Page 1

H

I 4105

DIOXIDE

CARBON

Instruction Manual

HI 4105HI 4105

HI 4105

HI 4105HI 4105

Carbon Dioxide

Ion

Selective Electrode

1

Page 2

HI 4105 Carbon Dioxide ElectrodeHI 4105 Carbon Dioxide Electrode

HI 4105 Carbon Dioxide Electrode

HI 4105 Carbon Dioxide ElectrodeHI 4105 Carbon Dioxide Electrode

I. I.

Introduction:Introduction:

I.

Introduction:

I. I.

Introduction:Introduction:

The Hanna HI 4105 Carbon Dioxide gas sensing electrode

is a combination electrode designed for the measurement

of Carbon Dioxide in aqueous solutions such as water, soft

drinks or wine, samples. Carbonate and Bicarbonate ions

are also measured by conversion to Carbon Dioxide gas

upon ISA addition.

II.II.

SpecificationsSpecifications

II.

Specifications

II.II.

SpecificationsSpecifications

Type: CO2 gas sensing

electrode with glass pH

internal, Ag/ AgCl

reference and gas

permeable membrane.

2-

Species detected: CO

-

,HCO

, CO

3

3

2

CO2 Measurement Range: 0.02 M to 4 x 10-4M

880 to 17.6 ppm

2-

Interfering ions: SO2/SO

3

, H2S/S

2-

Operating Temperature: 0 to 40°C

Operating pH: 4-5 pH

Dimensions: 12 mm (OD) X 120

mm (insertion)

0.47”x 4.72”

Wetted materials: Delrin®, body and cap

with PTFE membrane

Connection: BNC

2

3

Page 3

III.III.

Theory of OperationTheory of Operation

III.

Theory of Operation

III.III.

Theory of OperationTheory of Operation

::

:

::

The Carbon Dioxide electrode is a complete potentiometric

cell that contains both a silver/silver chloride (Ag/AgCl)

reference and a pH measurement element. These elements

are housed within a thermoplastic body in a chloride ioncontaining electrolyte, and are isolated from the sample by

a PTFE membrane.

ISA addition changes the pH of the sample to approximately 4.7 pH and Bicarbonate (HCO

2-

(CO

) ions in the sample are converted to carbon dioxide

3

-

) and carbonate

3

(CO2). The CO2 in the sample solution diffuses through the

PTFE membrane where it dissolves into the thin film of fill

solution found between the membrane and the internal pH

membrane. Here it converts back into bicarbonate and

hydrogen ions. The pH changes proportionally with the

concentration of dissolved gas in the sample solution. Diffusion of CO2 continues until the partial pressures of the gas

in the sample and thin film are equal.

The Nernst expression for an Carbon Dioxide sensor is expressed in the equation below. Note that the potential is a

function of the Carbon Dioxide gas, which in turn is related

to the hydrogen ion concentration. The glass internal,

Ag/AgCl reference, equilibrium constant and Henry’s law

constant are rolled into the E’ and Eo terms. The Nernst

equation for the sensor becomes the equation noted below:

E = E’+2.3RT/nF log [CO2]= E

E = observed potential

E’ = Reference and fixed internal voltages

o

+0.059 log [H

+

]

IV.IV.

Design ElementsDesign Elements

IV.

Design Elements

IV.IV.

Design ElementsDesign Elements

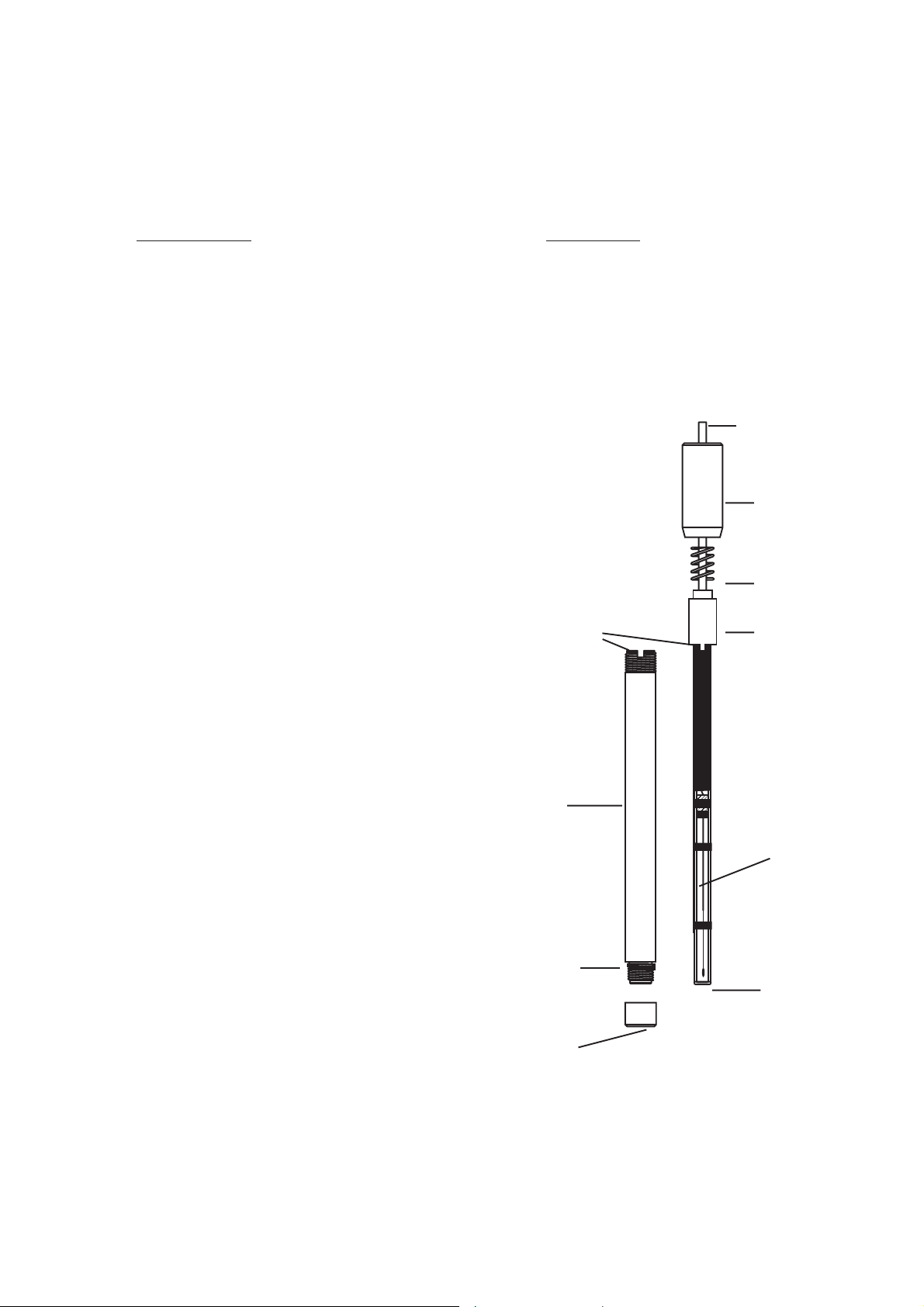

The Hanna HI 4105 Carbon Dioxide gas sensor has 3 main

parts. These are the membrane/membrane cap, outer probe

body with antirotation key and the pH/reference assembly

which includes the outer electrode cap, spring, inner cap

and pH/reference electrode assembly.

pH/reference electrode assembly

cable

outer electrode

cap

spring

antirotation key inner cap

Outer probe body

Reference

electrode

R = gas constant (8.314 J/K Mol)

n= Charge on ion (equivalents/mol)

T = absolute temperature in K

4

F = Faraday constant (9.648 x 10

C/equivalent)

The mV should increase in a Nernstian manner as the

carbon dioxide partial pressure increases in the sample.

4

O-ring

pH

sensitive

membrane

Membrane/membrane cap

5

Page 4

V.V.

Equipment Required:Equipment Required:

V.

Equipment Required:

V.V.

Equipment Required:Equipment Required:

• Hanna HI 4222 pH/ISE/mV meter or other suitable

ion or pH/mV meter. (Note: log/linear graph paper is

useful if an ISE meter is not available).

• Hanna HI 180 magnetic stirrer or equivalent with

stirring bars. (Note: Isolate beakers from stirrer motor

heat by placing insulating material such as foam or

cork between them).

• Hanna HI 4000-71 gas sensor test vessel or

Hanna HI 76404 electrode holder or equivalent with

Beakers or other suitable measurement vessel with

plastic sealing film or wrap.

VI. VI.

Solutions Required for Calibration:Solutions Required for Calibration:

VI.

Solutions Required for Calibration:

VI. VI.

Solutions Required for Calibration:Solutions Required for Calibration:

Ionic Strength Adjuster (ISA), 500 mL: HI 4005-00

Hanna 0.1 M standard, 500 mL: HI 4005-01

Hanna 1000 ppm CO2 standard, 500 mL: HI 4005-03*

*Please Note: This calibration standards is ppm as CaCO

See Section XVII for additional solutions and accessories

used for maintenance.

Using volumetric pipettes and glassware prepare serial

dilutions of the standard. Select concentrations that will

approximately bracket the concentration of the samples to

be measured. Standards with concentrations less than

10-3M should be prepared fresh daily. Store solution in a

tightly sealed bottle without ISA added. 10 mL of HI 400500 ISA should be added to each 100 mL sample of standard and samples just prior to measurement. ISA adjusts

the pH of the sample or standard to about pH 4.7 thus

converting carbonate and bicarbonate ion to carbon dioxide. It also provides samples and standards a constant

ionic strength background that stabilizes the solutions activity coefficient and permits concentration to be measured

directly.

VIIVII

General GuidelinesGeneral Guidelines

VII.

General Guidelines

VIIVII

General GuidelinesGeneral Guidelines

• Calibration standards and sample solutions should

have the same ionic strength. ISA should be added to

both samples and standards immediately before taking measurements.

• Calibration standards and sample solutions should be

stirred at the same rate using identical sized stir bars.

Stir thoroughly and continuously.

• Calibration standards and sample solutions should be

at the same temperature. Thermally insulate solution

vessel from magnetic stirrer with cork or other insulating medium.

• Wait until sensor value has stabilized before taking

reading (at least 5 minutes when going from more

dilute to more concentrated samples, longer when the

order is reversed).

• Surface coating on the PTFE membrane will effect the

3

response. Inspect sensor before using. Wash off with a

jet of deionized water or mild detergent to remove

film.

• Replace PTFE membrane if damage is evident or a

droplet of internal electrolyte is seen.

• Rinse electrode with distilled or deionized water be-

tween samples and dab dry with lab wipe or other soft

disposable absorbent toweling.

• Check calibration every 1-2 hours. Recalibrate if nec-

essary.

• Position sensors at an angle of approximately 20° to

30° from verticle to reduce possibility of trapping gas

bubbles on on the membrane cap. Gas bubbles also

form from solution out-gassing due to temperature

change. Gently tap body of sensor to dislodge them.

• Close container with plastic wrap or use HI 4000-71

gas sensor test vessel to prevent gas from leaving.

• If electrode was left out in air for a prolonged period,

gently pulling cable will permit an exchange of fill

solution at the membrane surface. Re-Calibration is

required.

6

7

Page 5

Inner Electrode CheckInner Electrode Check

VIII. VIII.

Inner Electrode Check

VIII.

Inner Electrode CheckInner Electrode Check

VIII. VIII.

Prior to assembling the electrode for the

first timefirst time

first time or

first timefirst time

subsquently reactivating it after extended periods of dry

storage, the inner electrode assembly should be hydrated

and then tested as a pH electrode.

Prepare pH test solutions HI 4000-47-4 and HI 4000-477 by mixing and dissolving each buffer packet in separate

containers with 50 mL deionized water. These pH solutions

contain chloride ions and pH buffers that are used to verify

the inner electrode (pH internal) is operational. See

Section XVII for replacement accessories and maintenance

items.

For a new sensor:

Remove the protective shipping cap from the glass inner

electrode.

Protective shipping cap

• If sensor has been stored or shipped dry, it should be

“conditioned” by soaking the pH/reference assembly 1 hour or more in one of the pH test solutions.

• Avoid touching the pH glass with your fingers.

• Attention: The pH/reference assembly is fragile!

Support the upper portion of the internal cell while

immersing the glass and reference assembly. A tall

narrow container with weighted bottom is best. The

pH test solution should cover the bottom of the large

black band.

Test: Connect the BNC connector on the electrode cable to a

pH/mV (mV or ORP mode) meter. Carefully immerse

the sensor assembly into one of the buffers. When the

measurment stabilizes record the mV generated. Rinse

sensor tip in deionized water and dab dry between

buffers to prevent solution carry-over. Do not rub the

glass. Take a measurement in the second buffer and

record mV. Pay attention to minus sign if present.

For existing sensor:

Unscrew the upper cap on the top of the electrode and

carefully withdraw the internal pH/reference assembly.

For stable readings, glass should be covered to the

bottom of the long black band.

Use test

tube or

Test buffer

can be

used as a

conditioning

solution

for the

pH internal

graduated

cylinder

(weighed

Bottom) when

testing or

conditioning

pH internal

8

Calculate the difference in mV between the two solutions.

Example of typical values:

HI 4000-47- 7 -90.2 mV

HI 4000-47-4 80.66 mV

Difference 170.8 mV= 80.6-(-90.2)

A calculated value equal or greater than 160 mV is acceptable for ambient temperatures between 20° and 25°C.

9

Page 6

Electrode PreparationElectrode Preparation

IX. IX.

Electrode Preparation

IX.

Electrode PreparationElectrode Preparation

IX. IX.

1) Remove glass internal from sensor body and perform

inner electrode check. (See section VIII).

2) The HI 4105 sensor comes with three easily replaceable membrane caps (two which are spares). Remove

a cap from membrane box and screw on to lower

threads of outer probe body, compressing the o-ring

seal. Avoid touching working area of membrane with

your fingers as skin oil will change the membrane

properties.

3.) Using dropper provided, add about 2 mL of carbon

dioxide internal fill solution HI 4005-40 into outer

probe body.

4) Insert and position the inner glass/reference assembly into the outer body so that the anti-rotation key

sits in the cut out on the outer probe body.

HI 4105

E

XID

IO

D

N

BO

R

A

C

HI 4105

E

XID

IO

D

N

BO

R

A

C

5) Holding the electrode upright, slide spring and electrode cap down cable and screw cap on outer body

until fully engaged. Do not invert electrode. Do not

overtighten.

6) Install assembled electrode in gas sensor test vessel

or in electrode holder and connect cable connector to

pH/mV meter.

10

11

Page 7

Quick Check of Electrode SlopeQuick Check of Electrode Slope

X. X.

Quick Check of Electrode Slope

X.

Quick Check of Electrode SlopeQuick Check of Electrode Slope

X. X.

• Connect BNC (connector) to pH/mV/ISE meter.

• Place meter in mV mode.

• Place 100 mL of deionized water into a vessel with

stir bar. Add 10 mL of ISA Hanna HI 4005-00.

• Place sensor into prepared sample.

• Add 1 mL of 0.1 M Carbon dioxide standard to

beaker and stir sample. Wait approximately 5 minutes. Record the mV value when stable.

• Add an additional 10 mL of standard to the solution.

Record the mV when reading has stabilized (approximately 5 minutes). This value should be greater

than the previous noted (more positive).

• Determine the difference between the two mV values.

An acceptable value for this slope is 54±4 mV at

ambient temperatures between 20 and 25°C.

Note: HI 4005-03 standard may be used. The additions

must be 10mL and 100mL. The mV difference should

be approximately 47mV.

XI.XI.

Corrective actionCorrective action

XI.

Corrective action

XI.XI.

Corrective actionCorrective action

• Verify standard has been properly added.

• Verify ISA has been added in the correct ratio to the

standard (1 part ISA to 10 parts sample or standard).

• Verify that the upper cap has been screwed in all the

way.

• Verify electrode is connected properly to meter and the

meter is is powered .

• Verify membrane cap is tightened securely to probe

body.

• Examine the membrane for discoloration or perfora-

tions or for internal fill solution that might have

leaked through the PTFE membrane. Replace membrane cap if damaged.

If drift is seen:

• Verify electrode and standards are at same tempera-

ture.

• Verify electrode has adaquate fill solution.

• Verify electrode was not left in air for prolonged pe

12

XII. XII.

Sample HandlingSample Handling

XII.

Sample Handling

XII. XII.

Sample HandlingSample Handling

• For optimum results, allow samples and standards

and the HI 4105 electrode to reach the same temperature.

• As CO

is volatile, measure samples immediately af-

2

ter collection.

• If sample must be stored: Completely fill collection

bottle with dilute samples and tightly cap container

to prevent carbon dioxide loss or contamination from

other sources.

• If sample must be stored: For acetic samples. add

sodium hydroxide (10N) to raise pH to 8-9 for storage. Tightly close collection bottle.

• If sample must be stored: keep sample at a lower

temperature than it was collected at until time of

measurement.

• Add Hanna HI 4005-00 ISA just prior to measure-

ment to adjust standards and samples to a pH

between 4.2-5.2 for measurement. ISA must mix

thoroughly with solutions and time allowed to convert

carbonate and bicarbonate species to CO2 (dissolved).

• Covering sample and standards after adding ISA will

minimize carbon dioxide loss from the solution.

• Calibration standards and samples must be the same

ionic strength. The concentration for all dissolved species in a sample should not exceed 1M. Samples that

exceed this should

be diluted with CO2 free deionized water. Do not reduce CO2 below 10-4M. Multiply

the final result by the corresponding dilution factor.

13

Page 8

XIII. XIII.

r

Direct Calibration and MeasurementDirect Calibration and Measurement

XIII.

Direct Calibration and Measurement

XIII. XIII.

Direct Calibration and MeasurementDirect Calibration and Measurement

The direct measurement method is best used in the linear

working regions of the sensor. (See figure for typical sensor

response) and can be used when measuring many samples.

A direct reading ISE meter (HI 4222 or equivalent) determines concentration of the unknown by a direct reading

after calibrating the meter with the standards. The meter is

calibrated with two or more freshly made standards that

are in the measurement range of the unknowns. HI 400500 ISA is added prior to measurement and the solution is

stirred thoroughly and continuously. Covering the vessel to

prevent gas loss is advised.

A pH/mV meter in mV mode and semi-log graph paper

may also be used. Two or freshly prepared standards that

are in the measurement range of the unknowns (with ISA

added), are measured in mV mode on the meter. These

standards are plotted on semilog graph paper and their

points are connected to form a straight-line curve. When

samples are measured, their mV values are converted to

concentration by following the mV to the concentration axis

on the semi-log plot.

For both direct reading and mV convertion, ISA is added

prior to measurement, the solution stirred thoroughly and

continuously and the vessel should be covered to prevent

gas loss.

• Standards and solutions should be at the same tem-

perature. 10 mL of ISA is added to each 100 mL of

sample and standard.

• Protect these solutions from loss of dissolved gas by

covering and using promptly.

3. Follow section VII; General Guidelines to optimize test

set-up.

4. During calibration it is best to start with lower concentration samples first. Wait for a stable reading before

reading/recording values (approximately 5 minutes).

5. To prevent carry over and contamination of samples,

rinse sensors with deionized water and dab dry between samples.

6. Between measurements suspend sensor tip in a small

sample of CO2 Conditioning solution; HI 4005-45.

Rinse body with deionized water and dab dry before

placing in next sample.

7. Check HI 4105 electrode calibration every 2 hours by

verification of at least one calibration point.

Typical calibration curve for HI 4105 Carbon Dioxide ISE

In the lower concentration ranges the electrode calibration

becomes less linear, many more calibration points are

needed, and calibration will need to be repeated more

frequently. Known addition method may also be used in

these regions provided the actual slope of the sensor has

been determined.

Direct Measurement Procedure

1. Follow section IX to prepare sensor.

2. Follow section VI to prepare standards and solutions.

• Standards should bracket the measurement range of

interest and differ from each other by a factor of 10 in

the linear regions.

14

Typical response for HI 4105 Carbon Dioxide senso

-50

-70

-90

mV

-110

-130

-150

-170

1.5 2 2.5 3 3.5 4 4.5

-l og[M]

15

Page 9

Other Measurement TOther Measurement T

XIVXIV

. .

Other Measurement T

XIV

.

Other Measurement TOther Measurement T

XIVXIV

. .

echniquesechniques

echniques

echniquesechniques

Known Addition

An unknown concentration of carbon dioxide can be determined by adding a known amount (volume and concentration) of carbon dioxide standard to a known volume of

the sample. This technique is extremely useful for carbon

dioxide because changes in the sensor calibration are corrected for continuously because, the standard and sample

are measured within minutes of one another. The technique can use an ideal sensor slope, but actual slopes at

the temperature of measurement should be determined

and used if possible. This will improve accuracy.

1. The volume of the unknown sample (V

Sample

) is measured accurately and placed into the closed sample

vessel. The sensor is secured in the vessel and then the

vessel is placed on a stirrer.

2. ISA is added at 1 part per 10 parts sample.

3. When the measurement is stable the mV value is

noted.

4. A known amount, volume (V

(C

), of CO

Standard

mV values are again noted when the measurement is

standard is then added to the sample.

2

) and concentration

Standard

stable.

5. The mV change is then calculated (∆E).

6. Using the measured and calculated values, the

sample concentration (C

) can be determined.

Sample

7. The procedure can be repeated with a second standard

addition to verify slope and operation of the method.

Note:

This method is preprogrammed in the Hanna HI

4222pH/ISE/mV meter, which simplifies the method

greatly and permits repeated determinations easily.

Example:

Carbon Dioxide determination with known addition:

1. A 50 mL sample of unknown (V

) is placed in an

SAMPLE

clean vessel with an electrode. 5 mL of ISA is added

to the sample . The sample is covered and permitted

to mix throughly and continueously. The mV is then

recorded when the sensor has stabilized.

2. 5 mL (V

STANDARD

) of 0.1 M (C

) standard is then

STANDARD

added to the vessel and is permitted to mix. The mV

value increases as the concentration increases. (Note:

for other concentration samples, add a known volume

and concentration of standard to produce a 30 mV

change or greater.

3. The unknown carbon dioxide concentration in the

original sample (C

) can then be determined by

SAMPLE

using the equation provided.

.

C

sample

C

=

(V

(V

standardVstandard

)10

T

∆E/S

(V

sampl e+Vstandard+VISA

sample+VISA

- (VS’)

)= V

16

)= V

S’

V

S’

V

sample

T

17

Page 10

XV. XV.

Storage and Care of the HI 4105 sensorStorage and Care of the HI 4105 sensor

XV.

Storage and Care of the HI 4105 sensor

XV. XV.

Storage and Care of the HI 4105 sensorStorage and Care of the HI 4105 sensor

The HI 4105 sensor can be stored assembled and ready to

use in HI 4005-45 Conditioning solution overnight or

between measurements. After overnight storage, gently pull

on the cable to compress the spring mechanism thus

permitting electrolyte to exchange from the bulk to the thin

film between the membrane and glass. Calibration is

required after doing this.

For longer term storage (over a week), disassemble the

sensor completely and rinse off the internal pH/reference

assembly, the outer body and the membrane cap. It is

advised the membrane cap be discarded to prevent possible problems associated with reuse. Cover the glass tip

with the protective shipping cap and store parts securely in

the original shipping box. When reassembling the sensor

follow section IX.

XVI. XVI.

Conversion TConversion T

XVI.

Conversion T

XVI. XVI.

Conversion TConversion T

For COFor CO

For CO

For COFor CO

22

2

22

Moles/L (M) CO2 to ppm CO2 (mg/L) 4.4 X 10

ppm CO2 (mg/L) to M (Moles/L) 2.273 X 10

For CaCOFor CaCO

For CaCO

For CaCOFor CaCO

3 3

3

3 3

Moles/L (M) CO2 to ppm CaCO3 (mg/L) 1.00 X 10

(ppm)(ppm)

(ppm)

(ppm)(ppm)

ablesables

ables

ablesables

Multiply byMultiply by

Multiply by

Multiply byMultiply by

4

Multiply byMultiply by

Multiply by

Multiply byMultiply by

-3

5

XVII. XVII.

HI 4105 AHI 4105 A

XVII.

HI 4105 A

XVII. XVII.

HI 4105 AHI 4105 A

For CalibrationFor Calibration

For Calibration

For CalibrationFor Calibration

CodeCode

Code

CodeCode

ccessories and Replacement Pccessories and Replacement P

ccessories and Replacement P

ccessories and Replacement Pccessories and Replacement P

::

:

::

artsarts

arts

artsarts

HI 4005-00 Ionic Strength Adjuster (500 mL)

HI 4005-01 Hanna 0.1 M CO2 Standard

(500 mL)

HI 4005-03* Hanna 1000 ppm CO2 Standard

(500 mL)

*Please Note: This calibration standard is ppm as CaCO

For Maintenance:For Maintenance:

For Maintenance:

For Maintenance:For Maintenance:

HI 4005-40 Hanna Carbon Dioxide Fill Solution

(4 X 30 mL)

HI 4005-45 Hanna Carbon Dioxide Conditioning

Solution (500 mL)

HI 4000-47 Bulk package of 10 each

HI 4000-47-4 and HI 4000-47-7

Buffer Packets

HI 4005-53 Replacement Membranes Caps

(3 Membrane Caps)

HI 4000-54 Replacement pH/reference Electrode

Assembly for CO

2

HI 740155P Capillary Pipettes (20 piece)

3

18

19

Page 11

MAN4105 12/11 REV2

WARRANTY WARRANTY

WARRANTY

WARRANTY WARRANTY

Hanna Instruments Ion Selective Electrodes are warranted to

be free of defects in material and workmanship for 6 months

from date of purchase when used for their intended purpose

and maintained according to instructions. If they fail to work

when first used contact your dealer immediately. Damage due

to accidents, misuse, misapplication, tampering or lack of

prescribed maintenance is not covered.

Hanna Instruments reserves the right to modify the design,

construction or appearance of its products without advance

notice.

20

Loading...

Loading...