HanleyLED Concorde Cabinet System Installation Manual

GENERAL PURPOSE

RETROFIT SIGN

CONVERSION

FOR USE ONLY IN

ACCORDANCE WITH KIT

INSTRUCTIONS

KIT IS COMPLETE ONLY WHEN ALL PARTS

REQUIRED BY THE INSTRUCTIONS ARE PRESENT

12.18.18

BEFORE YOU BEGIN

Determine your light bar mounting method. Are you using pre-existing sockets to mount?

If so, Retrot Connectors are included. If not, be sure to purchase our Speed Spring Brackets

for fast and secure mounting.

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY

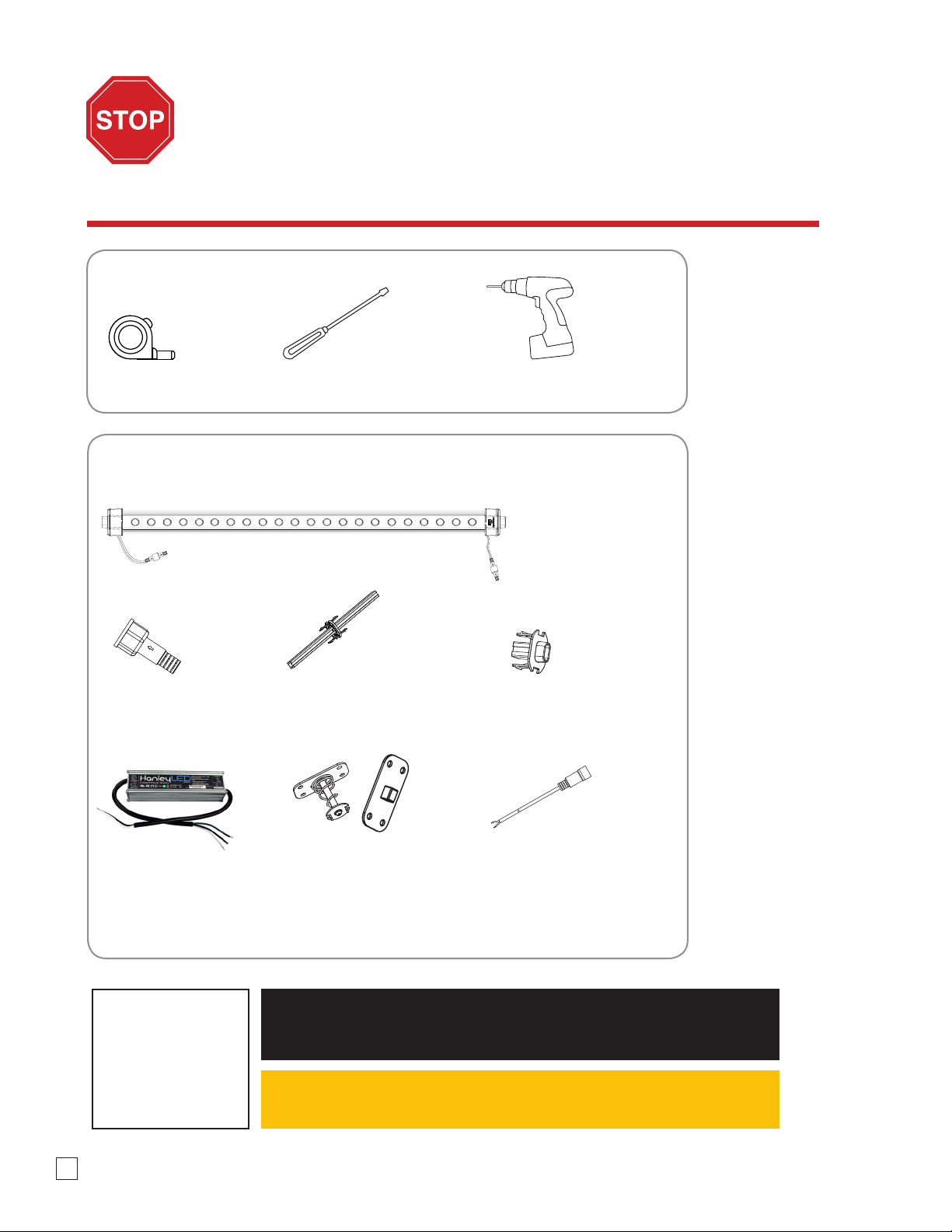

Tools required:

Screwdriver Electric DrillTape Measure

Components:

Concorde Cabinet Bars

24v Power Supply Speed Spring Bracket Set

(Spring and stationary)

Optional

Retrot (RF) ConnectorWatertight End Cap Concorde Joint

Concorde Cable Connectors

Optional

NOTE:

All materials removed

must be disposed of

in accordance with

applicable local, state,

and federal laws.

2

WARNING check polarity: All connections must be WHITE-TO-RED (+) and BLACK-TO-BLACK (-).

Reverse polarity connections may damage the LEDs and will void product warranty.

Caution: Turn o power to sign before inspecting or removing existing light source.

Power must remain o while installing the Concorde Cabinet System.

RETROFIT INSTALLATION GUIDE

Concorde Cabinet System

This guide is designed to aid in the installation of HanleyLED’s Concorde Cabinet System. Skilled trades people that are familiar with

general construction, electrical, and sign installation techniques should do the installation. Licensed electricians should provide all

installation and hook-up of both the primary and secondary input/outputs of the HanleyLED power supply. All installation and hookup should be done in accordance with all National and Local codes and permits. In no way is this document intended to construe

warranty or tness of use of the products described, nor is it intended to provide safety instruction for those installing the product.

THE FIELD INSTALLATION OF THIS RETROFIT SYSTEM INTO A SIGN IS SUBJECT TO THE

ACCECPANCE OF LOCAL INSPECTION AUTHORITY.

CAUTION: TURN OFF POWER TO THE SIGN BEFORE INSPECTING OR REMOVING EXISTING LIGHT

SOURCE. THE POWER MUST REMAIN OFF WHILE INSTALLING THE LED RETROFIT KIT.

Tools Required:

• Wire cutter & strippers

• Measuring tape

• Marking pens

• Drill

• Standard hardware and supplies in addition to the HanleyLED modules

installation guides (UL listing may be required on certain items)

Prepping the Channel Letter or Cabinet

Step 1

Remove existing neon or uorescent bulbs by having a licensed electrician disconnect and remove the neon transformers or

uorescent ballasts. Remove existing neon and standos or uorescent lamps. Leave uorescent sockets in cabinets with leads

disconnected. This should leave an empty channel letter or cabinet.

NOTE: ALL MATERIALS REMOVED MUST BE DISPOSED OF IN ACCORDANCE WITH

APPLICABLE LOCAL, STATE AND FEDERAL LAWS.

Step 2

Using a non- oil based cleaner, clean the back surfaces of the channel letter or cabinet where the LED modules will be mounted.

This is an important step for good adhesion of HanleyLED modules mounting tape.

Step 3

Installer should examine all parts that are not intended to be replaced by the retrot kit for damage and replace any damaged

parts prior to installation of the retrot kit. Do not make or alter any open holes in an enclosure of wiring or electrical

components during kit installation. Any existing holes in the letters or cabinet that will not be used in the installation of HanleyLED

modules should be patched to avoid water damage. Openings smaller than ½” diameter may be sealed with the appropriate

amount of rated caulk or sealant. Openings larger than ½” should be patched using an aluminum or zinc coated steel patch with

rivets and sealant.

Step 4

Proceed with the appropriate HanleyLED module installation guide for your specic product.

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

3

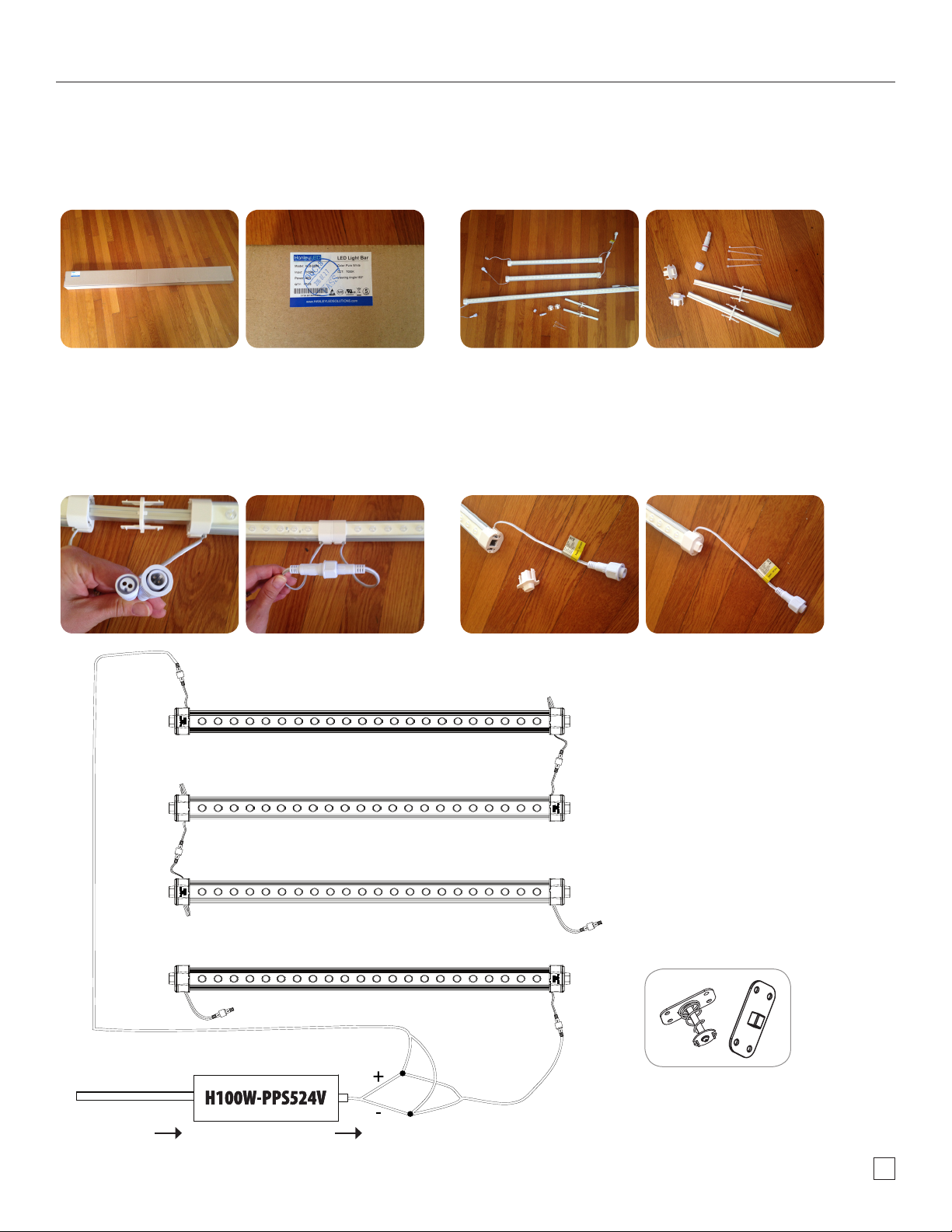

Concorde Cabinet System Quick Assembly

Step 1

Order the size light bar just as you would order your replacement orescent

lamps. Pick the size you want. Ever ything you’ll need to ass emble the bar will be

in the box. This guide shows how to ass emble a 96” Concorde LED Bar System.

Step 3

Connect all your Concorde pie ces by using the Concorde Connec tor Joints.

Tighten the watertight wire ports.

** Pay attention to the male and female ends when assembling.

Step 2

Make sure you have all your pieces for ass embly. Take all the Concorde

components out of the box.

Step 4

Place your Concorde Retrot (RF) Connector s on each side of the bar. The RF Connec tors mount

straight into the HO socket s of your existing cabinet making this an easy retrot install. Screw

in Watertight End Cap to the unused wire por t.

Input

Output

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

For new construction, the Conorde Speed

Spring brackets are available for purchas e

4

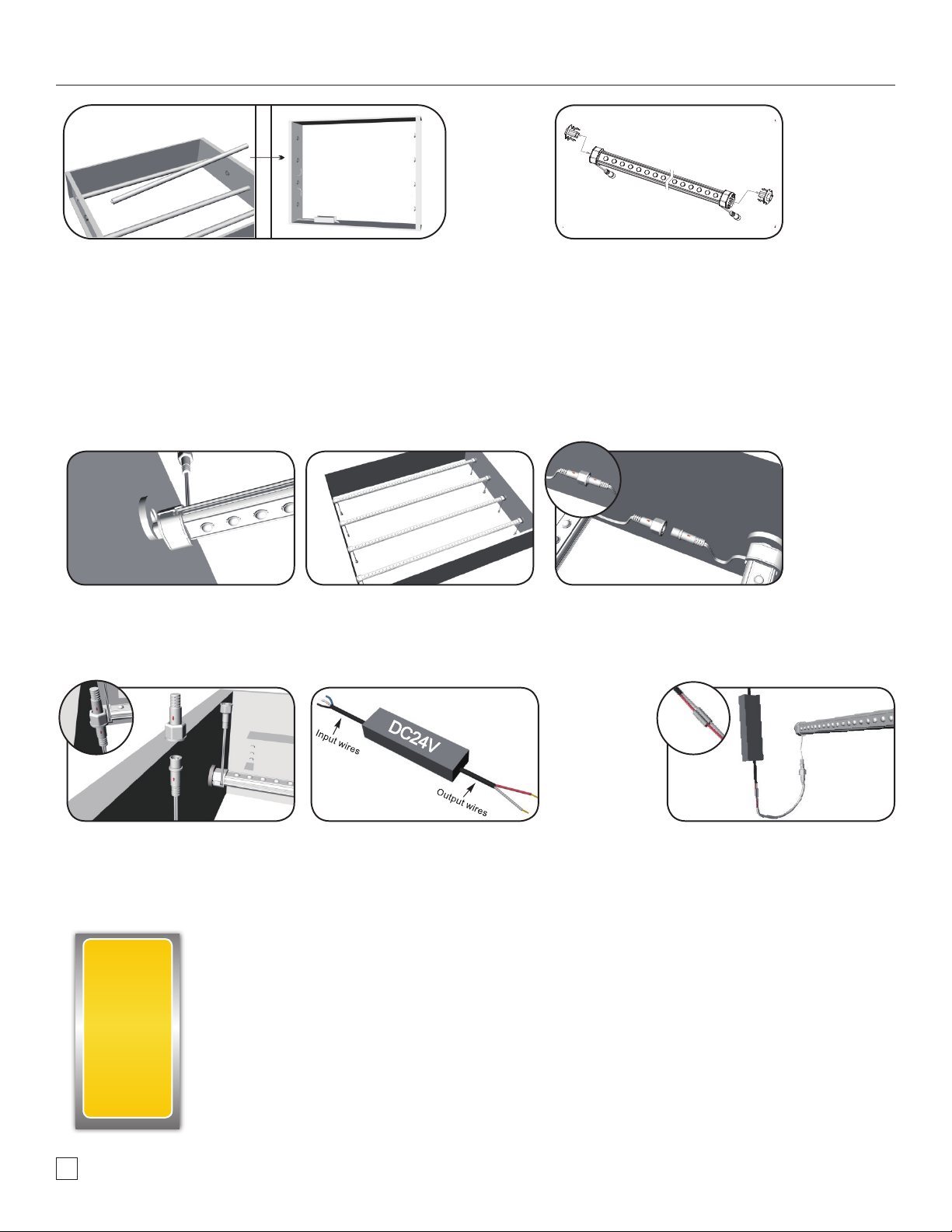

Retrot Installation For Use With Existing Fluorescent Box Signs

1. Remove Existing Fluorescent Tubes 2. Connect all light bar pieces, if necessary.

• Make sure power is o. Have a licensed electrician disconnect and remove all ballasts.

• Remove existing uorescent tubes, leaving uorescent lamp holders in place.

• Installers should disconnect lamp holder leads and make new connections from the LED driver directly to the LED

lamps. Lamp holders are to be used only for the purpose of holding the LED lamps in place.

• (Existing Signs Only) If removal of the existing lighting equipment eliminates the disconnect switch, as required by

applicable local, state, or country electrical codes; a new disconnect switch must be installed.

• (Existing Signs Only) Make sure the removal of lighting equipment does not compromise the integrity of the sign body

(i.e. water intrusion). Fill in all holes 0.5 in. (13 mm) or smaller with the appropriate amount of rated caulk or sealant.

For holes greater than 0.5 in. (13 mm), use an aluminum or zinc coated steel patch with rivets and sealant.

Install Retrot Connectors on each side of light bar.

3. Insert Light bars into lamp-sockets

End Cap provided in box, or use another extension cable

to tie the port back to the power supply.

This sign

has been

modied

to operate

LED lamps.

Do not

attempt

to install

or operate

uorescent

lamps in

this sign.

8. This sign has been modied to operate LED lamps. Do not attempt to

install or operate uorescent lamps in this sign. The marking for item

shall have a minimum letter height of 2.4 mm (3/32 in) and shall be in

Universal Bold, Arial Bold, Helvetica Bold, or Zurich BT Bold or equivalent

font. Markings in this image shall be provided verbatim.

4. Connections: Wire the Concorde bars with male and female connectors to make longer

cascade. (see Cascading Information Guidelines on page 7 to see how many bars can

be run in a series)

6. Mount power supply5. Unused wire ports should be capped with Watertight

• Identify input and output secondary wires. Connect the power unit to the supply

in accordance with the applicable local, state, and country electrical codes, and the

instructions found in the power supply installation guide. All power supplies must be

installed in a raceway or suitable electrical enclosure.

• If required, the disconnect switch shall be installed by qualied personnel, in

accordance with applicable local, state, and country electrical codes.

• Spacing between LED power supplies shall be at least 25.4 mm (1 in) from end to end

and 101.6 mm (4 in) from side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

7. Connect to power supply: Connect the white output

wire to the red Concorde cable wire and the black

output wire to the black cable wire. Connect female

cable end to male end coming o of Concorde bar and

tighten collar.

5

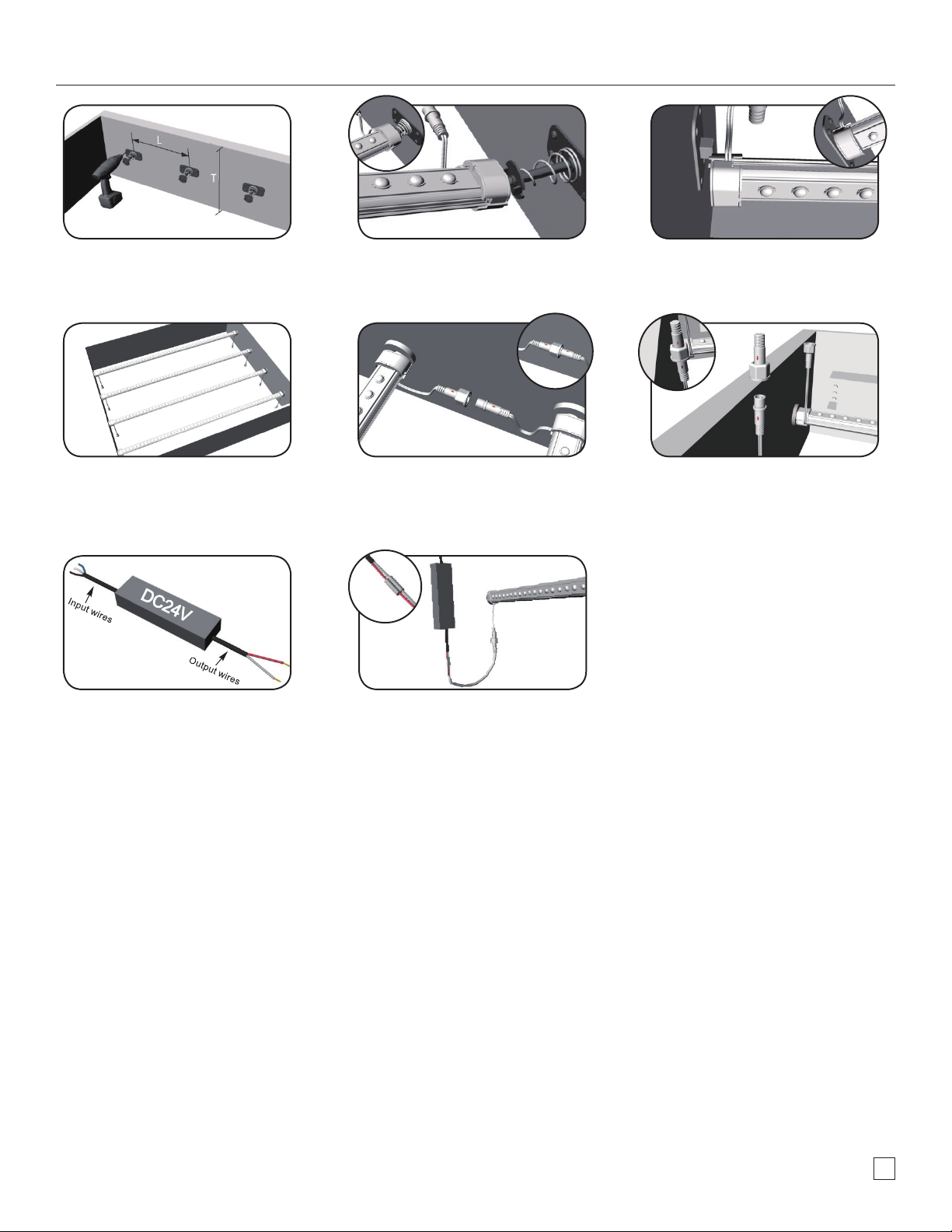

New Construction Installation

1. Mount Speed Spring Brackets and Stationary Brackets to each

side of sign box. (Mount bracket base parrallel to the direction

of your raceway)

4. Verify all LEDs of light bars point to sign face. 5. Connections: Wire the Concorde bars with male and female

2. lnsert Light bars onto Speed Spring Brackets rst. 3. Push the Concorde Bars down onto the Speed Spring Bracket,

connectors to make longer cascade. (see Cascading

Information Guidelines on page 7 to see how many bars can

be run in a series)

then insert other end onto stationary bracket.

6. Unused wire ports should be capped with Watertight End

Cap provided in box, or use another extension cable to tie

the port back to the power supply.

7. Mount power supply

• Identify input and output secondary wires. Connect the

power unit to the supply in accordance with the applicable

local, state, and country electrical codes, and the

instructions found in the power supply installation guide.

All power supplies must be installed in a raceway or suitable

electrical enclosure.

• If required, the disconnect switch shall be installed by

qualied personnel, in accordance with applicable local,

state, and country electrical codes.

• Spacing between LED power supplies shall be at least

25.4 mm (1 in) from end to end and 101.6 mm (4 in) from

side to side, in accordance with UL 48 Par. 4.2.3.2.3.1

8. Connect to power supply: Connect the white output wire to

the red Concorde cable wire and the black output wire to the

black cable wire. Connect female cable end to male end

coming o of Concorde lamp and tighten collar.

9. Make sure all wire connections are ready and correct.

Installation Guide | www.hanleyledsolutions.com | 800.542.9941

6

Loading...

Loading...