Page 1

Instruction Manual

HI 4421

DO/BOD/OUR/SOUR/Temperature

Bench Meter

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product. This manual will provide you with the necessary

information for correct use of the instrument.

Please read this instruction manual carefully before using the instrument.

If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com or see the

back side of this manual for our worldwide sales and technical service contacts.

These instruments are in compliance with

HI 4421 is warranted for two years against defects in workmanship and materials when used for their

intended purpose and maintained according to instructions. The probe is guaranteed for six months. This

warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact the dealer from whom you purchased the instrument. If under warranty, report

the model number, date of purchase, serial number and the nature of the failure. If the repair is not covered

by the warranty, you will be notified of the charges incurred. If the instrument is to be returned to Hanna

Instruments, first obtain a Returned Goods Authorization number from the Technical Service Department and

then send it with shipping costs prepaid. When shipping any instrument, make sure it is properly packed for

complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the date of

purchase.

directives.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

2

Page 3

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

WARRANTY ...................................................................................................................................... 2

PRELIMINARY EXAMINATION .............................................................................................................. 4

GENERAL DESCRIPTION ...................................................................................................................... 4

FUNCTIONAL DESCRIPTION ................................................................................................................ 5

SPECIFICATIONS ................................................................................................................................ 7

OPERATIONAL GUIDE ....................................................................................................................... 8

DISPLAYING MODES ......................................................................................................................... 9

SYSTEM SETUP............................................................................................................................... 12

DO SETUP......................................................................................................................... 18

BOD SETUP............................................................................................................................. 29

OUR SETUP.............................................................................................................. 31

SOUR SETUP.............................................................................................................. 33

DO CALIBRATION.............................................................................................................. 35

PRESSURE CALIBRATION.............................................................................................................. 37

DO MEASUREMENT.............................................................................................................. 38

BOD MEASUREMENT.............................................................................................................. 42

OUR MEASUREMENT ............................................................................................... 45

SOUR MEASUREMENT.............................................................................................................. 46

LOGGING ....................................................................................................................................... 47

PC INTERFACE .................................................................................................................................... 52

PROBE CONDITIONING & MAINTENANCE ..................................................................................... 52

TROUBLESHOOTING GUIDE .............................................................................................................. 53

ACCESSORIES .................................................................................................................................. 54

3

Page 4

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has

occurred during shipping. If there is any damage, notify your dealer or the nearest Hanna Service Center.

The meter is supplied complete with:

• HI 76408 DO probe for laboratory use with built-in temperature sensor

• HI 7041S Electrolyte solution (

• HI 76407A Membrane caps (2 pcs)

• HI 76404N Electrode Holder

• 12Vdc Power Adapter

• Instruction Manual

HI 4421 is supplied with 12 Vdc/230 Vac adapter.

HI 4421-01 is supplied with 12 Vdc/115 Vac adapter.

Note: Save all packing material until you are sure that the instrument works properly. Any defective item

must be returned in the original packing with the supplied accessories.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

HI 4421 is a professional bench meter with color graphic LCD for DO, BOD, OUR, SOUR and temperature

measurements.

The display viewing modes are: Basic information only, GLP information, Graph and Log History mode.

The main features of the instruments are:

• One input channel;

• Six measurement parameters: DO, BOD, OUR, SOUR, pressure and temperature;

• Automatic or user standard DO calibration;

• AutoHold feature to freeze the stable reading on the LCD (DO only);

• Two selectable alarm limits (for DO, BOD, OUR, SOUR);

• Three selectable logging modes: Automatic logging, Log on demand (manual logging) and AutoHold logging

mode (DO only);

• Up to 100 logging lots for automatic or manual modes, up to 200 OUR and SOUR reports and up to 200 BOD

method information entries;

• Selectable area and settable sampling period feature for automatic logging;

• GLP feature;

• Online and offline graph;

• User-friendly interface on large color graphic LCD (240x320 pixels);

• Opto-isolated PC interface via RS232 respectively USB.

30 mL)

4

Page 5

HI 4421 DESCRIPTION

FRONT PANEL

REAR PANEL

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

1) Liquid Crystal Display (LCD)

2) Main Keyboard

3) USB connector

4) ON/OFF switch

5) Power adapter socket

6) RS232 serial communication connector

7) DO probe input

5

Page 6

KEYBOARD DESCRIPTION

FUNCTION KEYS

To enter / exit calibration mode.

To select the desired measurement mode: DO, BOD, OUR, SOUR.

To enter Setup (System Setup, DO Setup, BOD Setup , OUR Setup or SOUR Setup) and to

access Log Recall function.

To obtain general informations about the selected option / operation.

VIRTUAL KEYS

The upper row keys are assigned to the virtual keys placed on the bottom of the LCD, which allow you to

perform the displayed function, depending on the current menu (e.g.

mode).

and

in Measure

LCD GENERAL DESCRIPTION

6

Page 7

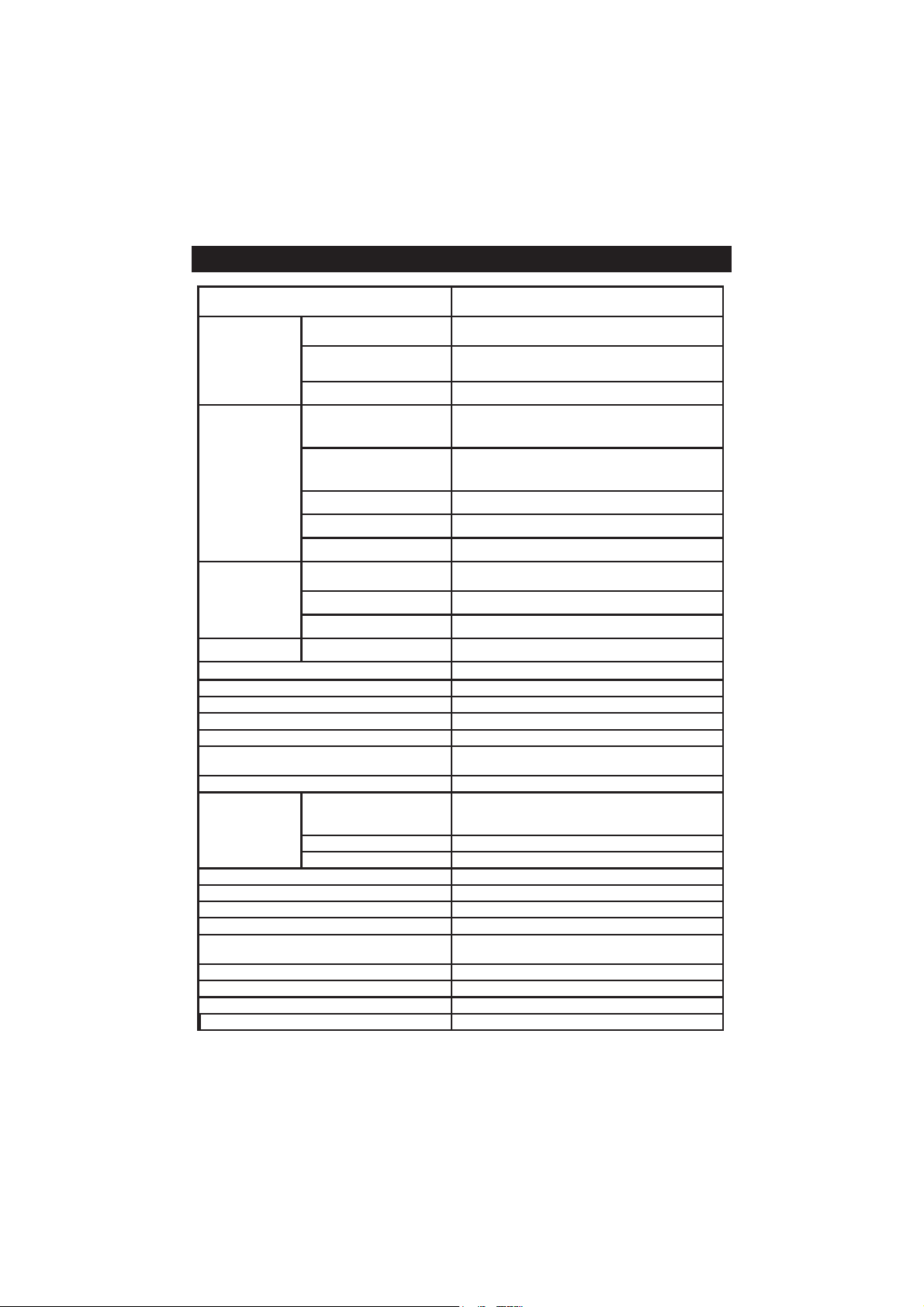

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

egnaRmpp00.09ot00.0

OD

erutarepmeT

cirtemoraB

erusserp

.pmocytinilaSegnaRL/g,tpp54ot0

draobyeK)syeklautriv4(syek8

eborPni-tliuberutarepmethtiwcihpargoraloP

ecafretniCP

serutaeFgniggoL

PLGofninoitarbilac,atadnoitarbilactsaL

noitarbilaC

DCLslexip043x042DCLcihparGroloC

snoisnemiD)"7.3x1.9x3.6(mm49x132x061

thgieW)bl6.2(gK2.1

noituloseR

ycaruccAtigid1±gnidaerfo%5.1±

egnartnemerusaeM

egnarnoitasnepmocOD

noituloseRK,F°,C°1.0

ycaruccAK,F°,C°2.0±

stinUK,F°,C°

egnaR

noituloseRgHmm1

ycaruccAtigidtnacifingistsael1+gHmm3±

)dnameDnegyxOlacimehcoiB(DOBseY

)etaRekatpUnegixO(RUO

)etaRekatpUnegixOcificepS(RUOSseY

egarotSataDlanretxEoN

selpmasdroceR

lavretnigniggoLces000003ot1

epyTcitamotuA,launaM

revaSthgilkcaB)citamotua(seY

edomdnEotuAylnoOD

)RUOS,RUO,DOB,OD(mralA)stimiledistuO/edisnI(seY

dradnatsnoitarbilaCnoitarutas%001dna0

1244IH

noitarutas%0.006ot0.0

mpp10.0

noitarutas%1.0

C°0.021ot0.02-

F°0.842ot0.4-

K1.393ot1.352

C°0.05ot0.0

F°0.221ot0.23

K1.323ot1.732

gHmm058ot054

raBm3311ot065

seY

detalosi-otpO

BSU,232SR

stol001otpu

gniggoLcitamotuAroftol/selpmas00001

gniggoLlaunaMroftol/selpmas0005

dradnatsresU/citamotuA

)stniop2ro1(

7

Page 8

OPERATIONAL GUIDEOPERATIONAL GUIDE

OPERATIONAL GUIDE

OPERATIONAL GUIDEOPERATIONAL GUIDE

POWER CONNECTION

Plug the 12 Vdc adapter into the power supply socket.

Note: These instruments use non volatile memory to retain the meter settings, even when unplugged.

PROBE CONNECTION

For DO, BOD, OUR or SOUR measurements connect a DO probe to the DIN connector located on the rear panel

of the instrument.

INSTRUMENT START UP

• Turn the instrument on from the power switch located on the rear panel of the instrument.

• Please wait until the instrument finishes the initialization process.

Note: It is normal for the loading process to take a few seconds. If the instrument doesn’t display the next

screen, restart the meter using the power switch. If the problem persists, contact your dealer.

8

Page 9

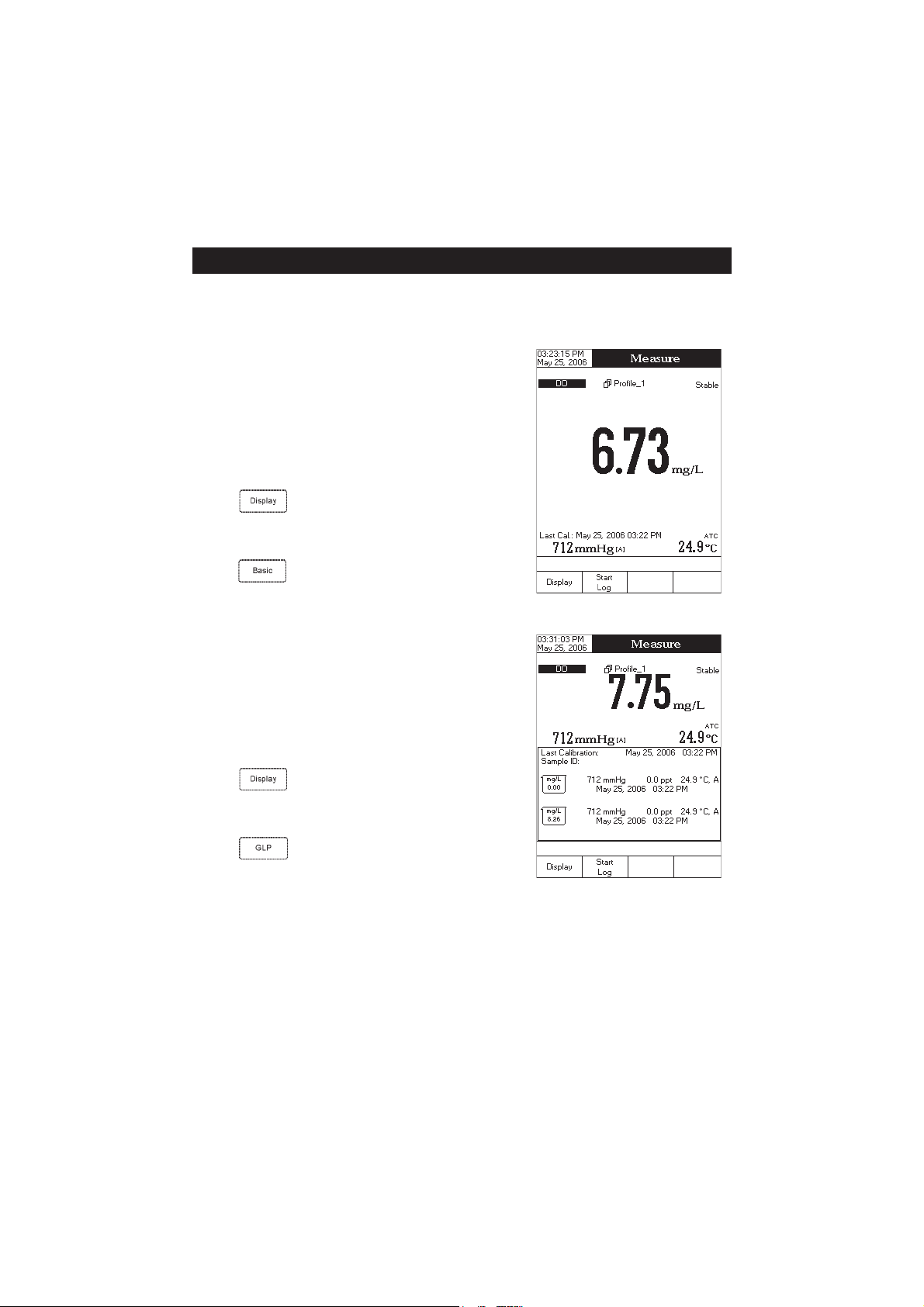

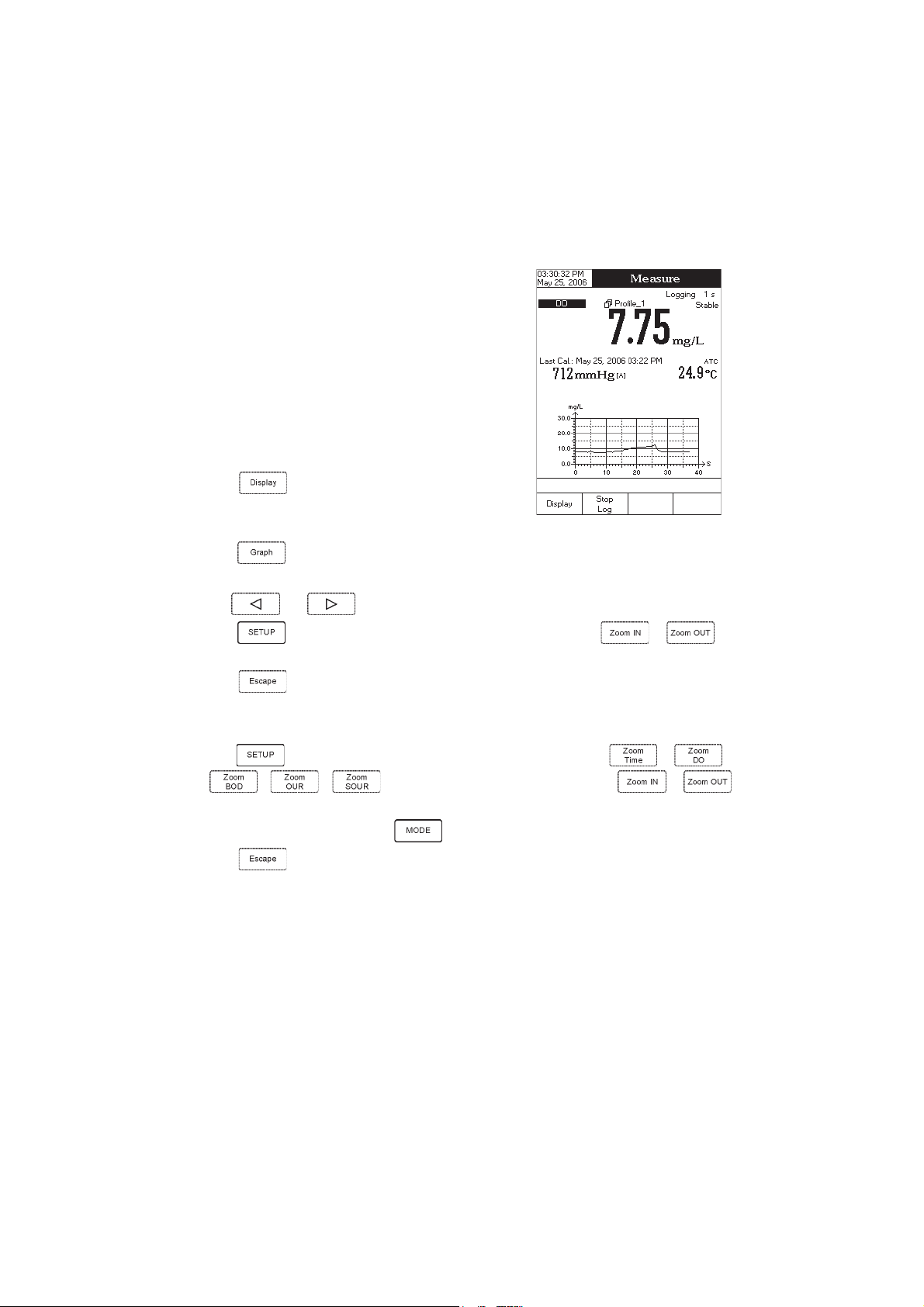

DISPLAYING MODESDISPLAYING MODES

DISPLAYING MODES

DISPLAYING MODESDISPLAYING MODES

For each measurement mode (DO, BOD, OUR or SOUR) the following display configurations are available:

Basic, Good Laboratory Practice (GLP), Graph and Log History.

Basic

Accessing this option, the measured value and its units are

displayed on the LCD, along with the temperature value, temperature compensation mode, pressure value, pressure compensation

mode and minimal GLP data.

To choose the Basic displaying mode:

• Press

Configuration” message will be displayed in the Reminder

messages area.

• Press

tion for the selected measurement mode.

GLP

Accessing this option, a detailed GLP data will be displayed on the

LCD for DO

Sample ID, Buffer Value, Pressure Value, Salinity Value, Temperature Value, Temperature Compensation, the Date and Time.

To access the GLP displaying mode:

• Press

Configuration” message will be displayed in the Reminder

messages area.

• Press

data.

while in

. The instrument will display the basic informa-

measure modes: Last Calibration Date and Time,

while in

. The instrument will display the detailed GLP

Measure

mode. The “Choose Display

Measure

mode. The “Choose Display

9

Page 10

Graph

Accessing this option, the online graph with currently logged

values (DO, BOD, OUR or SOUR vs. Seconds) could be displayed.

If there is no active log, the previously logged data for the

selected parameter will be plotted.

Notes: • If no data were logged, the graph displaying mode

will not be accessible.

• If no automatic log is saved, the offline graph will not

be available.

To access the offline / online graph:

• Press

Configuration” message will be displayed in the Reminder

messages area.

• Press

When the online graph is displayed:

• Use and to move the graph along the horizontal (

• Press to access the zoom menu for the vertical (

vertical axis zooming.

• Press

When the offline graph is displayed:

• Use the arrow keys to move the graph along the horizontal and vertical axes.

• Press

to zoom the selected axis.

Note: While in zoom graph menu the

• Press

while in

.

Measure

mode. The “Choose Display

Time

Parameter

to return to the main menu.

to access the zoom menu for the horizontal and vertical axes. Use or /

/ / to switch between the active zooming axes. Press or

key is not accessible.

to return to the main menu.

) axis. Use or for

) axis.

10

Page 11

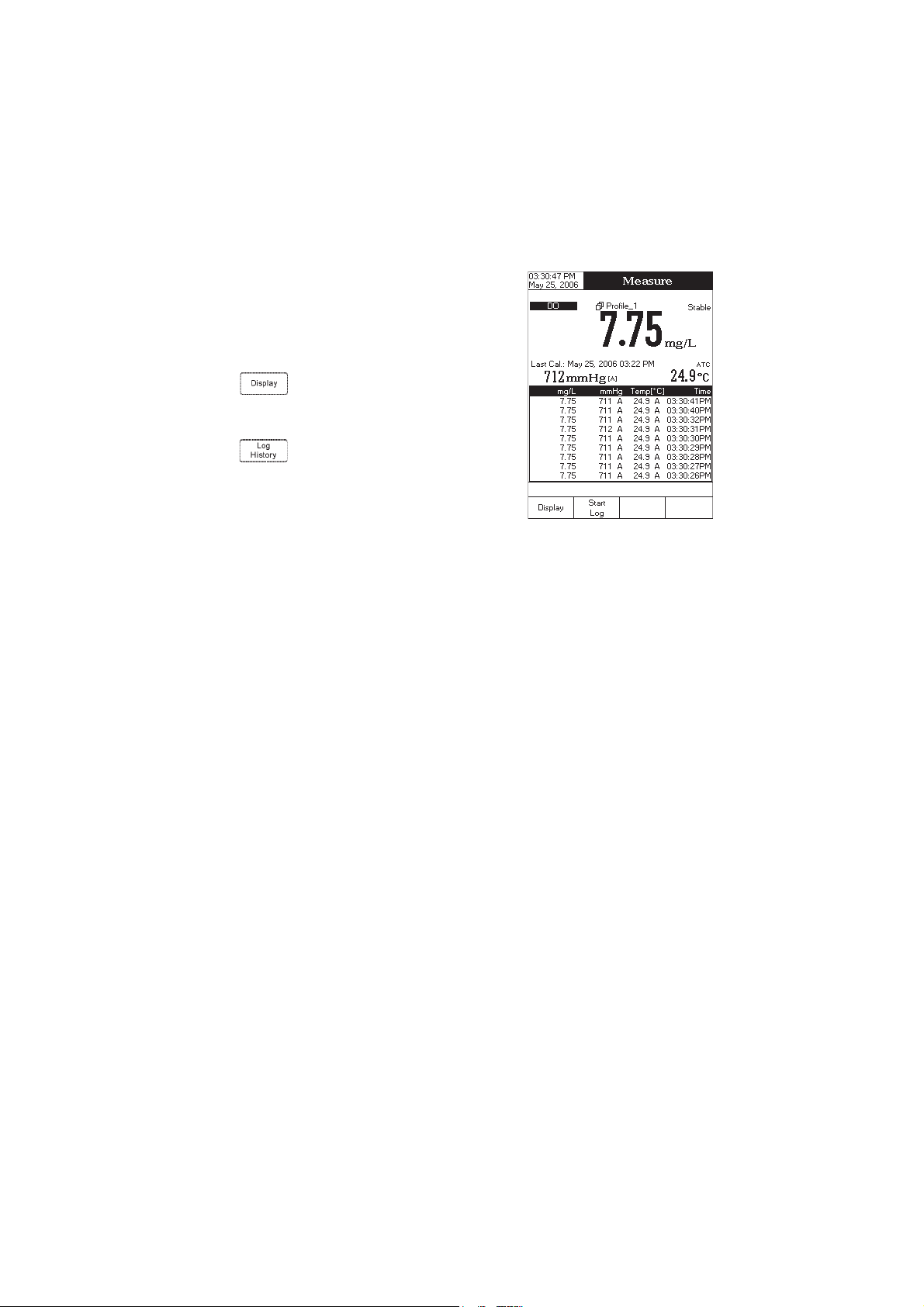

Log History

Accessing this option, last logged records will be displayed on the LCD.

The log history list also contains the appropriate DO / BOD / OUR /

SOUR values, the logged temperature, the temperature source, as

well as the records time stamp.

To access the Log History displaying mode:

• Press

play Configuration” message will be displayed in the Reminder

messages area.

• Press

regarding the selected measure mode.

Notes: • When an alarm condition is active, the logged records will have an exclamation mark (!).

• When a meter is in auto-hold, the logged records will have an “H” symbol.

• If another measure mode is selected, the Log History will be cleared.

• If the temperature unit is changed, all logged temperature values will be automatically displayed

while in

. The instrument will display the log history

in the new temperature unit.

Measure

mode. The “Choose Dis-

11

Page 12

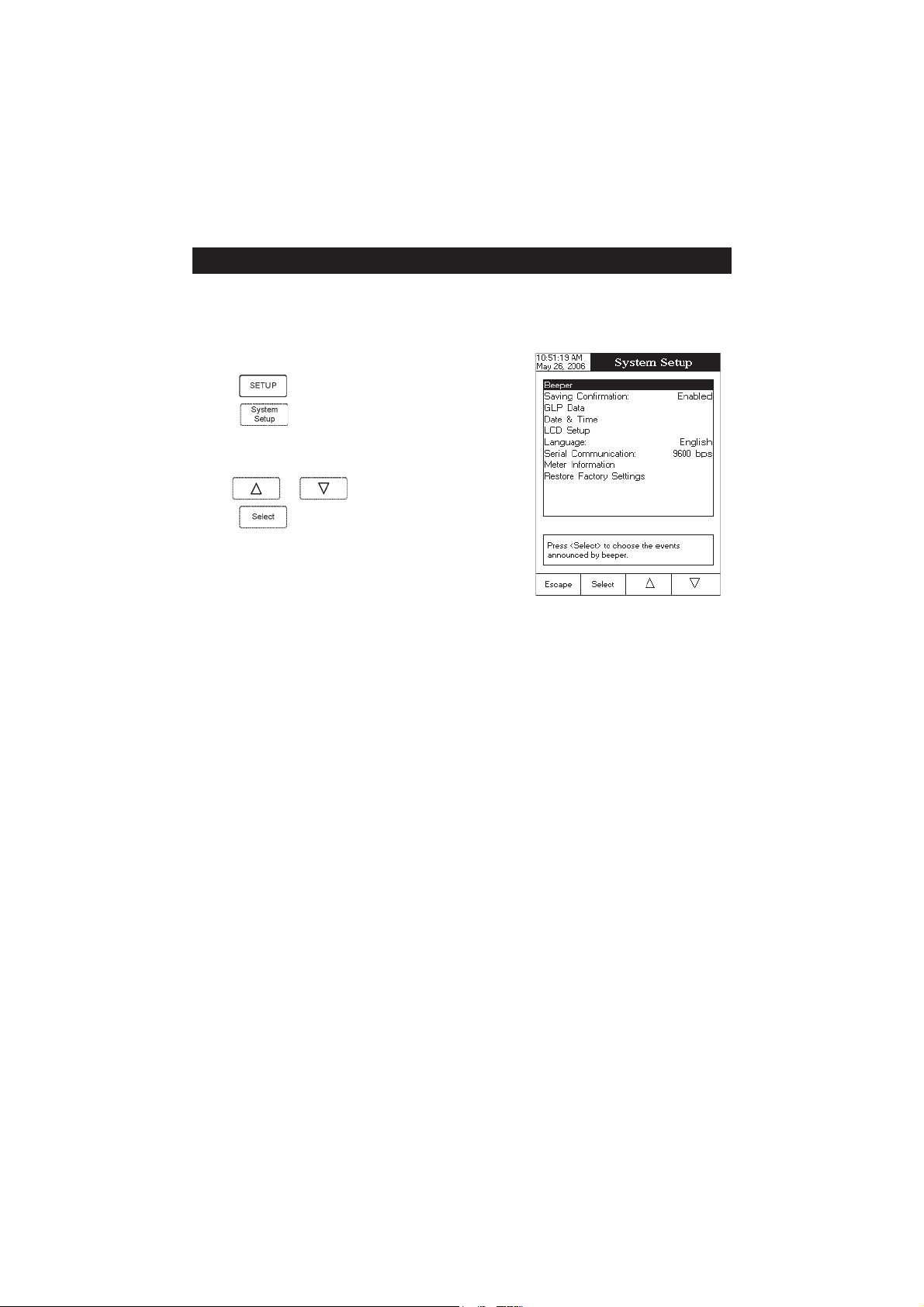

SYSTEM SETUPSYSTEM SETUP

SYSTEM SETUP

SYSTEM SETUPSYSTEM SETUP

The System Setup menu allows the user to customize the user interface, consult the meter information, set the

external serial communication interface and to restore the manufacturer settings.

Accessing System Setup

• Press

while in

Measure

mode.

• Press

on the LCD.

To access a System Setup option:

• Use

• Press

The following is a detailed description of the System Setup option

screen.

Beeper

This option allows the user to enable or disable the beeper. When the beeper is enabled, a specific beep will

be heard when the reading becomes stable, when an alarm condition is reached,

a wrong key is pressed.

. The system setup options will be displayed

or to highlight the desired option.

to access the selected option.

when pressing a key or if

Stability Indicator

When the reading becomes stable, the instrument delivers a medium beep only if this option is activated, along

with the “Stable” indicator on the LCD.

Alarm

If this option is activated, a continuous double beep will be heard each time the set limits in

exceeded, along with the “Alarm” indicator on the LCD.

Measure

mode are

Key Pressed

If this option is activated, a short beep will be heard each time a valid key is pressed.

Wrong Key

If this option is activated, a long beep will be heard when an incorrect key is pressed.

12

Page 13

To set the Beeper:

• Use

or to select the

Beeper

option.

• Press

desired beeper associated event you want to modify.

• Press

beeper status option.

• Press

menu or press

Saving Confirmation

When enabling this option, a prompt will appear on the LCD alerting

the user to save the modified values by pressing

without saving by pressing

and return to the editing mode by pressing

modified values will be saved automatically.

To enabled /disabled the saving confirmation:

• Use

• Press and use or to choose enabled

/ disabled.

• Press

cancel operation.

and use or to highlight the

and use or to highlight the

to confirm your selection and return to the

to return without changing.

or canceling the saving operation

or to select the

to confirm your selection or press

Saving Confirmation

Beeper

, exiting

. If disabled, the

option.

to

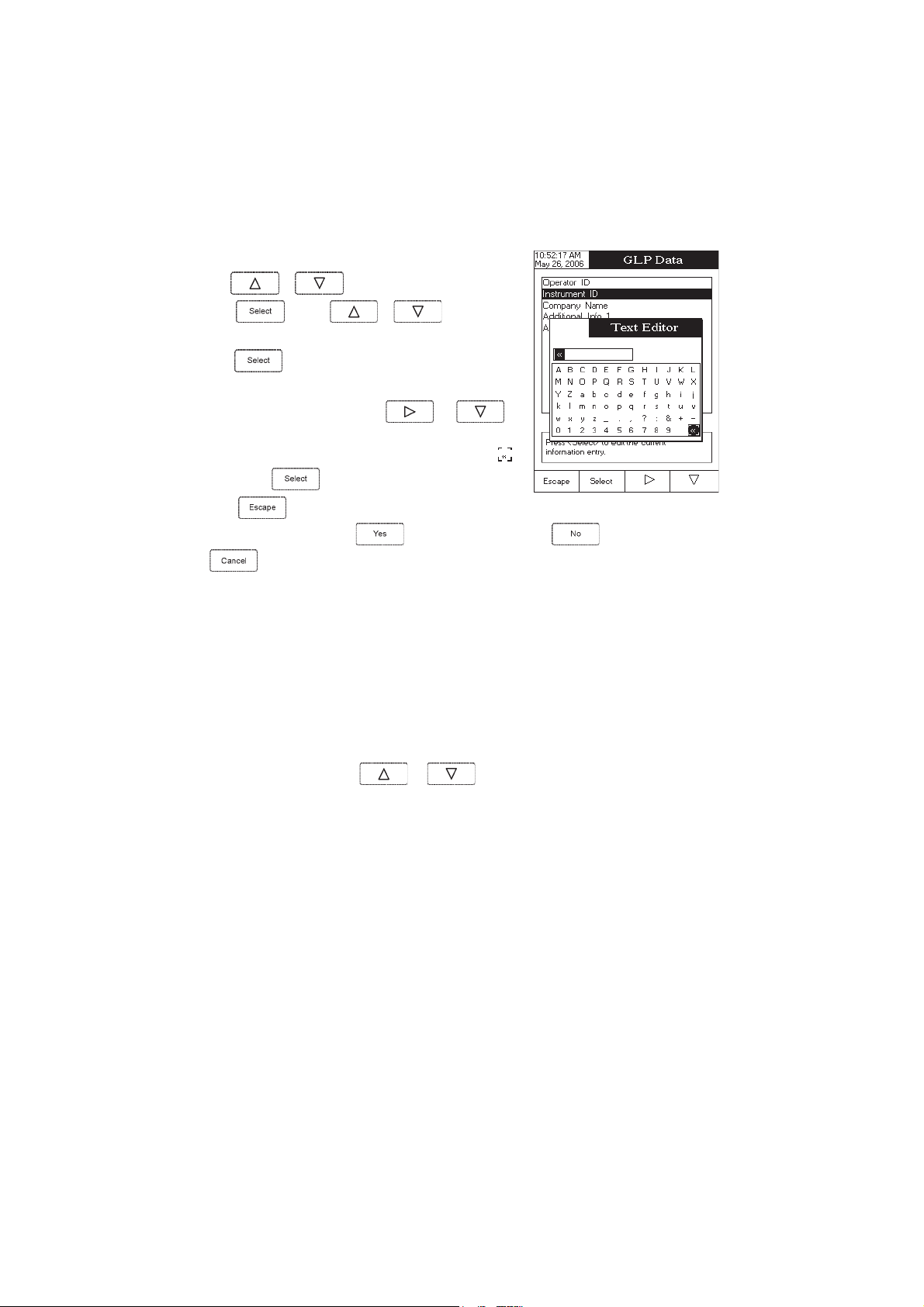

GLP Data

This option allows the user to set general information which will appear in the log reports. The edited text can have

max 10 characters.

Operator ID

Instrument ID

Company Name

Additional Info 1 & Additional Info 2

– edit the operator’s name.

– edit an identification name / number for the instrument.

– edit the company name.

– for general purpose notations.

13

Page 14

To set the GLP data:

• Use

or to select the

GLP Data

option.

• Press

desired option.

• Press to edit the desired information. The Text Editor menu

will be displayed on the LCD.

• Enter the desired information by using

highlight the desired character. It is also possible to delete the last

character by positioning the cursor on the Backspace character (

and pressing

• Press

Confirmation

Date & Time

This option allows the user to set the current date & time and the format in which they appear. These parameters

will be displayed on the

Set Date and Time

This option allows you to set the current date (year / month / day) and time (hour / minute / second).

Notes: • Only years starting with 2000 are accepted.

• The time is set using the selected time format. For 12 Hour time format only, the AM / PM can

and use or to highlight the

and to

)

.

to return to the

is enabled, press to accept the modified option, to escape without saving or

to return to the editing mode. Otherwise, the modified options are saved automatically.

Measure

also be selected with

GLP Data

menu. If the

screens and also when storing measured data.

or .

Saving

Set Time Format

This option allows you to choose between 12 Hour (AM / PM) time format and 24 Hour time format from the

displayed pop-up box.

Set Date Format

This option allows you to choose the desired date format from the available formats: DD/MM/YYYY; MM/DD/YYYY;

YYYY/MM/DD; Mon DD, YYYY; DD-MM-YYYY and YYYY-Mon-DD.

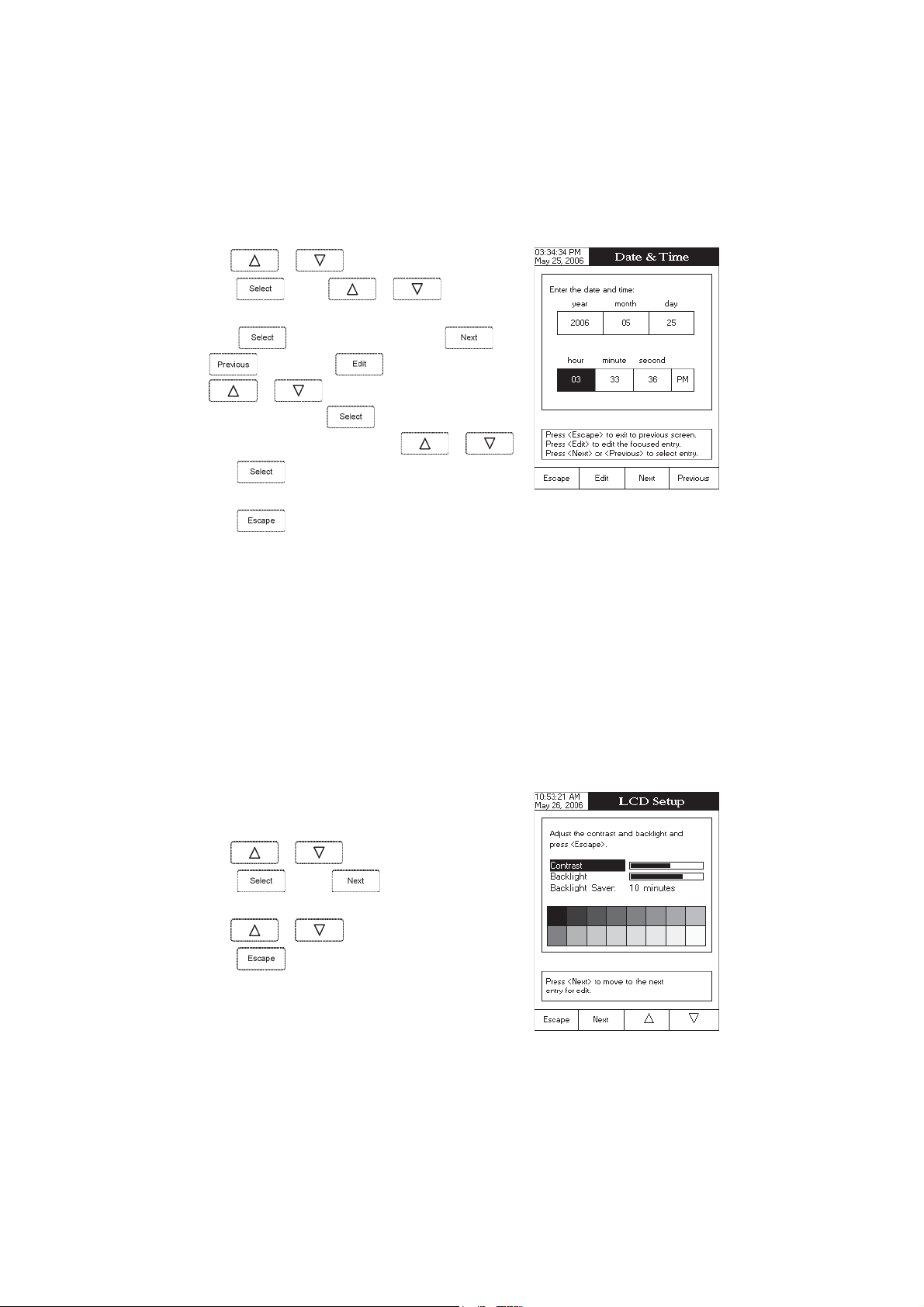

To set the Date & Time:

14

Page 15

• Use or to select the

• Press and use or to highlight the

desired option you want to modify.

• Press

to confirm your selection. Use and

and then use to modify the value with

or (for

Set Date and Time

Date & Time

option). For the

option.

other two options press

select one of the displayed formats with

• Press

& Time

• Press

Note: If the time is changed with more than one hour before last measure parameters user calibration, a pop-up

warning will appear on the LCD, notifying the user that a date/time conflict has occured and some timedependent features could work improperly (e.g.

LCD Setup

This option allows the user to set the

parameter can be adjusted within 7 steps, while the

be set from 1 to 60 minutes or it can be disabled (OFF). All the changes are visible on the LCD for each parameter.

Note: If the instrument backlight is turned off after the set period of time, press any key to turn it back on.

To set the LCD:

• Use or to select the

to confirm your selection and return to the

options.

to return to the previous mode.

to confirm your selection and

or .

Date

GLP, Log

Contrast

, the

Backlight

of the LCD and the

Backlight

parameter within 4 steps. The

LCD Setup

option;

).

Backlight Saver

. The

Contrast

Backlight Saver

can

• Press

parameter;

• Use

• Press return to the

and use key to highlight the desired

or to adjust the selected parameter;

System Setup

menu with saving.

15

Page 16

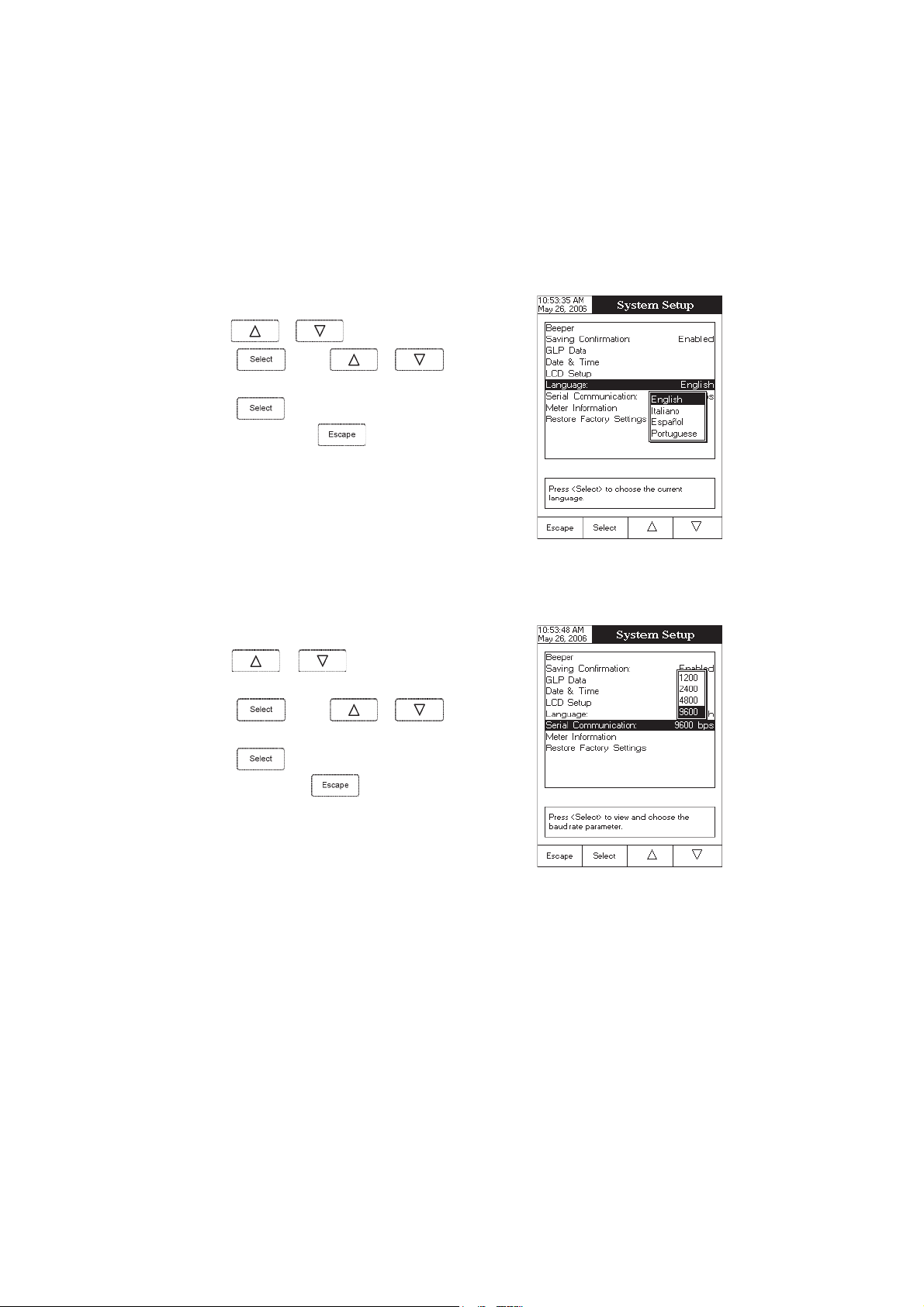

Language

This option allows the user to choose the desired language for the user interface.

To select the Language:

• Use

or to select the Language option.

• Press

desired language.

• Press

menu or press

Setup

menu without changing.

Serial Communication

This option allows the user to set the desired speed for the serial communication (baud rate) between the

instrument and PC from

To set the serial communication:

• Use

option.

• Press

desired baud rate.

• Press

menu or press

Setup

and use or to highlight the

to confirm your selection and return to the

to return to the

1200, 2400, 4800 or 9600

or to select the

and use or to highlight the

to confirm your selection and return to the

to return without changing.

Serial Communication

System

System Setup

.

System

Note: The meter and the PC application must have the same baud

rate.

16

Page 17

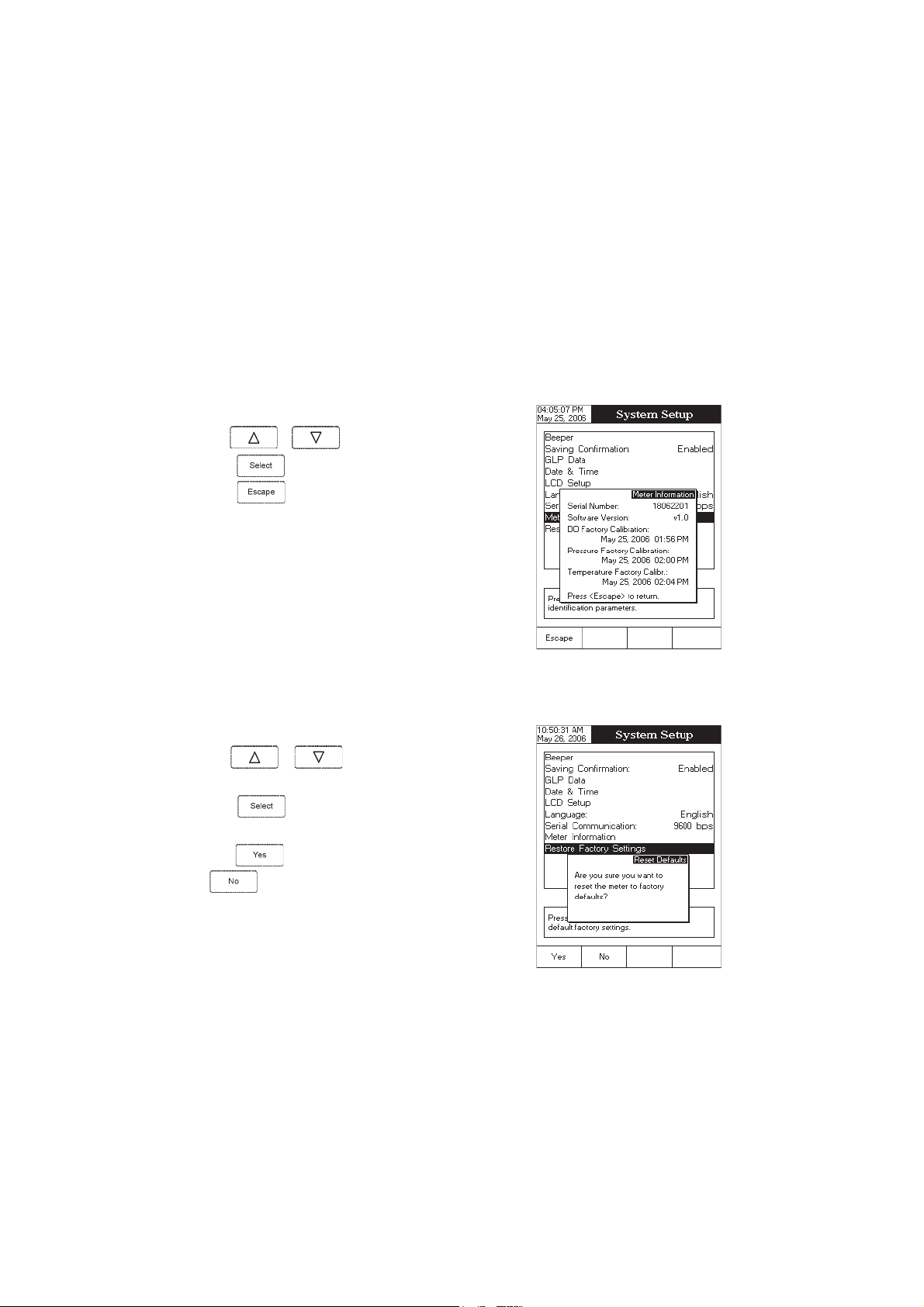

Meter Information

This option provides general information about the instrument serial number (each instrument has an unique identification

serial number), the software version and the factory calibration date and time (for DO, pressure and temperature).

Note: All the instruments are factory calibrated for DO, pressure and temperature. After one year from last factory

calibration, the warning will appear at meter startup to inform the user that a new factory calibration is

required.

To view the meter information:

• Use or to select the

Meter Information

option.

• Press

press

Restore Factory Settings

This option allows the user to reset the instrument to the default factory settings.

To restore the factory settings:

• Use

option.

• Press

displayed, asking for confirmation.

• Press to confirm and return to the

to confirm and to view the meter information or

to return to the

or to select the

to confirm your selection. A pop-up box will be

System Setup

Restore Factory Settings

menu.

System Setup

to return without restoring defaults.

or press

17

Page 18

DODO

SETUP SETUP

DO

SETUP

DODO

SETUP SETUP

The DO Setup menu allows the user to set the parameters related to the DO measurement.

Accessing DO Setup

• Press

select the

• Press

To access a DO setup options:

• Use

while in

DO

measure mode.

and then to access

or to highlight the desired option.

Measure

mode and then to

DO Setup

menu.

• Press

exit setup.

The following is a detailed description of the

screens.

Profile

Choosing this option the measuring and the calibration mode can be customized. Up to 10 profiles can be

defined by the user.

The available options are:

Save Current Profile:

Load Profile:

Delete Profile:

to access the selected option or to

DO Setup

save the current profile.

load from available profiles.

delete a profile.

option

18

Page 19

Save Current Profile

To save the current profile:

• Use

or to select the

Profile

option.

• Press

text editor box will be displayed on the LCD.

• Enter the desired profile name by using

highlight the desired character and then press

to the text bar. It is also possible to delete the last character by

positioning the cursor on the Backspace character (

• Press

Note: The saved profile will automatically become the current profile.

and then select

.

to return to the Profile options.

Save Current Profile

and to

) and pressing

option. The

to add it

Load Profile

To load the user customized profile:

• Use

• Press

Load Profile

• Press

displayed on the screen.

• Use

or to select the

option.

or to select the desired profile and press

and use or to highlight the

.

A list with all customised profiles will be

Profile

option.

to

confirm or

to exit without selecting.

19

Page 20

Delete Profile

To delete one of the existing profiles:

• Use

• Press

Delete Profile

• Press

the screen.

• Use

or to select the

and use or to highlight the

option.

.

A list with all customised profiles will appear on

or to select the desired profile and press

.

Profile

option.

• Press

Reading Mode

This option allows the user to select between

To set the reading mode:

• Use

• Press and use or to highlight the

desired option.

• Press

cancel operation.

to return to the previous menu.

Direct

and

Direct/AutoHold

or to select the

to confirm your selection or press to

Reading Mode

option.

DO reading modes.

20

Page 21

Temperature Units

The user can choose from the

To set the temperature unit:

• Use

option.

• Press

or to highlight the

and then use or to select

Celsius, Fahrenheit

• Press to confirm your selection or press to

cancel operation.

Barometer

From the

Barometer

To access a

• Use

Barometer

or to highlight the

Celsius, Fahrenheit

or

Kelvin

temperature units.

Temperature Units

or

Kelvin

degrees unit

menu the user can choose the pressure source and units, as well as the pressure.

option:

.

Barometer

option from the

DO Setup

menu.

• Press to access the

Pressure Source

The user can choose between

To set the

pressure source:

• Use

option.

• Press

Automatic

• Press

cancel operation.

Note:Note:

Note: If

Note:Note:

reference during measurements is set manually. If

pressure source is chosen, a pressure calibration in one point

can be performed (see

or to highlight the

and then use or to select

or

Manual

to confirm your selection or press to

Manual

pressure source is chosen, the pressure used as

Barometer

Manual

and

pressure source.

Pressure Calibration

option.

Automatic

pressure source.

Pressure Source

Automatic

).

21

Page 22

Pressure

To set the pressure:

• Use or to highlight the

• Press

/ decrease the value.

• Press

Pressure Units

The user can choose from the

To set the pressure unit:

• Use

option.

• Press

between

• Press to confirm your selection or press to

cancel operation.

and then use

to save or press

or to highlight the

and then use or to select

mmHg

and

mbar

mmHg

units

or

.

mbar

Pressure

option.

or to increase

to cancel operation.

pressure units.

Pressure Units

Salinity

The user can edit the sample salinity fot DO compensation.

To edit the sample salinity:

• Use

• Press

/ decrease the value.

• Press

or to highlight the

and then use

to save or press

or to increase

to cancel operation.

Salinity

22

option.

Page 23

Calibration

Using DO standards

The meter can be calibrated in a single or multi-points (up to two points), using 2 DO standards (0.0%, 100%)

or using the custom standards.

The following options are available for calibration:

Standard Recognition

The user can choose between

• Use

option.

• Use

Standard

• Press to confirm your selection or press to

cancel operation.

or to highlight the

or to choose from

option

.

Automatic

recognition (from 2 Hanna standards available) or

Standard Recognition

Automatic

or

User

User Standard

.

Calibration Reminder

This option allows the user to set the calibration reminder as

To set the calibration reminder:

• Use

minder

• Press

or to choose the desired option

• Press to confirm your selection or press to

cancel operation.

or to highlight the

option.

to confirm your selection and then use

.

Daily, Periodic

Calibration re-

23

or

Disabled

.

Page 24

Set Reminder Period

Daily

reminder - the user can set the time from the day when the reminder is to appear.

Periodic

reminder - the user can set the time from the last calibration (days, hours and minutes) after which the

reminder appears.

To set the reminder period:

• Use or to highlight the

option.

• Press

previous entry to be edited.

• Press and use or to set the desired

value, then press

• Press to return to the previous menu.

and use / to select next /

to save the modified value.

Set Reminder Period

Clear Calibration

Accessing this option, the existent DO calibration can be cleared. If the calibration is cleared, another calibration

has to be performed.

To clear calibration:

• Use

or to highlight the

Clear Calibration

option.

• Press

• Press

to clear calibration. A pop-up menu will be displayed asking for confirmation.

to confirm or press to escape without saving and return to the Calibration options.

24

Page 25

Measurement Unit

The user can select the desired measurement unit. The available options

are:

% Sat and mg/L.

• Use or to highlight the

option.

• Press

• Use or to select

• Press to confirm your selection or press to

cancel operation.

Sample ID

This option allows the user to give to the measured samples an identification number/name. Two

options are available:

to confirm your selection.

ID Increment

and

Measurement Unit

% Sat

or

mg/L.

Edit Sample ID

.

ID Increment

– the sample ID will be edited alphanumerically by the user.

None

Automatic

every new log lot notification.

To select the ID increment mode:

• Use

• Press

• Press

– the sample ID will be automatically incremented at

or to highlight the

option.

and then use or to highlight

the desired option.

to confirm your selection or press

cancel operation.

ID Increment

to

Sample ID

25

Page 26

Edit Sample ID

This option allows the user to edit the sample ID (numeric - auto-increment mode, alphanumeric - user editable).

To edit the Sample ID:

• Use

or to select the Sample ID option.

• Press

• Edit numerically / alphanumerically the sample ID.

• Press to save the current sample ID or press

Log

This option allows the user to edit the settings related to the logging feature, as following:

and use or to highlight the

Edit Sample ID

to cancel operation.

option and then press .

Logging Type

Three logging types are available:

Automatic logging

option).

Manual logging

AutoHold logging

To set the sample logging type:

• Use

• Press

Automatic, Manual

• Press

cancel operation.

- the readings are logged automatically at constant time intervals (see

( log on demand)- the readings are logged each time

- the readings are logged automatically at each auto-hold event occured.

or to highlight the

and use or to choose from

or

to confirm your selection or press to

Auto Hold

Automatic, Manual

Logging Type

.

and

AutoHold.

option.

is pressed.

Sampling Period

26

Page 27

Logging Data Configuration

This option allows the user to select the parameters that accompany a

logged value:

Operator ID, Company Name, Aditional Info 1

To customise the logging data configuration:

• Use

Configuration

• Press

the parameter by selecting

each option.

• Press

Date/Time, Calibration Data, Sample ID, Instrument ID

and

Aditional Info 2

or to highlight the

option.

and then use or to enable

Yes

or to disable it by selecting

to return to the previous menu.

Logging Data

.

No

for

Sampling Period

This option allows the user to select the desired sampling period for

automatic logging.

To set the sampling period:

• Use

or to highlight the

Sampling Period

option.

,

• Press

desired option from

• Press

cancel operation.

and use or to select the

1, 2, 5, 10, 30

to confirm your selection or press to

seconds.

New Lot

Accessing this option, the new manually logged readings will be put in a new log lot.

To generate a new lot:

• Use

• Press

• Press

Note: The

or to highlight the

to generate a new manual lot. A pop-up menu will be displayed to ask for confirmation.

to confirm or press to escape without saving and return to the Log options.

New Lot

option is available only for manual logging.

New Lot

option.

27

Page 28

Alarm

This option allows the user to define two alarm limits for the measurements.

Alarm State

The following options are available:

Disabled

Inside Limits

Outside Limits

To set the alarm state:

• Use

– the alarm will be disabled.

– the alarm will notify the user when the measured value is inside the preset limits.

– the alarm will notify the user when the measured value is outside the preset limits.

or to highlight the

Alarm State

option.

• Press

desired option.

• Press to confirm your selection or press

cancel operation.

Alarm Limits

This option allows the user to set the alarm limits for the measured

value.

Note: The alarm high value cannot be lower than the alarm low

value.

To set the alarm limits:

• Highlight the

• Use or to select the low / high alarm limit and

then press

• Use

alarm value.

• Press to return to the

and use or to highlight the

Alarm Limits

or to increase / decrease the selected

option and then press

.

Alarm

.

options.

to

28

Page 29

BODBOD

SETUP SETUP

BOD

SETUP

BODBOD

SETUP SETUP

The BOD Setup menu allows the user to set the parameters related to the resistivity measurements.

Accessing BOD Setup

• Press

select resistivity range.

• Press

while in

and then to access

Measure

mode and then to

BOD Setup

menu.

To access a

• Use

• Press

The following is a description of the Resistivity Setup option

screens.

Profile - see

Temperature Units - see

Measurement Unit - see

Method Configuration

This option allows the user to edit the BOD method configuration.

To edit the options:

• Highlight the

BOD Setup

option:

or to select the desired option.

to confirm your selection.

DO Setup

section.

DO Setup

DO Setup

Method Configuration

section.

section.

option and then press

.

• Use or to select the parameter and then press

.

• Use

value.

• Press to return to the previous screen.

or to increase / decrease the parameter

29

Page 30

Barometer - see

DO Setup

section.

Salinity - see

Sample ID - see

Log -

see

Alarm - see

DO Setup

DO Setup

DO Setup

section.

DO Setup

section.

section.

section.

30

Page 31

OUROUR

SETUP SETUP

OUR

SETUP

OUROUR

SETUP SETUP

The OUR Setup menu allows the user to set the parameters related to the OUR measurement.

Accessing OUR Setup

• Press

select OUR range.

• Press and then

To access a OUR Setup option:

• Use

while in

or to highlight the desired option.

Measure

mode and then to

to access OUR Setup menu.

• Press

The following is a description of the OUR Setup option screens.

Profile - see

Temperature Units - see

Method Configuration

This option allows the user to edit the OUR method configuration.

To edit the options:

• Highlight the

to access the selected option.

DO Setup

section.

DO Setup

section.

Method Configuration

option and then press

.

• Use or to select the parameter and then press

.

• Use

value.

or to increase / decrease the parameter

31

Page 32

Barometer - see

DO Setup

section.

Salinity - see

Sample ID - see

Log -

see

Alarm - see

DO Setup

DO Setup

DO Setup

section.

DO Setup

section.

section.

section.

32

Page 33

SOURSOUR

SETUP SETUP

SOUR

SETUP

SOURSOUR

SETUP SETUP

The SOUR Setup menu allows the user to set the parameters related to SOUR measurement and calibration.

Accessing SOUR Setup

• Press

select

• Press

SOUR

while in

range.

and then

Measure

mode and then to

to access

SOUR Setup

menu.

To access an

• Use

• Press to access the selected option.

The following is a description of the

Profile - see

Temperature - see

Method Configuration

This option allows the user to edit the SOUR method configuration.

To edit the options:

• Highlight the

SOUR Setup

DO Setup

option:

or to highlight the desired option.

SOUR Setup

section.

DO Setup

section.

Method Configuration

options.

option and then press

.

• Use or to select the parameter and then press

.

• Use

value.

• Press to return to the previous screen.

three

or to increase / decrease the parameter

33

Page 34

Barometer - see

DO Setup

section.

Salinity - see

Sample ID - see

Log -

see

Alarm - see

DO Setup

DO Setup

DO Setup

section.

DO Setup

section.

section.

section.

34

Page 35

DO CALIBRATIONDO CALIBRATION

DO CALIBRATION

DO CALIBRATIONDO CALIBRATION

It is recommended to calibrate the instrument frequently, especially if high accuracy is required.

The DO range should be recalibrated:

• Whenever the DO probe is replaced.

• At least once a week.

• Before BOD, OUR, SOUR measurements.

• After testing aggressive chemicals.

• When calibration reminder is activated (“DO Cal Expired”).

• If the readings are far from the calibration point.

Note:BOD, OUR and SOUR readings are automatically derived from the DO readings and no specific

calibration is needed.

The following options are available for the Dissolved Oxygen calibration:

• one point automatic zero calibration at 0% saturation or 0 mg/L

• one point automatic slope calibration at 100% saturation or 8.26 mg/L

• 1 point manual calibration using a standard value set by the user in % saturation or mg/L

When automatic calibrations are performed it is assumed that the standard value is the saturated DO value at 25 °C,

0 g/L salinity and 760 mmHg.

When manual calibrations are performed it is assumed that the standard value is the DO value at the current

pressure, temperature and salinity.

Initial preparation

Make sure the probe is ready for measurements, i.e. the membrane is filled with electrolyte and the probe is

connected to the meter.

For an accurate calibration, it is recommended to wait for at least 15 minutes to ensure precise conditioning of

the probe.

Remove the protective cap from the DO probe.

Make sure the salinity value has been set to the salinity of the standard.

Probe conditioning

At startup, the probe is under polarization with a fixed voltage of approximately 800 mV for 1 minute.

Probe polarization is essential for stable measurements with the same recurring degree of accuracy.

With the probe properly polarized, oxygen is continually consumed when it passes through the sensitive

diaphragm and dissolves in the electrolyte solution contained in the probe.

Whenever measurements are taken with a non-polarized probe, the oxygen level revealed is both that of the

tested solution, as well as that present in the electrolyte solution. This measurement is incorrect.

35

Page 36

Keep the protective cap on during polarization time and remove it for calibration and measurements.

To calibrate the meter:

• Insert and rinse the probe in the first beaker in order to

decontaminate it;

• Insert the probe in the second beaker;

• Tap the probe repeatedly to remove any air bubbles that may

be trapped inside the sleeve.

• Enter in calibration mode by pressing ;

• Wait to stabilize;

• You can delete a previously performed calibration by pressing

When the automatic standard recognition is selected:

• The calibration point will be automatically selected from the two standards available.

• Press to perform the calibration or to exit calibration.

Note:If you want to perform automatic DO calibration in two points, perform the calibration at 0% saturation

first and then at 100% saturation.

When the user standard is selected:

• The calibration can be performed only in one point.

• Edit the desired standard value by using

• Press to finish the calibration or to exit calibration.

and .

36

.

Page 37

If

Automatic

point can be performed.

To perform pressure calibration:

pressure source is chosen from the

PRESSURE CALIBRATIONPRESSURE CALIBRATION

PRESSURE CALIBRATION

PRESSURE CALIBRATIONPRESSURE CALIBRATION

Pressure Source

menu (see

DO Setup

), a pressure calibration in one

• Press

• Use

• Press to finish the calibration or to exit

calibration.

to clear the current calibration;

or to modify the pressure value;

37

Page 38

DO MEASUREMENTDO MEASUREMENT

DO MEASUREMENT

DO MEASUREMENTDO MEASUREMENT

Make sure the instrument has been calibrated before taking DO measurements.

DIRECT MEASUREMENT

To measure the DO of a sample using the Direct reading mode:

• Press

• Select the

• Submerge the DO probe and tap

air bubbles that may be trapped inside the sleeve. Allow time

for the reading to stabilize.

• The measured DO value will be displayed together with the

temperature and pressure values.

Notes: • For accurate DO measurements, a water movement of

• If the reading is out of range, “-----” will be displayed.

and then to select DO measure mode.

Direct

reading mode (see DO

0.3 m/s is required. This is to ensure that the oxygendepleted membrane surface is constantly replenished.

A moving stream will provide adequate circulation.

Setup

).

it repeatedly to remove any

DIRECT/AUTOHOLD MEASUREMENT

To measure DO of a sample using the Direct/AutoHold reading mode:

• Select the Direct/AutoHold reading mode (see DO

• If pressing

ing on the display until the stability criterion is reached. The DO

value will be frozen on the display, along with “AutoHold”

indicator.

• To return to normal measure mode press

, the “AutoHold” indicator will start blink-

Setup

38

).

.

Page 39

SALINITY COMPENSATION

If the sample contains significant concentration of salinity, the read out values must be corrected, taking into

account the lower degree of oxygen solubility in this situation.

Before taking any DO measurements remember to set the salinity value from the DO setup menu.

The salinity affects the DO concentration, decreasing its value. The table below shows the maximum oxygen solubility

at various temperatures and salinity levels.

Cº

l/g0l/g01l/g02l/g03l/g53

006.4146.3147.2109.1105.110.23

218.3119.2170.2192.1119.015.63

490.3152.2174.1137.0183.012.93

644.2156.1119.0122.0198.98.24

838.1190.1104.0157.944.94.64

0182.1185.0139.923.930.90.05

2177.0111.0105.929.856.86.35

4192.0186.901.955.803.82.75

6168.982.937.812.879.78.06

8154.909.893.809.766.74.46

0280.965.870.806.783.70.86

2237.832.877.733.721.76.17

4204.839.794.770.778.62.57

5242.897.763.759.657.60.77

6290.856.732.738.646.68.87

8218.783.789.616.624.64.28

0345.741.757.693.622.60.68

2392.709.645.691.630.66.98

4350.786.633.610.658.52.39

6328.674.641.638.586.58.69

8316.682.669.566.515.54.001

0414.690.697.505.563.50.401

2422.639.536.553.522.56.701

4440.677.584.512.590.52.111

6478.516.533.570.579.48.411

8407.574.502.559.458.44.811

0545.533.570.538.457.40.221

leveLaeSta)l/g(ytinilaS

Fº

NoteNote

Note: The relationship between salinity and chlorinity for sea water is given by the equation below:

NoteNote

Salinity (g/l) = 1.80655 Chlorinity (g/l)

39

Page 40

BAROMETRIC PRESSURE COMPENSATION

The dissolved oxygen saturation value varies with pressure, so it is important to compensate the effect that

pressure has on DO measurements.

leveLaeSevobasreteM,edutitlA

Cº

0m003m006m009m0021m0051m0081m0012m0042m0072m0003m0033m0063m0093m0004

06.411.416.311.316.211.217.112.118.014.010.017.93.90.99.80.23

28.313.318.214.219.115.110.116.012.019.95.92.98.85.84.86.53

41.316.212.217.113.119.015.011.017.93.90.97.84.80.89.72.93

64.210.215.111.117.013.019.96.92.99.86.82.89.76.75.78.24

88.114.110.116.012.018.95.91.98.84.81.88.75.73.72.74.64

013.119.015.011.017.94.90.97.84.81.88.75.72.79.68.60.05

218.014.010.016.93.99.86.83.80.87.74.71.79.66.65.66.35

413.019.96.92.99.85.82.89.76.74.71.78.66.63.62.62.75

619.95.92.98.85.82.89.76.73.70.78.65.63.61.60.68.06

815.91.98.85.81.88.76.73.70.78.65.63.60.68.57.54.46

021.98.84.81.88.75.73.70.77.65.62.60.68.56.55.50.86

227.84.81.88.75.72.70.77.65.62.60.68.56.54.53.56.17

424.81.88.75.72.70.77.65.62.60.68.56.54.52.51.52.57

523.80.87.74.71.78.66.64.61.69.57.55.53.51.50.50.77

621.88.75.72.70.77.65.62.60.68.56.54.52.50.59.48.87

828.75.73.70.77.65.62.60.68.56.54.52.50.58.47.44.28

036.73.70.78.65.63.60.68.56.54.52.50.58.46.46.40.68

233.70.78.65.63.61.68.56.54.52.50.58.47.45.44.46.98

431.78.66.63.61.69.56.54.52.50.59.47.45.43.43.42.39

638.66.63.61.69.57.55.53.51.59.47.45.44.42.41.48.69

836.64.61.69.57.55.53.51.59.47.45.44.42.41.40.44.001

044.62.69.57.55.53.51.59.47.46.44.42.41.49.39.34.401

242.60.68.56.53.52.50.58.46.44.43.41.40.48.38.36.701

440.68.56.54.52.50.58.46.45.43.41.40.48.37.37.32.111

648.56.54.52.50.58.47.45.43.42.40.49.37.36.35.38.411

847.55.53.51.59.47.45.44.42.40.49.37.36.35.34.34.811

055.53.51.59.47.46.44.42.41.49.38.36.35.34.33.30.221

Fº

m

40

Page 41

The meter contains a built-in barometer, and it is able to automatically compensate for changes in barometric

pressure. If another pressure value than the barometer’s reading is to be used, then the manual pressure

feature must be enabled. (See

DO Setup

).

The table below contains a conversion altitude (m) to pressure (mmHg) for the altitude values from the

previous table.

edutitlA

000300600900210051008100120042007200030033006300930004

)m(

erusserP

067237507976456036706485365245225305484764164

)gHmm(

41

Page 42

BOD MEASUREBOD MEASURE

BOD MEASURE

BOD MEASUREBOD MEASURE

Biochemical oxygen demand (BOD) is an indicator for the concentration of biodegradable organic matter

present in a sample of water. It can be used to determine the general quality of the water and its degree of

pollution. BOD measures the rate of oxygen uptake by microorganisms in a sample of water at a fixed

temperature and over a given period of time. To ensure that all other conditions are equal, a very small

amount of microorganism seed is added to each sample being tested. This seed is typically generated by

diluting activated sludge with deionized water. The samples are kept at 20 ºC in the dark and tested for

dissolved oxygen (DO) after five days. The loss of dissolved oxygen in the sample, once correction have been

made for the degree of dilution, is called the BOD5.

Before running an BOD measurement remember to set the BOD method configuration from the BOD setup menu

and make sure the instrument has been calibrated on DO.

To take the BOD measurement:

• Press

mode.

• Press

and then to select BOD measure

to access the BOD data management screen.

MENTMENT

MENT

MENTMENT

• Press

between

• Press

• Press

available. The seed records will have the symbol “*” dis-

played before the bottle ID.

to add a new sample or a new seed. Select

and .

to repeat the initial DO measurement.

to access the list of the samples and seeds

42

Page 43

• Press

sponding to the selected bottle ID.

• Press to load the method data to the measurement

screen.

• If the time difference between the current reading and the

selected reading is more than 1 day,

stead

• Press to display the BOD value.

to display the BOD information screen corre-

appears in-

and the BOD value can be calculated.

• If there are at least two BOD values calculated then you can

press

• Press

to enter the

to access the

Select Bottle ID

BOD Select View

screen.

screen.

43

Page 44

• From the

using

method to the

• Press

Bottle ID

• Press

Available Bottle ID

or and press to add the

Selected Bottle ID

to delete a selected method from the

list.

to switch between the two lists.

list select the desired bottle ID

list.

Selected

• When in

additionals options corresponding to the selected bottle ID.

• Press for each sample to display the results containing the seed correction.

Selected Bottle ID

list, press

to access

44

Page 45

OUR MEASUREOUR MEASURE

OUR MEASURE

OUR MEASUREOUR MEASURE

MENTMENT

MENT

MENTMENT

The OUR is used to determine the oxygen consumption or respiration rate. It is defined as the mg/L of oxygen

consumed per hour.

The following equation is used for OUR determination:

where:

DO

= Dissolved oxygen level at start of test

START

DO

= Dissolved oxygen level at end of test

END

t

= Elapsed time of test in seconds

ELAPSED

total volume/sample volume = Dilution factor of sample

Before starting an OUR measurement remember to set the OUR configuration from the OUR setup menu and make

sure the instrument has been calibrated on DO.

To measure the OUR of a sample:

• Press

and then to select OUR measure mode.

• Press

to start taking the measurement.

• At the end of the measurement the meter will display the

computed OUR value, the duration of the measurement and

the pressure and temperature values.

45

Page 46

s

SOUR MEASURESOUR MEASURE

SOUR MEASURE

SOUR MEASURESOUR MEASURE

MENTMENT

MENT

MENTMENT

The Specific Oxygen Uptake Rate (SOUR), also known as the oxygen consumption or respiration rate, is defined

as the milligram of oxygen consumed per gram of volatile suspended solids (VSS) per hour. This quick measurement

has many advantages: rapid measure of influent organic load and biodegradability, indication of the presence of

toxic or inhibitory wastes, degree of stability and condition of a sample, and calculation of oxygen demand rates

at various points in the aeration basin.

The following equation is used for SOUR determination:

SOUR = OUR / Solids Weight

where:

OUR is the Oxygen Uptake Rate (see equation on the previous page)

Solids Weight is the

Total solids

or the

Volatile suspended solids

weight in g/L

Temperature correction:

The SOUR value is corrected to 20 °C (68 °F) according to the Farrel and Bhide equation:

SOUR

=SOUR

20

xΘ

T

(20-T)

Where T is the measured temperature in °C and Θ is a temperature dependent variable:

Θ= 1.05 for T above 20 °C

Θ= 1.07 for T below 20 °C

This calculation is valid only for temperature values in the range 10 to 30 °C. Temperature correction is

performed only if the option SOUR @20°C is enabled. (see

Method Configuration

in

SOUR Setup

)

Before starting a SOUR measurement remember to set the SOUR configuration from the setup menu and make

sure the instrument has been calibrated on DO.

To measure the SOUR of a sample:

• Press

and then to select OUR measure mode.

• Press to start taking the measurement.

• At the end of the measurement the meter will display the

computed SOUR value, the duration of the measurement and

the pressure and temperature values.

46

Page 47

LOGGINGLOGGING

LOGGING

LOGGINGLOGGING

This feature allows the user to log DO, BOD, OUR, SOUR and temperature. The logging behaviour is dependent

Logging Type

on the

Logging Data Configuration

The

and

Reading Mode

(DO only) options from the parameter setup.

options from the appropriate parameter setup must be set first in order to be

saved into the log report.

Regarding data logging, the available logging modes (DO only) are shown in the table below:

edoMgniggoLepyTgniggoLedoMgnidaeR

1 citamotuAtceriD

2 citamotuAdloHotuA/tceriD

3 launaMtceriD

4 launaMdloHotuA/tceriD

5 dloHotuAdloHotuA/tceriD

LOGGING MODE 1

This logging mode can be used to monitor a chemical reaction. By choosing this logging mode,

be available in

Measure

mode.

will

To log data using this mode:

• Press

while in

Measure

mode to start the logging

session. The “Logging” and the Sampling Period indicators will

be displayed on the LCD and data will be stored at the set

sampling period.

Note: While automatic logging is running, the measured pa-

rameter setup is not available. A warning message will

be displayed if the setup is accessed.

• If accessing Graph option while logging, the online graph can

be visualized on the LCD (see

Display Mode

section).

• If accessing Log History option while logging, last logged data

can be visualized on the LCD (see

• To stop the logging session, press

Display Mode

section).

. The Log Save

screen will display the log lot ID, the settable log interval / sampling:

• Press

to adjust the log interval and / or the log sampling or press to save the current log.

47

Page 48

• Press

or to adjust the logging start-stop time or the log

to enter log interval edit menu and use

sampling. Press

• Press to exit log interval edit menu and then press

• While the instrument is saving the data, a “Please wait...”

pop-up message will be displayed on the LCD.

LOGGING MODE 2 (DO only)

This logging mode can be used for multiple samples measurement.

By choosing this logging mode,

available in

To log data using this mode:

• Press

• To store another frozen value, press again.

or to adjust next / previous parameter.

to save the current log.

Measure

session. When the measured value is frozen on the LCD by

pressing

logged value is the one that has been frozen on the LCD until

returning to normal logging mode by pressing

The “Logging” and “AutoHold” indicators will be displayed on

the LCD.

to save the current value and use

and will be

mode.

while in

Measure

mode to start the logging

and the stability criterion is reached, the

.

• To stop the logging session, press

.

48

Page 49

LOGGING MODE 3

This logging mode can be used for any sample measurements. By

choosing this logging mode,

mode.

To log data using this mode:

• Press

record. The “Logged” indicator will be displayed on the LCD.

• The records will be stored in one lot. In order to change the

logging lot, see the measured parameter setup for details, Log

option, New Lot generation.

LOGGING MODE 4

This logging mode can be used for multiple samples measurement. By choosing this logging mode,

while in

will be available in

Measure

mode to manually log a

Measure

and will be available in

To log data using this mode:

• Press while in

was pressed. When the measured value is frozen on the LCD by pressing

reached, the logged value is the one that has been frozen on the LCD.

• To store another frozen value, press

• The records will be stored in one lot. In order to change the logging lot, see the measured unit

details, Log option, New Lot generation.

LOGGING MODE 5

This logging mode can be used for multiple samples measurement. By choosing this logging mode,

and will be available in

Note: If the Reading Mode option is set as Direct and the Logging Mode 5 session is started, a warning popup will be displayed on the LCD, informing the user that the Reading Mode option must be set as Direct/

AutoHold in order to use this logging mode.

To log data using this mode:

• Press

frozen on the LCD, after

while in

Measure

mode.

Measure

mode to manually log a record. Each value is logged at the time when the key

and the stability criterion is

to return to normal logging mode and then again.

Measure

mode.

Measure

mode to start the logging session. The logged values are only the ones

was pressed and the stability criterion reached.

Setup

for

• To store another frozen value, press to return to normal logging mode and then again.

49

Page 50

• To stop the logging session, press

Notes: • For the automatic logging, if the maximum logging time (24h) has been reached, a warning pop-up

will be displayed on the LCD in order to save the current log and start another one in a new lot.

• If 100 lots have been saved or maximum 10000 records have been manually stored, a warning

pop-up will be displayed on the LCD in order to delete one lot or to select a new lot for the

manual logging to log other records.

LOG RECALL

This feature allows the user to view all stored data. If no data were logged, the “No records were found” message

will be displayed on the LCD in the Log Recall screen. Otherwise, the instrument will display all the memorized lots

in accordance with the selected option: Automatic Log or Manual Log.

To view the memorized data:

• Press

while in

Measure

mode.

.

• Press

be displayed in the Reminder messages area.

• Press

type. All logged lots for the selected Log Report type will be

displayed on the LCD.

• To filter the displayed lots, press and then the

desired unit

Only the selected measurement unit lots will be displayed

on the LCD.

• Select the desired lot with or and press

will be displayed on the LCD for a short period. The user customised report will be displayed on the LCD.

Note: For automatic logging only, it is possible to view the plotted graph.

• Press

• By pressing

• If pressing while the graph is displayed, the zoom menu for the horizontal and vertical axes will

be accessed. Press

zooming axes and then zoom in or out on the selected axis by pressing the appropriate virtual key.

. The “Choose Log Report Type” message will

or to select the desired Log Report

, ,

to display the logged / report data from the highlighted lot. The “Please wait...” message

to display the graph.

it is possible to move the graph along the horizontal or vertical axis with the arrow keys.

or / / / to switch between the active

or .

50

Page 51

• Press to return to the previous menu.

To delete lots:

• Press

while in

Log Recall

mode.

• Press

mode. Otherwise, press

mode.

• After selecting one of the deleting modes, use

“Please wait...” message will be displayed on the LCD

until the selected lot or all lots are deleted.

• Press and then press to exit deleting

mode and return to

• Press

Measure

Note: Logged lots should also be deleted whenever “Please

Delete Old Log Files” or “Low Data Logging Space”

message appears on the LCD, in the Reminder messages

area.

or to access delete or delete all

to return to

to select one lot and then press or

to delete the selected lot or all lots. The

Log Recall

to exit

mode.

view mode.

Log Recall

Log Recall

mode and return to

view

or

51

Page 52

TWIST

AND

PULL

UNSCREW

fig. 1

fig. 2

PC INTERFACEPC INTERFACE

PC INTERFACE

PC INTERFACEPC INTERFACE

Data transmission from the instrument to the PC can be done with the HI 92000 Windows® compatible

software (optional). HI 92000 also offers graphing and on-line help feature.

Data can be exported to the most popular spreadsheet programs for further analysis.

HI 4421 instrument has two available serial interfaces: RS232 and USB. The desired serial interface can be

selected from the settings window of the HI 92000 software.

If choosing the RS232 serial interface, use the optional Hanna HI 920010 cable connector to connect your

instrument to a PC. Make sure that your instrument is switched off and then plug one connector to the

instrument RS232 socket and the other one to the serial port of your PC.

Note: Other cables than HI 920010 may use a different configuration. In this case, communication between

instrument and PC may not be possible.

If choosing the USB serial interface, use a standard USB cable to connect your instrument to the PC.

For both serial interfaces, make sure that the instrument and the HI 92000 software have the same baud rate

and the appropriate communication port.

PROBE CONDITIONING & MAINTENANCEPROBE CONDITIONING & MAINTENANCE

PROBE CONDITIONING & MAINTENANCE

PROBE CONDITIONING & MAINTENANCEPROBE CONDITIONING & MAINTENANCE

The oxygen probe is made of reinforced plastic for maximum durability. A thermistor

temperature sensor provides temperature measurements of the sample. Use the protective

cap when not in use.

To replace the membrane or refill with electrolyte, proceed as follows:

Remove the protective cap by gently twisting, and pulling and pulling it off the body of the

probe (see fig. 1).

Unscrew the membrane cap by turning it counterclockwise (see fig. 2).

Wet the sensor by soaking the bottom 2 cm (1’’) of the probe in electrolyte for five minutes.

Rinse the new membrane cap, supplied with the meter with electrolyte solution while

shaking it gently. Refill with clean electrolyte solution.

Gently tap the sides of the membrane cap with your finger tip to ensure that no air bubbles remain

trapped. Do not tap directly the bottom with your finger, as this will damage the membrane.

Make sure that the rubber O-ring sits properly inside the membrane cap.With the sensor

facing down, slowly screw the membrane cap clockwise. Some electrolyte will overflow.

The Platinum cathode (#8 in the Probe Functional Description page 8) should always be bright and untarnished.

If it is tarnished or stained, the cathode should be cleaned. You can use a clean lint-free cardboard or cloth. Rub

the cathode very gently side to side 4-5 times. This will be enough to polish and remove any stains without

damaging the platinum tip. Afterwards, rinse the probe with deionized or distilled water and install a new

membrane cap using fresh electrolyte and follow the steps above. Recalibrate the instrument.

52

Page 53

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

SMOTPMYSMELBORPNOITULOS

swohsyalpsiD"-----"

.stnemerusaemgnirud

otsliafretemehT

sevigroetarbilac

.sgnidaerytluaf

t'nseodtnemurtsniehT

ehterusaem

ehtmorferutarepmet

.eborp

erasgninrawticilpxE

gniruddeyalpsid

.noitarbilac

seodtnemurtsniehT

ehtedirrevoton

.ssecorpgnidaol

.rorre

fotuognidaeR

.egnar

.egnar

sieborpehT

.degamad

eborpehT

sirosneserutarepmet

.nekorb

degamad/ytriD

detanimatnoc,eborp

.sdradnats

erawtfos/gnizilaitinI

.snoitcurtsni

.rodnevruoy

;retemehtetarbilaceR

sielpmasehtkcehC

elbarusaemehtnihtiw

.eborpehtecalpeR

.eborpehtecalpeR

deyalpsidwolloF

tnemurtsniehttratseR

.hctiwsrewopehtgnisu

tcatnocstsisreprorreehtfI

"detceteDrorrE"

.putratstapu-pop

.rorrenoitazilaitinIyb(rorreehtezilausiV

"seY"gnisserp.)yek

firodnevruoytcatnoC

.sruccororrelacitirc

53

Page 54

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

HI 7040M Zero Oxygen Solution, 230 mL

HI 7040L Zero Oxygen Solution, 500 mL

HI 7041S Refilling Electrolyte Solution, 30 mL

PROBE CLEANING SOLUTIONSPROBE CLEANING SOLUTIONS

PROBE CLEANING SOLUTIONS

PROBE CLEANING SOLUTIONSPROBE CLEANING SOLUTIONS

HI 7061M General Cleaning Solution, 230 mL bottle

HI 7061L General Cleaning Solution, 500 mL bottle

HI 8061M General Cleaning Solution, 230 mL FDA approved bottle

HI 8061L General Cleaning Solution, 500 mL FDA approved bottle

OTHER ACCESSORIESOTHER ACCESSORIES

OTHER ACCESSORIES

OTHER ACCESSORIESOTHER ACCESSORIES

HI 76408 DO probe for laboratory use with built-in temperature sensor

HI 76407A/P 5 spare membranes

HI 710005/8 12Vdc voltage adapter (US plug)

HI 710006/8 12Vdc voltage adapter (European plug)

HI 920010 9 to 9-pin RS232 cable

HI 92000 Windows

®

compatible software

54

Page 55

RECOMMENDATIONS FOR USERS

Before using these products, make sure they are entirely suitable for the environment in which they are used.

Operation of these instruments in residential areas could cause unacceptable interferences to radio and TV equipment,

requiring the operator to follow all necessary steps to correct interferences.

During operation, ESD wrist straps should be worn to avoid possible damage to the probe by electrostatic discharges.

Any variation introduced by the user to the supplied equipment may degrade the instruments’ EMC performance.

To avoid electrical shock, do not use these instruments when voltages at the measurement surface exceed 24 VAC or 60

VDC.

To avoid damage or burns, do not perform any measurement in microwave ovens.

55

Page 56

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and Technical offices, please see

www.hannainst.com

.

56

MAN4421

10/06

Loading...

Loading...