Page 1

CHLORIDE

HI 4007

7

HI 410

CHLORIDE

COMBINATION

Instruction Manual

HI 4007HI 4007

HI 4007

HI 4007HI 4007

HI 4107HI 4107

HI 4107

HI 4107HI 4107

Chloride Ion

Selective Electrode

Half-cell

Combination

1

Page 2

HI 4007 Chloride Half-cellHI 4007 Chloride Half-cell

HI 4007 Chloride Half-cell

HI 4007 Chloride Half-cellHI 4007 Chloride Half-cell

HI 4107 Chloride Combination ElectrodeHI 4107 Chloride Combination Electrode

HI 4107 Chloride Combination Electrode

HI 4107 Chloride Combination ElectrodeHI 4107 Chloride Combination Electrode

I. I.

Introduction:Introduction:

I.

Introduction:

I. I.

Introduction:Introduction:

The Hanna HI 4007and HI 4107 are ion selective electrodes designed for the measurement of chloride ions in

aqueous solutions. The HI 4007 is a solid state half-cell

sensor that requires a separate reference. The HI 4107 is a

combination ion selective electrode.

IIII

SpecificationsSpecifications

II.

Specifications

IIII

SpecificationsSpecifications

Type: Solid State electrode with

a Silver Chloride pellet.

Ion(s) measured: Chloride (Cl-)

Measurement range: 1.0 M to 5 X 10

-5

M

35,500 to 1.8 ppm

Interfering ions: Cyanide, and Mercury ions

must be absent. Ratio of interfering ion to Cl- must be less

than the ratio indicated below:

for CO

-

2-

3

2-

3

iodide

carbonate

thiosulfate

1.0 for l

3.5 for Br-bromide

1.0 for OH-hydroxide

0.01 for S2O

Operating Temperature: 0-80°C

Operating pH: 2-11 pH

Dimensions: 12 mm (OD) X 120 mm

nominal insertion

(0.47” X 4.72”)

Connection: BNC

2

Page 3

III. III.

Theory of OperationTheory of Operation

III.

Theory of Operation

III. III.

Theory of OperationTheory of Operation

::

:

::

The HI 4007 or HI 4107 chloride electrodes are potentiometric devices used for the rapid determination of free chloride ions in ground water, boiler water and drinking water.

The electrode functions as a sensor or ionic conductor. The

HI 4007 requires a separate reference electrode to complete

its electrolytic circuit. The HI 4107 has a reference electrode

incorporated in its design. The silver chloride pellet is practically insoluble in the test solutions being measured and

produces a potential change due to changes in the sample’s

ion activity. When the ionic strength of the sample is fixed

by the addition of ISA, the voltage is proportional to the

concentration of chloride ions in solution and the electrode

follows the Nernst equation.

E= E

+ 2.3 RT/nF log A

a

ion

E= observed potential

Ea= Reference and fixed internal voltages

R= gas constant (8.314 J/K Mol)

n= Charge on ion (-1)

A i=ion activity in sample

T= absolute temperature in K

F= Faraday constant (9.648 x 10

3

4

C/equivalent)

Page 4

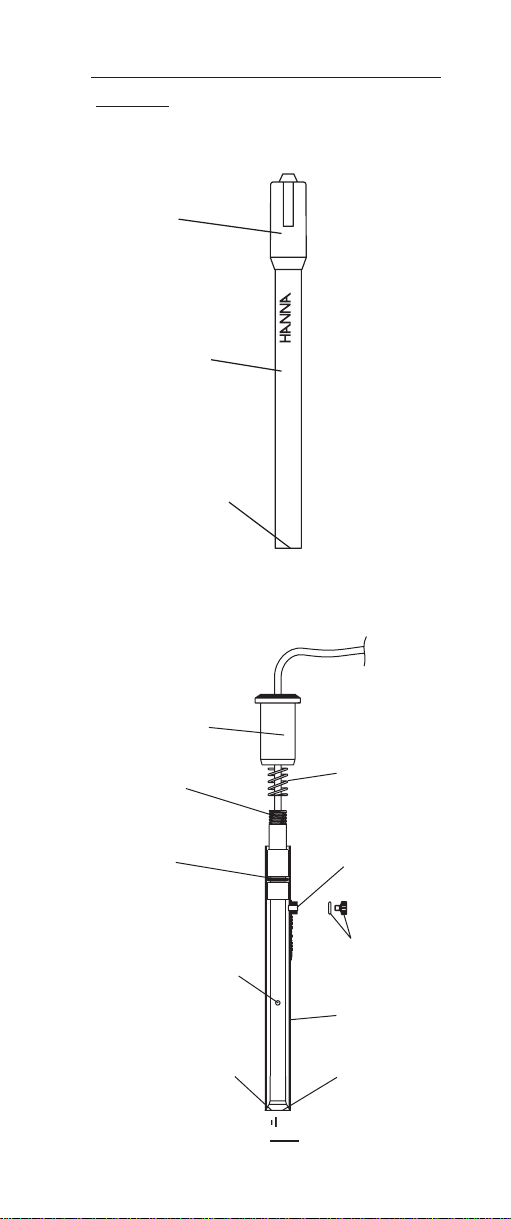

IV. IV.

Design elements of the HI 4007 and HI 4107Design elements of the HI 4007 and HI 4107

IV.

Design elements of the HI 4007 and HI 4107

IV. IV.

Design elements of the HI 4007 and HI 4107Design elements of the HI 4007 and HI 4107

electrodeselectrodes

electrodes

electrodeselectrodes

Cap

HI 4007

RIDE

CHLO

Sensor

Handle

Sensing

Membrane

Upper Cap

Upper

Threads

O-Ring

Ceramic Junction

on Inner Stem

Liquid junction

Spring

Fill Hole

O-Ring and

Plug

Outer Sleeve

Sensing

Membrane

4

Page 5

V. Equipment required:V. Equipment required:

V. Equipment required:

V. Equipment required:V. Equipment required:

• Hanna HI 5315 Double Junction Reference Electrode

with HI 7072 Fill Solution for HI 4007.

• Hanna HI 4222 pH/ISE/mV meter or other suitable

ion or pH/mV meter. (Note: log/linear graph paper is

useful if an ISE (ion) meter is not available.

• Hanna HI 180 Magnetic Stirrer or equivalent with

Teflon coated stirring bars (HI 731320). (Note: isolate beakers from stirrer motor heat by placing insulating material such as foam or cork between them).

• Hanna HI 76404 Electrode Holder or equivalent.

• Plastic beakers (HI 740036P) or other suitable mea-

surement vessel.

VI. VI.

Solutions RequiredSolutions Required

VI.

Solutions Required

VI. VI.

Solutions RequiredSolutions Required

for Chloride Measurementsfor Chloride Measurements

for Chloride Measurements

for Chloride Measurementsfor Chloride Measurements

Select appropriate Hanna Instruments standard and ISA

from the list below:

0.1 M Sodium Chloride Standard, 500mL HI 4007-01

100 ppm Chloride standard, 500 mL HI 4007-02

1000 ppm Chloride standard, 500 mL HI 4007-03

ISA, 500 mL HI 4000-00

Using volumetric pipettes and glassware make dilutions to

bracket the concentration of the samples. Standards with

concentrations < 10

-3

M (35.5 ppm) should be prepared

daily.

Two mL of Hanna ISA for Halide electrodes (HI 4000-00)

should be added to 100 mL of sample or standard.

A user prepared acetate pH buffer may also be used to

adjust samples to approximately 4 pH. Add 10 mL per 100

mL sample or standard. Prepare 250 mL by dissolving

19.5 g ammonium acetate and 15.0 mL glacial acetic

acid in 200 mL deionized water and diluting to volume.

5

Page 6

A user supplied oxidizing reagent may be used to supress

interferences such as hydroxide, sulfide, bromide, ammonia or cyanide . Add 10 mL to 100 mL standard or sample.

Permit sample to mix 10 minutes before measurements are

taken. Discard samples and

standards promptly as the

chloride in these will oxidize upon standing making them

unrelible. Do not permit electrodes to remain in this solution for long periods of time. Work in a hood and protect

eyes and skin. Prepare oxidizing reagent by diluting 6.25

mL analytical grade concentrated nitic acid into approximately 800 mL deionized water. Mix carefully. Dilute to 1

liter.

VIIVII

General GuidelinesGeneral Guidelines

VII.

General Guidelines

VIIVII

General GuidelinesGeneral Guidelines

• Calibration standards and sample solutions should

have the same ionic strength. ISA, acetate buffer or

oxidizing reagent should be added to both samples

and standards in the same ratio.

• Calibration standards and sample solutions should

be at same temperature.

• Thermally insulate beaker with standard or sample

from magnetic stirrer.

• Calibration standards and sample solutions should

be stirred at the same rate using identical sized TFE

coated stir bars.

• Rinse electrode pair with distilled or deionized water

between samples and gently dry off using soft disposable absorbent toweling. Do not rub sensor surface.

• Presoaking chloride sensor in a dilute standard will

optimize response. Do not use concentration above

10-3M.

• A scratched, pitted, or tarnished pellet surface can

cause drift, a loss of low level response, or poor repeatability. Optimum response can be restored by removing the damaged surface with the microabrasive strip

HI 4000-70.

6

Page 7

• Avoid large changes in temperature (thermal shock)

as it may damage the sensor.

HI 4007

• Remove protective cover from sensor tip.

• Prepare HI 5315 reference electrode by filling electro-

lyte reservoir with HI 7072 fill solution.

• Place sensor and reference electrodes into electrode

holder and connect cable connectors to meter.

HI 4107

• Remove the protective plastic wrap that covers the

ceramic junction before assembling sensor for the first

time.

• HI 7072 reference fill solution should be added daily

to electrolyte reservior before electrode use.

• During measurement always operate electrode with

the fill hole open.

• During normal use, fill solution will slowly drain out

of the tapered cone junction at the lower portion of the

electrode. Excessive loss (>4 cm drop within 24 hours)

is not normal. If this occurs verify cap is tightened and

the interface between the internal cone and outer

body is free of debris.

• Add fill solution daily to maintain a good head pressure. For optimum response, this level should be maintained and not be allowed to drop more than 2-3 cm

(1-inch) below fill hole. It must cover the ceramic

found on the inner stem.

• If an erratic measurement occurs, check to see if foreign matter is seen trapped near the internal cone.

Drain and refill with fresh fill solution.

7

Page 8

VIII. VIII.

Electrode PreparationElectrode Preparation

VIII.

Electrode Preparation

VIII. VIII.

Electrode PreparationElectrode Preparation

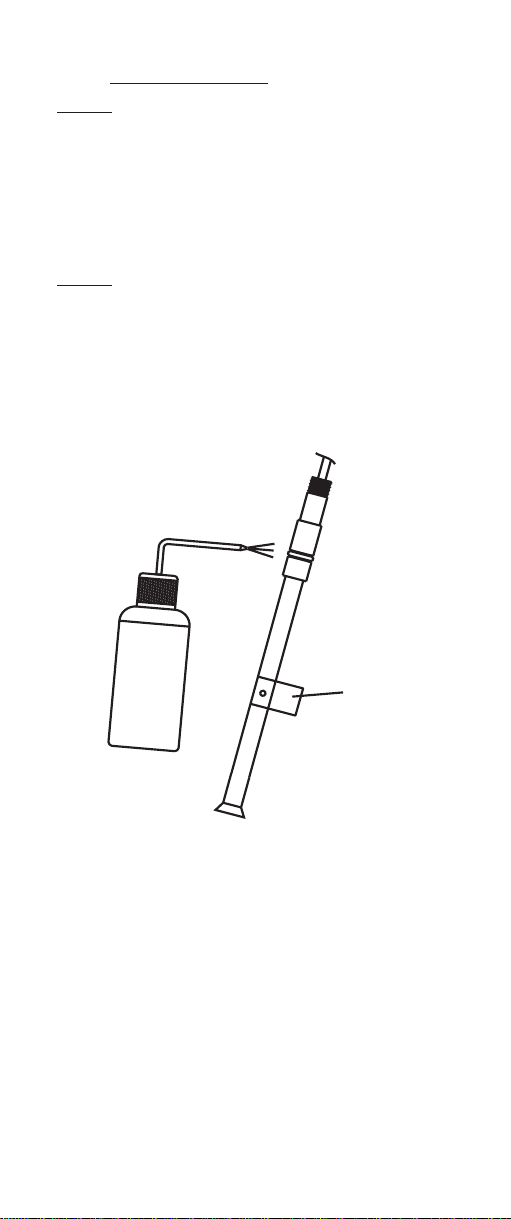

HI 4007

1. Remove protective cover from sensor tip.

2. Prepare reference electrode by filling outer electrolyte

reservoir with HI 7072.

3. Place sensor and reference electrodes into electrode

holder and connect cable connectors to meter.

HI 4107

1. Unwrap plastic film seal found over ceramic junction

on inner stem and discard. This is only used for shipping and long term storage.

2. Rinse inner stem with deionized water making certain

to wet the o-ring found on the inner stem.

Remove

Water

Deionized

3. Reassemble electrode by gently pushing the inner

assembly into the outer body, sliding spring down

cable, and screwing cap into place.

4. Remove fill hole cover and o-ring on fill hole spout.

5. Using the dropper pipette provided, add a few drops

HI 7072 fill solution to the electrode, wetting the oring and rinsing out the fill solution chamber.

8

Parafilm

Page 9

6. Holding the body of the electrode gently press upper

cap with your thumb. This permits the fill solution to

drain out of the body. Release cap and verify electrode returns to its original position. (You may need to

gently assist for this to occur).

COMBINATION

CHLORIDE

HI 4107

7. Tighten the electrode cap onto the body and fill electrode body until fill solution volume is just below fill

hole.

8. Position electrode in a Hanna HI 76404 electrode

holder (or equivalent) and connect plug to meter.

9

Page 10

IX. IX.

Quick Check of Electrode SlopeQuick Check of Electrode Slope

IX.

Quick Check of Electrode Slope

IX. IX.

Quick Check of Electrode SlopeQuick Check of Electrode Slope

• Connect sensors to pH/mV/ISE meter

• Place meter in mV mode.

• Place 100 mL of DIW into a beaker with stir bar.

• Place reference and measuring half-cell into prepared

sample.

• Add 1 mL of a standard (0.1 M or 1000 ppm standard) to beaker. Record the mV value when stable.

• Add an additional 10-mL of standard to the solution.

Record the mV when reading has stabilized. This

value should be less than the previous noted (more

negative).

• Determine the difference between the two-mV values.

An acceptable value for this slope is -56 ± 4 mV.

X. X.

Corrective actionCorrective action

X.

Corrective action

X. X.

Corrective actionCorrective action

• Verify protective cap has been removed.(HI 4007)

• Verify plastic film has been removed from inner

stem.(HI 4107)

• Verify electrodes are connected properly to meter and

meter is powered.

• Verify dilute standards are freshly made and stored.

Remake solutions if appropriate.

• If the sensor slope just misses the suggested slope

window, soaking the sensor in a dilute standard may

solve the problem. (Choose 10

-3

M chloride or 100

ppm standard).

• A scratched sensing surface can be polished with HI

4000-70 polishing strip. Cut off approximately 1

inch of the micro-abrasive strip. Wet the frosted side

with deionized water and place against damaged

membrane of the electrode. Place your thumb against

the shiny backing and slowly rotate back and forth

while applying gentle pressure. Continue polishing

until you are satisfied with the surface.

10

Page 11

If dark deposits appears on polishing strip move the

paper slightly and continue polishing.

• If the sensor slope just misses the suggested slope

window, soaking the sensor in a standard may solve

the problem.

• If the membrane is damaged, the response becomes

extremely sluggish, or the slope of the electrode has

decreased significantly, and procedures above have

not helped, the sensor should be replaced.

XI. XI.

Direct Calibration and MeasurementDirect Calibration and Measurement

XI.

Direct Calibration and Measurement

XI. XI.

Direct Calibration and MeasurementDirect Calibration and Measurement

This method is a simple procedure for measuring many

samples. A direct reading ISE meter (HI 4222 or equivalent) determines concentration of the unknown by a direct

reading after calibrating the meter with the standards. The

meter is calibrated with two or more freshly made standards that are in the linear measurement range of the

unknowns. More calibration standards are required in nonlinear regions. Unknowns are read directly. At very low

levels of chloride, special precautions must be employed for

reproducible measurements. Water used for standards must

be chloride free and sensors and glassware must be rinsed

repeatedly with this water to prevent carry over. In the

region where the electrode response appears curved, more

calibration points are needed, and calibration will need to

be repeated more frequently.

A pH/mV meter in mV mode with semi log graph paper

may also be used. Two or more freshly prepared standards

that are in the measurement range of the unknowns are

measured in mV mode on the meter.

These values are plotted on the semi-log paper and the

points are connected to form a straight-line curve. When

samples are measured, their mV values are converted to

concentration by following the mV to the concentration axis

on the semi-log plot.

11

Page 12

Procedure

1) Follow sections VIII and IX to prepare sensors for

measurement.

2) Follow section VI to prepare standards/ solution. Standards should bracket and fall within the range of

interest.

Two mL HI 4000-00 ISA, or 10 mL acetate pH buffer

or 10 mL of oxidizing reagent is added to 100 mL of

both samples and standards. Add stir bar and mix

before taking measurements. Measurements using

the oxidizing reagent must be made 10 minutes after

mixing and not permitted react longer.

3) Follow section VII; General Guidelines to optimize test

set-up.

4) During calibration it is best to start with lower concentration samples first. Wait for a stable measurement

before recording values. Slightly longer equilibrations are required at lower concentrations .

5) To prevent carry over and contamination of samples,

rinse sensors with DIW and blot dry between samples.

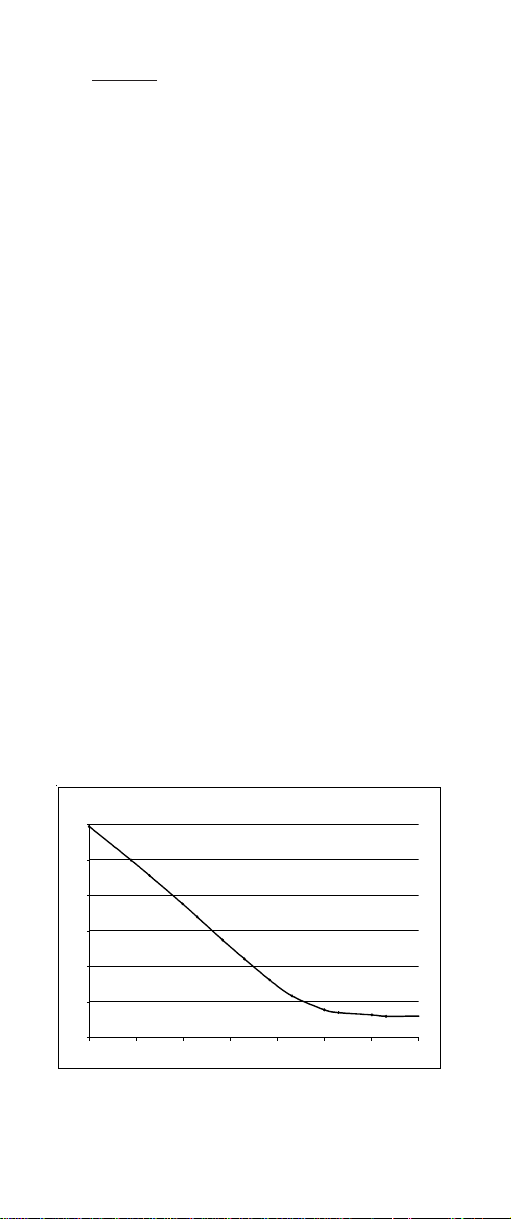

Typical Linearity for HI 4007 and HI 4107 Chloride

0

50

100

150

mV

200

250

300

01234567

-Log of Concentration

12

Page 13

XII. XII.

Other Measurement TOther Measurement T

XII.

Other Measurement T

XII. XII.

Other Measurement TOther Measurement T

echniquesechniques

echniques

echniquesechniques

Known Addition (for Cl-)

An unknown concentration can be determined by adding a

known amount (volume and concentration) of measured

ion to a known volume of the sample. This technique is

called Known Addition. The method can use an ideal

sensor slope, but actual determined slopes at the temperature of measurement should be used if known. This method

is preprogrammed in the Hanna HI 4222 pH/ISE/mV meter,

which simplifies the method greatly.

Example: Chloride ion determination with known addition.

1. A 50 mL sample of unknown (Vsample) is placed in

a clean plastic beaker with a chloride sensor. Add 2

mL of acetate pH buffer or HI 4000-00 ISA (V

ISA)

OR if

chloride l electrode interferences are known to exist,

add 50 mL oxidizing reagent (V

). Mix well. and

ISA

record the stable mV value. (mV 1)

2. 5 mL (Vstd) of 10-3M (Cstd) standard is added to the

beaker and the mV value decreases. The unknown

chloride concentration in the original sample

(Csample) can then be determined by the following

equation.

C

=

sample

(V

(V

sample+Vstandard+VISA

(V

sample+VISA

C

standardVstandard

∆E/S

)10

T

)= V

- (VS’)

)= V

S’

V

S’

V

sample

T

3. The procedure can be repeated with a second standard addition to verify slope and operation of the

method.

13

Page 14

TitrationTitration

Titration

TitrationTitration

A chloride electrode may be used as an indicator to follow

the progress of a chloride tiration with silver nitrate. The

electrode can be used in colored samples where other

indicators suffer from interferences. During the titration the

sensor follows the decrease in chloride concentration while

small additions of silver nitate titrant are added. The silver

reacts with the chloride ions forming a precipitate of silver

chloride. At the stoichiometric end point, a large change in

mV occurs. Measurements may be automated by use of

the Hanna Titrator HI 901 or titrated manually.

XIII.XIII.

pHpH

XIII.

pH

XIII.XIII.

pHpH

The HI 4107 and HI 4007 electrodes may be used in

solutions with pH values between 2 and 11. Samples that

fall beyond this range should be adjusted with acetate pH

buffer. See Section VI.

XIV. SXIV. S

torage and Care of the HI 4007 andtorage and Care of the HI 4007 and

XIV. S

torage and Care of the HI 4007 and

XIV. SXIV. S

torage and Care of the HI 4007 andtorage and Care of the HI 4007 and

HI 4107 sensorsHI 4107 sensors

HI 4107 sensors

HI 4107 sensorsHI 4107 sensors

The HI 4007 sensor can be stored in very dilute standards

(<10-4 M) for short periods of time and should be stored

dry with the protective cap on when not in use.

The model HI 4107 combination electrode can be left in

dilute standards (<10-4 M) for short time periods.

For long term storage, the electrode should be drained and

washed of salts with distilled ot deionized water. Unscrew

the upper cap and move outer sleeve up cable. Wrap the

ceramic junction on the inner stem with Parafilm® or

other sealing wrap. Place the protective cap provided over

the sensor membrane. Store dry disassembled electrode in

storage box provided with electrode.

14

Page 15

XV. XV.

Conversion tablesConversion tables

XV.

Conversion tables

XV. XV.

Conversion tablesConversion tables

--

-

--

For ClFor Cl

For Cl

For ClFor Cl

Multiply byMultiply by

Multiply by

Multiply byMultiply by

Moles/L (M) to ppm (mg/L) 3.500 x 10

ppm (mg/L) to M (moles/L) 2.857 x 10

4

-5

15

Page 16

MAN4107 05/08

WARRANTY WARRANTY

WARRANTY

WARRANTY WARRANTY

Hanna Instruments Ion Selective Electrodes are warranted

to be free of defects in material and workmanship for 6

months from date of purchase when used for their intended

purpose and maintained according to instructions. If they

fail to work when first used contact your dealer immediately.

Damage due to accidents, misuse, misapplication, tampering

or lack of prescribed maintenance is not covered.

Hanna Instruments reserves the right to modify the design,

construction or appearance of its products without advance

notice.

16

Loading...

Loading...