Hankinson International DH-25, DH-45, DH-6000, DH-80, DH-115 Instruction Manual

...

7610.479.9 1/22/97

Instruction Manual

DH Series

GENERAL SAFETY

INFORMATION

1. Pressurized devices: This equipment is

a pressure containing device. Do not

exceed maximum operating pressure as

shown on equipment serial number tag.

Make sure equipment is depressurized

before working on or disassembling it

for service.

2. Electrical: This equipment requires

electricity to operate. Install equipment

in compliance with national and local

electrical codes. Standard equipment is

supplied with NEMA 4, 4x electrical

enclosures and is not intended for

installation in hazardous environments.

Disconnect power supply to equipment

when performing any electrical service

work.

3. Breathing Air: Air treated by this

equipment may not be suitable for

breathing without further purification.

Refer to OSHA standard 1910.134 for

the requirements for breathing quality

air.

IMPORTANT:

READ PRIOR TO STARTING THIS

EQUIPMENT

A.

UNPACKING

This shipment has been thoroughly checked,

packed and inspected before leaving our plant.

It was received in good condition by the

carrier and was so acknowledged.

1. Check for Visible Loss or Damage. If this

shipment shows evidence of loss or damage

at time of delivery to you, insist that a notation

of this loss or damage be made on the delivery

receipt by the carrier’s agent.

2. Check for Concealed Loss or Damage. When a

shipment has been delivered to you in

apparent good order, but concealed damage is

found upon unpacking, notify the carrier

immediately and insist on his agent inspecting

the shipment. Fifteen days from receipt of

shipment is the maximum time limit for

requesting such inspection. Concealed

damage claims are not our responsibility as

our terms are F.O.B. point of shipment.

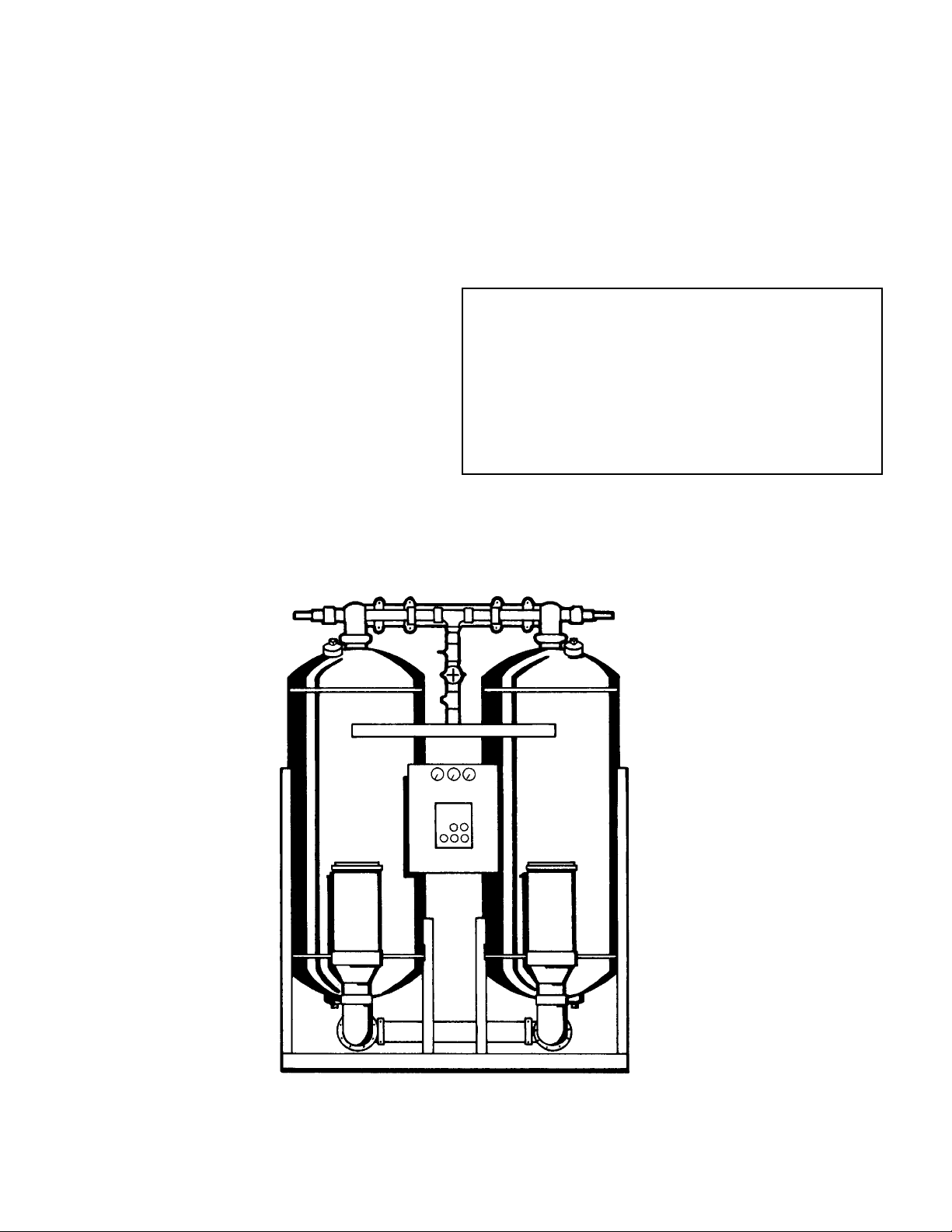

MOVING CAUTION:

B.

Do not lift by piping. Use lifting lugs or fork lift.

®

PRESSURE-SWING

DESICCANT TYPE

COMPRESSED

AIR DRYERS

MODEL RATED FLOW DESIGNATED AS MODELS

DH-25 25 SCFM 25

DH-45 45 SCFM 45

DH-6000 60 SCFM 60

DH-80 80 SCFM 80

DH-115 115 SCFM 115

DH-165 165 SCFM 165

DH-260 260 SCFM 260

DH-370 370 SCFM 370

DH-450 450 SCFM 450

DH-590 590 SCFM 590

DH-750 750 SCFM 750

DH-930 930 SCFM 930

DH-1130 1130 SCFM 1130

DH-1350 1350 SCFM 1350

DH-1550 1550 SCFM 1550

DH-2100 2100 SCFM 2100

DH-3000 3000 SCFM 3000

DH-4100 4100 SCFM 4100

DH-5400 5400 SCFM 5400

SERVICE DEPARTMENT (724) 746-1100

1

CONTENTS

1.0 DESCRIPTION ............................................................................................................................ 4

1.1 Function...................................................................................................................................... 4

1.2 Description of Operation.......................................................................................................... 5

2.0 INSTALLATION .......................................................................................................................... 6

2.1 Location in a compressed air system...................................................................................... 6

2.2 Minimum & Maximum Operating Conditions .......................................................................... 6

2.3 Mounting..................................................................................................................................... 6

2.4 Piping.......................................................................................................................................... 6

2.5 Electrical connections..............................................................................................................10

2.6 Provisions for purge exhaust ..................................................................................................10

2.7 Initial Desiccant Charge ...........................................................................................................10

3.0 OPERATION ..............................................................................................................................12

3.1 Start-up ......................................................................................................................................12

3.2 Operational check points.........................................................................................................14

3.3 Shut-down ................................................................................................................................ 15

3.4 Loss of power ...........................................................................................................................15

3.5 Design parameters ..................................................................................................................16

3.6 Determining purge and outlet flows .......................................................................................16

3.7 Outlet dew points vs. inlet temperatures ...............................................................................16

4.0 MAINTENANCE .........................................................................................................................18

4.1 Desiccant replacement.............................................................................................................18

4.2 Pilot air filter cartridge replacement (models 370 & larger only) ........................................18

4.3 Fuse Replacement (automatic purge models only)...............................................................19

4.4 Battery replacement (automatic purge models only)...........................................................19

4.5 Test Mode ..................................................................................................................................19

5.0 TROUBLESHOOTING ...............................................................................................................21

NOTE

Supplemental instructions for units supplied with the

optional Automatic Purge Saving System are shown in italics.

2

MINI INSTRUCTIONS

For complete instructions on installation, operation, and maintenance, consult manual.

I . INSTALLATION

1. Install on level surface.

2. Ambient temperature range: 35 to 120°F (1.7 to 49°C) [ if low ambient package supplied: -10 to 120°F (-23 to 49°C) ]

3. Install purge mufflers if shipped separately.

4. Connect air from compressor to inlet.

• Maximum compressed air temperature: 120°F (49°C)

• Maximum compressed air pressure: Refer to serial number tag.

• Minimum compressed air pressure: See section 2.2.1.2 .

5. Connect outlet to air system.

6. Refer to serial number tag for correct voltage. Make electrical connection to terminal strip in electrical enclosure. Standard units: connect

line to position 5, neutral to position 6 and ground to position 7.

Automatic purge saving system: connect wires to positions 2 and 3; ground to position 1.

7. Set controller for 120V or 240V using selector switch.

I I. START UP

1. Set or verify controller settings. See section 3.1.1.

2. SLOWLY pressurize unit.

3. Energize dryer by turning on/off switch on. ("I" is on; "O" is off)

4. Adjust purge air flow rate. Turn purge rate valve until Purge Pressure Gauge reads as shown in the following table.

NOTE: One tower must be purging when setting purge pressure.

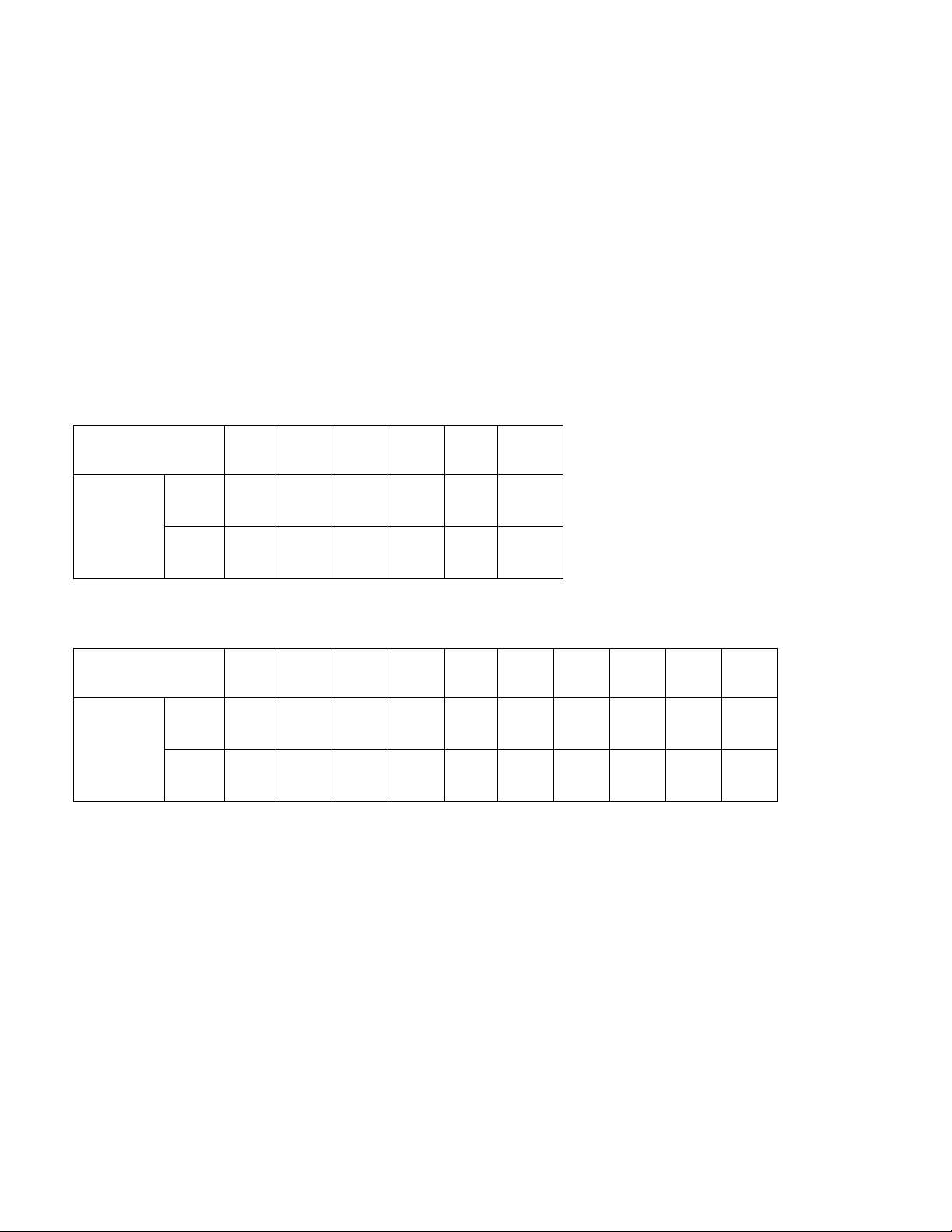

150 psig M.W.P. models

INLET PRESSURE 60-100 110 120 130 140 150

(psig)

CYCLE

TIME

SETTING

10

Min.

4

Min.

45 43 41 39 37 36

70 66 63 60 58 56

250 psig M.W.P. models

INLET PRESSURE 125 130 135 140 145 150 175 200 225 250

(psig)

CYCLE

TIME

SETTING

10

Min.

4

Min.

80 79 78 77 76 75 70 64 60 57

—————132123115108102

III . OPERATIONAL CHECKPOINTS

1. Check that dryer is energized (indicating lights are illuminated)

2. MOISTURE INDICATOR - Indicator should be green (Allow 4 hours after start up for indicator to turn green).

3. TOWER PRESSURE GAUGES -

• Tower on line should read line pressure

• Tower off line should read 2 psig or less while purging. If pressure exceeds 2 psig replace purge muffler elements.

NOTE: An extra set of elements is shipped with dryer.

4. PURGE PRESSURE GAUGE - Verify proper setting.

5. CHECK FOR ALARM CONDITION.

IV . DEPRESSURIZATION

Isolate dryer. Run timer until both tower pressure gauges read 0 psig.

3

1.0 DESCRIPTION

1.1 Function

1.1.1 Dryer Dual tower regenerative desiccant dryers are an economical

and reliable way to dry compressed air to dew points below the freezing

point of water (dew points as low as -150°F [1 ppb @ 100 psig, 7.0 kgf/

2

] are possible) or reduce the moisture content of compressed air when

cm

used in critical process applications.

These dryers continuously dry compressed air by using two identical

towers, each containing a desiccant bed. While one tower is on-stream

drying the compressed air, the other tower is off-stream being regenerated

(reactivated, i.e., dried out). The towers are alternated on- and off-stream

so that dry desiccant is always in contact with the wet compressed air. In

this way a continuous supply of dry air downstream is possible.

Desiccant dryers lower the dew point of compressed air by adsorbing the

water vapor present in the compressed air onto the surface of the

desiccant. Desiccant is a highly porous solid containing extensive surface

area.

Adsorption occurs until the partial pressure of the water vapor in the air

and that on the surface of the desiccant come into equilibrium. As

adsorption occurs, heat is released (referred to as the heat of adsorption)

and is stored in the bed for use during regeneration.

Desiccant is regenerated by driving off (desorbing) the water collected on

its surface. Pressure-swing (also called heatless or heaterless because no

outside heat is added) dryers regenerate by expanding a portion (approximately 14 - 15% at 100 psig, 7 kgf/cm

pressure. This “swing in pressure” causes the expanded air to become

very dry (have a very low vapor pressure). This very dry air (called purge

air) plus the stored heat of adsorption allows the moisture to desorb from

the desiccant. The purge air then carries the desorbed water out of the

dryer.

2

) of the dried air to atmospheric

1.1.2 Optional Automatic Purge Saving System

The Automatic Purge Saving System is designed to save energy (purge

air) when pressure-swing dryers are operated at reduced loads.

The patented Purge Saving System operates by monitoring the changes

in temperature within the desiccant beds. These changes in temperature

are the result of heat (thermal energy) that is released when a bed is online drying (heat of adsorption), and the heat that is used when a bed is

off-line being regenerated (heat of desorption).

The magnitude of these changes in temperature is an indirect measure of

the water vapor content in the air being dried. This information is used to

determine the time a tower stays on line during the drying cycle.

4

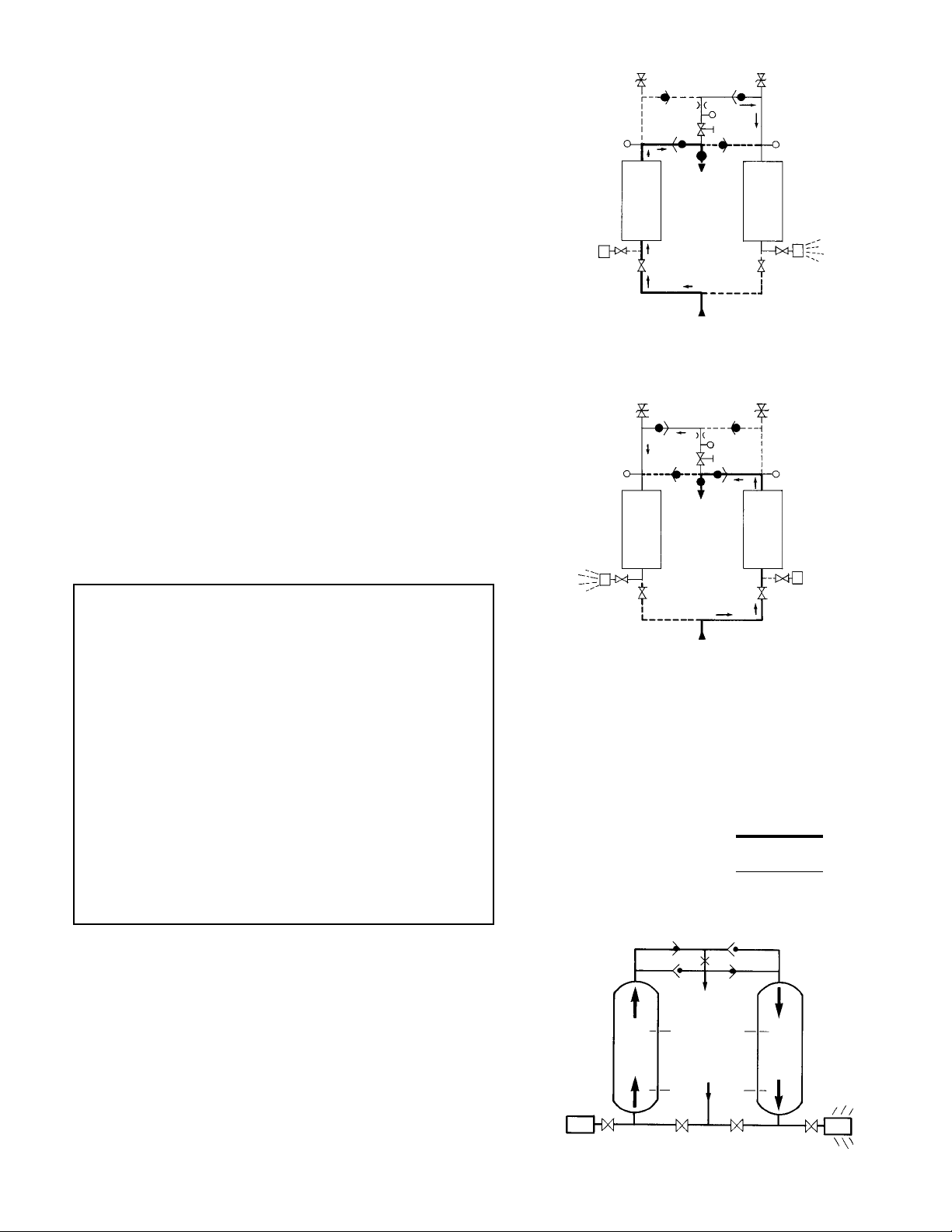

1.2 Description of Operation

1.2.1 Dryer

(4A) where the air is dried. After the air is dried it flows through check

valve (5A) and then to the dryer outlet.

main air stream prior to the outlet. The purge stream flow rate is controlled

by the adjustable purge rate valve (6) and the purge orifice (7).

pressure, is directed through check valve (5D) to tower (4B). As the purge

flow passes over the desiccant in tower (4B), it removes the water vapor

which was deposited there while the tower was on-line drying. The purge

air then passes through purge and repressurization valve (9B) and purge

muffler (10B) to the atmosphere.

allowing tower (4B) to repressurize slowly. Adequate repressurization time

is allowed so that tower 4B is fully repressurized before switchover. After a

controlled time period, air inlet switching valve (3B) opens and inlet

switching valve (3A) closes, purge and repressurization valve (9A) then

opens.

stream while tower (4A) is being regenerated by the purge air stream. The

operation of the inlet switching and purge and repressurization valves is

sequenced by the control system located in the electrical box.

(Refer to Figure 1A.)

Compressed air flows through inlet switching valve (3A) to tower

A portion of the dry air, the purge stream, branches off from the

The purge flow, which has been throttled to near atmospheric

After regeneration, purge and repressurization valve (9B) closes

(Refer to Figure 1B.)

Tower (4B) is now drying the main air

8

5C 5D

7

2

5A

3A

INLET

5C

5A

6

11

OUTLET

FIGURE 1A

7

6

11

OUTLET

2

1

TOWER

4A

10A

9A

TOWER 4A DRYING: TOWER 4B REGENERATING

88

1

TOWER

4A

5B

5D

5B

TOWER

4B

3B

TOWER

4B

8

1

9B

10B

1

1.2.2 Optional Automatic Purge Saving System (Refer to Figure 1C)

Assume Tower A is on-line drying the air while tower B has just

gone off-line to be regenerated. At the beginning of tower B’s regeneration cycle a temperature measurement is made at position B1. After the

tower has been regenerated, another measurement is made at B1. The

drop in temperature sensed during regeneration is an indirect measure

of the water vapor content of the inlet air. The Purge Saving System’s

microprocessor then uses this information to calculate an allowable

temperature rise in the bed during the drying cycle.

When tower B goes back on-line, a temperature probe at

position B2 measures the initial bed temperature at this point and then

monitors the bed until the calculated temperature rise occurs. The

temperature rise occurs as heat of adsorption is released during the

drying process. The time for the temperature rise to occur depends on

flow rate. At 100% flow the temperature rise takes five minutes, at 50%

flow it takes 10 minutes.

When the calculated temperature rise is reached, the towers

switch with tower A now drying and tower B being regenerated. Tower B

regenerates for 3.9 minutes, repressurizes, and remains idle until it is

called upon for the next drying cycle.

9A

10A

TOWER 4B DRYING: TOWER 4A REGENERATING

1. Pressure Gauges

2. Purge Pressure Gauge

3. Inlet Switching Valves

4. Desiccant Drying Towers

5. Check Valves

6. Adjustable Purge Rate Valve

3A

Process Stream

Purge Stream

9B

3B

INLET

FIGURE 1B

7. Purge Orifice

8. Pressure Relief Valves

9. Purge / Repressurization Valves

10. Purge Mufflers

11. Moisture Indicator

LEGEND

OUTLET

10B

TOWER

A

A2

INLET

A1

FIGURE 1C

B2

B1

TOWER

B

5

2.0 INSTALLATION

2.1 Location in the compressed air system.

NOTE

Air Compressor should be adequately sized to handle air system demands

as well as purge loss. Failure to take this into account could result in

overloading air compressors and/or insufficient air supply downstream.

NOTE

It is desirable to install dryer where compressed air is at the lowest

possible temperature (downstream of aftercoolers) and the highest

possible pressure (upstream of pressure reducing valves) without

exceeding the maximum working pressure.

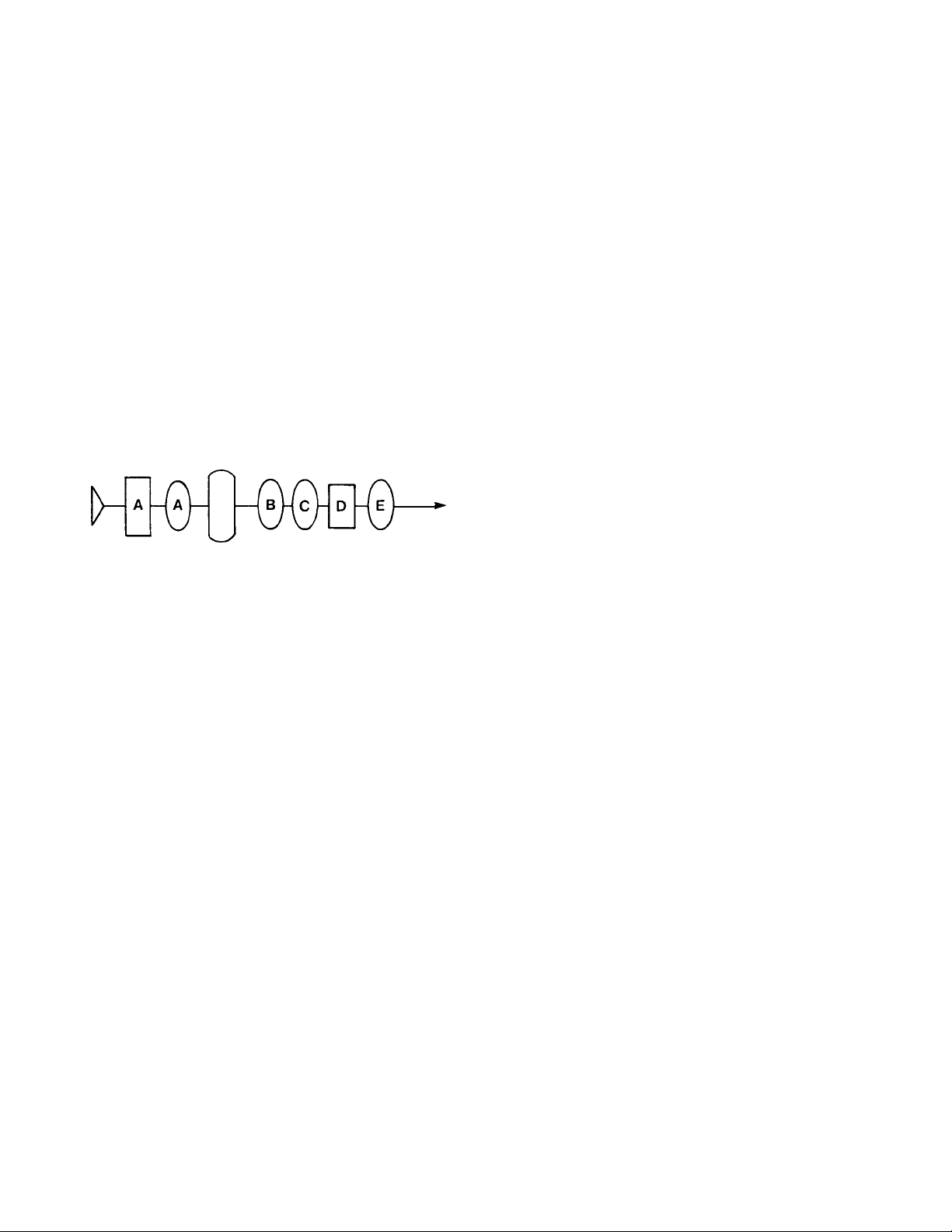

(A) AFTERCOOLER/SEPARATOR - Compressed air entering dryer must be

cooled to at least 120°F (49°C). Use aftercooler and separator if higher

temperatures are present.

NOTE

Installation of a refrigerated dryer ahead of a pressure-swing desiccant

dryer does not increase desiccant dryer capacity or reduce purge flow

requirements. However a cooling unit installed ahead of the desiccant

dryer reduces the inlet air temperature and outlet air dew point.

Separator

(Refer to Figure 2A)

Desiccant

Dryer

2.2 Minimum & Maximum Operating Conditions

The compressed air supply inlet should be checked periodically to ensure

that equipment design specifications are not exceeded. Normally the

compressor installation includes intercoolers, aftercoolers, separators,

receivers, or similar equipment which adequately pretreat the compressed

air supply in order to avoid excessively high air temperatures and liquid

slugging of downstream equipment.

2.2.1 Compressed air conditions

2.2.1.1 Maximum working pressure:

Refer to dryer Serial Number Tag.

Do not operate the dryer at pressures above the maximum

pressure shown on the tag.

2.2.1.2 Minimum working pressures:

150 psig (10.5 kgf/cm

60 psig (4.2 kgf/cm2) for dryers operated on a 10 minute cycle

80 psig (5.6 kgf/cm

250 psig (17.6 kgf/cm

125 psig (8.8 kgf/cm2) for dryers operated on a 10 minute cycle

150 psig (10.5 kgf/cm

If lower inlet pressures are encountered, consult factory.

2.2.1.3 Maximum inlet compressed air temperature:

120°F (49°C)

WARNING

2

) MWP models -

2

) for dryers operated on a 4 minute cycle

2

)MWP models -

2

) for dryers operated on a 4 minute cycle.

Compressor

Aftercooler

Receiver

Prefilter(s)

FIGURE 2A

Afterfilter

(B & C) PREFILTERS - Adequate filtration is required upstream of the

dryer in order to protect the desiccant bed from contamination. The

following filtration are recommended:

B - Particulate/Gross Liquid Removal

- On heavily contaminated systems

use a gross contaminant filter to remove solids and high inlet liquid

concentrations.

C - Oil Aerosol Removal

- On systems with lubricated compressors, use

an oil removal filter to remove oil aerosols and protect desiccant bed from

oil contamination.

(D) DESICCANT DRYER

(E) AFTERFILTER - To ensure downstream air purity (prevent desiccant

dust from traveling downstream) adequate filtration downstream of the

dryer is required. Typically 1 micron filtration is specified although finer

filtration is available.

OR

Oil Vapor Adsorber

- Use as an afterfilter to remove oil vapor and its

subsequent taste and odor and to protect down-stream components from

solid particles 0.01 micron and larger.

NOTE

By-pass lines and isolation valves are recommended so that maintenance

work can be performed without shutting off the air supply.

NOTE

If inlet air is higher than 120°F (49°C) the air must be precooled

with an aftercooler.

2.2.2 Ambient temperatures:

Minimum:

Standard units: 35°F (1.7°C)

Units with optional low ambient package: - 10°F (-23°C)

Maximum: 120°F (49°C)

NOTE

If dryer is installed in ambients below 35°F (1.7°C) heat tracing of

the prefilters and inlet piping and valves is necessary to prevent

condensate from freezing. If installing heat tracing, observe electrical

class code requirements for type of duty specified.

2.3 Mounting

Install dryer on a level pad on floor. Holes are provided in the

floor stand base angles for floor anchors if desired.

NOTE

Floor anchors must be used if area is subject to vibrations.

2.4 Piping

2.4.1 Inlet and Outlet connections

Observe location of inlet and outlet connections as indicated in

Figure 2B, 2C, or 2D and connect inlet and outlet piping.

NOTE

All piping must be supported so as not to bear on the dryers or

filters.

2.4.2 Isolation valves

If isolation valves are installed, it is recommended that gate

valves be used to ensure that dryer is pressurized slowly. This is

particularly true if isolation valves are placed before and after preand afterfilters where rapid pressurization could cause excessive

pressure drop across filter cartridges.

6

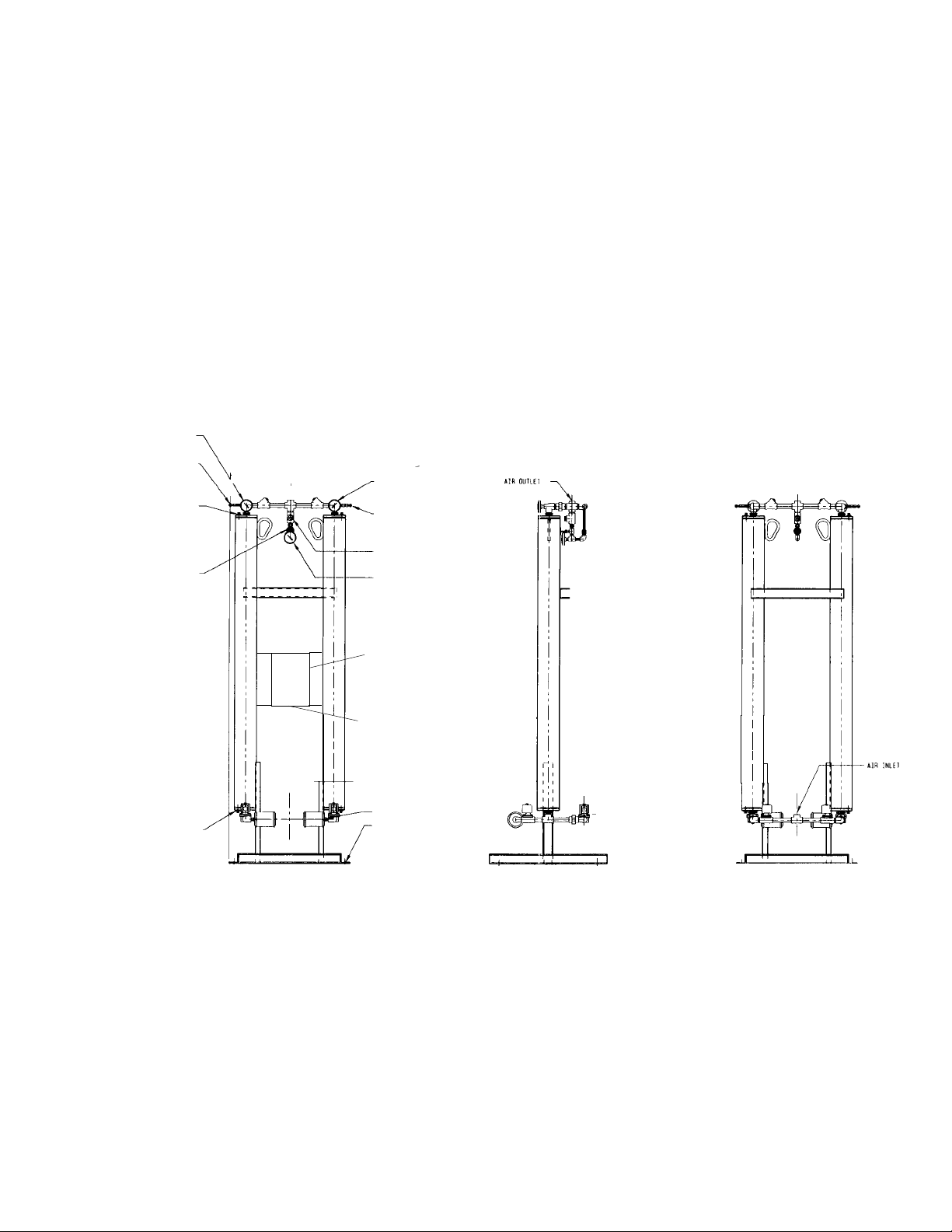

Left Tower Pressure

Gauge

Left Tower Pressure

Relief Valve

Desiccant Fill Port

Purge Pressure

Adjustment Valve

FIGURE 2B Models 25 through 80

Right Tower Pressure

Gauge

Right Tower

Pressure Relief Valve

Moisture

Indicator

Purge Pressure

Gauge

Control Panel

Desiccant Drain Port

Electrical Entry

(7/8")

Purge Muffler

3/4" Dia.

Mounting Holes

FRONT VIEW RIGHT SIDE VIEW REAR VIEW

7

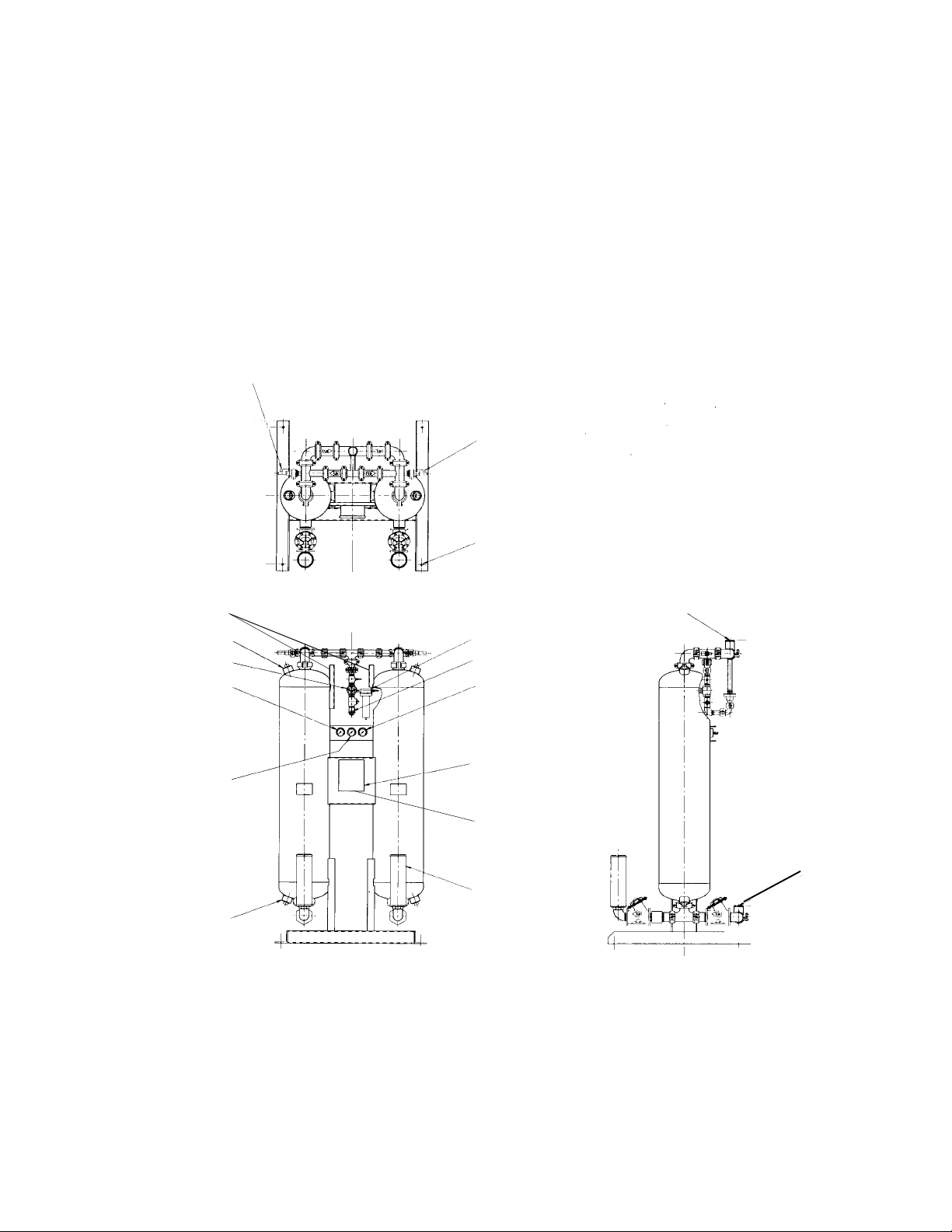

FIGURE 2C Models 115 through 2100

Left Tower Pressure

Relief Valve

C

D

A

B

*

*

L

Right Tower Pressure Relief Valve

3/4" (19mm) Dia. Mounting Holes

2" (51mm)

Lifting Lugs

Desiccant Fill Port

Purge Pressure Adjustment Valve

Left Tower Pressure Gauge

Purge Pressure Gauge

Desiccant Drain Port

E

"G" Air Outlet

Pilot Air Filter (Models 370 & larger)

Moisture Indicator

Right Tower

Pressure Gauge

Control Panel

Electrical Entry

(7/8")

Purge Muffler

*Models 115 through 260 use solenoid valves. Models 370 and larger use air operated butterfly valves.

K

F

"G" Air Inlet

*

*

J

H

8

Loading...

Loading...