Page 1

HI 5315

REFERENCE

Instruction Manual

HI 5315HI 5315

HI 5315

HI 5315HI 5315

Reference Electrode

1

Page 2

HI 5315 Reference ElectrodeHI 5315 Reference Electrode

HI 5315 Reference Electrode

HI 5315 Reference ElectrodeHI 5315 Reference Electrode

I.I.

IntroductionIntroduction

I.

Introduction

I.I.

IntroductionIntroduction

The Hanna HI 5315 reference electrode is a silver-silver

chloride double junction half-cell designed for use with ion

selective electrodes or pH sensors. The electrode utilizes a

quick flush sleeve design. The external reference electrolyte

chamber is refillable. The internal chamber is a permanently filled, gel stabilized, chloride containing electrolyte.

IIII

SpecificationsSpecifications

II.

Specifications

IIII

SpecificationsSpecifications

Type: Ag/AgCl

Operating Temperature: 0-85°C

Operating pH: 0 to 14 pH

Dimensions: 12 mm (OD) x 120 mm

insertion (0.47” x 4.72”)

Connection: Banana Plug

Wetted Materials: PEI

SHE

E°

(calculated): 0.238V

III.III.

Theory of operationTheory of operation

III.

Theory of operation

III.III.

Theory of operationTheory of operation

A reference half-cell provides the electrolytic contact necessary to permit a voltage gradient to be measured across a

measurement membrane, such as an ISE. A Ag/AgCl electrode is the most common type of reference. The Nernst

expression for this type half-cell is expressed in the equation below. Note that the potential is a function of the

chloride concentration.

o

E=E

A chloride electrolyte completes the electrical circuit in the

inner half-cell. A bridge electrolyte is used as a buffer zone

between the inner half-cell and the sample. A small stable

liquid junction voltage is generated where the sample and

electrolyte come into contact. The size of this voltage, the

identity of the diffusing ions and how this barrier is formed

dictate stability. The barrier zone for this reference is a

narrow ring shaped opening formed between the outer

sleeve and the lower edge of the skirt shaped inner body.

- 0.059 log [Cl

AgCl

--

-

-]

2

Page 3

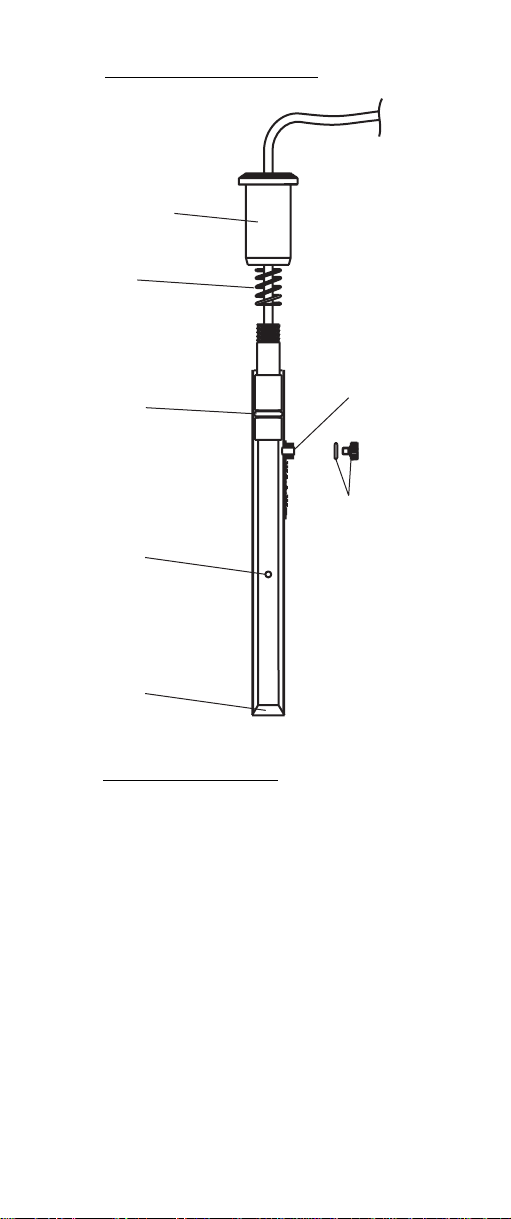

IVIV

..

HI 5315 design elementsHI 5315 design elements

IV

.

HI 5315 design elements

IVIV

..

HI 5315 design elementsHI 5315 design elements

Upper Cap

Spring

O-Ring

Ceramic Junction

on Inner Stem

Liquid junction

V. V.

Reference Fill SolutionsReference Fill Solutions

V.

Reference Fill Solutions

V. V.

Reference Fill SolutionsReference Fill Solutions

Fill Hole

O-Ring and

Plug

The fill solution used in the external electrolyte chamber of

this electrode is replaceable. Table 1 lists Hanna‘s ion

selective electrode (ISE) offering along with the recommeded

fill solutions used when making an ion measurement. A

bottle of this solution is provided with the ISE when shipped.

The fill solutions listed will not interfere with the sensing

electrode or react with the sample. They are formulated to

minimize liquid junction potentials and to produce the

most stable and reproducible electrode potential.

ThThw b

Verify you are using the correct fill solution with your

electrode.

ab

3

Page 4

d reproducible potential.

1ELBAT1ELBAT

1ELBAT1ELBAT

Recommended Fill Solutions for ISERecommended Fill Solutions for ISE

1ELBAT

Recommended Fill Solutions for ISE

Recommended Fill Solutions for ISERecommended Fill Solutions for ISE

edoCnoitpircseDnoituloSlliF

2004IHllec-flahedimorBIH2707

3004IHllec-flahmuimdaCIH2707

4004IHllec-flahmuiclaCIH2807

7004IHllec-flahedirolhCIH2707

8004IHllec-flahcirpuCIH2707

9004IHllec-flahedinayCIH2707

0104IHllec-flahediroulFIH5707

1104IHllec-flahedidoIIH2707

2104IHllec-flahetafluS/daeLIH2707

3104IHllec-flahetartiNIH8707

4104IHllec-flahmuissatoPIH6707

5104IHllec-flahedifluS/revliSIH2707

VI.VI.

Electrode Preparation:Electrode Preparation:

VI.

Electrode Preparation:

VI.VI.

Electrode Preparation:Electrode Preparation:

1. Remove the Parafilm® seal wrapped over the ceramic

junction on inner stem and discard. This is only used

for shipping and long term storage.

2. Rinse inner body with deionized water making certain

to wet o-ring found on the inner stem.

Remove

Water

Deionized

4

Parafilm

Page 5

3.

Reassemble electrode by gently pushing the inner

assembly into the outer body (from the bottom).

Slide the spring and upper cap down the cable and

over the top of the inner stem. Screw the upper cap

into place.

4. Unscrew and remove the fill hole plug and o-ring on

fill hole spout.

5.

Select the appropriate fill solution from Table 1. Use

the dropper pipette provided to add a few drops of fill

solution to the electrode. Invert electrode to wet the oring and rinse the electrolyte chamber.

6. Holding the body of the electrode gently press the

upper cap with your thumb. This permits the fill

solution to drain out of the body. Release your thumb

and verify electrode returns to its original position.

(You may need to gently assist for this to occur).

E

C

N

E

5

R

1

E

3

F

5

E

I

R

H

7. Tighten the upper electrode cap onto the body and fill

electrode body until the fill solution volume is just

below the fill hole.

8. Position the reference electrode with appropriate ion

selective electrode (ISE) in a Hanna HI 76404 electrode

holder (or equivalent) and connect banana plug to

the reference jack of the ISE meter.

5

Page 6

VII.VII.

General GuidelinesGeneral Guidelines

VII.

General Guidelines

VII.VII.

General GuidelinesGeneral Guidelines

• During measurement always operate electrode with

the fill hole open.

• Verify protective cap has been removed.

• During normal use, fill solution will slowly drain out

of the tapered cone junction at the bottom of the

electrode. Excessive loss (>4 cm drop within 24 hours)

is not normal. If this occurs verify the upper cap is

tightened and the interface between the internal cone

and outer body is free of debris.

• Add fill solution daily to maintain a good head

pressure. For optimum reference response, this level

should be maintained and not be allowed to drop

more than 2-3 cm (1-inch) below fill hole.

• When changing from one fill solution to another, drain

1st fill solution, rinse with an aliquot of the new

solution, drain, then refill with new fill solution.

• Components found in the fill solutions should not

interfere with the ion being measured. Verify the correct

solution is being used.

• Do not use an electrode if crystallized salts are visible

inside the electrode. Drain electrode, disassemble and

rinse internal body with deionized water. Reassemble

and refill with fresh fill solution.

• If an erratic measurement occurs, check to see if foreign

matter is seen trapped near the internal cone. Drain

and refill with fresh fill solution.

• The internal chamber of this electrode is gel filled. If

the electrode has been left dry for long periods of time

the gel may be dehydrated giving unstable readings.

Disassemble electrode and soak internal assembly in

HI 7075 fill solution. Verify the ceramic junction is

wetted by the fill solution. Warming the solution

slightly (50°C) before soaking it will hasten this

process. Permit the electrode to cool completely while

immersed in this solution.

6

Page 7

VIII.VIII.

Disassembly - AssemblyDisassembly - Assembly

VIII.

Disassembly - Assembly

VIII.VIII.

Disassembly - AssemblyDisassembly - Assembly

Disassembly is normally not required or recommended. If

crystals or other matter are seen between outer body and

inner cone, the electrode may be disassembled for cleaning

or inspection. Protect the cone surface from oils or dirt by

using gloves or lab tissues.

1. Drain fill solution from electrode body by depressing

the upper cap while holding the outer body.

2. Rinse inner body with deionized water and drain by

pressing the upper cap.

3. Unscrew upper cap and slide cap and spring up the

sensor cable toward the connector.

4. Push the inner body through the outer sleeve by gently

pushing down on the inner body near the threads.

5. Grasp the cone and gently pull assembly out of sleeve.

6. Cone may be cleaned with deionized water and a soft

lab tissue (HI 731318).

7. Clean and inspect internal surface of outer body.

8. Reassemble electrode by gently pushing the inner

stem assembly into the outer body, sliding spring

down cable, and screwing cap into place. (Refer to

Section VI; Electrode Preparation).

9. Refill electrolyte, flush junction, and then top off

electrolyte.

IXIX

StorageStorage

IX.

Storage

IXIX

StorageStorage

The HI 5315 reference electrode may be stored in air or

aqueous solutions between sample measurements.

If the electrode will be used frequently and needs to be

ready for use, take measures to prevent evaporation of fill

solution. Top off fill solution, replace o-ring and fill hole

plug on the fill hole opening, and place protective cap over

junction tip. Store electrode upright. Before using, flush

junction once and top off fill solution.

For long term storage, disassemble electrode and wash all

salts from assembly with deionized water. Wrap ceramic

junction on inner stem with Parafilm® or other sealing

film. Store dry and disassembled.

7

Page 8

MAN5315 07/06REV4

WARRANTY WARRANTY

WARRANTY

WARRANTY WARRANTY

Hanna Instruments ISE series electrodes are warranted to be free of

defects in material and workmanship for 6 months from date of purchase

when used for their intended purpose and maintained according to

instructions. If they fail to work when first used contact your dealer

immediately. Damage due to accidents, misuse, misapplication,

tampering or lack of prescribed maintenance is not covered.

Hanna Instruments reserves the right to modify the design, construction

or appearance of its products without advance notice.

8

Loading...

Loading...