Page 1

Instruction Manual

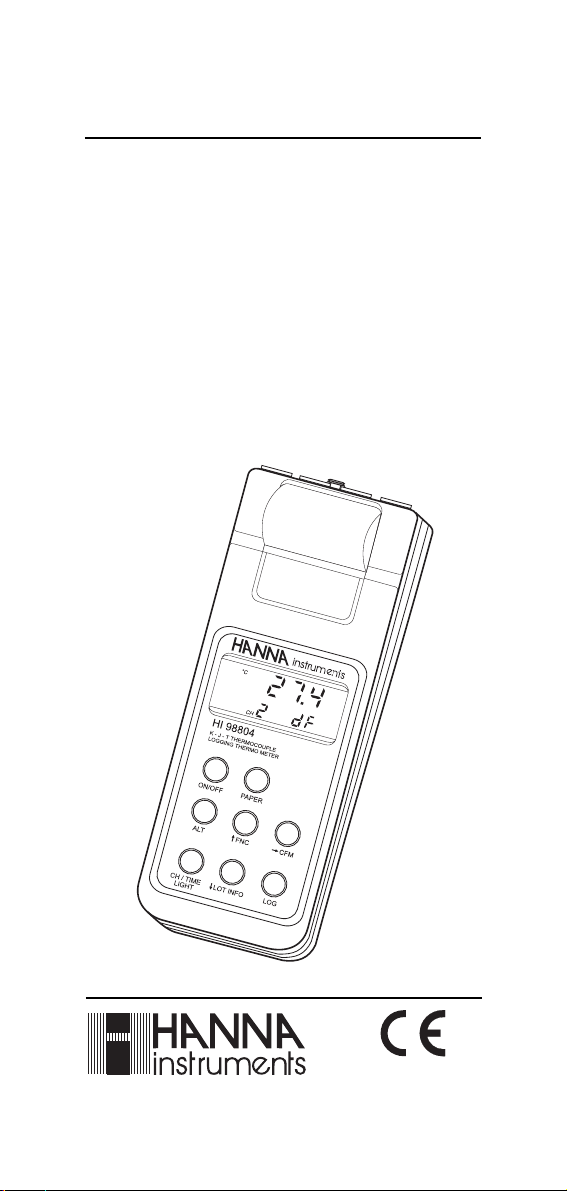

HI 98701 - HI 98801

HI 98704 - HI 98804

Portable Microprocessor

Printing and Logging

K-J-T Thermocouple

Thermometers

www.hannainst.com

These Instruments are in

Compliance with the

CE Directives

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments Product.

Please read this instruction manual carefully before using the instru-

ment.

This manual will provide you with all the necessary information for the

correct use of the instrument, as well as a precise idea of its versatility

in a wide range of applications.

If you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com.

These instruments are in compliance with directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ..................................................................3

GENERAL DESCRIPTION .......................................................................... 3

FUNCTIONAL DESCRIPTION..................................................................... 5

SPECIFICATIONS .................................................................................. 6

INITIAL PREPARATION ............................................................................ 7

SETUP MODE .................................................................................. 8

TAKING TEMPERATURE MEASUREMENTS ...............................................14

TEMPERATURE CALIBRATION PROCEDURES ...........................................15

HI98801 / HI98804 PRINTING / LOGGING FUNCTIONS......................... 17

HI98701 / HI98704 PRINTING FUNCTIONS.......................................... 20

GOOD LABORATORY PRACTICE (GLP) ..................................................... 22

OTHER FEATURES ................................................................................22

DATA TRANSFER TO PC ........................................................................ 23

MEMORY ORGANIZATION ..................................................................... 24

PRINTER MAINTENANCE ....................................................................... 25

FAULT CONDITIONS ............................................................................. 25

BATTERY REPLACEMENT .......................................................................26

K-TYPE THERMOCOUPLE PROBES ......................................................... 27

ACCESSORIES ...................................................................................... 30

WARRANTY ..........................................................................................31

CE DECLARATION OF CONFORMITY........................................................ 31

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner,

Hanna Instruments Inc., 584 Park East Drive, Woonsocket, Rhode

Island, 02895 , USA.

2

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occurred during shipping.

If there is any damage, notify your Dealer.

Each thermometer is supplied complete with:

• AA size Alkaline Batteries (4 pcs)

• Instruction Manual

• Paper rolls (5 pcs)

• Rugged Carrying Case.

Note: Save all packing material until you are sure that the instrument

functions correctly. All defective items must be returned in their

original packaging together with the supplied accessories.

GENERAL DESCRIPTION

The Hanna Instruments portable thermocouple thermometers with

built-in printers are microprocessor-based and enable you to accurately measure temperature and record data.

The thermocouple type is user selectable to best suit the temperature

range of your application. K, J and T thermocouple types can be

selected.

The instruments housing is made of rugged and lightweight material

making it truly portable.

The meters come equipped with an easy-to-read LCD with backlight

feature for comfortable reading even in dark environments.

A user friendly interface provides clear messages regarding errors,

functions and more.

The GLP features provide a guarantee of data consistency.

Measurements can be performed with lab-grade precision in the field as

well as in the laboratory.

An alarm time-out is available to alert the user if too much time has

elapsed since the last calibration and that re-calibration may be

required.

The meters provide a controlled access to calibration and GLP settings

through a password protection method.

3

Page 4

The Battery Error Preventing System (BEPS) recognizes batteries levels

as they become weaker.

To prolong battery life, the backlight and printing features are disabled when the batteries are getting low; "LOBAT" indication is displayed

on LCD to warn the user of this condition. However, the meter continues to measure correctly even when the low battery indication is

displayed. The meter automatically switches itself off when the batteries are too weak to support proper function.

The meters are equipped with an internal lithium battery that powers

the clock circuit even in the absence of power supplies.

For long term field and lab applications, these meters can be connected

to a 12VDC adapter.

HI98801 and HI98804 have the capability to store the measurements

in memory at a user selectable interval from 1 to 180 minutes. This

information can be retrieved at a later time and also printed.

HI98801 and HI98804 also allow the transfer of stored data to a

computer via the HI9200 infrared transmitter connected to the computer RS232 port.

Each meter can also be uniquely identified by the user by assigning an

ID code.

4

Page 5

FUNCTIONAL DESCRIPTION

1) Power adapter plug

2) Temperature Probe Connectors (1 or 4 according to model)

3) LCD Display

4) PAPER key, to move the paper up

5) ON/OFF key, to turn the meter on or off

6) ALT key, to alternate key function

7) CH/TIME key (HI98704 and HI98804 only) to select input channels, to view date and time, and to enable backlight (with ALT)

TEMP/TIME key (HI 98701, HI 98801 only)

to select temperature reading, to view date and time, and to

enable backlight (with ALT)

8) LOG key, to store and/or print measurements

9) LOT INFO key (HI 98801 and HI 98804 only)

to move down or view logging information (with ALT)

key (HI 98701 and HI 98704 only) to move down

10)CFM key, to move right or confirm values (with ALT)

11) FNC key, to move up or select function codes (with ALT)

5

Page 6

SPECIFICATIONS

Range (*) K -200.0 to 999.9 °C ; 1000 to 1370 °C

-300.0 to 999.9 °F ; 1000 to 2500 °F

J -200.0 to 760.0 °C

-300.0 to 999.9 °F ; 1000 to 1400 °F

T -200.0 to 400.0 °C

-300.0 to 750.0 °F

Resolution K 0.1°C (-99.9 to 999.9 °C); 1°C (1000 to 1370 °C)

0.2 °C (-200.0 to -100.0 °C)

0.2°F (-199.9 to 999.9 °F); 1°F (1000 to 2500°F)

0.3 °F (-300.0 to -200.0 °F)

J 0.1 °C (-149.9 to 760.0 °C)

0.2 °C (-200.0 to -150.0 °C)

0.1 °F (32.0 to 999.9 °F); 1 °F (1000 to 1400 °F)

0.2 °F (-300.0 to 32.0 °F)

T 0.1 °C (-99.9 to 400.0 °C)

0.2 °C (-200.0 to -100.0 °C)

0.1°F (300.0 to 750.0°F);0.2°F (-149.9 to 300.0°F)

0.3 °F (-300.0 to -150.0 °F)

Accuracy ±0.5 °C (-200.0 to 999.9 °C); ±1°C outside

(@20°C/68°F) ±1°F

for one year (excluding probe error)

Typical EMC Dev. ±5 °C; ±9 °F

Channels HI98701/HI98801: 1 channel

HI98704/HI98804: 4 channels

Probe K , J or T-type thermocouple

Cold Junction sensor NTC 10K ; 0.1°C resolution ; ±0.3°C accuracy

Printer Low power impact type-belt, 14 characters

per line; 38 mm plain paper (HI 710034)

Printing/Logging 1, 2, 5,10, 15, 30, 60, 120 and 180 minutes

Interval

Auto shut-off Selectable at 5, 10, 15, 30, 45 or 60 minutes

Power supply 4x1.5V AA alkaline type/350 hours typical life

(with 2700mA/h batteries, without printing and

backlight).

12 VDC adapter (HI710005 or HI710006)

Environment 0 to 50°C (32 to 122°F);

0-95% RH non-condensing

Dimensions 220 x 82 x 66 mm (8.7 x 3.2 x 2.6")

Weight 500 g (18 oz)

(*) Tables from NIST Monograph 175 revised to ITS-90 are used

6

Page 7

INITIAL PREPARATION

ON/OFF

Each meter is supplied complete with batteries. Remove the back

cover, unwrap the batteries and install them while paying attention to

the polarity. Alternatively, connect the HI 710005 or HI 710006

voltage adapter to the power adapter plug.

To prepare the instrument for use, choose the most appropriate temperature probe(s) for your application (see accessories) and connect it

(them) to the connector(s) located on the top of the instrument.

With the meter facing you, channel #1 is the first connector on the

top left hand side.

To switch the meter on, press the ON/OFF key.

The batteries charge status or "LINE" message

(if external power adapter is connected) will be

displayed on the LCD for a few seconds.

The meter is now ready to operate.

To maximize battery life, the meter is automatically switched off after a

user selectable period of non-use (this feature is enabled and set to 5

minutes by default; it can be disabled or changed through setup code

40). If in logging mode, after the period of non-use, the meter will

continue to monitor the temperature periodically at the end of every

logging interval. Only the "LOG" indication will be visible on LCD.

While storing data in memory, during the sleep mode, the reading will

appear briefly on the LCD.

To reactivate the display press the ON/OFF key.

Note: When the use of an alternate function (FNC, CFM and LOT

INFO) is requested, press and hold the ALT key first and then

the second listed key.

7

Page 8

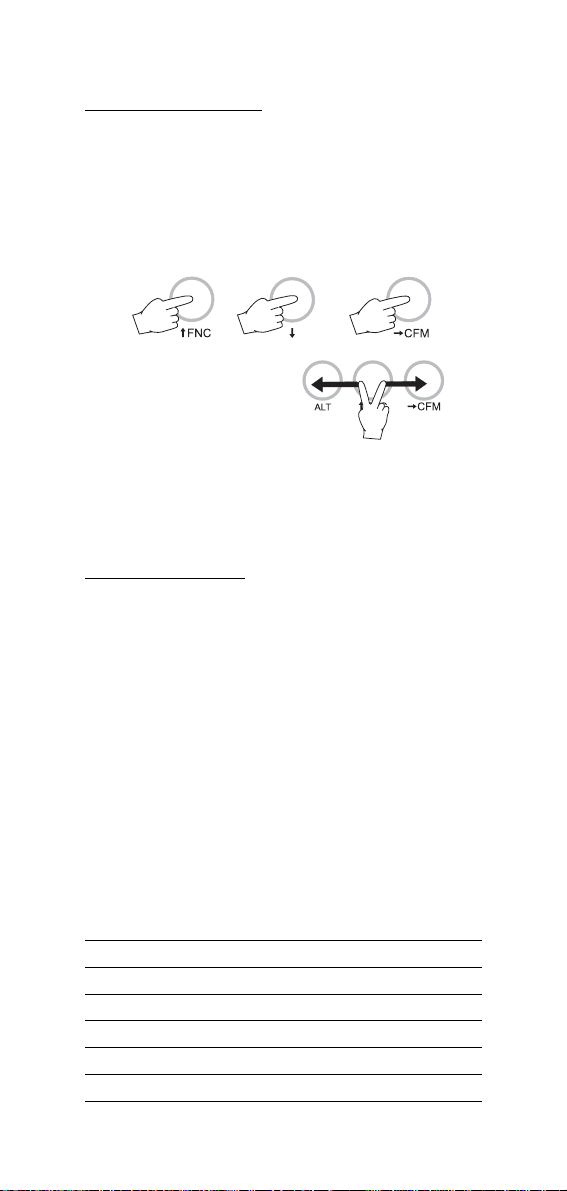

SETUP MODE

Setup can be used to view data regarding instrument status (e.g.

battery charge) or GLP data (e.g. calibration date) or to view or print

the logged data. It also allows the user to change the meter parameters (e.g. time) and to gain access to stored data.

• To enter this mode ensure the meter is

not logging and then press the ALT and

FNC keys.

• The scrolling message "Insert the function code or press "ALT" -

"FNC" to escape" in the upper LCD and the indication "F 00" with

the first digit blinking in the lower LCD will be displayed.

• Enter the first digit of the code of the parameter you want to set

using the or key and pass to the next digit with . The

second digit will start blinking.

• Enter the second digit using the or

key.

• Press ALT and CFM to confirm the code.

• If the entered code doesn't exist the "Err"

message will be displayed for a few seconds and then the message "Insert the

function code or press ALT - FNC to escape" will recommence scrolling in the

upper LCD.

8

Page 9

PASSWORD PROTECTION

Setting of the GLP parameters (calibration alarm time-out, instrument

ID code, time and date) can be password protected. If password is set

to a value different from 0000 (factory setting), the user will be asked

to enter the password.

• Select the desired GLP parameter code.

• Enter the password by the arrow keys.

• Press the ALT and CFM keys to

confirm.

• If password is wrong the meter will return to the function selection

mode without any warning message.

• If password is correct, the meter provides access to the parameter.

PARAMETERS SETTING

• Once the parameter code has been entered, the appropriate mes-

sage will scroll across the LCD for a few seconds.

• The current value of the selected parameter on the upper LCD and

the parameter code on the lower LCD will be displayed. The first

digit will blink if the parameter can assume continuous values. All

the digits will blink if the parameter can assume only a fixed set of

values.

• Enter the new value using the arrow keys.

• Press ALT and CFM to confirm the value.

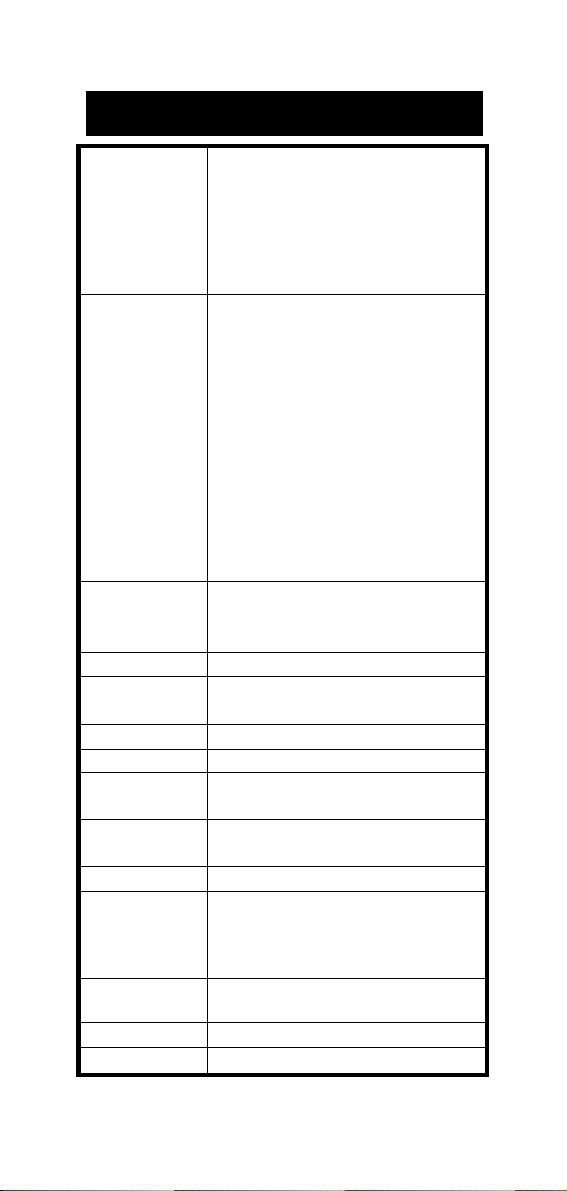

The following table lists the setup codes along with the description of

the specific setup items, their valid values and the factory settings

(default):

Code Valid values Default

00 Lot data printing/scrolling100÷16 00

01 Print lots data summary

02 Printer enable

1

1

On(enabled); Off(disabled) On

03 Logging interval 1,2,5,10,15,30,60,120,180 1

05 Log on demand delete1 or Reset sample number

06 Timed data delete

1

9

2

Page 10

Code Valid values Default

10 Show GLP data

11 Calibration alarm time-out On(enabled); Off(disabled) On

20 Instrument ID code 0000÷9999 0000

30 Current time

31 Current day

32 Current month

33 Current year

3

3

3

3

hh:mm 00:00

dd 01

MM 01

YYYY 1998

40 Auto-Off/Power down time-out Off,5,10,15,30,45,60 5

41 Battery level test

50 RS232 baud rate

1

1200, 2400, 4800 4800

60 Firmware version

70 Thermocouple type selection "dEF"(K) ; "J"(J) ; "t"(T) "dEF"

71 Celsius/Fahrenheit selection °C ; °F °C

99 Password

4

0000÷9999 0000

Note: If a wrong code is entered the "Err" message is displayed on

LCD for a few seconds.

Note: Code 05 has a different function in HI9880x and HI9870x

series as explained in detail in the following.

1

In HI 98801 and HI 98804 only.

2

In HI 98701 and HI 98704 only.

3

The meter automatically checks for entered time/date accuracy as follows:

0≤hh≤23; 0≤mm≤59; 01≤dd≤28/29/30/31; 1≤MM≤12; 1998≤YYYY≤2097.

4

To change the password, the correct code must be entered first. If the password

has been forgotten, the password protected features are no longer accessible; in

this case contact your nearest Hanna Service Center.

SETUP MESSAGES LIST

cod. 00: Lot data Printing

cod. 01: Lot table Printing

cod. 02: Printer enable

cod. 03: Log Interval

cod. 05: Press "ALT CFM" to reset the sample number or "ALT FNC" to escape

or: Press "ALT CFM" to delete Lot00 or "ALT FNC" to escape

cod. 06: Press "ALT CFM" to delete Lot 01-16 or "ALT FNC" to escape

cod. 10: GLP

cod. 11: Calibration alarm time-out

cod. 20: Instrument ID Code

cod. 30: Hour - Minute

cod. 31: Day

cod. 32: Month

10

1

2

Page 11

cod. 33: Year

cod. 40: Auto OFF

cod. 41: Battery test

cod. 50: Baud rate

cod. 60: Release code

cod. 70: Thermocouple type

cod. 71: Celsius or Fahrenheit

cod. 99: Pass Code

Some of the most important functions are explained below in a step by

step sequence.

TO SCAN LOGGED DATA (HI98801 and HI98804 only)

COD. 00 - Lot data Printing / Scrolling

• Select the code 00.

• The message "Lot data Printing" will scroll twice across LCD.

• The upper LCD will then display L 00

with the 00 blinking.

• Set the desired lot by the arrow keys. L00 is the lot of data of the

"log on demand" and L 01 to L 16 are the lots of the "timed log".

• Press the ALT and CFM keys to confirm the lot number.

• If the lot doesn't contain data, the "no data" message will scroll

across the LCD twice and the meter will return to setup mode.

• If the lot contains one or more data the

LCD will display the sample number in

its upper part and Sn in the lower part.

Note: In the L 00 lot (log on demand) the sample number will be

displayed with 3 digits (001).

• Select the sample number to scan by the arrow keys.

Printing logged data

• Press ALT and CFM to print logged data.

• If the selected sample number is invalid (equal to 0 or bigger than

the number of samples), the "Err" message will be displayed for a

few seconds.

• If the sample number is correct, the samples starting from the

selected one to the last sample of the lot will be printed. To stop

printing before the last sample is reached, press and hold the ALT

and PAPER keys until the printer stops.

• During printout the LCD will display the sample number being

printed at that moment. If printout is stopped the LCD will show

11

Page 12

the last printed sample number. It is then possible to select

another sample.

• Press the ALT and FNC keys to return to setup mode.

Viewing logged data

• Press CH/TIME (HI98804 only) or TEMP/TIME (HI98801 only) to

view data of the selected sample. Data will be displayed in the

following order:

channel 1 temperature reading

channel 2 temperature reading (HI 98804 only)

channel 3 temperature reading (HI 98804 only)

channel 4 temperature reading (HI 98804 only)

date

time

• If CH/TIME or TEMP/TIME is pressed when the time is displayed,

the LCD will pass to the next Sample number.

• It is then possible to scroll the data of the next sample by pressing

CH/TIME or TEMP/TIME or select a different sample by the arrow

keys.

• to return to setup mode, press ALT and FNC when the meter

displays the sample number.

Cod. 02 - Lot summary printout

• Select the code 02.

• The message "Lot table Printing" will scroll twice across LCD.

• The meter will then print a complete set of information based on

the data stored in memory:

a - lot number

b - logging interval

c - starting date

d - number of samples

e - starting time

f - logged channels numbers.

Note For lot 00 the number of samples only will be printed.

DELETE LOGGED DATA (HI98801 and HI98804 only)

• Select code 05 to delete the Log on Demand data or code 06 to

delete the Timed Log Data.

• A scrolling message will be displayed.

• Press the ALT and CFM keys to confirm deletion.

• It is also possible to escape without data deletion pressing the ALT

and FNC keys.

12

Page 13

TO RESET PRINTING SAMPLE NUMBER

(HI98701 and HI98704 only)

This feature resets the print on demand sample number to 001.

• Select the code 05

• A scrolling message will be displayed.

• Press the ALT and CFM keys to confirm reset or ALT and FNC to

escape.

GLP DATA

Cod. 10 - viewing GLP data

• Select the code 10

• A message will scroll twice across LCD.

• The LCD will then display the instrument identification (ID) code.

• Press to scan remaining data, in the following order:

channel 1 last calibration date (DD.MM)

channel 1 last calibration year

Note: Data can be viewed in reverse order pressing the key.

• Press ALT and FNC to return to function selection mode.

Code 20 - setting the identification (ID) code

When using several identical meters it may be useful to uniquely

identify them by assigning an ID code to each meter.

• Select code 20. A message will scroll across LCD.

• Enter a 4-digit value using the arrow keys.

• Press ALT and CFM to confirm the value.

TESTING BATTERY LEVEL

• Select code 41. The message "Battery test" will scroll across LCD.

• If the meter is connected to an external power adapter, the LCD

will display "LINE" otherwise it will display bAtt on the upper

display, and the remaining percentage of battery charge (100%

means fully charged battery and 0% corresponds to the minimum battery voltage

that allows the meter to operate).

SELECTING THE THERMOCOUPLE TYPE

Three types of thermocouple can be connected to the meter:K, J and T.

• Select code 70.

• The types are indicated with "dEF" for K-type, "J" for J-type and

"t" for T-type. Choose the desired type using the arrow keys.

• Press ALT and CFM to confirm the value.

13

Page 14

TAKING TEMPERATURE MEASUREMENTS

To prepare the instrument for use, choose the most appropriate temperature probe(s) for your application (see accessories) and connect it

(them) to the connector(s) located on the top of the instrument.

The factory default thermocouple type is K, represented with the "dF"

indication. If needed, select a different type (J and T types also

available) through setup code 70.

With the meter facing you, channel #1 is the first connector on the

top left hand side.

Press the ON/OFF key to power on the instrument.

To take temperature measurements, insert the

probe in the sample to be tested and allow

the reading to stabilize. The temperature is

displayed on the upper LCD. The lower LCD

displays the selected channel number (HI98704 and HI98804 only).

The meter selects channel 1 as default. Press CH/

TIME (HI98704 and HI98804 only) or TEMP/TIME

(HI98701, HI98801 only) to view the reading of the

other channels, the cold junction temperature, date

and time in the following order:

• channel 2 temperature reading (4-channel versions only)

• channel 3 temperature reading (4-channel versions only)

• channel 4 temperature reading (4-channel versions only)

• cold junction temperature reading ( "C J" appears in the lower LCD)

• date

• time

Pressing CH/TIME or TEMP/TIME again, the meter returns to channel 1

temperature reading.

If the reading is out of range or the probe is

not connected to a channel, the LCD will

display a dashed line in place of the reading.

Note: To choose between "°C " and "°F" unit, enter the setup code 71.

Note: The meter is factory calibrated. After 1

year since last thermocouple calibration the "DATE" symbol starts blinking

on the LCD to warn the user that a recalibration is suggested to

maintain the accuracy of the meter. It is recommended that

recalibration is performed by authorized technical personnel

only. Contact your nearest HANNA service center.

14

Page 15

TEMPERATURE CALIBRATION PROCEDURES

(for technical personnel only)

The meter is factory calibrated. However, as a general rule, it is

recommended to have all thermometers recalibrated at least once a

year. It is recommended that recalibration is performed by authorized

technical personnel only to assure the accuracy of the instrument.

Contact your nearest HANNA service center for a quick and accurate

annual recalibration.

Both thermocouple inputs and cold junction can be calibrated.

A two-point calibration at 0.000 mV and 41.269 mV has to be

performed in order to store the new thermocouple calibration data in

memory. Cold junction calibration is at one point only, corresponding

to the environment temperature.

COLD JUNCTION CALIBRATION

1. Press CH/TIME or TEMP/TIME until the cold junction temperature

reading is displayed.

2. Press ALT, CFM and PAPER simultaneously while the meter is not

printing nor logging to enter calibration mode.

3. User is prompted to enter password if it has been set to a value

different from 0000, otherwise skip to step 6.

4. Enter the password using the arrow keys.

5. Press ALT and CFM to confirm the password or CH/TIME or TEMP/

TIME to exit.

6. If password is correct or not set, the meter

will display "25.0°C" (or "77.0°F"), with

the "2" (or "7") blinking, on the upper

LCD and "C CJ" on its lower part; if

wrong, it will return to measurement mode without any message.

7. Enter the actual cold junction temperature (the environment temperature measured with a reference thermometer) using the arrow

keys (temperature must be between 0 and 50 °C).

8. When the "S" symbol blinks in the lower

LCD, the reading is stable and calibration

can be confirmed pressing ALT and CFM.

9. The LCD will display CALC for a few seconds and then the meter

returns to normal operational mode.

15

Page 16

THERMOCOUPLE CALIBRATION

1. With a mV simulator, input 0.000 mV at channel #1 of the meter.

2. Ensure the meter is not displaying the cold junction temperature

and press ALT, CFM and PAPER simultaneously while the meter is

not printing nor logging to enter calibration mode.

3. User is prompted to enter password if it has been set to a value

different from 0000, otherwise skip to step 6.

4. Enter the password using the arrow keys.

5. Press ALT and CFM to confirm or CH/TIME or TEMP/TIME to exit.

6. If password is correct or not set, the meter

will display "0°C" on the upper LCD and

"C 0" on its lower part; if wrong, it will

return to measurement mode without any

message.

7. When the "S" symbol blinks in the lower

LCD, the reading is stable and calibration

can be confirmed pressing ALT and CFM.

8. The LCD will display CALC for a few seconds.

9. The second calibration point "1000°C"

will be displayed on the upper LCD and

"C 0" on its lower part.

10. Input 41.269 mV at channel #1 of the meter.

11. When the "S" symbol blinks in the lower

LCD, the reading is stable and calibration

can be confirmed pressing ALT and CFM.

12. "CALC" is displayed on the upper LCD for a few seconds and then

the meter returns to normal operational mode.

Note: Even though only channel #1 is used during calibration, all

the channels and all the thermocouple types are calibrated.

Note: If a wrong input is connected or channel #1 is left open, when

confirming the calibration point the LCD will display "Err".

Note: To escape before ending the calibration procedure press CH/TIME

or TEMP/TIME.

Note: When connecting a mV simulator to the meter use two wires of the

same material of the simulator terminals to avoid undesired thermocouple junctions that could alter the mV input of the meter.

Note: Avoid touching the meter connectors if possible and wait about 15

minutes for temperature stabilization after connections before proceeding with the calibration steps.

16

Page 17

HI 98801 - HI 98804

PRINTING / LOGGING FUNCTIONS

Two different modes to print / log data are available:

1. Timed logging; samples are stored and printed (if print function is

active) at fixed time intervals. Data are stored in the lots 01 to 16.

2. Log on demand; samples are stored and printed (if print function

is active) when the LOG key is pressed. Data are stored in the lot

00. It's possible to perform the Log on demand either in normal

mode or in Timed logging mode.

It is possible to switch from logging without printing to logging with

printing in two ways:

• set the function code 02 to "On" to enable printing, to "Off" to

disable printing

• press ALT and PAPER to toggle between printer enabled and

printer disabled while in Timed logging.

Note: In timed logging mode, channels with no probe connected are

not logged nor printed. If all the channels are disconnected,

the message "no connected probe" will scroll across the LCD.

Note: cold junction temperature is not logged nor printed.

TIMED LOGGING MODE

To start Timed logging, press ALT and LOG.

The lot number will be displayed for a few

seconds then the LOG symbol will appear on

LCD and if printer is enabled a first set of

data will be printed. The "LOG" symbol will

be fixed if printer is enabled and will blink if

printer is disabled.

The printout provides the following information:

a - Lot number

b - Logging interval

c - Date (only for the first printed

sample of the lot or of the day)

d - Sample number

e - Time

f - Readings ("----" means out of range).

Note: If no keys are pressed, the meter enters standby mode to

prolong the battery life and only the "LOG" indication will be

visible on LCD. While logging, during the sleep mode, the last

17

Page 18

logged reading will appear briefly on the LCD. To reactivate the

LCD press ON/OFF.

TO STOP LOGGING

In order to stop the recording mode, press

ALT and LOG keys (press ON/OFF first, if

meter is in sleep mode).

A last printout reporting the number of logged

samples (e.g. S.00009) will be produced if

printer is enabled.

Notes:

• It is recommended to use the adapter during logging in printing

mode, especially when many printouts are going to be taken.

• Before proceeding with logging with printing, make sure there is

enough paper for your measurements. When the paper is finished

the meter will not advise the operator and the printouts could be

lost. If this happens, data will continue to be stored in memory,

and it is always possible to print the data at a later time through

setup code 00.

• It is possible to insert a new paper roll during logging session.

• Once in the logging mode, the interval cannot be changed. Exit

the logging mode first (pressing the ALT and LOG keys) to set a

new interval.

• If the LOG key is pressed while in logging with printing mode, a

printout is produced without affecting the running sample number

and the value is stored in Log on demand area.

LOW BATTERY CONDITION

Printout is automatically disabled when battery charge weakens. The

last message "Stop log" will be printed and data will continue to be

stored in memory with the LOG and LOBAT

symbols blinking on LCD. If the user attempts

to enable the printer while in low battery

condition the message "bAtt" will appear for

a few seconds on the LCD.

Note: When an external adapter or new batteries are connected, the

printing must be manually enabled in order to return to logging

with printing mode.

LOG ON DEMAND

In measuring or Timed log mode, press LOG to store

the current reading. The LCD will display "Stor" and

18

Page 19

the value will be stored in the lot 00 (log on demand data area). If

the print function is enabled, a printout is also produced providing the

following information:

a - Date

b - Sample number

c - Time

d - Readings ("----" means out of

range or probe not connected)

Note: When the Log on demand data area is full and the LOG key is

pressed, the sample will not be stored and the LCD will display

"FULL". In this case it is necessary to delete the Log on demand

data to proceed.

TO VIEW LOGGING INFORMATION

If the ALT and LOT INFO keys are pressed during logging, the meter

displays for a few seconds the current lot and the number of logged

samples. The meter then returns to normal operational mode automatically.

If ALT and LOT INFO are pressed while the meter is not logging, the

last logged lot in the lower LCD and the number of logged samples in

the upper LCD are displayed. It is then possible to scroll through the

following lot information with the key:

• lot starting date (dd.mm)

• lot starting year

• lot starting time (hh.mm)

• lot logging interval

• logged channels (HI 98804 only)

By pressing the key again, the meter displays the number of

logged samples again.

When the number of logged samples is displayed, it possible to pass

to another lot with the and keys. Press to view the older

lots or to view the more recent ones.

If is pressed when the last lot is displayed, the meter displays the

lot 00 (log on demand). By pressing the key again, the meter will

pass to the oldest lot.

Note For lot 00, only the number of samples will be displayed.

To exit from the logging info viewing mode press ALT and LOT INFO

again or CH/TIME (HI98804 only) or TEMP/TIME (HI98801 only).

19

Page 20

TO RETRIEVE LOGGED DATA

Logged data can be viewed on LCD or printed. To view or print logged

data see "TO SCAN LOGGED DATA" in the "SETUP MODE" paragraph.

The logging meters also allow the downloading of logged data to PC.

To download data to PC see "DATA TRANSFER TO PC" paragraph.

HI 98701 - HI 98704

PRINTING FUNCTIONS

Two different modes to print data are available:

1. Timed printing; samples are printed at fixed time intervals. Data

lots from 01 to 16 are available.

2. Print on demand; samples are printed when the LOG key is

pressed. It's possible to perform the print on demand either in

normal mode or in Timed printing mode.

Note: In timed printing mode, channels with no probe connected are

not printed. If all the channels are disconnected, the message

"no connected probe" will scroll across the LCD.

Note: cold junction temperature is not printed.

TIMED PRINTING MODE

To start Timed printing, press ALT and LOG.

The lot number will be displayed for a few

seconds then the LOG symbol will appear on

LCD and a first set of data will be printed.

The printout provides the following information:

a - Lot number

b - Logging interval

c - Date (only for the first printed

sample of the lot or of the day)

d - Sample number

e - Time

f - Readings ("----" means out of range).

Note: If no keys are pressed, the meter enters standby mode to

prolong the battery life and only the "LOG" indication will be

visible on LCD. While timed printing during the sleep mode, the

last printed reading will appear briefly on the LCD. To reacti-

vate the LCD press ON/OFF.

20

Page 21

TO STOP PRINTING

In order to stop the recording mode, press

ALT and LOG keys (press ON/OFF first, if

meter is in sleep mode).

A last printout reporting the number of printed

samples (e.g. S.00009) will be produced.

Notes:

• It is recommended to use the adapter during printing mode,

especially when many printouts are going to be taken.

• Before proceeding with printing, make sure there is enough paper

for your measurements. When the paper is finished the meter will

not advise the operator and the printouts could be lost.

• It is possible to insert a new paper roll during printing session.

• Once in the timed printing mode, the interval cannot be changed.

Exit the timed printing mode first (pressing the ALT and LOG keys)

to set a new interval.

• If the LOG key is pressed while in timed printing mode, a printout

is produced without affecting the running sample number.

LOW BATTERY CONDITION

Printing is automatically interrupted when

battery charge weakens. The last message

"Stop log" will be printed and the LOBAT

symbol will blink on LCD.

Note: When an external adapter or new batteries are connected, a

new printing session must be manually restarted.

LOG ON DEMAND

In measuring or timed printing mode, press LOG to

print the current readings. The printout provides the

following information:

a - Date

b - Sample number

c - Time

d - Readings ("----" means out of

range or probe not connected)

Note: If the user attempts to print while in low battery condition the

message "bAtt" will appear for a few seconds on the LCD.

Note: It is possible to reset the sample number of the print on

demand to 001 (see "TO RESET PRINTING SAMPLE NUMBER"

in "SETUP MODE" paragraph).

21

Page 22

GOOD LABORATORY PRACTICE (GLP)

GLP is a set of functions that allows the storage or retrieval (when

necessary) of data regarding the maintenance and status of the meter.

LAST CALIBRATION DATE

Last calibration date is stored automatically after a successful calibration. The last calibration date can be displayed through setup code 10

(see "SETUP MODE" paragraph).

CALIBRATION ALARM TIME-OUT

The meter checks if the time-out time, fixed at 1 year, has expired

every time it is turned on. It is possible to enable/disable this feature

through setup code 11. The default value is "0n".

If the time has expired, the message "Cal

date" scrolls across the LCD. The "DATE" symbol will blink to remind to the user to perform

a new calibration soon.

Note: The alarm time-out is based on thermocouple calibration only.

GLP AND RS232 (HI98801 and HI98804 only)

GLP data (ID code and last calibration date) can be retrieved from a PC

through the RS232 communication feature (see "Data transfer to PC").

OTHER FEATURES

LCD BACKLIGHT

The LCD can be illuminated to allow the user to see the readings even

in dark environments. This feature can be enabled/disabled pressing

the ALT and LIGHT keys. If the LCD backlight feature is enabled, the

LCD remains illuminated until the feature is disabled pressing the ALT

and LIGHT keys. The LCD backlight can be disabled in order to save

power and it is automatically disabled when battery charge weakens.

Note: When an external power supply is connected to the instrument,

the backlight is not automatically enabled.

Note: When LOBAT appears on LCD it is not possible to enable

backlight. If the user attempts to enable the LCD backlight in

low battery condition, the meter will show "batt" on LCD.

Real Time Clock (RTC)

The instrument has an internal Real Time Clock (RTC) circuit with a

backup lithium battery. This allows the meter to update time and date

even when both batteries and external power adapter are disconnected.

22

Page 23

DATA TRANSFER TO PC

HI 98801 - HI 98804 only

HI98801 and HI98804 contain infrared transmitting circuitry.

Ensure there isn't any logging process active.

Press CH/TIME or TEMP/TIME to set the meter to time or date mode

and simply place your data-logger on a HI9200 Infrared Transmitter

(ensuring that the two infrared LEDs are placed on top of each other)

and the memory content can then be downloaded to your PC through

the HI9200's RS232 port. Just ensure that baud rate on instrument

(setup code 50) and on PC downloading program are set to the same

value.

During the data transfer the instrument displays the message "r 232".

To stop communication, press CH/TIME or TEMP/TIME to display the

temperature reading or take the meter out of the transmitter when it's

not displaying "r232".

Using the HI9200 Infrared Transmitter, all recorded data can be fed

to your Personal Computer for easy reproduction, storage or elaboration without the need of cables between the meter and the transmitter.

Data transmission from the instrument to the PC is now much easier

with new HI92000 Windows® compatible application software offered

by Hanna Instruments.

HI92000 allows you to use the powerful capabilities of most spread

sheet programs (e.g. Excel©, Lotus 1-2-3©). Simply open your file

downloaded by HI92000 from your spread sheet program and then it

is possible to make any elaboration available with your software (e.g.

graphics, statistic analysis).

User friendly, HI92000 offers a variety of features and has an on line

help to support you throughout any situation.

To install HI92000 you need a 3.5" drive and a few minutes to follow

the instructions conveniently printed on the disk label.

Windows® is registered Trademark of "Microsoft Co."

Excel© Copyright "Microsoft Co."

Lotus 1-2-3© Copyright "Lotus Co."

23

Page 24

MEMORY ORGANIZATION

HI 98801 - HI 98804 only

Logged data are stored in the internal EEPROM and are retained even

if batteries and external power are disconnected.

MEMORY CAPACITY

• 14000 data samples divided into 16 lots (lots 01 to 16)

• 9999 data samples maximum for a single channel

• 300 data samples for the Log on demand (lot 00).

TIMED LOG (lots 01 to 16)

Each time a new logging period starts, it automatically starts from the

next available lot. If the last lot was the 16th, the new logging period

restarts from lot 01 overwriting previously logged data.

When Timed logging memory is full, the meter overwrites the oldest

lot data progressively reducing the old lots. In this case the starting

time, date and the dimension of the old lot are updated.

Note: The oldest lot data are erased without any warning message.

Note: Timed logging memory can be entirely erased through the

setup code 06.

If the meter is powered only by the external power supply and there is

a temporary power black out during logging, when power returns, the

logging continues normally if no samples have been lost, otherwise

the current lot is ended and a new lot starts. If printer is enabled, the

"...Stop..." message will be printed. In any case, during scrolling the

former lot will be preceded by the "Interrupted Lot" message and the

latter by "Continuation Lot" to indicate the interruption.

LOG ON DEMAND (Lot 00)

When Log on demand data area is full the meter shows the "FULL"

message to warn the user that the data are not stored in memory.

Erase the memory area through setup code 05 to continue logging

data on demand.

24

Page 25

PRINTER MAINTENANCE

TO CHANGE THE INK CARTRIDGE

When printouts become faint, it might be necessary to change the ink

cartridge. Contact your Hanna authorized center.

TO INSERT THE PAPER ROLL

The meters use plain

paper rolls 38 mm

width. To insert a new

roll open the paper

cover pulling it gently

and take the cylinder

away.

Insert the paper edge in

the printer slot and feed

the printer by pressing the

PAPER key.

Allow about 5 cm (2") of paper to exit

from the printer and replace the paper

cover.

FAULT CONDITIONS

The printing/logging thermometers are factory programmed to automatically diagnose a fault and to display error codes on the LCD.

PRINTER ERROR

Whenever a printer fault condition is detected, the printer stops and

the message "Printer error" scrolls across the upper LCD with the error

code (see below) fixed on the secondary one.

1 = Motor locked

2 = Printer clutch jammed

3 = Selection lever fault

I2C BUS ERROR

In case of an I2C bus fatal error due for example to a defective

EEPROM or RTC, the message "Serial bus error" keeps scrolling across

LCD from right to left indefinitely. Meter should be returned for repair

(see warranty section).

25

Page 26

-

BATTERY REPLACEMENT

When the batteries are inserted and no power adapter is connected,

the meter can recognize different batteries charge levels.

1. Fully charged batteries. The backlight and printer can be enabled.

2. Weakening batteries - "LOBAT" symbol blinks on LCD. The backlight and printer are automatically disabled and it is not possible

to enable them until new batteries are inserted or an external

power adapter is connected.

3. Weak batteries - "LOBAT" symbol stays still on lower LCD. Backlight and printer are disabled and meter can work for about 20

hours. If in Timed logging mode with the power down function

enabled this time can be longer.

4. Dead batteries - LCD shuts off. The instrument stops working to

avoid erroneous readings.

Note It is not possible to activate backlight and printer when the

instrument is in a low battery condition. If the user attempts to

enable these functions without replacing the batteries or connecting the

external power adapter, the meter will

show "batt" on LCD.

Battery replacement must only take place in a non hazardous area

using 1.5V alkaline AA type batteries.

In order to replace run down batteries, simply remove the two screws on the rear cover

of the instrument and replace the four 1.5V

AA batteries with new ones, paying attention to the correct polarity.

A 12VDC power adapter can also be used to

power the unit (see the accessories paragraph).

Note: The instrument uses the following configuration.

+

It is recommendable to purchase the Hanna HI710005 and HI710006

voltage adapters that use the proper polarity configuration.

However, the meters can be used with other adapters. In this case,

remember to check the correct polarity of your adapter before connecting it to the meter.

26

Page 27

K-TYPE THERMOCOUPLE PROBES

WITH DETACHABLE HANDLE & MINI-CONNECTOR

(to be plugged into HI 766HD probe handle)

HI 766PA Roller surface probe, max 320°C/600°F

100mm

280mm

7.8"

11"

HI 766PB Surface probe, max 650°C/1200°F

200mm

7.9"

HI 766PC Penetration probe, max 900°C/1650°F

155mm

6.1"

3mm

0.12"

4"

HI 766PD Air probe, max 300°C/570°F

250mm

9.8"

27

3mm

0.12"

Page 28

HI 766PE1 General use probe, max 900°C/1650°F

155mm

6.1"

3mm

0.12"

HI 766PE2 General use probe, max 900°C/1650°F

200mm

7.8"

HI 766HD Rugged thermocouple probe handle with 1m (3.3' ) cable

fitted with a mini-connector

WITH INTEGRAL HANDLE, 1 m CABLE & MINI-CONNECTOR

5mm

0.20"

HI 766A Roller surface probe, max 320°C/600°F

280mm

11"

420mm

13.3"

16.5"

HI 766B Surface probe, max 650°C/1200°F

400mm

15.7"

28

260mm

10.2"

100mm

4"

Page 29

HI 766B1 90° surface probe, max 450°C/840°F

30mm

300mm

11.8"

1.2"

HI 766B2 Surface probe, max 900°C/1650°F

8mm

0.3"

130mm

5.1"

HI 766B3 Small surface probe with insulated shaft, max 200°C/390°F

5mm

0.2"

130mm

5.1"

HI 766C Penetration probe, max 900°C/1650°F

260mm

10.3"

120mm

4.8"

3mm

0.12"

HI 766D Air probe, max 300°C/570°F

385mm

15.2"

245mm

9.6"

HI 766E1 General use probe, max 900°C/1650°F

260mm

10.2"

29

120mm

4.7"

3mm

0.12"

3mm

0.12"

Page 30

HI 766E2 General use probe, max 900°C/1650°F

360mm

13.8"

220mm

8.5"

5mm

0.2"

HI 766F High temperature wire probe without handle, max 1100°C/2000°F

255mm

10"

1.5mm

0.06"

HI 766F1 Flexible probe without handle, max 480°C/900°F

2mm

1m

3.3’

0.08"

HI 766TV1 Pipe clamp probe, max 200°C/390°F

35mm

Max.

1.4"

ACCESSORIES

HI710005 Voltage adapter from 115 VAC to 12 VDC

HI710006 Voltage adapter from 230 VAC to 12 VDC

HI 710031 Rugged carrying case

HI 710034 Plain Paper Spare Rolls (10 pcs)

HI 710035 Spare Ink Cartridge (1 pc)

HI 740027 1.5V AA batteries (4 pcs)

HI 9200 Infrared Transmitter (HI98801,HI98804 only)

HI 92000 Windows® compatible software for data transfer to PC

(HI98801,HI98804 only)

Windows® is registered Trademark of "Microsoft Co."

30

Page 31

WARRANTY

All Hanna Instruments meters are warranted for two years against

defects in workmanship and materials when used for their intended

purpose and maintained according to instructions. The electrodes

and the probes are warranted for a period of six months. This

warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is

not covered by the warranty, you will be notified of the charges

incurred. If the instrument is to be returned to Hanna Instruments, first

obtain a Returned Goods Authorization number from the Customer

Service department and then send it with shipping costs prepaid.

When shipping any instrument, make sure it is properly packaged for

complete protection.

Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make

sure that they are entirely suitable for

the environment in which they are

used.

Operation of these instruments in residential area could cause unacceptable

interferences to radio and TV equipments, requiring the operator to take

all necessary steps to correct interferences.

Any variation introduced by the user

to the supplied equipment may degrade the instrument's EMC performance.

To avoid electrical shock, do not use

these instruments when voltages at

the measurement surface exceed

24VAC or 60 VDC.

To avoid damages or burns, do not perform any measurement in microwave ovens.

31

Page 32

03/02

www.hannainst.com

MAN98804R2

Loading...

Loading...