Page 1

Instruction Manual

HI 95715

Ammonia Medium Range ISM

www.hannainst.com

This Instrument is in

Compliance with the CE Directives

1

Page 2

Dear Customer,

Thank you for choosing a Hanna product. This manual will provide you with the necessary

information for the correct use of the instrument. Please read it carefully before using the meter. If

you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com.

This instrument is in compliance with

directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ..............................................................................................3

GENERAL DESCRIPTION ......................................................................................................4

ABBREVIATIONS ................................................................................................................4

SPECIFICATIONS ................................................................................................................5

PRECISION AND ACCURACY.................................................................................................5

PRINCIPLE OF OPERATION..................................................................................................6

FUNCTIONAL DESCRIPTION.................................................................................................7

GUIDE TO DISPLAY CODES..................................................................................................9

GENERAL TIPS FOR AN ACCURATE MEASUREMENT.............................................................11

MEASUREMENT PROCEDURE ............................................................................................13

VALIDATION PROCEDURE..................................................................................................15

CALIBRATION PROCEDURE................................................................................................16

BATTERY REPLACEMENT ...................................................................................................18

ACCESSORIES .................................................................................................................18

CE DECLARATION OF CONFORMITY....................................................................................19

WARRANTY .................................................................................................................19

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent

of the copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895 , USA.

2

Page 3

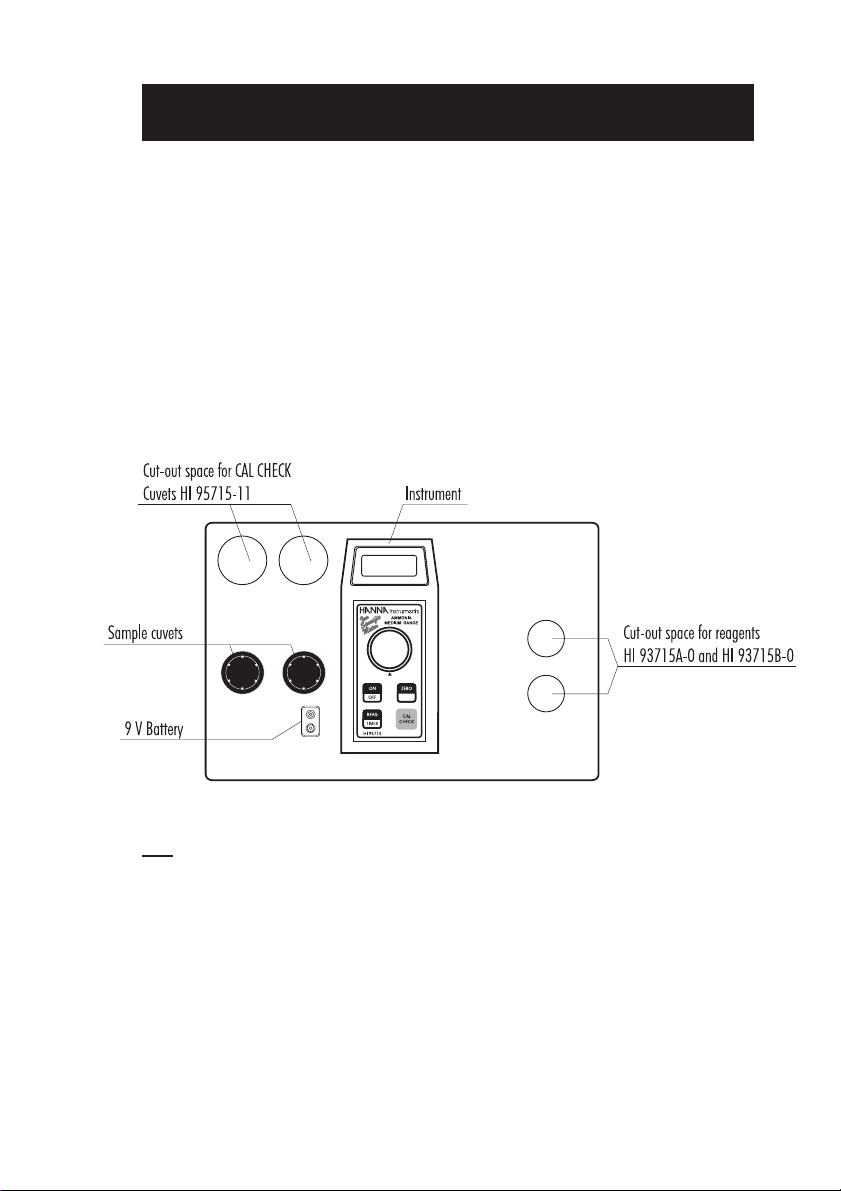

PRELIMINARY EXAMINATION

Please examine this product carefully. Make sure that the instrument is not damaged. If any

damage occurred during shipment, please notify your Dealer.

Each HI 95715 Ion Selective Meter is supplied complete with:

• Two Sample Cuvets and Caps

• 9V Battery

• Tissue for wiping cuvets

• Instruction Manual and Quick Reference Guide

• Instrument Quality Certificate

• Rigid carrying case

Note:save all packing material until you are sure that the instrument works correctly.

Any defective item must be returned in its original packing.

3

Page 4

GENERAL DESCRIPTION

The HI 95715 is an auto diagnostic portable microprocessor meter that benefits from Hanna’s

years of experience as a manufacturer of analytical instruments. It has the advanced optical

system based on a LED light source and a narrow band interference filter that allows most

accurate and repeatable readings. All instruments are factory calibrated and the electronic and

optical design minimizes the need of frequent calibration.

With the powerful CAL CHECK validation function you are able to validate good performance of

your instrument at any time. The validation procedure is extremely user friendly. Just use the

exclusive Hanna ready-made, NIST traceable standards to verify the performance of the

instrument and recalibrate if necessary.

All instruments are splash proof and the LED (Light Emitting Diode) and filter units are protected

from dust or dirt by a transparent cup. This makes the instruments fulfill field applications.

Display codes aid the user in routine operation. The meter has an auto-shut off feature that will

turn off the instrument after 10 minutes of non use or after 1 hour if left in the calibration mode.

The meter uses an exclusive positive-locking system to ensure that the cuvet is in the same

position every time it is placed into the measurement cell. It is designed to fit a cuvet with a larger

neck making it easier to add both sample and reagents. The cuvet is made from special optical

glass to obtain best results.

The HI 95715 meter measures the ammonia nitrogen (NH

0.00 to 9.99 mg/L (ppm) range. The method is an adaptation from ASTM Manual of Water and

Environmental Technology, D1426-93, Nessler Method.

The reagents are in liquid form and are supplied in bottles. The amount of reagent is precisely

dosed to ensure the maximum repeatability.

-N) content in water samples in the

3

ABBREVIATIONS

American Society for Testing and Materials

ASTM:

degree Celsius

°C:

degree Fahrenheit

°F:

Liquid Crystal Display

LCD:

Light Emitting Diode

LED:

milligrams per liter. mg/L is equivalent to ppm (part per million)

mg/L:

milliliter

mL:

4

Page 5

SPECIFICATIONS

Range 0.00 to 9.99 mg/L

Resolution 0.01 mg/L for measurement

0.1 mg/L for calibration and validation

Precision ±0.12 mg/L @ 6.00 mg/L

Typical EMC Deviation ±0.01 mg/L

Light Source Light Emitting Diode with narrow band interference filter @ 466 nm

Light Detector Silicon Photocell

Method Adaptation of the ASTM Manual of Water and Environmental Technology,

D1426-93, Nessler Method. The reaction between ammonia and the

reagents causes a yellow tint in the sample.

Environment 0 to 50°C (32 to 122°F); max 95% RH non-condensing

Battery Type 1 x 9 volt

Auto-Shut off After 10' of non-use in measurement mode;

after 1 hour of non-use in calibration mode.

Dimensions 180 x 83 x 46 mm (7.1 x 3.3 x 1.8")

Weight 290 g (10 oz.).

REQUIRED REAGENTS

Code Description Quantity/test

HI 93715A-0 First Reagent 4 drops (6 drops in seawater)

HI 93715B-0 Second Reagent 4 drops (10 drops in seawater)

(as NH3-N)

PRECISION AND ACCURACY

Precision is how closely repeated measurements

agree with each other. Precision is usually expressed

as standard deviation (SD).

Accuracy is defined as the nearness of a test result to

the true value.

Although good precision suggests good accuracy,

precise results can be inaccurate. The figure explains

these definitions.

In a laboratory using a standard solution of 6.00

mg/L ammonia nitrogen (NH

representative lot of reagents, an operator obtained

with a single instrument a standard deviation of

0.12 mg/L.

-N) and a

3

5

Page 6

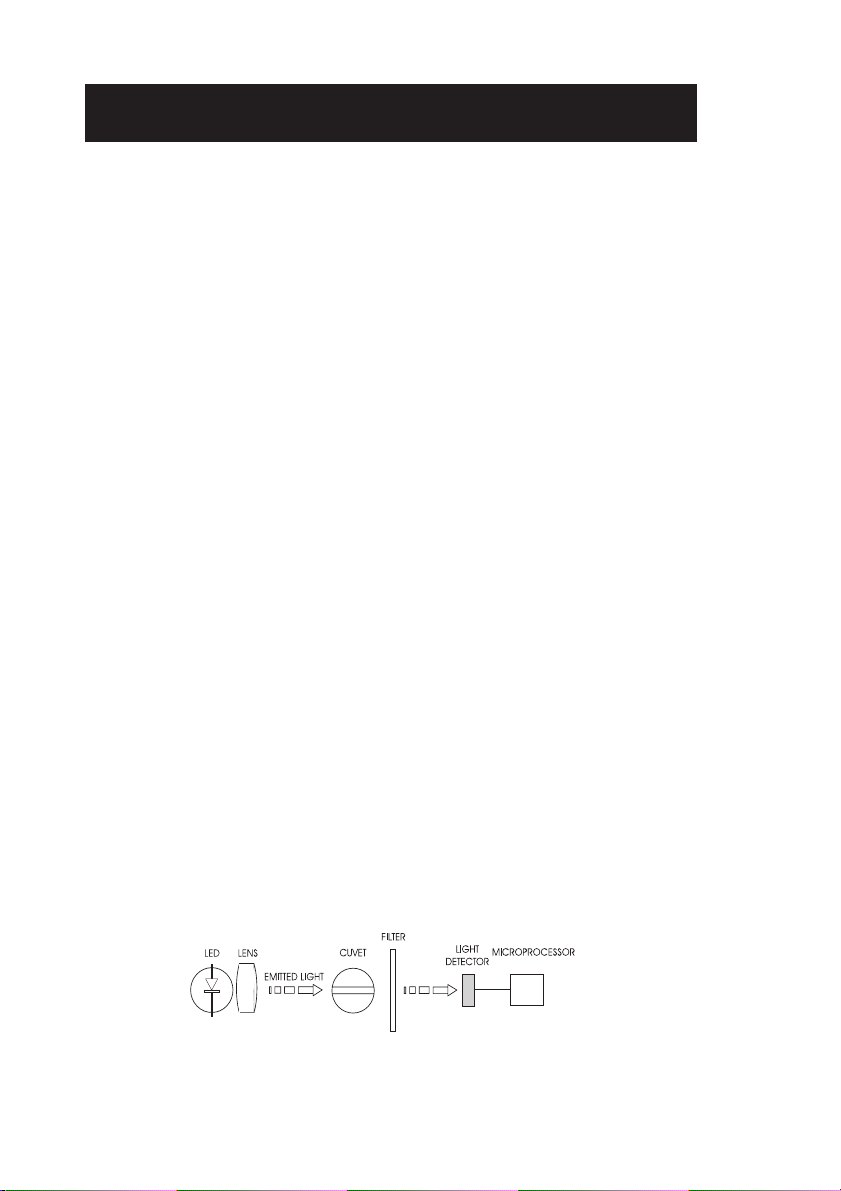

PRINCIPLE OF OPERATION

Absorption of Light is a typical phenomenon of interaction between electromagnetic radiation and

matter. When a light beam crosses a substance, some of the radiation may be absorbed by atoms,

molecules or crystal lattices.

If pure absorption occurs, the fraction of light absorbed depends both on the optical path length

through the matter and on the physical-chemical characteristics of the substance according to the

Lambert-Beer Law:

-log I/I

Where:

-log I/Io= Absorbance (A)

Io= intensity of incident light beam

I = intensity of light beam after absorption

ελ= molar extinction coefficient at wavelength λ

c = molar concentration of the substance

d = optical path through the substance

Therefore, the concentration "c" can be calculated from the absorbance of the substance as the

other factors are known.

Photometric chemical analysis is based on the possibility to develop an absorbing compound from

a specific chemical reaction between sample and reagents. Given that the absorption of a

compound strictly depends on the wavelength of the incident light beam, a narrow spectral

bandwidth should be selected as well as a proper central wavelength to optimize measurements.

The optical system of Hanna's HI 95715 colorimeter is based on a Light Emitting Diode (LED)

combined with a narrow-band interference filter to guarantee both high performance and reliable

results.

= ελ c d

o

or

A = ελ c d

HI 95715 block diagram (optical layout)

6

Page 7

A microprocessor controlled LED emits radiation which is first optically conditioned and beamed

to the sample contained in the cuvet. The optical path is fixed by the diameter of the cuvet. Then

the light is spectrally filtered to a narrow spectral bandwidth, to obtain a light beam of intensity

or I.

I

o

The photoelectric cell collects the radiation I that is not absorbed by the sample and converts

it into an electric current, producing a potential in the mV range.

The microprocessor uses this potential to convert the incoming value into the desired measuring

unit and to display it on the LCD.

The measurement process is carried out in two phases: first the meter is zeroed and then the actual

measurement is performed.

The cuvet has a very important role because it is an optical element and thus requires particular

attention. It is important that both the measurement and the calibration (zeroing) cuvets are

optically identical to provide the same measurement conditions. Whenever possible use the same

cuvet for both. It is necessary that the surface of the cuvet is clean and not scratched. This to avoid

measurement interference due to unwanted reflection and absorption of light. It is recommended

not to touch the cuvet walls with hands.

Furthermore, in order to maintain the same conditions during the zeroing and the measuring

phases, it is necessary to close the cuvet to prevent any contamination.

FUNCTIONAL DESCRIPTION

1) Liquid Crystal Display (LCD)

2) Cuvet Holder

3) Cuvet alignment indicator

4) ON/OFF key

5) ZERO key

6) READ/TIMER key

7) CAL CHECK key

7

Page 8

KEYPAD DESCRIPTION

• ON/OFF: to turn the meter on and off.

• ZERO: to zero the meter prior to measurement.

• READ/TIMER: this is a bi-functional key, just press for making a measurement, or hold the

key for 3 seconds to start a pre-programmed countdown prior to measurement.

• CAL CHECK: this bi-functional key allows to perform validation of the instrument just pressing

the CAL CHECK key, or hold the key for 3 seconds to enter the calibration mode.

OPERATING MODES

• Measurement mode: default operation mode, enables both validation and measurement.

• Calibration mode: may be entered by keeping CAL CHECK pressed for three seconds (the “CAL”

icon appears), it enables calibration of the instrument.

DISPLAY ELEMENTS DESCRIPTION

1) four digit main display area.

2) CAL: appears when the instrument operates in the calibration mode.

3) the Month and Day icons appear above the number of month and day when a date is

displayed.

4) the blinking “Battery” icon appears when the battery voltage is getting low.

8

Page 9

GUIDE TO DISPLAY CODES

This prompt appears for 1 second each time the instrument is

turned on.

This indicates that the meter is in a ready state and zeroing can

be performed.

Sampling in Progress. This flashing prompt appears each time the

meter is performing a measurement.

This indicates that the meter is in a zeroed state and measurement

can be performed.

Light over range: the cuvet is not inserted correctly and an excess

ambient light is reaching the detector. If the cover is properly

installed, then contact your dealer or the nearest Hanna Customer

Service Center.

The blinking "BAT" indicates that the battery voltage is getting low

and the battery needs to be replaced.

This indicates that the battery is dead and must be replaced. Once

this indication is displayed, the meter will lock up. Change the

battery and restart.

“Configuration”: this indicates that the meter has lost its

configuration. Contact your dealer or the nearest Hanna Customer

Service Center.

CALIBRATION MODE MESSAGES

The date of the last calibration appears on the LCD each time the

calibration mode is entered. If calibration is performed for the first

time, “F.CAL” appears.

This indicates that the factory calibration is selected.

9

Page 10

The flashing digits indicate that:

1) the month can be set

2) the day can be set

“Storage”: this prompt appears for 1 second at the end of the

calibration procedure, to indicate that the calibration data has

been stored.

“Error”: the concentration of the calibration solution used is not

correct. Repeat the calibration procedure with the right standard

solution, and verify it is not expired. If the calibration procedure fails

again, contact your dealer or the nearest Hanna Customer Service

Center.

ERROR MESSAGES

a) on zero reading

This indicates that the zeroing procedure failed due to a low signalto-noise ratio. In this case press ZERO again.

“No Light”: the instrument cannot adjust the light level. Please check

that the sample does not contain any debris.

“Light Low”: there is not enough light to perform a measurement.

Please check the preparation of the zero cuvet.

“Light High”: there is too much light to perform a measurement.

Please check the preparation of the zero cuvet.

b) on sample reading

There is too much light for the sample measurement. Please check

if the right sample cuvet is inserted.

“Inverted”: the sample and the zero cuvet are inverted.

“Zero”: a zero reading was not taken. Follow the instruction in

the measurement procedure for zeroing the meter.

10

Page 11

Under range. A blinking "0.00" indicates that the sample absorbs

less light than the zero reference. Check the procedure and make

sure you use the same cuvet for reference (zero) and measurement.

A flashing value of the maximum concentration indicates an

over range condition. The concentration of the sample is beyond

the programmed range: dilute the sample and re-run the test.

A flashing value lower than the maximum concentration indicates

a low signal-to-noise ratio condition. In this case accuracy of the

result is not guaranteed. Repeat the measurement procedure.

GENERAL TIPS FOR AN ACCURATE MEASUREMENT

The instructions listed below should be carefully followed during testing to ensure best accuracy.

• Color or suspended matter in large amounts may

cause interference, therefore these should be

removed by treatment with active carbon and by

prior filtration.

• For a correct filling of the cuvet: the liquid in

the cuvet forms a convexity on the top; the

bottom of this convexity must be at the same

level of the 10 mL mark.

• Proper use of the dropper:

(a) to get good reproducible results, tap the dropper on the table for several times and wipe

the outside of the dropper tip with a cloth.

(b) always keep the dropper bottle in a vertical position while dosing the reagent.

(a) (b)

11

Page 12

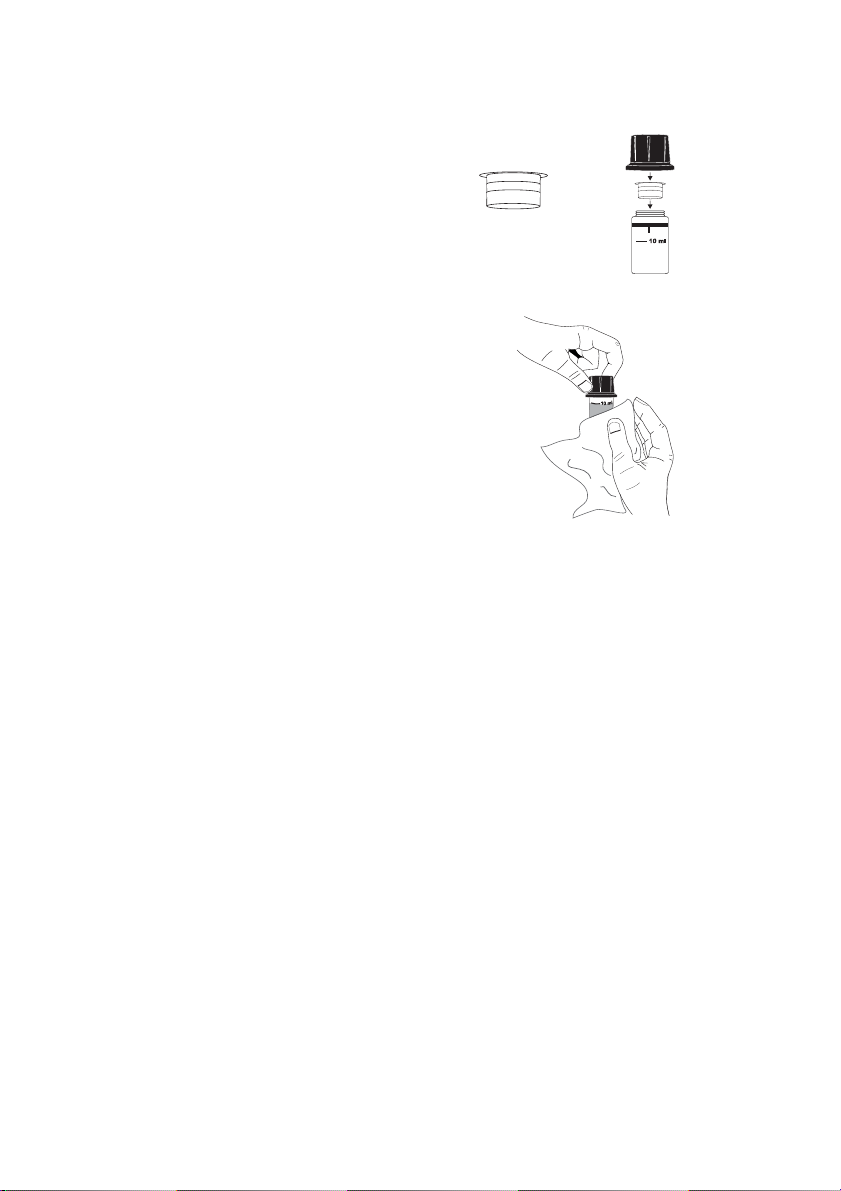

• It is important that the sample does not contain

any debris. This would corrupt the reading.

• In order to avoid reagent leaking and to obtain

more accurate measurements, it s recommended

to close the cuvet first with the supplied HDPE

plastic stopper and then with the black cap.

• Each time the cuvet is used, the cap must be

tightened to the same degree.

• Whenever the cuvet is placed into the measurement

cell, it must be dry outside, and completely free

of fingerprints, oil or dirt. Wipe it thoroughly with

HI 731318 (tissue for wiping cuvets, see chapter

ACCESSORIES) or a lint-free cloth prior to insertion.

• Do not let the reacted sample stand too long after

reagent is added, or accuracy will be lost.

• It is possible to take multiple readings in a row,

but it is recommended to take a new zero reading

for each sample and to use the same cuvet for

zeroing and measurement.

• After the reading it is important to discard

immediately the sample, otherwise the glass might

become permanently stained.

• All the reaction times reported in this manual are

referred to 20°C (68°F). As a general rule of

thumb, they should be doubled at 10°C (50°F)

and halved at 30°C (86°F).

• In order to maximize accuracy, prior to a

measurement follow the validation procedure

to be sure that the instrument is properly

calibrated. If necessary, calibrate the instrument.

12

Page 13

MEASUREMENT PROCEDURE

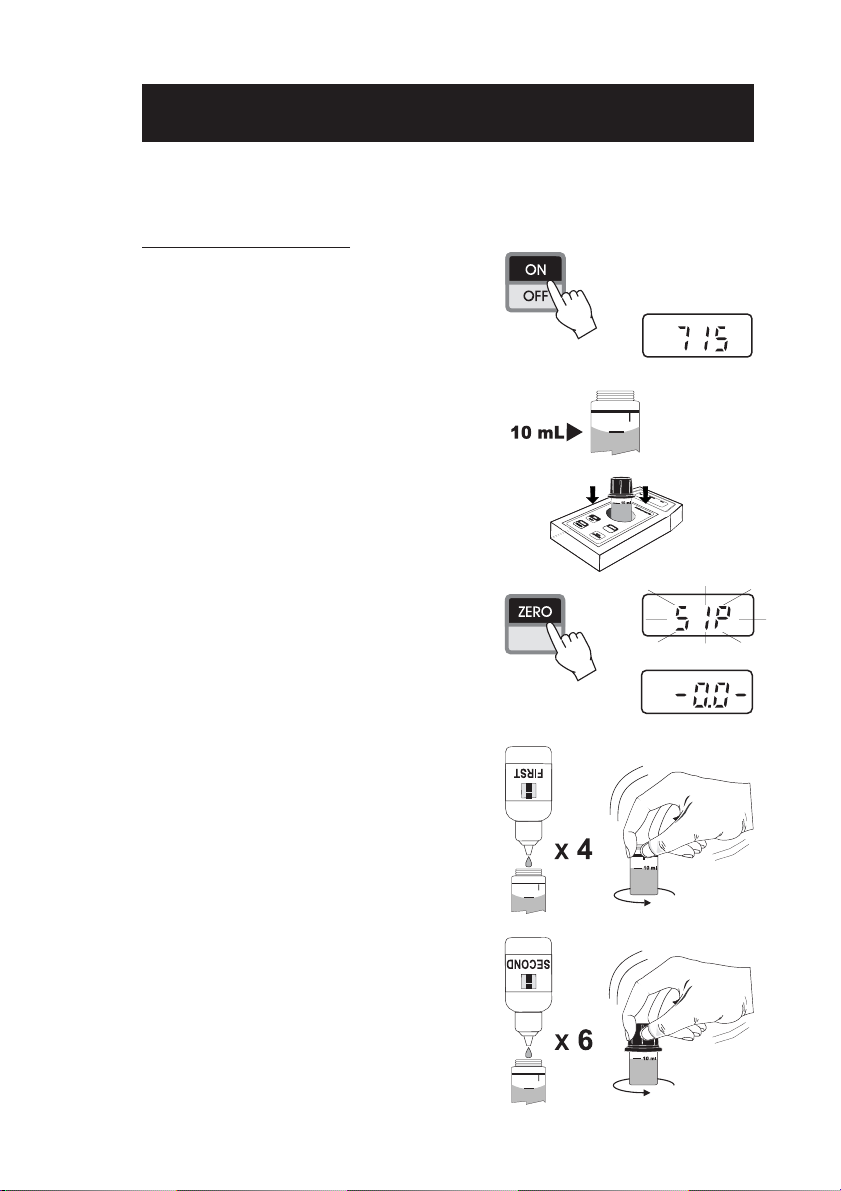

Turn the meter on by pressing ON/OFF and follow instruction manual to perform either the

MEASUREMENT, VALIDATION or CALIBRATION PROCEDURE.

MEASUREMENT PROCEDURE

• Turn the meter on by pressing ON/OFF.

• When the LCD displays “715”, it is ready.

• Fill the cuvet with 10 mL of unreacted sample,

up to the mark, and replace the cap.

• Place the cuvet into the holder and ensure that

the notch on the cap is positioned securely into

the groove.

• Press ZERO and “SIP” will blink on the display.

• After a few seconds the display will show

“ -0.0- ”. The meter is now zeroed and ready

for measurement.

• Remove the cuvet, open it and add 4 drops of

HI 93715A-0 First Reagent (6 drops in case

of seawater analysis). Swirl the cuvet gently

to mix.

• Add 4 drops of HI 93715B-0 Second Reagent

to the cuvet (10 drops in case of seawater

analysis). Replace the cap and swirl the cuvet

to mix.

13

Page 14

• Replace the cuvet into the holder and ensure

that the notch on the cap is positioned securely

into the groove.

• Hold READ/TIMER for three seconds. The

display will show the countdown prior to

measurement.

Alternatively, wait for 3 minutes and 30 seconds

and just press READ/TIMER.

In both cases “SIP” will blink during

measurement.

• The instrument directly displays concentration

in mg/L of ammonia nitrogen (NH3-N) on the

Liquid Crystal Display.

• To convert the reading to mg/L of ammonia

(NH

), multiply by a factor of 1.216.

3

INTERFERENCES

or

• Organic compounds like: chloramines, various aliphatic and aromatic amines, glycine,

(positive error).

To eliminate these interferences distillation is required.

• Organic compounds like: aldehydes, alcohols (e.g. ethanol) or acetone (negative error).

To eliminate these interferences distillation is required.

2-

• Sulfide (S

• Hardness above 1 g/L as Calcium Carbonate (CaCO

): may cause turbidity.

).

3

14

Page 15

VALIDATION PROCEDURE

Use the validation procedure to ensure that the instrument is properly calibrated.

Warning: do not validate or calibrate the instrument with standard solutions other than the Hanna

CAL CHECK Standards, otherwise erroneous results will be obtained. For accurate Validation and

Calibration, please perform test at room temperature: 18 to 25°C (64.5 to 77.0°F).

• Turn the meter on by pressing ON/OFF.

When the LCD displays “715”, it is ready.

• Place the CAL CHECK Standard Cuvet A into the

holder and ensure that the notch on the cap is

positioned securely into the groove.

• Press ZERO and “SIP” will blink on the display.

• After a few seconds the display will show

“-0.0-”. The meter is now zeroed and ready for

validation.

• Remove the cuvet and place the CAL CHECK

Standard HI 95715-11 Cuvet B into the holder.

Ensure that the notch on the cap is positioned

securely into the groove.

• Press CAL CHECK and “SIP” will blink during

measurement.

• Wait for a few seconds and the display will

show the validation standard value.

The reading should be within specifications as

reported on the Cal Check Standard Certificate.

If the value found is out of specifications,

please check that the cuvets are free of

fingerprints, oil or dirt and repeat validation. If

results are still found out of specifications then

recalibrate the instrument.

15

Page 16

CALIBRATION PROCEDURE

Note: it is possible to interrupt calibration procedure at any time by pressing ON/OFF.

Warning: do not validate or calibrate the instrument with standard solutions other than the Hanna

CAL CHECK Standards, otherwise erroneous results will be obtained. For accurate Validation and

Calibration, please perform test at room temperature: 18 to 25°C (64.5 to 77.0°F).

CALIBRATION PROCEDURE

• Turn the meter on by pressing ON/OFF.

• When the LCD displays “715”, it is ready.

• Enter the calibration mode by holding CAL CHECK

for three seconds.

• The date of the last calibration appears (e.g.:

month “01”, day “08”). “F.CAL” means that

the factory calibration is selected.

Note: at this point it is possible to reset the

instrument to restore FACTORY CALIBRATION,

see instructions page 18.

• Place the CAL CHECK Standard Cuvet A into the

holder and ensure that the notch on the cap is

positioned securely into the groove.

or

• Press ZERO and “SIP” will blink on the display.

• After a few seconds the display will show

“-0.0-”. The meter is now zeroed and ready for

calibration.

• Remove the cuvet.

• Place the CAL CHECK Standard HI 95715-11

Cuvet B into the holder and ensure that the

notch on the cap is positioned securely into the

groove.

16

Page 17

• Press READ/TIMER and “SIP” will blink during

measurement.

• The instrument will show for three seconds the

Cal Check standard value.

Then the date of last calibration (e.g.: “01.08”)

appears on the display, or “01.01” if the factory

calibration was selected. In both cases the

number of the month is blinking, ready for

date input.

Note: if the display shows “ERR” the calibration

procedure failed. Verify that the CAL CHECK

Standards HI 95715-11 Cuvets, A and B, are

free from fingerprints or dirt and that they are

inserted correctly.

DATE INPUT

• Keep READ/TIMER pressed to scroll to the

desired month number (01-12).

• When the correct month has been set, press

ZERO to confirm. Now the display will show the

day number blinking. Keep READ/TIMER pressed

to scroll to the desired day number (01-31).

Note: it is possible to change from day to

month and vice versa by pressing ZERO.

or

• When both the day and month have been

selected, hold CAL CHECK for three seconds to

store date and calibration values. The instrument

will show for one second “Stor”, to confirm

that the new calibration data has been accepted.

• The instrument will return automatically to the

measurement mode by displaying "715" on

the LCD.

17

Page 18

E

FACTORY CALIBRATION RESET

It is possible to restore factory calibration:

• Enter the calibration mode by holding CAL CHECK

for three seconds.

• Hold ZERO for 10 seconds. The display will

show for 2 seconds “F.CAL” and "715" appears.

The factory calibration is automatically restored

and the instrument is ready for measurement.

BATTERY REPLACEMENT

Battery replacement must only take place in a

non-hazardous area.

Simply slide off the battery cover on the back of

the meter. Detach the battery from the terminals

and attach a fresh 9V battery while paying attention

to the correct polarity. Insert the battery and replace

the cover.

9V

SLID

OFF

ACCESSORIES

REAGENT SETS

HI 93715-01 Reagents for 100 tests

HI 93715-03 Reagents for 300 tests

OTHER ACCESSORIES

HI 95715-11 CAL CHECK Standard Cuvets

HI 710009 Blue rubber boot

HI 710010 Orange rubber boot

HI 721310 9V battery (10 pcs)

HI 731318 Tissue for wiping cuvets (4 pcs)

HI 731331 Glass cuvets (4 pcs)

HI 731335 Caps for cuvets (4 pcs)

HI 93703-50 Cuvets cleaning solution (230 mL)

(1 set)

18

Page 19

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are

entirely suitable for your specific application and for

the environment in which they are used.

Operation of these instruments may cause

unacceptable interferences to other electronic

equipments, this requiring the operator to take all

necessary steps to correct interferences.

Any variation introduced by the user to the supplied

equipment may degrade the instruments' EMC

performance.

To avoid damages or burns, do not put the instrument

in microwave oven. For yours and the instrument safety

do not use or store the instrument in hazardous

environments.

WARRANTY

HI 95715 is warranted for two years against defects in workmanship and materials when used

for its intended purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact your dealer. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is not covered by the warranty,

you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization

Number from the Customer Service Department and then send it with shipment costs prepaid.

When shipping any instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the

date of purchase.

Hanna Instruments reserves the right to modify the design, construction and appearance of its

products without advance notice.

19

Page 20

www.hannainst.com

20

MAN95715R1 09/03

Loading...

Loading...