Page 1

1

HI 4211 & HI 4212

pH/mV/ISE/Temperature

Bench Meters

Instruction Manual

www.hannainst.com

Page 2

2

HI 4211 and HI 4212 are warranted for two years against defects in workmanship and materials when used

for their intended purpose and maintained according to instructions. Electrodes and probes are guaranteed for

six months. This warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact the dealer from whom you purchased the instrument. If under warranty, report

the model number, date of purchase, serial number and the nature of the failure. If the repair is not covered

by the warranty, you will be notified of the charges incurred. If the instrument is to be returned to Hanna

Instruments, first obtain a Returned Goods Authorization number from the Technical Service Department and

then send it with shipping costs prepaid. When shipping any instrument, make sure it is properly packed for

complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the date of

purchase.

Dear Customer,

Thank you for choosing a Hanna Instruments product. This manual will provide you with the necessary

information for correct use of the instrument.

Please read this instruction manual carefully before using the instrument.

If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com or see the

back side of this manual for our worldwide sales and technical service contacts.

These instruments are in compliance with

directives.

WARRANTY

Page 3

3

TABLE OF CONTENTS

WARRANTY ...................................................................................................................................... 2

PRELIMINARY EXAMINATION .............................................................................................................. 4

GENERAL DESCRIPTION ...................................................................................................................... 4

FUNCTIONAL DESCRIPTION ................................................................................................................ 5

SPECIFICATIONS ................................................................................................................................ 8

OPERATIONAL GUIDE ....................................................................................................................... 9

DISPLAYING MODES ......................................................................................................................... 11

SYSTEM SETUP ............................................................................................................................... 14

pH SETUP ...................................................................................................................................... 20

mV SETUP ..................................................................................................................................... 32

ISE SETUP (HI 4212 only) .............................................................................................................. 33

pH CALIBRATION & MEASUREMENTS ................................................................................................. 39

mV & RELATIVE mV MEASUREMENTS ................................................................................................ 44

ISE CALIBRATION & MEASUREMENTS (HI 4212 only) ........................................................................ 46

LOGGING ....................................................................................................................................... 57

PC INTERFACE .................................................................................................................................... 62

pH BUFFER TEMPERATURE DEPENDENCE .......................................................................................... 63

ELECTRODE CONDITIONING & MAINTENANCE ..................................................................................... 64

TROUBLESHOOTING GUIDE .............................................................................................................. 66

TEMPERATURE CORRELATION FOR pH SENSITIVE GLASS ...................................................................... 67

ACCESSORIES .................................................................................................................................. 68

Page 4

4

GENERAL DESCRIPTION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has

occurred during shipping. If there is any damage, notify your dealer or the nearest Hanna Service Center.

For HI 4211 and HI 4212 ordering codes the instruments are supplied with:

• 12VDC Power Adapter

• Instruction Manual

For HI 4211-01 and HI 4212-01 ordering codes the following accessories are also included:

• HI 1131B Glass-body Combination pH Electrode

• HI 7662-T Temperature probe

• pH 4.01 & 7.01 Buffer solutions, 20 mL each

• HI 7071S Electrolyte solution

• HI 76404N Electrode Holder

• HI 180 H/D Magnetic Stirrer

Note: Save all packing material until you are sure that the instrument works correctly. Any defective item

must be returned in the original packing with the supplied accessories.

PRELIMINARY EXAMINATION

HI 4211 and HI 4212 are professional bench meters with graphic LCD for pH, ORP (Oxidation Reduction

Potential), ISE (HI 4212 only) and Temperature measurements with Calibration Check.

The display can be configured as a single channel or dual channel display (HI 4212 only) in various modes: Basic

information only, GLP information, Graph mode and Log History mode. Each channel can be configured as pH, mV,

Relative mV or ISE (HI 4212 only).

The main features of the instruments are:

• One (HI 4211), or two (HI 4212) input channels;

• Manual selection, automatic and semiautomatic pH calibration up to five points, with standard (1.68, 3.00,

4.01, 6.86, 7.01, 9.18, 10.01 and 12.45) and custom buffers (up to 5 custom buffers);

• Manual Selection and Custom Standard ISE calibration up to five points, with standard (up to five standard

solutions for each measurement unit) and custom solutions (up to 5 custom solutions), with or without

temperature compensation;

• AutoHold feature to freeze first stable reading on the LCD;

• Two selectable alarm limits;

• Five selectable logging modes: Automatic logging with and without AutoHold feature, Manual logging with

or without AutoHold and AutoHold logging mode;

• Up to 100 logging lots;

• Selectable log interval and log sampling features for Automatic logging;

• GLP feature;

• Online and offline graph;

• User-friendly interface on large B/W graphic LCD (320x240 pixels);

• PC interface via RS232, and USB.

Page 5

5

HI 4211 DESCRIPTION

FRONT PANEL

REAR PANEL

1) Liquid Crystal Display (LCD)

2) Main Keyboard

3) USB connector

4) ON/OFF switch

5) Power adapter socket

6) RS232 serial communication connector

7) Temperature probe socket

8) BNC electrode connector for pH/ORP measurements

9) Reference input socket

FUNCTIONAL DESCRIPTION

Page 6

6

HI 4212 DESCRIPTION

FRONT PANEL

REAR PANEL

1) Liquid Crystal Display (LCD)

2) Main Keyboard

3) USB connector

4) ON/OFF switch

5) Power adapter socket

6) RS232 serial communication connector

7) Temperature probe socket (Channel 2)

8) BNC electrode connector for pH/ORP/ISE measurements (Channel 2)

9) Reference input socket (Channel 2)

10) Temperature probe socket (Channel 1)

11) BNC electrode connector for pH/ORP/ISE measurements (Channel 1)

12) Reference input socket (Channel 1)

Page 7

7

KEYBOARD DESCRIPTION

FUNCTION KEYS

VIRTUAL KEYS

The upper row keys are assigned to the virtual keys placed on the bottom of the LCD, which allow you to

perform the displayed function, depending on the current menu (e.g.

, and in

Measure mode).

Note: All the virtual keys are assigned to the focused channel (HI 4212 only).

LCD GENERAL DESCRIPTION

To enter/exit calibration mode.

To select the desired measurement mode, pH, mV, Rel mV (or ISE – HI 4212 only).

To enter Setup (System, pH, mV or ISE) and to access Log Recall function.

To obtain general informations about the selected option/operation.

Page 8

8

SPECIFICATIONS

1124IH 2124IH

EGNAR

– Hp000.02ot000.2

± Vm0.0002

– 01*1

6–

01*99.9ot

01

.cnoc

– /Cº0.021ot0.02 – K51.393ot51.352/Fº0.842ot0.4

NOITULOSER

Hp100.0/Hp10.0/Hp1.0

Vm1.0

–

.c

noc100.0/.cnoc10.0/.cnoc1.0/.cnoc1

K1.0/Fº1.0/Cº1.0

YCARUCCA

Fº86/Cº02@

± Hp1.0

± Hp10.0

± Hp200.0 ± DSL1

± Vm2.0 ± DSL1

–

± )snoitnelavonom(%5.0

± )snoitnelavid(%1

± /Cº2.0 ± /Fº4.0 ± K2.0

egnartesffoVmevitaleR ± Vm0.0002

noitarbilaCHp

elbaliavasreffubdradnats8,noitarbilactniop-evifotpU

,10.7,68.6,10.4,00.3,86.1( 54.21,10.01,81.9 ,) sreffubmotsuc5dna

noitarbilaCESI –

,noitarbilactniop-evifotpU

elbaliavasnoitulosdradnatsdexif5

,tinutnemerusaemhcaerof

snoitulosmotsuc5dna

slennahctupnI 1 2

noitasnepmocerutarepmeT

morfcitamotuArolaunaM

– /Cº0.021ot0.02 – K393ot352/Fº0.842ot0.4

edortcelEHp B1311IH

eborperutarepmeT T-2667IH

ecafretniCP BSUdna232SRdetalosi-otpo

ecnadepmitupnI 01

21

smho

ylppusrewoP retpadaCDV21

snoisnemiD )”7.3x1.9x3.6(mm49x132x061

thgieW )bl6.2(gK2.1

tnemnorivnE

K323–372/Fº221–23/Cº05–0

gnisnednoc-nonHR%59.xam

ytnarraW sraey2

Page 9

9

POWER CONNECTION

Plug the 12 VDC adapter into the power supply socket.

Notes: • These instruments use non volatile memory to retain the pH, Ion calibrations and all other

settings, even when unplugged.

• Make sure a fuse protects the main line.

ELECTRODE AND PROBE CONNECTIONS

For pH or ORP measurements connect a pH/ORP electrode with internal reference to the BNC connector

located on the rear panel of the instrument (for the desired channel – HI 4212 only).

For ISE measurements (HI 4212 only) connect, to the desired channel, an ISE electrode with internal

reference to the BNC connector located on the rear panel of the instrument.

For electrodes with a separate reference connect the electrode’s BNC to the BNC connector and the electrode’s

reference to the reference input socket.

For temperature measurements and automatic temperature compensation connect the temperature probe to the

appropriate socket (for the desired channel – HI 4212 only).

INSTRUMENT START UP

• Turn the instrument on from the power switch located on the rear panel of the instrument.

• Please wait until the instrument finishes the initialization process.

Note: It is normal for the loading process to take a few seconds. If the instrument doesn’t display the next

screen, restart the meter using the power switch. If the problem persists, contact your dealer.

OPERATIONAL GUIDE

Page 10

10

CHANNEL SELECTION (HI 4212 only)

• Press

while in Measure mode to access channel

selection menu. Four available options will be displayed:

Channel 1, Channel 2, or multi-channel with the first or the

second channel focused. The “Choose Channel Configuration”

message is displayed in the Reminder messages area.

• Select the desired option by pressing the appropriate key:

,

, or . The instrument will enter in the

selected option Measure mode.

Page 11

11

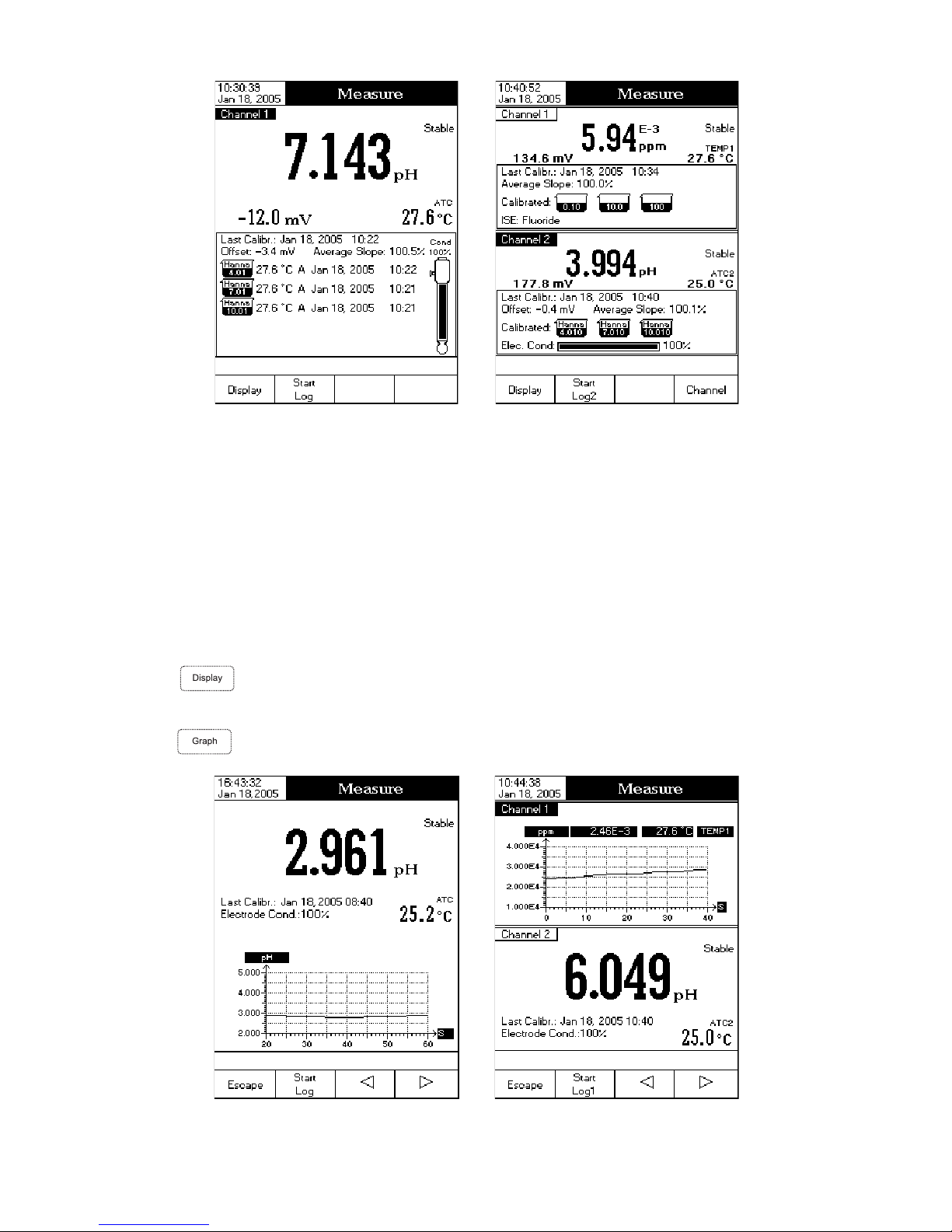

DISPLAYING MODES

For each measurement mode (pH, mV, Rel mV or Ion) the following display configurations are available:

Basic, Good Laboratory Practice (GLP), Graph and Log History.

Basic

Accessing this option, the measured value and its units are displayed on the LCD, along with the temperature

value, temperature compensation mode, and GLP data.

To choose the Basic displaying mode:

• Press

while in Measure mode. The “Choose Display Configuration” message will be displayed in

the Reminder messages area.

• Press

. The instrument will display the basic information for the selected measurement mode.

GLP

Accessing this option, detailed GLP data will be displayed on the LCD for pH Measure and ISE Measure modes

only: Last Calibration date and time, Offset and Slope values, Calibration Buffers/Standards and general

information regarding the buffers/standards: the calibration temperature, temperature compensation mode,

date and time. For pH Measure, the Electrode Condition is also displayed on the LCD in percent.

Note: If only a one-point pH calibration is performed or the current calibration does not include at least two consecutive

standard buffers of pH 4.01, 7.01 (6.86) and 10.01 (9.18) buffers, the Electrode Condition will be unknown.

To access the GLP displaying mode:

• Press

while in Measure mode. The “Choose Display Configuration” message will be displayed in

the Reminder messages area.

• Press . The instrument will display the detailed GLP data.

Page 12

12

Graph

Accessing this option, the online graph with currently logged values (pH, mV, Rel mV, or ISE vs. Seconds) will

be displayed.

If there is no active log, the previously logged data for the selected parameter will be plotted.

Notes: • If no data were logged, the graph displaying mode will not be accessible.

• If no automatic log is saved, the offline graph will not be available.

To access the offline / online graph:

• Press

while in Measure / Logging mode. The “Choose Display Configuration” message will be

displayed in the Reminder messages area.

• Press

.

Page 13

13

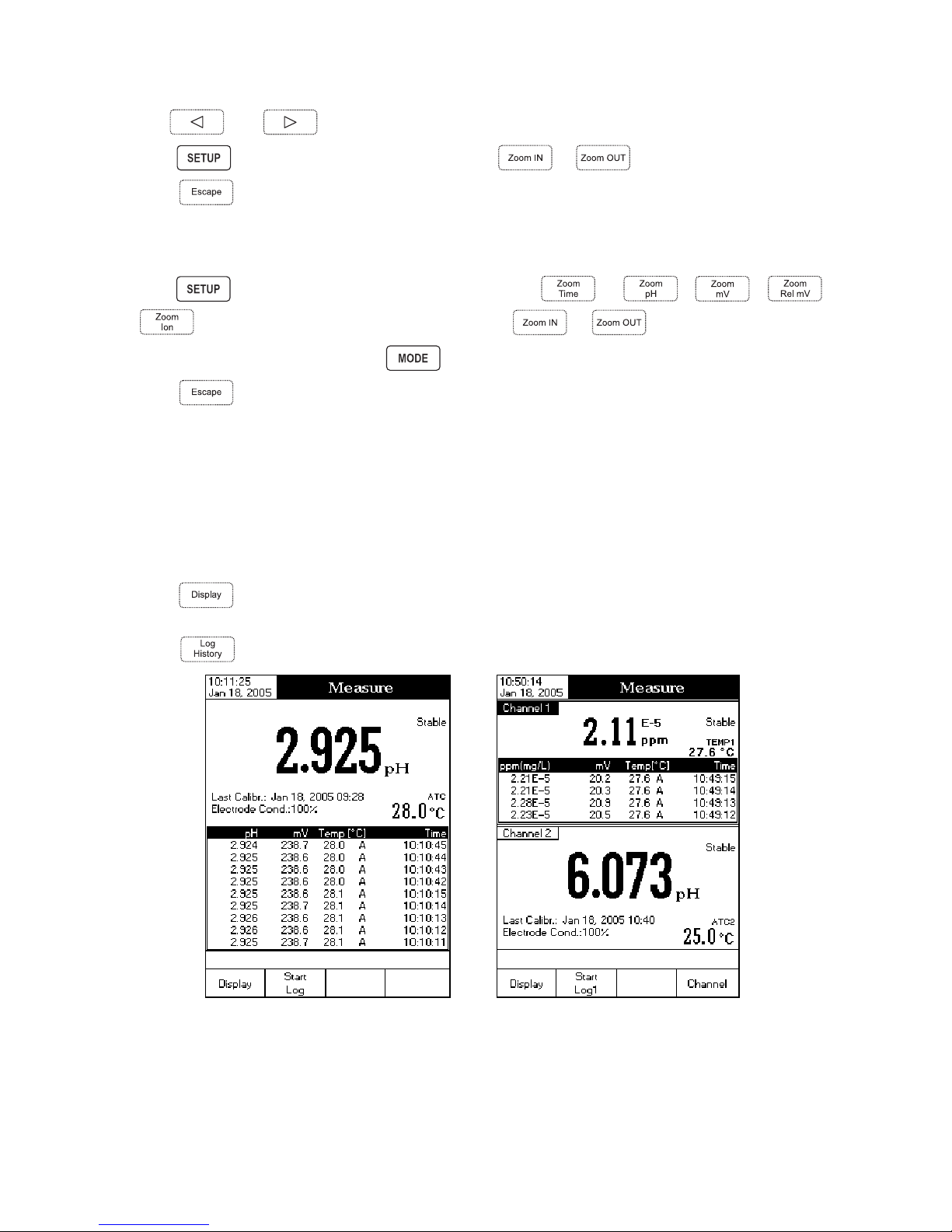

When the online graph is displayed:

•Use

and to move the graph along X (Time) axis.

• Press to access the zoom menu for Y axis. Use or for zooming Y (parameter) axis.

• Press

to return to the main menu.

When the offline graph is displayed:

• Use the arrow keys to move the graph along X (Time) and Y (parameter) axes.

• Press

to access the zoom menu for X and Y axes. Use , or / / /

to switch between the active zooming axes. Press or to zoom the selected axis.

Note: While in zoom graph menu the key is not accessible.

• Press

to return to the main menu.

Log History

Accessing this option, last logged records will be displayed on the LCD. The log history list also contains the appropriate

mV values, the logged temperature, the temperature compensation source, as well as the records time stamp.

Note: If no data were logged, the “Log History Empty” message will be displayed on the LCD.

To access the Log History displaying mode:

• Press

while in Measure mode. The “Choose Display Configuration” message will be displayed in

the Reminder messages area.

• Press . The instrument will display the log history regarding the selected Measure mode.

Notes: • When an alarm condition is active, all logged records will have an exclamation mark (!).

• If another Measure mode is selected, the Log History will reset.

• If the temperature unit is changed, all logged temperature values will be automatically displayed

in the new temperature unit.

Page 14

14

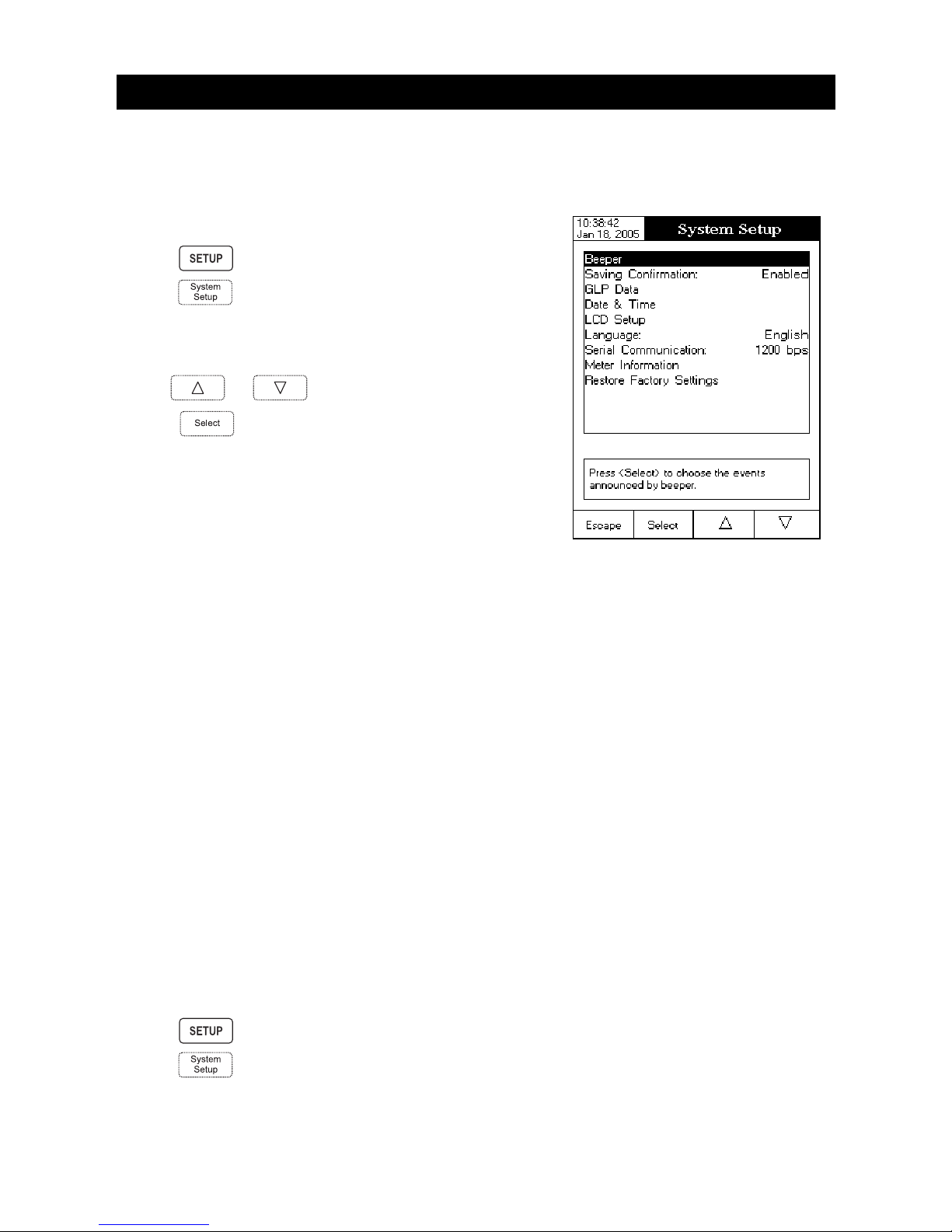

SYSTEM SETUP

The System Setup menu allows the user to customize the user interface, consult the meter information, set the

external serial communication interface and to restore the manufacturer settings.

Accessing System Setup

• Press

while in Measure mode.

• Press

. The system setup options will be displayed on

the LCD.

To access a System Setup option:

• Use

or to highlight the desired option.

• Press

to access the selected option.

The following is a detailed description of the System Setup option

screen.

Beeper

This option allows the user to enable or disable the beeper. When the beeper is enabled, a specific beep will

be heard when the reading becomes stable, when an alarm condition is reached, when pressing a key or if

a wrong key is pressed.

Stability Indicator

When the reading becomes stable, the instrument delivers a medium beep only if this option is ON, along with the

“Stable” indicator on the LCD.

Alarm

If this option is ON, a continuous double beep will be heard each time the set limits in Measure mode are

exceeded, along with the “Alarm” indicator on the LCD.

Key Pressed

If this option is ON, a short beep will be heard each time a valid key is pressed.

Wrong Key

If this option is ON, a long beep will be heard when an incorrect key is pressed.

To set the Beeper:

• Press

while in Measure mode.

• Press

.

Page 15

15

• Use

or to select the Beeper option.

• Press

and use or to highlight the

desired beeper status option you want to modify.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection and return to the Beeper

menu or press

to return to the Beeper menu without

changing.

Saving Confirmation

When enabling this option, a prompt will appear on the LCD alerting the user to save the modified values by

pressing

, exiting without saving by pressing or canceling the saving operation and return to the

editing mode by pressing

. If disabled, the modified values will be saved automatically.

To modify the Saving Confirmation option:

• Press

while in Measure mode.

• Press

.

•Use

or to select the Saving Confirmation option.

• Press

and use or to highlight the

desired Saving Confirmation option.

• Press

to confirm your selection or press to

cancel operation.

GLP Data

This option allows the user to set general information which will appear in the log reports. The options are

available for both channels (HI 4212 only) and can have a max of 10 characters.

Operator ID – this option allows you to edit the name of the operator.

Instrument ID – this option allows you to edit an identification name/number for the instrument.

Company Name – this option allows you to edit the company name.

Additional Info 1 & Additional Info 2 – for general purpose notations.

Page 16

16

To set the GLP Data:

• Press

while in Measure mode.

• Press

.

• Use

or to select the GLP Data option.

• Press

and use or to highlight the

desired option.

• Press

to edit the desired information. The Text Editor menu

will be displayed on the LCD.

• Enter the desired information by accepting the highlighted character

which is added to the text bar, using

. The and

keys help the user select the desired character. It is also

possible to delete the last character by positioning the cursor on the

Backspace character (

) and pressing .

• Press

to return to the GLP Data options. If the Saving Confirmation is enabled, press to accept

the modified option,

to escape without saving or to return to the editing mode. Otherwise,

the modified options are saved automatically.

Date & Time

This option allows the user to set the current date & time and the format in which they appear. These parameters

will be displayed on the Measure screens and also when storing measured data.

Set Date and Time

This option allows you to set the current date (year/month/day) and time (hour/minute/second).

Notes: • Only years starting with 2000 are accepted.

• The time is set using the selected time format. For 12 Hour time format only, the AM/PM can also

be selected with

or .

Set Time Format

This option allows you to choose between 12 Hour (AM/PM) time format and 24 Hour time format from the

displayed pop-up menu.

Set Date Format

This option allows you to choose the desired date format from 6 available options: DD/MM/YYYY; MM/DD/YYYY;

YYYY/MM/DD; Mon DD, YYYY; DD-MM-YYYY and YYYY-Mon-DD.

To set the Date & Time:

• Press

while in Measure mode.

• Press

.

Page 17

17

• Use

or to select the Date& Time option.

• Press

and use or to highlight the

desired option you want to modify.

• Press

to confirm your selection. Use /

to select next/previous entry to be edit. Press and use

or to set the desired value, then press

to save the modified value (for Set Date and Time option). For

the other two options press

to confirm your selection

and select one of the displayed options with

or .

• Press

to confirm your selection and return to the Date &

Time options.

• Press

to return to Date & Time options (for Set Date and Time option only). If the Saving Confirmation

is enabled, press

to accept the modified option, to escape without saving or to

return to the editing mode. Otherwise, the modified option is saved automatically.

Note: If the time is changed with more than one hour before last pH/ION calibration, a pop-up warning will

appear on the LCD, notifying the user that a date/time conflict has occured and some time-dependent

modes could work improperly (e.g. Measure, GLP, Log).

LCD Setup

This option allows the user to set the Contrast, the Backlight of the LCD and the Backlight Saver. The Contrast

parameter can be adjusted within 7 steps, while the Backlight parameter within 4 steps. The Backlight Saver can

be set from 1 to 60 minutes or it can be OFF (disabled). All the changes are visible on the LCD for each parameter.

Note: If the instrument backlight is turned off after the set period of time, press any key to turn it back on.

To set the LCD Setup:

• Press

while in Measure mode.

• Press

.

• Use

or to select the LCD Setup option.

• Press

and use key to highlight the desired parameter.

• Use or to adjust the contrast / backlight or to

set the desired backlight saver time.

• Press

to confirm the modified options and return to the

System Setup menu.

Page 18

18

Language

This option allows the user to choose the desired language in which all information will be displayed.

To select the Language:

• Press

while in Measure mode.

• Press

.

• Use

or to select the Language option.

• Press

and use or to highlight the

desired language.

• Press

to confirm your selection and return to the System

Setup menu or press

to return to the System Setup

menu without changing.

Note: After selecting the desired language, a warning pop-up is

displayed on the LCD, informing the user that the selected

language becomes the current language only after restarting

the instrument.

Serial Communication

This option allows the user to set the desired speed for the serial communication (baud rate) between the

instrument and PC. The meter and the PC program must have the same baud rate.

To set the Serial Communication:

• Press

while in Measure mode.

• Press

.

• Use

or to select the Serial Communication

option.

• Press

and use or to highlight the

desired baud rate.

• Press

to confirm your selection and return to the System

Setup menu or press

to return to the System Setup

menu without changing.

Meter Information

This option provides general information about the instrument serial number (each instrument has an unique identification

serial number), the software version and the factory calibration date and time (for mV and temperature).

Page 19

19

Note: All the instruments are factory calibrated for mV and temperature. After one year following factory

calibration, the “Factory Calibration Due” message will appear on the LCD, in the Reminder messages

area, notifying the user that the instrument should be taken to the nearest Hanna Customer Service for

factory calibration.

To view the Meter Information:

• Press

while in Measure mode.

• Press

.

• Use

or to select the Meter Information option.

• Press

to confirm your selection and to view the Meter

Information or press

to return to the System Setup

menu.

Restore Factory Settings

This option allows the user to reset the instrument to the default factory settings.

To restore the Factory Settings:

• Press

while in Measure mode.

• Press

.

• Use

or to select the Restore Factory Settings

option.

• Press

to confirm your selection. A pop-up menu will be

displayed, asking for confirmation.

• Press

to confirm your selection and return to the System

Setup or press

to return to the System Setup menu

without restoring defaults.

• Press to return to Measure mode.

Page 20

20

The pH Setup menu allows the user to set the parameters associated with pH measurement and calibration.

These parameters can be set specifically for each channel (HI 4212 only). The settings will be applied only

to the active channel.

Accessing pH Setup

• Press

while in Measure mode and then to

select pH range for the desired channel.

• Press

and then to access pH Setup menu.

To access a pH Setup option:

• Use

or to highlight the desired option.

• Press

to access the selected option.

The following is a detailed description of the pH Setup option

screens.

Temperature

The temperature has a direct influence on pH. This option allows the user to choose the temperature source and

units, as well as the desired manual temperature for manual temperature compensation mode.

Temperature Source (HI 4212 only)

If using a temperature probe, Automatic Temperature Compensation will be performed relative to the displayed

temperature, with the “ATC” indicator displayed on the LCD. For HI 4212 only, the ATC option can be selected for

Channel 1 or Channel 2, in accordance with the active channel utilizing a probe, or for both channels if two

temperature probes are used. If no temperature probe is detected, Manual Temperature Compensation will be

performed, with the “MTC” indicator on the LCD.

Temperature Unit

Accessing this option, the desired temperature unit can be chosen (Celsius, Fahrenheit or Kelvin degrees) and the

meter will automatically make the conversion for the selected unit.

Manual Temperature

If no temperature probe is connected, the desired temperature can be set manually. The default setting is 25°C.

If the measured temperature is different, the value can be manually adjusted in order to obtain an accurate pH

reading.

pH SETUP

Page 21

21

To set one of the Temperature options:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Temperature option.

• Press

and use or to highlight the

desired Temperature option you wish to modify.

• Press

and use or to highlight the

desired option (for Temperature Source & Unit options) or use

or to adjust the temperature value between

the displayed limits (for Manual Temperature option).

• Press

to confirm your selection (for Temperature Source &

Unit options) or press

to save the current value (for Manual

Temperature option). Otherwise, press

to cancel operation.

Calibration

This option allows the user to set all the data regarding the pH calibration process.

Buffer Entry Type

Three entry modes for the pH buffers used for calibration are available:

Automatic

– the instrument automatically selects the closest buffer to the measured pH value from the edit buffer group.

Semiautomatic – the instrument automatically selects the closest buffers to the measured pH value from all

available buffers and you can choose the one used.

Manual Selection – the desired pH buffer is manually selected from all available buffers, regardless of measured value.

To set the Buffer Entry Type:

• Press while in pH Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the

Buffer Entry Type option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Page 22

22

1st Cal. Point

Two options are available for the 1st Cal. Point parameter: Point and Offset.

If Point option is selected, the slope values adjacent to the calibration points will be reevaluated (normal calibration).

If at least a two-point calibration has been performed and an offset correction of the electrode is wanted

(maintaining the existing slope values), perform a one-point calibration using the Offset option.

To set the 1st Cal. Point:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the 1st

Cal. Point option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Edit Custom Buffers

If you want to use other buffers than the ones already memorized, the Edit Custom Buffers option is available,

allowing you to set the desired pH buffers. Up to five pH custom buffers can be set.

To edit/set the Custom Buffers:

• Press while in pH Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the Edit

Custom Buffers option.

• For a previous set value, press to set the custom buffer value

to “----” if desired and confirm the setting by pressing

,

otherwise press

to edit the selected custom buffer.

• While in edit custom buffer menu press

to set the custom

buffer value to 7.000 pH and then use

or to set

the desired custom buffer value.

Page 23

23

• Press

to exit custom buffer edit menu. If the Saving Confirmation is enabled, press to accept

the modified option,

to escape without saving or to return to the editing mode. Otherwise,

the modified option is saved automatically.

• Use

key to select the next custom buffer to be set or press to return to Calibration options.

Edit Buffer Group

Accessing this option the user can edit the desired group of five pH buffers for automatic buffer recognition

(Automatic Buffer Entry Type). If the Buffer Group already contains five pH buffers, at least one pH buffer has to

be removed in order to add another buffer.

To edit/set the Buffer Group:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the Edit

Buffer Group option.

• Press

and use and to choose the pH

buffer to be included in the buffer group.

• Press

or to add/remove the selected pH buffer

to/from the buffer group.

• Press

to return to Calibration options and to save the changes.

Calibration Reminder

In order to have accurate readings, the instrument must be calibrated frecquently. Three options are available for

the calibration reminder: Daily, Periodic or Disabled.

To set the Calibration Reminder:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Calibration option.

• Press

and use or to highlight the

Calibration Reminder option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Page 24

24

Set Reminder Period

If choosing Daily or Periodic options for the Calibration Reminder, the Set Remind Period must be accessed in order to set

the time interval until next calibration. The time interval between two calibrations can be set up to 1 day / 1 year for

Daily / Periodic options.

Note: If Set Reminder Period parameter is accessed and the Calibration Reminder is disabled, a warning

message appears on the LCD informing the user that the reminder period can be set only if the Calibration

Reminder is set as Daily or Periodic.

To set the Reminder Period:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Calibration option.

• Press

and use or to highlight the Set

Reminder Period option.

• Press

and use / to select next/previ-

ous entry to be edit.

• Press

and use or to set the desired

value, then press

to save the modified value.

• Press

to return to the Calibration options. If the Saving Confirmation is enabled, press to

accept the modified option,

to escape without saving or to return to the editing mode.

Otherwise, the modified option is saved automatically.

Clear Calibration

Accessing this option, the existent pH calibration relative to the selected channel can be cleared. If the calibration

is cleared, another calibration has to be performed.

To clear Calibration:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the

Clear Calibration option.

• Press

to clear calibration. A pop-up menu will be

displayed asking for confirmation.

• Press

to confirm or press to escape without

saving and return to the Calibration options.

Page 25

25

Sample ID

This option allows the user to give to the measured samples an identification number/name. Two Sample ID

options are available: ID Increment Mode and Edit Sample ID.

ID Increment Mode

Two increment modes for the sample ID can be selected:

None

– the sample ID will be fixed and it can be set alphanumerically.

Automatic

– the sample ID will be increased with 1 from the set value, for each new log lot.

To set the ID Increment Mode:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Sample ID option.

• Press

and use or to highlight the ID

Increment Mode option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Edit Sample ID

This option allows the user to edit the sample ID.

Note: If the ID Increment Mode is set to None, the sample ID can be set alphanumerically, otherwise it can be

set only numerically.

To edit the Sample ID:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Sample ID option.

• Press

and use or to highlight the Edit

Sample ID option.

• Press

to confirm your selection.

• If the selected increment mode is None, the Text Editor menu will be

displayed on the LCD, allowing you to enter the desired sample

number/name by accepting the highlighted character which is added

in the text bar, using

. The and keys help

Page 26

26

the user to select the desired character. It is also possible to delete the last character by positioning the cursor on

the Backspace character and pressing

.

• Press

to return to Sample ID options. If the Saving

Confirmation is enabled, press

to accept the modified

option,

to escape without saving or to

return to the editing mode. Otherwise, the modified options

are saved automatically.

• If the selected increment mode is Automatic, the desired sample ID

value can be set using or .

• Press

to save the current value or press to

cancel operation.

Stability Criteria

This option allows the user to select the signal stability criterion for the measured parameter (pH, mV, ISE):

Fast – this criterion will give faster results with less accuracy.

Medium – this criterion will give medium speed results with medium accuracy.

Accurate – this criterion will give slower results with high accuracy.

To set the Stability Criteria:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Stability Criteria option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Reading Mode

This option allows the user to select between Direct and Direct/AutoHold pH reading mode. If choosing the second

option, the current reading can be frozen on the LCD when

is pressed and if the stability criterion is reached.

Page 27

27

To set the Reading Mode:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Reading Mode option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Log

This option allows the user to edit the logging settings: Logging Type, Logging Data Configuration, Sampling Period

and New Lot.

Logging Type

Three logging types are available: Automatic, Manual and AutoHold. With the Automatic type the values are

logged automatically at constant time intervals while with the Manual type the user has the capability to log a

measured value by pressing

. With the AutoHold type the stored values are only the ones frozen on the LCD

after the logging session was started.

To set the Logging Type:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Log option.

• Press

and use or to highlight the

Logging Type option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Logging Data Configuration

This option allows the user to select the parameters that accompany a logged value: Date/Time/Channel,

Calibration Data, Sample ID, Instrument ID, Operator ID, Company Name, Aditional Info 1 and Aditional Info 2.

Page 28

28

To set the Logging Data Configuration:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Log option.

• Press

and use or to highlight the

Logging Data Configuration option.

• Press

and use or to highlight the desired

parameter to be logged in file.

• Press

to confirm your selection and use or

to enable the parameter by selecting Yes or to disable

it by selecting No.

• Press

to confirm your selection or press to cancel operation.

Sampling Period

This option allows the user to select the desired sampling period for automatic logging type.

To set the Sampling Period:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Log option.

• Press

and use or to highlight the

Sampling Period option.

• Press

and use or to select the desired

option.

• Press

to confirm your selection or press to

cancel operation.

New Lot

Accessing this option, a new manual lot can be generated next time you want to manually log a measured value.

Note: If New Lot option is accessed and the Logging Type is Automatic, a warning message appears on the LCD

informing the user that a new lot can be created only if the Logging Type is set as Manual.

To generate a New Lot:

• Press while in pH Measure mode.

• Press

.

Page 29

29

• Use

or to select the Log option.

• Press

and use or to highlight the

New Lot option.

• Press

to generate a new manual lot. A pop-up menu

will be displayed asking for confirmation.

• Press

to confirm or press to escape without

saving and return to the Log options.

Alarm

This option allows the user to edit the alarm settings: Alarm State and Alarm Limits. If the Alarm option is enabled,

a continuous double beep will be heard, along with the “Alarm” indicator blinking on the LCD, each time the set

limits in Measure mode are exceeded.

Alarm State

Three modes are available for the Alarm State option:

Disabled – the alarm will be disabled.

Inside Limts – the alarm will notify the user when the measured value is inside the set limits.

Outside Limits – the alarm will notify the user when the measured value is outside the set limits.

To set the Alarm State:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Alarm option.

• Press

and use or to highlight the

Alarm State option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Alarm Limits

This option allows the user to set the alarm limits for the measured value.

Note: The Alarm High value can not be lower than the Alarm Low value.

Page 30

30

To set the Alarm Limits:

• Press

while in pH Measure mode.

• Press

.

• Use or to select the Alarm option.

• Press

and use or to highlight the

Alarm Limits option.

• Press

and use / to select next/previous

entry to be edit.

• Press

and use or to set the desired

value, then press

to save the modified value.

• Press

to return to the Alarm options. If the Saving

Confirmation is enabled, press

to accept the modified

option,

to escape without saving or to return

to the editing mode. Otherwise, the modified option is saved

automatically.

Isopotential Point

This option allows the user to edit the isopotential point of the electrode used for pH measurements. The isopotential point

is the mV reading for an electrode at which temperature has no effect on the measurement. The ideal electrode has an

isopotential point of 0.0 mV and 7.00 pH, while an actual electrode tipically deviates slightly from the ideal values.

If the actual isopotential pH for an electrode is known, it can be set by accessing this option. The isopotential pH

limits (low and high) will be displayed on the LCD.

Note: If the isopotential point has been modified, recalibration

must be performed for the respective channel.

To set the Isopotential Point:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the Isopotential Point option.

• Press

and set the desired isopotential pH value using

or .

• Press

to save the current value or press to

cancel operation.

Page 31

31

pH Resolution

Accessing this option, the desired pH resolution can be set, with one (x.x), two (x.xx) or three (x.xxx) decimals.

To set the pH Resolution:

• Press

while in pH Measure mode.

• Press

.

• Use

or to select the pH Resolution option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Page 32

32

mV SETUP

The mV Setup menu allows the user to set the parameters associated with mV and Relative mV

measurements. These parameters can be set specifically for each channel (HI 4212 only). The settings will

be applied only to the active channel.

Accessing mV Setup

• Press

while in Measure mode and then or

to select mV / mV Rel range for the desired channel.

• Press

and then to access mV Setup menu.

To access a mV Setup option:

• Use

or to highlight the desired option.

• Press

to access the selected option.

The following is a detailed description of the mV Setup option

screens.

Temperature – See pH Setup section, page 20.

Note: To access mV Setup, press

and then .

Sample ID – See pH Setup section, page 20.

Stability Criteria – See pH Setup section, page 20.

Reading Mode – See pH Setup section, page 20.

Log – See pH Setup section, page 20.

Alarm – See pH Setup section, page 20.

Note: The Alarm Limits (Low and High) are set in mV units.

Page 33

33

ISE SETUP (HI 4212 only)

The ISE Setup menu allows the user to set the parameters regarding ISE measurement and calibration.

These parameters can be set specifically for each channel. The settings will be applied only to the active

channel.

Accessing ISE Setup

• Press

while in Measure mode and then to

select ISE range for the desired channel.

• Press

and then to access ISE Setup menu.

To access an ISE Setup option:

• Use

or to highlight the desired option.

• Press

to access the selected option.

The following is a detailed description of the ISE Setup option

screens.

Reading Mode

This option allows the user to select the desired reading mode: Direct, Direct/AutoHold, Known Addition, Known

Subtraction, Analyte Addition and Analyte Subtraction. Except Direct and Direct/AutoHold, all the other methods

are incremental (see ISE Theory section for details, page 54).

Direct

If using Direct reading mode, the ion concentration can be read directly from the instrument. Make sure the

instrument was calibrated before taking measurements.

Direct/AutoHold

If using Direct/AutoHold reading mode, the ion concentration can be frozen on the LCD after starting the AutoHold

mode.

Known Addition

In the Known Addition method a standard with a known concentration of the measured ion is added to the sample. The

difference in mV potential is then used to calculate the concentration of the ion in the sample.

Known Subtraction

In the Known Subtraction method a standard with a known concentration is added to the sample, reacting with the

ion to be measured. The stoichiometric ratio between standard and sample must be known. The ion concentration

is then calculated using the difference in mV potential.

The method is especially usefull when there is no available ISE for the measured ion.

Page 34

34

Analyte Addition

This method is similar to the Known Addition method, with the difference that an aliquot of sample is added to a

standard of known concentration. The sample and standard contain the same ion to be measured. The ion

concentration is then calculated using the difference in mV potential.

Analyte Subtraction

In the Analyte Subtraction method an aliquot of sample is added to a standard of known concentration, reacting

with the ion to be measured. The stoichiometric ratio between standard and sample must be known. The ion

concentration is then calculated using the difference in mV potential. The method is especially usefull when there

is no available ISE for the measured ion.

To set the Reading Mode:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Reading Mode option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Temperature – See pH Setup section, page 20.

Notes: • To access ISE Setup, press

and then .

• The Temperature Compensation option is also included in the Temperature parameter.

Temperature Compensation

This option allows the user to enable / disable the temperature

compensation for the measurement of Ion concentration.

To set the Temperature Compensation:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Temperature option.

• Press

and use or to highlight the

Temperature Compensation option.

• Press

and use or to enable / disable

the Temperature Compensation.

Page 35

35

• Press

to confirm your selection or press to cancel operation.

Note: If an ISE calibration was performed and the Temperature Compensation option is changed, a warning

message appears on the LCD informing the user to perform a new calibration or to set the previous option

in order to perform accurate measurements.

Calibration

This option allows the user to set all the data regarding the Ion calibration process.

Standard Entry Type

Two entry modes for the standard solutions used for calibration are available:

Manual Selection

– when the calibration is started, the desired standard solution can be manually selected from

a standard solutions list (0.1 ppm, 1 ppm, 10 ppm, 100 ppm and 1000 ppm).

Custom Standard

– when the calibration is started, each standard solution can be manually set (in ppm units) in

a displayed pop-up menu.

To set the Standard Entry Type:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Calibration option.

• Press

and use or to highlight the

Standard Entry Type option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Calibration Reminder – See Calibration option from pH Setup section, page 20.

Set Reminder Period – See Calibration option from pH Setup section, page 20.

Clear Calibration – See Calibration option from pH Setup section, page 20.

Electrode Type

This option allows the user to select the desired Ion Selective Electrode used for measurements from a list:

Ammonia, Bromide, Cadmium, Calcium, Carbon Dioxide, Chloride, Chlorine, Cupric, Cyanide, Fluoride, Iodide,

Lead, Nitrate, Potassium, Silver, Sodium, Sulfate, Sulfide and five custom ISE. For the standard ISE it is possible

to view the Ion constants (Name, Molar Weight and Electric Charge/Slope), while for the custom ISE all these

constants can be manually set.

Page 36

36

To set the Electrode Type:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Electrode Type option.

• Press

and use or to select the desired

standard ISE or a custom one from the list.

For standard ISE:

• Press

to visualize the Ion constants and then press

at any time to exit Ion Constants view mode.

• Press

to confirm your selection and return to ISE

Setup options.

For custom ISE:

• Press

to edit the Ion constants for the selected

custom ISE. Use

or to select the desired

Ion constant and press

to enter Ion constant edit

mode or

to cancel operation.

• For the Ion name the Text Editor menu will be displayed

on the LCD. Enter the desired information by accepting

the highlighted character which is added in the text bar,

using

. The and keys help the

user to select the desired character. It is also possible to

delete the last character by positioning the cursor on the

Backspace character and pressing

. Press

to return to the Ion Constants menu. If the Saving

Confirmation is enabled, press

to accept the

modified option,

to escape without saving or

to return to the editing mode. Otherwise, the

modified option is saved automatically.

• To set the appropriate Ion molar weight (in g/mol units)

use or and then press to save

the current value or press

to cancel operation.

Page 37

37

• To select the appropriate Electric Charge/Slope use

or and then press . If the Ion

electric charge is None, its slope can be manually set by

pressing

. A pop-up menu will be displayed on

the LCD, in which the slope value can be set using

or . Press to save the modified value or

press

to return to the Ion Constants menu.

Note: If an ISE calibration was performed and a different Ion

Selective Electrode is selected (standard or custom), a

warning message appears on the LCD informing the user to

perform a new calibration or to select the previous ISE in

order to perform accurate measurements.

Concentration Unit

Accessing this option, the user can select the desired concentration unit for the measured ion or chemical compound.

The available concentration units are: ppt (g/L), ppm (mg/L), ppb (μg/L), mg/mL, M (mol/L), mmol/L and %w/v.

To set the Concentration Unit:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Concentration Unit option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Sample ID – See pH Setup section, page 20.

Stability Criteria – See pH Setup section, page 20.

Log – See pH Setup section, page 20.

Note: The Logging Data Configuration option includes also the Ion Constants parameter. If you want it to appear

in the log reports, it must be enabled.

Alarm – See pH Setup section, page 20.

Note: The Alarm Limits (Low and High) are set in the selected concentration unit of the measured ion or chemical

compound and are displayed in a scientific format (value and value exponent).

Page 38

38

Isopotential Point

This option allows the user to edit the isopotential point of the electrode used for ion measurements. The ion

selective electrodes have different isopotential points. If temperature compensation is desired for the ion

measurements, the isopotential point value is absolutely necessary.

The isopotential point is always edited in ppm (mg/L) units.

To set the Isopotential Point:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the Isopotential Point option.

• Press

and use or to increase / decrease

the isopotential point value.

• Press

key to save the modified value.

• Press

to return to the Ion Setup options. If the Saving

Confirmation is enabled, press

to accept the modified option,

to escape without saving or to return to the editing

mode. Otherwise, the modified option is saved automatically.

Note: If an ISE calibration was performed and the Isopotential Point option is changed, a warning message

appears on the LCD informing the user to perform a new calibration or to set the previous option in order

to perform accurate measurements.

ISE Significant Digits

Accessing this option, the number of ISE significant digits can be set, with one (x), two (xx) or three (xxx)

significant digits.

To set the ISE Significant Digits:

• Press

while in ISE Measure mode.

• Press

.

• Use

or to select the ISE Significant Digits

option.

• Press

and use or to highlight the

desired option.

• Press

to confirm your selection or press to

cancel operation.

Page 39

39

pH CALIBRATION & MEASUREMENTS

pH CALIBRATION

Calibrate the instrument often, especially if high accuracy is required.

The instrument should be recalibrated:

• Whenever the pH electrode is replaced.

• At least once a week.

• After testing aggressive chemicals.

• When “No pH Calibration” or “pH Calibration Expired” message appears on the LCD, in the Reminder messages area.

PREPARATION

Pour small quantities of the buffer solutions into clean beakers. If possible, use plastic beakers to minimize

any EMC interferences.

For accurate calibration and to minimize cross-contamination, use two beakers for each buffer solution. One

for rinsing the electrode and one for calibration.

If you are measuring in the acidic range, use pH 7.01 or 6.86 as first buffer and pH 4.01/3.00 or 1.68 as

second buffer. If you are measuring in the alkaline range, use pH 7.01 or 6.86 as first buffer and pH 10.01/

9.18 or 12.45 as second buffer.

For extended range measurements (acidic and alkaline), perform a five-point calibration by selecting five of

the available buffers.

CALIBRATION PROCEDURE

Calibration has a choice of 8 memorized buffers: pH 1.68, 3.00, 4.01, 6.86, 7.01, 9.18, 10.01, 12.45 and

up to 5 custom buffers.

For accurate measurements it is recommended to perform a five-point calibration. However, at least a two-point

calibration is suggested.

pH Calibration screen description

Page 40

40

Three buffer entry types are available: Automatic, Semiautomatic and Manual Selection. The default option is

Manual Selection.

To calibrate the instrument using Manual Selection buffer entry type:

• Press

. If the instrument was calibrated before and calibration was not cleared, the old calibration

can be cleared by pressing

. After 10 seconds, will no longer be available.

Note: It is very important to clear calibration history when a new electrode is used

because most errors and warning messages that appear during calibration

depend on calibration history.

• Immerse the pH electrode and the temperature probe approximately 4 cm

(1½”) into a buffer solution of your choice (pH 1.68, 3.00, 4.01, 6.86, 7.01,

9.18, 10.01, 12.45 or a custom buffer) and stir gently. The temperature probe

should be close to the pH electrode.

• Select the used pH calibration buffer with

or . The “Please

wait...” message will appear on the LCD until the reading is stable or the buffer

is validated.

• If the pH buffer is validated,

will appear on the LCD. Press to update calibration. The

calibration buffer will be added to the Calibrated Buffers section.

• Immerse the pH electrode and the temperature probe into the next buffer solution and follow the above

procedure or press

to exit calibration.

Notes: • The new added calibration point will replace an old one

if the difference between them is ±0.2 pH.

• If the existing stored calibration is full (five calibration

points), a pop-up menu will be displayed on the LCD

in which you can select with

or

keys the buffer you want to replace with the current

buffer. Press

to delete the selected buffer

and then press

to update calibration with

the new buffer.

• When in MTC mode, if pressing

after entering

pH calibration and while a HANNA pH calibration buffer

with a x.xxx resolution is selected, a pop-up menu will

be displayed on the LCD in which the temperature value

can be ajusted using

or . Press

to save the new temperature value.

Page 41

41

• When in MTC mode, if pressing after entering

calibration and while a custom pH calibration buffer is

selected, a pop-up menu will be displayed on the LCD

in which the custom buffer and the temperature value

can be ajusted by pressing

and then

or keys. Press to save the modified

value and then

/ to select next/

previous value to be adjusted.

• When in ATC mode, if pressing

after entering

calibration and while a standard pH buffer (with a

x.xxx resolution) or a custom pH buffer is selected, a

pop-up menu will be displayed on the LCD in which

the buffer value can be ajusted using

or

. Press to save the new buffer value.

• If the Automatic buffer entry type has been selected for the calibration procedure, the instrument

will automatically select the closest buffer to the measured pH value from the edit buffer group

(see pH Setup for details, page 20).

• If the Semiautomatic buffer entry type has been selected for the calibration procedure, the instrument

will automatically select the closest buffers to the measured pH value from all the available buffers

and the used buffer value can be selected with or .

CALIBRATION MESSAGES

• Wrong buffer. Please check the buffer: this message appears when the difference between the pH

reading and the value of the selected calibration buffer is significant. If this message is displayed, check

if you have selected the appropriate calibration buffer.

• Wrong buffer temperature: this message appears if the buffer temperature is out of the defined buffer

temperature range.

• Clean the electrode or check the buffer. Press <Accept> to update calibration: this message alerts the

user that some dirt or deposits could be on the electrode. Refer to the electrode Cleaning Procedure (see page 65).

• Slope too low. Please check the buffer / Slope too high. Please check the buffer: these messages appear

if the current slope is under 80% or over 110% of default slope. Recalibrate the instrument using fresh buffers.

• Slope too low. Press <Clear Cal> to clear old calibration / Slope too high. Press <Clear Cal>

to clear old calibration: these messages appear as a result of an erroneous slope condition. Follow

displayed instructions.

Page 42

42

• Unrecognized buffer. Please check the buffer or the buffer list (for Semiautomatic and Automatic buffer entry

type): this message appears if the current buffer value is not close to any of the buffers from the buffer list/group.

Check if the current buffer is present in the buffer list or the appropriate buffer group was selected.

• The current buffer was already calibrated. Press <Accept> to recalibrate in this point, or change

the buffer: this message appears when calibration is performed in one of the previous calibrated buffers.

Follow displayed instructions.

pH MEASUREMENTS

Make sure the instrument has been calibrated before taking pH measurements.

DIRECT MEASUREMENT

To measure the pH of a sample using the Direct reading mode:

• Press

and then to select pH Measure mode

(for the selected channel – HI 4212 only).

• Select the Direct reading mode (see pH Setup for details, page 20).

• Submerge the electrode tip and the temperature probe

approximately 4 cm (1½”) into the sample to be tested.

Allow time for the electrode to stabilize.

• The measured pH value will be displayed on the LCD, together

with a short GLP information or “Not Calibrated” message if

no pH calibration was performed.

Note: If the reading is out of range, “-----” will be displayed

on the LCD.

DIRECT / AUTOHOLD MEASUREMENT

To measure pH of a sample using the Direct/AutoHold reading mode:

• Press

and then to select pH Measure mode

(for the selected channel – HI 4212 only).

• Select the Direct/AutoHold reading mode (see pH Setup for

details, page 20).

• Submerge the electrode tip and the temperature probe

approximately 4 cm (1½”) into the sample to be tested.

Allow time for the electrode to stabilize.

• The measured pH value will be displayed on the LCD. If pressing

, the “AutoHold” indicator will start blinking on the LCD

until the stability criterion is reached. The pH value will be

frozen on the LCD, along with “AutoHold” indicator.

Page 43

43

• To return to normal Measure mode press

.

Note: If the reading is out of range, “-----” will be displayed on the LCD.

Outside Cal Range feature warns the user if the current reading is

out of the calibrated area. The calibrated area is that part of the pH

range in which the calibration point assures an accurate reading. If

the reading is taken out of the calibration area, the “Outside Cal

Range” message will start blinking on the LCD. The calibrated area

is calculated in according with the pH resolution used during the

reading. To avoid having this message, the calibration points have

to be well distributed in the desired measurement range.

If measurements are taken successively in different samples, it is

recommended to rinse the electrode thoroughly with deionized

water or tap water and then with some of the next sample to

prevent cross-contamination and to condition the electrode before

immersing it into the sample solution.

The pH reading is affected by temperature. In order to measure the pH accurately, the temperature effect must

be compensated. To use the Automatic Temperature Compensation (ATC) feature, connect and submerge the

HI 7662-T temperature probe into the sample as close as possible to the electrode and wait for a few seconds.

If the temperature of the sample is known, Manual Temperature Compensation (MTC) can be performed by

disconnecting the temperature probe.

Notes: • For single channel pH measurements (HI 4211) “MTC” or “ATC” indicators will be displayed on the LCD,

while for dual channel pH measurements (HI 4212) “MTC” or “ATC1”/”ATC2” indicators will be

displayed, depending on the temperature compensation mode and selected channel.

• For mV/Rel mV measurements “NO PROBE” or “TEMP” indicators will be displayed on the LCD (HI 4211

only), respectively “NoProbe” or “TEMP1”/”TEMP2” indicators (HI 4212 only) for mV/Rel mV/ISE

measurements, depending on the temperature compensation mode and selected channel.

• When in MTC mode, the temperature can be modified by pressing

for pH Measure mode and

for mV/Rel mV Measure mode (HI 4211 only) if the Reading Mode option is Direct (HI 4212

only). The temperature value can be ajusted with

or from –20.0 ºC to 120.0 ºC. Press

to save the new temperature value or press to return to Measure mode.

• When in ATC mode for pH, respectively TEMP for mV/Rel mV, “-----” will be displayed on the LCD if

the measured temperature is under or over temperature range (–20.0 ºC to 120.0 ºC).

Page 44

44

mV & Relative mV MEASUREMENTS

mV/ORP MEASUREMENTS

Oxidation-reduction potential (ORP) measurements provide the quantification of the oxidizing or reducing power of the

tested sample.

To correctly perform a redox measurement, the surface of the ORP electrode must be clean and smooth.

DIRECT MEASUREMENT

To measure the mV of a sample using the Direct reading mode:

• Press

and then to enter mV Measure mode

(for the selected channel – HI 4212 only).

• Select the Direct reading mode (see mV Setup for details, page 32).

• Submerge the tip of the ORP electrode (4 cm/1½”) into the

sample to be tested and allow a few seconds for the reading

to stabilize.

• The instrument will display the measured mV value on the LCD.

Note: If the reading is out of range, “-----” will be displayed

on the LCD.

DIRECT/AUTOHOLD MEASUREMENT

To measure mV of a sample using the Direct/AutoHold reading mode:

• Press

and then to select mV Measure mode

(for the selected channel – HI 4212 only).

• Select the Direct/AutoHold reading mode (see mV Setup for

details, page 32).

• Submerge the tip of the ORP electrode approximately 4

cm (1½”) into the sample to be tested and allow a few

seconds for the reading to stabilize.

• The measured mV value will be displayed on the LCD. If

pressing

, the “AutoHold” indicator will start blinking

on the LCD until the stability criterion is reached. The mV value

will be frozen on the LCD, along with “AutoHold” indicator.

• To return to normal Measure mode press

.

Note: If the reading is out of range, “-----” will be displayed

on the LCD.

Page 45

45

Relative mV MEASUREMENTS

To measure the Relative mV of a sample:

• Press

and then to enter Relative mV

Measure mode.

• The instrument will display the measured Relative mV value

on the LCD, together with a short GLP information about the

last calibration or “Not Calibrated” message if no Rel mV

calibration was performed (no Rel mV offset set).

Notes: • If the measured mV potential is out of range, “-----”

will be displayed on the LCD.

• If pressing

while in Relative mV Measure

mode, the Relative mV offset screen will be displayed on the LCD. Press

to clear the existing

Relative mV or use

or to adjust the

Relative mV value and then press

to save the

current Relative mV. Press

at any time to

return to Relative mV Measure mode.

• Before performing a Rel mV calibration, make

sure that the electrode is immersed into the sample

to be measured.

Page 46

46

ISE CALIBRATION & MEASUREMENTS

(HI 4212 only)

ISE CALIBRATION

For greatest accuracy, it is recommended to calibrate the instrument frequently. The instrument should also be recalibrated

whenever “No ISE Calibration” or “ISE Calibration Expired” message appears on the LCD, in the Reminder messages area.

Due to electrode conditioning time, the electrode must be kept immersed a few seconds to stabilize. The user

will be guided step by step during calibration with easy to follow messages on the display. This will make

the calibration a simple and error-free procedure.

PREPARATION

Pour small quantities of the standard solutions into clean beakers. If possible, use plastic beakers to minimize

any EMC interferences.

For accurate calibration and to minimize cross-contamination, use two beakers for each standard solution. One for

rinsing the electrode and one for calibration.

Note: For accurate measurements, add the appropriate ISAB (Ionic Strength Adjustment Buffer) to the

calibration standards.

CALIBRATION PROCEDURE

Up to five-point calibration is possible, using five memorized standard solutions: 0.1, 1, 10, 100, 1000 ppm

and 5 custom solutions.

The ISE calibration and measurement can be performed with or without temperature compensation. If the

temperature compensation option is enabled, the isopotential point of the electrode must be set in ISE Setup in

order to perform correct concentration measurements.

Before calibrating, make sure that the appropriate Electrode Type has been selected in ISE Setup according to the

measured Ion/compound.

ISE Calibration screen description

Page 47

47

Two standard entry types are available: ManualSelection and Custom Standard. The default option is Manual Selection.

A. To calibrate the instrument using Manual Selection standard entry type:

• Press

. If the instrument was calibrated before and calibration was not cleared, the old calibration can be

cleared by pressing

. After 10 seconds, will no longer be available.

Note: It is very important to clear calibration history when a new electrode is used

because most errors and warning messages that appear during calibration

depend on calibration history.

• Add ISAB to all standard solutions.

• Immerse the Ion Selective Electrode and the temperature probe approximately 4

cm (1½”) into the less concentrated standard solution and stir gently.

• Select the used standard solution concentration with

or . The

“Please wait...” message will appear on the LCD until the reading is stable or

the concentration is validated.

Note: When in ATC mode, if pressing

a pop-up menu will be displayed on the LCD in which the

concentration value can be ajusted using

or . Press to save the new

concentration value.

• If the standard solution concentration is validated,

will appear on the LCD. Press to update

calibration. The calibration point value will be added to the Calibrated Standards section.

• The “Please wait...” message will appear on the LCD for 10 seconds and until the reading is stable, time in

which immerse the ion selective electrode and the temperature probe into the next standard solution and

follow the above procedure or press

to exit calibration.

B. To calibrate the instrument using Custom Standard entry type:

• Press . If the instrument was calibrated before and calibration was not cleared, the old calibration

can be cleared by pressing

. After 10 seconds, will no longer be available.

Note: It is very important to clear calibration history when a new electrode is

used because most errors and warning messages that appear during

calibration depend on calibration history.

• Add ISAB to all standard solutions.

• Immerse the Ion Selective Electrode and the temperature probe approximately 4

cm (1½”) into the less concentrated standard solution and stir gently.

• When the stability condition is reached and 10 seconds elapsed, a pop-up menu

will appear on the LCD in which the standard concentration value can be set.

• Press

/ to select next/previous entry to be edit. Press and use or

to set the desired value. Press to save the modified value and then press to

store the set concentration value.

Page 48

48

• If the standard solution concentration is validated,

will appear on the LCD. Press to update

calibration. The calibration point value will be added to the Calibrated Standards section.

• The “Please wait...” message will appear on the LCD until the reading is stable and 10 seconds elapsed,

time in which immerse the Ion Selective Electrode and the temperature probe into the next standard solution

and follow the above procedure or press

to exit calibration.

Notes: • The new added calibration point will replace an old

one if the difference between them is less than 20%

of the standard solution.

• If the existing stored calibration is full (five calibration points), a pop-up menu will be displayed on the

LCD in which you can select with

or

the standard solution you want to replace with the

current one. Press

to delete the selected

calibrated point and then press

to update cali-

bration with the new standard solution.

• If the isopotential point of the electrode is unknown, the

ion calibration and measurements can be performed only

without temperature compensation (see ISE Setup, Temperature option for details, page 33). When the temperature

compensation option is disabled, at least a two-point

calibration must be performed in order to perform ISE

measurements. Otherwise, “-----” will appear on the LCD.

• When in MTC mode, if pressing

after enter-

ing ISE calibration and while a standard solution is

selected, a pop-up menu will be displayed on the LCD

in which the concentration and the temperature value

can be ajusted by pressing

and then

or keys. Press to save the modified

value and then

/ to select next/

previous value to be adjusted.

CALIBRATION MESSAGES

• Wrong standard solution. Please check the standard solution: this message appears when the

difference between the ppm reading and the value of the selected standard solution concentration (ppm)

is significant. If this message is displayed, check if you have selected the appropriate calibration standard.

Page 49

49

• Wrong new slope. Please check the standard solution: this message appears if the current slope

exceeds slope window (50% to 120% of default slope for the corresponding ion charge - see ISE Theory

section for details, page 54). Recalibrate the instrument using fresh standards.

• Wrong old slope. Press <Clear Cal> to clear old calibration: this message appears as a result of