Page 1

Instruction Manual

BL 7916 • BL 7917

pH and ORP

Measuring & Dosing

System

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna product.

Please read this instruction manual carefully before using the pump.

If you need additional technical information, do not hesitate to e-mail

us at tech@hannainst.com.

These instruments are in compliance with the directives.

WARRANTY

All Hanna Instruments pumps are warranted for one year against defects in

workmanship and materials when used for their intended purpose and maintained

according to instructions. This warranty is limited to repair or replacement free of

charge. Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered. If service is required, contact the dealer from whom you

purchased the instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is not covered by

the warranty, you will be notified of the charges incurred. If the instrument is to be

returned to Hanna Instruments, first obtain a Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs

prepaid. When shipping any instrument, make sure it is properly packaged for

complete protection.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ........................................................ 3

GENERAL DESCRIPTION ................................................................ 4

FLOW RATE CHART .......................................................................5

FUNCTIONAL DESCRIPTION BL 7916 ............................................ 6

FUNCTIONAL DESCRIPTION BL 7917 ............................................ 7

SPECIFICATIONS........................................................................... 8

VALVE / HOSE ASSEMBLY DIAGRAM............................................. 9

MECHANICAL DIMENSIONS ........................................................ 10

INSTALLATION ........................................................................... 11

OPERATIONAL GUIDE ................................................................. 18

pH CALIBRATION ....................................................................... 22

TROUBLESHOOTING GUIDE ........................................................ 23

MAINTENANCE ........................................................................... 24

ELECTRODE CONDITIONING AND MAINTENANCE ........................... 26

TAKING REDOX MEASUREMENTS ................................................. 30

CHEMICAL COMPATIBILITY GUIDE................................................ 32

ACCESSORIES ............................................................................. 34

CE DECLARATION OF CONFORMITY.............................................. 38

PRELIMINARY EXAMINATION

Remove the pump from the packing material and examine it carefully

to make sure that no damage has occurred during shipping. If there

is any noticeable damage, notify your Dealer.

Each pump is supplied complete with:

• discharge and suction valves

• LDPE tubing, 7 m (23')

• power cord

• instruction manual

Note: Save all packing material until you are sure that the pump

functions correctly. Any defective item must be returned in the

original packaging together with the supplied accessories.

READ THE INSTRUCTIONS ATTENTIVELY

BEFORE INSTALLING OR OPERATING YOUR PUMP

The BL electronic dosing pumps are easy to use. We recommend,

however, that you read the entire manual before using the pump.

Familiarity with the features and controls of the unit will give you a

better idea of the dosing potential and help reduce operator errors.

Please operate the pump only as directed in the instruction manual.

Follow all general safety guidelines during operation.

Remember: electrical devices are potentially hazardous. Check that the

voltage of the installation matches the voltage indicated on the

specification label on the back of the pump.

Note: It is the responsibility of the user to install and ground the

pump properly; it is highly recommended to install an external

switch.

Each pump is protected by a 1 A/250 V fuse that is located together

with 1 spare in a drawer on the power socket under the pump.

Always store chemicals in safe, out of reach places. Follow the

directions for use with each chemical. Do not assume chemicals are the

same because they look alike. Hanna Instruments cannot be held

responsible for the misuse of chemicals or the pump.

Always wear protective clothing (gloves and safety glasses) when

working near chemical dosing pumps. When pumping chemicals,

make sure all tubes are securely attached to the fittings. It is

recommended that tubing is shielded to prevent possible injury in

case of rupture or accidental damage.

Avoid using a pipe wrench or pliers on plastic parts and connectors.

2

3

Page 3

These are best tightened with an open end or crescent wrench. Avoid

overtightening these parts as this could cause damage to the seats

and threads.

If a hose is used, it should be securely fastened to columns, walls,

braces, etc. This will ensure that the hose connection will remain tight

and leak free. Shield the hose from direct sunlight. Sunlight can

cause an autocatalytic reaction with some chemicals and weaken the

hose walls.

The arrow on the pump head indicates the direction of chemical flow

and should always point upwards (vertically). Never position the

pump horizontally with suction and discharge valves horizontal.

Locate the pump in an area out of the reach of children and pets.

All pumps undergo stringent tests to ensure that they comply with

their stated specifications and are calibrated at the maximum rated

pressure.

Unplug the instrument from the power supply before

replacing the fuse or making any electrical connections.

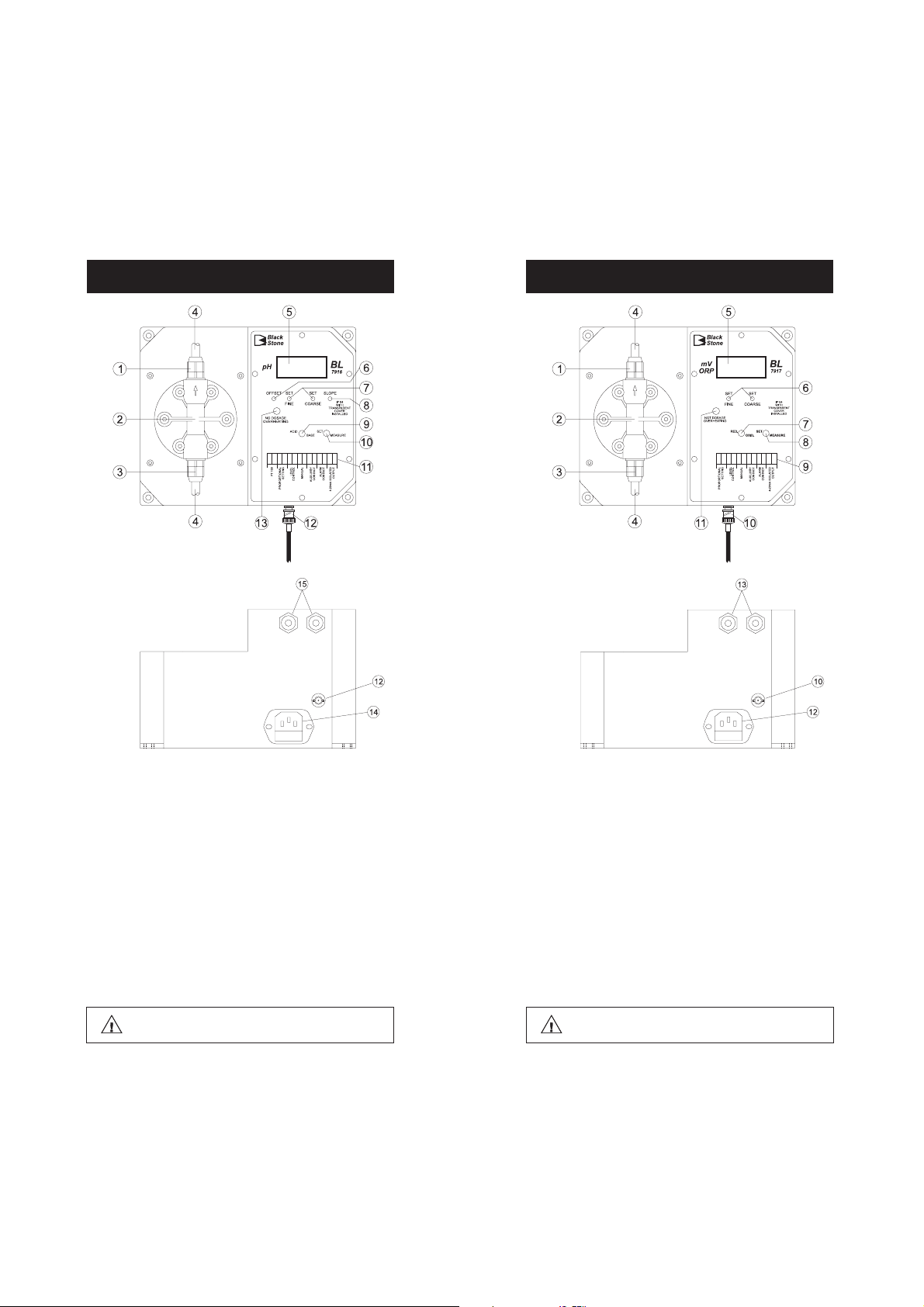

FLOW RATE CHART

The following chart shows the inverse relationship between flow rate

and pressure.

GENERAL DESCRIPTION

The BL 7916 and BL 7917 Control/Pump System offer respectively a

pH and ORP monitoring system with proportional control of a

diaphragm pump and an LCD readout.

Features include:

• Two advanced instruments in one compact unit

• Proportional control for precisely maintained set-points

• Rugged construction with a one-piece casing and a transparent cover to protect controls and terminals

• Chemically resistant non-clogging pump head and superior

materials for all components in contact with the chemicals

being dosed (see page 32 for details)

• Convenient installation with all controls on front panel

• A solenoid-driven pump

• Automatic overheat protection and a built-in LCD display

• Alarm output: the alarm of the BL 7916 will be activated if

the measured pH value is 2 pH units higher or lower than the

setpoint. BL 7917's alarm will activate if the mV value is

200mV higher or lower than the setpoint.

• Auxiliary dosing contacts. This will drive other equipment such

as mixers, priming pumps, etc.

4

The table below shows typical reduction of the flow rate with an

increase of pressure. The pump supplied with the system has a

capacity of 13.3 LPH (3.5 GPH) at 0.5 BAR (7.4 PSI).

BL 7916 / BL 7917

FLOW / PRESSURE

BAR (PSI) LPH (GPH)

0.5 (7.4)

1.0 (14.7)

2.0 (29.4)

3.0 (44.1)

4.0 (58.8)

13.3 (3.46)

11.7 (3.04)

10.1 (2.63)

9.0 (2.33)

7.8 (2.03)

5

Page 4

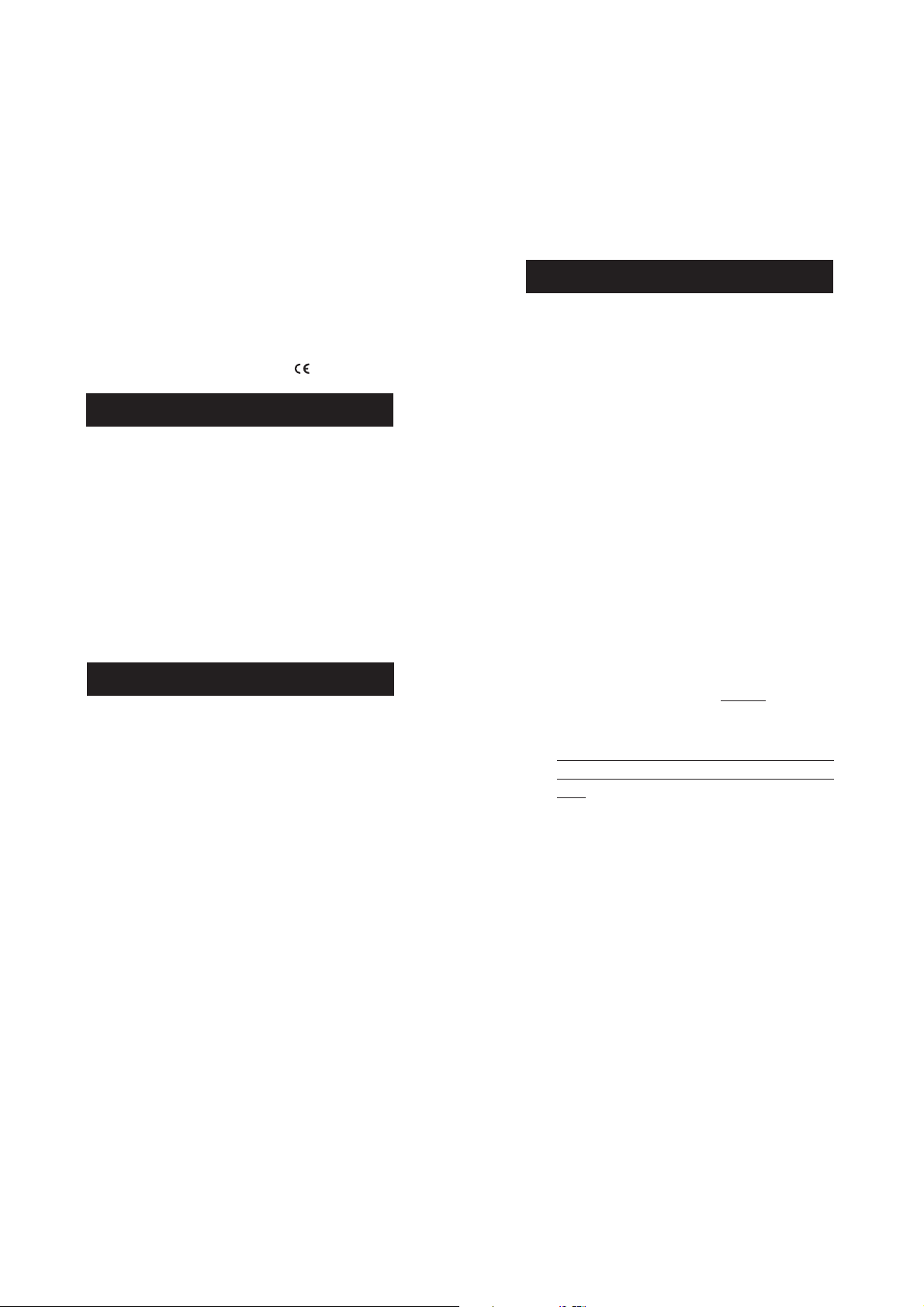

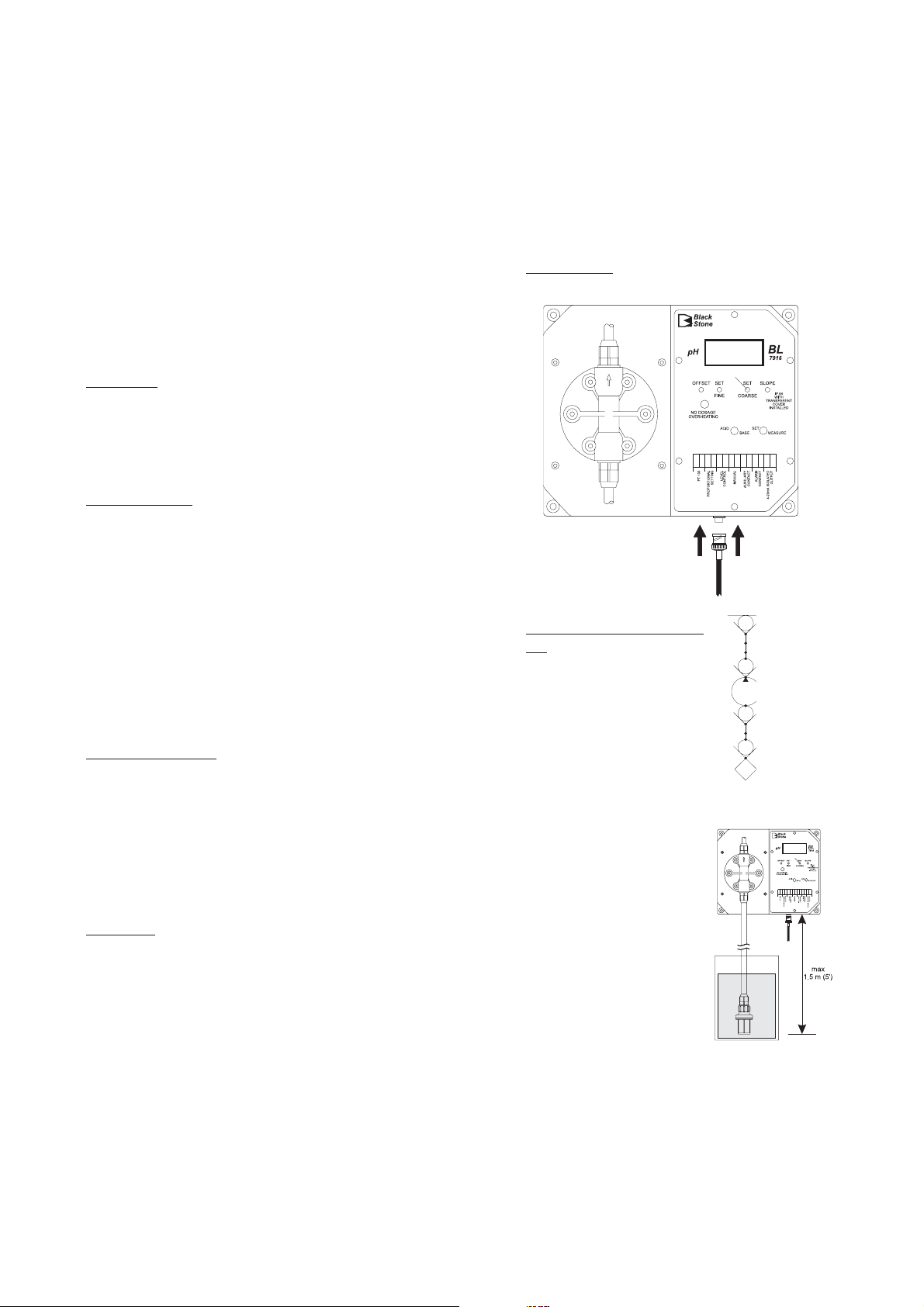

FUNCTIONAL DESCRIPTION BL 7916

FUNCTIONAL DESCRIPTION BL 7917

1. Discharge Valve Assembly

2. Pump head

3. Suction Valve Assembly

4. Hose

5. Liquid Crystal Display

6. Offset Calibration Trimmer

7. Setpoint Adjustment Trimmers (FINE and COARSE)

8. Slope Calibration Trimmer

9. Acid/Base Selection Switch

10. Display Mode Selection Switch (SET or MEASURE)

11. Terminal Connections

12. BNC Connector for pH electrode

13. Overheating LED

14. Power Socket and Fuse Holder

15. Cable Glands

Unplug the instrument from the power supply before

replacing the fuse or making any electrical connections.

6

1. Discharge Valve Assembly

2. Pump head

3. Suction Valve Assembly

4. Hose

5. Liquid Crystal Display

6. Setpoint Adjustment Trimmers (FINE and COARSE)

7. Reduction/Oxidation Selection Switch

8. Operating Mode Selection Switch (SET or MEASURE)

9. Terminal Connections

10. BNC Connector for ORP electrode

11. Overheating LED

12. Power Socket and Fuse Holder

13. Cable Glands

Unplug the instrument from the power supply before

replacing the fuse or making any electrical connections.

7

Page 5

SPECIFICATIONS

BL 7916D BL 7916U

Range 0.00 to 14.00 pH

Resolution 0.01 pH

Accuracy (@20°C/68°F) ±0.01 pH

Typical EMC Deviation ±0.1 pH

Input Impedance 10¹² Ohm

Dosage Proportional, acid or base, user selectable

Dosing Contact Isolated, 2A, Max. 240V, resistive load, 1,000,000 strokes

Alarm Contact Isolated, 2A, Max. 240V, resistive load, 1,000,000 strokes

Calibration Offset: ±1 pH with trimmer

Slope: 85 to 115% with trimmer

Recorder Output 4 to 20 mA (isolated)

Power Supply 230 Vac ±15% 115 Vac ±15%

50/60 Hz (40 W) 50/60 Hz (40 W)

Environment 0 to 50°C (32 to 122°F);

RH max 95% non-condensing

Dimensions 221 x 142 x 181 mm (8.7 x 5.6 x 7.1'')

Weight Approximately 5 kg (11 lb.)

BL 7917D BL 7917U

Range -999 to +999 mV

Resolution 1 mV

Accuracy (@20°C/68°F) ±5 mV

Typical EMC Deviation ±6 mV

Input Impedance 10¹² Ohm

Dosage Proportional, oxidizing or reducing, user selectable

Dosing Contact Isolated, 2A, Max. 240V, resistive load, 1,000,000 strokes

Alarm Contact Isolated, 2A, Max. 240V, resistive load, 1,000,000 strokes

Recorder Output 4 to 20 mA (isolated)

Power Supply 230 Vac ±15% 115 Vac ±15%

50/60 Hz (40 W) 50/60 Hz (40 W)

Environment 0 to 50°C (32 to 122°F);

RH max 95% non-condensing

Dimensions 221 x 142 x 181 mm (8.7 x 5.6 x 7.1)

Weight Approximately 5 kg (11 lb.)

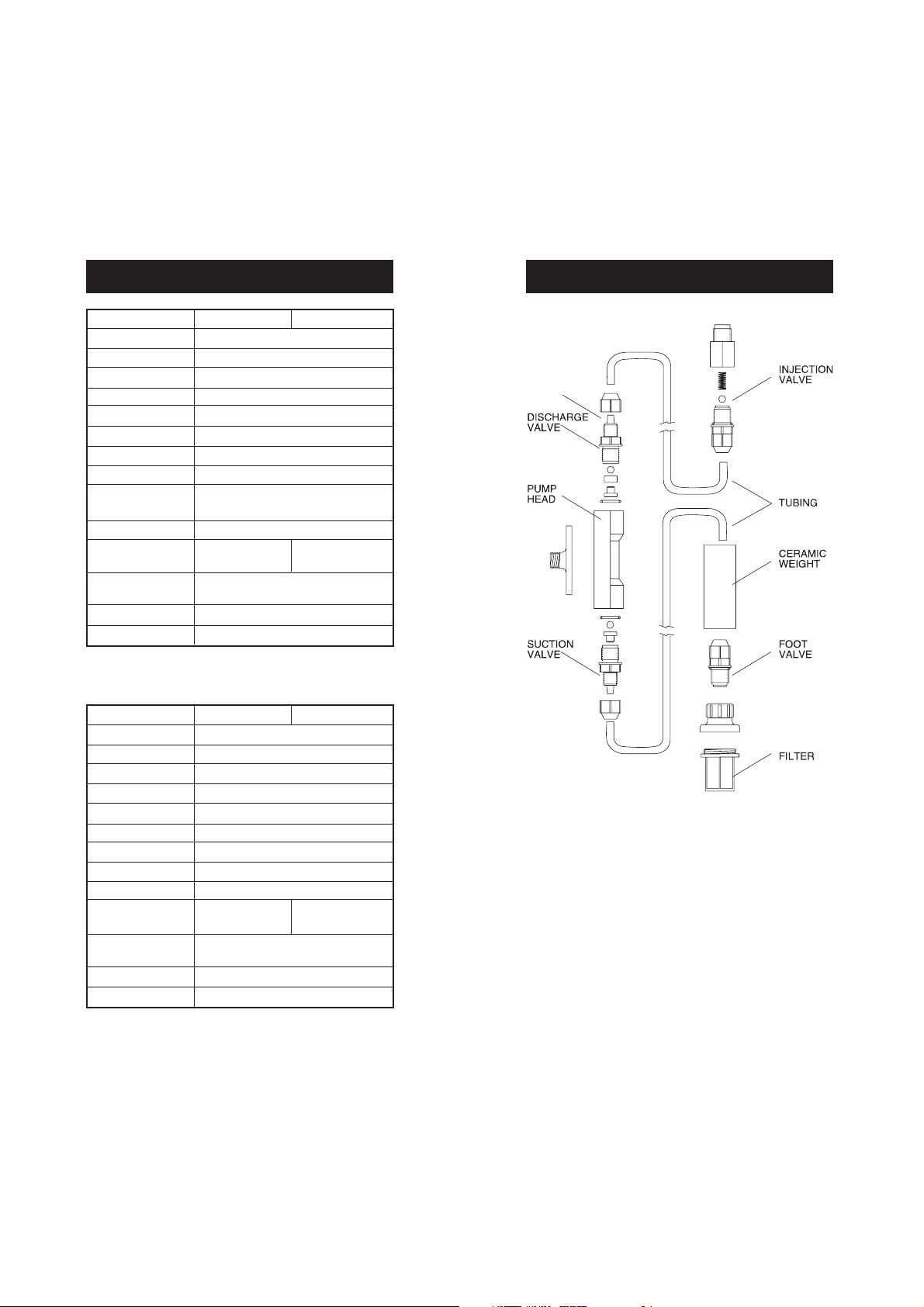

VALVE / HOSE ASSEMBLY DIAGRAM

NECK

8

9

Page 6

MECHANICAL DIMENSIONS

110mm

m

"

1

m

"

110mm

8.70"

INSTALLATION

The Controller/Pump series of instruments are enclosed in a modular

housing for maximum protection. The dimensioned illustrations show

the layout of the Controller/Pumps and how they utilize the one-piece

polypropylene, injection-molded housing. Since there are no joints or

screws holding different sections of the housing together, the case is

extremely rugged and sturdy.

BOTTOM VIEW

181m

164mm

6.45"

17mm

.67"

142m

5.60

7.13

29mm

5.08"

99mm

3.90"

5mm

0.19"

4.33"

55mm

2.16"

204mm

221mm

4.33"

FRONT VIEW

pH

8.03"

Materials Needed

• LDPE hose (7 meter/22 feet) (included) or other type of tubing

(PTFE, for example) more suitable for a specific application

(optional)

• Power cord (included)

Optional Accessories

• 4 each, ceramic weights (HI 721008)

• 1 each, foot valve assembly (HI 721005)

• 1 each, injection valve assembly (HI 721004)

Location

A suitable location should:

• be near to a power source

• be conveniently close to the injection point

• allow easy access to the flow rate control and pipe or hose

connections

• be no more than 1.5 meters (5 feet) above the operating

position of the suction valve assembly.

Dimensions for Installation

BlackStone Pumps are designed for permanent installation.

The pump can be mounted directly on a wall or tank (see page 10 for

the specific mounting dimensions).

Power Requirements

BlackStone pumps are designed to operate to specifications within the

following voltage ranges:

100 - 130 Volts for 115 Vac models

200 - 250 Volts for 230 Vac models

10

11

Page 7

To ensure maximum performance, check the voltage at the point of

-

supply to verify that it is sufficient. It is recommended that you install a

1 Amp circuit breaker between the pump and the power supply. This

will give additional protection to the internal circuit and provide a

convenient way to disconnect the power supply prior to servicing the

pump, if needed.

Injection Point

• Choose an injection point that allows you to mount the

injection valve assembly vertically.

• The spring in the injection valve assembly (HI 721004) adds

approximately 1.5 bar of back pressure. If pumping into a

high back pressure, the spring should be removed.

Other Considerations

• If you are mounting the system to a wall, column, etc., be sure

it is strong enough to support the weight of the entire system.

• The ambient temperature of the pump, when in operation,

should be between 0 and 50°C (32 to 122°F) and should be

protected from direct exposure to outdoor elements (direct sunlight, rain, extreme temperatures, high humidity, etc.).

• Generally speaking, the shorter the suction distance, the more

efficient the pump operates.

• The pump should be placed in a conventional location that will

allow easy access to the control and connections. It should be

placed so that regular visual inspections of the connections and

hoses are facilitated.

Vertical Surface Mounting

Once you have selected the best installation site, simply screw or bolt

the unit into a wall or mounting panel above the chemical feed tank.

The 4 mounting screw holes on the pump will accommodate up to a 5

mm (3/16") screw or bolt (remember to use heavy screws or bolts to

secure the system). Be sure you do not over tighten and cause excessive

stress on the mounting holes.

Make sure to leave a slight overhang in front to allow for the

connection cable.

Power Supply

Connect the power cord to the female socket of the pump and by doing

so also grounding it. The power socket contains a 1 A/250 V fuse.

Since there is no on/off switch, it is suggested to install an outside

switch.

Probe connections

Connect the pH/ORP electrode to the BNC socket of the pump.

Permanent Connection using 3/8" PVC

pipe

All piping for the pump feed and discharge should be plumbed to the location

of the pump.

The threads on both valve assemblies

allow the use of standard 3/8" (European) pipe fittings for permanent pipe

connections.

Diagram for Rigid Pipe Hose

UNION C ONNECTION

ADAPTER

DISCHARGE VALVE

PUMP

SUCTION V ALVE

ADAPTER

FOOT V ALVE

FILTER

The foot valve assembly (HI 721005)

should always hang vertically and not

lay horizontal on the bottom of the tank

or drum.

A vertical assembly will ensure that the

valve is positioned properly and prevent

loss of prime.

For the US standard installations, use

PVC adapters to connect the suction and

discharge valves to the PVC pipe.

12

13

Page 8

Hose Connections

• Cut a long enough section of the

hose to reach the suction valve of the

pump head from the feed tank. Allow some slack in the hose and be

sure it is not kinked or twisted.

• Slip a hose connector onto the hose

over the head valve and up to the

bottom of the threads ensuring it is

fully seated.

• Slide the connector up to the threads

and tighten to form a seal.

• Slip the ceramic weight (HI 721008)

and a connector over the other end

of the hose.

• Repeat the same installation procedure for the hose connections

on the discharge end with the injection assembly (HI 721004)

• Secure the hose so that its movement is minimized when the

pump is operating. Excessive hose movement could cause the

connectors to loosen and result in leakage.

Assembling the Hose to the Valve

The end of the valve is specially tapered

to form a leak free seal when the hose is

properly installed.

Be sure to seat the hose completely so

that there is no gap. Push the hose until

it covers the end of the valve completely.

• Attach the foot valve assembly

(HI 721005) to the hose and slide

the connector up to the threads and

tighten to form a seal.

14

Suction and Discharge Valves

The suction and discharge valves located

on the pump head should not be interchanged as they are different internally.

The discharge valve is fitted with a valve

guide and will not function properly if

used on the suction side.

15

Page 9

LEGEND

HOSE PIPE

CONNECTION

RESEVOIR

MANUAL

SHUTOFF

VALVE

PUMP

FILTER /

FOOT VALVE

CHECK VALVE

EXAMPLE OF TYPICAL INSTALLATIONS

Flooded Suction Installation

Suggested Installation for consistent output when using a low

stroke rate. Also suggested for

highly viscous chemicals.

A slight suction pressure avoids

self-priming problems, especially

with high viscosity liquids.

Suction Lift Installation

Suggested installation for most in-line

applications with nominal output and

pressures.

The maximum self-priming height is

1.5 m (5 ft.). It is advisable to install

a level controller in order to stop the

pump when feed tank (reservoir) liquid

level is low.

Downhill Installation

Suggested installation when pumping from one container to another,

each at different levels and with only nominal pressure.

START-UP

At start-up, purge all chemical gases and air from the suction tubing,

valves and pump head. Start the pump.

When all the air or gas is vented, the solution being metered will

appear in the output line.

Note: Only when operating under pressure, the pump must be

started unloaded.

Uphill Installation

Suggested installation whenever the supply is located higher than

the discharge point; typically a waste water application.

It is important to install the Injection valve to prevent siphoning.

16

17

Page 10

OPERATIONAL GUIDE

• Unscrew and remove the transparent front panel cover and

gasket seal for access to the terminals.

• Remove the protective plastic plate covering the terminals by

removing the 2 screws on both sides of the plate.

+ -

+ -

TERMINAL CONNECTIONS BL 7917

Pt100 (for BL 7916 only)

A 2-wire Pt100 can be connected to provide automatic temperature

compensation of the pH measurements. The pump is supplied with a

110 Ohm resistor connected to the 2 Pt100 terminals. This delivers a

fixed temperature compensation of 25°C (77°F). The Pt100 is recommended only in special instances where very high accuracy is

absolutely necessary since the error is only 0.03 pH for a temperature

difference of 10°C in the pH 6 to 8 range. The error will consequently

be less than 0.09 pH at readings from pH 4 to 10 when the

temperature is in the 15°C (59°F) to 35°C (95°F) range.

PROPORTIONAL SETTING

The pump is supplied with a 10K resistor connected to these

terminals. With this value the pump works at 100% of the rating

when the difference between measure and setpoint is more than

150 mV (BL 7917) or 1.5 pH (BL 7916). It goes into proportional

dosing for values less than the above.

You can vary this hysteresis band by simply changing the resistor as

follows:

BL 7916 BL 7917

0.50 pH 1.91 K 50 mV 1.91 K

1.00 pH 4.87 K 100 mV 4.87 K

1.50 pH 10 K 150 mV 10 K

2.00 pH 21 K 200 mV 21 K

TERMINAL CONNECTIONS BL 7916

18

LEVEL CONTROL

The pump is supplied with these two terminals short-circuited. A

contact coming from a level controller (e.g. HI 7871, HI 7873) can be

connected to these terminals. If this contact is closed, the pump works

normally. If it opens, the unit will not pump even if the controller

commands it.

19

Page 11

For example, a level controller can be placed in the tank of the liquid

being dosed so that the pump is stopped when the chemicals are

exhausted.

MANUAL

An auxiliary switch can be connected to these terminals to force the

unit to pump whatever value is measured by the controller. This

might be needed for example when the pump needs to be primed.

AUXILIARY CONTACT

The controller can drive a relay when the measure overtakes the

setpoint. The contact available on the terminals can be normally open

or closed. It can be used as a switch to drive an external mixer when

the pump is dosing, or can activate an auxiliary pump or any other

device. With BL 7916, the contact can be selected to remain open

when the pH value is within the set limits (the pump is not dosing)

and closed when the pump is dosing or viceversa.

By shorting the Common (middle) terminal with the NO or NC

terminal on the driving circuit inside the controller section, a normally

open or a normally closed state can be achieved, as shown below:

ALARM CONTACT

If the reading drifts from the setpoint by more than ±2.00 pH in

BL 7916 and ±200 mV in BL 7917, an external alarm can be

activated. The contact is rated at 2 amps at 220VAC. No power is

supplied through the system and it is an open/closed contact only.

With BL 7916, the contact can be selected to be closed when the

alarm is activated and open when the alarm is off or viceversa. Short

the middle terminal located on the driving circuit inside the controller

section with the NO or NC terminal (see above).

4-20 mA ISOLATED OUTPUT

A 4-20 mA proportional output is available in these connections:

4 mA=0 pH; 20 mA=14 pH (BL 7916)

and

4 mA=-999 mV; 20 mA=+999 mV (BL 7917).

The output is optically isolated.

20

SETPOINT ADJUSTMENTS

• Move the display selector switch to SET.

• With a small screwdriver adjust the SET COARSE trimmer to

display a value close to the desired setpoint e.g. 7.00.

• Adjust the SET FINE trimmer to display the exact setpoint value.

• Once the desired setpoint is achieved, move the display selector

switch back to MEASURE.

ACID OR BASE SELECTION (BL 7916 only)

If an acid chemical is to be dosed, move the

ACID/BASE switch to ACID. This means that

the pump will dose when pH measurements

are higher than the setpoint.

If an alkaline chemical is to be dosed, move

the ACID/BASE switch to BASE. This means

that the pump will dose when pH measurements are lower than the setpoint.

REDUCING OR OXIDIZING SELECTION (BL 7917 only)

If a reducing chemical is to be dosed, move

the RED/OXID switch to RED. This means that

the pump will dose when redox measurements are higher than the setpoint.

If an oxidizing chemical is to be dosed, move

the RED/OXID switch to OXID. This means

that the pump will dose when the redox

measurements are lower than the setpoint.

The wires and cables needed for all connections can be fed through

the two cable fittings located below the terminals. It is important to

attach these cables properly because pump vibrations could loosen

them. Replace the transparent cover and fasten the screws.

21

Page 12

pH CALIBRATION

TROUBLESHOOTING GUIDE

BL 7916 only:

• Ensure that the display selector switch is set to MEASURE and dip

the electrode tip in a neutral buffer solution (pH 7.01).

• Adjust the OFFSET trimmer to display 7.01 on the LCD.

• Rinse the electrode with clean water and

dip the electrode tip in pH 4.01 (acidic)

or pH 10.01 (alkaline) buffer solution.

• Adjust the slope trimmer to read 4.01 or 10.01 on the LCD.

The slope calibration with pH 4.01 buffer is suggested if the controller

will be used for acid measurements or pH values below 7, pH 10.01

is in turn recommended for alkaline measurements or pH values

above 7.

22

ELECTRICAL

The pump does not operate when turned ON:

• Check the power supply and connections. Voltage should be

between 100 - 130 VAC for 115 V models and between 200

- 250VAC for 230 V models.

• See Installation section on page 11 or call your dealer or the

nearest Hanna Customer Service Center for technical assistance.

OPERATING

Display does not indicate:

• Check that the pump is properly plugged in

• Check the fuse.

Display shows 1 on the far left hand side:

• Check electrode and/or electrode cable.

"No Dosage" LED is lit:

• Check the tank where the level controller is working or verify

the connection on the terminals (they must be short for the

pump to dose).

LIQUID

The pump operates but does not prime:

• Check for a clogged or loose filter on the suction valve

assembly. Retighten if necessary.

• Check to see if the pump is too high above the foot valve

assembly (HI 721005) in the feed tank. This vertical distance

should not exceed 1.5 meters (5 feet). Either lower the pump

or raise the feed tank.

• Check the pump head, suction and discharge valves for

blockage.

Pump flow rate is reduced:

• Check the pump head, discharge and injection valve assembly

for any clogging. Clean and reassemble.

• Check for any additional back pressure created since the last

flow rate was conducted.

• Check for any changes in the viscosity of the chemical being

used.

• Be sure that valves have been properly installed in the pump

head.

23

Page 13

Leakage at the connections:

• Be sure that the hose is fully seated and hose connectors are

tight.

• Be sure that valves are tight and O-rings are in place.

Leakage around the pump head:

• Be sure that the valves are tight and O-rings are in place and

the head screws (hex bolts) are tight.

MAINTENANCE

Your BlackStone Pump is designed to give you years of trouble-free

service. Maintenance should be the preventative type, that is, periodic

cleaning and inspecting for any damage or leakage.

CLEANING THE SUCTION, DISCHARGE AND INJECTION

VALVES

Remove the valves from the pump head, the injection fitting and the

feed.

Keep the suction and discharge valves separated as they are not

interchangeable.

Disassemble each valve and clean it with a neutral liquid. Inspect the

PVDF springs. After cleaning the glass balls, inspect them for any

excessive wear due to abrasion from the chemical. Replace if necessary

with parts from HI 721102, HI 721105, HI 721004 and HI 721005

(see page 34 for listing).

When reinstalling the valves into the pump head, tighten by hand

first and then with a wrench ¼ to ½ turn.

SCHEDULED MAINTENANCE

After 50 hours

Tight the pump head screws with a torque force of 2.5 Nm (22"

lbf).

After 12 months

It is recommended to replace HI 721102, HI 721103 (suction and

discharge valves assemblies) as well as the O-rings. The LDPE hose can

also deteriorate over time and, for safety reasons, should also be

changed with HI 720032.

After 24 months

It is recommended to replace HI 721102, HI 721103, HI 720032

and HI 721106.

INSPECTING THE HOSE (if used as supplied with the pump)

Inspect to see if the hose has worn out or weakened due to the

chemicals. Pay particular attention for any signs of abrasion or discoloration. Also check the connectors to ensure they are tight.

Replace if necessary with parts from HI 720032.

CLEANING THE PUMP HEAD

The pump head should be cleaned at regular intervals and at

least once a year. Remove the deposits that form in the cavities with

a solution that is neutral to the chemical the pump has been dosing.

Inspect the head for any cracks or worn areas.

Replace if necessary with parts from HI 721106 (pump head).

24

25

Page 14

ELECTRODE CONDITIONING

AND MAINTENANCE

These bubbles can be removed by "shaking down" the electrode as

you would do with a glass thermometer.

If the bulb and/or junction are dry, soak the electrode in HI 70300

storage solution for at least one hour.

For refillable electrodes**:

If the refill solution (electrolyte) is more than 2½ cm (1") below the fill

hole, add HI 7082 3.5M KCl electrolyte solution for double junction or

HI 7071 3.5M KCl+AgCl electrolyte solution for single junction

electrodes.

For AmpHel® electrodes:

If the electrode does not respond to pH changes, the battery is run

down and the electrode should be replaced.

TEST MEASUREMENT

Rinse the electrode tip with distilled water.

Immerse the tip (bottom 4 cm / 1½") in the sample and stir gently

for approximately 30 seconds.

For a faster response and to avoid cross contamination of the samples,

rinse the electrode tip with the solution to be tested, before taking

your measurements.

STORAGE

To minimize clogging and assure a quick response time, the glass

bulb and the junction should be kept moist and not allowed to dry

out. This can be achieved by installing the electrode in such a way

that it is constantly in a well filled with the sample (stream or tank).

When not in use, replace the solution in the protective cap with a few

drops of HI 70300 storage solution.

Follow the Preparation Procedure above before taking measurements.

NEVER STORE THE ELECTRODE WITH DISTILLED OR DEIONIZED WATER.

* Only available with refillable electrodes. For industrial applications, gel-filled

electrodes are preferable due to lesser maintenance requirements.

PREPARATION

Remove the protective cap.

DO NOT BE ALARMED IF ANY SALT DEPOSITS ARE PRESENT.

This is normal with electrodes and they will disappear when rinsed

with water.

During transport tiny bubbles of air may have formed inside the glass

bulb. The electrode cannot function properly under these conditions.

26

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for the connection

to the controller must be intact and there must be no points of broken

insulation on the cable or cracks on the electrode stem or bulb.

Connectors must be perfectly clean and dry. If any scratches or cracks

are present, replace the electrode. Rinse off any salt deposits with

water.

**For industrial applications, gel-filled electrodes are preferable due to lesser maintenance requirements.

AmpHel® is a registered Trademark of "Hanna Instruments"

27

Page 15

For refillable electrodes**:

Refill the electrode with fresh electrolyte (HI 7071 for single junction or

HI 7082 for double junction electrodes). Allow the electrode to stand

upright for 1 hour. Follow the Storage Procedure above.

CLEANING PROCEDURE

General Soak in HI 7061 general cleaning solution for

approximately 30 minutes.

Removal of films, dirt or deposits on the membrane/junction:

Protein Soak in HI 7073 protein cleaning solution for 15

minutes.

Inorganic Soak in HI 7074 inorganic cleaning solution for

15 minutes.

Oil/ grease Rinse with HI 7077 Oil & Fat cleaning solution.

IMPORTANT: After performing any of the cleaning procedures rinse

the electrode thoroughly with distilled water, drain and refill the

reference chamber with fresh electrolyte (not necessary for gel-filled

electrodes), and soak the electrode in HI 70300 storage solution for at

least 1 hour before reinstalling it.

TROUBLESHOOTING

Evaluate your electrode performance based on the following.

• Noise (Readings fluctuate up and down) could be due to:

- Clogged/Dirty Junction: Refer to the Cleaning Procedure

above.

- Loss of shielding due to low electrolyte level (refillable

electrodes only): refill with HI 7071 for single junction or HI

7082 for double junction electrodes.

• Dry Membrane/Junction: Soak in HI 70300 storage solution for

at least 1 hour. Check to make sure the installation is such as to

create a well for the electrode bulb to constantly remain moist.

• Drifting: Soak the electrode tip in warm HI 7082 solution for

one hour and rinse tip with distilled water (if necessary, refill with

fresh HI 7071 for single junction electrodes and HI 7082 for

double junction electrodes).

• Low Slope: Refer to the cleaning procedure above.

• No Slope: - Check the electrode for cracks in glass stem or

bulb (replace the electrode if cracks are found).

- Make sure cable and connections are not damaged nor lying in a pool of water or solution.

• Slow Response/Excessive Drift: Soak the tip in Hanna Solution HI 7061 for 30 minutes, rinse thoroughly in distilled water

and then follow the Cleaning Procedure above.

• For ORP Electrodes: polish the metal tip with a lightly

abrasive paper (paying attention not to scratch the surface) and

wash thoroughly with water.

Note: with industrial applications, it is always recommended to keep

at least one spare electrode handy. When anomalies are not

resolved with a simple maintenance, change the electrode

(and recalibrate the controller) to see if the problem is

alleviated.

**For industrial applications, gel-filled electrodes are preferable due to lesser maintenance requirements.

28

29

Page 16

TAKING REDOX MEASUREMENTS

Redox measurements allow the quantification of the oxidizing or

reducing power of a solution, and are commonly expressed in mV.

Oxidation may be defined as the process during which a molecule (or

an ion) loses electrons and reduction as the process by which electrons

are gained.

Oxidation is always coupled together with reduction so that as one

element gets oxidized, the other is automatically reduced, therefore

the term oxidation-reduction is frequently used.

Redox potentials are measured by an electrode capable of absorbing

or releasing electrons without causing a chemical reaction with the

elements with which it comes into contact.

The electrodes most usually available for this purpose have gold or

platinum surfaces; gold possesses a higher resistance than platinum

in conditions of strong oxidation such as cyanide, while platinum is

preferred for the measurements of oxidizing solutions containing

halides and for general use.

When a platinum electrode is immersed in an oxidizing solution a

monomolecular layer of oxygen is developed on its surface. This layer

does not prevent the electrode from functioning, but it increases the

response time. The opposite effect is obtained when the platinum

surface absorbs hydrogen in the presence of reducing mediums. This

phenomenon is rough on the electrode.

To make correct redox measurements the following conditions must

prevail:

– The surface of the electrode must be cleaned and smooth.

– The surface of the electrode must undergo a pretreatment in

order to respond quickly.

Because the Pt/PtO system depends on the pH, the pretreatment of

the electrode may be determined by the pH and the redox potential

values of the solution to be measured.

As a general rule, if the ORP mV reading corresponding to the pH

value of the solution is higher than the values in the table below, an

oxidizing pretreatment is necessary; otherwise a reducing pretreatment is necessary:

pH mV pH mV pH mV pH mV pH mV

0 990 1 920 2 860 3 800 4 740

5 680 6 640 7 580 8 520 9 460

10 400 11 340 12 280 13 220 14 160

Reducing pretreatment: immerse the electrode in HI 7091 solution for

a few minutes.

Oxidizing pretreatment: immerse the electrode in HI 7092 solution for

a few minutes.

If the pretreatment is not performed, the electrode will take significantly longer to respond.

As with pH electrodes, gel-filled redox electrodes are more suitable for

industrial applications due to lesser maintenance requirements. However, if working with refillable electrodes, the electrolyte level should

not fall more than 2½ cm (1") below the fill hole and topped up if

necessary. Use HI 7071 refill solution for single junction and HI 7082

for double junction electrodes.

In the event that measurements are performed with solutions containing sulfides or proteins, the cleaning of the diaphragm of the

reference electrode must be performed more often.

In order to have a correct functioning of the ORP electrode, immerse

it into HI 7020 and measure the response; the obtained value should

be within 200 and 275 mV.

After this functional test, it is suggested to wash the electrode

thoroughly with water and proceed to the oxidizing or reducing

pretreatment before taking measurements.

When not in use, the electrode tip should be kept moist and far from

any type of mechanical stress which might cause damage. This can be

achieved by installing the electrode in such a way that it is constantly

in a well filled with the sample (stream or tank). The protective cap

can also be filled with HI 70300 storage solution if the electrode is not

being used at all.

Note: With industrial applications, it is always recommended to keep

at least one spare electrode handy. When anomalies are not

resolved with a simple maintenance, change the electrode to

see if the problem is alleviated.

30

31

Page 17

CHEMICAL COMPATIBILITY GUIDE

PARTIAL LISTING OF CHEMICALS THAT CAN BE USED

WITH BLACKSTONE PUMPS

(Rated for 45°C. For higher temperatures consult your dealer or

nearest Hanna Customer Service Center)

Adipic Acid

Alcohol Amyl

Alcohol, Diacetone

Alcohol, Isoproyl

Alcohol, Methyl

Aluminium, Ammonium Sulfate

Aluminium Chloride

Aluminium Sulfate

Alums

Ammonium Carbonate

Ammonium Chloride

Ammonium Fluoride

Ammonium Hydroxide

Ammonium Nitrate

Ammonium Phosphate

Ammonium Sulfate

Aqua Ammonia

Arsenic Acid

Barium Carbonate

Barium Chloride

Barium Hydroxide

Barium Sulfate

Beer

Beet Sugar Liquors

Bismuth Carbonate

Back Liquor

Bleach

Borax

Boric Acid

Bromic Acid

Butyric Acid

Calcium Bisulfite

Calcium Carbonate

Calcium Chlorate

Calcium Chloride

Calcium Hydroxide

Calcium

Hypochlorite

Calcium Nitrate

Calcium Sulfate

Carbonic Acid

Castor Oil

Caustic Soda

Chloral Hydrate

Chromic Acid 50%

Citric Acid

Copper Chloride

Copper Cyanide

Copper Nitrate

Copper Sulfate

Corn Oil

Cottonseed Oil

Cresylic Acid

Crude Oil

Dextrose

Detergents (general)

Diesel Fuel

Dictyl Phthalate

Disodium Phosphate

Ethanol (1-95%)

Ethylene Dichloride

Ethylene Glycol

Fatty Acids

Ferric Chloride

Ferric Nitrate

Ferric Sulfate

Ferrous Chloride

Ferrous Sulfate

Fluoboric Acid

Fluosilicic Acid

Formaldehyde

Fruit Juice Pulp

Fuel Oil

Gallic Acid

Gasoline, Refined

Glucose

Glycerine or Glycerol

Glycolic Acid 30%

Hexane

Hydrazine

Hydrobromic Acid 20%

Hydrochloric Acid (Concentrated)

Hydrochloric Acid (Diluted)

Hydrofluoric Acid 60%

32

Hydrogen Sulfide Aqueous

Solution

Hypochlorous Acid

Kerosene

Lactic Acid

Lard Oil

Lauric Acid

Lead Acetate

Linoleic Acid

Linseed Oil

Lithium Salts

Magnesium Carbonate

Magnesium Chloride

Magnesium Hydroxide

Magnesium Nitrate

Magnesium Oxide

Magnesium Sulfate

Maleic Acid

Malic Acid

Mercuric Chloride

Methanol

Methyl Sulfate

Milk

Mineral Oils

Noptha Petroleum

Nickel Chloride

Nickel Sulfate

Nitric Acid 50%

Oils and Fats

Oleic Acid

Olive Oil

Oxalic Acid

Palmitric Acid

Perchloric Acid 70%

Perchloroethylene

Petroleum Oils (sour)

Phenol

Phosphoric Acid

Photographic Solutions

Plating Solutions

Potassium Carbonate

Potassium Bromide

Potassium Chlorate

Potassium Chloride

Potassium Cyanide

Potassium Ferrocyanide

Potassium Hydroxide

Potassium Nitrate

Potassium Permanganate 10%

Potassium Phosphate

Potassium Sulfate

Propyl Alcohol

Propylene Dichloride

Sea Water

Silver Nitrate

Silver Plating Solutions

Soaps

Sodium Acetate

Sodium Bicarbonate

Sodium Bisulfate

Sodium Bisulfite

Sodium Borate

Sodium Chlorate

Sodium Chloride

Sodium Cyanide

Sodium Fluoride

Sodium Hexametaphosphate

Sodium Hydroxide 50%

Sodium Hypochlorite 18%

Sodium Metaphosphate

Sodium Nitrate

Sodium Peroxide

Sodium Phosphate

Sodium Silicate

Sodium Sulfate

Sodium Sulfide

Sodium Sulfite

Sodium Thiosulfate

Sour Crude Oil

Stannic Chloride

Stannous Chloride

Stearic Acid

Sulfur

Sulfuric Acid Concentration

Sulfurous Acid

Tannic Acid

Tanning Liquors

Tartaric Acid

Tetrachlorethane

Tetraethyl Lead

Tetralin

Tin Salts

Vegetable Oils

Vinegar

Water Acid, Mine

Water, Fresh

Water, Distilled

Water, Salt

Whiskey

Wines

Zinc Chloride

Zinc Sulfate

33

Page 18

ACCESSORIES

®

T

Y

SPARE PARTS

HI 721102 Discharge Valve (Glass Ball, Valve O-Ring, Hose Con-

nector)

HI 721101 Pump head, O-Ring, 6 screws and washers

HI 721106 Pump head, Large PTFE Diaphragm, Aluminum

Piston and Aluminum Disk

TUBE NUT HEAD NIPPLE SPACER

CHECK

BALL

VALVE

SEAT

VITON

O-RING

HI 721103 Suction Valve (Glass Ball, Valve O-Ring, Hose Connec-

tor)

CHECK

VITON®

O-RING

BALL

VALVE

SEAT

HEAD NIPPLE TUBE NU

HI 721003 10 x Glass Balls and 10 x Valve O-Rings

HI 721004 Injection Valve Assembly

CHECK

PVDF

SPRING

BALL

VALVE ASSEMBLYINJECTION NIPPLE KYNAR®

HI 721005 Foot Valve Assembly

FILTER FILTER HOLDER

VALVE ASSEMBL

HI 721006 PVDF Springs, 4 pcs

HI 720032 LDPE Hose - 100 m (330')

HI 721008 Ceramic Weights, 4 pcs

PUMP HEAD DIAPHRAGM

pH CALIBRATION SOLUTIONS

HI 7004M pH 4.01 buffer solution, 230 mL bottle

HI 7004L pH 4.01 buffer solution, 500 mL bottle

HI 7006M pH 6.86 buffer solution, 230 mL bottle

HI 7006L pH 6.86 buffer solution, 500 mL bottle

HI 7007M pH 7.01 buffer solution, 230 mL bottle

HI 7007L pH 7.01 buffer solution, 500 mL bottle

HI 7009M pH 9.18 buffer solution, 230 mL bottle

HI 7009L pH 9.18 buffer solution, 500 mL bottle

HI 7010M pH 10.01 buffer solution, 230 mL bottle

HI 7010L pH 10.01 buffer solution, 500 mL bottle

ORP SOLUTIONS

HI 7020M 200-275mV test solution, 230 mL bottle

HI 7020L 200-275mV test solution, 500 mL bottle

HI 7091M Reducing pretreatment solution, 230 mL

HI 7091L Reducing pretreatment solution, 500 mL

HI 7092M Oxidizing pretreatment solution, 230 mL

HI 7092L Oxidizing pretreatment solution, 500 mL

MAINTENANCE SOLUTIONS

HI 70300M Storage solution, 230 mL botte

HI 70300L Storage solution, 500 mL bottle

HI 7061M General cleaning solution, 230 mL botte

HI 7061L General cleaning solution, 500 mL bottle

HI 7073M Protein cleaning solution, 230 mL botte

HI 7073L Protein cleaning solution, 500 mL bottle

HI 7074M Inorganic cleaning solution, 230 mL botte

HI 7074L Inorganic cleaning solution, 500 mL bottle

HI 7077M Oil & Fat cleaning solution, 230 mL bottle

34

35

Page 19

HI 7077L Oil & Fat cleaning solution, 500 mL bottle

HI 7071 3.5M KCl+AgCl electrolyte solution, 4x50 mL, for

single junction electrodes

HI 7072 1M KNO3 electrolyte solution, 4x50 mL

HI 7082 3.5M KCl electrolyte solution, 4x50 mL, for double

junction electrodes

RECOMMENDED pH ELECTRODES

All electrodes are gel-filled and with ceramic junction unless otherwise

indicated.

HI 1090T Screw connector, external PG13.5 thread, double junc-

tion, glass-body

HI 1110S Screw connector, single junction, glass-body

HI 1130B/3 BNC connector, 3 m (9.9') cable, single junction, glass-

body with external thread

HI 1110T Screw connector, external PG13.5 thread, double junc-

tion, glass-body with ground glass junction

HI 1114S Screw connector, double junction plastic-body

HI 1134B/3 BNC connector, 3 m (9.9') cable, double junction,

plastic body with external thread

HI 1115S Screw connector, single junction, refillable with side-

arm, glass-body

HI 1135B/3 BNC connector, 3 m (9.9') cable, single junction,

refillable with side-arm, glass-body

HI 1210T Screw connector, external PG13.5 thread, double junc-

tion, plastic body, cloth junction

HI 1910B BNC connector, 1 m (3.3') cable, double junction,

plastic body with built-in amplifier and external thread

HI 1912B BNC connector, 1 m (3.3') cable, double junction,

plastic body with built-in amplifier and external thread

HI 1912B/5 BNC connector, 5 m (16.5') cable, double junction,

plastic body with built-in amplifier and external thread

HI 2114B/5 BNC connector, 5 m (16.5') cable, double junction,

plastic body with external thread and cloth junction

HI 2910B/5 BNC connector, 5 m (16.5') cable, double junction,

plastic body with built-in amplifier and cloth junction

PLATINUM ORP ELECTRODES

HI 2930B/5 BNC connector, 5 m (16.5') cable, double junction, Pt,

plastic body with built-in amplifier, external thread

and cloth junction

HI 3110S Screw connector, single junction, Pt, glass-body

HI 3130B/3 BNC connector, 3 m (9.9') cable, Pt, glass-body with

external thread

HI 3110T Screw connector, external PG13.5 thread, double

junction, Pt, glass-body

HI 3115S Screw connector, single junction, Pt, refillable with

side-arm, glass-body

HI 3135B/3 BNC connector, 3 m (9.9') cable, single junction, Pt,

refillable with side-arm, glass-body

HI 3210T Screw connector, external PG13.5 thread, double junc-

tion, Pt, plastic body

HI 3410S Screw connector, double junction, Pt, plastic body

HI 3430B/3 BNC connector, 3 m (9.9') cable, double junction, Pt,

plastic body with external thread

HI 3932B/5 BNC connector, 5 m (16.5') cable, double junction, Pt,

plastic body with built-in amplifier and external thread

GOLD ORP ELECTRODES

HI 4110S Screw connector, single junction, Au, glass-body

HI 4130B/3 BNC connector, 3 m (9.9') cable, single junction, Au,

glass-body with external thread

HI 4932B/5 BNC connector, 5 m (16.5') cable, double junction,

Au, plastic body with built-in amplifier and external

thread

OTHER ACCESSORIES

ChecktempC Electronic thermometer (range -50.0 to 150.0°C)

ChecktempF Electronic thermometer (range -58.0 to 302°F)

HI 8614 pH transmitter

HI 8614L pH transmitter with LCD

HI 8615 ORP transmitter

HI 8615L ORP transmitter with LCD

BL PUMPS Dosing pumps with flow rate from 1.5 to 20 LPH

HI 7871 & HI 7873 Level controllers

HI 6050 & HI 6051 Submersible electrode holders

HI 6054 & HI 6057 Electrode holders for in-line applications

HI 778P Screened coaxial cable with screw connectors

HI 8427 pH/ORP electrode simulator

HI 931001 pH/ORP electrode simulator with LCD

36

37

Page 20

CE DECLARATION OF CONFORMITY

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the environment in which they are used.

Operation of these instruments in residential areas could cause unacceptable interference to radio and TV equipment.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

Unplug the instruments from power supply before replacing the fuse or making any

electrical connections.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance

notice.

Page 21

SALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and complete list of Sales and

Technical offices, please see www.hannainst.com

MAN7916R3

07/05

Loading...

Loading...