3158050 Rev. E 1/08

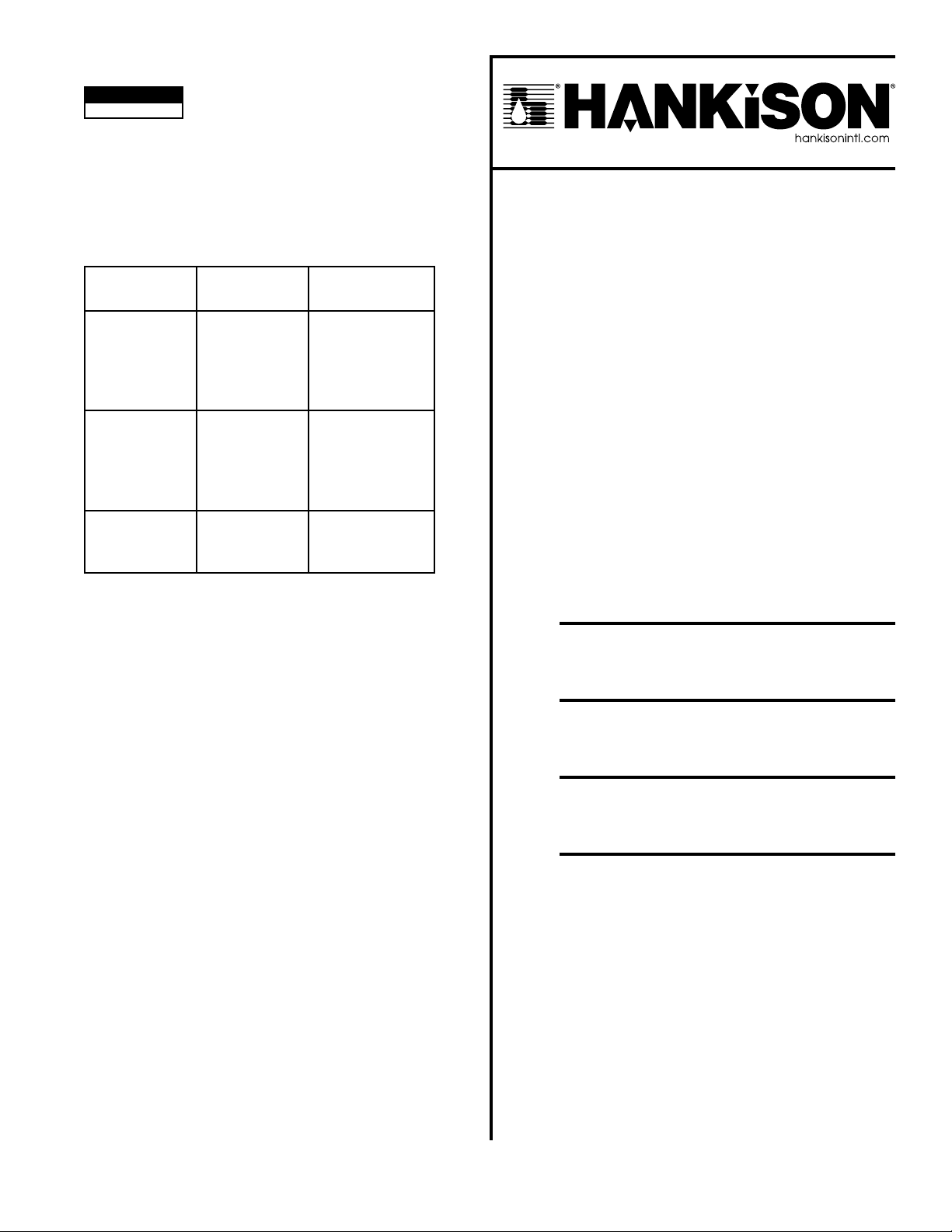

XX-XXX-X

Internal Use Only

3158050e / 080102

INSTRUCTION MANUAL

HBP SERIES

MODELS

HBP500

HBP600

HBP750

HBP900

HBP1050

HBP1300

HBP1500

HBP1800

HBP2200

HBP2600

HBP3200

HBP3600

HBP4300

RATED

FLOW

500 SCFM

600 SCFM

750 SCFM

900 SCFM

1050 SCFM

1300 SCFM

1500 SCFM

1800 SCFM

2200 SCFM

2600 SCFM

3200 SCFM

3600 SCFM

4300 SCFM

MODEL

REFERENCE

500

600

750

900

1050

1300

1500

1800

2200

2600

3200

3600

4300

Contents

1.0 General Safety Information ........................... 2

2.0 Receiving, Storing, and Moving ..................... 2

3.0 Description .................................................... 3

4.0 Installation ..................................................... 3

5.0 Instrumentation .............................................. 8

6.0 Operation ....................................................... 12

7.0 Maintenance .................................................. 29

8.0 Troubleshooting ............................................. 31

BLOWER PURGE

DESICCANT

COMPRESSED

AIR DRYERS

Drawings

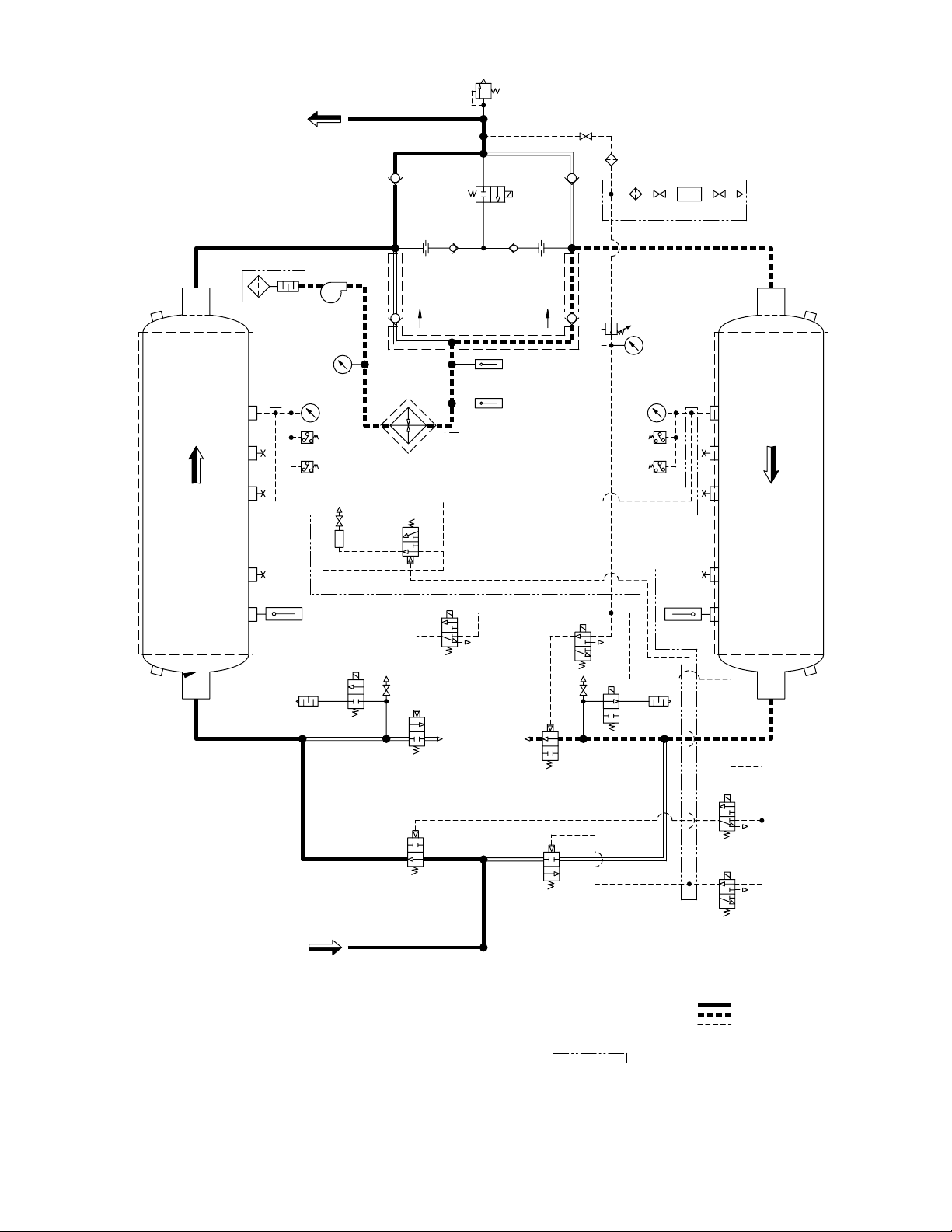

P&ID Schematic Models 500 through 600 ............ 34

P&ID Schematic Models 750 through 4300 .......... 36

Electrical Schematic – 460VAC, 3 phase .............. 38

Electrical Schematic – 575VAC, 3 phase .............. 39

Electrical Schematic – 380VAC, 3 phase .............. 40

Electrical Schematic – 415VAC, 3 phase .............. 41

Electrical Data – Fusing & Wire Sizing .................. 42

WARRANTY .......................................................... 44

SERVICE DEPARTMENT : (724) 746-1100

1.0 General Safety Information

DANGER—Immediate hazard which will result in severe

injury or death.

This equipment is designed and built with safety as a

prime consideration; industry-accepted safety factors

have been used in the design. Each dryer is checked at

the factory for safety and operation. All pressure vessels which fall under the scope of ASME Section VIII,

are hydrostatically tested in accordance with the latest

addenda. A factory-installed safety relief valve is standard

on each dryer.

WARNING — The following safety rules must be

observed to ensure safe dryer operation. Failure to

follow these rules may void the warranty or result in

dryer damage or personal injury.

1. Never install or try to repair any dryer that has been

damaged in shipment. See the Receiving and Inspection instructions in this manual for appropriate

action.

2. This equipment is a pressure-containing device.

Never operate the dryer at pressures or temperatures

above the maximum conditions shown on the data

plate.

Never dismantle or work on any component of the

dryer or compressed air system under pressure.

Vent internal air pressure to the atmosphere before

servicing.

3. This equipment requires electricity to operate. Install

equipment in compliance with national and local electrical codes. Standard equipment is supplied with

NEMA 4, 4X electrical enclosures and is not intended

for installation in hazardous environments.

Never perform electrical service on the dryer unless

the main power supply has been disconnected. Parts

of the control circuit may remain energized when the

power switch is turned off.

WARNING—Hazard or unsafe practice which could

result in severe injury or death.

CAUTION—Hazard or unsafe practice which could result

in minor injury or in product or property damage.

The dryer data plate, attached to the electrical control

box, contains critical safety and identification information. If the data plate is missing or defaced, immediately

contact your local distributor for a replacement.

2.0 Receiving, Storing, and Moving

2.1 Receiving and Inspection

This shipment has been thoroughly checked, packed

and inspected before leaving our plant. It was received

in good condition by the carrier and was so acknowledged.

Immediately upon receipt, thoroughly inspect for visible

loss or damage that may have occurred during shipping.

If this shipment shows evidence of loss or damage at

time of delivery to you, insist that a notation of this loss or

damage be made on the delivery receipt by the carrier’s

agent. Otherwise no claim can be enforced against the

carrier.

Also check for concealed loss or damage. When a shipment has been delivered to you in apparent good order,

but concealed damage is found upon unpacking, notify

the carrier immediately and insist on his agent inspecting

the shipment. The carrier will not consider any claim for

loss or damage unless an inspection has been made. If

you give the carrier a clear receipt for goods that have

been damaged or lost in transit, you do so at your own

risk and expense. Concealed damage claims are not our

responsibility as our terms are F.O.B. point of shipment.

Shipping damage is not covered by the dryer warranty.

4. Air treated by this equipment may not be suitable

for breathing without further purification. Refer to

OSHA standard 1910.134 for the requirements for

breathing quality air.

5. Certain parts of the dryer are not insulated and may

become hot during normal operation of the dryer. Do

not touch any of these areas without first determining

the surface temperature.

6. Use only genuine replacement parts from the manufacturer. The manufacturer bears no responsibility for

hazards caused by the use of unauthorized parts.

Safety instructions in this manual are boldfaced for

emphasis. The signal words DANGER, WARNING and

CAUTION are used to indicate hazard seriousness levels

as follows:

2

2.2 Storing

Store the dryer indoors to prevent damage to any electrical or mechanical components. All packaging material

should be left in place until the dryer is in position.

2.3 Handling

The dryer is designed to be moved by means of the shipping skid or the base channels. The dryer may also have

lifting lugs for use with an overhead crane. Be sure to

attach all of the lift points and use appropriate spreader

bars to prevent damage to the dryer.

CAUTION — Never lift the dryer by attaching hooks

or slings to the piping, or to any part other than the

lifting lugs. Severe structural damage could occur.

3.0 Description

3.1 Function

Blower purge type regenerative dryers are an economical and reliable way to dry compressed air to dew points

below the freezing point of water. Desiccant dryers lower

the dew point of compressed air by adsorbing the water

vapor present in the compressed air onto the surface of

the desiccant. Adsorption continues until equilibrium is

reached between the partial pressure of the water vapor

in the air and that on the surface of the desiccant.

systems supplied by a lubricated air compressor, use a

High Efficiency Oil Removal Filter. A coarser filter will

be required upstream of the Oil Removal Filter if heavy

liquid or solid loads are present.

To ensure downstream air purity (prevent desiccant dust

from traveling downstream) adequate filtration downstream of the dryer is required. A High Temperature

Afterfilter, typically rated at 450°F (232°C) operating

temperature and capable of removing all desiccant

fines 1 micron and larger should be installed at the dryer

outlet.

These dryers continuously dry compressed air by using

two identical towers, each containing a desiccant bed.

While one tower is on-stream drying, the other tower is

off-stream being regenerated (reactivated, i.e. dried out).

The towers are alternated on- and off-stream so that dry

desiccant is always in contact with the wet compressed

air. In this way a continuous supply of dry air downstream

of the dryer is possible. The switching from one tower

to the other is controlled by a solid-state controller on

either a fixed time basis (standard) or a demand basis

(optional).

When a tower is placed off-line, it is slowly depressurized and the desiccant is regenerated. First, a blower

draws in ambient air which is heated. The heated air

flows through the desiccant bed, desorbs the moisture

from the desiccant, and carries the desorbed water out

of the dryer. The blower and heater are turned off when

the desiccant bed is fully heated. When configured for

cooling, a portion of the dry compressed air is diverted

from the main air flow and throttled to near atmospheric

pressure. This extremely dry, low pressure air passes

through the hot off-line tower, partially cooling the desiccant bed and reducing the dew point spike after tower

change over. At the end of the cooling stage, the tower

is repressurized to full line pressure. This prevents desiccant bed movement and downstream pressure loss when

the tower goes back on-line.

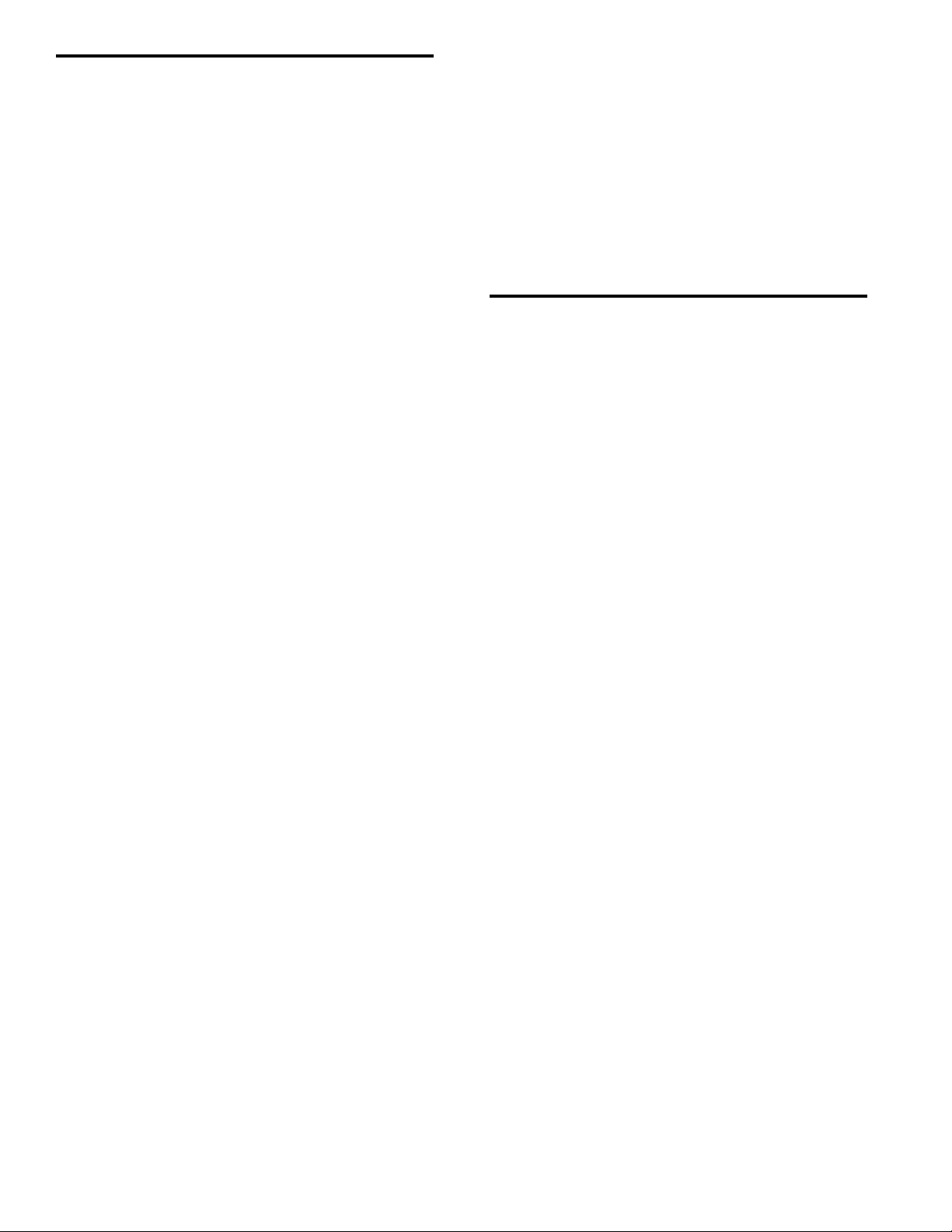

4.0 Installation

4.1 System Arrangement

Install the dryer downstream of an aftercooler, separator,

receiver, and high-efficiency oil-removing filter(s) so that

the dryer inlet air is between 40°F (4.4°C) and 120°F

(49°C) and contains no liquid water or oil. Liquid water

and/or inlet air temperatures above 100°F (37.8°C) can

reduce drying capacity. Contact your local distributor

for information on proper dryer sizing at elevated inlet

air temperatures.

Adequate filtration is required upstream of the dryer in

order to protect the desiccant bed from liquid and solid

contamination. Use an Air Line Filter in systems supplied by a non-lubricated (oil-free) air compressor. In

DANGER — This dryer must be fitted with a high

efficiency coalescing filter and liquid drainer that is

maintained properly. Failure to do so could result

in an in-line fire.

WARNING — The afterfilter, if installed, must be rated

for 450°F (232°C).

4.2 Ambient Air Temperature

Locate the dryer under cover in an area where the ambient air temperature will remain between 35°F (2°C) and

120°F (49°C).

NOTE: If dryer is installed in ambients below 35°F

(2°C), low ambient protection requiring heat tracing

and insulation of the prefilter bowls, auto drains and/

or sumps, and lower piping with inlet switching and

purge/repressurization valves is necessary to prevent

condensate from freezing. If installing heat tracing, observe electrical class code requirements for type of duty

specified. Purge mufflers and their relief mechanisms

must be kept clear from snow and ice buildup that could

prevent proper discharge of compressed air.

4.3 Location and Clearance

Install the dryer on a level pad. Ensure the dryer is

level by grouting or shimming as necessary. Holes are

provided in the dryer base members for floor anchors.

Securely anchor the dryer frame to the floor. Allow 24

inches clearance on all sides of the dryer for servicing. Provide adequate clearance for prefilter element,

afterfilter element and heater element replacement.

Provide protection for the dryer if it is installed where

heavy vehicles or similar portable equipment is likely to

cause damage.

4.4 Piping and Connections

All external piping must be supplied by the user unless

otherwise specified. Refer to Figure 2 for connection

sizes. Inlet and outlet isolation valves and a vent valve

are recommended so the dryer can be isolated and

depressurized for servicing. The connections and pipe

fittings must be rated for or exceed the maximum operating pressure given on the dryer nameplate and must

be in accordance with industry-wide codes. Be sure all

3

Compressor Aftercooler Separator Receiver Prefilters Afterfilters ReceiverDesiccant Dryer

Figure 1

Typical System Configuration

piping is supported. Do not allow the weight of any piping to bear on the dryer or filters. Piping should be the

same size as or larger than the dryer connection. Piping

smaller than the dryer connections will cause high pressure drop and reduce drying capacity.

If the purge exhaust piping must be extended outside the

dryer area, choose a combination of diameters, lengths,

and turns that limits the additional pressure drop to 1/4

psid or less. BACK PRESSURE WILL CAUSE DRYER

MALFUNCTION. Consult the factory for piping details

if required.

WARNING — Do not operate dryer without installed

mufflers. Exhausting compressed air directly to

atmosphere will result in noise levels above OSHA

permissible levels and rapidly expanding gas could

potentially cause harm to persons or property.

Dryer bypass piping may be installed to allow uninterrupted airflow during servicing. If the downstream application cannot tolerate unprocessed air for short periods,

install a second dryer in the bypass line.

CAUTION — Do not hydrostatically test the piping

with the dryer in the system. The desiccant will be

damaged if saturated with water.

4.5 Electrical Connections

WARNING — These procedures require entering

gaining access to the dryer’s electrical enclosure(s).

All electrical work must be performed by a qualified

electrical technician.

Connect the proper power supply to the dryer according

to the electrical drawings in the back of this manual. Be

sure to follow all applicable electrical codes.

NOTE: A disconnect switch is not provided as standard

equipment and therefore, must be supplied by the customer.

Dry contacts (voltage free) are provided in the low tension electrical enclosure for a remote alarm. The contact

ratings are shown on the electrical drawing.

Connections to voltage-free common alarm contacts

with a minimum 5-amp rating can be made at terminals

TB4-1 through 3.

• Terminal TB4-3 is the common alarm connection.

• Terminal TB4-1 is the N.O.. (normally open) contact

connection.

• Terminal TB4-2 is the N.C. (normally closed) contact

connection.

• The alarm relay coil is energized when power is

supplied to the controller input terminals and there

is no alarms.

• The coil is de-energized when power is removed or

when an alarm condition exists.

NOTE: Before turning high voltage on to the dryer, an

ohmic test should be performed on the heater elements

to insure they are dry before proceeding with start-up.

This should be done after extended shut downs and long

delays between delivery and start-up. Connect one lead

of a megger to an unpainted surface of the control panel

or dryer frame. Connect the other lead to each phase

on the load side of the contactor. Adjust the megger to

the 1500 volt setting. Perform the ohmic test on each

zone of the heaters. A minimum value of 500k ohms

must be obtained.

CAUTION - Failure to ohmic test heaters after extended periods may cause heater failure.

4.5.1 RS-232 Connections

RS-232 connections can be made at the 3-pin connector

labeled J3 and located at the upper left-handed corner

of the control board. A cable for this connection can be

purchased through your distributor.

4.6 Initial Desiccant Charge

Blower purge type regenerative dryers use activated

alumina as the desiccant in the dryer towers.

Models 500 through 1050 are shipped with activated

alumina (1/8” bead) in the dryer towers. Desiccant is

shipped loose with all other standard models.

4

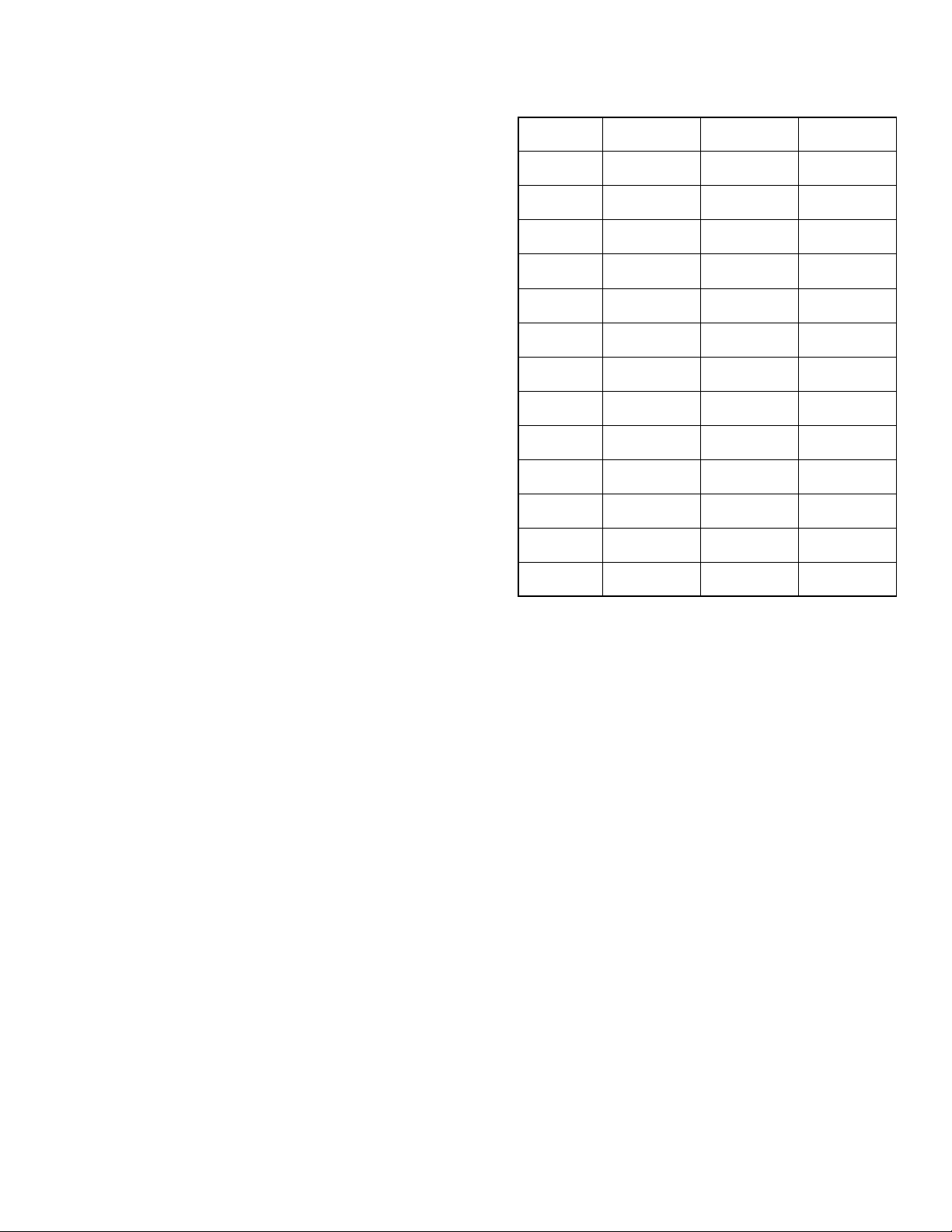

All desiccant shipped loose must be added to the

dryer chambers before the dryer is put into service

Refer to TABLE 1, DESICCANT REQUIREMENTS for

desiccant type and quantity per tower.

TO ADD DESICCANT

WARNING — The following procedure provides instructions for adding the initial desiccant to the towers. If replacing desiccant, refer to the “Procedure

for Desiccant Charge Replacement” in Section 7.0.

1. Verify pressure gauges of both towers indicate

0 psig. If not, depressurize the towers according to

the shutdown instructions in Section 6.

2. Remove the pipe plug or fill port flange cover (where

applicable) from the desiccant fill port at the top of

each tower. Refer to Figure 3 for the fill port location.

CAUTION – Pouring desiccant creates a fine dust;

safety goggles, gloves and a dust mask should be

worn by personnel installing desiccant. Refer to the

Material Safety Data Sheet that accompanies desiccant shipped loose for more complete information.

CAUTION – Do not tamp the desiccant in the towers.

Tamping damages desiccant and causes dusting.

3. Refer to Table 1 for desiccant quantity per tower.

When using Table 1 you will find the desiccant quan-

tities listed in layers. Each layer will vary in depth

due to the type, quantity and purpose of the desiccant. Layer 1 must be installed first at the bottom of

the vessel followed by layer number 2 etc., until the

complete charge of desiccant has been installed.

TABLE 1

DESICCANT REQUIREMENTS

(Quantity per Tower)

Layer

Model

500

600

750

900

1050

1300

1500

1800

2200

2600

3200

3600

4300

* AA = Activated Alumina

** TS = Tabular Support

1 2 3

354#

1/8” bead AA

453#

1/8” bead AA*

590#

1/8” bead AA

590#

1/8” bead AA*

710#

1/8” bead AA

48#

1/4” bead AA*

92#

1/4” bead AA*

92#

1/4” bead AA*

161#

1/4” bead AA

161#

1/4” bead AA*

258#

1/4” bead AA*

258#

1/4” bead AA*

719#

1/2” bead TS**

1/8” bead AA*

1/8” bead AA*

1/8” bead AA*

1/8” bead AA*

1/8” bead AA*

1/8” bead AA*

1/8” bead AA*

1/4” bead AA*

— —

— —

— —

— —

— —

876#

1167#

1167#

1706#

1706#

2119#

2353#

146#

1/8” bead AA*

—

—

—

—

—

—

—

2679#

4. Utilizing an appropriate sized funnel, fill each desiccant tower as follows:

a. Install the required quantity of tabular support or

activated alumina in layer 1 of each tower.

b. Level layer 1 and each subsequent layer of desic-

cant as added to each chamber.

c. Finish filling each tower with desiccant until all

desiccant has been installed. LIGHT tapping

on the tower sides with a soft-face mallet should

yield additional free space to allow installation of

all desiccant required. DO NOT TAMP OR RAM

DESICCANT.

5. Clean the fill port closure. Replace the fill plug using

Teflon tape or another pipe thread sealant suitable

for compressed air service. Reinstall fill port flange

cover (where applicable) in each desiccant tower.

5

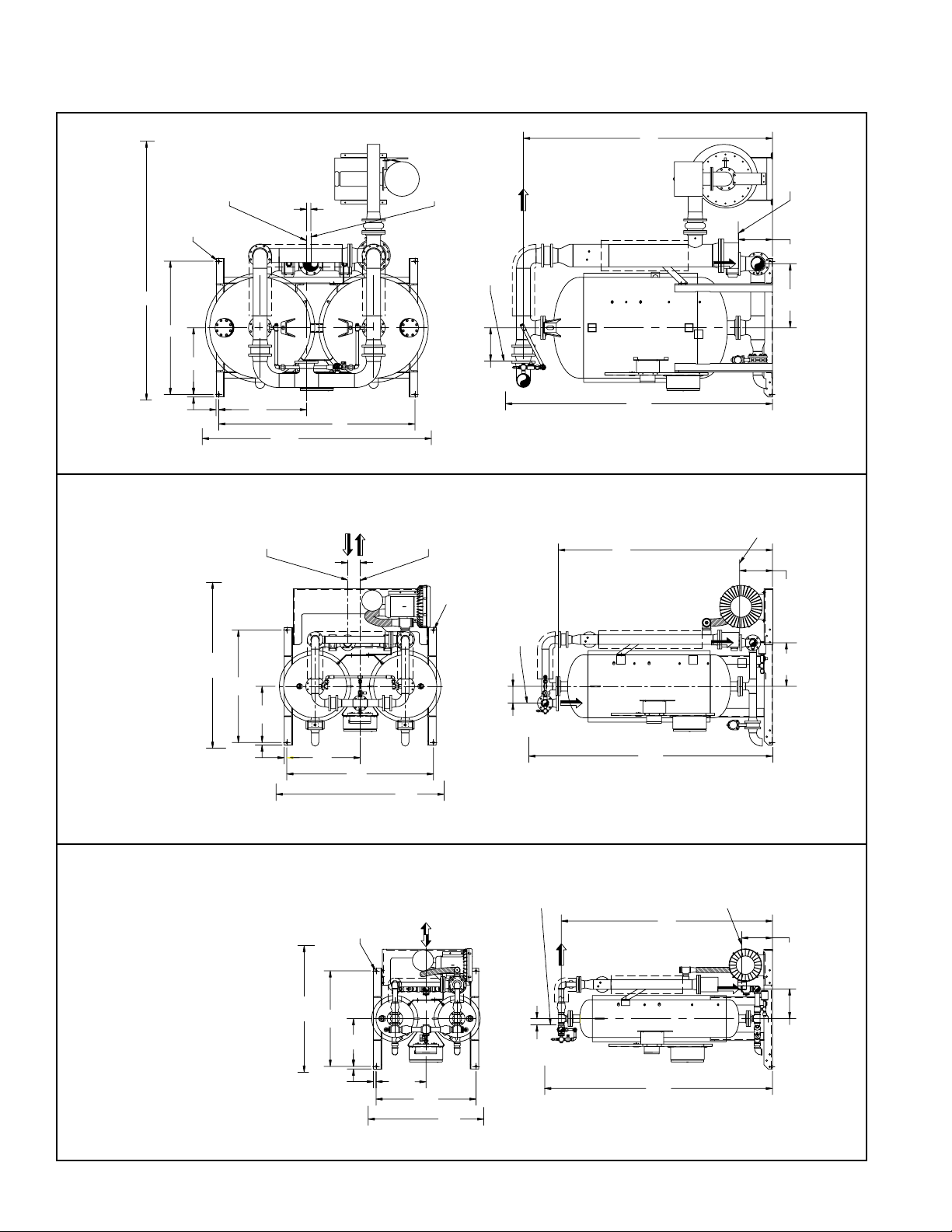

Dimensions and Connections

CENTERLINE OF

CUSTOMER DRY GAS

OUTLET CONNECTIO

N

TOP VIEW

R

SLOT

(TYP 4 PLACES

)

CENTERLINE OF

CUSTOMER WET GA

S

INLET CONNECTION

SIDE VIEW

(RIGHT CHAMBER REMOVED FOR CLARITY)

T

GAS OUTLET

E

(MAX)

F

G

C

D

B

A

(MAX)

H

K

N

(MAX)

P

L

S

GAS INLET

M

FACE OF CUSTOMER

WET GAS INLE

T

CONNECTION

FACE OF CUSTOMER

DRY GAS OUTLET

CONNECTION

R

SLOT

(TYP 4 PLACES)

TOP VIEW

SIDE VIE

W

(RIGHT CHAMBER REMOVED FOR CLARITY)

S

GAS INLET

T

GAS OUTLET

H

E

(MAX)

F

G

C

D

B

A

(MAX)

N

(MAX)

P

L

M

K

E

(MAX)

R SLOTS

(T

YP 4 PLACES)

TOP VIEW

SIDE VIEW

(RIGHT CHAMBER REMOVED FOR CLARITY)

S

AIR INLET

T

AIR OUTLET

F

C

D

B

A

(MAX)

N

(MAX)

M

L

P

K

G

Figure 2 (continued on next page)

(Contact factory to request certified drawings)

VIEW III

3200 through 4300 scfm

VIEW II

6

750 through 2600 scfm

VIEW I

500 — 600 scfm

Dimensions and Connections

Figure 2 (continued from previous page)

DIMENSIONS IN INCHES

A 53 55 60 60 64 66 80 80 85 85 85 85 109

B 46.3/4 47.9/16 52.11/16 52.11/16 56.7/16 57.5/16 69.13/16 69.13/16 73.3/8 73.3/8 82.7/8 82.7/8 93.3/8

MODEL 500 600 750 900 1050 1300 1500 1800 2200 2600 3200 3600 4300

VIEW REF. I I II II II II II II II II III III III

C 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4 1.1/4

E 59 60 68 68 62 73 79 79 86 89 107 116 123

D 23.3/8 23.13/16 26.5/8 26.5/8 29.9/16 30 34.7/8 34.7/8 38.9/16 38.9/16 36.9/16 36.9/16 41.13/16

F 45.1/2 45.1/2 53.1/2 53.1/2 53.1/2 53.1/2 53.1/2 53.1/2 59.1/2 59.1/2 59.1/2 59.1/2 63.1/2

G 22.3/4 22.3/4 26.3/4 26.3/4 26.3/4 26.3/4 26.3/4 26.3/4 29.3/4 29.3/4 29.3/4 29.3/4 31.3/4

DIMENSIONS IN MILLIMETERS

L 12.11/16 13.3/16 13.7/16 13.7/16 13.3/16 13.3/16 15.5/8 15.5/8 17.1/4 17.1/4 14.9/16 16.9/16 16.1/4

H — — 1.1/4 1.1/4 3.1/4 3.1/4 5.15/16 5.15/16 4.3/8 4.3/8 3/4 5 2

K 3 3 8 8 8 8 8 8 7.1/4 7.1/4 15.7/8 15.7/8 15.7/8

M 96.15/16 100.7/16 100.11/16 100.11/16 99.13/16 104.13/16 101.7/8 101.7/8 115.7/8 115.7/8 115.13/16 122.1/16 118.1/2

P 13.3/16 14.3/16 15.3/4 15.3/4 16.3/4 17.3/4 20.3/4 20.3/4 22.1/4 22.1/4 26.1/2 27.1/2 30.1/2

N 105 108 114 114 113 118 116 116 128 128 128 134 130

S 2 NPT 2 NPT 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 6 FLANGE 6 FLANGE

R 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4 7/8 X 1.1/4

T 2 NPT 2 NPT 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 6 FLANGE 6 FLANGE 6 FLANGE

WT/LBS 1,900 2,200 2,500 2,600 3,000 3,600 5,400 5,500 8,100 8,200 9,400 9,900 12,350

MODEL 500 600 750 900 1050 1300 1500 1800 2200 2600 3200 3600 4300

F 1156 1156 1359 1359 1359 1359 1359 1359 1511 1511 1511 1511 1613

A 1346 1397 1524 1524 1626 1676 2032 2032 2159 2159 2159 2159 2769

B 1187 1208 1338 1338 1434 1456 1773 1773 1864 1864 2106 2106 2372

VIEW REF. I I II II II II II II II II III III III

E 1491 1531 1734 1734 1580 1862 2009 2009 2186 2256 2708 2955 3132

C 32 32 32 32 32 32 32 32 32 32 32 32 32

D 594 604 677 677 750 761 886 886 980 980 929 929 1062

G 578 578 679 679 679 679 679 679 756 756 756 756 806

L 322 335 341 341 335 335 397 397 438 438 370 421 413

H — — 32 32 83 83 151 151 111 111 19 127 51

K 76 76 203 203 203 203 203 203 184 184 403 403 403

M 2462 2551 2557 2557 2535 2662 2588 2588 2943 2943 2942 3100 3010

N 2664 2753 2903 2903 2870 2997 2946 2946 3246 3246 3246 3404 3313

P 335 360 400 400 425 451 527 527 565 565 673 699 775

S 2 NPT 2 NPT 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 6 FLANGE 6 FLANGE

R 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32 22 X 32

T 2 NPT 2 NPT 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 3 FLANGE 4 FLANGE 4 FLANGE 4 FLANGE 6 FLANGE 6 FLANGE 6 FLANGE

WT/KGS 862 998 1,134 1,179 1,361 1,633 2,449 2,495 3,674 3,719 4,264 4,491 5,602

7

5.0 Instrumentation

The following instrumentation helps in monitoring dryer

operation and performance. Instruments which are

available as options are so noted.

Blower Purge Air dryers are rated NEMA 4 and include

the following:

• Solid State Controls

• Chamber Pressure Gauges

• Purge Flow Pressure Gauge

• Energy Management (Option A)

• Energy Management System & Dew Point Transmitter

(Option B)

5.1 Controls

The solid-st ate dr yer co ntro ls are locat ed in a

polycarbonate, NEMA Class 4/4X, IP66 rated electrical

enclosure mounted to a center panel located between

the two desiccant towers. Control features include:

• 15 LED’s to indicate operating status and fault

conditions.

5.5 Dew Point Transmitter

This option monitors and displays outlet pressure dew

points and provides an alarm signal if the dew point

exceeds user-specified set point. Recommen ded

calibration interval is 12 months. Contact the service

department for details.

Operation – The dew point is measured at the dryer

operating pressure and is displayed in the operator

interface. If the dew point is outside of the temperature

range, the display will indicate an over-range (high

dew point) or under-range (low dew point) condition. A

defective sensor assembly or an electronics malfunction

could also cause the transmitter to indicate underrange.

• Two line text display to provide status and diagnostic

messages.

• Upon power loss, dryer “fails safe” (inlet valve

remains in position). On power recovery, controller

resumes where power was lost.

5.2 Chamber Pressure Gauges

A gauge mounted on the gauge panel indicates which

chamber is on-stream and which is regenerating. The

gauge for the onstream tower indicates operating

pressure; the gauge for the regenerating tower indicates

0 psig.

5.3 Purge Flow Pressure Gauge

A gauge mounted on the gauge panel of the dryer

indicates purge air pressure.

5.4 Energy Management System

Th e opt ional Energy Manag ement System (EMS)

automatically adjusts dryer operation to compensate

for changes in operating conditions. Air samples are

continuou sly taken from the on-stream to wer and

passed ov er a moisture probe which sense s both

temperature and relative humidity. The moisture content

of the air within the desiccant bed is then precisely

determined. The on-stream tower will not depressurize

and regenerate until a predetermined set point has been

reached. This elimination of unnecessary regeneration

reduce s energy cons ump tion and e xte nds d ryer

desiccant and component life.

8

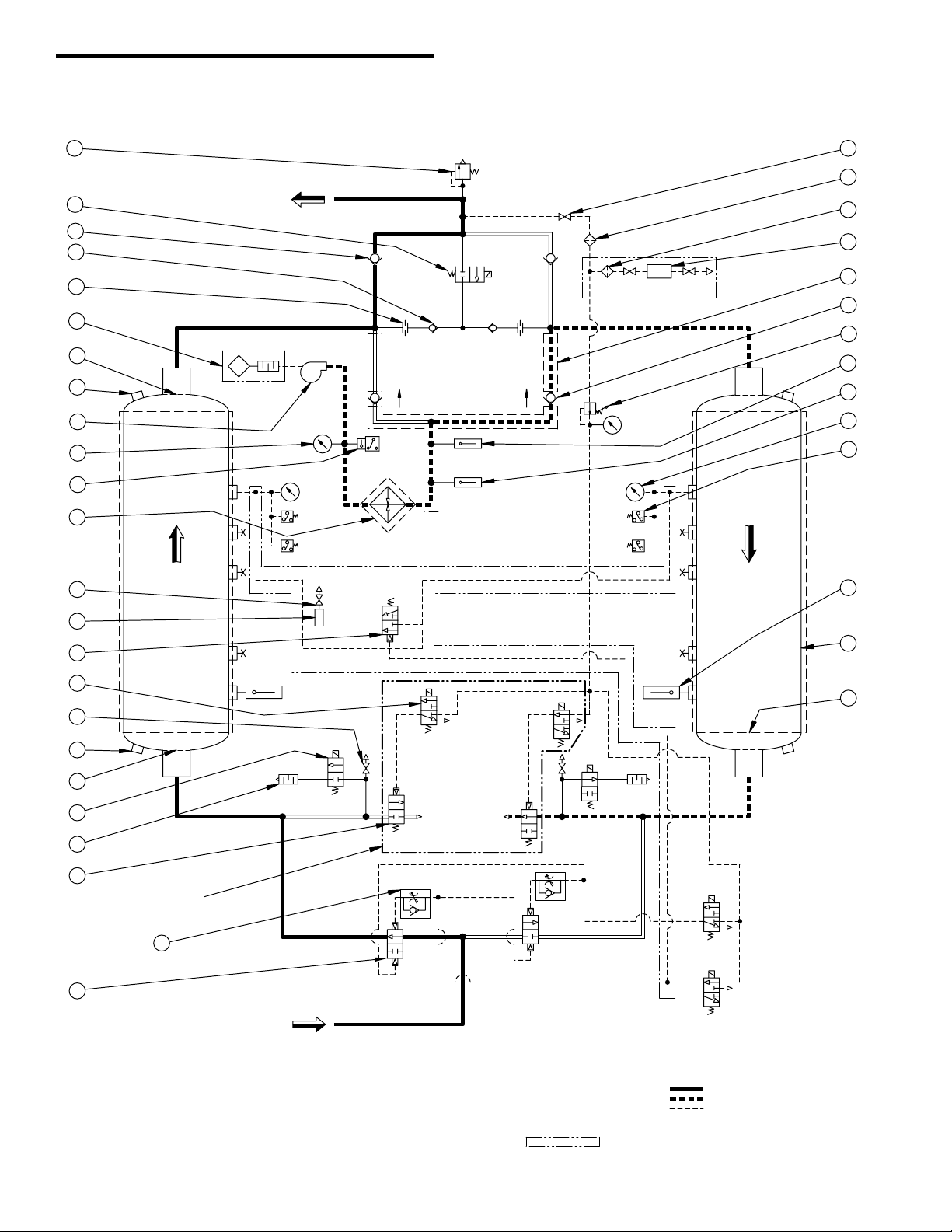

RS232

P1

P2

PURGE INLET

CHECK VALVE

TOP VIEW

ASME RELIEF VALVE

OUTLET CHECK VALVE

DESICCANT

FILL PORT

LEFT TOWER

PRESSURE GAUGE

PRESSURE REGULATOR

& PILOT AIR FILTER

DEWPOINTER

(OPTIONAL)

TOWER PURG

E

EXHAUST VALVE

FRONT VIEW

TOWER

DEPRESS VALV

E

DESICCANT

DRAIN POR

T

TO

WER

INSULATION

(OPTIONAL

)

CONTRO

L

ENCLOSURE

HIGH TENSIO

N

ENCLOSURE

RIGHT TOWER

PRESSURE GA

UGE

PURGE

PRESSURE GAUGE

REPRESS VALV

E

HEATER TEMP

THERMOCOUPLE

(CENTER END IN PIPE)

(OPPOSITE SIDE)

HEATER OVERTEMP RTD

PURGE

HEATER WITH

INSULATION

PURGE SUCTION

FILTER SILENCER

PURGE BLOWER

AND MOTOR

REAR VIEW

TOWER INLET

VALV

E

ASME CODE TAG

HOT PIPE INSULATION

P1P

2

P3

P4

TOWER BLOWDOWN VALVE

General Layout Drawing

Figure 3

(Models 500 through 600)

9

LEFT TOWER PURGE

EXHAUST VALVE

DEWPOINTE

R

(OPTIONAL)

PRESSURE REGULATOR

& PILOT AIR FILTER

LEFT TOWER

PRESSURE GAUGE

DESICCANT

FILL PORT

LEFT OUTLET

CHECK VALV

E

PURG

E

PRESSURE GAUGE

RIGHT TOWER

PRESSURE GAUGE

CONTROL ENCLOSURE

HIGH TENSION ENCLOSUR

E

TOWER INSULATION

(OPTIONAL)

DESICCANT

DRAIN PORT

RIGHT TOWE

R

DEPRESS VALV

E

ASME RELIEF VALV

E

REPRESS VALV

E

TOP VIEW

FRONT VIEW

PURGE

HEATER WITH

INSULATIO

N

PURGE SUCTION

FILTER SILENCER

PURGE BLOWER

AND MOTO

R

REAR VIEW

LEFT TOWER

INLET VALV

E

ASME CO

DE TAG

LEFT PURGE INLE

T

CHECK VALV

E

HOT PIPE INSULATION

AIR

OUTLET

AIR

INLET

LEFT TOWER

DEPRESS VALV

E

RIGHT TOWER PURGE

EXHAUST VALV

E

RIGHT OUTLET

CHECK VALV

E

AIR

OUTLET

AIR

INLET

LEFT TOWER

PURGE EXHAUST

VALV

E

PURGE EXHAUST

RIGHT TOWE

R

PURGE EXHAUST

VALV

E

PURGE EXHAUST

TOWER BLOW

-

DOWN VALV

E

HEATER TEMP

THERMOCOUPLE

(CENTER END IN PIPE)

(OPPOSITE SIDE)

HEATER OVERTEMP RT

D

10

General Layout Drawing

(Models 750 through 2600)

Figure 3a

TOP VIEW

OUTLET

CHECK VALV

E

ASME RELIEF VALV

E

DESICCANT

FILL PORT

LEFT TOWER

PRESSURE GAUGE

PRESSURE REGULATOR

& PILOT AIR FILTER

DEWPOINTE

R

(OPTIONAL)

TOWER PURGE

EXHAUST VALV

E

FRONT VIEW

TOWER

DEPRESS VALVE

DESICCANT

DRAIN PORT

TOWER INSULATION

(OPTIONAL)

HIGH TENSION

ENCLOSUR

E

CONTROL

ENCLOSUR

E

RIGHT TOWER

PRESSURE GAUGE

PURGE PRESSUR

E

GAUGE

REPRESS

VALV

E

PURGE BLOWER

AND MOTO

R

PURGE BLOWER

THROTTLING VALV

E

PURGE SUCTION

FILTER SILENCER

PURGE HEATER

WITH INSULATION

HEATER

OVERTEMP RT

D

HOT PIPE

INSULATIO

N

PURGE INLET

CHECK VALV

E

TOWE

R

INLET VALV

E

REAR VIEW

HEATER TEMP

THERMOCOUPLE

(CENTER END IN PIPE

)

(OPPOSITE SIDE

)

CHAMBER

BLOW-DOWN

VALV

E

Figure 3b

General Layout Drawing

(Models 3200 through 4300)

11

6.0 Operation

6.1 Controls

A solid-state controller controls valve and heater operation, monitors all critical operating conditions, and indicates operating status on a 2-line LCD display operator

interface. The controller receives input data from pressure switches, temperature sensors and the operator

interface. The operator interface displays information

about the dryer operating status and is used to change

the dryer operating mode.

6.2 Operating Modes

6.2.1 Automatic and Manual Advance

The drying and regeneration cycles are divided into

discrete steps. The operator selects either one of the

automatic advance modes (Energy Management, Dew

Point Control, or Fixed Cycle) or manual advance mode

(Test Cycle) through the operator interface.

Selecting any of the automatic advance modes enables

a timer in the controller to advance the program step-bystep according to the programmed schedule.

Setting up the controller for manual advance disables the

timer and the operator can advance the program one step

at a time. This mode is used for diagnostic purposes.

6.2.2 Fixed, Energy Management or Dew Point

Control Operation

The operator interface is used to select either Fixed,

Energy Management or Dew Point Control operation. In

Fixed Cycle operation, each tower is on-line (drying) for a

fixed time period regardless of the operating conditions.

In Energy Management or Dew Point Control operation,

a tower remains on-line until the desiccant bed has been

fully utilized. For lower than designed moisture loads,

this results in longer drying cycles, longer time between

regenerations and, therefore lower energy consumption.

Energy Management or Dew Point Control operation

are optional features.

6.3 Operating Sequence Description

1. Left Tower Drying – Right Tower Regenerating

At the start of the Left Tower Drying cycle, Left Inlet

Valve V1 opens, Right Inlet Valve V2 closes to isolate the two towers. Wet, compressed air flows up

through the left tower where it is dried. The dry air

exits the dryer through the Left Outlet Check Valve

V7.

Next, the Right Depressurization Valve V10 is

opened and the right tower is slowly depressurized.

Air exits through exhaust muffler M2.

After the right tower has depressurized, the Right

Purge Valve V4 is opened and the Blower M and

Heater H1 are energized. The heated air flows

through the Right Purge Check Valve V6, down

through the right tower, and exits through the Right

Purge Valve V4. The Blower intake air is filtered

to keep dust and dirt from entering the dryer. The

Blower M and Heater H1 are de-energized when

the temperature at the bottom of the right tower,

as sensed by the Right Tower Temperature Sensor

RTD2, reaches the Heat Termination set point. This

indicates that the bed has been fully heated.

Note: Blower will continue to run briefly at the end

of the Heating Step to sweep residual heat from the

heater.

The Repressurization Valve V11 is opened. A portion

of the dry air from the left tower now flows through

Repressurization Valve V11. This air is throttled to

near atmospheric pressure by Repressurization/

Sweep Orifice O2. The dry, low pressure air flows

down through the right tower cooling the desiccant

bed, and exits through the Right Tower Purge Exhaust Valve V4.

The Cooling Step continues until:

a) the right tower bed temperature falls to 150°F

or,

b) it is time to repressurize the right tower,

whichever occurs first.

Note: In fixed cycle, the bed will normally be partially

cooled because the repressurization step will occur

before the bed temperature can fall to 150°F.

Note: In Energy Management or Dew Point Control,

as the drying time extends beyond 4 hours, additional

cooling time becomes available thus the cooling

step will frequently terminate based on temperature

providing complete bed cooling.

At the end of the Cooling Step, the Right Tower Purge

Exhaust Valve V4 is closed. The right tower slowly

repressurizes to full line pressure and is ready to go

back on-line.

Note: Bed cooling can be disabled by moving JP4

to the “ON” position.

2. Right Tower Drying – Left Tower Regenerating

At the start of the Right Tower Drying cycle, Right

Inlet Valve V2 opens, Left Inlet Valve V1 closes to

isolate the two towers. Wet, compressed air flows

up through the right tower where it is dried. The dry

air exits the dryer through the Right Outlet Check

Valve V8.

Next, the Left Depressurization Valve V9 is opened

and the left tower is slowly depressurized. Air exits

through exhaust muffler M1.

12

WET GAS

INLET

DRY GA

S

OUTLET

SOL 'D'

V1

SOL 'F'

M1

V9

RTD

1

V3

V4

V2

SOL 'B

'

M2

SOL 'A

'

SOL 'G'

V1

0

RTD

2

V6

1PS

(RTD4/HS1)

ENERGY MGMT OPTION

SET @ 176°F

DRYING

EXH.

3PS

SET

@

5 PSIG

SOL 'C'

2

1

3

LEFT

TOWER

SET

@

45 PSI

G

M

RTD

3

SET @ 650°F

1T

C

SET @ 370°F

V5

2P

S

SET @ 176°F

4P

S

SET

@

5 PSI

G

REGE

N

SET

@

45 PSIG

SET AT

100 PSIG

RIGH

T

TOWE

R

V8

V12 V13

SOL 'E'

V7 V11

RV

1

SET @ 165 PSI

G

DEWPOINTER OPTION

DP

A

SOLENOID VA

LVES 'B', 'D', & 'G' ARE SHOWN ENERGIZED,

SYMBOLS ARE PER ANSI Y32.10 "GRAPHIC SYMBOLS FOR FLUID POWER DIAGRAMS."

SOLENOID VA

LVES 'A', 'C', 'E', & 'F' ARE SHOWN DE-ENERGIZED.

AS SHOWN FLOW DIRECTION IS:

INDICATES OPTION

3.

2.

1.

PILOT GAS LINE

RIGHT CHAMBER REGEN

LEFT CHAMBER DRYING

NOTES

4.

BD2BD1

H1

PI3

PI1

PI2

F1

PR&G

F2

O2

V1

4

O1

Figure 4

Sequence of Operation — Fixed Cycle Operation

Left Chamber Drying – Right Chamber Regenerating (shown)

(continued on next page)

13

After the left tower has depressurized, the Left Purge

P

EM

S

LEFT

TOWER

RIGHT

TOWER

Valve V3 is opened and the Blower M and Heater

H1 are energized. The heated air flows through the

Left Purge Check Valve V5, down through the left

tower, and exits through the Left Purge Valve V3.

The Blower intake air is filtered to keep dust and dirt

from entering the dryer. The Blower M and Heater

H1 are de-energized when the temperature at the

bottom of the left tower, as sensed by the Left Tower

Temperature Sensor RTD1, reaches the Heat Termination set point. This indicates that the bed has

been fully heated.

The Repressurization Valve V11 is opened. A portion

of the dry air from the right tower now flows through

Repressurization Valve V11. This air is throttled to

near atmospheric pressure by Repressurization/

Sweep Orifice O1. The dry, low pressure air flows

down through the left tower cooling the desiccant

bed, and exits through the Left Tower Purge Exhaust

Valve V3.

The Cooling Step continues until:

a) the left tower bed temperature falls to 150°F

or,

b) it is time to repressurize the left tower,

whichever occurs first.

6.3.1 Energy Management Control (optional)

Operation of the Energy Management Control cycle is

identical to the fixed cycle except the cycle is extended

until the desiccant bed in the on-line tower has been fully

utilized. The off-line tower is regenerated and remains

in a stand-by mode after being repressurized.

Figure 5 shows the air sampling system for the Energy

Management System – EMS option. A 3-way pilot valve

directs an air sample from the drying tower to the EMS

sensor. The EMS sensor detects the relative humidity

and temperature of the air sample. The air sample then

exhausts to atmosphere. The drying tower remains online until the moisture front arrives at the sensor.

Note: In fixed cycle, the bed will normally be partially

cooled because the repressurization step will occur

before the bed temperature can fall to 150°F.

Note: In Energy Management or Dew Point Control,

as the drying time extends beyond 4 hours, additional

cooling time becomes available thus the cooling

step will frequently terminate based on temperature

providing complete bed cooling.

At the end of the Cooling Step, the Left Tower Purge

Exhaust Valve V3 is closed. The left tower slowly

repressurizes to full line pressure and is ready to go

back on-line.

Note: Bed cooling can be disabled by moving JP4

to the “ON” position.

Figure 5

Optional Moisture Sensing

Energy Management System (EMS)

14

6.4 Control Board Jumpers

In the upper left hand corner of the control board there

are eight two-pin jumpers labeled JP1 through JP8. Only

five of the eight jumper pairs are utilized. Pairs JP6-JP8

are used for factory settings and testing. NOTE: Do

not install jumpers in the ON position on pairs JP6

through JP8. The jumper is a removable bridge that is

used to make or break continuity between two pins that

form a pair. When installed in the ON position, the jumper

is place on both pins of the pair and continuity between

the pins is established. When installed in the OFF position, the jumper is removed or stored on a single pin and

continuity is broken. Jumper functions are as follows:

1. JP1 – Dryer Type

Jumper JP1 is used to select the dryer type configu-

ration. It is installed in the ON position for Blower

Purge dryer configuration.

2. JP2 – Energy Management

Jumper JP2 is installed in the ON position when an

Energy Management sensor is installed. The jumper

is installed in the OFF position when no Energy

Management sensor is installed.

3. JP3 – Dew Point Transmitter

Jumper JP3 is installed in the ON position when a

Dew Point Transmitter is installed. The jumper is

installed in the OFF position when no Dew Point

Transmitter is installed.

NOTE: “Energy Management” can co-exist with the

dew point transmitter option. Dryer control based

on the ENERGY MANAGEMENT or DEWPOINT

CONTROL is selected on Screen 1 of the Set Up

Mode.

If DEWPOINT CONTROL is not selected then the

dew point signal does not control the dryer cycle but

still serves a monitoring and alarm function.

8. JP8 – Set Up

Jumper JP8 is factory installed in the OFF position

to disable access to “factory” set up screens. The

jumper is installed in the ON position during final

inspection at the factory to set controller to match

customer requirements.

6.5 Operator Interface

Refer to Figure 6 , Front Panel Overlay for information

regarding the location and function of the LEDs, switches,

and text display.

6.5.1 Front Panel LED’s

• Power On - green

• Alarm - red

• Service / Maintenance reminder - amber

• Filters (pre, after, and pilot) service / maintenance

reminders - amber

• Inlet switching and purge / repressurization valve status (On = valve open; Off = valve closed) - green

• Left and right tower status (heating) - amber

• Left and right tower status (drying) - green

• Left and right tower pressure switch status (On =

switch closed; Off = switch open) - green

6.5.2 Front Panel Switches

The front panel contains four momentary-contact pushbutton switches. Refer to Figure 6, Front Panel Overlay

for the appropriate icon associated with each switch.

Pushing on the overlay icon actuates the switch.

Data Display Switch

Th is switch is used to step th rough the display

screens.

Select Switch

This button is located to the left of the text display window.

Refer to the Front Panel Operation Section for additional

information.

4. JP4 – Cooling Cycle

Jumper JP4 is installed in the ON position to disable

the Cooling Cycle. The jumper is installed in the OFF

position to enable a Cooling Cycle.

5. JP5 – Switching Failure

Jumper JP5 is installed in the ON position to enable

Switching Failure. The jumper is installed in the OFF

position if Switching Failure is disabled.

6. JP6 – Not Used

NOTE: Jumpers JP7 and JP8 are used by the factory

during final inspection to download language text and to

enable ‘factory’ set-up screens.

7. JP7 – Download Language Text

Jumper JP7 is factory installed in the OFF position

to disable Language Text download. The jumper is

installed in the ON position to allow for language text

download due to either language corrections or new

language installation.

ENTER Switch

This button is located to the right of the text display

window. Refer to the Front Panel Operation Section for

additional information.

Alarm Reset Switch

This button is normally used to reset an alarm or service

reminder. Refer to the Front Panel Operation Section

for additional information.

15

Left Tower Drying LED

Left Purge Valve LED

On=valve open

Off=valve closed

Left Inlet Valve LED

On=valve open

Off=valve closed

Left Tower

Heating LED

Filter Service /

Maintenance LED

Vacuum Fluorescent

Text Display

Select switch

Power On LED

Data Display Switch

Communications Icon

Filter Service /

Maintenance LED

Filter Service /

Maintenance LED

Right Tower Pressure

Switch LED:

On=Tower pressurized

Right Tower Drying LED

Right Purge Valve LED

On=valve open

Off=valve closed

Right Tower

Heating LED

Right Inlet Valve LED

On=valve open

Off=valve closed

Enter Switch

Maintenance / Service

Reminder LED

Alarm LED

Reset Switch for Alarm

Left Tower Pressure

Switch LED:

On=Tower Pressurized

RS232

6.5.3 Front Panel Operation

1. There are five operating modes for the Heated

Desiccant Dryer Control.

a. Program Mode

b. Setup Mode

c. Alarm & Service Mode

d. Display Mode

e. Test Mode

2. Each Mode is described below.

6.5.4 Program Mode

1. Press and hold and for 3 seconds to enter

Program Mode.

2. Program Mode is comprised of the screens that are

described below.

3. There are three (3) ways to exit Program Mode.

a. Press after making the selection in the final

b. At any screen, press and hold for 3 sec-

c. The controller automatically exits Program Mode

16

screen.

onds.

if no button is pressed within 60 seconds.

Figure 6

Front Panel Overlay

4. Upon exiting Program Mode the controller will switch

Screen 1: Select the Language

1. Press to scroll through the choices: ENGLISH,

2. When finished, press to save the selection and

Screen 2: Select the Service Level

1. Pr ess to toggle bet w een N ORMA L and

to Display Mode.

ENGLISH

FRANCAIS and ESPANOL.

move to next screen.

SERVICE LEVEL

NORMAL

SEVERE.

a. NORMAL Service Intervals are:

i. 4000 hours for filters

ii. 8000 hours for desiccant

iii. 8000 hours for valves

b. SEVERE Service Intervals are:

i. 2000 hours for filters

ii. 4000 hours for desiccant

iii. 4000 hours for valves

2. When finished, press to save the selection and

move to next screen.

Screen 3: Reset the Timer for Filter Service

FILTER SERVICE

RESET? NO

1. Press to toggle between NO and YES.

2. When finished, press to acknowledge the

selection and move to next screen.

Screen 4: Reset the Timer for Desiccant Service

DESICCANT SERVICE

RESET? NO

1. Press to toggle between NO and YES.

2. When finished, press to acknowledge the

selection and move to next screen.

Screen 5: Reset the Timer for Valve Service

VALVE SERVICE

RESET? NO

Screen 7: Set Point for Dew Point Demand Control

(Displayed only when JP3 “on”)

DPNT CNTL SETPT

±XX°C ±XXX°F

1. Press to increment the setting to the desired

value.

a. Standard set point is

-30°C -22°F

.

b. The allowable range of values is from

-80°C -112°F

+10°C +50°F

to

in 5°C/9°F

increments.

Note: Must be set “drier” than Dew Point Sensor

Alarm Set Point (screen 6).

2. When finished, press to acknowledge the

selection and exit the Program Mode.

Screen 8: Set the Heat Termination Set Point

HEAT TERM SET-PT

XX°C XXX°F

1. Press to increment the setting to the desired

temperature value.

a. Refer to P&ID diagrams in the back of this manual

for Heat Termination set points (see set point

values for RTD1 and RTD2).

b. The allowable range of values are:

60° - 160°C 140° - 320°F

in 10°C increments.

1. Press to toggle between NO and YES.

2. When finished, press to acknowledge the selection and move to next screen.

Screen 6: Set Alarm Point for the Dew Point

Sensor (Displayed only when JP3 “on”)

DEWPOINT ALARM

±XX°C ±XXX°F

XX MIN SW DELAY

1. Press to increment the setting to the desired

value.

a. Standard set point is

-20°C -4°F

.

b. Th e a l l o w a b l e r a n g e o f v a l u e s i s f r o m

-80°C -112°F

+10°C +50°F

to

in 5°C/9°F

increments.

2. When finished, press to acknowledge the selection and scroll to the switchover delay set point

screen.

a. Standard set point is

b. The allowable range of values are

60 MIN

.

30 to 120 MIN

in 10 minute increments.

3. When finished, press to acknowledge the selection and move to next screen. Exit Program Mode

when there are no more active screens to display.

2. When finished, press to acknowledge the selection and move to next screen. Exit Program Mode

when there are no more active screens to display.

Screen 9: Set Points for Energy Management

(Displayed only when JP8 “on”)

ENRGY MGMT SETPT

XX%RH

XX MBAR .XXX PSI

1. Press to increment the setting to the desired

maximum RH value.

a. Factory set point is

60%RH

. The factory setting

should not require adjustment.

b. The allowable range of values are

20 to 80%RH

in 5% increments.

2. When finished, press to acknowledge the selection and scroll to the pressure set point screen.

3. Press to increment the setting to the desired

maximum vapor pressure value.

a. Standard set point for a -40°F dew point dryer

16 MBAR (0.232 PSI)

.

is

Note: Standard set point for a -100°F dew point

dryer

b. The allowable range of values

3 to 34 MBAR (0.044 to 0.493 PSI)

4 MBAR (0.058 PSI)

is

.

in

is

1 MBAR

increments.

17

c. This setting may be field adjusted to increase or

decrease the outlet dew point at tower switchover.

4. When finished, press to acknowledge the selection and move to next screen.

Screen 10: Set Points for High Humidity Alarm

(Displayed only when JP8 “on”)

HIGH HUMIDITY

XX%RH

XX MBAR .XXX PSI

XX MIN SW DELAY

1

. Press to increment the setting to the desired

maximum RH value.

a. Factory set point is

75%RH

. The factory setting

should not require adjustment.

b. The allowable range of values are

20 TO 80%RH

in 5% increments.

Note: Value must be set above Energy Manage-

ment Maximum RH Value Set Point (screen 9).

6.5.5 Setup Mode

1. Press and hold for 3 seconds to enter Setup

Mode.

2. Setup Mode is comprised of the screens that are

described below.

3. There are two ways to exit Setup Mode.

a.

Press after making the selection in Screen 1.

b. The controller automatically exits Setup Mode if

no button is pressed with 60 seconds.

4. One of two things will happen upon exiting Setup

Mode.

a. The controller will switch to Display Mode if

ENERGY MANAGEMNT, FIXED CYCLE or

DEWPOINT CONTROL is selected.

b. The controller will switch to Test Mode if TEST

CYCLE is selected.

Screen 1: Select the Cycle Type

CYCLE TYPE

ENERGY MANAGEMNT

2. When finished, press to acknowledge the selection and scroll to the pressure set point screen.

3. Press to increment the setting to the desired

maximum vapor pressure value.

a. Factory set point for a -40°F dew point dryer is

24 MBAR (0.348 PSI)

.

Note: Factory set point for a -100°F dew point

dryer is

5 MBAR (0.073 PSI)

.

b. The allowable range of values is

3 to 34 MBAR (0.044 to 0.493 PSI)

in 1 MBAR incre-

ments.

Note: Value must be set above Energy Man-

agement Maximum Vapor Pressure Set Point

(screen 9).

4. When finished, press to acknowledge the selection and scroll to the switchover delay set point

screen.

a. Factory set point is

b. The allowable range of values are

60 MIN.

.

30 to 120 MIN

in 10 minute increments.

5. When finished, press to acknowledge the selection and move to next screen. Exit Program Mode

when there are no more active screens to display.

1. Press to scroll through the choices:

a. ENERGY MANAGEMNT (displayed only when

JP2 is in the ON position)

b. DEWPOINT CONTROL (displayed only when JP3

is in the ON position)

c. FIXED CYCLE

d. MANUAL CYCLE

2. When finished, press to save the selection and

exit the Setup Mode.

18

6.5.6 Alarm & Service Mode

1. Alarm & Service Mode is active when the controller

is in Display Mode. It is not active in Program Mode,

Setup Mode, or Test Mode.

2. Local alarm consists of a blinking alarm LED and an

alarm message display.

3. Alarm messages have prior ity over Se rvice

messages. Service messages have priority over

Display Messages.

4. After an alarm condition has been corrected, if:

a. Alarm is “self-clearing” then,

i. The alarm LED stops blinking (LED on); the

alarm message continues to be displayed.

ii. The alarm reset button must be depressed to

clear the alarm LED (LED off) and the alarm

message.

b. Alarm must be manually reset, then:

i. The alarm LED continues to blink and the

alarm message continues to be displayed.

ii. The alarm reset button must be depressed

to:

1. Clear the alarm LED (LED off)

2. Clear the alarm message and

3. Restart the dryer cycle.

5. When an alarm condition has not been corrected

and the “alarm reset” button is pressed, the alarm

will not clear except as follows:

a. The alarm conditions will clear for 5 seconds,

then reappear if the alarm condition persists, this

applies to the following alarms:

i. Heater: High Inlet Temperature.

ii. Heater: Low Temperature

iii. Humidity Sensor: High Humidity Alarm

iv. Humidity Sensor: Under-Range or Over-

Range Alarm

v. Dew Point Sensor: High Dew Point Alarm

vi. Dew Point Sensor: Under-Range or Over-

Range Alarm

6. There are three alarms for each tower that are

triggered by the tower pressure switches. These

alarms can occur in any operating mode (Manual,

Fixed, Energy Management, or Dew Point Demand

Cycle).

Following is a brief description of each alarm.

a. Left or Right tower, drying, low pressure

i. Drying tower pressure switch is open during

the drying cycle.

b. Left or Right tower, regenerating, high pressure

i. Regenerating tower pressure switch is closed

while purge valve is open (after an initial time

delay).

c. Left or Right tower, regenerating, low pressure

i. Regenerating tower pressure switch is open

at the end of the regenerating cycle.

d. On alarm condition, the blower and heater are

de-energize, the cycle sequence is stopped, a

local alarm is displayed and the common alarm

relay is de-energized.

e. These alarms are self-clearing.

7. Heater High Inlet Temperature

a. Model sizes 3200, 3600 and 4300 are equipped

with a temperature switch located in the piping

between the blower and heater.

b. If during the Heat Cycle this temperature switch

opens, indicating a rise in temperature above

the factory setting (refer to Electrical Schematic

drawings at the back of this manual for set point),

an alarm is activated.

c. On alarm condition, the blower and heater are

de-energized, the cycle sequence is stopped, a

local alarm is displayed and the common alarm

relay is de-energized.

d. This alarm must be manually reset.

8. The dryer is equipped with RTD temperature sensors.

There are out of range alarms for each.

a. The standard left tower, right tower, and heater

RTDs (RTD1, RTD2, RTD3) are scaled from

-20°F(-28°C) to 890°F (477°C), “Out of Range”

conditions are as follows:

i. Over-range - temperature abov e 850°F

(454°C)

ii. Under-range - temperature below -20°F

(-28°C)

iii. Note: The controller will annunciate a “Heater

Overtemperature” alarm in lieu of an “Over

Range” alarm when the heater sensor is

disconnected.

b. The Energy Management RTD4 is scaled from

-20°F(-28°C) to 429°F(220°C), “Out of Range”

conditions are as follows:

i. Over-range - temperatures above 400°F

(204°C)

ii. Under-range - temperatures below -20°F (-

28°C)

c. On alarm condition, a local alarm is displayed and

the common alarm relay is de-energized.

d. Over-range and Under-range alarms are self-

clearing.

19

ALARM MESSAGES

LEFT TOWER ALARMS RIGHT TOWER ALARMS OTHER ALARMS

ALARM LEFT TOWER

DRYING

LOW PRESSURE

ALARM LEFT TOWER

REGENERATING

HIGH PRESSURE

ALARM LEFT TOWER

REGENERATING

LOW PRESSURE

ALARM LEFT TOWER

TEMP UNDER-RANGE

ALARM LEFT TOWER

TEMP OVER-RANGE

ALARM LEFT TOWER

OUTLET DEW POINT

ALARM RIGHT TWR

DRYING

LOW PRESSURE

ALARM RIGHT TWR

REGENERATING

HIGH PRESSURE

ALARM RIGHT TWR

REGENERATING

LOW PRESSURE

ALARM RIGHT TWR

TEMP UNDER-RANGE

ALARM RIGHT TWR

TEMP OVER-RANGE

ALARM RIGHT TWR

OUTLET DEW POINT

ALARM HEATER

OVER-TEMPERATURE

ALARM HEATER

LOW TEMPERATURE

ALARM ENRGY MGNT

UNDER-RANGE

ALARM ENRGY MGNT

OVER-RANGE

ALARM BLOWER

MOTOR OVERLOAD

ALARM HEATER

HIGH TEMP IN

ALARM LEFT TOWER

HIGH HUMIDITY

ALARM LEFT TOWER

DEW POINT

UNDER-RANGE

ALARM LEFT TOWER

DEW POINT

OVER-RANGE

ALARM RIGHT TWR

HIGH HUMIDITY

ALARM RIGHT TWR

DEW POINT

UNDER-RANGE

ALARM RIGHT TWR

DEW POINT

OVER-RANGE

20

9. Heat Low Temperature

a. RTD3 is used to detect Heater Low Tempera-

ture.

b. Alarm if the heater temperature is less than 250°F

(121°C) within 15 minutes after the Heat Cycle is

initiated (15 minute delay also applies after power

recovery).

c. On alarm condition, display local alarm and de-

energize common alarm relay.

d. This alarm is self-clearing.

10. Heater Over-Temperature

a. RTD3 is used to detect Heater Over-Tempera-

ture.

b. Alarms anytime that the Heater temperature

exceeds 650°F (343°C).

c. On alarm condition, de-energize heat cycle, stop

cycle sequence, display local alarm and de-energize common alarm relay.

d. This alarm must be manually reset.

11. Blower Overload

a. Alarm condition when blower overload contact

closes.

13. Dew Point Sensor

a. High Dewpoint Alarm

i. The user enters an alarm value through the

Program Mode.

ii. If the measured dew point exceeds the alarm

value, the outlet dew point alarm is indicated.

b. Under-range alarm - Dew point below -148°F

(-100°C)

c. Over-range alarm - Dew point greater than

+109°F (+43°C)

d. On alarm condition,

i. Local alarm is displayed and the common

alarm relay is de-energized.

ii. If dryer is set up for Dewpoint Control, the dryer

sequence continues, but bypasses the “HOLD”

step and proceeds to tower switchover after 4

hours of drying.

iii. This alarm is self-clearing, at which time the

alarm LED stops blinking and control switches

back to Dewpoint Control.

b. On alarm condition, de-energize heat cycle, stop

cycle sequence, display local alarm and de-energize common alarm relay.

c. This alarm must be manually reset.

Alarms for Optional Devices

12. Energy Management a. High Humidity Alarm:

i. Measured moisture level exceeds the air alarm

value entered through the Program Mode.

b. Humidity Sensor:

i. Under-range: RH% < -15%

ii. Over-range: RH% > 115%

c. RTD:

i. Over-range: Temperature above 448°F

(231°C)

ii. Under-range: Temperature below -20°F

(-28°C)

d. On alarm condition:

i. Local alarm is displayed and the common

alarm relay is de-energized.

ii. If the dryer is set up for Energy Management

Control, the dryer sequence continues, but

bypasses the “HOLD” step and proceeds to

tower switchover after 4 hours of drying.

iii. This alarm is self-clearing, at which time the

alarm LED stops blinking and control switches

back to Energy Management control.

21

Service Due Messages

14. There are two service levels (normal and severe)

as described in Program Mode. Each service level

has preset time intervals for servicing the filters,

desiccant, and valves. Time continues to accumulate

as long as power is supplied to the controller, whether

the controller is switched on or off.

When a service time interval expires (see also 14.d

below), the controller operates as follows.

a. The service LED blinks and the appropriate

service message is shown on the text display.

i. When the service interval for filters has expired

(see also d below), the three filter LED’s also

blink.

b. The dryer continues to cycle normally. The LED’s

for the valve’s, pressure switches, and desiccant

towers are not used for service indication.

c. Press the Reset button to extinguish the service

LED and to clear the service message from the

text display.

d. If the dryer has 1 or 2 filter monitors, the timer

for filter service is disabled. When the filter

monitor(s) send an alarm signal (change filter)

to the controller, the controller displays the same

LED’s and messages it would if the timer for filter

service had expired.

6.5.7 Display Mode

1. Display Mode is active when the user exits Program

Mode or Setup Mode and no alarms are active

(unless MANUAL CYCLE was selected in Setup

Mode).

2. Display Mode is comprised of dryer status screens

and dryer display screens (described below). The

controller automatically alternates the display

between the Status Screens and selected Display

Screens.

3. The user can override the automatic screen scroll

by pressing to step through each of the Display

Screens shown on the next page. Automatic

scrolling will resume when is pressed or if

not depressed for 60 seconds.

4. The Ene rgy Sa vings and Service Reminders

Display Screens (Filters, Desiccant, and Valves) are

alternated in sequence with the current dryer status

screen.

15. Examples of the text display are shown on page 18

and below for each alarm and service reminder. The

second line of the alarm screens contains up to three

messages which are scrolled through, displaying

each one for 2 seconds.

SERVICE DUE MESSAGES

SERVICE DRYER

FILTERS

SERVICE DRYER

DESICCANT

SERVICE DRYER

VALVES

22

DRYER STATUS SCREENS

LEFT TOWER DRYING

LT DRYING

RT DEPRESSURIZE

LT DRYING

RT HEATING

LT DRYING

RT COOLING

LT DRYING

RT REPRESSURIZE

LT DRYING

RT HOLDING

(Not displayed in FIXED Cycle)

TOWER SWITCHOVER TOWER SWITCHOVER

RIGHT TOWER DRYING

LT DEPRESSURIZE

RT DRYING

LT HEATING

RT DRYING

LT COOLING

RT DRYING

LT REPRESSURIZE

RT DRYING

LT HOLDING

RT DRYING

(Not displayed in FIXED Cycle)

Energy Savings

(Not displayed in FIXED Cycle)

ENERGY SAVINGS

XX%

Note: Energy Savings will appear

after seven days of continuous use.

Service reminder (filters)

HOURS TO SERVICE

FILTERS: XXXX

Service reminder (desiccant)

HOURS TO SERVICE

DESICCANT: XXXX

Service reminder (valves)

HOURS TO SERVICE

VALVES: XXXX

DRYER DISPLAY SCREENS

Outlet Dew Point

(Displayed only if JP3 is ON)

DEW POINT

±XX°C ±XXX°F

Left Tower Temperature

LT TEMP

±XX°C ±XXX°F

Right Tower Temperature

RT TEMP

±XX°C ±XXX°F

Heater Temperature

HEATER TEMP

±XX°C ±XXX°F

Dewpoint Demand SetPoint

(Displayed only if JP3 is ON)

DWPT CNTL SETPT

±XX°C ±XXX°F

Energy Mgmt Signal

(Displayed only if JP2 is ON)

ENERGY MGMT SGNL

XX%RH XXX°F XX°C

XX MBAR X.XX PSI

Energy Mgmt Setpoint

(Displayed only if JP2 is ON)

ENERGY MGMT SET

XX MBAR X.XX PSI

(This is the calculated “hold” set-point,

which is based on the sample air temperature.)

23

6.5.8 Test Mode

1. Test Mode is active when the user exits Program

5. Upon entering Test Mode, the program can be at any

one of the ten steps.

Mode after selecting operation in MANUAL CYCLE.

6. To exit Test Mode:

a. Press and hold for 3 seconds to exit Test

2. Test Mode is comprised of ten (10) screens (screen

descriptions follow the table below on the next page).

Each screen corresponds to one of ten program

steps (described in the table below).

3. Press to advance from one screen (test step) to

the next.

Mode. The display switches to Screen 2 of Setup

Mode.

b. Use to select ENERGY MANAGEMENT,

DEWPOINT CONTROL or FIXED CYCLE.

c. Press and hold for 3 seconds to exit Setup

Mode and activate Display Mode.

d. Dryer operation continues from the last step active

IMPORTANT: Be sure to read and understand all

when exiting the Test Mode.

cautions listed with the screen (program step) descriptions.

4. If the temperature is out of range, the second line of

the display will read “OVER-RANGE” or “UNDERRANGE” instead of the temperature reading. (Refer

to screens 2, 3, 4, 6, 7, and 8.)

Program Step 1 2 3 4 5 6 7 8 9 10

LT status Drying Drying Drying Drying Drying Off Depress Heat Cool Repress

RT status Off Depress Heat Cool Repress Drying Drying Drying Drying Drying

1PS Closed Closed Closed Closed Closed Closed

2PS Closed

3PS Closed Closed Closed Closed Closed Closed

4PS Closed

LT drying solenoid (B) On On On On On Off Off Off Off Off

LT depress solenoid (F) Off Off Off Off Off Off On On On Off

LT purge solenoid (C) Off Off Off Off Off Off Off On On Off

RT drying solenoid (A) Off Off Off Off Off On On On On On

RT depress solenoid (G) Off On On On Off Off Off Off Off Off

RT purge solenoid (D) Off Off On On Off Off Off Off Off Off

LT inlet valve (V1) Open Open Open Open Open Closed Closed Closed Closed Closed

LT depress valve (V9) Closed Closed Closed Closed Closed Closed Open Open Open Closed

LT purge valve (V3) Closed Closed Closed Closed Closed Closed Closed Open Open Closed

RT inlet valve (V2) Closed Closed Closed Closed Closed Open Open Open Open Open

RT depress valve (V10) Closed Open Open Open Closed Closed Closed Closed Closed Closed

RT purge valve (V4) Closed Open Open Open Closed Closed Closed Closed Closed Closed

Repress valve (V11) Open Closed Closed Open Open Open Closed Closed Open Open

Temp display - location Left Right Right Right Right Right Left Left Left Left

Closed

then Open

Closed

then Open

Open Open

Open Open

Open then

Closed

Open then

Closed

Closed Closed Closed Closed Closed

Closed Closed Closed Closed Closed

Closed

then Open

Closed

then Open

Open Open

Open Open

Open then

Closed

Open then

Closed

24

Table 2

Cycle Sequence Steps

TEST MODE SCREENS

Screen 1: Step 1

TEST1: LT DRYING

LT: XX°C XXX°F

Screen 2: Step 2

TEST2: DEPR RT

RT: XX°C XXX°F

Note: Sequence step will not advance to HEAT

until depressurization time has elapsed and

tower has fully depressurized. Exception: If

switching failure is disabled then pressure

condition is ignored.

Screen 3: Step 3

TEST3: HEAT RT

RT: XX°C XXX°F

To prevent bed over-heating in test mode: If the

RT temperature > heat termination set point, then

Screen 3 will display for a maximum of 1 minute

before automatically advancing to next step.

Screen 6: Step 6

TEST6: RT DRYING

RT: XX°C XXX°F

Screen 7: Step 7

TEST7: DEPR LT

LT: XX°C XXX°F

Note: Sequence step will not advance to HEAT

until depressurization time has elapsed and

tower has fully depressurized. Exception:

If switching failure is disabled then pressure

condition is ignored.

Screen 8: Step 8

TEST8: HEAT LT

LT: XX°C XXX°F

To prevent bed over-heating in test mode: If the

LT temperature > heat termination set point, then

Screen 8 will display for a maximum of 1 minute

before automatically advancing to next step.

Screen 4: Step 4

TEST4: COOL RT

LT: XX°C XXX°F

If the RT temperature < cool termination set point,

then Screen 4 will display for a maximum of 1 minute

before automatically advancing to next step.

Screen 5: Step 5

TEST5: REPR RT

LT: XX°C XXX°F

Note: Sequence step will not advance to tower

SWITCHOVER until repressurization time

has elapsed and tower has fully pressurized.

Exception: If switching failure is disabled

then pressure condition is ignored.

Screen 9: Step 9

TEST9: COOL LT

LT: XX°C XXX°F

If the LT temperature < cool termination set point,

then Screen 9 will display for a maximum of 1 minute

before automatically advancing to next step.

Screen 10: Step 10

TEST10: REPR LT

LT: XX°C XXX°F

Note: Sequence step will not advance to tower

SWITCHOVER until repressurization time

has elapsed and tower has fully pressurized.

Exception: If switching failure is disabled

then pressure condition is ignored.

25

6.6 Start-up

6.6.1 Controller Settings

Set or verify settings on Controller. Detailed operational

points are presented in section 6.5.

WARNING - Enclosure may have live electric parts.

De-energize dryer before opening enclosure.

6.6.2 Initial Pressurization

SLOWLY pressurize dryer to full line pressure. (If the

dryer was installed with inlet and outlet isolation valves,

the inlet isolation valve should be slowly opened while

the outlet isolation valve remains closed.)

During initial start-up, check the entire system for leaks.

If necessary, de-pressurize the dryer and correct any

leaks.

NOTE: Read the off-line tower pressure gauge when the

tower is purging (air exhausting from muffler).

6.7.5 Process Valves

Determine if air control valves are operating and

sequencing correctly.

6.7.5.1 Valves – Models 500 and 600

Inlet switching valves are normally open, pneumatically

piston-actuated, Y-angle poppet valves. A yellow indicator

can be seen through a clear window at the top of the actuator housing when the valve is in the open position.

Purge exhaust valves are normally closed, pneumatically piston-actuated, Y-angle poppet valves. A yellow

indicator can be seen through a clear window at the top

of the actuator housing when the valve is in the open

position.

6.6.2.1 Energy Management Sensor (if installed)

Open and adjust the sample exhaust valve until a very

slight, continuous gas bleed is felt exhausting out of the

sample cell.

6.6.2.2 Dew Point Sensor (if installed)

Ensure that the supply air valve is open (one turn).

Open and adjust the sample exhaust valve until a very

slight, continuous gas bleed is felt exhausting out of the

sample cell.

6.6.3 Energizing the Dryer

Energize the dryer controls.

NOTE: The switching failure alarm may be activated if the

unit is energized before it is pressurized. To deactivate

alarm, allow dryer to cycle to next step and press the

reset button.

6.6.4 Bringing the Dryer On-line

Establish a normal flow through the dryer. Slowly open

the outlet isolation valve if present. Close any dryer

bypass valves.

6.7 Operational Check Points

6.7.1 Power to unit

Check periodically that there is power to the unit

(indicating lights illuminated).

6.7.2 Alarms

Periodically check for flashing red alarm LED.

6.7.3 Tower Status LEDs

Illuminated LEDs indicate which tower is on-line drying

or off-line regenerating.

6.7.4 Tower Pressure Gauges

Periodically check tower pressure gauges to verify

that the pressure gauge of the on-line tower reads line

pressure and the pressure gauge of the off-line tower

reads below 2 psig (0.14 kgf/ cm2).

12 volt DC, normally-closed, 3-way pilot solenoid valves

are wired to the controller and are used to direct pilot air

to the actuators of the inlet switching and purge/repressurization valves.

Dryers are equipped with a safety relief valve that has

been sized to provide overpressure protection due to a

fire for both desiccant towers.

6.7.5.2 Valves – Models 750 through 4300

Inlet switching valves are resilient seated butterfly valves

with double acting pneumatic rack and pinion actuators.

A yellow arrow indicator located on the top of the actuator

output shaft points to valve position indicator icons. Pilot

air is directed to actuator ports to open both inlet valves

upon loss of power.

(Model 750 only) Purge exhaust valves are normally

closed, pneumatically piston-actuated, Y-angle poppet

valves. A yellow indicator can be seen through a clear

window at the top of the actuator housing when the valve

is in the open position.

(Models 900 through 4300) Purge exhaust valves are

resilient seated butterfly valves with spring return, fail

closed, pneumatic rack and pinion actuators. A yellow

arrow indicator located on the top of the actuator output

shaft points to valve position indicator icons. Pilot air is

directed to actuator ports to close both purge/repressurization valves upon loss of power.

12 volt DC, single solenoid, 4-way pilot valves are wired

to the controller and are used to direct pilot air to the

actuators of the inlet switching and purge/repressurization valves.

Two mainline outlet and two purge line check valves

are installed in the upper piping to control the flow of

outlet and purge air. Check valve sticking will result in

excessive air discharge through a muffler. Excessive air

discharge through the muffler can be associated with a

leaking outlet check valve on the same side or a purge

check valve of the opposite side tower.

26

Dryers are equipped with a safety relief valve that has

been sized to provide overpressure protection due to a

fire for both desiccant towers.

b. Advances directly to the beginning of whichever

stage of HEAT or COOL it had been at when

power was interrupted.

The tower pressure gauge of the on-line tower should

read line pressure. Air should not be leaking from the

purge-repressurization valve of the on-line tower.

The tower pressure gauge of the off-line tower should

read below 2 psig (0.14 kgf/ cm2) while that tower is

purging. If excessive air is exhausting during the purge

cycle, the inlet-switching valve on the same side may

have failed to close or a check valve may be sticking.

6.8 Dryer Shut Down

1. If the dryer installation is equipped with dryer bypass

and inlet and outlet isolation valves, the bypass valve

should be opened and the inlet and outlet isolation

valves closed.

2. De-energize the dryer’s electrical supply.