONAL DIAGRAM HI 9920FUNCTIONAL DIAGRAM HI 9920

ORP CONTROLLER ORP CONTROLLER

ORP CONTROLLER

ORP CONTROLLER ORP CONTROLLER

FRONT PANEL

13

1

3

4

5

ORP

6

7

8

9

11

12

mV

ALARM

50

0

mV

PROPORTIONAL SETTINGS

ON

OFF

150

200

HI 9920

SET POINT

COARSE FINECAL

SET

OXID

RED

DOSING

READ

45100

2.557.5

1

0

90

MINUTES

SECONDS

TIMER

mV

ALARM

100

0

200

mA OUTPUT

4/20 0/20

ALARM

SET mV

10

LINE

Left panel

1. Liquid Crystal Display

3. Fine setpoint trimmer

4. Coarse setpoint trimmer

5. Calibration trimmer

6. Dosing LED visual signal

7. READ for actual measurement and SET for setpoint

adjustment

8. Oxidization or Reduction Dosage selection

9. Alarm LED and switch to disable the alarm

11. Overdosage timer

12. Proportional ORP band and time cycle settings

14

16

18

19

20

21

22

23

Right panel

13. ORP alarm setting from 0 to 200 mV

14. Short the terminals if a ground probe is not in use, or

connect the ground probe wire to the Matching Pin terminal

16. Recorder output contacts

18. 0 to 20 or 4 to 20 mA isolated output switch

19. Triple contact alarm in a normally-closed (NC) or a normally

open (NO) position.

12

Page 13

20. Powered dosage terminals (Relay)

21. 110/115V or 220/240V power configuration

22. Incoming power terminals

23. Fuses

BOTTOM CONNECTION

24

25

24. Female BNC socket for combination ORP electrode

25. 4-mm Banana socket for ground probe

Unplug the instrument from the power supply before

wiring and replacing the fuses.

13

Page 14

Specifications HI 9920

RANGE -500 to 1500 mV

RESOLUTION 1 mV

ACCURACY ±5mV

(@20°C/68°F)

TYPICAL EMC ±6 mV

DEVIATION

mA OUTPUT User-selectable 0 to 20 mA or 4 to 20 mA

CALIBRATION Through "CAL" trimmer

SETPOINT

From -500 to 1500 mV with "COARSE" and "FINE"

RANGE 2 trimmers with "OXID" or "RED" selection for oxidizing

or reducing dosage

PROPORTIONAL ORP setting is adjustable from 0 to 200 mV and

CONTROL time cycle from 0 to 90 seconds

ALARM

CONTACT

DOSING TERMINALS Relay terminals (115 to 240V, Max.2A,1,000,000

strokes) are activated when mV exceeds the setpoint

with “RED” dosage or when mV falls below the

setpoint with “OXID” selection

POWER SUPPLY 220/240V or110/115V at 50/60Hz

ENVIRONMENT -10 to 50 °C (14 to 122 °F)

WEIGHT 1.6 Kg (3.5 lb.)

ENCLOSURE 181 x 221 x 142mm (7.1 x 8.7 x 5.6")

CASE MATERIAL Fiber-reinforced, self-extinguishing ABS

over the -500 to 1500 mV range with isolated output

Normally open or normally closed isolated outputs

(Max. 2A, Max. 240V, resistive load, 1,000,000 strokes).

Terminals are activated when the ORP value varies by

more than the user selectable interval (0 to 200mV)

from setpoint, or due to overdosage

max. 95% RH non-condensing

CONECTIONS & WIRINGCONECTIONS & WIRING

CONECTIONS & WIRING

CONECTIONS & WIRINGCONECTIONS & WIRING

GENERAL POINTS

relay terminalsrelay terminals

• The

relay terminals of the controllers are

relay terminalsrelay terminals

means that you can simply hook up your pumps or electrovalves

directly to the controller and do not need additional power

supply.

• Unscrew the 4 screws on the right hand panel and remove the

cover and the gasket. Thread the wires through the access ports

on the right hand side of the controller.

14

poweredpowered

powered. This

poweredpowered

Page 15

BeforeBefore

•

connecting the controller to the mains, wire connecting the controller to the mains, wire

Before

connecting the controller to the mains, wire

BeforeBefore

connecting the controller to the mains, wire connecting the controller to the mains, wire

the controller completelythe controller completely

the controller completely and make all the connections for

the controller completelythe controller completely

pumps, alarm, electrode, set the alarm threshold and adjust the

settings. Upon completion,

replace the coverreplace the cover

replace the cover.

replace the coverreplace the cover

Only then

connect the controller to the power supply.

ELECTRODE & GROUND PROBE CONNECTIONS

ELECTRODE WITH

BNC CONNECTION

MATCHING PIN FOR GROUND PROBE

WIRING ACCESS

PORTS

• Simply attach any combination pH or ORP electrode with a

male BNC connector (such as HI 1002/3 or HI 2002/3) to the

female BNC socket located on the bottom of the casing and twist

it into a secure position.

• All models provide for a Ground Probe (differential input) to

reduce electrical noise and interference. The

controllers are shipped with the Matching Pin

and Reference terminals shorted (see 14 - Functional Diagram). If you are not using a matching

pin (ground probe),

the next two paragraphs.

• It is recommended that only electrodes that incorporate a matching pin (such as HI 1003/3 or HI 2003/3) are utilized. In this

case simply

matching pin to the socketmatching pin to the socket

matching pin to the socket located next to the BNC

matching pin to the socketmatching pin to the socket

connector on the outer casing (see 25 - Functional Diagram) and

remove the jumperremove the jumper

remove the jumper shorting the matching pin terminals.

remove the jumperremove the jumper

• When using a separate probe for grounding purposes, wire it to

the Matching Pin terminal on the right hand panel and

the jumperthe jumper

the jumper (see 14 Functional Diagram).

the jumperthe jumper

leave the terminals shortedleave the terminals shorted

leave the terminals shorted and skip

leave the terminals shortedleave the terminals shorted

attach the 4-mm banana connector of theattach the 4-mm banana connector of the

attach the 4-mm banana connector of the

attach the 4-mm banana connector of theattach the 4-mm banana connector of the

removeremove

remove

removeremove

NOTE:

NEVER leave the jumper in when

using an electrode with a matching

pin. This can shorten the life of the

electrode (reference) drastically.

15

REMOVE WHEN

USING MATCHING PIN

Page 16

RELAY CONNECTIONS

• Wire the external device or devices (pumps or electrovalves)

directly to the relay terminal strip of the controller (see 20 Functional Diagram). The

do not need an external power supplydo not need an external power supply

you

do not need an external power supply for the pump

do not need an external power supplydo not need an external power supply

terminals are poweredterminals are powered

terminals are powered and hence

terminals are poweredterminals are powered

or electrovalve. There is one terminal strip for HI 9910 and

HI 9920 and two for HI 9911.

BL DOSING PUMP

pH

20

10

0

-10

0.511.5

0pH2.0

ON

ALARM

OFF

30

40

PROPORTIONAL SETTINGS

COARSE

ACID

ALK

50

60

MTC

70

80

SET POINT

°C

45

090

SECONDS

pH

HI 9910

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

FINE SLOPEOFFSET

ALARM

SET

SET pH

DOSING

READ

2.557.5

10

1

MINUTES

ALARM DOSINGTIME

LINE

ALARM CONNECTIONS

• The operator can select an alarm threshold of 0.0

to 2.0 pH for HI 9910 and HI 9911 or 0 to 200

mV for HI 9920 by turning the alarm knob (see 13

of Functional Diagram). If the actual measurements

are above or below the setpoint by a margin

greater than the user-selectable alarm threshold,

the alarm terminal is activated. The alarm can be

selected as normally closed ("NC") by connecting the external

device to the C and NC terminals or normally open ("NO") by

connecting the external device to the C and NO terminals.

• When activated, the alarm contacts will open or close, triggering

the mechanism of your choice. When the

all other terminalsall other terminals

all other terminals (such as dosing relay etc.)

all other terminalsall other terminals

disactivateddisactivated

disactivated. The alarm LED light also comes on.

disactivateddisactivated

alarm is activatedalarm is activated

alarm is activated

alarm is activatedalarm is activated

pH

ALARM

1

0

TEMP. COMP.

MTC ATC

4/20 0/20

mA OUTPUT

areare

are

areare

2

10

0

-10

0.511.5

0pH2.0

pH

ALARM

20

ON

OFF

30

40

50

60

PROPORTIONAL SETTINGS

SET POINT

COARSE

ACID

ALK

MTC

70

°C

80

090

SECONDS

pH

HI 9910

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

FINE SLOPEOFFSET

ALARM

SET

SET pH

DOSING

READ

45

2.557.5

10

1

MINUTES

ALARM DOSINGTIME

LINE

EXTERNAL ELECTRICAL

DEVICE ACTIVATED BY

AN ALARM CONDITION

16

Page 17

ALARM

ON

OFF

• The alarm ON/OFF switch is only to

ALARM DOSING TIME

MINUTES

1

10

2.5

5

7.5

the alarm terminalthe alarm terminal

the alarm terminal (e.g. the buzzer will

the alarm terminalthe alarm terminal

disabledisable

disable

disabledisable

not sound). However, all other functions such as

disactivation of the dosing relay remain unvaried, i.e. the pump

ceases to dose until the alarm condition is alleviated.

• The controllers provide for

automatic fail-safeautomatic fail-safe

automatic fail-safe security by

automatic fail-safeautomatic fail-safe

activating the alarm if there is a power failure, regardless of

whether the NC or NO configurations were chosen.

• The alarm is also activated if the maximum

dosage time is exceeded. The overdosage timer

can be set from 1 to 10 minutes. For HI 9911,

two timers for acid and alkaline corrections can

be independently selected.

• Once in an alarm condition, the alarm contact remains activated

until the switch is manually put in the off position or the

measurements returns to normal values.

Model Alarm is activated when the reading varies by :

HI 9910 0 to 2.0 pH (selectable) above or below the setpoint

HI 9911 0 to 2.0 pH (selectable) lower than the ALKALINE setpoint or

higher than the ACID setpoint

HI 9920 0 to 200 mV (selectable) above or below the setpoint

RECORDER OUTPUT CONNECTIONS

• The recorder output contacts are

isolatedisolated

isolated from the controller circuitry

isolatedisolated

to avoid interference. Select between

0 to 20 or 4 to 20 mA with the

Output mA

selector

selector (see 18 - Functional Diagram) before wiring. The output

mA value is proportional and is the pH or ORP value over the

entire range. For example, when measuring pH 7, the output

values are 10 mA or 12 mA based on whether the 0-20 or 4-20

output were respectively selected.

RECORDER

pH

ALARM

30

20

10

0

-10

0.511.5

0pH2.0

PROPORTIONAL SETTINGS

ON

OFF

40

50

SET POINT

COARSE

ACID

ALK

60

MTC

70

°C

80

090

SECONDS

pH

HI 9910

ALARM

1

0

2

TEMP.COMP.

MTC ATC

4/20 0/20

mA OUTPUT

FINE SLOPEOFFSET

READ

45

SET

2.557.5

1

ALARM DOSINGTIME

ALARM

SET pH

DOSING

10

MINUTES

LINE

17

0/204/20

Page 18

TEMPERATURE COMPENSATION

Neutral

Line

POWER

SUPPLY

220 VAC

Configuration

L

L1

N1

Neutral

Line

POWER

SUPPLY

L

L1

N1

110 VAC

Configuration

110 VAC

Configuration

(HI 9910 and HI 9911 only)

• Manual Temperature Compensation:

the MTC position (see 17-Functional Diagram). Then manually set

the temperature by turning the dial (see 10 - Functional

Diagram) to the correct working temperature.

ATCMTC

Temp. compensation

selector

• Automatic Temperature Compensation:

the ATC position (see 17-Functional Diagram). Then wire a Pt

100 probe such as HI 5001/5 to the controller’s terminals as

shown.

Pt 100 1-grey

Pt 100 2-brown

Pt 100 3-yellow

Pt 100 shield

1-grey

2-brown

3-yellow

shield

HI 5001/5 is made of stainless steel. For solutions

not compatible with stainless steel, use the glassbody HI 5002/5 or other appropriate 3-wire Pt

100 probe.

Move the selector to

30

40

20

10

0

-10

50

Move the selector to

1

2

3

MAIN POWER SUPPLY CONNECTION

BeforeBefore

•

connecting the unit to the mains connecting the unit to the mains

Before

connecting the unit to the mains, make sure

BeforeBefore

connecting the unit to the mains connecting the unit to the mains

that the

controller is completely wiredcontroller is completely wired

controller is completely wired and that all

controller is completely wiredcontroller is completely wired

connections for pump, alarm, electrode, etc. have been made.

60

MTC

70

°C

80

• For 220-240V, short the L1 and N1 terminals. Then wire the external power supply

to the three terminals as shown.

• For 110-115V, short the L and L1 terminals

and

the N1 and Neutral. Then wire

the external power supply to the three

terminals as shown.

• Replace the cover with the gasket and screw it tight with the 4

screws provided.

Only thenOnly then

Only then connect the controller to the mains.

Only thenOnly then

18

Page 19

NORMAL OPERATION andNORMAL OPERATION and

ATCMTC

NORMAL OPERATION and

NORMAL OPERATION andNORMAL OPERATION and

MEASUREMENTMEASUREMENT

MEASUREMENT

MEASUREMENTMEASUREMENT

Make sure that the controller has been properly calibrated before

commencing and that the pH or ORP setpoint(s) have been adjusted

(see the following pages).

The pH or ORP electrodes and any ground probes must be properly

connected and wired to the controller (see preceding pages). Remove

the protecteive cap if it is still on the tip of the electrode.

Ensure that the electrode is properly installed and lies perma-

SET

nently in the solution to a depth of at least 4cm/1.5”. The

selector (see 7 - Functional Diagram) must be on the "READ"

READ

position.

If temperature compensation is necessary (HI 9910 and HI 9911),

make sure that the temperature probe is also immersed in the

solution and the selector is on ATC (see 17 - Functional Diagram).

For manual temperature compensation, the selector should be on MTC with the dial showing

the temperature of the solution.

30

40

50

20

ATCMTC

10

0

-10

60

MTC

70

°C

80

The actual pH or ORP value of the solution will be displayed on the

LCD.

SET

8.00

READ

All controllers provide for a visual dosing status

through an LED. With HI 9910 and HI 9920 the

DOSING LED lights up when the controller is in the

pH or ORP dosage mode and the terminals are

activated.

Likewise, HI 9911 provides for two LED’s, one for

ACID and another for ALK (alkaline) dosage when

the appropriate terminals are activated.

19

DOSING

ACID

FEED

ALK

Page 20

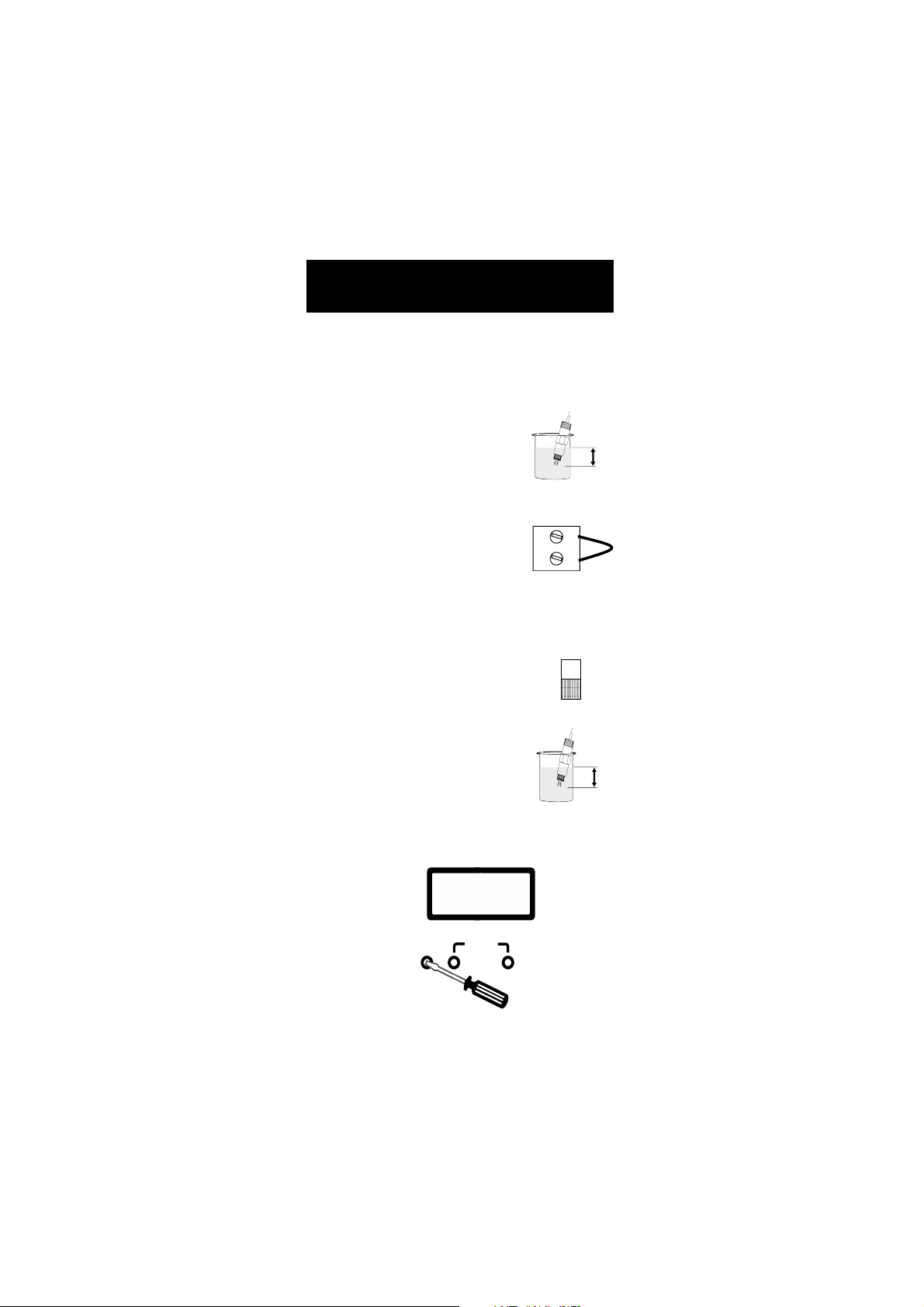

pH pH

4cm

(1½")

HI 7007

CALIBRATIONCALIBRATION

pH

CALIBRATION

pH pH

CALIBRATIONCALIBRATION

(HI 9910 and HI 9911)

Make sure that the pH electrode and any ground probe have been

properly connected and wired to the controller (see preceding pages)

and that the meter is plugged to the mains.

Calibration should be ideally performed at a temperature similar to

that of the liquid to be monitored.

Use a Checktemp (or an accurate thermometer)

as reference for temperature compensation.

Remove the electrode cap if it is still on the

electrode.

During calibration, move the electrode and the

separate ground probe (if in use) together from

one buffer to the next.

If no separate ground probe is being used, make sure

that the Reference and the Matching Pin terminals are

shorted (see 14 - Functional Diagram).

If the electrode incorporates a ground probe/matching pin (HI 1003/3)

then remove the jumper.

• Turn the switch to the "READ" position.

HI 7007

HI 7007

SET

(1½")

(1½")

4cm

4cm

READ

OFFSET ADJUSTMENT:

• Rinse the tip of the electrode with pH

7.01 solution (HI7007), then dip the

bottom 4 cm (1.5”) of the electrode (and

ground probe) in the pH 7.01 buffer.

• Place the Checktemp thermometer in the buffer solution. Turn the

dial (see 10 - Functional Diagram) to show the same temperature

30

40

50

60

MTC

70

°C

80

ATCMTC

Temp. compensation

selector

20

10

0

-10

20

Page 21

as that on the Checktemp and make sure the selector is in the

MTC position (see 17 - Functional Diagram).

• Wait for the measurement to stabilize and then adjust the

"OFFSET" trimmer to display pH

7.01 on the LCD if the tempera-

pH

7.01

ture of the buffer solution is at

25°C (77°F).

• If the temperature of the buffer

COARSE

SET POINT

FINE SLOPEOFFSET

solution is not 25°C (77°F),

refer to the chart at the end of the manual for the appropriate

buffer value at a given temperature and adjust the trimmer

accordingly.

SLOPE ADJUSTMENT:

• Rinse the electrode (and ground probe)

thoroughly with water and immerse the

bottom 4 cm (1.5”) in a pH 4.01

(HI 7004) or a pH 10.01 (HI 7010)

buffer solution.

HI 7004

Note: Use pH 4.01 if you are going to be monitoring acidic solutions

or pH 10.01 for alkaline samples.

• Stir the electrode and wait for the display to stabilize before

adjusting the "SLOPE" trimmer to display pH 4.01 (or 10.01) on

the LCD if the temperature of the buffer solution is at 25 °C

(77 °F). Otherwise, refer to the

chart at the end

pH

4.01

of the manual

COARSE

SET POINT

FINE SLOPEOFFSET

for the appropriate buffer value

and adjust the

trimmer accordingly.

The pH calibration is now complete.

(1½")

4cm

21

Page 22

ORP CALIBRATIONORP CALIBRATION

4cm

(1½")

HI 7020

4cm

(1½")

HI 7020

ORP CALIBRATION

ORP CALIBRATIONORP CALIBRATION

(HI 9920)

Make sure that the ORP electrode and any ground probe have been

properly connected and wired to the controller (see preceding pages)

and that the meter is plugged to the mains.

Remove the electrode cap if it is still on the electrode.

During calibration, introduce both the electrode

and the ground probe (if in use) to the known

solution. An immersion level of 4 cm (1.5”) is

recommended.

If no separate ground probe is being used, make sure that the

Reference and the Matching Pin terminals are

shorted (see 14 - Functional Diagram).

If the electrode incorporates a ground probe/matching pin (HI 2003/3)

then remove the jumper.

SET

• Turn the switch to the "READ" position.

READ

• Immerse the electrode in a HI 7020

(or

another known) ORP solution and wait for

a few minutes for the reading to stabilize.

• Adjust the CAL trimmer to 230 ±20 mV (or a known value).

ORP

mV

230

SET POINT

COARSE FINECAL

22

Page 23

ADJUSTEMENT OF SETPOINT(S)ADJUSTEMENT OF SETPOINT(S)

ADJUSTEMENT OF SETPOINT(S)

ADJUSTEMENT OF SETPOINT(S)ADJUSTEMENT OF SETPOINT(S)

Make sure that the electrode (and any ground probe) is properly

installed and calibrated (see the preceding pages).

FOR HI 9910

Turn the switch to the "SET" position (see 7 - Functional Diagram).

The display will show the previously adjusted value (e.g. pH 8.00).

SET

8.00

READ

Using a small screwdriver, first adjust the setpoint through the

COARSE trimmer and then fine tune it to your required level with the

FINE trimmer (see 3 and 4 - Functional Diagram) until the desired

set value is displayed (e.g. pH 6.00).

pH

6.18

SET POINT

FINE SLOPEOFFSET

COARSE

pH

6.00

SET POINT

FINE SLOPEOFFSET

COARSE

DOSING DIRECTION

Select the direction of dosing through the "ACID"/”ALK” switch (see 8

- Functional Diagram). In order to dose acidic substances (i.e. lower

the pH value) leave the selector on "ACID". When dosing base or

alkaline solutions (to increase the pH) select the “ALK” position.

e.g. Dosing acidic liquids

Setpoint = pH 6.00

Measured value = pH 7.00

To reach the setpoint you need to dose acid, therefore

move the switch to the "ACID" position (see 8 - Functional

Diagram).

23

ACID

ALK

Page 24

e.g. Dosing base liquids

ACID

Set point = pH 6.00

Measured value = pH 4.00

To adjust the sample stream to the setpoint, you need to

dose base, therefore select "ALK".

ALK

FOR HI 9911 (DUAL-POINT ADJUSTMENT)

a) ACID SETPOINT and DOSAGE

Turn the switches to "SET" and “ACID” (see 7 and 8 - Functional

Diagram) to

lower

set the upper limitset the upper limit

set the upper limit and to direct the controller to

set the upper limitset the upper limit

the pH. The display will show the higher setpoint (e.g. pH

7.00).

SET

ACID

7.00

READ

ALK

Using a small screwdriver, adjust the “ACID SET” trimmers. First

adjust the “COARSE” trimmer and then fine tune with the “FINE”

trimmer (see 3 and 4 - Functional Diagram) until the desired set

value is displayed (e.g. pH 8.00).

pH

7.00

ACID SET

COARSE FINE SLOPEOFFSET

ALKALINE SET

pH

8.00

ACID SET

COARSE FINE SLOPEOFFSET

ALKALINE SET

a) ALKALINE SETPOINT and DOSAGE

Turn the switches to "SET" and “ALK” (see 7/8 - Functional Diagram)

set the lower limitset the lower limit

to

set the lower limit and to direct the controller to

set the lower limitset the lower limit

increase

the

pH. The display will show the lower setpoint (e.g. pH 6.00).

SET

ACID

6.00

READ

ALK

24

Page 25

Using a small screwdriver, adjust the “ALKALINE SET” trimmers. First

adjust the “COARSE” trimmer and then fine tune with the “FINE”

pH

5.18 5.00

ACID SET

COARSE FINE SLOPEOFFSET

ALKALINE SET

pH

ACID SET

COARSE FINE SLOPEOFFSET

ALKALINE SET

trimmer (see 3 and 4 - Functional Diagram) until the desired set

value is displayed (e.g. pH 5.00).

NOTE:

• The “FINE” trimmer can adjust up to ±1.5 pH.

• Should you use the HI 9911

for a single-point dosage, it is

recommended to adjust the “ALKALINE SET” trimmers to 0.00 pH

if you are dosing acid solutions to lower the pH and adjust the

“ACID SET” trimmers to your desired values. Likewise, when

dosing only base solutions, set the “ACID SET” trimmers to 14.00

pH and adjust the “ALKALINE SET” trimmers to your desired

value.

FOR HI 9920

SET

650

READ

Turn the switch to the "SET" position (see 7 - Functional Diagram).

The display will show the previously adjusted value (e.g. mV 650).

Using a small screwdriver, first adjust the setpoint through the

“COARSE” trimmer and then fine tune it with the “FINE” trimmer (see

3 and 4 - Functional Diagram) until the desired set value is

displayed (e.g. mV 700).

ORP

mV

680

SET POINT

COARSE FINECAL

25

ORP

mV

700

SET POINT

COARSE FINECAL

Page 26

DOSING DIRECTION

Select the direction of dosing through the "OXID"/”RED” switch (see 8

- Functional Diagram). For reducing dosage (i.e. lowering the mV

value) leave the selector on "RED". Likewise, for oxidizing solutions (to

increase the mV) select the “OXID” position.

e.g. Dosing reducing substances

OXID

Setpoint = mV 650

Measured value = mV 700

switch to the "RED" position (see 8 - Functional Diagram).

RED

e.g. Dosing oxidizing substances

Setpoint = mV 650

OXID

Measured value = mV 500

To adjust the sample stream to the setpoint, you need to

dose oxidants, therefore select "OXID".

RED

PROPORTIONAL CONTROLPROPORTIONAL CONTROL

PROPORTIONAL CONTROL

PROPORTIONAL CONTROLPROPORTIONAL CONTROL

In order to optimize the controlling process and reduce the amount of

chemicals used, it is recommended to use a proportional dosage

appropriate for the system.

1

0.5

0

pH

PROPORTIONAL SETTINGS

1.5

2.0

45

090

SECONDS

All models allow for a proportional band (0 to 2.0 pH or 0 to 200 mV

delta) as well as a time cycle (from 0 to 90 seconds) to be set. The

proportional dosage is obtained by personalizing a current pulse

whose height equals the pH or ORP proportional delta and the

length corresponds to the selected time cycle.

The controller will enter

or minus the preselectedor minus the preselected

or minus the preselected delta. It will then keep the dosing

or minus the preselectedor minus the preselected

proportional dosageproportional dosage

proportional dosage at

proportional dosageproportional dosage

setpoint plussetpoint plus

setpoint plus

setpoint plussetpoint plus

relay activated for a period proportional to the difference between the

measurement and the setpoint over the cycle.

26

Page 27

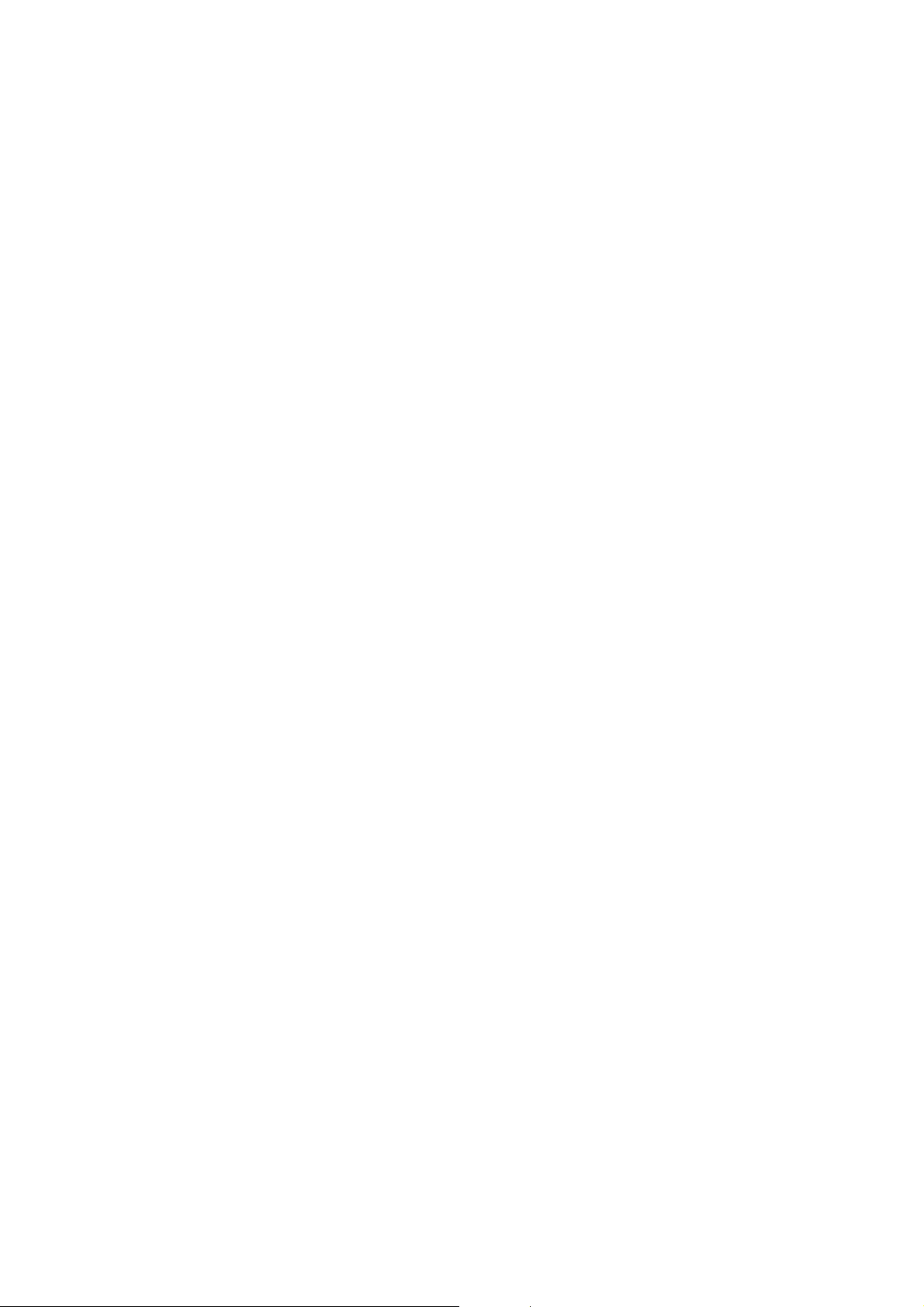

e.g. pH proportional control

D pH

Seconds15 30 45

60

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

15 30 45 60

Setpoint = pH 5.00

Measured value = 6.50

Delta = 6.5 - 5.0 = 1.5 pH

Proportional settings: pH set to 2 and time cycle to 60 seconds.

1

0.5

1.5

45

0

pH

PROPORTIONAL SETTINGS

090

2.0

SECONDS

The controller will be dosing acids to reduce pH to the desired limit.

Since it is 1.50/2.00 = 75% away from the ideal setting, it will

keep the dosing terminals

activated for 75% of the time

over the predetermined 60

seconds. The relay is hence

theoretically activated for 45

D pH

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

60

15 30 45 60

Seconds15 30 45

seconds and off for 15 seconds.

In order to avoid over dosage with fast responding samples or highly

concentrated chemicals or under dosage with slow reacting or weak

chemicals, the controller provides even a more accurate control.

As the graphs show, it does

that by stopping the dosage

as soon as the current pulse

curve intersects the dosage

curve.

D pH

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

60

15 30 45 60

Seconds15 30 45

This means shortening the dosage period if the chemicals have

reacted quickly or lengthening it if the measured pH

continues to drift from the

ideal setpoint as can be seen

from the graphs.

27

Page 28

.g. ORP proportional control

Setpoint = 725 mV

Measured value = 700 mV

Delta = 725 - 700 = 25 mV

Proportional settings = mV set to 100 and time cycle to 60 seconds.

50

0

mV

PROPORTIONAL SETTINGS

150

200

45100

090

SECONDS

The controller will be dosing reductants to reduce redox to the desired

value. Since it is 25/100 = 25% away from the ideal setting, it will

keep the dosing relay activated for 25% of the time

over the predetermined 60

seconds. The terminals are

hence activated for 15 seconds and off for 45 seconds

D mV

100

75

50

25

60

15 30 45 60

Seconds15 30 45

until the next cycle.

NOTE:

• If the setting is left at 0 pH or 0 mV, the controller will operate as

an on/off control with no proportional dosage. In this case the

controller will operate with a 0.1 pH or 7 mV hysteresis.

Do not set the time cycle to zeroDo not set the time cycle to zero

•

Do not set the time cycle to zero. This causes the relay to

Do not set the time cycle to zeroDo not set the time cycle to zero

chatter and can be detrimental to your system and pumps.

28

Page 29

OVERDOSAGE TIMEROVERDOSAGE TIMER

OVERDOSAGE TIMER

OVERDOSAGE TIMEROVERDOSAGE TIMER

All models provide for an overdosage alarm

system ranging from 1 to 10 minutes . The

5

2.5

7.5

operator can set the maximum amount of

time that the dosage terminals should continuously remain activated. Should this period

1

MINUTES

ALARM DOSING TIME

10

elapse, the alarm terminals are activated

(and dosage disactivated to ensure that chemicals have not run out

or pumps or electrovalves have not ceased to function properly).

5

2.5

ALK

7.5

HI 9911 provides for two independent such

5

TIMER

10

ACID

7.5

10

controls, one for acid dosage and another for

alkaline.

2.5

1

1

MINUTES

29

Page 30

pHpH

VALUES AT VARIOUS VALUES AT VARIOUS

pH

VALUES AT VARIOUS

pHpH

VALUES AT VARIOUS VALUES AT VARIOUS

TEMPERATURESTEMPERATURES

TEMPERATURES

TEMPERATURESTEMPERATURES

Please refer to the following chart for a more accurate pH calibration:

TEMP pH VALUES

°C °F 4.01 6.86 7.01 9.18 10.01

0

32

4.01

6.98

7.13

9.46

10.32

5

41

4.00

6.95

7.10

9.39

10.24

10

50

4.00

6.92

7.07

9.33

10.18

15

59

4.00

6.90

7.04

9.27

10.12

20

68

4.00

6.88

7.03

9.22

10.06

25

77

4.01

6.86

7.01

9.18

10.01

30

86

4.02

6.85

7.00

9.14

9.96

35

95

4.03

6.84

6.99

9.10

9.92

40

104

4.04

6.84

6.98

9.07

9.88

45

113

4.05

6.83

6.98

9.04

9.85

50

122

4.06

6.83

6.98

9.01

9.82

55

131

4.07

6.84

6.98

8.99

9.79

60

140

4.09

6.84

6.98

8.97

9.77

65

149

4.11

6.85

6.99

8.95

9.76

70

158

4.12

6.85

6.99

8.93

9.75

For instance, if the buffer temperature is 25°C (77°F), calibrate

the meter to read 4.01, 7.01 or 10.01 on the display.

If the buffer temperature is 20°C, calibrate it to 4.00, 7.03 or

10.06.

If the buffer temperature is 50°C, calibrate it to 4.06, 6.98 or

9.82.

30

Page 31

REDOX MEASUREMENTREDOX MEASUREMENT

REDOX MEASUREMENT

REDOX MEASUREMENTREDOX MEASUREMENT

(HI 9920)(HI 9920)

(HI 9920)

(HI 9920)(HI 9920)

Redox measurements allow the quantification of the oxidizing or

reducing power of a solution, and are commonly expressed in mV.

Oxidation may be defined as the process during which a molecule (or

an ion) loses electrons and reduction as the process by which electrons

are gained.

Oxidation is always coupled together with reduction so that as one

element gets oxidized, the other is automatically reduced, therefore

the term oxidation-reduction is frequently used.

Redox potentials are measured by an electrode capable of absorbing

or releasing electrons without causing a chemical reaction with the

elements with which it comes into contact.

The electrodes most usually available for this purpose have gold or

platinum surfaces; gold possesses a higher resistance than platinum

in conditions of strong oxidation such as cyanide, while platinum is

preferred for the measurements of oxidizing solutions containing

halides and for general use.

When a platinum electrode is immersed in an oxidizing solution a

monomolecular layer of oxygen is developed on its surface. This layer

does not prevent the electrode from functioning, but it increases the

response time. The opposite effect is obtained when the platinum

surface absorbs hydrogen in the presence of reducing mediums. This

phenomenon is rough on the electrode.

To make accurate redox measurements the surface of the electrode

must be clean and smooth. At certain mV and pH values, the ORP

electrode requires a considerable amount of time before it reads the

proper value. This is at times due to the fact that it is moving from

a reducing to an oxidizing state. Once it reaches a stable condition

though, it reacts rapidly to changes.

Hence when the process is first set up allow sufficient time for the ORP

electrode to adapt itself to the sample stream.

As with pH electrodes, gel-filled redox electrodes are more suitable for

industrial applications due to less maintenance requirements.

In the event that measurements are made in solutions containing

heavy doses of sulfide or protein, the diaphragm of the reference

electrode must be cleaned more often.

In order to test that the ORP electrode is functioning properly,

immerse it into a HI 7020 solution. The measured value should be

31

Page 32

between 200 and 250 mV.

When not in use, the electrode tip should be kept moist in order for

the reference junction, especially Teflon models, to respond quickly.

Otherwise, soak the electrode overnight in a HI 70300 storage

solution or allow more time upon installation for its stabilization. Also

keep the electrode far from any type of mechanical stress which might

cause damage.

Install the electrode in such a way that it is constantly in a well filled

with the sample (stream or tank) and does not dry up.

The protective cap should also be filled with a few drops of HI 70300

storage solution if the electrode is not being used at all.

Note:Note:

Note: With industrial applications, it is always good practice to

Note:Note:

keep at least one spare electrode handy. When anomalies are

not resolved with a simple maintenance, change the electrode

to see if the problem is alleviated.

32

Page 33

ELECTRODE CONDITIONINGELECTRODE CONDITIONING

ELECTRODE CONDITIONING

ELECTRODE CONDITIONINGELECTRODE CONDITIONING

& MAINTENANCE& MAINTENANCE

& MAINTENANCE

& MAINTENANCE& MAINTENANCE

PREPARATION

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DEPOSITS ARE PRESENT.

This is normal with electrodes and they will disappear when rinsed

with water.

During transport tiny bubbles of air may have formed inside the glass

bulb (membrane). Shake down the electrode as you would do with a

glass thermometer to remove these bubbles.

If the bulb and/or junction are dry, soak the electrode in a HI 70300

Storage Solution overnight.

STORAGE

To minimize clogging and assure a quick response time, the glass

bulb and the junction should be kept moist and not allowed to dry

out. This can be achieved by installing the electrode in such a way

that it is constantly in a well filled with the sample (stream or tank).

When not in use, pour a few drops of HI 70300 Storage Solution or,

in its absence, HI 7007 pH 7.01 Buffer Solution in the protective

cap and replace it on the electrode.

Note: NEVER STORE THE ELECTRODE IN DISTILLED OR DEIONIZED

WATER.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for the connection

to the controller must be intact and there must be no points of broken

insulation on the cable or cracks on the electrode stem or bulb.

Connectors must be perfectly clean and dry. If any scratches or cracks

are present, replace the electrode. Rinse off any salt deposits with

water.

CLEANING PROCEDURE

Soak in Hanna HI7061 General Cleaning Solution for ½ hour.

For more specific cleaning procedures, refer to the electrode’s instruc-

tion manual.

IMPORTANT: After performing any of the cleaning procedures rinse

the electrode thoroughly with distilled water and recalibrate the

controller.

33

Page 34

TROUBLESHOOTING

Evaluate your electrode performance based on the following.

• Noise (Readings fluctuate up and down) could be due to a

clogged/dirty junction: Refer to the Cleaning Procedure above.

• Dry Membrane/Junction: Soak in Storage Solution HI 70300

overnight. Check to make sure the installation is such as to create

a well for the electrode bulb to constantly remain moist.

• Low Slope: Refer to the cleaning procedure above.

• No Slope: - Check the electrode for cracks in glass stem or bulb

(replace the electrode if cracks are found).

- Make sure cable and connections are not damaged nor lying in a pool of water or solution.

• Slow Response/Excessive Drift: Soak the tip in Hanna Solution HI 7061 for 30 minutes, rinse thoroughly with distilled

water and then recalibrate the meter.

• For ORP Electrodes: Polish the metal tip with a lightly abrasive

paper (paying attention not to scratch the surface) and wash

thoroughly with water.

Note: With industrial applications, it is always recommended to keep

at least one spare electrode handy. When anomalies are not

resolved with a simple maintenance, change the electrode

(and recalibrate the controller) to see if the problem is

alleviated.

SUGGESTED INSTALLATIONSSUGGESTED INSTALLATIONS

SUGGESTED INSTALLATIONS

SUGGESTED INSTALLATIONSSUGGESTED INSTALLATIONS

for pH/ORP ELECTRODESfor pH/ORP ELECTRODES

for pH/ORP ELECTRODES

for pH/ORP ELECTRODESfor pH/ORP ELECTRODES

The electrode should be installed in such a way that its tip

permanently lies in the solution whether in a well, tank or on the

discharge pipe.

SHORT DISTANCE, INDOOR INSTALLATION

Due to the low currents involved, a very high grade of insulation is

required. A dry environment is needed in order to obtain a level of

insulation not lower than 10

This type of connection is very delicate and requires constant attention

to maintain proper operating conditions.

The conventional electrodes may be used for indoor applications but

the cable length should not exceed 10 m (33').

12

Ω.

34

Page 35

MEDIUM DISTANCE, INDOOR/OUTDOOR

INSTALLATION

When an outdoor installation is required, it is normally necessary to

install a transmitter to obtain accurate readings at distances from 10

to 50 m (33-165').

Since the introduction of AmpHel electrodes these distances are no

longer a problem. You can now connect your meter directly to an

AmpHel electrode, saving the cost of a transmitter.

The standard cable length of the AmpHel electrode is 5 m (16.5').

Additional lengths of regular cable up to 50 m (165'), can be

installed without special connectors. It is recommended to use coaxial

cables due to their excellent insulation, even though, Amphel electrodes can operate with both.

AmpHel electrodes have a micro-amplifier in the electrode cap to boost

the signal, drastically reducing susceptibility to noise and drift.

For more details about these or other specially made electrodes,

consult the Hanna process and water treatment literature, or call the

Hanna Office nearest to you.

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

pH ELECTRODES

HI 1002/3 Double Teflon junction with external threads

HI 1003/3 Double Teflon junction with matching pin

HI 2911B/5 Preamplified, double Teflon junction

ORP (Pt) ELECTRODES

HI 2002/3 Double Teflon junction with external threads

HI 2003/3 Double Teflon junction with matching pin

HI 2931B/5 Preamplified, double Teflon junction

ORP (AU) ELECTRODES

HI 2012/3 Double Teflon junction with external threads

HI 2013/3 Double Teflon junction with matching pin

Hanna manufactures hundreds of pH and ORP electrodes for a

wide variety of process and water treatment applications. Consult

the specific handbooks for electrodes and process instrumentation,

or simply call the Hanna Office nearest to you for a complete list.

35

Page 36

pH CALIBRATION SOLUTIONS

HI 7004L pH 4.01 buffer solution, 460 mL

HI 7007L pH 7.01 buffer solution, 460 mL

HI 7010L pH 10.01 buffer solution, 460 mL

ORP SOLUTIONS

HI 7020L 200-275mV ORP solution, 460 mL

HI 7091L Pretreatment reducing solution, 460 mL

HI 7092L Pretreatment oxidizing solution, 460 mL

ELECTRODE STORAGE SOLUTION

HI 70300L Storage solution, 460 mL

ELECTRODE CLEANING SOLUTIONS

HI 7061L General purpose cleaning solution, 460 mL

HI 7073L Protein cleaning solution, 460mL

HI 7074L Inorganic cleaning solution, 460mL

HI 7077L Oil & fat cleaning solution, 460 mL

OTHER ACCESSORIES

BL PUMPS Dosing pumps (several models are available with

flow rates from 1.5 to 18.3 lph / 0.4 to 4.8 gph)

ChecktempC Pocket-size thermometer (range -50.0 to 150.0°C)

ChecktempF Pocket-size thermometer (range -58.0 to 302.0°F)

HI 6050 Submersible electrode holder (605 mm/23.8" long)

HI 6051 Submersible electrode holder (1105 mm/43.5" long)

HI 6054B Electrode holder for in-line applications

HI 5001/5 3-wire Pt100 stainless steel temperature probe

HI 5002/5 3-wire Pt100 glass temperature probe

HI 8427 pH and ORP Electrode Simulator and high imped-

ance tester with 1 m (3.3') Coaxial Cable ending in

a male BNC connector (HI 7858/1)

HI 931001 pH and ORP Electrode Simulator with LCD Display

and 1 m (3.3') Coaxial Cable ending in a male BNC

connector (HI 7858/1)

36

Page 37

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

All Hanna controllers are warranted for two years against defects

in workmanship and materials when used for their intended purpose

and maintained according to instructions.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered. This warranty is limited to free of

charge repair or replacement of the meter only, if any malfunctioning

is due to manufacturing defects.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair

is not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments,

first obtain a Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs

prepaid. When shipping any instrument, make sure it is properly

packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty

card within 14 days from the date of purchase.

All rights are reserved. Reproduction in whole or in part is

prohibited without the written consent of the copyright owner,

Hanna Instruments Inc., 584 Park East Drive, Woonsocket,

Rhode Island, 02895 , USA.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance

notice.

37

Page 38

OTHER PRODUCTS FROM HANNAOTHER PRODUCTS FROM HANNA

OTHER PRODUCTS FROM HANNA

OTHER PRODUCTS FROM HANNAOTHER PRODUCTS FROM HANNA

• CABLES AND CONNECTORS

• CALIBRATION AND MAINTENANCE SOLUTIONS

• CHEMICAL TEST KITS

• CHLORINE METERS

• CONDUCTIVITY/TDS METERS

• DISSOLVED OXYGEN METERS

• HYGROMETERS

• ION SPECIFIC METERS (Colorimeters)

• MAGNETIC STIRRERS

• Na/NaCl METERS

• pH/ORP/Na ELECTRODES

• pH METERS

• PROBES (DO, µS/cm, RH, T, TDS)

• PUMPS

• REAGENTS

• SOFTWARE

• THERMOMETERS

• TITRATORS

• TRANSMITTERS

• TURBIDITY METERS

• Wide Range of ACCESSORIES

Most Hanna meters are available in the following formats:

• BENCH-TOP METERS

• POCKET-SIZED METERS

• PORTABLE METERS

• PRINTING/LOGGING METERS

• PROCESS METERS (Panel and Wall-mounted)

• WATERPROOF METERS

• METERS FOR FOOD INDUSTRY

For additional information, contact your dealer or the nearest Hanna

Customer Service Center.

You can also e-mail us at tech@hannainst.com.

38

Page 39

CE DECLARATION OF CONFORMITYCE DECLARATION OF CONFORMITY

CE DECLARATION OF CONFORMITY

CE DECLARATION OF CONFORMITYCE DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

We

Hanna Instruments Srl

V.ledelle industrie 12

35010 Ronchi di Villafranca (PD)

ITALY

herewith certify that the wall-mounted instruments:

HI 9910 HI 9911 HI 9920

have been tested and found to be in compliance with the following regulations:

IEC 801-2

IEC 801-3

IEC 801-4

EN 55022

EN 61010-1

Electrostatic Discharge

RF Radiated

Fast Transient

Radiated, Class B

User Safety Requirement

Date of Issue: 07-06-1999

D.Volpato- Engineering Manager

On behalf of

Hanna Instruments S.r.l.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment in which they are used.

Operation of these instruments in residential areas could cause unacceptable interference to radio and TV equipment.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

Unplug the instruments from power supply before replacing the fuse or making any

electrical connections.

39

Page 40

HANNA LITERATUREHANNA LITERATURE

HANNA LITERATURE

HANNA LITERATUREHANNA LITERATURE

Hanna publishes a wide range of catalogs and handbooks for an equally wide range of applications.

The reference literature currently covers areas such as:

• Water Treatment

• Process

• Swimming Pools

• Agriculture

• Food

• Laboratory

• Thermometry

and many others. New reference material is constantly

being added to the library.

For these and other catalogs, handbooks and leaflets,

contact your dealer or the Hanna Customer Service

Center nearest to you. To find the Hanna Office in

your vicinity, check our home page at

www.hannainst.com.

http://www.hannainst.com

PRINTED IN PORTUGAL

MAN9910-20 10/99

Loading...

Loading...