HANKISON Filter Monitor Instruction Manual

7610.718.14 4/02

INSTRUCTION MANUAL

Introduction

The Filter Monitor continuously monitors the differential

pressure (pressure drop) across a filter and alerts the

operator of the need for element replacement when

any of three operating criteria are met:

1. Maximum elapsed time (service interval) before

change-out - operator alerted when user selected

time period elapses.

2. Maximum allowable differential pressure - operator

alerted when user selected maximum differential

pressure occurs.

3. Intelligence - operator alerted when the optimum time

to replace the element(s) has occurred. The Monitor

calculates this using the element type, the initial characteristic pressure drop and historical pressure drop data.

Recommended Settings for HF Series Filters

1. Maximum time before element replacement: Grades 9, 7, 6, 5, 3, - 12 MONTHS;

Grades 1 - 6 MONTHS;

2. Maximum pressure differential:

HF Series Setting Element

Grade psid kgf/cm

Grade 9 3 0.21 0.20 B

Grade 7 4 0.28 0.28 C

Grade 6 4 0.28 0.28 D

Grade 5 5 0.35 0.34 E

Grade 3 6 0.42 0.41 F

Grade 1 3 0.21 0.20 G

Programming Instructions

(Short version - for complete instructions see page 3)

1. To begin programming, press and hold ENTER button

for 3 seconds.

2. Press and hold the scroll button to input maximum

service interval (1 to 15 months) - press ENTER.

3. Press and hold the scroll button to select pressure unit

of measure (KG/CM

4. Press and hold the scroll button to input maximum

pressure drop (0.01 to 1.00 KG/CM

15 PSI) Use Left Shift and Right Shift buttons to select

advance rate (e.g. by ones, tenths, or hundredths) press ENTER.

5. Press and hold the scroll button to select the element

letter type (see chart above) - press ENTER.

6. Select Initalize or Run mode.

Initalize - Scroll until initial pressure drop and run icons

are displayed. (To be selected during initial installation

and element charge out).

Run -Scroll until run icon only is displayed. (To be

selected if Monitor is reprogrammed without changing

the element).

7. Press ENTER to start program.

2

,PSI, or BAR). - press ENTER.

SHIFT LEFT

BUTTON

SHIFT RIGHT

BUTTON

2

2

or BAR; 0.1 to

bar Letter Type

FILTER

MONITOR

LIQUID

CRYSTAL

DISPLAY

INITIAL P ICON

SCROLL

BUTTON

ENTER

BUTTON

OPERATOR

ALERT LIGHT

(RED LED)

RUN ICON

SERVICE DEPARTMENT: (724) 746-1100

1

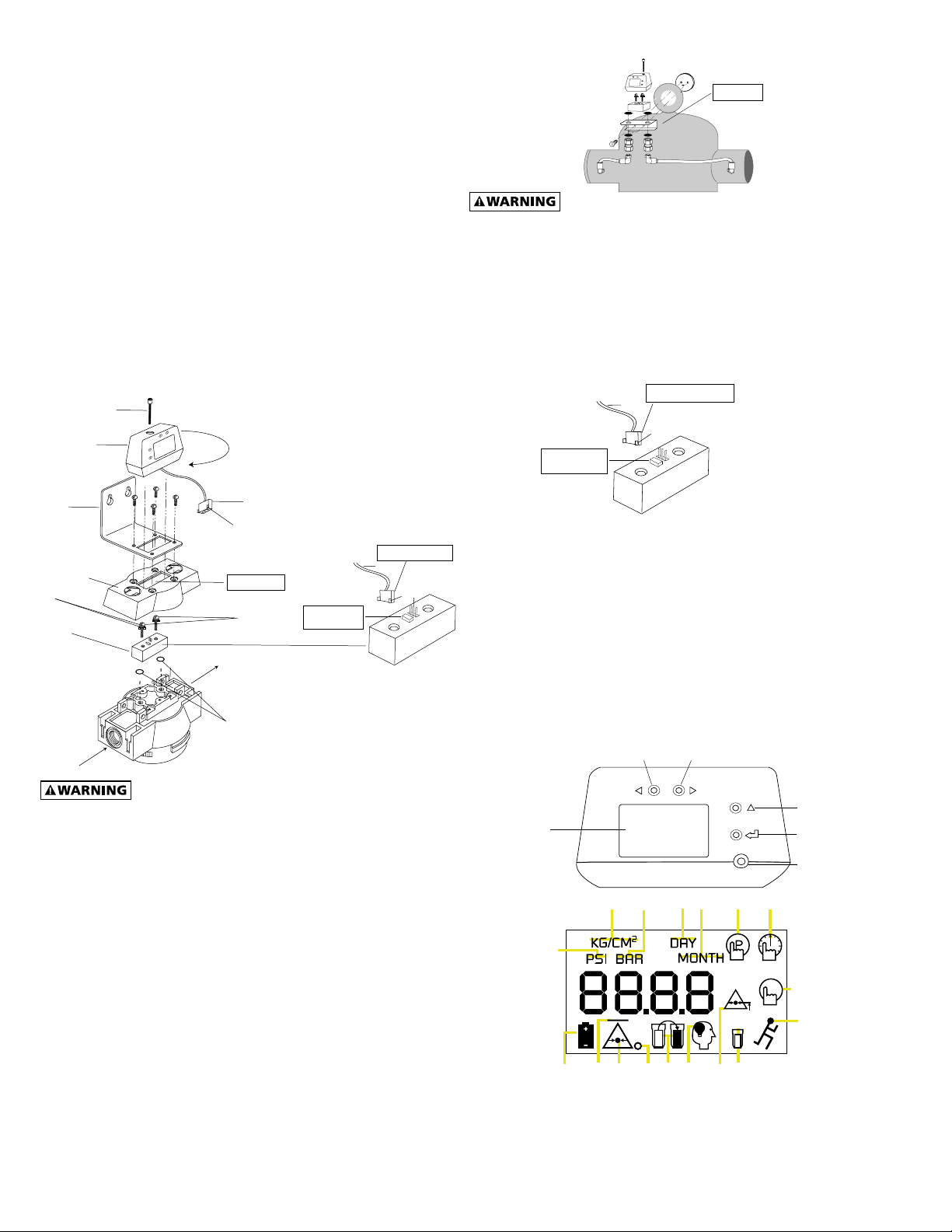

1.0 INSTALLATION

1

2

34

5

67

9

101112131415

16

17

8

1.1 Operating conditions

Maximum operating pressure: 250 psig, 17.6 kgf/cm2,

17.2 bar

Maximum compressed air temperature: 180°F, 82 °C

Minimum/maximum ambient temperature: 10/130°F,

-12/54°C

1.2 Mounting

A. Changing orientation on units with Monitor

installed

1. Remove Monitor mounting screw.

2. Lift Monitor and turn 180°.

Note: Make certain that connector to mounting block is

not disconnected.

3. Reinstall Monitor to mounting block with mounting

screw.

B. Retro-fitting bowl/head type housings

MOUNTING SCREW

MONITOR

C. Pressure vessel type housings

MOUNT TO VESSEL

AS SHOWN

OR REMOTELY TO WALL.

IN

OUT

Make certain filter is depressurized before disassembly.

1. If mounting hardware has not been previously

installed, remove inlet/outlet port plugs and install

fittings, tubing, couplings, and brackets using parts

from Mounting Kit.

2. Connect mounting block to couplings using o-rings

and transmission bolts supplied with Monitor.

NOTE: Torque bolts to 30 inch-pounds (3.4 N-m). Do not

over tighten.

MOUNT WITH LEGS FACING

RAISED RECTANGLE

LEAD

LEG

MOUNT WITH

RAISED RECTANGLE

ON INLET SIDE

OPTIONAL

FILTER

BRACKET

GASKETS

MOUNTING

BLOCK

CAP

IN

OUT

O-RINGS

LEAD

LEG

ENLARGE OPENING

IF NECESSARY

TRANSMISSON

BOLTS

MOUNT WITH

RAISED RECTANGLE

ON INLET SIDE

Make certain filter is depressurized before disassembly.

1. Remove existing differential pressure devices or port

plugs if installed.

2. Install mounting block on filter head using o-rings,

gaskets and transmission bolts supplied with Monitor.

NOTE: Torque bolts to 30 inch-pounds (3.4 N-m). Do not

over tighten.

IMPORTANT: Mount block so that raised rectangle is next to

the INLET (high pressure or upstream) side of filter.

Note: Enlarge opening in cap if necessary. A pattern for a

larger cutout is located on underside of cap.

3. Connect lead from Monitor to prongs in mounting

block.

IMPORTANT: Position connector so that legs on connector

are on same side as raised rectangle.

4. Mount Monitor on mounting block using mounting

screw provided.

NOTE: Monitor may be rotated 180° so that it faces forward

with filter flowing from left-to-right or right-to-left.

2

MOUNT WITH LEGS FACING

RAISED RECTANGLE

LEAD

LEG

IMPORTANT: Mount block so that raised rectangle is next to

the INLET (high pressure or upstream side) connection.

3. Connect lead from filter monitor to prongs in

mounting block.

IMPORTANT: Connect so that legs on connector are on same

side as raised rectangle.

4. Mount Monitor on mounting block using mounting

screw provided.

2.0 OPERATION

2.1 Display Legend

SHIFT RIGHT

BUTTON

SCROLL

BUTTON

ENTER

BUTTON

OPERATOR

ALERT LIGHT

(RED LED)

LIQUID

CRYSTAL

DISPLAY

SHIFT LEFT

BUTTON

LED DISPLAY

1. Unit of measure selection - pressure - pounds per

square inch.

2. Unit of measure selection - pressure - kilograms per

square centimeter.

3. Unit of measure selection - pressure - bar.

Loading...

Loading...