Page 1

Instruction Manual

HI 98703

Portable Turbidimeter

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product. This manual will provide you with the

necessary information for correct use of the instrument.

Please read this instruction manual carefully before using the instrument.

If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com

or see the back side of this manual for our worldwide sales and technical service contacts.

This instrument is in compliance with

directives.

WARRANTY

HI 98703 is warranted for two years against defects in workmanship and materials when used

for its intended purpose and maintained according to instructions. This warranty is limited to

repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact the dealer from whom you purchased the instrument. If under

warranty, report the model number, date of purchase, serial number and the nature of the failure.

If the repair is not covered by the warranty, you will be notified of the charges incurred. If the

instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization

number from the Technical Service Department and then send it with shipping costs prepaid.

When shipping any instrument, make sure it is properly packed for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the

date of purchase.

TABLE OF CONTENTS

WARRANTY ........................................................................................................................................................... 2

PRELIMINARY EXAMINATION ....................................................................................................................................3

GENERAL DESCRIPTION .......................................................................................................................................... 4

TAG IDENTIFICATION SYSTEM .................................................................................................................................. 5

ABBREVIATIONS .................................................................................................................................................... 5

PRINCIPLE OF OPERATION ......................................................................................................... ..............................6

MEASUREMENT UNITS ............................................................................................................................................ 7

FUNCTIONAL DESCRIPTION ...................................................................................................................................... 8

SPECIFICATIONS ................................................................................................................................................... 11

GENERAL TIPS FOR AN ACCURATE MEASUREMENT ................................................................................................... 12

MEASUREMENT PROCEDURE ................................................................................................................................. 19

CALIBRATION PROCEDURE ....................................................................................................................................22

LOGGING ............................................................................................................................................................ 26

GOOD LABORATORY PRACTICE (GLP) ...................................................................................................................... 29

SETUP ................................................................................................................................................................ 31

LCD BACKLIGHT ................................................................................................................................................... 35

TAG INSTALLATION ............................................................................................................................................... 35

LAMP REPLACEMENT ............................................................................................................................................. 36

BATTERIES MANAGEMENT .................................................................................................................................... 36

PC INTERFACE ..................................................................................................................................................... 38

ERROR CODES ....................................................................................................................................................38

ACCESSORIES ......................................................................................................................................................3 9

RECOMMENDATIONS FOR USERS ...........................................................................................................................39

2

Page 3

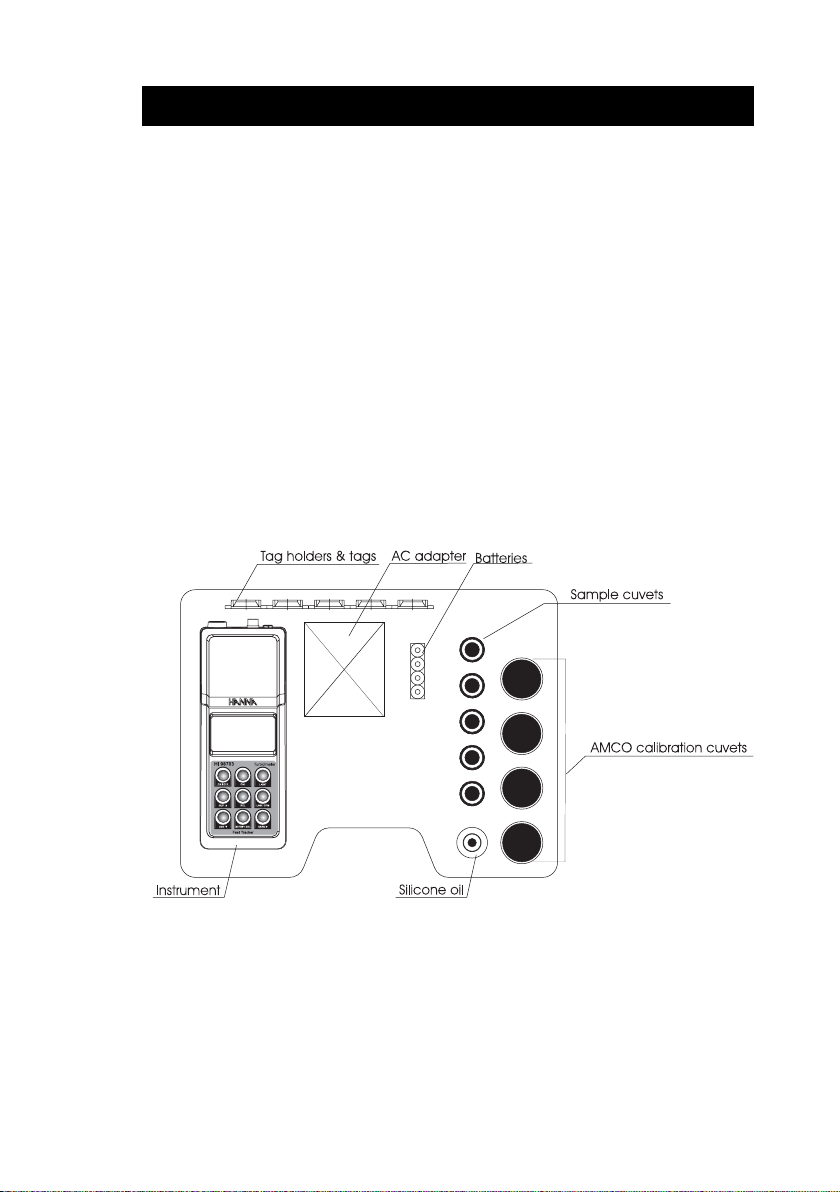

PRELIMINARY EXAMINATION

Please examine this product carefully. Make sure the instrument is not damaged. If any damage

has occurred during the shipment, please notify your dealer.

This HI 98703 Portable Turbidimeter is supplied complete with:

• Five Sample Cuvets and Caps

• Calibration Cuvets (HI 98703-11)

• Silicone Oil (HI 93703-58)

• Tissue for wiping the cuvets

• Five Tag holders with Tags (HI 920005)

• Batteries (4 pcs.)

• AC Adapter

• Instruction Manual

• Instrument Quality Certificate

• Rigid carrying case

Note:Save all packing material until you are sure that the instrument works correctly. Any

defective item must be returned in the original packing with the supplied accessories.

3

Page 4

GENERAL DESCRIPTION

GENERAL DESCRIPTION

HI 98703 is a high accuracy EPA compliant portable turbidimeter that benefits from Hanna’s years of

experience as manufacturer of analytical instruments. The HI 98703 meets and exceeds the requirements

of the USEPA Method 180.1 for wastewater and Standard Method 2130 B for drinking water.

The instrument is specially designed for water quality measurements, providing a reliable and

accurate reading on low turbidity values.

The HI 98703 instrument measures the turbidity of a sample in the 0.00 to 1000 NTU (Nephelometric

Turbidity Units) range. An effective algorithm calculates and converts the readings in NTU.

The instrument has an EPA compliance reading mode which rounds the reading to meet EPA reporting

requirements.

Depending on the measured probe and needed accuracy, normal measurement, continuous

measurement, or signal averaging measurement can be selected.

The instrument is based on a state-of-the-art optical system, which guarantees accurate results. The

optical system, consisting in a tungsten filament lamp and two detectors (scattered and transmitted),

assures long term stability and minimizes stray light and color interferences. It also compensates for

variations in intensity of the lamp, minimizing the need of frequent calibration.

The 25 mm round cuvets made from special optical glass guarantee the repeatability and consistency

of the measurements.

Calibration can be easily performed at any time in two, three ot four points (<0.1, 15, 100 and

750 NTU-adjustable calibration points), using the supplied or user prepared standards.

HI 98703 has complete GLP (Good Laboratory Practice) functions that allows traceability of the calibration

conditions. The last calibration points, time and date can be checked at any time by a single touch.

HI 98703 has a very user-friendly interface, with an easy to read, large LCD (Liquid Crystal Display).

The displayed codes guide the user step by step with routine operation and through calibration.

Confirmation and acoustic signals help the user during instrument operation.

The HI 98703 turbidimeter is a truly splash proof portable instrument. It is supplied with a rigid

carrying case that offers protection for harsh environments.

One battery set is enough for at least 1500 measurements. The battery charging percentage and low

battery condition are displayed on the LCD to avoid unexpected battery failure. In order to save the

battery life, the instrument has an auto shut-off feature and will turn off after 15 minutes of non-use.

In addition, the instrument is equipped with backlight and the current time is continuously displayed

on the LCD.

The instrument also provides a logging function. Up to 200 measurements can be stored in the

internal memory and consulted at any time. Data can be downloaded to a PC for storing or further

analysis through one of the two available ports: RS232 or USB.

For advanced field applications, the HI 98703 turbidimeter is equipped with Tag Identification

System (TIS) that makes data collecting and management simpler than ever.

4

Page 5

TAG IDENTIFICATION SYSTEM

Hanna is the first manufacturer of turbidity instruments that has decided to add the unique T.I.S. - Tag

Identification System to our Portable Turbidimeters, to meet the more restrictive needs of the users

and fit all advantages of this system to the turbidity measurements and data management.

The system is designed for scientific and industrial applications, or to prove during safety audits and

inspections that samples have been truly taken on pre-established locations.

The system is as easy to install as to operate. Just fix the so-called

sites that need to be checked often, and with this the T.I.S. is setup. The tag contains a computer chip

embedded in a durable stainless steel can. It is designed to withstand the harsh environments,

indoors or outdoors. The number of tags that can be installed is practically unlimited, because each

tag has a unique identification code.

Immediately after tags installation you can start collecting data. Use the Portable Turbidimeter to

take measurements and memorize the test result by pressing the Log-on-Demand key. Then, the

instrument will ask for the tag identification. Simply touching the

connector on the Portable Turbidimeter does identify and authenticate logging, by storing the

iButton® serial number, time and date stamp.

The power of the T.I.S. features resides in the PC application. Download all test data to your PC and

use our HI 92000 Windows® compatible application software for further data management. You can

sort or filter all your collected test data on different criteria like on a specific sampling location,

parameter, date and time intervals, or fix range to filter measured values. The data can be plotted in

a graph, exported to other common Windows® applications or printed for reporting purpose.

It is also possible to add new tags later on, thus increasing an already existing database. Each time the

PC software recognizes a new added tag, it will ask for a description of the new sampling location.

iButton® tags near your sampling

iButton® with the matching

ABBREVIATIONS

NTU Nephelometric Turbidity Units

JTU Jackson Turbidity Units

FTU Formazin Turbidity Units

USEPA US Environmental Protection Agency

LCD Liquid Crystal Display

RTC Real Time Clock

RH Relative Humidity

TIS Tag Identification System

ID Identification

iButton® is registered Trademark of “MAXIM/DALLAS semiconductor Corp.”

5

Page 6

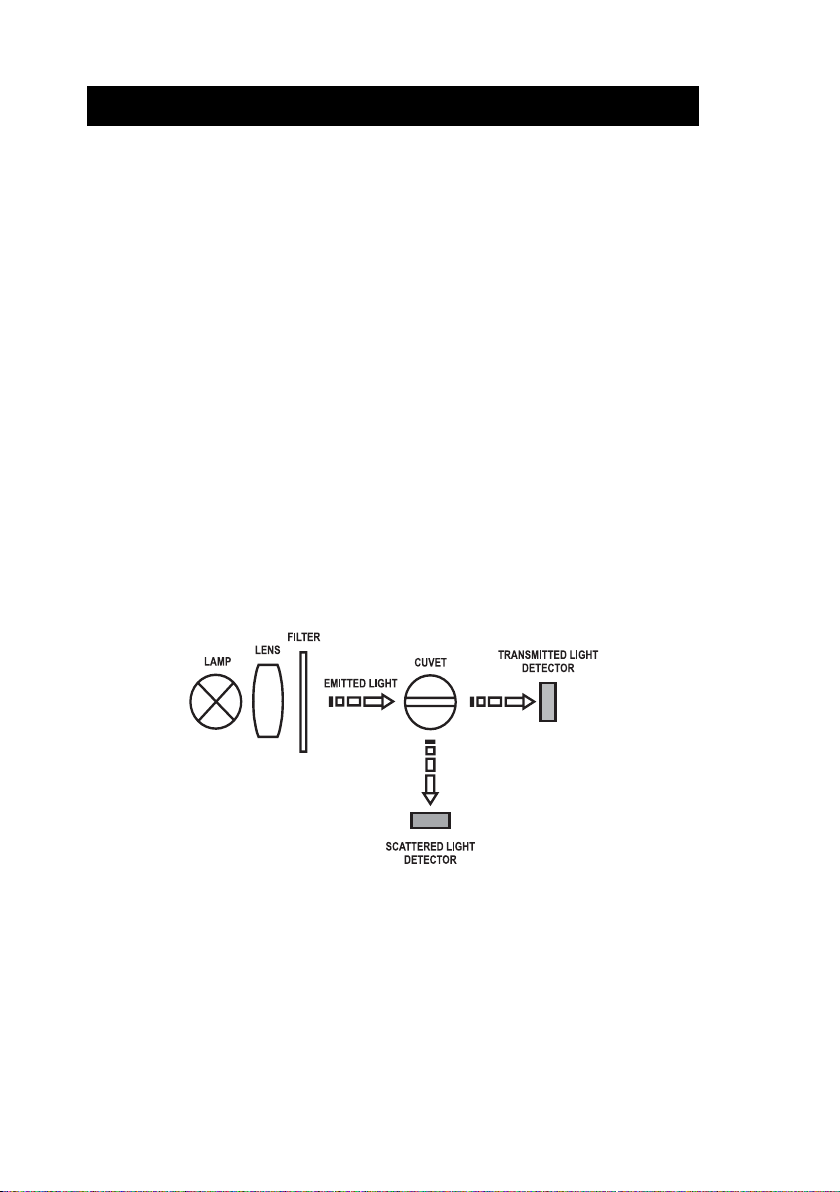

PRINCIPLE OF OPERATION

Turbidity of the water is an optical property that causes light to be scattered and absorbed, rather than

transmitted. The scattering of the light that passes through a liquid is primarily caused by the

suspended solids. The higher the turbidity, the greater the amount of scattered light. Because even

the molecules in a very pure fluid scatter light to a certain degree, no solution will have zero

turbidity.

The USEPA Method 180.1 specify the key parameters for the optical system to measure turbidity

for drinking, saline and surface water in a 0 to 40 NTU range, using the nephelometric method.

The HI 98703 Portable Turbidimeter is designed to meet or exceed the criteria specified by the

USEPA Method 180.1 and Standard Method 2130 B.

The light beam that passes through the sample is scattered in all directions. The intensity and pattern

of the scattered light is affected by many variables like wavelenght of the incident light, particle size,

shape, refractive index and color.

The Hanna’s HI 98703 is based on a state-of-the-art optical system that guarantee both high

performance and reliable results.

This optical system includes a tungsten filament lamp, a scattered light detector (90

transmitted light detector (1800). The microprocessor of the instrument calculates from the signals

that reaches the two detectors, the NTU value, using an effective algorithm. This algorithm corrects

and compensates for interferences of color, making the HI 98703 turbidimeter color-compensated.

0

) and a

The optical system and measuring technique alow the compensation of lamp intensity fluctuations,

minimizing the need of frequent calibration.

The lower detection limit of a turbidimeter is determined by the so called “stray light”. Stray light

is the light detected by the sensors, that is not caused by light scattering from suspended particles.

The optical system of HI 98703 turbidimeter is designed to have very low stray light, providing

accurate results for low turbidity samples. However, special care must be taken when measuring low

turbidities (see General Tips for an Accurate Measurement for sample preparation and measuring

techniques).

6

Page 7

MEASUREMENT UNITS

)

Many methods were used to measure turbidity over the years. The Jackson Candle Turbidimeter was

used to measure turbidity as Jackson turbidity units (JTU). The Secchi Disk is commonly used to

measure turbidity in lakes and other deep waters (mg/L SiO2). Both methods are visual and are not

considered very accurate. To obtain more accurate readings a nephelometer should be used as a

turbidity reading instrument.

The HI 98703 turbidimeter reports the measurements only in NTU (Nephelometric Turbidity

Units). NTU units are equal to FTU units (Formazine Turbidity Units). The conversion table

between these measurement units is shown bellow:

UTJ UTF/UTN OiS

UTJ 1 91 05.2

UTF/UTN 350.0 1 31.0

OiS

)L/gm( 4.0 5.7 1

2

L/gm(

2

7

Page 8

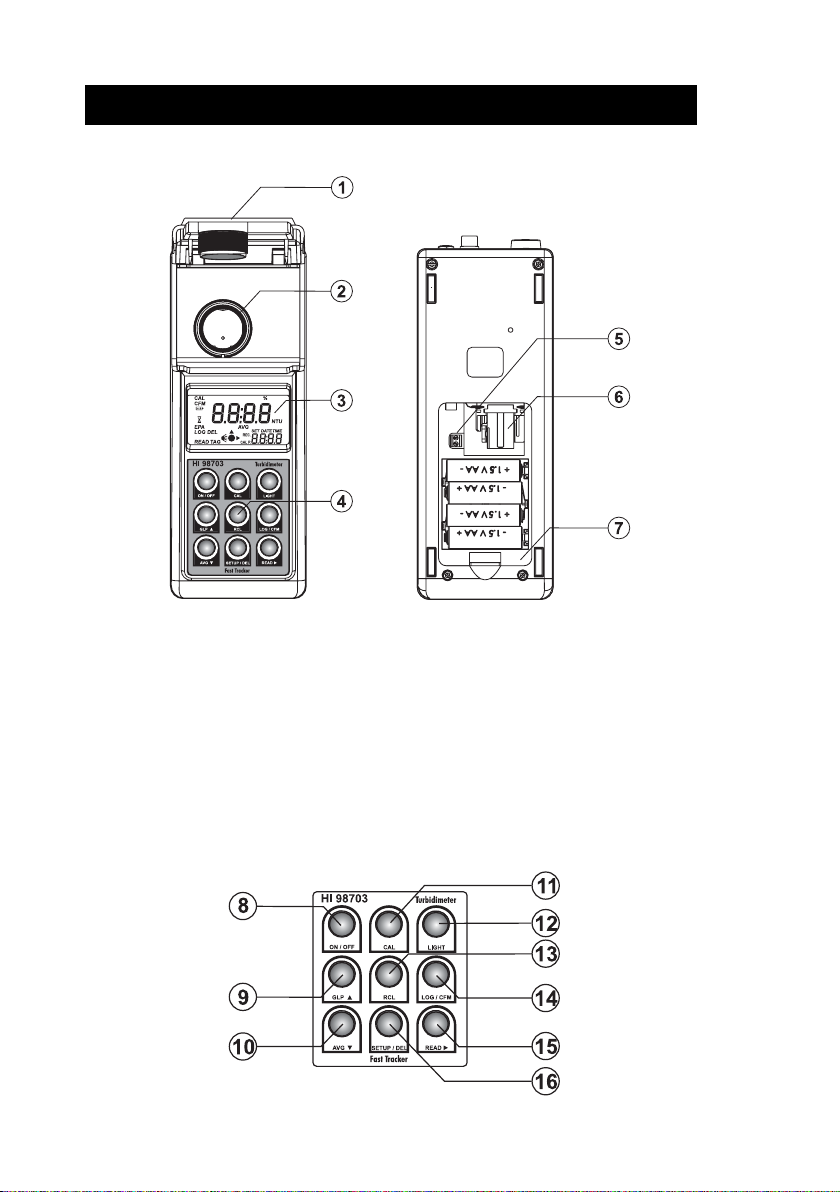

FUNCTIONAL DESCRIPTION

INSTRUMENT DESCRIPTION

1) Cuvet Lid. Close the cuvet lid prior to start a measurement.

2) Cuvet Holder. Insert the cuvet into the holder with the cuvet mark matching the case mark.

3) Liquid Crystal Display (LCD). The LCD has backlight for better visibility in dark environments.

4) Keypad. Splash proof resistant.

5) Lamp connector. Connect the new lamp using a screwdriver during lamp changing procedure.

6) Lamp. Replacable tungsten lamp.

7) Battery Lid. Remove the battery lid in order to change batteries or replace the lamp.

KEYPAD DESCRIPTION

8

Page 9

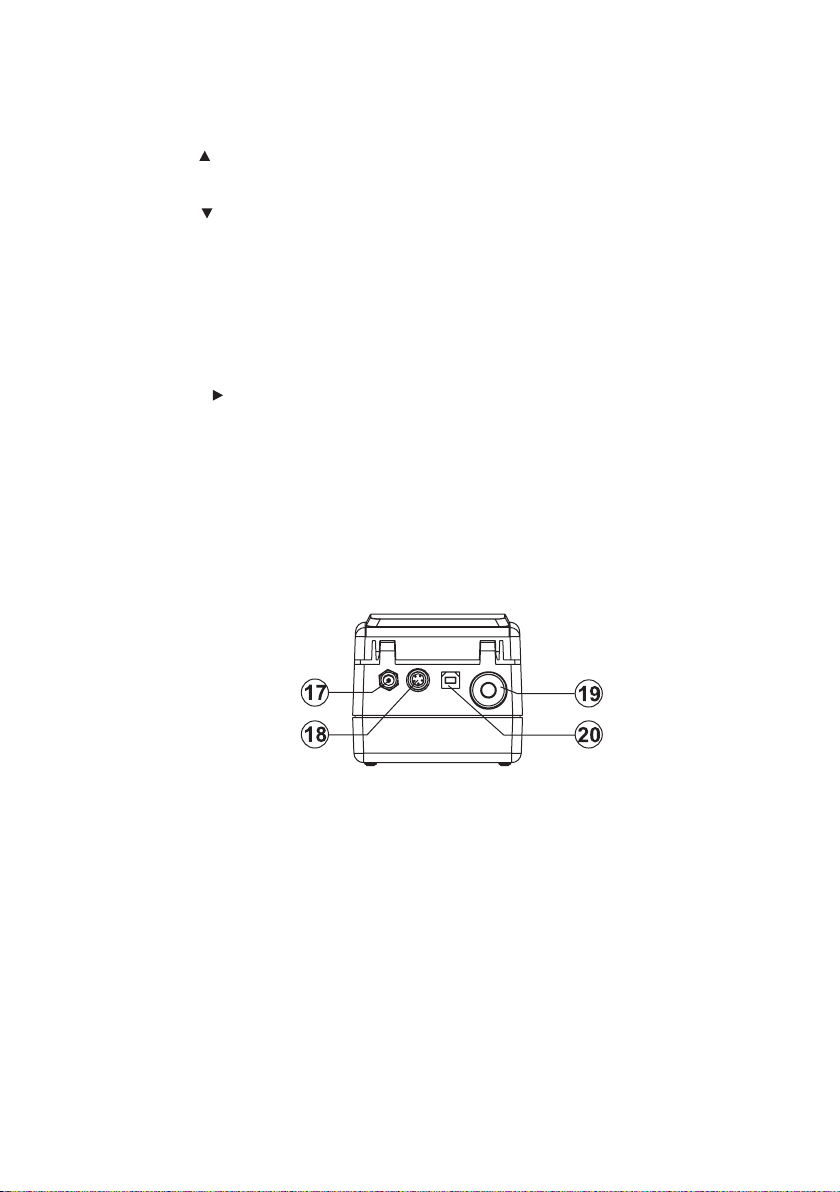

8) ON/OFF, press to turn the instrument ON/OFF. If no key is pressed for more than 15

minutes, the instrument automatically shuts off.

9) GLP

10) AVG

11) CAL, press to enter/exit calibration. During setup it is used to start/stop editing a parameter.

12) LIGHT, press to turn ON/OFF the backlight.

13) RCL, press to enter/exit viewing log content.

14) LOG/CFM, press to save the log records or to confirm the selected option.

15) READ

16) SETUP/DEL, press to enter/exit setup. The DEL function is available in Log Recall to delete

CONNECTORS DESCRIPTION

, press to enter/exit GLP feature. In SETUP it is used to increase the set values. In Log

Recall it is used to select a newer record (scroll up).

, press to set the average reading mode ON/OFF. In SETUP it is used to decrease the

set values. In Log Recall it is used to select an older record (scroll down).

, press to start a measurement. Press and hold READ to make a continuous

measurement. In Log Recall it is used to see the content of a record. In GLP it is used to

see all available informations. In SETUP, during date or time editing, it is used to move the

focus on the next setting item.

one or all records. In GLP it is used to delete the user calibration.

17) AC adapter connector, used to connect an external AC Adapter.

18) RS232 connector, used to transfer data through the RS232 connection. Use HI 920011

serial cable to connect to the PC.

19) Tag reader connector. Touch the tag with the connector to read the location identification

number during logging.

20) USB connector, used to transfer data to the PC.

9

Page 10

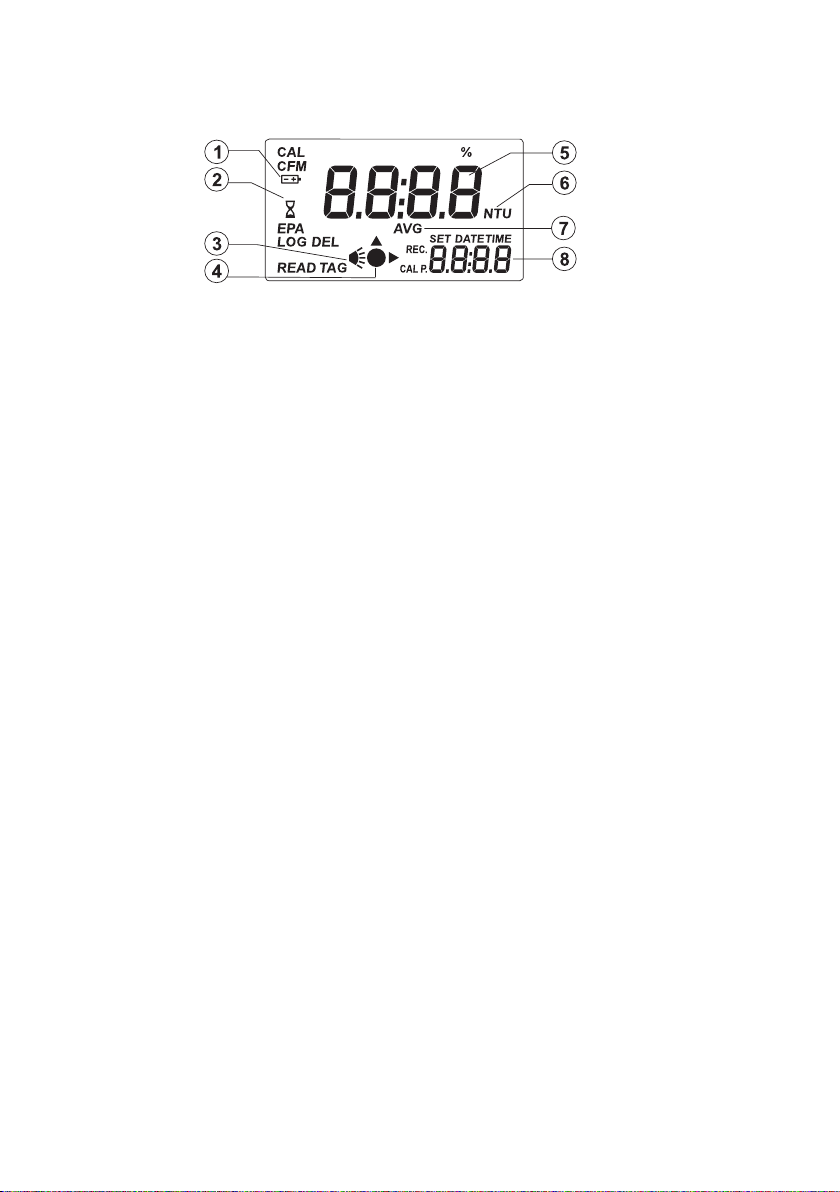

DISPLAY DESCRIPTION

1) Battery icon. When it is ON, it shows that the instrument works on battery. When blinking,

the batteries are almost empty and need to be replaced.

2) Wait icon. It is displayed when the instrument performs an internal checkup.

3) Lamp icon. The lamp icon is shown when the lamp is turned on.

4) Measurement icon. The icon shows the measuring scheme of the instrument.

5) Four digit main display. The main display shows the turbidity value after one measurement.

Depending on the instrument working mode, other values or messages are displayed.

6) Measurement units. The turbidity is measured in NTU. When average or continuous mode is

selected, the “NTU” tag blinks for each new displayed value. For conversions in other units

see Measurement Units section.

7) AVG icon. When selected, the measurement will be taken in average mode. The “NTU” tag

will blink for each new displayed value.

8) Four digit secondary display. The secondary display shows the current time (if selected) or

other values/messages.

BEEPER

A beeper is used to make the user interface more friendly. An error or invalid key press is

signaled by a long beep. A confirmation beep is signaled by a short beep. The beeper is

selectable as ON or OFF in Setup Menu.

10

Page 11

SPECIFICATIONS

Range 0.00 to 9.99 NTU

10.0 to 99.9 NTU

100 to 1000 NTU

Range Selection Automatically

Resolution 0.01 NTU from 0.00 to 9.99 NTU

0.1 NTU from 10.0 to 99.9 NTU

1 NTU from 100 to 1000 NTU

Accuracy ±2% of reading plus 0.02 NTU

Repeatibility ±1% of reading or 0.02 NTU, whichever is greater

Stray Light < 0.02 NTU

Typical EMC Deviation ±0.05 NTU

Light Source Tungsten filament lamp

Lamp Life Greater than 100,000 readings

Light Detector Silicon Photocell

Method Ratio Nephelometric signal (90') scatter light ratio transmitted light

Adaptation of the USEPA Method 108.1 and Standard Method

2130 B

Display 60 x 90mm LCD with backlight

Standards 15, 100 and 750 NTU

Calibration One, two or three point calibration

LOG Memory 200 records

Serial Interface RS232 or USB 1.1

Environment 0 to 50°C (32 to 122°F); max 95% RH non-condensing

Power supply 4 x 1.5V AA alkaline batteries or AC adapter

Auto Shut-off After 15 minutes of non-use

Dimensions 224 x 87 x 77 mm (8.8 x 3.4 x 3.0”)

Weight 512 g (18 oz.)

11

Page 12

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

HI 98703 is a highly accurate turbidimeter. To meet the instrument performance and fully

benefit of its properties it is very important that the analyst perform accurate, precise and

repeatable readings using proper measurement techniques. Special care must be taken during

sample preparation and handling.

The instructions listed below should be carefully followed during measurement and calibration to

ensure best accuracy.

CUVET

The cuvet is part of the optical system in all measurements. The light reaches the sample by

passing through the cuvet glass. As a result, the measurement can be affected by the glass

imperfections, dirt, dust, scratches, or fingerprints present on the cuvet surface.

CUVET HANDLING

The cuvets should be free of scratches or cracks. Any cuvet with visible scratches will be

discarded. The cuvets should be periodically washed with acid. After washing, the cuvets should

be well rinsed many times with distilled or deionized water. Allow cuvets to air-dry and store

them for long periods of time with caps, to avoid dirt entering inside. Always handle the cuvet

by touching only the cap or its top side (over the horizontal line).

Always store the cuvets in separate boxes or with separators between them to avoid scratches on

the surface.

CUVET PREPARATION

Whenever a cuvet is used, it must be clean inside and outside. When it is placed into the

instrument, it must be dry outside, completely free of fingerprints or dirt.

If the cuvet is not indexed, put the cuvet with the factory mark aligned with the sign on the

instrument top.

12

Page 13

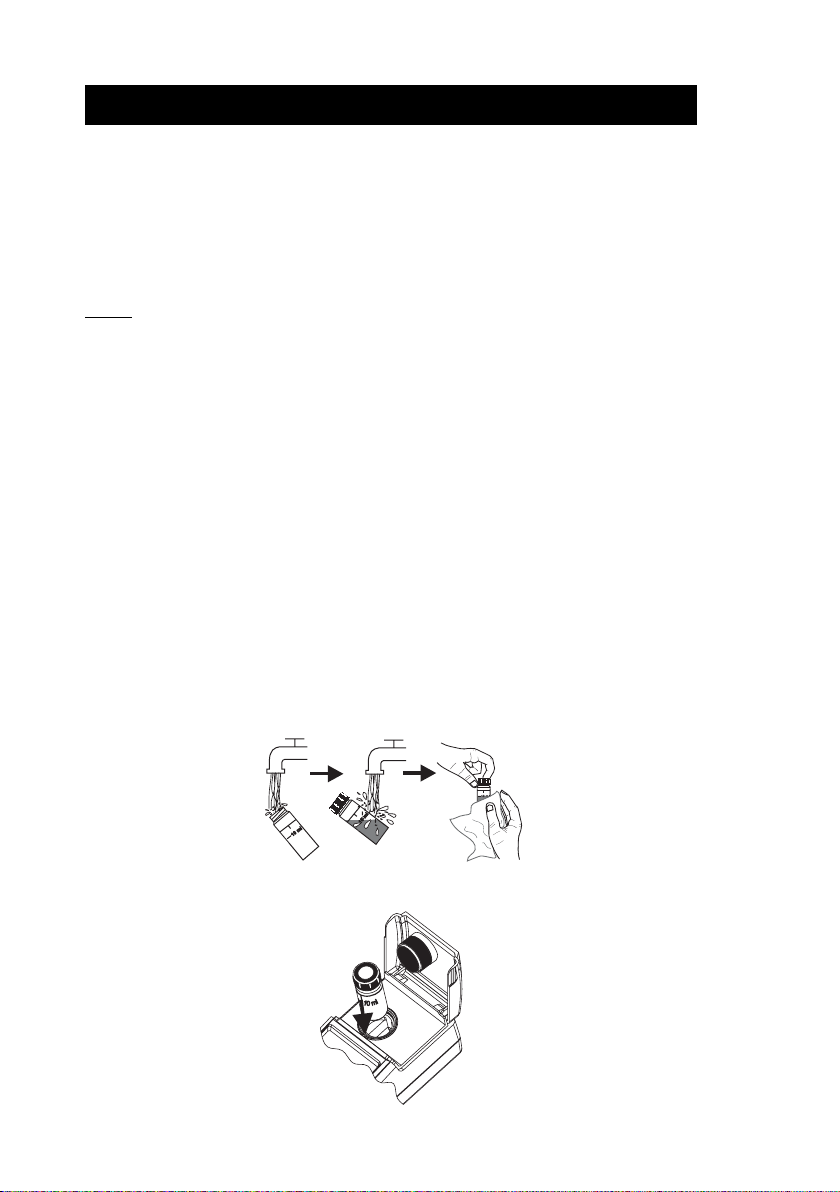

CUVET OILING

To hide minor imperfections and scratches, the cuvets should be oiled outside with the supplied

silicone oil. This is very important, especially for low turbidity samples (< 1 NTU), otherwise

scratches can contribute and alter turbidity readings.

The silicone oil has the same refractive index as the glass and will not alter the turbidity readings.

It is important to apply only a thin layer of silicone oil.

Warning: Do not apply the oil in excess, it may retain dirt or contaminate the cuvet holder of the

instrument, altering the turbidity readings.

It is very important to apply the silicone oil on a clean, dry cuvet. Apply a few drops of oil and wipe

the cuvet thoroughly with a lint-free cloth. Wipe off the excess of oil till you obtain a thin, uniform

layer. If the procedure is correctly followed, the cuvet should appear nearly dry with no visible oil.

Note: The supplied cloth for oiling should be stored together with the silicone oil bottle and cuvets,

taking care to avoid contamination with dirt. After a few oiling procedures the cloth will

contain enough oil to wipe the bottle with it without adding more oil. From time to time add

some drops of oil on the cuvet to provide the necessary oil quantity in the cloth.

INDEXING A CUVET

It is very important for low turbidity readings to always insert the cuvet into the instrument in the

same position.

All cuvets are factory indexed. This index can be used to put the cuvet with the factory mark on the

cuvet aligned with the sign on the instrument top.

To further reduce the effect of glass imperfections, the cuvet can be indexed and use this new index

as the position mark.

For indexing one cuvet or matching multiple cuvets the continuous reading mode is suggested. In this

mode if READ

After first reading is displayed, it is possible to open the cuvet lid and rotate the cuvet without

generating an error condition. The turbidity is immediately displayed, reducing drastically the

measurement time. The lamp of the instrument will turn off only when READ is released.

Note: The instrument can not perform continuous readings if the average mode is on.

is kept pressed, multiple successive readings are taken without turning off the lamp.

13

Page 14

In order to index a cuvet follow the next steps:

• Fill the cuvet with high quality water (<0.1 NTU)

up to the line.

• Clean and oil the cuvet as described before.

• Turn the instrument ON.

• Insert the cuvet into the instrument and press

. Record the reading.

READ

• Open the instrument lid, slightly rotate the cuvet

and take a new reading.

• Repeat the last step until you read the lowest

NTU value. Alternatively, keep READ

and, after the first value is displayed, open the

lid and start rotating the cuvet until the lowest

NTU value is displayed.

• Mark this position on the thicker white band on

the top of the cuvet with a water resistant pencil.

• Always use this position to align it with the

sign on the instrument top.

pressed

14

Page 15

MATCHING MULTIPLE CUVETS

Precise measurements require the use of a single cuvet. If it is not possible, the cuvet selection

and matching must be performed before taking measurements.

In order to match multiple cuvets follow the next

steps:

• Fill some cuvets with high quality water

(<0.1 NTU) up to the line.

• Clean and oil the cuvets as described before.

• Turn the instrument ON.

• Insert the first cuvet into the instrument and

press READ

. Record the reading.

• Record the position of the cuvet and the

displayed reading.

• Mark this position on the thicker white band on

the top of the cuvet with a water resistant pencil.

• Insert the second cuvet into the instrument and

take a reading.

15

Page 16

• Open the instrument lid, slightly rotate the cuvet and take a new reading.

• Repeat the last step for the second cuvet until the reading is within 0.01 NTU of the value

obtained for the first cuvet.

• Alternatively, keep READ

rotating the cuvet until the displayed value matches the first cuvet.

• Mark this position on the second cuvet with a water resistant pencil.

• Follow the same procedure for all the necessary cuvets.

Note: If the cuvet is indexed, use the index to position it in the instrument.

SAMPLING TECHNIQUE

When taking turbidity measurements it is very important to select a representative sample. For

consistent results, follow the next tips when sampling:

• Gently mix the water before taking the sample.

• If the sample is taken from a pipe, discard the first few liters.

• If measuring a non uniform source, collect samples from different places and mix them.

When measuring the collected sample, keep in mind the following:

• Samples should be analyzed immediately after collection because the turbidity can change in time.

• To avoid dilution of the sample it is better to rinse the cuvet with a quantity of sample and then

discard. Only after this you can fill the cuvet with sample.

• Pay attention that cold samples do not condense on the sample cell.

pressed and, after the first value is displayed, open the lid and start

REMOVING AIR BUBBLES

Any air bubbles present in the sample will cause high turbidity readings. To obtain accurate

measurements, remove the air bubbles using one of these methods:

• Application of a partial vacuum;

• Addition of a surfactant, such as Triton X-100;

• Use of an ultrasonic bath;

• Heating the sample.

Sometimes it is necessary to combine two or more methods for efficient air bubble removal.

Note: Each method can alter the sample turbidity, if misused, so they have to be used with caution.

16

Page 17

APPLICATION OF VACUUM

Vacuum works by decreasing the atmospheric pressure. In this way the bubbles from the solution

came out to the surface.

Application of vacuum is a very simple procedure and can be applied with any vacuum source at hand.

The simplest equipment at hand is a syringe and a rubber stopper for vacuum degassing.

Notes: • Pay attention that the vacuum equipment be clean and oil-free.

• It is not recommended to apply vacuum to a viscous sample that contains volatile

components. In such cases the vacuum can determine the volatile component of the

viscous sample to increase the bubbles from the sample.

ADDITION OF SURFACTANT

Surfactant addition works by changing the surface tension of the water. In this way bubbles are

released from the sample. This method is effective in samples that are supersaturated with air.

The procedure consists in the addition of a drop of surfactant in the cuvet before adding the sample

to be analyzed.

A convenient surfactant to use for degassing is Triton X-100.

Warning: Pay attention that changing the surface tension will cause a rapid settling of particles that

cause turbidity. To avoid this problem, analyze as soon as possible the sample.

Do not shake vigorously the sample because the surfactant may foam. If you are using the same

cuvet, rinse it before adding a new sample in order to avoid surfactant accumulation.

Surfactant contribution to the turbidity readings is negligible.

Note: Surfactant addition should be used for degassing only when other methods are ineffective.

USE OF AN ULTRASONIC BATH

The ultrasonic waves are very effective in removing air bubbles from samples. However, ultrasonic

waves should be used with care because they can alter sample turbidity characteristics, by modifying

the shape and size of particles which cause turbidity. The ultrasonic waves can also break the existing

air bubbles, leading to a complication of the degassing process.

In order to avoid excess application of the ultrasonic waves you can apply ultrasound until all visible

air bubbles are removed, and then measure the sample turbidity. This is the most used procedure for

degassing.

If you are not sure that all air bubbles were removed, apply ultrasonic waves again for a short period

of time and then measure the turbidity. Repeat this procedure until the turbidity is increasing instead

of decreasing, sign that turbidity of the sample was altered.

In order to degas a sample fill a clean cuvet with sample and immerse it (1/2 to 2/3 immersed) in

an ultrasonic bath. Follow the degassing procedure described above. Only after the degassing

procedure is finished, the cuvet can be capped.

17

Page 18

HEATING THE SAMPLE

Use of heat to remove air bubbles, although very effective in some cases, should be handled with care

because it can alter the turbidity of the sample. When heating a sample, the volatile components

from the sample can vaporize, the suspended components can dissolve or the sample characteristics

can change.

Therefore, the heating procedure should be used with extreme care.

The best way is to use a warm water bath and immerse the cuvet with sample into the bath. Heat the

sample only until the visible bubbles are removed.

Note: Always cool the heated sample to the original sample temperature before measurement.

The heating procedure can be used in combination with vacuum or ultrasonic waves application for

a more effective air bubble removal.

18

Page 19

MEASUREMENT PROCEDURE

When taking any turbidity measurements several basic rules should be followed:

• Use always cuvets without scratches or cracks because they can cause inaccurate readings.

• Cap always the cuvets to avoid spillage of the sample into the instrument.

• Close always the lid of the instrument during measurement.

• Keep the lid of the instrument closed when it is not used to prevent dust or dirt entering.

• Put always the instrument on a flat, rugged surface when taking measurements.

• Do not operate in direct sunlight.

• Do not use too much oil to prevent contamination of the optical system.

To take turbidity measurements, follow the next steps:

• Turn the instrument ON by pressing ON/OFF.

When dashes are displayed on the LCD, the

instrument is ready. On the secondary LCD the

current time appears, if selected in SETUP menu.

• Fill a clean, dry cuvet with 10 mL of sample up

to the mark, taking care to handle the cuvet by

the top.

• Replace the cap.

• Wipe the cuvet thoroughly with a lint-free cloth

to remove any fingerprints, dirt or water spots.

• Apply silicone oil on the cuvet and wipe with a

lint-free cloth to obtain an even film over the

entire surface of the cuvet.

Note: It is very important to oil the cuvet, espe-

cially for low turbidity values (< 1 NTU) to

hide the glass imperfections that can influence the reading.

• Place the cuvet into the instrument. Align the

mark from the cuvet with the sign on the instrument case and close the lid.

Note: If you have a cuvet with orientation mark,

place the cuvet into the instrument with the

orientation mark aligned with the sign on

the instrument top.

19

Page 20

NORMAL MEASUREMENT

This type of measurement can be used for regular measurements, when the sample is stable and

normal accuracy is required. In normal measurement mode, the lamp is ON for a minimum period of

time (about 7 seconds), saving the battery life. Normal measurement takes about 10 seconds.

If normal measurement is selected, the “AVG” tag will not be displayed.

• Press READ to start the measurement.

The display will show blinking dashes and the

icons for cuvet, detectors and lamp will appear

during measurement.

At the end of the measurement, the instrument

directly displays turbidity in NTU.

CONTINUOUS MEASUREMENT

This measurement mode can be used when many measurements have to be taken in a short period

of time. The feature is also useful to evaluate a very fast settling sample. This measurement mode

is recommended for indexing cuvets. After the first reading is taken, the lid opening will not generate

any errors.

The first value is displayed after about 10 seconds and then a new reading is displayed each second.

In order to make a continuous measurement keep READ

measurements are taken. The display will show blinking dashes and the icons for cuvet, detectors

and lamp will appear. When a new value is displayed, the cuvet icon and the measurement unit will

briefly blink.

The last value remains on the display after the READ is released.

pressed until the desired number of

AVERAGED MEASUREMENT

Select this measurement mode when samples that cause unstable readings are analyzed. By averaging

several readings, the random noise generated by the sample is reduced and accurate measurements

can be taken.

This mode can also be selected when high accuracy measurements are desired. In the average mode

10 measurements are averaged in a short period of time (about 20 seconds). The initial value is

displayed after 10 seconds and the display is updated every second with an intermediate value.

• To select the averaged measurement mode press

AVG

.

When this mode is selected, the AVG icon will

be displayed on the LCD.

20

Page 21

• Press READ to start the average reading mode.

t

The display will show blinking dashes and the

icons for cuvet, detectors and lamp will appear

during measurement. When a new partial value

is displayed, the cuvet icon and the measurement

unit will blink shortly.

When the measurement is ended, the final

averaged result is displayed directly in NTU.

RANGE AND UNITS

HI 98703 automatically selects the correct range

to display the results with the highest accuracy. If

the measured value is higher than 1000 NTU (over

range), the display will show the maximum value

blinking.

The instrument has an EPA compliance reading

mode. If this feature is activated in SETUP, “EPA”

tag will appear on the LCD and the readings will be

rounded to meet EPA reporting requirements, as

shown in the table:

UTN

0.1-0.0 50.0

01-1 1.0

04-01 1

001-04 5

004-001 01

0001-004 05

0001> 001

seraeNotdroceR

21

Page 22

CALIBRATION PROCEDURE

HI 98703 has a powerful calibration function that compensates for lamp aging or changing. The

calibration can be done using the suplied calibration solutions or user prepared standards.

HI 98703 turbidimeter is supplied with 4 AMCO standards: <0.1 NTU, 15 NTU, 100 NTU and 750

NTU. The Hanna standards are specially designed for this instrument. The turbidity standards have a

shelf life and should not be used after the expiration date.

Alternatively, formazin standards can be used. It is recommended that the prepared calibration

solutions to be close to the default calibration points.

The first point should be near 0 NTU. The second point can be chosen between 10 and 20 NTU, the

third point between 50 and 150 NTU and the fourth point between 600 and 900 NTU.

FORMAZIN PREPARATION

In order to prepare formazin 4000 NTU stock solution, follow the next procedure:

Solution I Dissolve 1.000 grams of hydrazine sulfate, (NH2)2 H2SO4, in distilled, deionized

water and dilute to 100 mL in a volumetric flask.

Warning: Handle hydrazine sulfate with care because it is a carcinogen reagent. Avoid inhalation,

ingestion, or skin contact. Formazin solution can also contain some hydrazine traces.

Solution II Dissolve 10.000 grams of hexamethylenetetramine, (CH2)6N4, in distilled, deionized

water and dilute to 100 mL in a volumetric flask.

Stock solution Mix 10 mL Solution I and 10 mL Solution II in a flask. Let the stock solution stays

48 hours at 25±3°C (77±5°F). This will result in a 4000 NTU formazin suspension. It is very

important for the formation of the formazin polymer to maintain the same temperature.

The stock solution (4000 NTU) can be stored up to one year in proper conditions. Store formazin in

amber glass bottle or any UV-light blocking bottle.

To obtain a high quality formazin always use pure reagents and high-purity water.

To prepare the calibration standards, dilute the stock solution with the same high-purity water you

used for the preparation of the stock solution.

The diluted formazin solutions are not stable. They should be used immediately after preparation

and discard immediately after use.

If the prepared formazin is used, enter the actual standard value by pressing UP or DOWN key to edit

the value of the second, third or fourth calibration point.

CALIBRATION

For best results, the measurement techniques must be followed during calibration. If formazin

standards are used, mix the cuvets gently for about 1 minute and then allow the standard to settle for

one more minute before calibration.

Calibration can be performed in two, three or four points. It is possible to interupt calibration

procedure at any time by pressing CAL or ON/OFF.

22

Page 23

TWO-POINT CALIBRATION

• Turn the instrument on by pressing ON/OFF.

When the LCD displays dashes, the instrument

is ready.

• Enter calibration mode by pressing CAL.

The display will show “CAL P.1” and no

suggested value. This first point is used to

check the optical system.

• Place the <0.1 NTU standard cuvet into the

holder and ensure that the cuvet mark is aligned

with the sign on the instrument top.

• Close the lid and press READ . The display

will show blinking dashes and the icons for

cuvet, detectors and lamp will appear during

measurement. Alternatively, press LOG/CFM to

skip the first point.

• The second calibration point (15.0 NTU) is

then displayed on the primary LCD, “CAL P.2”

on the secondary LCD, and “READ” tag will

blink.

• If the prepared formazin is used, edit the

displayed value by pressing UP or DOWN keys

until the display shows the correct value.

• Remove the first standard cuvet and place the

15.0 NTU standard cuvet (or the prepared one)

into the holder and ensure that the cuvet mark

is aligned with the sign on the instrument top.

• Close the lid and press READ

will show blinking dashes and the icons for

cuvet, detectors and lamp will appear during

measurement.

. The display

23

Page 24

• At the end of the measurement, the third calibration

point (100 NTU) is displayed on the primary LCD,

“CAL P.3” on the secondary LCD, and “READ” tag

will blink.

• At this moment it is possible to exit calibration

by pressing CAL. The instrument will memorize

the two-point calibration data and will return

to measurement mode.

THREE-POINT CALIBRATION

To perform a three-point calibration, continue the

procedure with the following steps:

• Remove the second standard cuvet.

• Place the 100 NTU standard cuvet (or the

prepared formazin standard) into the holder,

with the cuvet mark aligned with the sign on

the instrument.

• Close the lid and press READ

will show blinking dashes and the icons for

cuvet, detectors and lamp will appear during

measurement.

• At the end of the measurement, the fourth

calibration point (750 NTU) is displayed on the

primary LCD and “CAL P.4” on the secondary LCD.

• At this moment it is possible to exit calibration

by pressing CAL. The instrument will memorize

the three-point calibration data and will return

to measurement mode.

FOUR-POINT CALIBRATION

To perform a four-point calibration, continue the

procedure with the following steps:

• Remove the third standard cuvet.

• Place the 750 NTU standard cuvet (or the prepared

formazin standard) into the holder, with the cuvet

mark aligned with the sign on the instrument.

. The display

24

Page 25

• Close the lid and press READ . The display

will show blinking dashes and the icons for

cuvet, detectors and lamp will appear during

measurement.

• At the end of the measurement, the four-point

calibration is completed and the instrument

returns automatically to measurement mode.

OUT CAL RANGE FUNCTION

The instrument has an Out Cal Range function to

prevent taking measurements in a range where the

calibration does not assure the best results. The range

where the calibration assures correct measurements is

up to 40 NTU for two-point calibration and up to 150%

of the third point value for three-point calibration.

The display will show a blinking “CAL” tag each time the

measurements are taken outside the calibration range.

CALIBRATION ERRORS

• If the read value during calibration is too far

from the set value, the instrument will show

“-LO-” or “-HI-” error.

• If the calculated calibration coefficients are outside

a certain range, the “CAL Err” message is displayed.

or

CALIBRATION DELETION

HI 98703 is factory calibrated. It is possible to restore

factory calibration by deleting last performed calibration.

To delete last calibration, follow the next steps:

• Enter the GLP feature by pressing GLP

.

The date of the last calibration will be displayed

on the LCD.

• Press READ

to see the information related to

calibration. The last panel is the one with delete

calibration.

• Press SETUP/DEL to delete the current

calibration. After deletion the instrument will

automatically return to measurement mode.

25

Page 26

LOGGING

HI 98703 has a log space for up to 200 records. With each measurement, the date, time and tag ID

is stored. In this way, each record is fully characterized and can be easily analyzed when downloading data on the PC application (HI 92000).

LOGGING

The log function is active after a valid measurement

is obtained (no errors).

• To log a value, press LOG/CFM when the

measurement result is displayed.

The instrument asks to READ TAG for identification

of the sampling location. The location for the new

record is also displayed on the secondary LCD.

• To read the ID code for the sampling location

identification, simply touch the

the matching connector, located on the back of

the instrument (see Connectors Description,

page 9). Alternatively, press again LOG/CFM to

store the record without the tag ID code.

iButton

®

tag with

or

• If the tag is successfully read, the instrument will

beep once, displaying the unique hexadecimal

code of the tag, and store the data.

After data is stored, the instrument returns to

measurement mode.

Notes: • If the tag is not read within 20 seconds,

the logging procedure is canceled.

• A measurement can be stored only once.

Also an over range value can be stored.

• If less than ten free records are available, the

“LOG” tag will blink while storing data.

• If the log memory is full, the “LoG FULL” message

will appear for a few seconds on the LCD and the

instrument will return to measurement mode

without storing the new record.

To store a new record, delete one or more records.

or

26

Page 27

VIEW LOGGED DATA

The stored records can be viewed at any moment

by pressing RCL. To return to normal measurement

mode, press RCL again .

LOG SEARCHING

The log records are stored in chronological order.

The first displayed record is the last stored one.

• Press UP or DOWN keys to scroll the log memory

record by record. By keeping pressed the UP or

DOWN keys, the scrolling speed will increase.

The scrolling of the log is possible from any

panel of the record, except “Delete last log”

and “Delete all logs” panels.

• When scrolling the log, the number of the record is displayed for one second on the secondary

LCD, together with “TAG” if the identification

of the sampling location was made.

When the end of the log is reached, an error beep

is heard.

RECORD VIEWING

Each record contains more information than the

measured value. The additional information is

grouped in several panels.

Press READ

The record panels are displayed one by one in a

circular way.

Each record contains the following panels:

• The record value (turbidity value) and record

number.

Note: If the logged sample value is an over range

• The hexadecimal string of the tag for the

sampling location ID.

Note: If the ID data are missing, dashes are

to scroll through the record panels.

reading, the maximum value (1000) will

be displayed blinking.

displayed instead.

27

Page 28

• Measurement date in YYYY.MM.DD format.

• Measurement time in hh:mm format.

• Delete the last record panel (only for last record).

• Delete all records.

DELETE LAST RECORD

To log other values, the last record or all records

have to be deleted.

• To delete the last record, press SETUP/DEL while

in delete last records panel.

• The instrument asks for confirmation and if

LOG/CFM is pressed, the last record is deleted.

To abort the delete function, press READ

instead of LOG/CFM.

• After the record is deleted, the instrument goes

immediately to the first panel of the previous

record. If the log becomes empty, dashes will

be displayed for one second and the instrument

will return to idle mode.

DELETE ALL RECORDS

To delete all records, scroll the log until delete all

records panel is displayed on the LCD.

• To delete all records press SETUP/DEL while in

delete all records panel.

28

Page 29

• The instrument asks for confirmation and if

LOG/CFM is pressed, all records are deleted.

To abort the delete function, press READ

instead of LOG/CFM.

• After all records are deleted, dashes are

displayed for one second and the instrument

returns to idle mode.

GOOD LABORATORY PRACTICE (GLP)

The GLP feature allows the user to view last calibration data. Also, the user calibration can be

deleted.

Press GLP to enter or exit GLP data consulting.

Several functions are available when in GLP menu.

Press READ

to scroll the following GLP data:

• The last calibration date, in YYYY.MM.DD

format. If no calibration was performed, the

factory calibration message, “F.CAL”, will be

displayed on the LCD.

• The time of the last calibration in hh:mm

format.

• First calibration point: 0.00 NTU if skipped or

the actual read value (e.g. 0.01 NTU).

• Second calibration point.

or

or

29

Page 30

• Third calibration point (if available).

• Fourth calibration point (if available).

• Delete calibration panel.

To delete calibration:

• Press SETUP/DEL while in the delete calibration

panel of the GLP.

The user calibration will be deleted and the

factory calibration will be restored. The instrument

will enter automatically in idle mode.

30

Page 31

SETUP

Setup mode allows viewing and modifying the instrument parameters.

The blinking “CAL” tag during setup mode suggest to press CAL for parameters editing.

• To enter/exit SETUP, press SETUP/DEL.

• To select the parameter to be edit, press UP or

DOWN keys until the desired panel is displayed.

SET EPA COMPLIANCE MODE

When EPA compliance reading is ON, “EPA” message

is displayed on the secondary LCD and the reported

values are rounded to meet EPA reporting

requirements.

• To edit the EPA mode, press CAL when EPA

compliance reading panel is displayed.

The parameter setting and “CFM” tag will start

blinking.

• Press the UP or DOWN keys to set ON or OFF

the EPA compliance mode.

• Press LOG/CFM to save the setting. The new

selected option of the parameter will be

displayed on the LCD.

Alternatively, press CAL to exit without saving

the new settings.

SET BEEPER

The HI 98703 has a built-in beeper that signals

the tag read, the key press and the error conditions.

The beeper can be selected to be ON or OFF.

• To set the beeper ON/OFF, press CAL when set

beeper panel is displayed.

The beeper status and “CFM” tag will start

blinking.

31

Page 32

• Press the UP or DOWN keys to set the beeper

ON/OFF.

• Press LOG/CFM to save the change. The new

selected option will be displayed on the LCD.

Alternatively, press CAL to exit without saving

the changes.

SHOW / HIDE THE TIME

You can choose between showing or hiding the

current hour and minutes on the LCD.

• To set hiding or showing the time, press CAL

when show/hide time panel is displayed.

The time show status and “CFM” tag will start

blinking.

• Press the UP or DOWN keys to set lcd / hide for

time.

• Press LOG/CFM to save the change. The new

selected option will be displayed on the LCD.

Alternatively, press CAL to exit without saving

the changes.

SET THE DATE

The HI 98703 turbidimeter has a built-in real

time clock (RTC). The RTC time is used to generate

a unique time stamp for each recorded value and to

automatically store the last calibration date. The

current time can be displayed on the LCD when the

instrument is in idle mode.

• To set the current date, press CAL when set date

panel is displayed. The date format is

YYYY.MM.DD. The last two digits of the year

value and “CFM” tag will start blinking.

• Press the UP or DOWN keys to set the year

value.

32

Page 33

• Press LOG/CFM or READ

month value. The month value will start

blinking.

• Press the UP or DOWN keys to set the month

value.

to start editing the

• Press LOG/CFM or READ

day value. The day value will start blinking.

• Press the UP or DOWN keys to set the day

value.

Note: To edit the year again, after the day was

set, press READ .

• Press LOG/CFM to save the new date. The new

date will be displayed on the LCD. Alternatively,

press CAL to exit without saving the changes.

SET THE TIME

• To set the current time, press CAL when set time

panel is displayed. The time format is hh:mm.

The hour value and “CFM” tag will start

blinking.

• Press the UP or DOWN keys to set the hour

value.

to start editing the

• Press LOG/CFM or READ

minutes. The minutes value will start blinking.

• Press the UP or DOWN keys to set the minutes

value.

Note: To edit the hour again, after the minutes

were edited, press READ

to start editing the

.

33

Page 34

• Press LOG/CFM to save the new time. The new

set time will be displayed.

Alternatively, press CAL to exit without saving

the changes.

SET INSTRUMENT ID

The instrument ID is a four digit number that can

be edited by the user. The instrument ID is

downloaded on the PC application, together with

the logged data. By setting a different ID for each

instrument it is possible to mix information from

many turbidimeters into the same database.

• To set the instrument ID, press CAL when set

instrument ID panel is displayed.

The default instrument ID is 0000. The existing

ID value and “CFM” tag will start blinking.

• Press the UP or DOWN keys to set the new

instrument ID. By pressing and holding the UP

or DOWN keys, the changing speed wil increase.

• Press LOG/CFM to save the change. The new

instrument ID will be displayed.

Alternatively, press CAL to exit without saving

the changes.

SET BAUD RATE

The HI 98703 has a RS232 and a USB link. When

the USB connection is used, the RS232 connection

becomes inactive.

To successfully communicate with the PC, the same

baud rate must be selected on the instrument and

on the PC application. The available baud rates are

1200, 2400, 4800 and 9600.

• To set the baud rate, press CAL when set baud

rate panel is displayed.

The parameter value and “CFM” tag will start

blinking.

34

Page 35

• Press the UP or DOWN keys to select the new

baud rate value.

• Press LOG/CFM to save the change. The new

selected baud rate will be displayed.

Alternatively, press CAL to exit without saving

the changes.

LCD BACKLIGHT

The LCD can be illuminated to allow the user to see the readings even in dark

environments.

To turn ON or OFF the backlight, press LIGHT.

The backlight will automatically shut-off after 25 seconds of non-use to

save the battery life.

TAG INSTALLATION

The tag is housed in a rugged metal that can withstand harsh environments. However, it is better

to protect the tag from direct rain.

Place the tag near a sampling point. Fix it securely with the provided screws, in such a way that

the metallic

iButton® is easily accessible for reading the tag.

The number of tags that can be installed is practically unlimited. Additional tags can be ordered

(HI 920005 - five tag holders with tags).

35

Page 36

LAMP REPLACEMENT

The instrument tungsten lamp has a life longer than 100,000 measurements. In case of lamp

failure, the defective lamp can be easily replaced. When the lamp is broken, the instrument displays

“no L” error message.

To replace the lamp follow the next steps:

• Remove the battery lid.

• Unscrew the lamp connection using a screwdriver.

• Unlock the lamp and extract it by pulling it out

from the lamp holder handler.

• Place the new lamp in the right position and

push it until is securely locked.

• Insert the lamp leads into the connector and

tight them using a screwdriver.

Warning: After lamp replacement the meter needs

to be recalibrated.

BATTERIES MANAGEMENT

For field measurements, HI 98703 is powered by 4 AA batteries.

The battery life is enough for 1500 normal measurements.

When the instrument is started, the remaining battery life is

estimated and reported in percents.

To preserve the battery it is better to use normal instead of

averaged measurements.

Continuous measurements keep the lamp on and should be

used with caution if the battery life is an issue.

To further save the battery life, the instrument will turn off

after 15 minutes of non-use. The backlight will be turn off

after 25 seconds since the last key was pressed.

The battery life is measured each time the lamp is turned on

and if the remaining battery life is less than 10%, the battery

tag will be displayed blinking on the LCD to warn the user that

the batteries need to be replaced.

When the batteries are completely discharged, “0% bAtt” message

will be displayed for one second and the instrument will turn off.

In order to use the instrument again, replace the batteries with

new ones or use an AC adapter.

36

Page 37

BATTERIES REPLACEMENT

To replace the batteries follow the next steps:

• Press ON/OFF to turn OFF the instrument.

• Open the batteries cover by pressing the locking clip.

• Take out the used batteries and insert 4 new 1.5 AA size batteries, while paying attention to the

correct polarity as indicated on the battery compartment.

• Replace the cover and press it until it locks.

• Turn the instrument ON.

Warning: Replace batteries only in a non-hazardous area.

USING AN AC ADAPTER

The HI 98703 can be powered from the AC adapter when used in laboratory. See the Accessories

section to select the correct AC adapter.

To power the instrument, simply connect the AC adapter to the instrument (see Connectors Description,

page 9).

It is not necessary to turn the instrument off when connecting the external adapter.

Note: The connection to the external adapter will not recharge the batteries.

37

Page 38

PC INTERFACE

To fully use the instrument tag identification system function, the measured data has to be

downloaded to a computer. The instrument can use RS232 or USB connection to communicate

with the PC.

When using the RS232 protocol, simply connect a HI 920011 serial cable between the

instrument and the computer.

To use the USB protocol, simply connect a regular USB cable between instrument and PC.

In both cases, the PC must run the HI 92000 application for successful data transfer.

ERROR CODES

HI 98703 has a powerful diagnostic system. The common errors are detected and reported for

easy diagnostic and maintenance.

RORRE NOITPIRCSED NOITCA

;3rrE–1rrE

8rrE;7rrE;6rrE

4rrE

PAC .desolctonsidilehT

Lon .thgilonronekorbpmaL

oLL .thgilhguonetoN

-OL-

-IH-

gniknilbgatyrettaB .wolootsiefilyrettabgniniamerehT .seirettabecalpeR

ttAb

.srorrelacitirC

.stnemerusaemtcerroc

.nwodstuhsdnaspeebtnemurtsniehT

dnaeciwtyltrohsspeebtnemurtsniehT

.sdnoces01retfanwodstuhs

tnerrucrofdesudradnatsehT

.wolootsitniopnoitarbilac

tnerrucrofdesudradnatsehT

.hgihootsitniopnoitarbilac

rofdegrahcsidooteraseirettabehT

ecivresannaHllaC

PUylsuoenatlumissserP

ehtteserotNWODdna

.stnetnocMORPEE

.dilehtesolC

nruter,stsisreprorreehtfI

.tnemurtsnieht

kcehC.pmalehtecalpeR

rofmetsyslacitpoeht

.snoitcurtsbo

metsyslacitpoehtkcehC

.snoitcurtsborof

dnadradnatsehtkcehC

.enotcerrocehtesu

dnadradnatsehtkcehC

.enotcerrocehtesu

.seirettabecalpeR

38

Page 39

ACCESSORIES

HI 93703-60 Caps for cuvets (4 pcs)

HI 710005 Voltage adapter from 115V to 12 VDC (USA plug)

HI 710006 Voltage adapter from 230V to 12 VDC (European plug)

HI 710012 Voltage adapter from 240V to 12 VDC (UK plug)

HI 710013 Voltage adapter from 230V to 12 VDC (South Africa plug)

HI 710014 Voltage adapter from 230V to 12 VDC (Australia plug)

HI 731318 Tissue for wiping cuvets (4 pcs)

HI 731331 Glass cuvets (4 pcs)

HI 740027P 1.5V AA battery (12 pcs)

HI 740231 Replacement lamp for EPA turbidimeter (1 pcs.)

HI 92000 Windows

®

compatible software

HI 920005 5 tag holders with tags

HI 920011 5 to 9 pins RS232 connection cable

HI 93703-50 Cuvets cleaning solution (230 mL)

HI 98703-58 Silicon oil (15 mL)

RECOMMENDATIONS FOR USERS

Before using this product, make sure that it is entirely suitable for your specific application and

for the environment in which it is used.

Operation of this instrument may cause unacceptable interferences to other electronic equipments,

requiring the user to follow all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instrument’s

EMC performance.

To avoid damage or burns, do not put the instrument in microwave ovens. For your own and the

instrument safety do not use or store the instrument in hazardous environments.

Hanna Instruments reserves the right to modify the design, construction and appearance of its products

without advance notice.

39

Page 40

SALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. (662) 619.0708.11 • Fax (662) 619.0061

02/06

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and Technical offices, please see

www.hannainst.com.

40

MAN98703

Loading...

Loading...