Page 1

HI 504

Panel-mounted,

Microprocessor-based

pH/ORP Process Controller

Instruction Manual

Page 2

Page 3

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MODEL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . 5

PRELIMINARY EXAMINATION . . . . . . . . . . . . . . . . . . 6

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 6

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . 8

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 10

MECHANICAL DIMENSIONS . . . . . . . . . . . . . . . . . 11

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CALIBRATION MODE . . . . . . . . . . . . . . . . . . . . . . 14

SETUP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CONTROL MODE . . . . . . . . . . . . . . . . . . . . . . . . . 42

IN-LINE CLEANING . . . . . . . . . . . . . . . . . . . . . . . 51

IDLE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

HOLD MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

ANALOG OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . 56

PC COMMUNICATION . . . . . . . . . . . . . . . . . . . . . 58

SHORT MESSAGING SERVICE (SMS) . . . . . . . . . . . . 71

MODEM CONNECTION . . . . . . . . . . . . . . . . . . . . 79

pH/ORP PROBE CHECK . . . . . . . . . . . . . . . . . . . . 81

SOLUTION COMPENSATION . . . . . . . . . . . . . . . . . 82

TEMPERATURE COMPENSATION . . . . . . . . . . . . . . 83

LAST CALIBRATION DATA . . . . . . . . . . . . . . . . . . . . 85

OFFSET AND SLOPE DIRECT SELECTION . . . . . . . . 87

EVENT LOG FILE SCROLLING . . . . . . . . . . . . . . . . 89

FAULT CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . 91

SELFTEST PROCEDURES . . . . . . . . . . . . . . . . . . . . . 92

ALARM - ERROR CONFIGURATION . . . . . . . . . . . . 100

pH VALUES AT VARIOUS TEMPERATURES . . . . . . . . 103

ELECTRODE CONDITIONING AND MAINTENANCE . 104

DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . 108

CE DECLARATION OF CONFORMITY . . . . . . . . . . 113

3

Page 4

WARRANTY

All Hanna Instruments meters are guaranteed for two

years (sensors, electrodes and probes for six months)

against defects in workmanship and materials when used for

their intended purpose and maintained according to instructions. This warranty is limited to repair or replacement free of

charge.

Damage due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the instrument. If under warranty, report the model

number, date of purchase, serial number and the nature of

the failure. If the repair is not covered by the warranty, you

will be notified of the charges incurred. If the instrument is to

be returned to Hanna Instruments, first obtain a Returned

Goods Authorization number from the Customer Service department and then send it with shipping costs prepaid. When

shipping any instrument, make sure it is properly packaged

for complete protection.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance notice.

Page 5

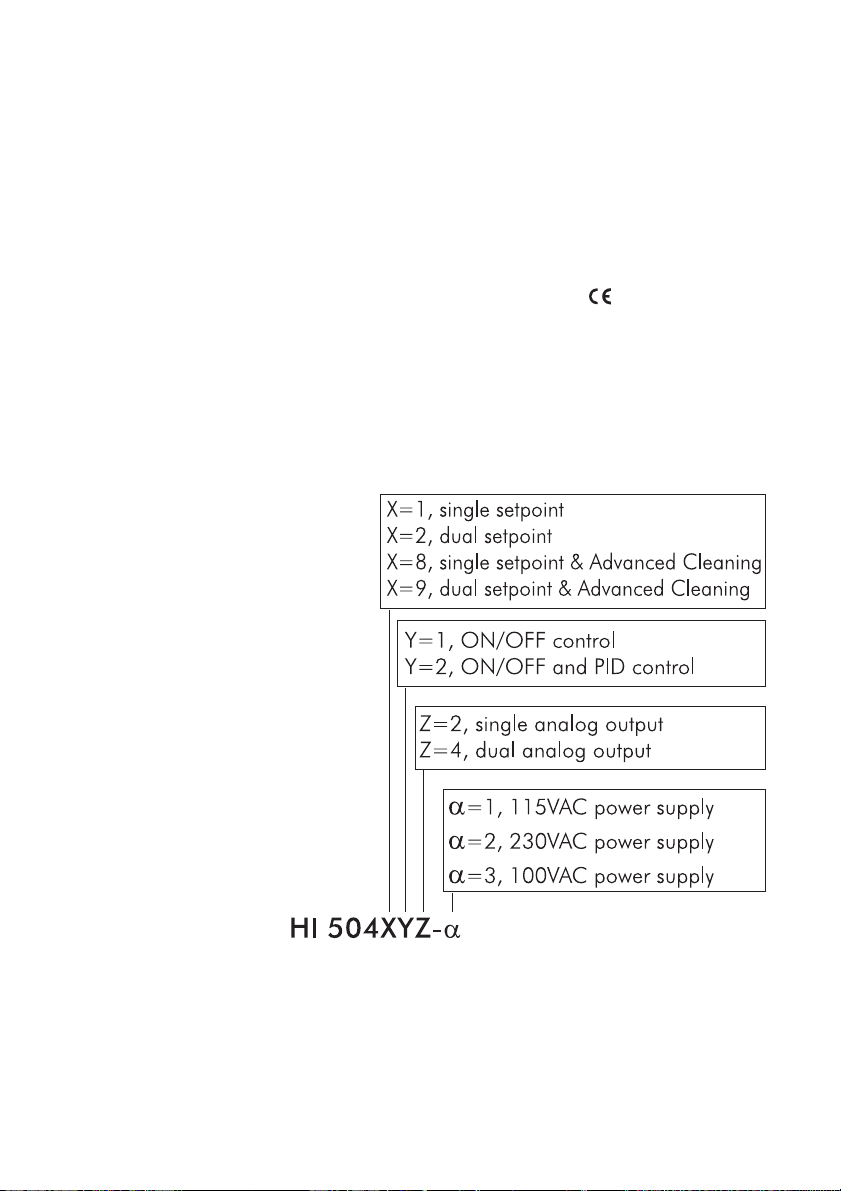

MODEL IDENTIFICATION

Dear Customer,

Thank you for choosing a Hanna Product.

Please read this instruction manual carefully before using the

instrument. It will provide you with the necessary information

for correct use of the instrument, as well as a precise idea of

its versatility.

If you need additional technical information, do not hesitate

to e-mail us at tech@hannainst.com.

This instrument is in compliance with directives.

The models HI 504XYZ-α are pH/ORP controllers.

The meaning of the last letters is according to the following

scheme:

© 2003 Hanna Instruments

All rights are reserved. Reproduction in whole or in part is prohibited without the

written consent of the copyright owner, Hanna Instruments Inc., 584 Park East Drive,

Woonsocket, Rhode Island, 02895 , USA.

5

Page 6

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has occurred

during shipping. If there is any noticeable damage, notify

your Dealer or the nearest Hanna Customer Service Center

immediately.

Note Save all packing materials until you are sure that the instru-

ment functions correctly. Any damaged or defective items must

be returned in their original packing materials together with

the supplied accessories.

GENERAL DESCRIPTION

The product is a real time microprocessor-based pH/ORP

controller. It provides accurate measurements, flexible

control capabilities and dual alarm signals.

The system is composed of a case inside which the signal

conversion circuitry, the microprocessor circuitry and the output

power drivers are contained.

MAIN FEATURES

• Configurations: for measure and control of pH or ORP, with

two separate sets of control settings. Thus no loss of settings

occurs when changing from pH to ORP and vice versa.

• Display: large LCD with 4 ½ 17 mm digits and 3 ½ 10 mm

digits.

• LEDs: a green LED (alarm relay) and a red LED for signaling

the device status.

• Alarm relay: one output relay for alarm condition (fail safe

mode: COM and NC are connected).

• Daily programmable control timing.

• Diagnostic features.

• pH/ORP probe check.

• Temperature sensor (Pt100 or Pt1000 type) with automatic

recognition and damage test.

• Hold management, including hold digital input to enter

hold mode with an external trigger.

• Logging of the last 100 error, configuration, calibration and

cleaning events.

6

Page 7

• Calibration and Setup procedures are password protected.

• Calibration: pH calibration at 2 points with two possible sets

of buffers (either 7.01 - 4.01 - 10.01 or 6.86 - 4.01 - 9.18),

or at 1 point with user-selectable value.

• Temperature compensation of the HANNA standard buffers.

• GLP features: old probe check, dead probe check, calibration time-out, last calibration data internally recorded (nonvolatile EEPROM memory): calibration date and time, pH

offset, pH slope, number of calibration points and correspondent pH values.

• Solution compensation of the pH reading.

• Manual temperature setting when the temperature probe is

not inserted or temperature is out of range.

• Input: pH/ORP electrode with BNC connector.

• Input: pH/ORP/Temperature Digital Transmitter (HI

504910) which can be connected up to 1.2 Km (0.5 miles)

far away.

• Output (0-20 or 4-20 mA): one analog output for recording of pH/ORP or controlling (only for models with PID).

• RS485 communication with Short Messaging Service (SMS)

for GSM phones.

• Data logging: 6000 samples pH/°C or ORP downloadable

through RS485 and HI92500 application software.

• Real time clock.

OPTIONAL FEATURES (depending on model)

• LEDs: four yellow LEDs are provided for signaling the energizing of relay 1, relay 2 (optional), relay 3 (optional) and

relay 4 (optional).

• Relays: 1, 2 or 4 output relays. The relays LEDs are switched

ON whenever the correspondent relay is energized (NO

and COM connected).

• Advanced Cleaning is provided through two cleaning commands

and variety of trigger events (relays 3 and 4 only).

• Output (0-20 or 4-20 mA): second independent analog

output for recording of temperature or controlling (only for

models with PID).

• PID control.

7

Page 8

FUNCTIONAL DESCRIPTION

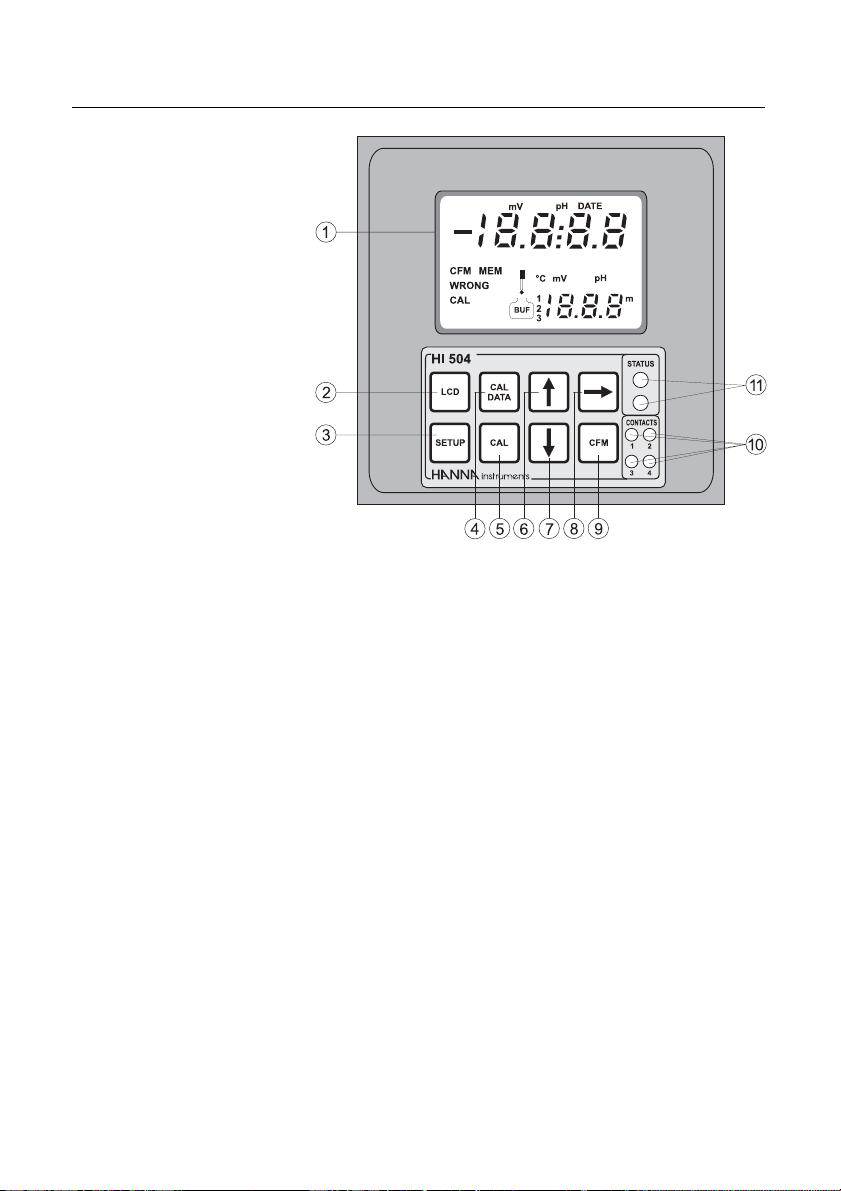

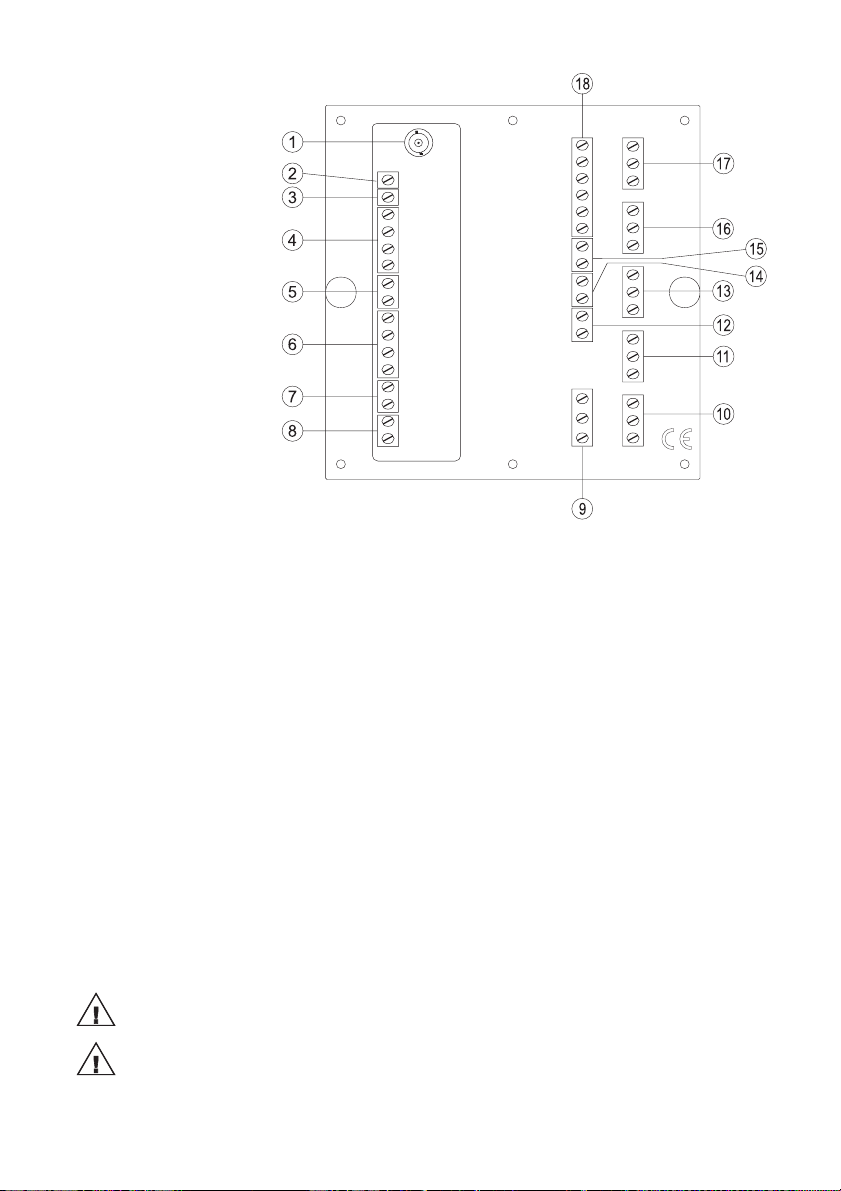

FRONT PANEL

1. Liquid Crystal Display

2. LCD key enters and exits the event scrolling mode. During pH

calibration, alternately displays pH buffer value or current

temperature

3. SETUP key enters and exits setup mode

4. CAL DATA key last calibration data viewing (enters and exits)

5. CAL key initiates and exits calibration mode

6. key increases the blinking digit/letter by one when selecting a

parameter. Advances forward while in last calibration data

viewing mode or event scrolling mode. Increases the temperature setting when temperature probe is not inserted

7. key decreases the blinking digit/letter by one when selecting a

parameter. Reverts backward while in last calibration data

viewing mode or event scrolling mode. Decreases the

temperature setting when temperature probe is not inserted

8. key moves to the next digit/letter (circular buffer) when selecting a parameter. Same as key during last calibration

data viewing mode. Move to the next piece of information

for the current event while in event scrolling mode

9. CFM key confirms current choice (and skips to the next item) ENTER

10. LEDs Relay’s 1, 2, 3, 4 activation

11. LEDs Controller Status, alarm activation

8

Page 9

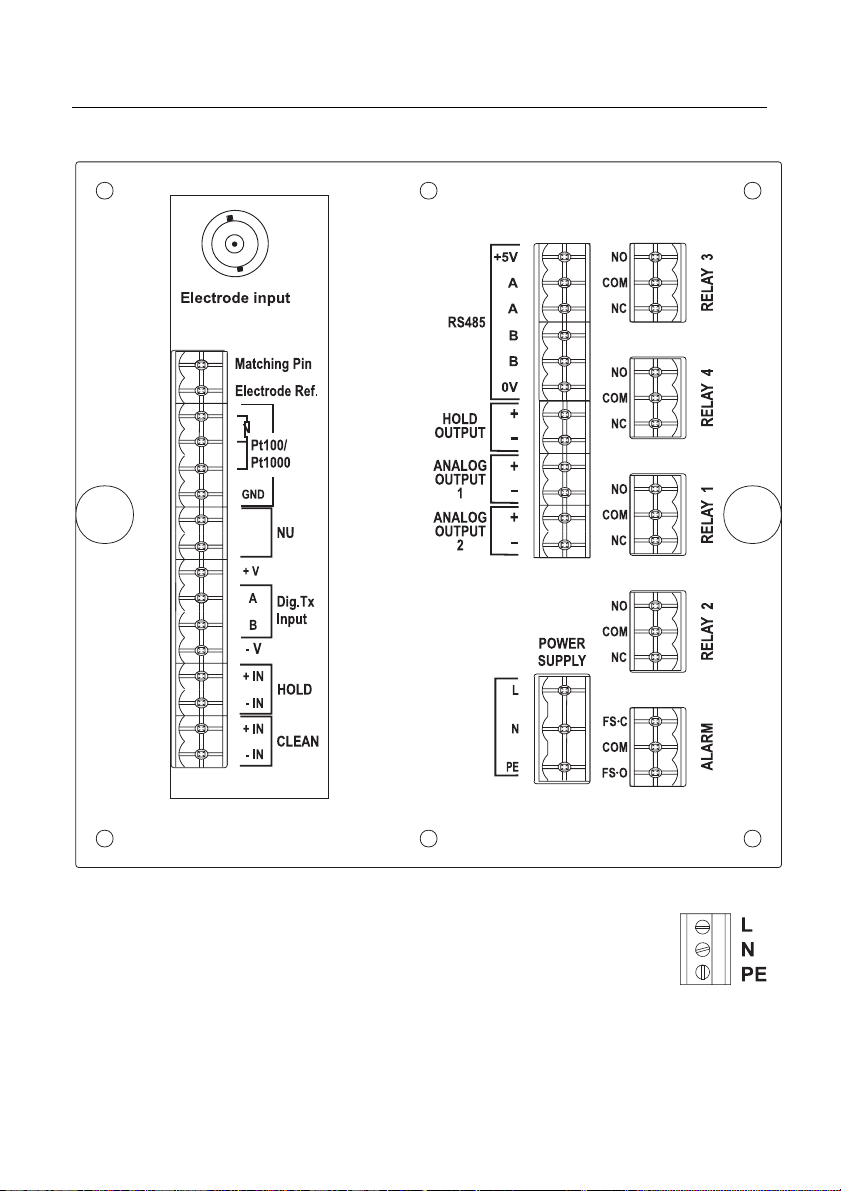

REAR PANEL

1. BNC Socket for pH or ORP electrode

2. Connection for Potential Matching Pin

3. Connection for electrode reference

4. Connections for Pt 100/Pt 1000 temperature sensor

5. Not Connected, for future use

6. Digital Transmitter input

7. HOLD input

8. Advanced Cleaning input (optional)

9. Power supply input

10. Alarm terminal

11. Relay 2 - second dosing terminal (optional)

12. Second analog output (optional)

13. Relay 1 - first dosing terminal

14. First analog output

15. HOLD output

16. Relay 4 - for Advanced Cleaning feature (optional)

17. Relay 3 - for Advanced Cleaning feature (optional)

18. RS485 output terminal

Unplug the meter before starting any electrical connections.

Disconnect the Potential Matching Pin when setup item I.04=”OFF”

9

Page 10

SPECIFICATIONS

Range -2.00 to 16.00 pH

Resolution 0.01 pH

Accuracy ±0.02 pH

(@20°C/68°F) ±2 mV

Typical EMC Deviation ±0.2 pH

Analog Input 4 to 20 mA

Digital Input for RS485

the pH/ORP/°C Transmitter

Other Digital Insulated Inputs • 2 digital insulated inputs: 1 for hold and 1 for

Digital Insulated Output A digital insulated contact closed upon hold mode

-2000 to 2000 mV

-30 to 130.0 ºC

1 mV

0.1 ºC above -10 ºC; 1 ºC below

±0.5 ºC (-9.9 to 130.0 ºC); ±1 ºC (-30 to -10 ºC)

±10 mV

±0.5 ºC

the advanced cleaning

• ON state: 5 to 24 VDC

10

Temperature compensation Automatic or manual from -30 to 130 ºC

Temperature probe With 3-wire or 2-wire Pt100/Pt1000 sensor

(with automatic recognition and damage test)

Installation Category II

Power Supply 230±10% VAC, 115±10% VAC or 100±10% VAC;

(depending on model) 50/60 Hz

Power Consumption 10 VA

Over Current Protection 400 mA 250V Quick Blow Fuse

Max. Oscillation Frequency 8 MHz

Relays 1, 2, 3, 4 Electromechanical relay SPDT contact outputs,

5A-250 VAC, 5A - 30 VDC (resistive load)

Fuse protected: 5A, 250V Quick Blow Fuse

Page 11

Alarm Relay Electromechanical Relay SPDT contact output,

Analog Output • 2 independent outputs

Analog Output Resolution 0.1‰ f.s.

Analog Output Accuracy ± 2‰ f.s.

Data logging 6000 pH/°C or ORP samples

Environment 0 to 50 ºC; max 85% RH non-condensing

Casing IP20 (housing); IP54 (front panel)

Enclosure single case ½ DIN

Weight approximately 1.6 kg (3.5 lb.)

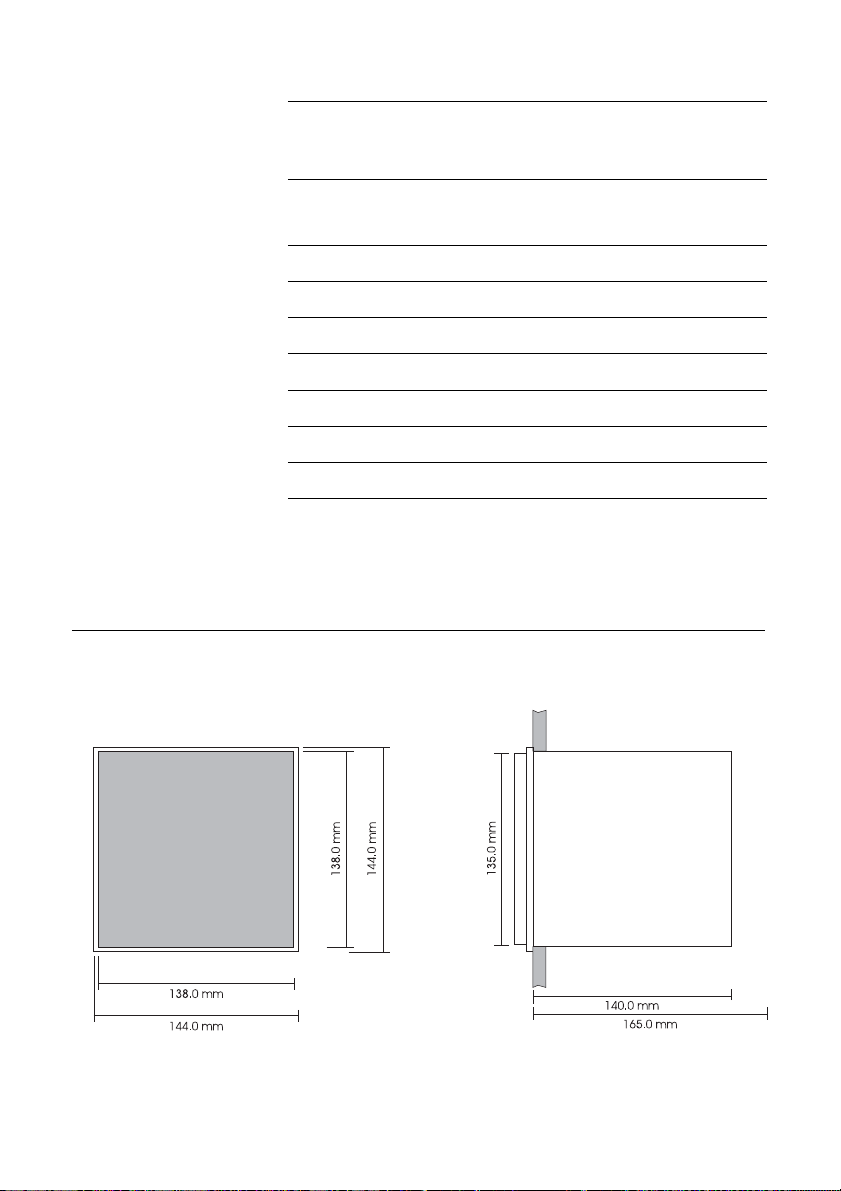

MECHANICAL DIMENSIONS

FRONT VIEW SIDE VIEW

5A - 250 VAC, 5A - 30 VDC (resistive load)

Fuse protected: 5A, 250V Quick Blow Fuse

• 0 - 22 mA (configuring as 0-20 mA or 4-20 mA)

11

Page 12

INSTALLATION

Refer to diagram on page #9

12

• Input power: Connect a 3-wire power cable

to the terminal strip line (L), earth (PE) and

neutral (N) terminal connections.

Power: 100VAC-120mA / 115VAC-100mA / 230VAC-50mA.

Line Contact: 400mA fuse inside.

PE must be connected to ground; leakage current 1mA.

Page 13

• Electrode: Connect the pH or ORP electrode to the BNC

socket (#1 at page 9).

To benefit from the differential (symmetrical) input, connect

the proper electrode wire (if available) or a cable with a

potential matching pin (grounding bar) to the relevant terminal (#2 at page 9) and enable the differential input

through the setup code I.04.

Note When it is not possible to immerse the Potential Matching Pin

together with the pH electrode in the solution (asymmetrical

input), disable the differential input through the setup code I.04.

In this case, detach the Potential Matching Pin from its connector. Failure to do so may cause damage of the reference

electrode.

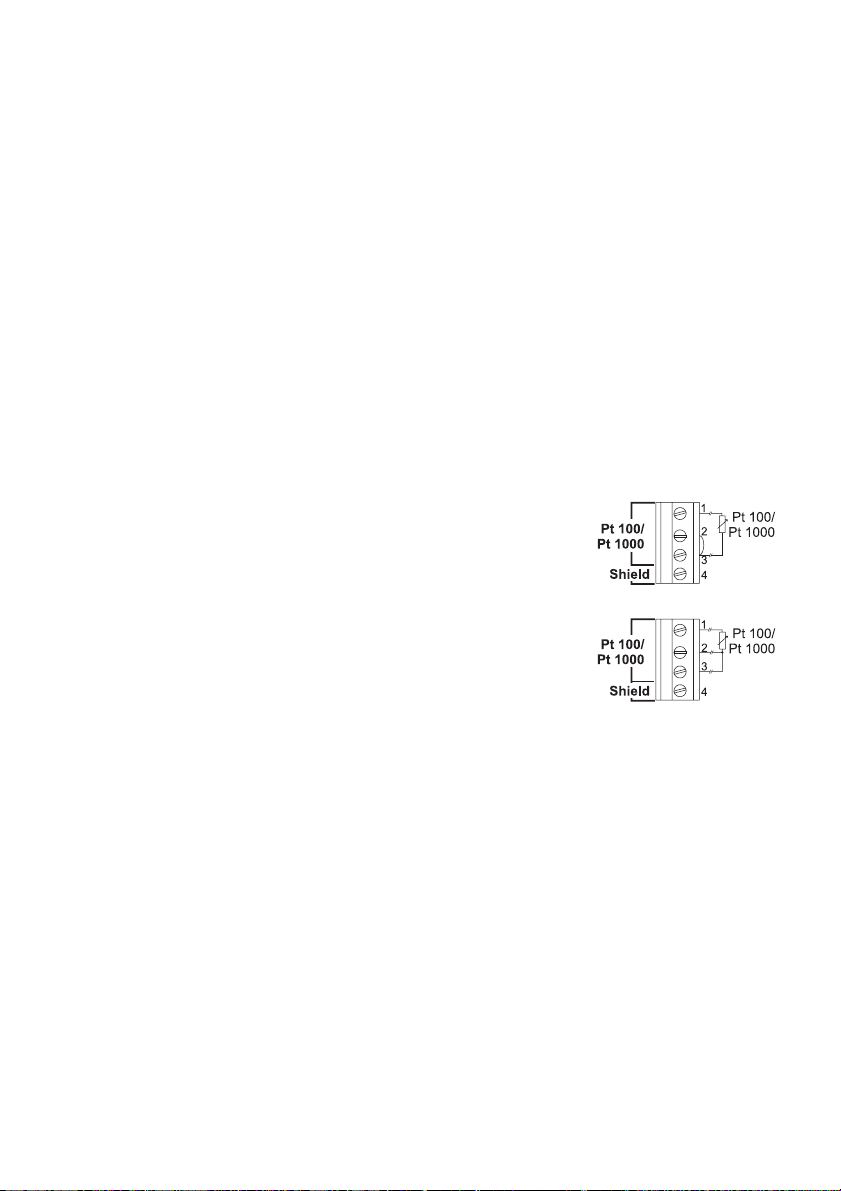

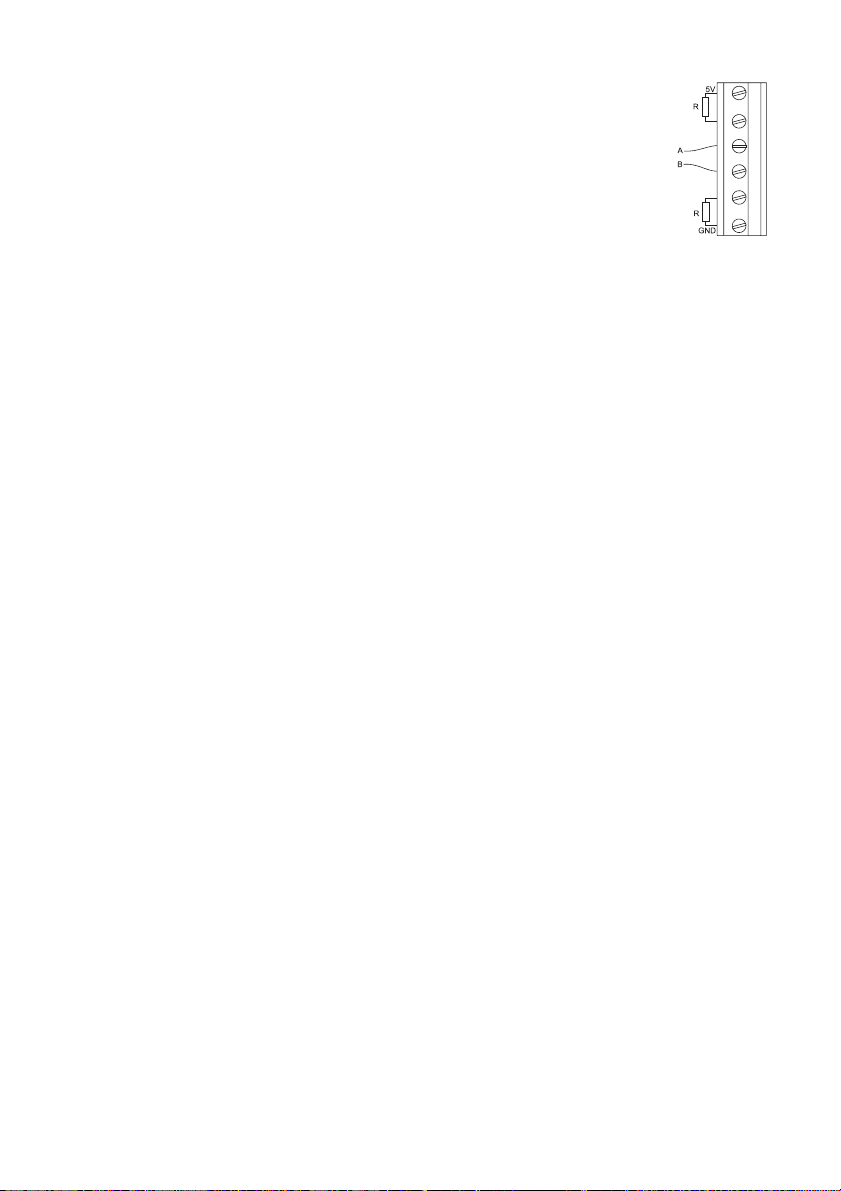

• Pt 100/Pt 1000 Terminals: these contacts (#4 at page 9)

connect the Pt 100/Pt 1000 temperature sensor for automatic temperature compensation of pH measurement. In

the case of shielded wire, connect the shield to pin 4.

In the case of a 2-wire sensor connect the Pt 100/Pt 1000 to pins 1

and 3, and short pins 2 and 3 with

a jumper wire.

If the Pt 100/Pt 1000 has more than

2 wires, connect the two wires of

one end to pins 2 and 3 (pin 2 is

an auxiliary input to compensate

for the cable resistance) and one

wire from the other end to pin 1.

Leave the fourth wire unconnected, if present.

Note The instrument automatically recognizes the sensor type (Pt

100 or Pt 1000).

• Analog Outputs: when using shielded cable, if the shield

is not connected at the other end of the cable, then connect it to the “+” terminal, otherwise leave it floating.

Note All cables connected to rear panel should end with cable lugs.

Note A circuit breaker (rated 10A max.) must be connected in

close proximity to the equipment, and in a position easy to

reach by the operator, for disconnection of the instrument

and of all the devices connected to the relays.

13

Page 14

CALIBRATION MODE

The calibration mode allows to calibrate the pH/ORP input,

temperature input and 4-20 mA analog outputs.

The controller is factory calibrated for all these parameters.

Periodical calibration of the instrument is recommended, in

particular when greatest accuracy is required and at least biyearly.

It is possible to calibrate the electrode over only one point,

but it is always good practice to perform a 2-point calibration.

To enter the calibration mode press the CAL key.

Enter the correct password and press the CFM key. If a wrong

password is entered, the instrument returns to the previous

mode.

Note If the meter is set as an ORP controller (setup item G.00), the

pH calibration, pH reading offset adjustment, and pH offset

and slope are not available. If the meter is selected as a pH

controller, no ORP calibration can be selected.

Note Any calibration procedure can be aborted at any time by

pressing the CAL key, and the instrument returns to the previous mode.

14

The pH/ORP controller can be calibrated through a onepoint or two-point calibration.

The pH calibration can not be performed if the pH electrode

is broken or leaking or the reference electrode is broken or

dirty and an error is active. The ORP calibration can not be

performed if the “Reference electrode broken or dirty” error is

active. For pH calibration the temperature probe should be

connected to the process meter.

All calibrations refer to the process controller. No calibration

for the Digital Transmitter can be performed by the process

controller, but the Digital Transmitter Calibrator must be used

for that.

Page 15

pH CALIBRATION

Initial Preparation

The pH and ORP calibrations can not be initiated while the

process controller is configurated to take measurements from

the Digital Transmitter.

It is recommended to perform pH calibration when the probe

is replaced and after any cleaning action.

To perform any pH calibration procedure, the instrument has

to be set as pH controller.

Pour small quantities of pH 7.01 (HI 7007) and pH 4.01

(HI 7004) or pH 10.01 (HI 7010) solutions into individual

beakers. If possible, use plastic beakers to minimize any EMC

interference.

For accurate calibration use different beakers for each buffer

solution, the first one for rinsing the electrode and the second

one for calibration. By doing this, contamination between

buffers is minimized.

RINSE

CALIBRATION

HI 7007

HI 7007

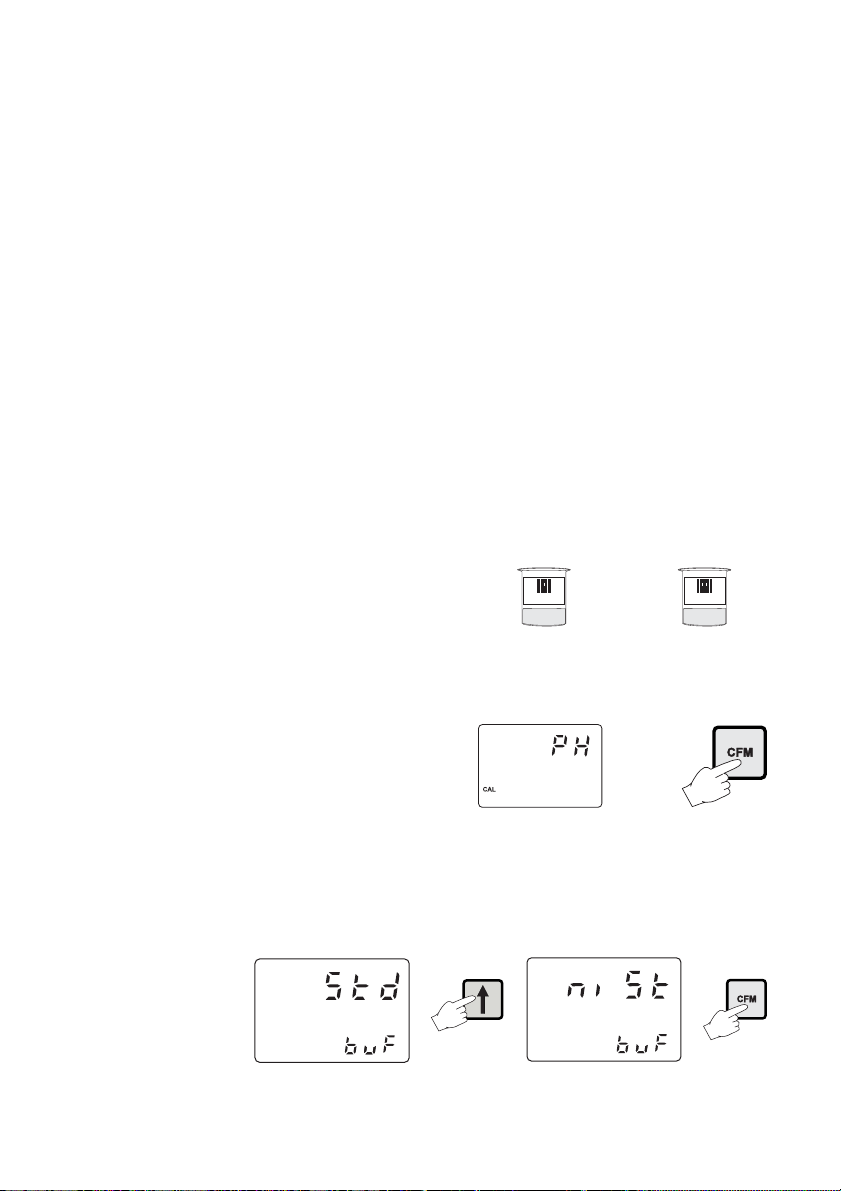

• Enter the calibration mode, select the pH calibration (by

moving through the menu with the and keys), then

press the CFM key.

• Choose the pH buffer set between the two available ones:

the standard set (4.01, 7.01, 10.01) and the NIST set (4.01,

6.86, 9.18). For the standard set confirm the “Std”; for the

NIST set confirm the “niSt” (use the and keys for select

between the two options).

15

Page 16

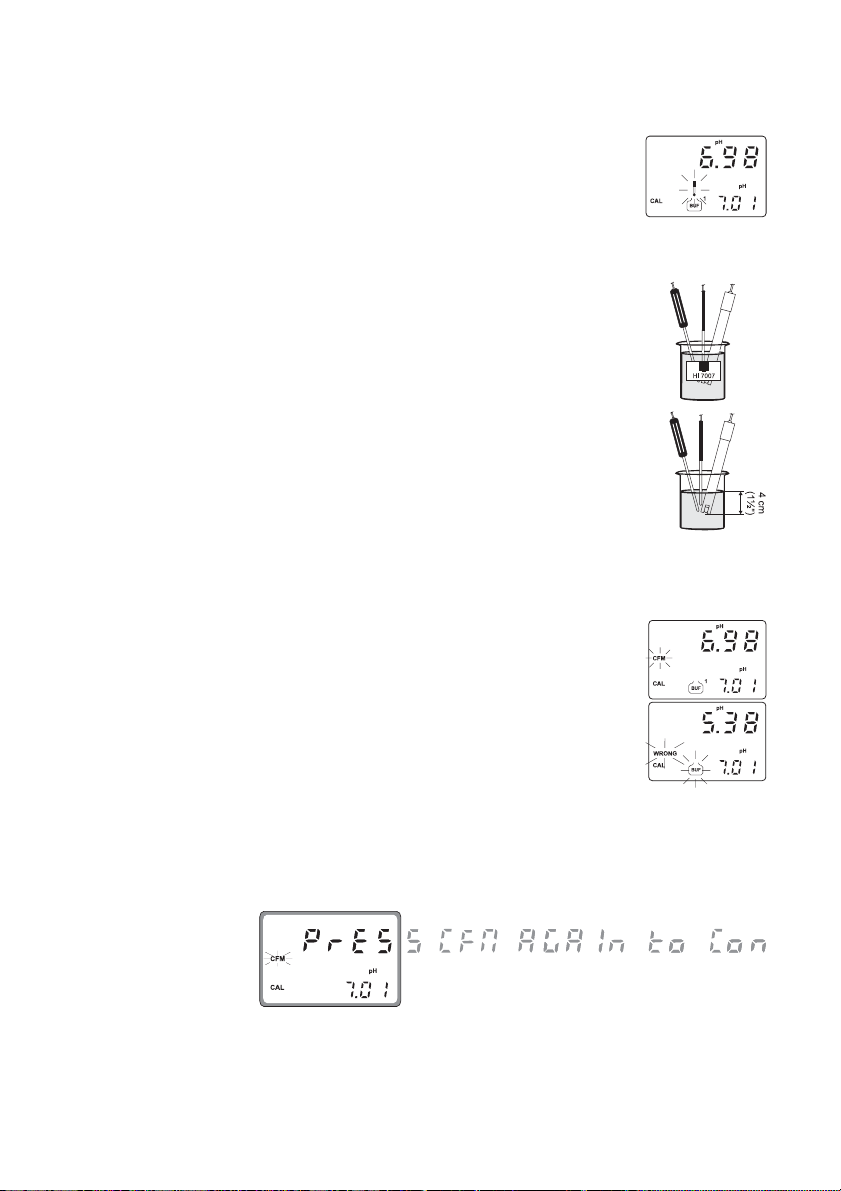

Two-point calibration

Note The electrode should be submerged ap-

Note When it is not possible to immerse the Potential Matching Pin

The default buffer set is the one used for last calibration,

even if the procedure was not completed.

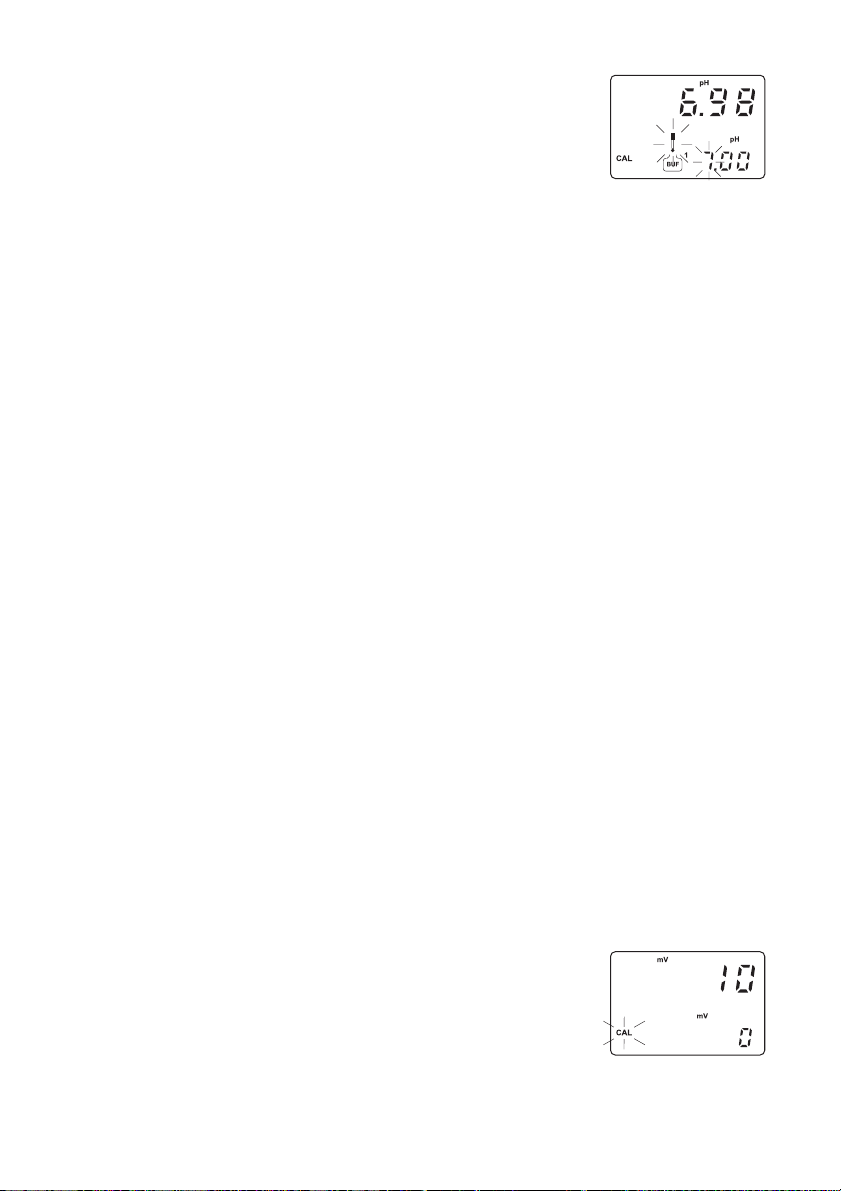

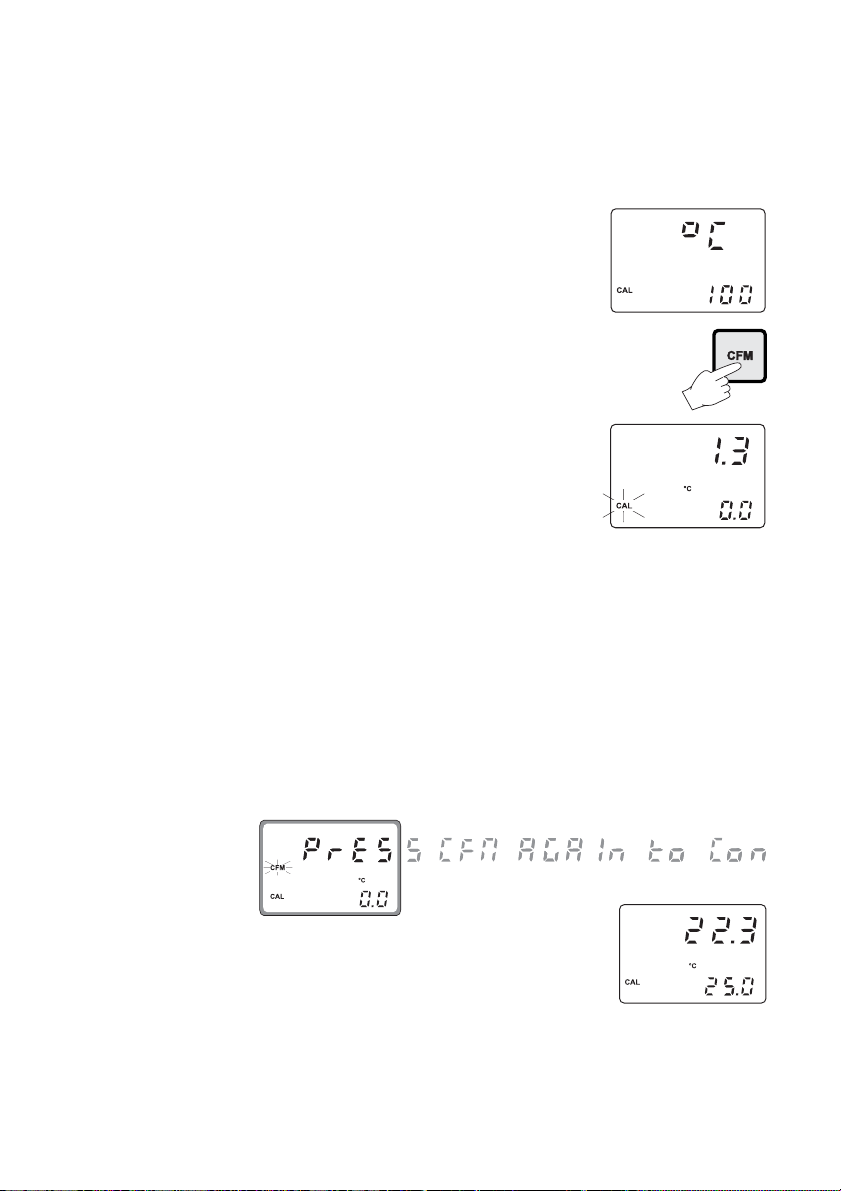

• Once confirmed the set of buffer values, the primary LCD shows the

measured pH value, while the secondary LCD displays the first required buffer

value.

• Remove the protective cap from the pH

electrode and immerse it into the buffer

solution (e.g. pH 7.01) together with

the Potential Matching Pin and the temperature probe, then stir gently.

proximately 4 cm (11/2’’) in the solution.

The temperature probe has to be located

as close as possible to the pH electrode.

together with the pH electrode in the solution, disable the

differential input by setting setup item I.04 to “OFF”.

• When the reading becomes stable, the

probe indicator will stop flashing (after

about 30 seconds), and if the pH value

is close to the selected buffer, the

“CFM” indicator will start blinking, otherwise the “WRONG” indicator, the pot

and the BUF tags will start blinking.

• In the first case press the CFM key to confirm calibration.

The meter will show the scrolling message “Press CFM again

to confirm the current buffer or right to escape” (to prevent

from confirming the calibration point inadvertently).

16

Pressing again CFM, the secondary LCD will display the

second expected buffer value.

Page 17

• In the second case (pH value not close to the buffer) the

meter will remain in the same state until the reading becomes unstable or the calibration mode is quitted.

• For the second buffer value it is possible to choose between pH 4.01 and pH 10.01 (or pH 4.01 and pH 9.18 if

the NIST set has been selected). Use the or key to

switch between the two possibilities.

• Once selected the buffer, the procedure is the same as for

the first calibration point.

Note A time-out of 1.5 minutes is present for the pH electrode

response time. During calibration, if the pH reading is not

stable after 1.5 minutes, the device displays twice the scrolling message “time-out”, then shows “WRONG” and it is not

possible to complete calibration.

• At the end of calibration, with the meter set as pH controller, the instrument checks if the offset is between -30 and

30 mV and the slope between 53.5 and 62 mV/pH. If the

values are not within these ranges, the message “OLd

ProbE” scrolls twice across the LCD. The electrode is still

working, but it is necessary to perform a cleaning procedure (see “Electrode conditioning and maintenance” and

“In-line Cleaning” sections) or replace it.

If the offset is outside the -60 to 60 mV range, the “dEAd

ProbE” message will scroll across the LCD and the corresponding error is activated. The electrode has to be replaced

as soon as possible because there is no reliability on the

measured pH values.

One-point calibration

A one-point calibration at a value different from the standard

buffer values is possible by entering the desired calibration

value. This is the actual pH value at the current calibration

temperature.

• Enter the pH calibration mode (no matter if the standard or

NIST buffer set is selected), then press the

SETUP key while the secondary LCD is displaying the first buffer value (pH 7.01 or pH

6.86).

17

Page 18

Note If SETUP key is pressed instead of CFM, the calibration value

ORP CALIBRATION

• The pH calibration value will switch

to 7.00, the first digit starts blinking

and it is possible to change its value

simply using the or key.

• Once selected the first digit value, press the key: the first

digit will be fixed and the second one will start blinking.

Pressing of the key repeatedly will result on circularly

moving on the secondary LCD.

• When the desired calibration value is reached (must be

within 0.00 to 16.00 pH), press the CFM key to confirm

and the calibration will proceed as described above.

• If the selected value is outside boundaries, the confirmation is not accepted and the first digit keeps blinking (waiting

for confirmation of a valid value).

selection is aborted and the meter reverts back to a two-point

calibration.

To perform ORP calibration it is necessary to connect an HI

931001 or HI 8427 simulator to the BNC socket.

The meter has to be set as ORP controller.

18

• Set item I.04 to “OFF” to disable the Matching Pin.

• A two-point calibration has to be performed: the first point

value is 0 mV and the second one can be chosen between

350 mV and 1900 mV.

• Enter the calibration mode, select the ORP calibration (use

the and keys to move through setup menu) and press

the CFM key.

• Set the HI 931001 or HI 8427 simulator to 0 mV.

• The primary LCD will display the current mV measure and the secondary

LCD will show the first calibration

point (0 mV).

Page 19

• When the reading becomes stable, if the ORP value is

close to the calibration point, the “CFM” indicator starts

blinking; otherwise the “WRONG” indicator blinks and

the “CAL” is fixed on.

• In the first case press CFM to confirm calibration. The

meter will proceed showing the scrolling message “Press

CFM again to confirm the current buffer or right to escape” (to prevent from confirming the calibration point

inadvertently). Pressing again CFM the secondary LCD will

display the second calibration point.

• In the second case (blinking “WRONG”) the meter will

remain in the WRONG state until the reading becomes

unstable or the calibration mode is exited by pressing the

CAL key.

• For the second calibration point it is possible to choose

between 350 mV or 1900 mV. Pressing the or key the

value on the secondary LCD will switch between the two

possibilities.

• Once selected the second calibration point, set the HI

931001 (350 mV) or HI 8427 (350 or 1900 mV) simulator to the same value and the calibration proceeds as for

the first point.

Note In ORP calibration there is no time-out.

ANALOG OUTPUT CALIBRATION

The instrument can be provided with one or two analog outputs, each of them can be calibrated.

• Connect an Ammeter or the HI 931002 calibrator to the

analog output to measure the current erogated by the meter.

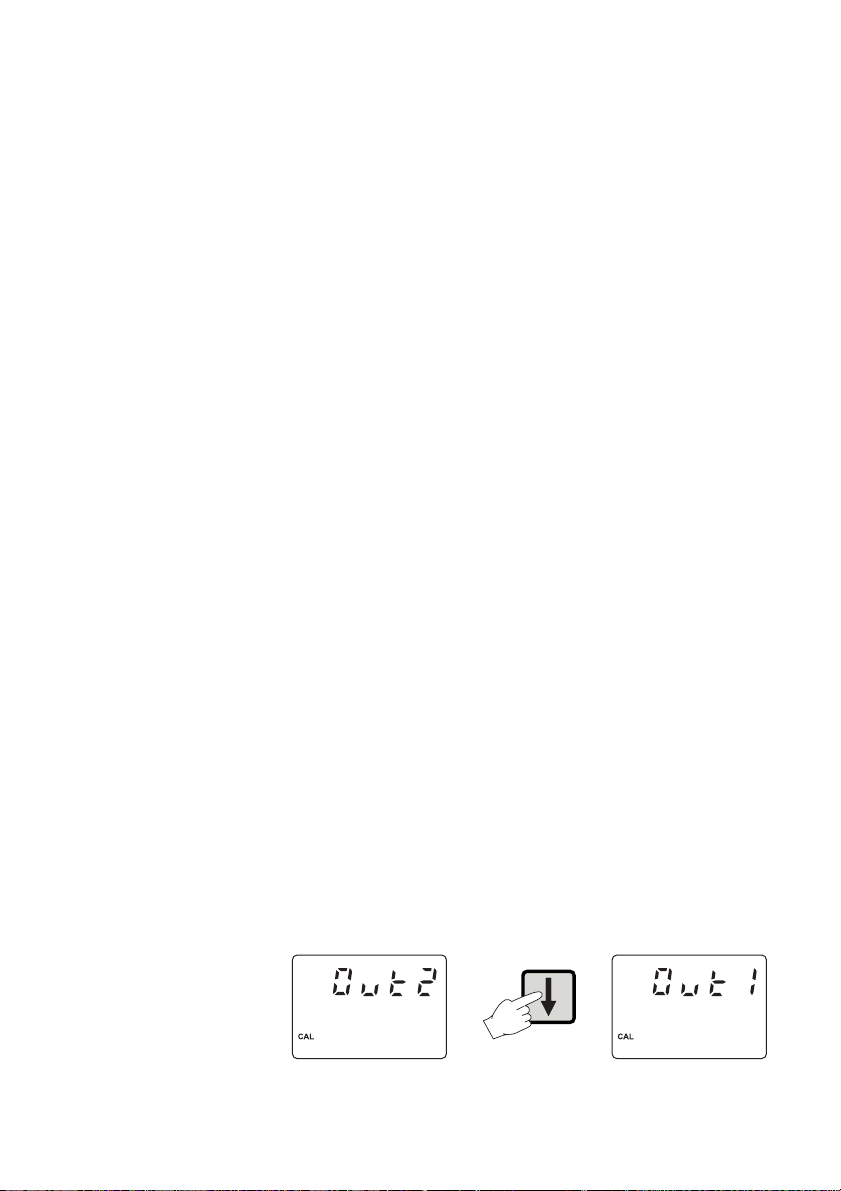

• Enter the calibration mode and move through the menu

using the or key until “Out 1” or “Out 2” message

appears on the primary LCD.

19

Page 20

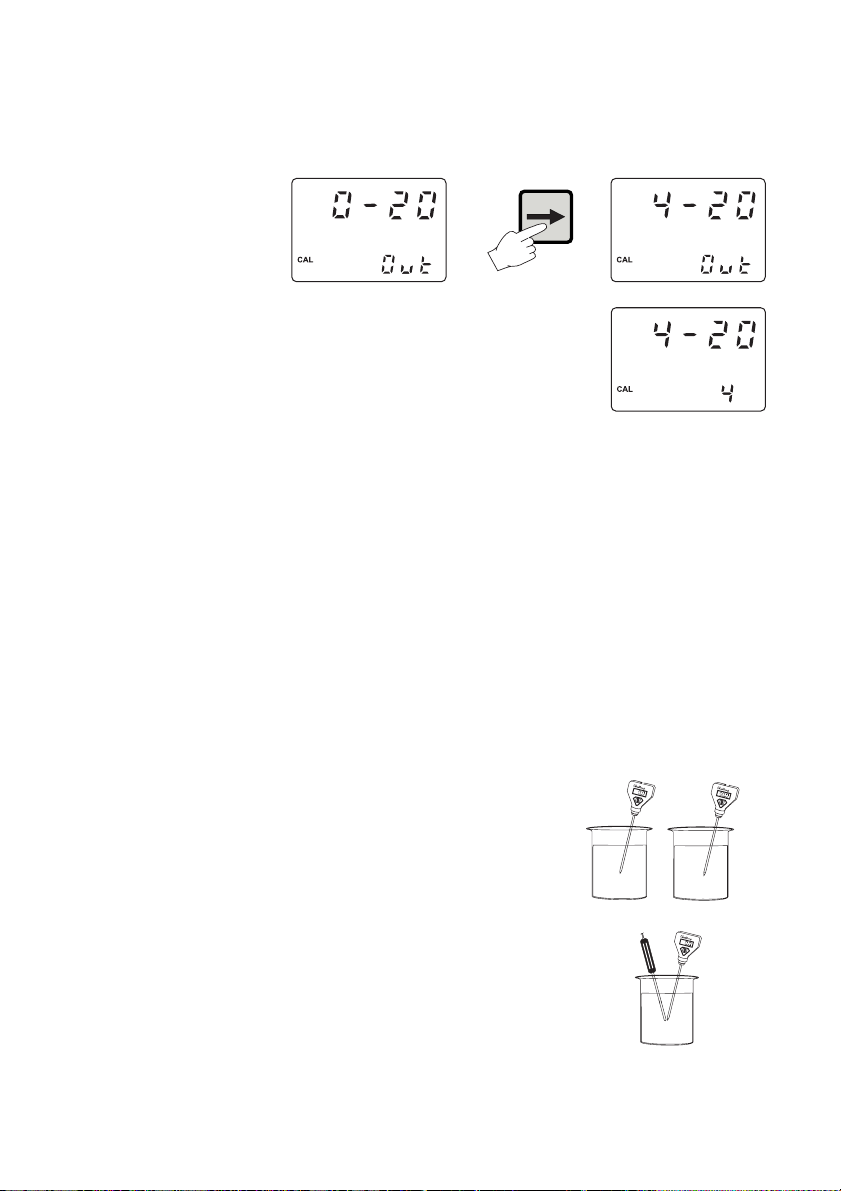

• Once visualized the selected output, press the key to

choose the range of the analog output (0-20 mA or 4-20

mA); then press the CFM key to confirm the choice.

• Once selected and confirmed the

range for the analog output, the

secondary LCD shows the first point

of calibration (1 or 4 mA) and the

primary LCD displays the range of

the actual calibration.

• With the tester check the real current value provided by the

instrument at the output port. If this value is different from

the expected one, it is possible to change the current

erogated by the instrument pressing the or key.

• Adjust the value until it matches with the first point of calibration, then press CFM to confirm. The instrument will

turn to the second calibration point (20 mA).

• The calibration procedure is the same as for the first point.

• Once the instrument is calibrated for both points (and confirmed), it will exit from the calibration menu.

TEMPERATURE CALIBRATION

• Prepare a beaker containing

crushed ice and water at 0°C (32°F)

and another one with hot water at

25°C (77°F) or 50°C (122°F).

• Use a Checktemp or another calibrated thermometer with a

resolution of 0.1° as a reference

thermometer.

• Immerse the temperature probe in

the beaker with ice and water as

near to the Checktemp as possible.

20

0 °C

(32 °F)

°C

0 °C

(32 °F)

50 ºC

(122 ºF)

°

C

°C

Page 21

Note The instrument can support Pt100 or Pt1000 temperature

sensor and calibration can be performed with anyone of these

two probes.

• After entering the calibration mode, move through the menu

(using the or key) to choose the temperature and the

correct kind of used probe; the primary LCD shows “°C” and the

secondary LCD gives indication

about the kind of probe (“100” indicates a Pt100 probe, while

“1000” stands for a Pt1000

probe).

Press the CFM key to confirm selection.

• The calibration has to be performed

over two points: the first point has to

be 0°C and the second one can be

chosen between 25°C and 50°C.

Once confirmed the type of calibration, the primary LCD

will display the current temperature measure and the secondary LCD will show the first calibration point (0°C).

• When the reading becomes stable, if the temperature value

is close to the calibration point the CFM tag starts blinking, otherwise the WRONG indicator will flash.

• In the first case press the CFM key to confirm calibration.

The meter will proceed showing the scrolling message “Press

CFM again to confirm the current buffer or right to escape” (to prevent from confirming the calibration point

inadvertently).

• Pressing again the CFM key, the secondary LCD will display the second

calibration point.

• In the case the measured temperature is not close to the

calibration value, the meter remains in the WRONG status

until the reading becomes unstable or the calibration mode

21

Page 22

VOLT CALIBRATION

is exited (by pressing the CAL key).

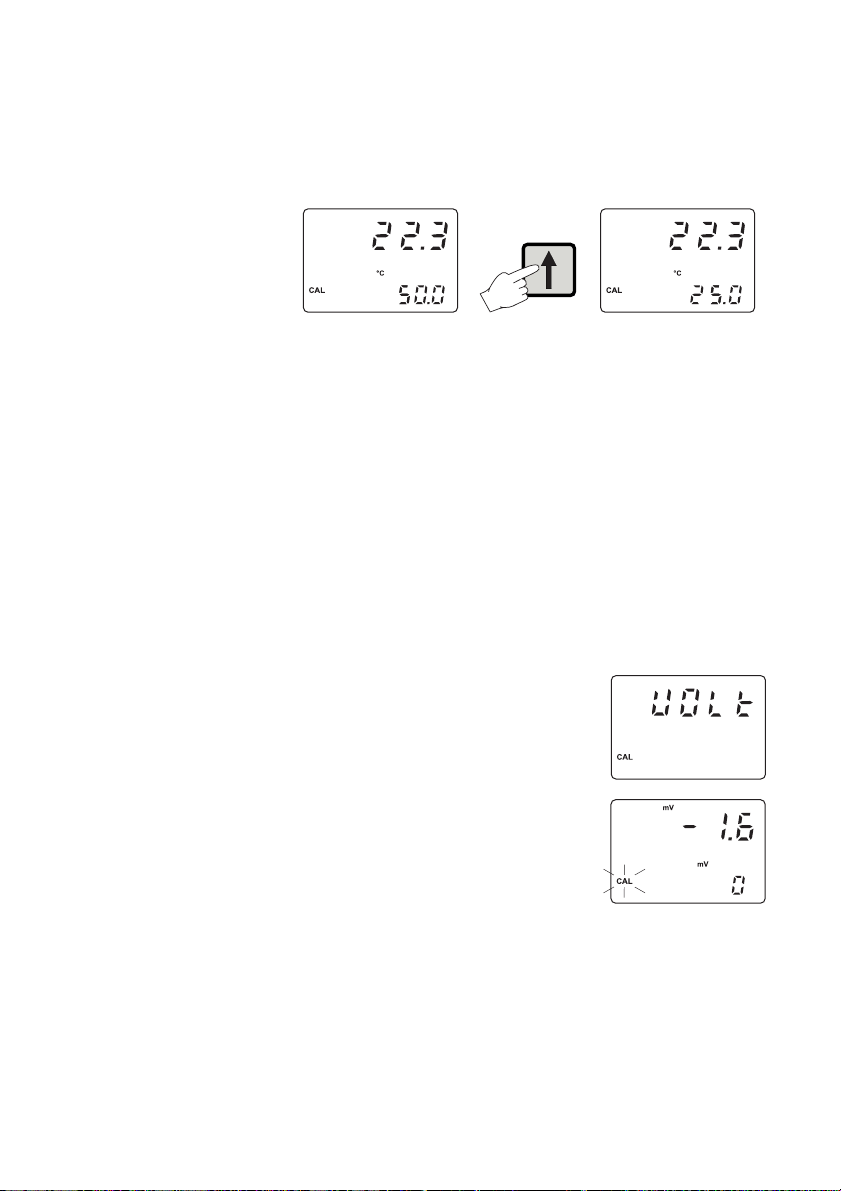

• When performing the second calibration point, it is possible to choose between two values, 25°C and 50°C. Pressing

the or key the value on the secondary LCD will switch

between the two possibilities.

• Once selected the value, immerse the temperature probe

in the second beaker as near as possible to the Checktemp

and the calibration procedure will be the same as for the

first point.

The instrument is factory calibrated; however the user may

also perform the Volt calibration, which is a procedure available for the meter configured as pH controller only.

During pH measurements the instrument reads a mV value

from the electrode and then converts it into a pH value.

• Set item I.04 to “OFF” to disable the Matching Pin.

• Connect a HI 931001 or HI 8427 simulator to the BNC

socket.

• Once entered the calibration mode,

move through the menu with or

key, select the Volt calibration (the

primary LCD shows “UOLt” message) and confirm it by pressing the

CFM key.

• After confirmation the primary LCD

will show the actual mV value and

the secondary LCD will display the

first calibration point.

• The calibration is performed over two points, 0 and 350 mV.

• Set the HI 931001 or HI 8427 simulator to 0 mV.

• When the reading becomes stable, if the measured value

is close to the calibration point the CFM tag starts blinking, otherwise the WRONG indicator will flash.

• In the first case press the CFM key to confirm calibration.

22

Page 23

The meter will proceed showing the scrolling message “Press

CFM to confirm the current buffer or right to escape” (to

prevent from confirming the calibration point inadvertently).

• Pressing again CFM the secondary LCD will display the

second calibration point.

• Set the HI 931001 or HI 8427 simulator to 350 mV and

follow the same procedure as for the first point.

• If the measured value is not close to the calibration value,

the meter will remain in the WRONG status until the reading becomes unstable or the calibration mode is exited (by

pressing the CAL key).

23

Page 24

SETUP MODE

The Setup Mode allows the user to set all needed characteristics of the meter.

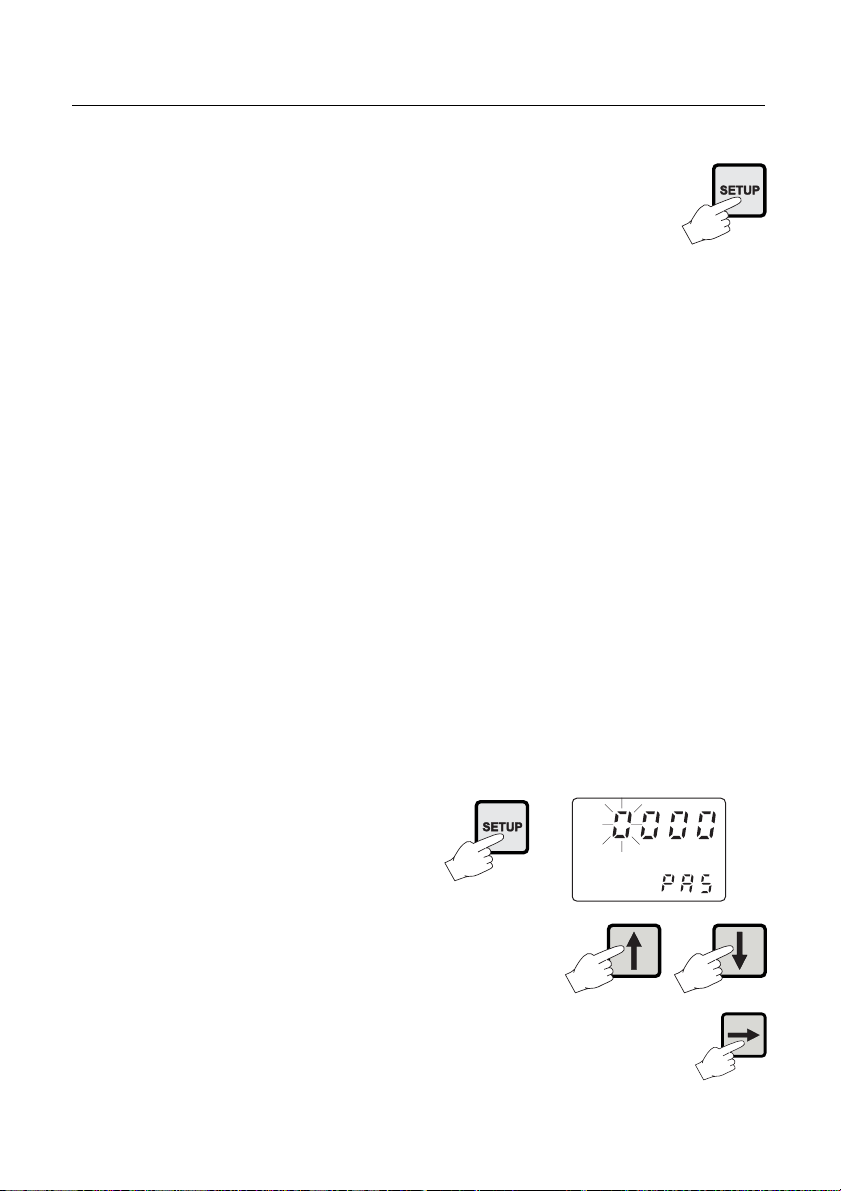

To enter the mode, press the SETUP key and

enter the password when the device is in idle or

control mode.

If the correct password is not entered, the user can only view

the setup parameters (except for passwords) without modifying them (and the device remains in control mode). An

exception is certain setup items, or flags, which can activate

special tasks, when set and confirmed.

To each setup parameter (or setup item) is assigned a three

characters (one letter followed by two digits) setup code which

is entered and displayed on the secondary LCD. The first

character identifies the group of setup items, while the two

digits identify the particular item within that group.

The setup codes can be selected after password is entered

and CFM key is pressed. When CFM is pressed, the current

setup item is saved on EEPROM and the following item is

displayed.

The possible transitions in setup mode are the following:

ENTERING THE PASSWORD

• Press SETUP to enter the setup mode. The primary LCD will

• Enter the first digit of the pass-

• Then move to the next digit with and

24

display “0000”, while the secondary LCD shows “PAS”.

The first digit of the primary LCD will blink.

word by using the or key.

enter a digit as described above. Continue

for the last two digits.

Page 25

Note The default password is set at “0000”.

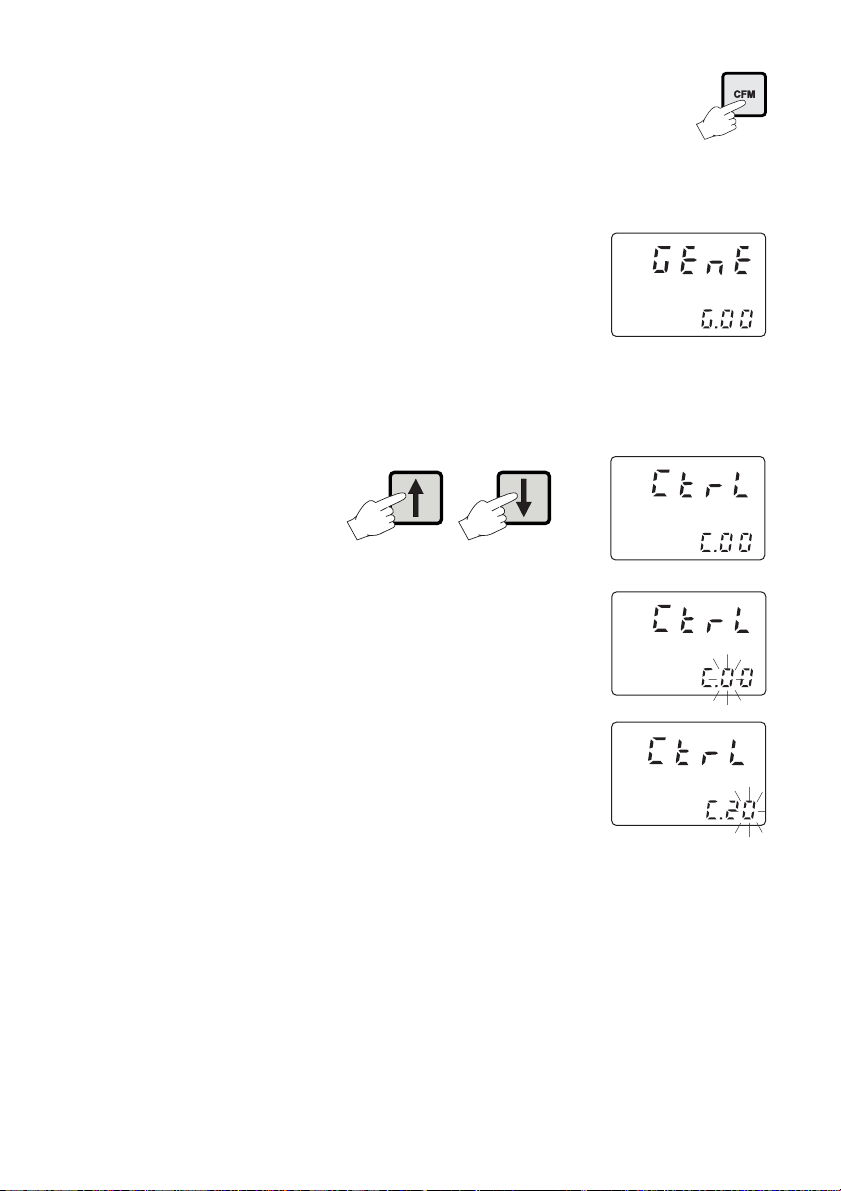

ENTERING SETUP ITEMS

• When the whole password has been inserted, press CFM to confirm it.

After confirmation of the password the

primary LCD will show the name of the

first setup group (see table) while the

secondary LCD will display the setup

code of the first item of the group.

• By pressing the or key it is possible to cycle through

the setup groups; the secondary LCD will always show the

code of the first item of the group.

• Once a group is selected, it is possible to choose an item manually.

Pressing the key, the first digit of

the setup code will start blinking.

Now it is possible to change its value

by pressing the or key.

• Pressing the key again, the first

digit will be fixed while the second

digit starts blinking and its value can

be changed as described above.

• By pressing the key again all the

digits will be fixed.

• If CFM key is pressed, the selected item is confirmed; the

secondary LCD will show the setup item code while the

primary LCD will display the current item value.

If a fixed set of values is available for the selected item, use

the or key to switch between them.

25

Page 26

Otherwise, if a numeric value has to be entered for the

item, use the or key to change the value of the blinking digit and the key to cycle through the number’s

digits.

• Once a value is set, press the CFM key to confirm. The

instrument will turn to the next item and the new item’s

value will be displayed on the primary LCD.

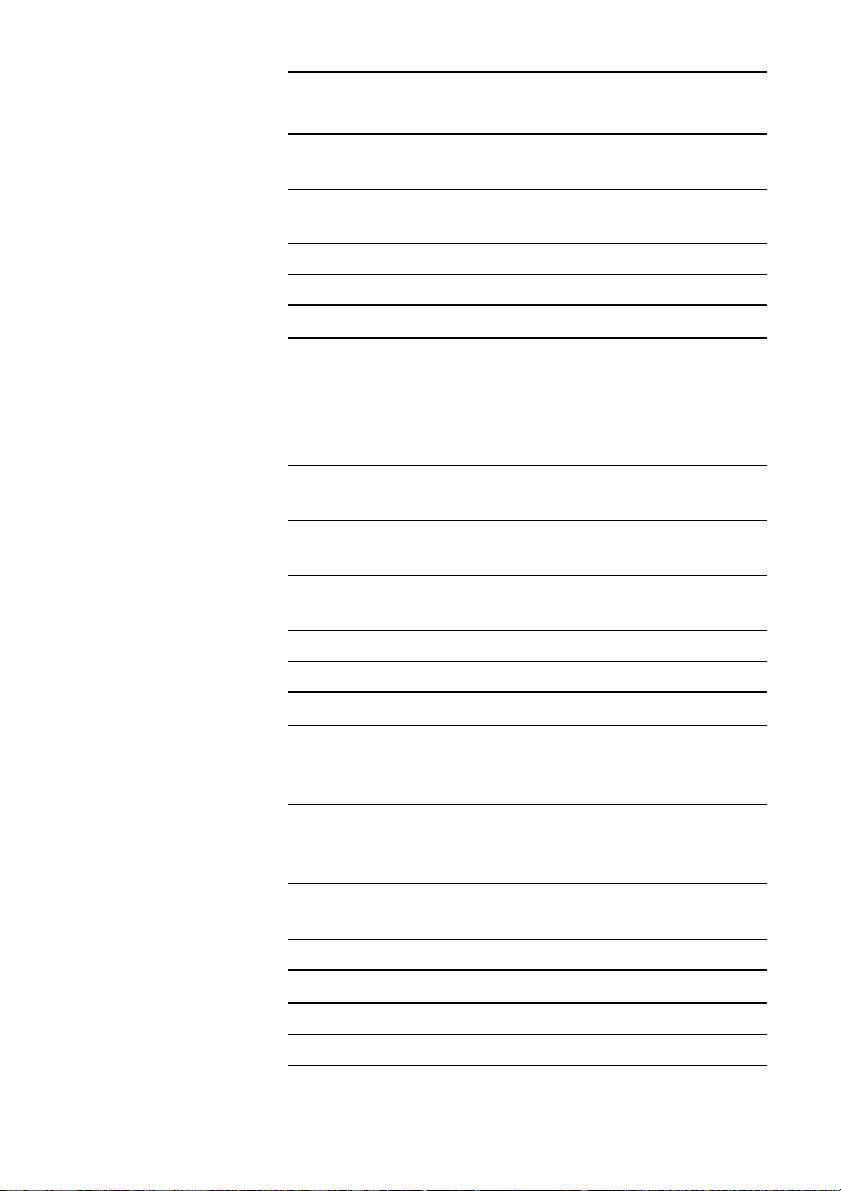

• If a wrong value is confirmed, the

WRONG indicator starts blinking,

the new value is not accepted and

the instrument will not switch to the

next item until a correct value will

be confirmed.

• Instead of selecting the item manually, it is possible to cycle

through all the items of a selected group by pressing repeatedly CFM key. The procedure to modify the item’s value

is the same described above.

If the last item of the group is reached, by pressing the

CFM key again the primary display will show the group

name and it will be possible to change the group by pressing the or key.

26

Note At any time for exiting the setup mode press the SETUP key. If

no modification has been confirmed, no setup item is

changed.

Page 27

Note While in the setup mode, if no activity is performed for about

5 minutes after entering the setup mode, the mode is automatically exited and the instrument returns to the previous

mode.

The below table lists the setup codes along with the description of

the specific setup items, their valid values and whether the item is

present for ORP mode.

Titles in Italic character (eg. “SETPOINT 1 “) represent different

subgroups within the same group. The subgroup name (eg.

“Set1”) is showed when entering the first item of the subgroup. To scroll through subgroups, use the key.

Depending on the device model, some of the below items or

item values may not be available.

Code Valid Values Default Present

for ORP

GENERAL (“GEnE”)

G.00 pH/ORP input “PH”, “OrP” (see note 10) “PH” yes

G.01 Temperature compensation “AtC”: Automatic “AtC” no

“USEr”: Manual (see notes 9, 25)

G.02 Manual or probe error -30 to 130.0 ºC 25.0 no

temperature (see notes 9, 25)

G.10 Factory ID 0000 to 9999 (see note 20) 0000 yes

G.11 Process ID alias RS485 address 0 0 to 99 (see note 20) 00 yes

G.12 Hardware Identifier 7 digits identification number, read only yes

(see notes 4, 20)

G.98 Calibration/hold password 0000 to 9999 (see notes 2, 20) 0000 yes

G.99 General password 0000 to 9999 (see notes 2, 20) 0000 yes

CONTROL (“CtrL”)

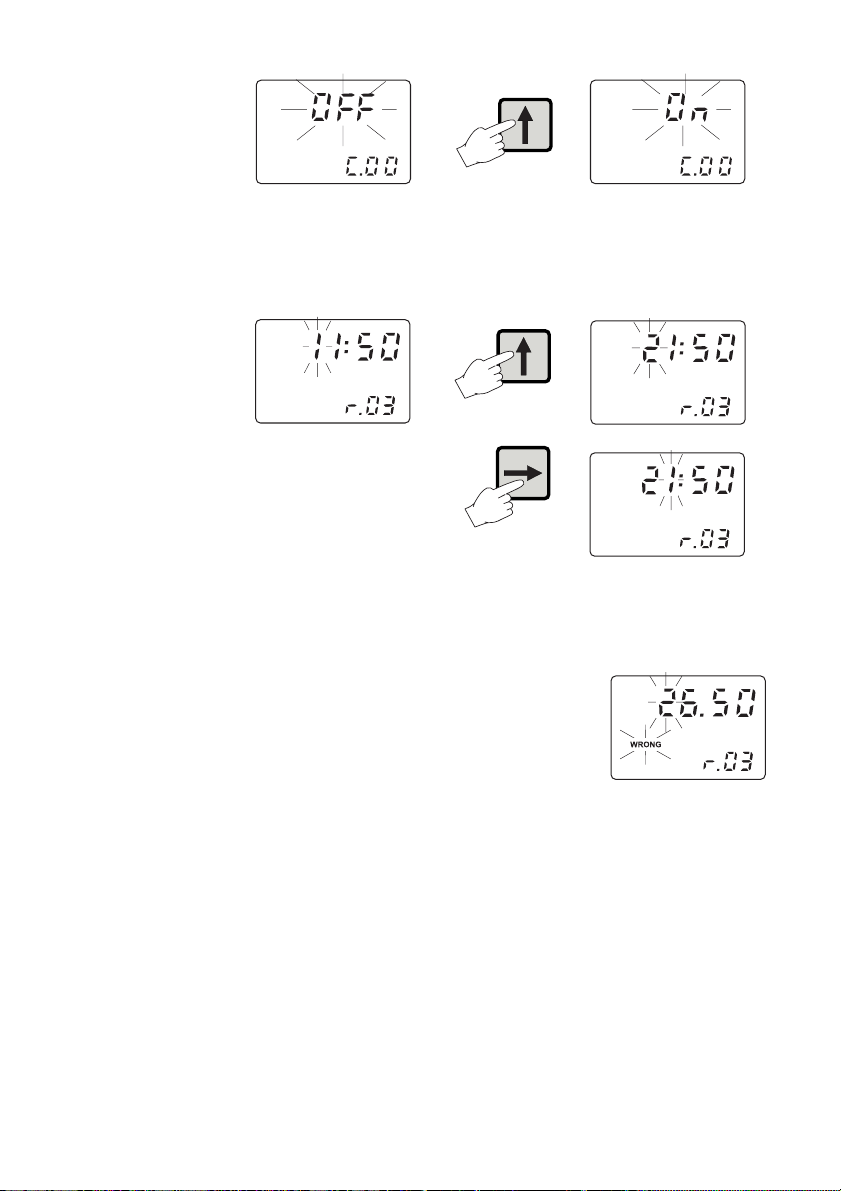

C.00 Control enable “OFF”: Control mode disabled “OFF” yes

“On”: Control mode enabled

SETPOINT 1 (“SEt1”)

C.10 Setpoint 1 mode (M1) “OFF”: Disabled “OOHI” yes

(see note 1) “OOHI”: ON-OFF, high set point

“OOLO”: ON-OFF, low set point

“PIdH”: P.I.D., high set point / “PIdL”: P.I.D., low set point

C.11 Setpoint 1 (S1) -2.00 to 16.00 pH or 8.00 pH or yes

(see note 1) -2000 to 2000 mV 500 mV

27

Page 28

Code Valid Values Default Present

for ORP

C.12 Hysteresis for setpoint 1 (H1) 0.00 to 18.00 pH or 1 pH or yes

(see note 1) 0 to 4000 mV 50 mV

C.13 Deviation for setpoint 1 (D1) 0.50 to 18.00 pH or 1 pH or yes

(see note 1) 25 to 4000 mV 50 mV

C.14 Reset time for setpoint 1 0.1 to 999.9 minutes 999.9 mins yes

C.15 Rate time for setpoint 1 0.0 to 999.9 minutes 0.0 mins yes

SETPOINT 2 (“SEt2”)

C.20 Setpoint 2 mode (M2) “OFF”: Disabled “OOLO” yes

(see note 1) “OOHI”: ON-OFF, high set point

“OOLO”: ON-OFF, low set point

“PIdH”: P.I.D., high set point

“PIdL”: P.I.D., low set point

C.21 Setpoint 2 (S2) -2.00 to 16.00 pH or 6.00 pH or yes

(see note 1) -2000 to 2000 mV -500 mV

C.22 Hysteresis for setpoint 2 (H2) 0.00 to 18.00 pH or 1 pH or yes

(see note 1) 0 to 4000 mV 50 mV

C.23 Deviation for setpoint 2 (D2) 0.50 to 18.00 pH or 1 pH or yes

(see note 1) 25 to 4000 mV 50 mV

C.24 Reset time for setpoint 2 0.1 to 999.9 minutes 999.9 mins yes

C.25 Rate time for setpoint 2 0.0 to 999.9 minutes 0.0 mins yes

ALARM (“ALAr”)

C.30 Alarm relay delta value 0.50 to 18.00 pH 1.00 pH yes

for setpoint 1 (A1) or or

(see notes 1, 22) 25 to 4000 mV 100 mV

C.31 Alarm relay delta value 0.50 to 18.00 pH 1.00 pH yes

for setpoint 2 (A2) or or

(see notes 1, 22) 25 to 4000 mV 100 mV

C.32 Maximum relay ON time 1-60 minutes 60 yes

(after that an alarm is generated)

C.33 Alarm mask time 00:00 to 30:00 minutes 00:30 yes

PROGRAMMABLE CONTROL TIMING (“tIME”)

C.41 Hold time start 00:00 to 23:59 (see note 8) 00:00 yes

C.42 Hold time stop 00:00 to 2 3:59 (see note 8) 00:00 yes

28

Page 29

Code Valid Values Default Present

for ORP

C.51 Monday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.52 Tuesday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.53 Wednesday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.54 Thursday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.55 Friday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.56 Saturday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.57 Sunday hold mode “OFF”: Disabled “OFF” yes

enable “On”: Enabled

C.60 Proportional control mode 01:00 - 30:00 minutes 05:00 yes

period

C.70 Hold mode end delay 00 to 99 seconds 00 yes

OUTPUT (“OutP”)

RELAYS (“rELA”)

O.01 Relay 1 mode “OFF”: Disabled “SEt1” yes

(see notes 19, 21) “SEt1”: Control, setpoint 1

“SEt2”: Control, setpoint 2

“SCLE”: Simple cleaning

“HOLd”: Energized in hold mode

O.02 Relay 2 mode “OFF”: Disabled “SEt2” yes

(see notes 19, 21) “SEt1”: Control, setpoint 1

“SEt2”: Control, setpoint 2

“SCLE”: Simple cleaning

“HOLd”: Energized in hold mode

O.03 Relay 3 mode “OFF”: Disabled “OFF” yes

(see notes 15, 19) “SCLE”: Simple cleaning

“ACLE”: Advanced cleaning / “HOLd”: Energized in hold mode

O.04 Relay 4 mode “OFF”: Disabled “OFF” yes

(see notes 15, 19) “SCLE”: Simple cleaning

“ACLE”: Advanced cleaning / “HOLd”: Energized in hold mode

29

Page 30

Code Valid Values Default Present

for ORP

0.05 Hold digital output “OFF”: Disabled “HOLd” yes

“HOLd”: Enabled upon hold mode

ANALOG OUTPUT #1 (“Out1”)

O.10 Analog output 1 mode “rECO”: Recorder “rECO” yes

(see notes 6, 21) “SEt”: Control, setpoint 1

O.11 Analog output 1 type “0-20”: 0-20 mA 4-20 (6) yes

“4-20”: 4-20 mA

O.12 Measurement value for -2.00 to 16.00 pH 0.00 pH or yes

analog output 1 minimum or -2000 to 2000 mV -2000 mV (6)

(O_VARMIN1) (O_VARMIN1 R O_VARMAX1-1 pH or 50 mV,

O_VARMIN1 R O_HOLD1R O_VARMAX1)

O.13 Measurement value for -2.00 to 16.00 pH 14.00 pH or yes

analog output 1 maximum or -2000 to 2000 mV 2000 mV (6)

(O_VARMAX1) (O_VARMIN1 R O_VARMAX1-1 pH or 50 mV,

O_VARMIN1 R O_HOLD1R O_VARMAX1)

O.14 Analog output 1 value upon “USEr”: User selected value “HOLd” yes

hold mode (see note 16) “HOLd”: Previous value is frozen

O.15 Analog output 1 value upon -2.00 to 16.00 pH 7.00 pH or yes

hold mode if O.14=”USEr” or -2000 to 2000 mV 0 mV (6)

(O_HOLD1) (it must be within the O_VARMIN1

to O_VARMAX1-1 interval)

ANALOG OUTPUT #2 (“Out2”)

O.20 Analog output 2 mode “rECO”: Recorder (temperature) “rECO” (pH) yes

(see notes 21, 26) “SEt”: Control, setpoint 2 (pH) or “OFF” (ORP)

or

“OFF”: Disabled

“SEt”: Control, setpoint 2 (ORP)

O.21 Analog output 2 type “0-20”: 0-20 mA “4-20” yes

“4-20”: 4-20 mA

O.22 Measurement value for -30 to 130.0 ºC 0 ºC no

analog output 2 minimum (O_VARMIN2 R O_VARMAX2-10 ºC,

(O_VARMIN2) O_VARMIN2 R O_HOLD2R O_VARMAX2)

O.23 Measurement value for -30 to 130.0 ºC +100.0 ºC no

analog output 2 maximum (O_VARMIN2 R O_VARMAX2-10 ºC,

(O_VARMAX2) O_VARMIN2 R O_HOLD2R O_VARMAX2)

30

Page 31

Code Valid Values Default Present

for ORP

O.24 Analog output 2 value upon “USEr”: User selected value “HOLd” no

hold mode (see note 16) “HOLd”: Previous value is frozen

O.25 Analog output 2 value upon -30 to 130.0 ºC 25ºC no

hold mode if O.24=”USEr” (it must be within the O_VARMIN2

(O_HOLD2) to O_VARMAX2-1 interval)

BAUD RATE (“bAud”)

O.30 Baud rate (see note 20) 1200, 2400, 4800, 9600, 19200 19200 yes

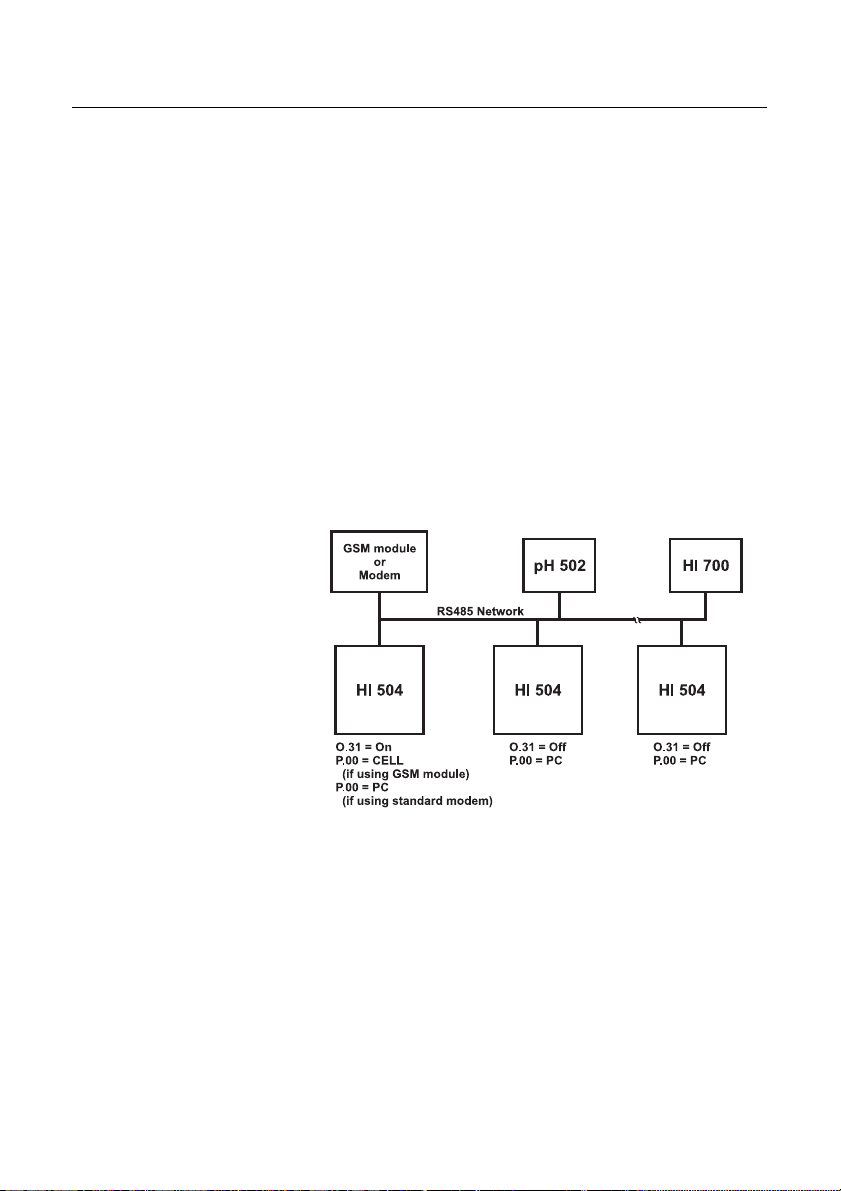

O.31 Modem calls answer enable “OFF”: Disabled “OFF” yes

(see note 20) “O n”: Enabled

INPUT (“InPU”)

I.00 Measurement input selection “Prob”: BNC “Prob” yes

(see note 12) “trAn”: Digital Transmitter

I.03 Digital Transmitter address 00 to 99 00 yes

(used only if I.00=”trAn”)

I.04 Potential matching pin “OFF”: unused (asymmetrical input) “On” yes

(see notes 24, 25) “On”: in use (symmetrical input)

I.10 Calibration time-out 00 to 99 days (00 means disabled) 90 no

I.11 Life check time “OFF”: life check disabled “OFF” yes

(see notes 11, 25) 1: 1 hour

2: 2 hours

4: 4 hours

I.12 Minimum pH probe slope 45 to 75 mV/pH 45 mV/pH no

(see note 25)

I.13 pH electrode impedance “OFF”: disabled “On” no

test enable (see note 25) “On”: enabled

I.14 Reference electrode impedance “OFF”: disabled “On” yes

test enable (see note 25) “On”: enabled

I.15 Max ref. electrode impedance 0.5 to 100.0 kΩ 50.0 kΩ yes

(see note 25)

REAL TIME CLOCK (“rtC”)

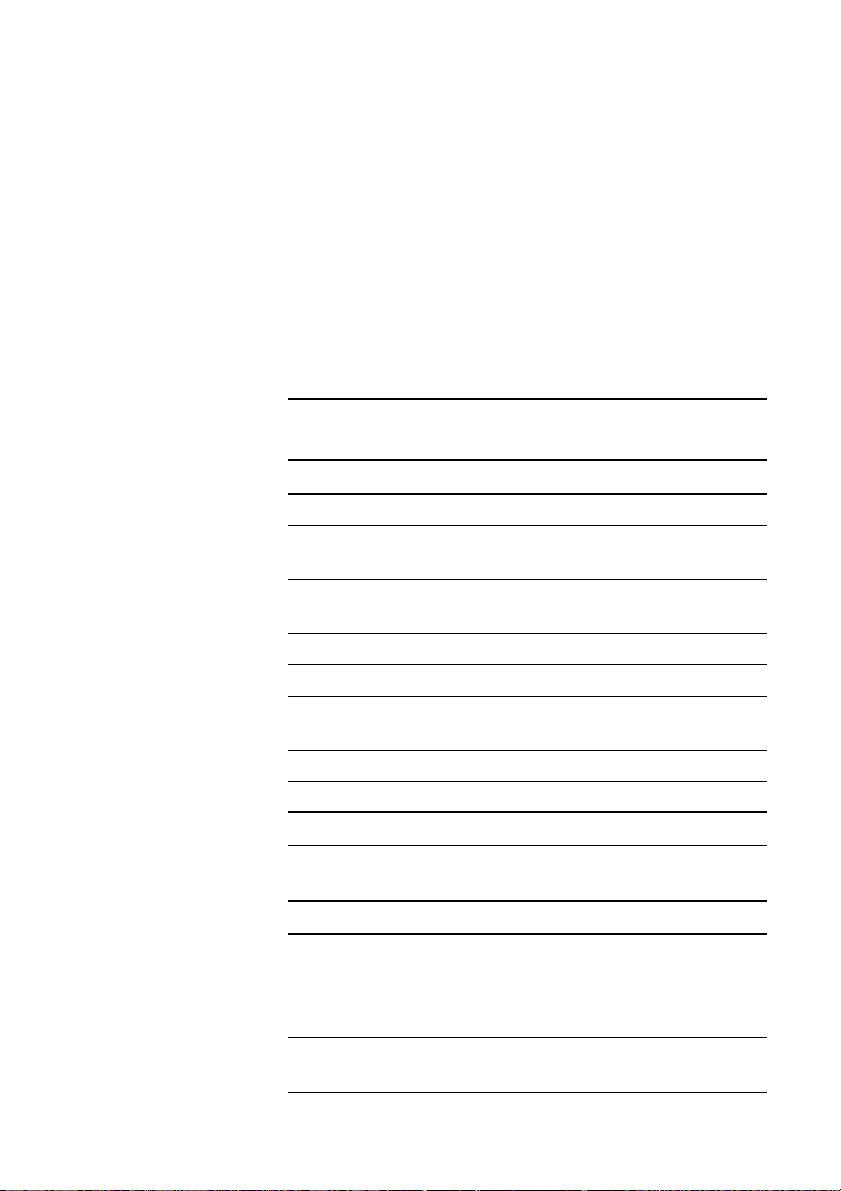

r.00 Current day 01 to 31 (see note 20) from RTC (5) yes

r.01 Current month 01 to 12 (see note 20) from RTC (5) yes

r.02 Current year 2000 to 2099 (see note 20) from RTC (5) yes

31

Page 32

Code Valid Values Default Present

for ORP

r.03 Current time 00:00 to 23:59 (see note 20) from RTC (5) yes

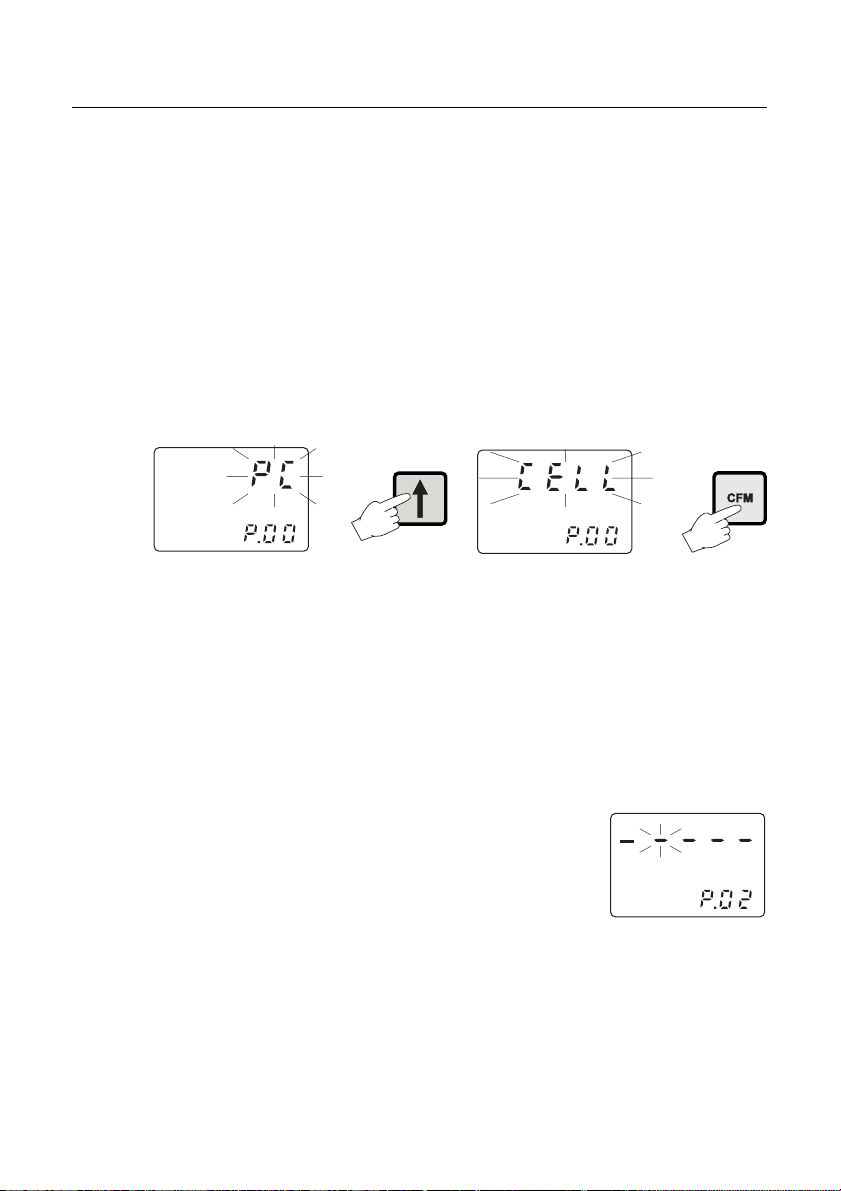

CELLULAR/PC CONNECTION (“PHOn”)

P.00 RS485 Connection type “PC”: PC Connection “PC” yes

(see note 20) “CELL”: Cellular module connection

P.01 PIN Number (see note 20) 0000 to 9999 0000 yes

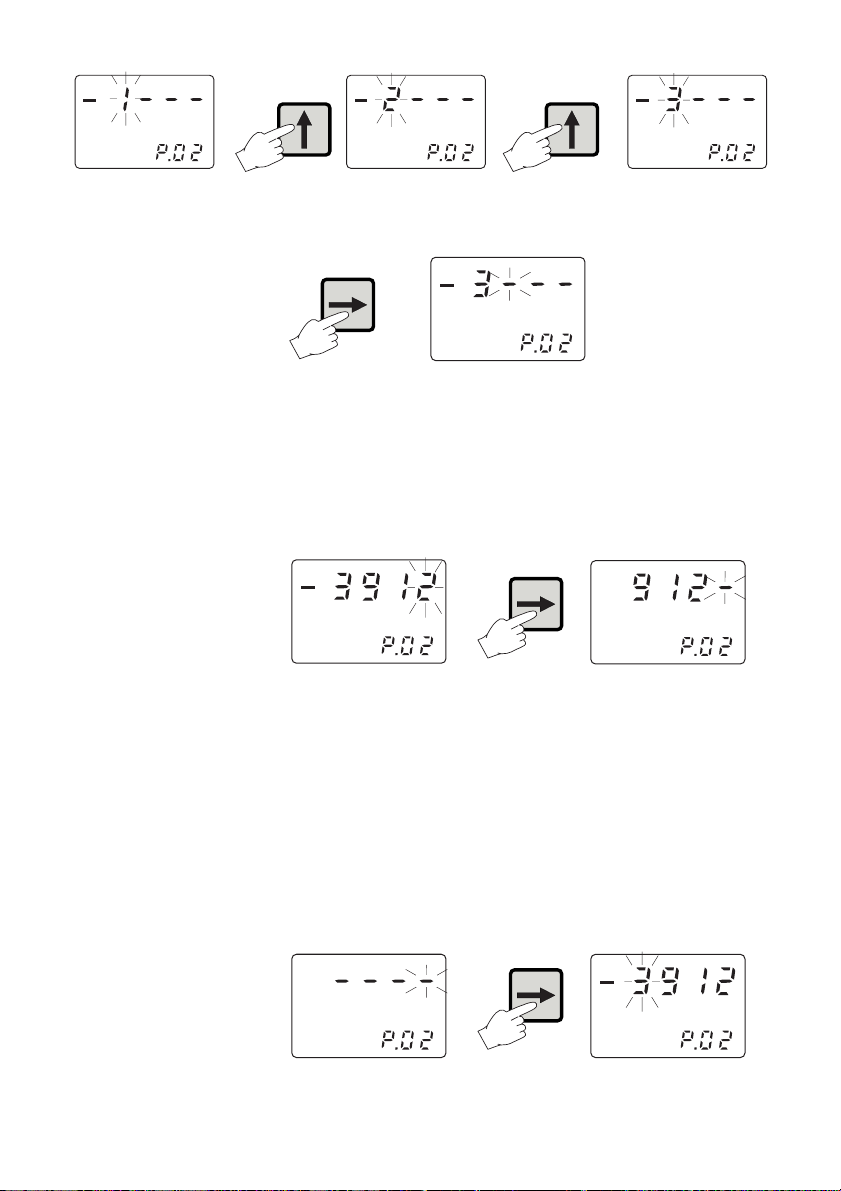

P.02 Telephone number #1 00000000000000000000 - - - - - - - - - - - - - - - - - - - -

(see notes 20, 27) to 99999999999999999999 yes

(“- - - - - - - - - - - - - - - - - - - -” indicates no number)

P.03 Telephone number #2 00000000000000000000 - - - - - - - - - - - - - - - - - - - -

(see notes 20, 27) to 99999999999999999999 yes

(“- - - - - - - - - - - - - - - - - - - -” indicates no number)

P.04 Number of remaining 000 to 200 100 yes

messages (see notes 20, 28) and 222

P.05 Number of repeated 0 to 5 2 yes

SMSs (see notes 20, 29)

P.06 Delay between two 05 to 60 minutes 10 yes

subsequent SMSs (see notes 20, 30)

P.07 SIM expiration day 01 to 31 01 yes

(see notes 20, 31)

P.08 SIM expiration month 01 to 12 01 yes

(see notes 20, 31)

P.09 SIM expiration year 2000 to 2099 2010 yes

(see notes 20, 31)

READING OFFSETS (“OFFS”)

F.00 pH or ORP actual value measured value -1.00 pH or measured yes

(see notes 17, 25) -200 mV to measured value value

+1.00 pH or +200 mV

F.01 pH or ORP reading offset -1.00 to +1.00 pH or 0.00 pH yes

adjustment (see note 25) -200 to +200 mV or 0 mV

F.10 Temperature actual value measured value -10.0 ºC to meas. value no

(for ATC only, see notes 18, 25) measured value +10.0 ºC (see note 17)

F.11 Temperature reading offset -10.0 to +10.0 ºC 0.0 ºC no

adjustment (for ATC only, see notes 18, 25)

32

Page 33

Code Valid Values Default Present

for ORP

SOLUTION COMPENSATION (“SOLC”)

S.00 Solution compensation enable “On”: compensation enabled “OFF” no

“OFF”: compensation disabled

S.10 pH value for point #1 -2.00 to 16.00 pH 7.00 pH no

S.11 Temperature value for -30 to 130.0 ºC 20 ºC no

point #1 (SCT1) |SCT1-SCT2| S 1.0 ºC

S.20 pH value for point #2 -2.00 to 16.00 pH 7.00 pH no

S.21 Temperature value for -30 to 130.0 ºC 30 ºC no

point #2 (SCT2) |SCT1-SCT2| S1.0 ºC

IN-LINE CLEANING (“CLEA”)

SIMPLE CLEANING (“SCLE”)

L.00 Rinsing time 5 to 99 s 20 s yes

L.01 Pause time 10 to 9999 minutes 1440 minutes yes

ADVANCED CLEANING (“ACLE”)

L.10 Pre-rinsing time 0 to 99 s 20 s yes

L.11 Detergent washing 0 to 99 s 10 s yes

L.12 Rinsing time 5 to 99 s 20 s yes

L.13 Pause time Min. pause time (L.14) to 1440 minutes yes

9999 minutes

L.14 Minimum pause time 10 to Pause time (L.13) 10 minutes yes

L.15 Cleaning trigger “ ti”: Timer only “ ti” yes

“ E”: Digital input or RS485 (external) only

“ti E”: Timer and digital input or RS485 (external)

“tiEM”: Timer masked by digital input (external)

L.16 Repeated cleaning number 0 to 10 0 yes

L.17 Number of cleaning 0 to 10 0 yes

without detergent

ERROR CONFIGURATION (“Erro”)

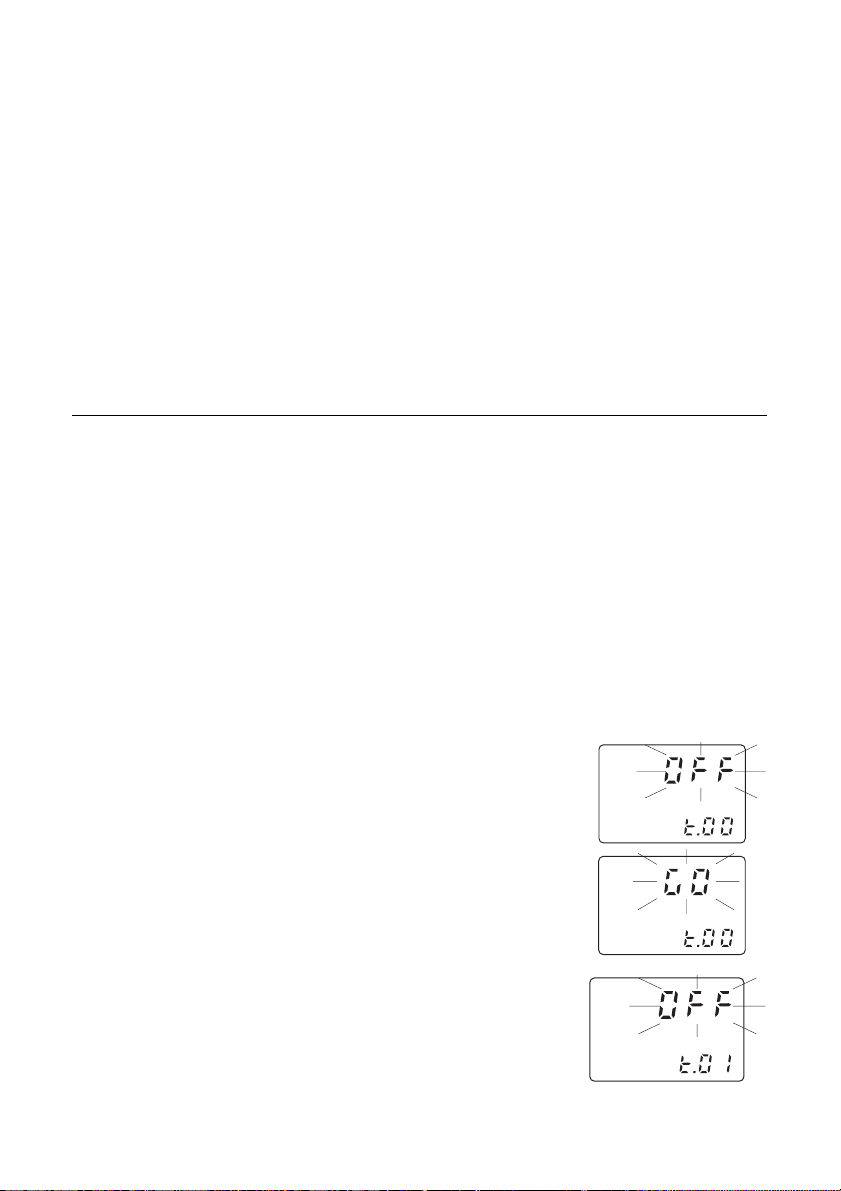

E.00 Alarm for setpoint 1 0 to 5 3 yes

error configuration and 24 to 29 (see note 7)

E.01 Alarm for setpoint 2 0 to 5 5 yes

error configuration and 24 to 29 (see note 7)

33

Page 34

Code Valid Values Default Present

for ORP

E.02 Max relay ON time 0 to 5 3 yes

error configuration and 24 to 29 (see note 7)

E.03 Life check error configuration 0 to 11 9 yes

(see note 11) and 24 to 35 (see note 7)

E.10 pH electrode broken 0 to 11 9 no

or leakage and 24 to 35 (see note 7)

E.11 Reference electrode broken 0 to 47 (see note 7) 21 yes

or dirty or not immersed

E.12 Old pH probe 0 to 11 0 no

error configuration and 24 to 35 (see note 7)

E.13 Dead pH probe 0 to 11 2 no

error configuration and 24 to 35 (see note 7)

E.14 Calibration time-out 0 to 11 0 no

error configuration and 24 to 35 (see note 7)

E.20 Temperature broken probe 0 to 11 3 no

error configuration and 24 to 35 (see note 7)

E.40 Digital Transmitter 0 to 11 9 yes

error configuration and 24 to 35 (see note 7)

E.50 Cellular error configuration 0 to 11 (see note 7) 3 yes

E.90 Power reset 0 to 11 2 yes

error configuration and 24 to 35 (see note 7)

E.91 EEPROM corruption 6 to 11 9 yes

error configuration and 30 to 35 (see note 7)

E.92 Watchdog error configuration 0 to 11 2 yes

and 24 to 35 (see note 7)

E.99 Level or pulse alarm relay “LE”: Level “LE” ye s

signal (see note 13) “PULS”: Pulse

TEST (“tESt”)

t.00 Display test “OFF”: To skip without testing “OFF” yes

“GO”: To start the display test

t.01 Keyboard test “OFF”: To skip without testing “OFF” yes

“GO”: To start the keyboard test

t.02 EEPROM test “OFF”: To skip without testing “OFF” yes

“GO”: To start the EEPROM test

34

Page 35

Code Valid Values Default Present

for ORP

t.03 Relays and LEDs test “OFF”: To skip without testing “OFF” yes

“GO”: To start the test

t.04 Analog output 1 test “OFF”: To skip without testing “OFF” yes

“GO”: To start the test

t.05 Analog output 2 test “OFF”: To skip without testing “OFF” yes

“GO”: To start the test

t.06 Hold digital input test “OFF”: To skip without testing “OFF” yes

“GO”: To start the test

t.07 Advanced cleaning “OFF”: To skip without testing “OFF” yes

digital input test “GO”: To start the test

Warning: cleaning actions could be t riggered by the input going high during the

test (see note 23).

t.08 Watchdog test “OFF”: To skip without testing “OFF” yes

“GO”: To start the watchdog test

Notes (1): M1 can not be set to “OOHI” or “OOLO” if O.10 is set to

“SEt” and vice versa;

if M1 = “OOHI” then 16.00 pH or 2000 mV S S1+A1;

if M1 = “OOLO” then -2.00 pH or -2000 mV R S1-A1;

if M1 = “PIdH” then D1 R A1 and 16.00 pH or 2000 mVSS1+A1;

if M1 = “PIdL” then D1 R A1 and -2.00 pH or -2000 mV R S1-A1;

M2 can not be set to “OOHI” or “OOLO” if O.20 is set to “SEt”

and vice versa;

if M2 = “OOHI” then 16.00 pH or 2000 mV S S2+A2;

if M2 = “OOLO” then -2.00 pH or -2000 mV R S2-A2;

if M2 = “PIdH” then D2 R A2 and 16.00 pH or 2000 mVSS2+A2;

if M2 = “PIdL” then D2 R A2 and -2.00 pH or -2000 mV R S2-A2;

if M1 = “OOHI” and M2 = “OOLO” then S1-H1S S2+H2;

if M1 = “OOLO” and M2 = “OOHI” then S2-H2S S1+H1;

if M1 = “PIdH” and M2 = “OOLO” then S1S S2+H2;

if M1 = “OOLO” and M2 = “PIdH” then S1+H1R S2;

35

Page 36

if M1 = “PIdL” and M2 = “OOHI” then S1R S2-H2;

if M1 = “OOHI” and M2 = “PIdL” then S1-H1S S2;

if M1 = “PIdH” and M2 = “PIdL” then S1S S2;

if M1 = “PIdL” and M2 = “PIdH” then S2S S1;

were the minimum deviation (DN) is 0.5 pH (pH) or 25 mV (mV).

(2): The calibration/hold password allows only calibrations

and hold mode through keyboard for service personnel, while

the general password allows everything (including calibration). Obviously, the general password and the calibration/

hold password cannot be viewed among other items when

the “SETUP” key is pressed without entering the right general

password. The pH controller is sold with the general password set to “0000”.

(3): When a wrong setup value is confirmed, the pH controller does not skip to the next setup item, but remains in the

current item displaying a blinking “WRONG” indicator till

the parameter value is changed by the user (the same thing

happens also for the setup code selection). In some situations user cannot succeed in getting a parameter set to the

desired value if related parameters are not changed accordingly first (e.g. to set a pH high set point to 10.00 the high

alarm must be set to a value greater than 10.00 first).

(4): The hardware identifier is a read only value.

(5): When the controller is powered, RTC is checked to see if

an RTC reset occurred since last software initialization (if one

ever took place). If this is the case the RTC is initialized with

the default date and time 01-01-2000 - 00:00. An EEPROM

reset does not affect the RTC settings.

(6): Output is pH or mV depending on the controlled magnitude setting (pH or ORP).

36

Page 37

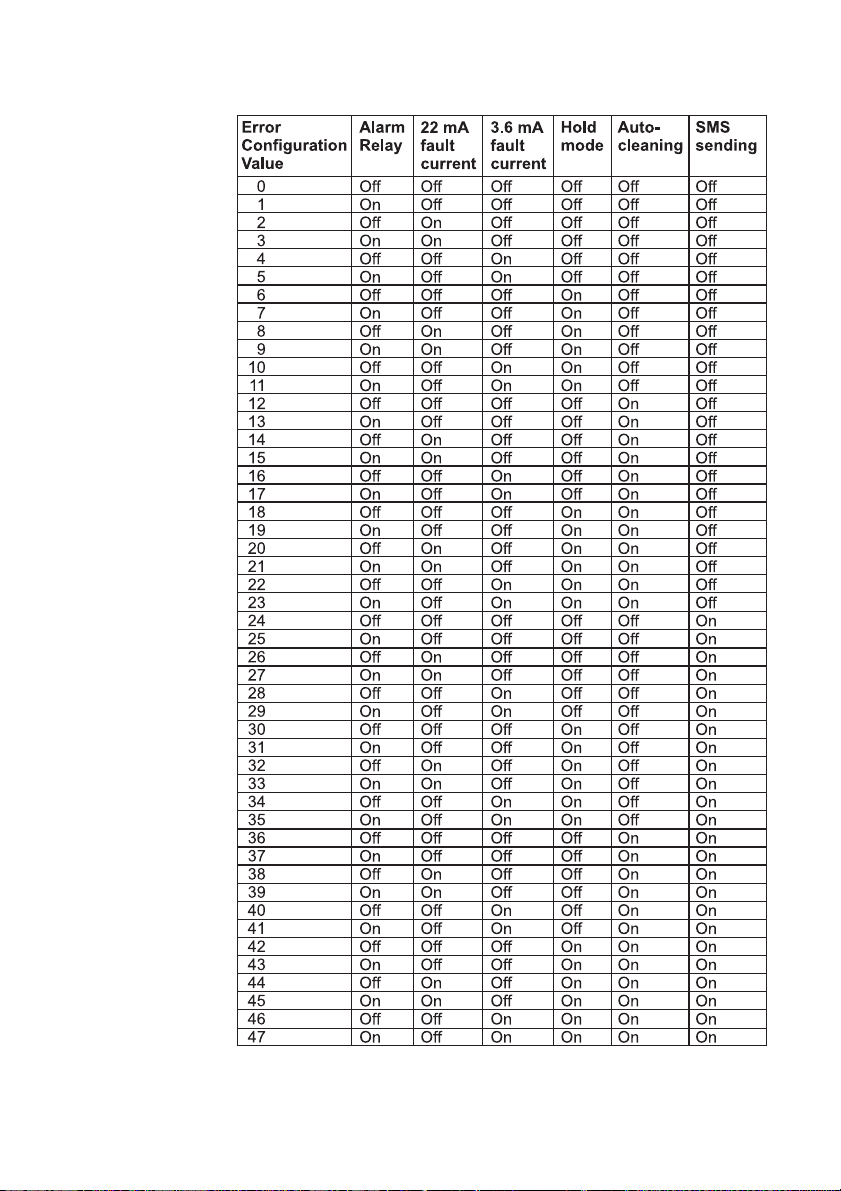

(7): The value for error configuration is coded like this:

37

Page 38

(8): The hold mode is never enabled by the control timing if

the “hold time start” is the same as the “hold time end”.

Items “C.41” and “C.42” apply to all days. The hold mode

can be enabled all day by using items “C.51” through “C.57”.

(9): See the “Temperature compensation” subsection for more

details on how the Automatic temperature compensation and

Manual temperature compensation work.

(10): Whenever the pH/ORP selection item is changed from

pH into ORP or vice versa all of the calibration and setup

data regarding pH (when changing to ORP) or ORP (when

changing to pH) are kept. They are automatically restored if

the controlled parameter is changed back later. The following setup items cannot vary when changing from pH to ORP

or vice versa (because they are items strictly related to the

instrument and not to the controlled magnitude): Factory ID,

Process ID alias RS485 address, Calibration/hold password,

General password, Baud rate, Modem calls answer enable,

Cellular/PC connection items, Hardware identifier and RTC

date and time. For proper operation while working with the

Digital Transmitter, this item must be equal to the correspondent one in the Digital Transmitter. If the two values do not

coincide a “Digital Transmitter error” is generated.

(11): A life check error is generated if the pH reading does not

vary for more than ±0.10 pH within the time selected through

the “life check time” item (pH controller) or mV reading for

more than ±10 mV within the same time (ORP controller).

(12): When the Digital transmitter (HI 504910) is used, the

temperature is measured by the transmitter along with pH

(pH controller), or ORP (ORP controller). These measurements are sent to the Process Controller. The calibration data

set for the Digital Transmitter is kept within the transmitter and

thus it is separated from the BNC set. This means that the

calibration slope and offset and the other GLP data are automatically switched from the BNC set to the Digital Transmitter set and vice versa when the measurement input is switched

from “Prob” to “trAn” respectively. For example, if the user

was using a pH electrode connected to the BNC, and at a

later time he starts using the transmitter, and after that the

measurement input selection is reverted back to “Prob”, it is

not necessary to calibrate the pH electrode again.

38

Page 39

(13): The alarm relay can be energized continuously (by selecting “LE” for “level”) or with a pulse (by selecting “PULS”

for “pulse”). The pulse length is fixed to about 5 seconds.

(14): When the instrument is configured as ORP controller

some of the above items or the item values are not anymore

available to the user.

(15): Relay 3 an relay 4 must be both set to “ACLE” in order

to have the advanced cleaning enabled. If only one of them

is set to “ACLE” then it will behave as it were set to “OFF”.

When the advanced cleaning is enabled, relay 3 is used for

water pouring while relay 4 is used for detergent pouring.

(16): “HOLd” and “USEr” are effective only when “O.10”

and “O.20” are set to “rECO”. In the other cases the analog

output is set automatically to the minimum value upon hold

mode (i.e. “O.14”, “O.15” and “O.24”, “O.25” have no

effect if “O.10” = “SEt” and “O.20” = “SEt” respectively).

(17): “measured value” is the reading value with a null reading offset adjustment.

(18): if the device is set for MTC (item G.01 to “USEr”) then

items F.10 and F.11 cannot be modified nor seen. When item

G.01 is changed from “AtC” into “USEr”, item F.11 is automatically zeroed.

(19): When the relays set to “SCLE” are all set to something

else, the simple cleaning action, if in progress, is aborted

immediately. When relay 3 or relay 4 or both of them are set

to something else than “ACLE”, and the advanced cleaning

is in progress, cleaning is aborted immediately (but a complete rinsing phase is done before the actual end of the cleaning session).

(20): These items do not vary when the pH/ORP input selection (“G.00”) is changed.

(21): If the relay 1 mode or the relay 2 mode is set to “SEt1”,

the analog output 1 mode can not be set to “SEt” and vice

versa. Similarly, if the relay 1 mode or the relay 2 mode is set

to “SEt2”, the analog output 2 mode can not be set to “SEt”

and vice versa.

(22): Alarm relay delta value for setpoint 1 determines the

value of the correspondent alarm threshold by being added

39

Page 40

to or subtracted from the setpoint value for a high (ON/OFF

or PID) or low (ON/OFF or PID) setpoint respectively. The

same is true for Alarm relay delta value for setpoint 2. A

small fixed hysteresis (0.2 pH for pH and 30 mV for ORP)

must be passed to have the alarm turned off (for a high

alarm the alarm is turned off below high alarm - hysteresis,

while for a low alarm the alarm is turned off above low alarm

+ hysteresis).

(23): The actual start of a cleaning action depends on how

relay 3, relay 4 and the Advanced Cleaning parameters have

been configured.

(24): If the item is set to “On”, the “m” tag near the secondary display will be fixed on.

If the item is set to “OFF” the connector for the Potential

Matching Pin must be left floating. Failure to do so may

cause damage of the reference electrode.

(25): When the Digital Transmitter is in use, the correspondent setting in the digital transmitter is used and this item is

not visible.

(26): This item is not visible for models without PID or without the second setpoint.

(27): An SMS will be sent to this telephone number (if different from “- - - - - - - - - - - - - - - - - - - -”) when an error

(configured for the SMS sending) occurs.

(28): This item sets the maximum number of SMS that the

instrument can send. Before this number reaches 0, an advising message will be sent to the phone number P.02 (and

P.03). This feature has been introduced to avoid the discharging of the credit of the SIM card. Once all the available

messages have been sent, the user is supposed to extract the

SIM card from the instrument and check the remaining credit

and expiration date of the card.

The item shows always the remaining available number of

SMS that can be sent, so its value is decremented every SMS

submission.

If the user sets this item to “222”, then no check will be made

on the maximum number of SMS and the instrument could

send an unlimited number of messages. In this case the item

value will not be decremented and no check will be made on

40

Page 41

the SIM expiration date.

(29): Every SMS sent by the instrument requires a reception

confirmation from the user (phone call to the instrument). If

this confirmation does not arrive (for example because the

message was lost or did not reach the Short Message Service

Center), it is possible to set the instrument in order to send

again the message. The maximum number of repeated messages is set through this item (see P.06 for the delay between

two subsequent messages). If this item is set to 0, then no

confirmation is waited by the instrument.

(30): This item sets the delay between the sending of two

subsequent messages. It has effect only if item P.05 value is 1

or greater.

(31): The SIM’s expiration date has to be inserted manually

through these items (P.07 - P.09). The user is supposed to

update these items every time a recharge of the card occurs.

Three advising messages are sent to the telephone number

configured in item P.02 (and P.03) when the card is going to

expire (two weeks before, one week before and the day before).

If the user sets the item P.04 to “222” then no check will be

made on the SIM expiration date.

41

Page 42

CONTROL MODE

The control mode is the normal operational mode for this meter.

During control mode HI 504 fulfills the following main tasks:

• convert information from pH/ORP and temperature inputs

• control relays and generate the analog outputs as deter-

• display alarm condition;

• perform cleaning actions according to the relays configuration;

• start and stop hold mode according to the programmed

• RS485 management.

In addition, the meter can log working data through RS485

connection. These data include:

• pH, mV and oC measured values;

• last calibration data;

• setup configuration (also from a remote workstation);

• event data.

In a normal situation, during control mode, the green LED is

ON and the error LED (red) is OFF. The red LED is never

fixed ON and blinks only upon an error.

The green LED is associated to the alarm relay and is OFF if

the alarm is active.

to digital values and show them on the display;

mined by the setup configuration;

control timing;

RELAY MODES

42

To deactivate the control mode set CONTROL ENABLE to

“OFF” in setup menu (CONTROL (“CtrL”) group).

When measurements are in overflow, the upper or lower range

limit is shown on the LCD with blinking digits.

There are four relay options that can be configured through

the setup menu to perform different tasks.

Once enabled, relays 1 and 2 can be used in four modes:

1. setpoint 1 (Analog output #1 must be set to recorder, “rECO”);

2. setpoint 2 (Analog output #2 must be set to recorder, “rECO”);

3. simple cleaning;

4. hold mode.

Page 43

In the first two cases the configuration of Setpoint (1 or 2)

determines the operating mode of the relay. Once enabled,

the control relay can be configured to control as a ON/OFF

or PID control of the acid/base dosage.

A High-hight Alarm is imposed for acid/base dosage time

when the relays are energized continuously. This parameter

can be set through setup procedure (CONTROL group, setup

item C.32). When the upper time boundary is reached, an

alarm is generated and device stays in alarm condition until

relay is de-energized.

If the “hold mode” is selected for the relay, then it is energized only when the meter is in hold mode. In this case there

is no time boundary for the ON state of the relay.

The option for relays 3 and 4 can be configured to operations in three modes:

1. simple cleaning;

2. advanced cleaning;

3. hold mode.

ON/OFF CONTROL MODE

Once a relay is enabled (set 1, set 2), the setpoint can be

configured to be activated as a high limit (“OOHI”) or as a

low limit (“OOLO”). In both cases the following values have

to be defined through setup:

• setpoint value (pH/mV; setup item C.11 or C.21);

• hysteresis for setpoint (pH/mV value; setup item C.12 or C.22).

A control device can be wired to the contact output.

Connect the device to the COM and NO

(Normally Open) or NC (Normally

Closed) terminals of the relay.

The ON relay state occurs when relay is energized (NO and

COM connected, NC and COM disconnected).

The OFF relay state occurs when relay is de-energized (NO

and COM disconnected, NC and COM connected).

The following graph shows relay state along with pH measured value (similar graph can be derived for mV control).

As shown below, when the measured pH exceeds the setpoint

threshold, the relay(s) is (are) energized, until the pH mea-

43

Page 44

sure falls below setpoint value minus hysteresis.

Such a behavior is suitable to control an acid dosing pump.

ON

OFF

P.I.D. CONTROL MODE

Setpoint –

Hysteresis

Setpoint

14

A relay enabled as a low setpoint, is energized when the pH

value is below the setpoint and is de-energized when the pH

value is above the sum of setpoint and the hysteresis. This

operational mode may be used to control an alkaline dosing

pump.

ON

OFF

Setpoint

Setpoint +

Hysteresis

14

PID control is designed to eliminate the cycling associated

with ON/OFF control in a rapid and steady way by means of

the combination of the Proportional, Integral and Derivative

control methods.

With the proportional function, the duration of the activated

control is proportional to the error value (Duty Cycle Control

Mode); as the measurement approaches setpoint, the ON

(relay energized) period diminishes.

44

Page 45

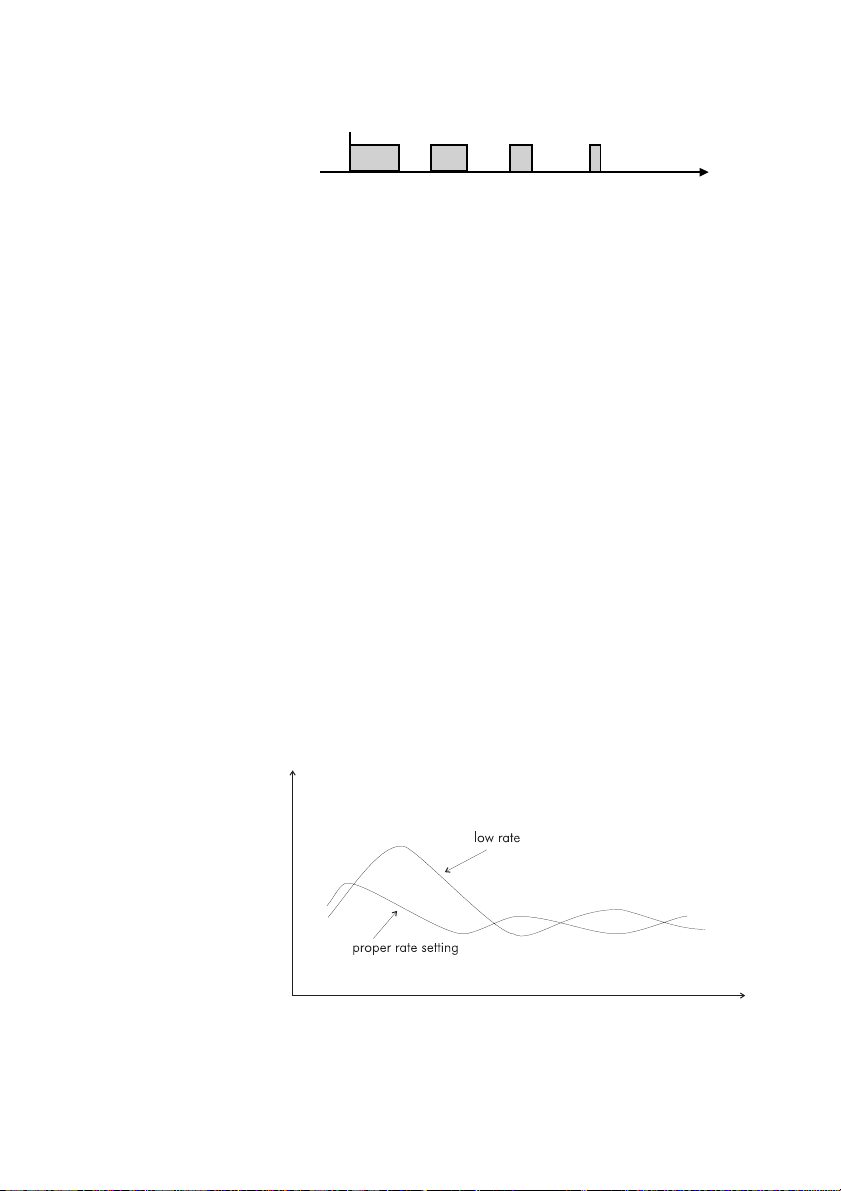

The following graph describes the pH process controller behavior. Similar graph may apply to the mV controller.

t

0

t0+T

t0+2T

c

t0+3T

c

c

During proportional control the process controller calculates

the relay activation time at certain moments t0, t0+Tc, t0+2T

etc. The ON interval (the shaded areas) is then dependent to

the error amplitude.

With the integral function (reset), the controller will reach a

more stable output around the setpoint providing a more

accurate control than with the ON/OFF or proportional action only.

The derivative function (rate action) compensates for rapid

changes in the system reducing undershoot and overshoot of

the pH value.

During PID control, the ON interval is dependent not only to

the error amplitude but even to the previous measurements.

Definitely PID control provides more accurate and stable control than ON/OFF controllers and it is best suitable in system

with a fast response, quickly reacting to changes due to addition of acid or base solution.

An example of how the response overshoot can be improved with

a proper rate action setting is depicted in the following graphic.

c

pH

RATE ACTION COMPENSATES FOR RAPID CHANGES t

45

Page 46

PID TRANSFER FUNCTION

The transfer function of a PID control is as follows:

with Ti = Kp/Ki, Td = Kd/Kp,

where the first term represents the proportional action, the

second is the integrative action and the third is the derivative

action.

Proportional action can be set by means of the Proportional

Band (PB). Proportional Band is expressed in percentage of the

input range and is related to Kp according to the following:

Kp = 100/PB.

Kp + Ki/s + s Kd = Kp(1 + 1/(s Ti) +s Td)

100%

Controller

output

46

0

Proportional Band

Error

The proportional action is set directly as “Deviation” in pH

and mV units respectively. Relation between Deviation (D)

and PB is:

D = Range * PB/100

Each setpoint has a selectable proportional band: PB1 for

setpoint1 and PB2 for setpoint2. Two further parameters must

be provided for both setpoints:

Ti = Kp/Ki, reset time, measured in minutes

Td = Kd/Kp, rate time, measured in minutes.

Ti1 and Td1 will be the reset time and rate time for setpoint1,

while Ti2 and Td2 will be the reset time and the rate time for

setpoint2.

Page 47

TUNING A PID CONTROLLER

The proportional, integrative, derivative terms must be tuned,

i.e. adjusted to a particular process. Since usually the process variables are not completely known, a “trial and error”

tuning procedure must be applied to get the best possible

control for the particular process. The target is to achieve a

fast response time and a small overshoot.

Many tuning procedures are available and can be applied

to HI 504. A simple and profitable procedure is reported in

this manual and can be used in almost all applications.

The user can vary five different parameters, i.e. the setpoint

(S1 or S2), the deviation (D1 or D2), the reset time, the rate

time and the proportional control mode period Tc .

Note User can disable the derivative and/or integrative action (for

P or PI controllers) by setting Td = 0 and/or Ti = MAX (Ti)

respectively through the setup procedure.

SIMPLE TUNING PROCEDURE

The following procedure uses a graphical technique of analyzing a process response curve to a step input.

Note This procedure allows only a rough setting of the PID param-

eters and could not fit all the processes.

It is suggested that I and D parameters be set by technical

personnel, because their inadequate values may cause undesired behaviors of the system.

Note Connecting an external device (chart recorder or PC) to the

controller, the procedure is easier and doesn’t need the use

of hand plotting the process variable (pH or mV).

1. Starting from a solution with a pH or mV value different

from the dosed liquid (at least a 3 pH or 150mV difference)

turn on the dosing device at its maximum capacity without

the controller in the loop (open loop process). Note the

starting time.

2. After some delay the pH or mV starts to vary. After more

delay, the pH or mV will reach a maximum rate of change

(slope). Note the time that this maximum slope occurs and

the pH or mV value at which it occurs. Note the maximum

slope in pH or mV per minute. Turn the system power off.

3. On the chart draw a tangent to the maximum slope point until

intersection with the horizontal line corresponding to the initial

47

Page 48

pH or mV value. Read the system time delay Tx on the time axis.

4. The deviation, Ti and Td can be calculated from the following:

• Deviation = Tx * max. slope (pH or mV)

• Ti = Tx / 0.4 (minutes)

• Td = Tx * 0.4 (minutes).

5. Set the above parameters and restart the system with the

controller in the loop. If the response has too much overshoot or is oscillating, then the system can be fine-tuned

slightly increasing or decreasing the PID parameters one

at a time.

Example:

the chart recording in the figure

aside was obtained continuously

dosing an alkaline solution to a

weak acid solution in a tank. The

initial settings will be:

Max. slope = 3 pH/5 mins = 0.6

pH/min

Time delay = Tx = approx. 7 mins

Deviation = Tx * 0.6 = 4.2 pH

Ti = Tx / 0.4 = 17.5 mins

Td = Tx * 0.4 = 2.8 mins

ALARM RELAY

48

The alarm relay functions in the following manner:

FS•C = NO (Normally Open)

Energized Relay

COM

FS•O = NC (Normally Closed)

De-energized Relay

During normal operation (no alarm condition) the alarm relay is energized; during an alarm condition or power failure

the relay will be de-energized. As long as a separate battery

power system is used an alarm will sound.

Example: High alarm set at 10 pH

Low alarm set at 4 pH

Page 49

An hysteresis will eliminate the possibility of continuous sequences ‘energizing/de-energizing’ of the alarm relay when

the measured value is close to the alarm setpoint. The hysteresis amplitude is 0.2 pH for pH and 30 mV for ORP.

Moreover the alarm signal is generated only after an user

selectable time period (alarm mask) has elapsed since the

controlled value has overtaken one alarm threshold. This

additional feature will avoid fake or temporary alarm conditions.

Note If the power supply is interrupted, the relay is de-energized as

if in alarm condition to alert the operator.

In addition to the user-selectable alarm relays, the meter is

equipped with the Fail Safe alarm feature.

The Fail Safe feature protects the process against critical

errors arising from power interruptions, surges and human

errors. This sophisticated yet easy-to-use system resolves these

predicaments on two fronts: hardware and software. To eliminate problems of blackout and line failure, the alarm function

operates in a “Normally Closed” state and hence alarm is

triggered if the wires are tripped, or when the power is down.

This is an important feature since with most meters the alarm

terminals close only when an abnormal situation arises, however, due to line interruption, no alarm is sounded, causing

extensive damage. On the other hand, software is employed

to set off the alarm in abnormal circumstances, for example, if

the dosing terminals are closed for too long a period. In both

cases, the red LED will also provide a visual warning signal.

The Fail Safe mode is accomplished by connecting the external alarm circuit between the FS•C (Normally Open) and

the COM terminals. This way, an alarm will warn the user

when pH goes over the alarm thresholds, the power breaks

down and in case of a broken wire between the process meter

49

Page 50

and the external alarm circuit.

Note In order to have the Fail Safe feature activated, an external

power supply has to be connected to the alarm device.

CONTROL THROUGH ANALOG OUTPUT

Instead of configuring relays, it is possible

to have an output signal (selectable

among 0-20 mA and 4-20 mA) proportional to the PID action at the analog output terminals.

With this output, the actual output level amplitude is varied

continuously (with an update delay of 5 seconds) between

the maximum and the minimum values rather than varying

the proportion of ON and OFF times (duty cycle control).

The output signal range can be selected through setup items

O.11 (output #1) and O.21 (output #2).

A device with analog input (e.g. a pump with a 0-20 mA

input) can be connected to these terminals.

The analog output #1 is associated to setpoint 1 and the

analog output #2 to setpoint 2.

To have a control through analog output, a setpoint has to

be configured to “PidL” or “PidH” and the corresponding

output has to be set to Control instead of Recorder: “SEt”

value in setup item O.10 (analog output #1) or O.20 (analog output #2).

In this case no relay can be associated with the same setpoint

to be used for the control, otherwise it is not possible to set

O.10 (or O.20) to “SEt”. On the other hand if a control

through analog output is already associated with a setpoint,

it is not possible to configure a relay to the same setpoint.

50

Page 51

IN-LINE CLEANING

The cleaning feature allows an automatic cleaning action of

the electrodes. To perform cleaning, the controller activates

an external device (pump).

Cleaning can be of two types:

• Simple cleaning: with water only, it can be triggered only

by a timer (periodical cleaning) or by an error for which a

cleaning action can be configured (i.e. a “Reference electrode broken or dirty” error).

• Advanced cleaning (optional): with water and detergent,

it can be triggered by the following events:

• timer (setup item L.15 set to “ti”);

• digital input or RS485 command (external trigger; setup

item L.15 set to “E”);

• timer and digital input or RS485 command (external trig-

ger; setup item L.15 set to “ti E”);

• timer masked by external digital input (an external digital

input disables the cleaning; setup item L.15 set to “tiEM”);

• error for which a cleaning action is configured (i.e. a

“Reference electrode broken or dirty” error).

The type of cleaning action is selected through the relays

configuration and the time between two consequent cleaning

(if timer configured) has to be set through setup item L.01 for

simple cleaning and L.13 for advanced cleaning.

Cleaning actions do never take place if no relay is configured for cleaning. The advanced cleaning requires both relays

3 and 4 configured for that kind of cleaning: relay 3 is associated with water and relay 4 corresponds to detergent.

A minimum pause time has to be set for advanced cleaning

(setup item L.14) to avoid continuous cleaning due to the

external trigger. A cleaning action with detergent can be followed by one or more actions without detergent, when desired.

Simple cleaning actions are performed in the following order:

• Rinsing time: the device enters hold mode; all relays con-

figured for simple cleaning are energized. If the device is in

normal measurement mode, the “rinSinG” message scrolls

on the LCD; otherwise (i.e. the device is in setup mode) the

cleaning is performed, but no message appears.

51

Page 52

• Hold mode end delay (set by item C.70): if the device

was controlling when the cleaning action started, then the

hold mode end delay must expire before restarting control.

Advanced cleaning actions are performed in the following order:

• Pre-rinsing time: the device enters hold mode and relay

3 is energized. If the device is in normal measurement mode,

the “PrE-rinSinG” message scrolls on the LCD.

• Detergent washing time: relay 4 is energized (and relay

3 continues to be energized). If the device is in normal

measurement mode, the “dEtErGEnt” message scrolls on

the LCD. It is possible to configure some cleaning without

detergent (setup item L.17). In this case the message displayed is “no dEtErGEnt”.

• Rinsing time: relay 4 is de-energized (and relay 3 contin-

ues to be energized). If the device is in normal measurement

mode, the “rinSinG” message scrolls on the LCD.

• Hold mode end delay: if the device was controlling when

the cleaning action started, then the hold mode end delay

must expire before restarting control.

The time each of these actions last for can be configured

through setup menu, items L.00 or L.10, L.11, L.12.

When performing a cleaning action (either “simple “ or “advanced”) with the device in normal measurement mode, the

secondary LCD displays a countdown for the seconds remaining to the cleaning action end.

52

If the “Repeated cleaning number” value (setup item L.16) is

different from 0, then the advanced cleaning is repeated a

number of times equal to this value after the first cycle (e.g.

one more cycle if L.16=1).