1 Product Overview

Version: 2.0.0

Date: 2019-07-23

No.: 0000000001

Tuya BT3L BLE Module

Product

Manual

Global Intelligent Platform

BT3L is an embedded Bluetooth low energy (BLE) module that Tuya has developed. It

consists of a highly integrated Bluetooth chip (TLSR8250F512ET32) and several

peripheral components, with an embedded Bluetooth network protocol stack and robust

library functions. BT3L also contains a low-power 32-bit multipoint control unit (MCU),

BLE 5.0 component, 2.4 GHz radio component, 4 MB flash memory, 48 KB static randomaccess memory (SRAM), and nine multiplexing I/O interfaces.

1.1 Features

Embedded low-power 32-bit MCU, which can also function as an application

processor

Dominant frequency: 48 MHz

Working voltage: 1.8 V to 3.6 V (Under 1.8 V to 2.7 V, the module can start but the RF

performance is not guaranteed. Under 2.8 V to 3.6 V, the module performance is

normal.)

Peripherals: nine pulse width modulation (PWM) interfaces

BLE RF features

Compatible with BLE 5.0

Up to 2 Mbit/s RF data rate

TX power: +10 dBm

RX sensitivity: –94.5 dBm at BLE 1 Mbit/s

Embedded advanced encryption standard (AES) hardware encryption

Onboard PCB antenna with 2.5 dBi gain

BT3L Datasheet

2

Working temperature: –20°C to +85°C

1.2 Applications

Smart LED lights

Smart households

Smart low-power sensors

BT3L Datasheet

3

Change History

No.

Date

Change Description

Version After

Change

1

2019-03-09

This is the first release.

1.0.0

2

2019-07-23

1. Optimized the pin definition.

2. Standardized the dimensional tolerances.

3.Updated the temperature range, oven

temperature, and working voltage settings.

4. Added packing methods.

2.0.0

BT3L Datasheet

4

Contents

1 Product Overview ............................................................................................................1

1.1 Features ................................................................................................................1

1.2 Applications...........................................................................................................2

Change History...................................................................................................................3

2 Module Interfaces............................................................................................................6

2.1 Dimensions and Footprint .....................................................................................6

2.2 Interface Pin Definition ..........................................................................................7

3 Electrical Parameters ......................................................................................................9

3.1 Absolute Electrical Parameters .............................................................................9

3.2 Electrical Conditions..............................................................................................9

3.3 Working Current ..................................................................................................10

4 RF Features...................................................................................................................11

4.1 Basic RF Features...............................................................................................11

4.2 RF Output Power.................................................................................................11

4.3 RF RX Sensitivity ................................................................................................12

5 Antenna Information ......................................................................................................12

5.1 Antenna Type......................................................................................................12

5.2 Antenna Interference Reduction..........................................................................12

6 Packaging Information and Production Instructions..........................................................13

6.1 Mechanical Dimensions ......................................................................................13

6.2 Production Instructions........................................................................................14

6.3 Recommended Oven Temperature Curve ..........................................................15

6.4 Storage Conditions..............................................................................................17

7 MOQ and Packing Information ......................................................................................18

8 Appendix: Statement .....................................................................................................18

BT3L Datasheet

5

Figures

Figure 2-1 BT3L pins..........................................................................................................6

Figure 6-1 BT3L mechanical dimensions .........................................................................13

Figure 6-2 HIC for BT3L ...................................................................................................14

Figure 6-3 Oven temperature curve .................................................................................16

Tables

Table 2-1 BT3L interface pins ............................................................................................7

Table 3-1 Absolute electrical parameters...........................................................................9

Table 3-2 Normal electrical conditions ...............................................................................9

Table 3-3 Current during constant transmission and receiving ........................................10

Table 4-1 Basic RF features.............................................................................................11

Table 4-2 Power during constant transmission ................................................................11

Table 4-3 RX sensitivity....................................................................................................12

BT3L Datasheet

6

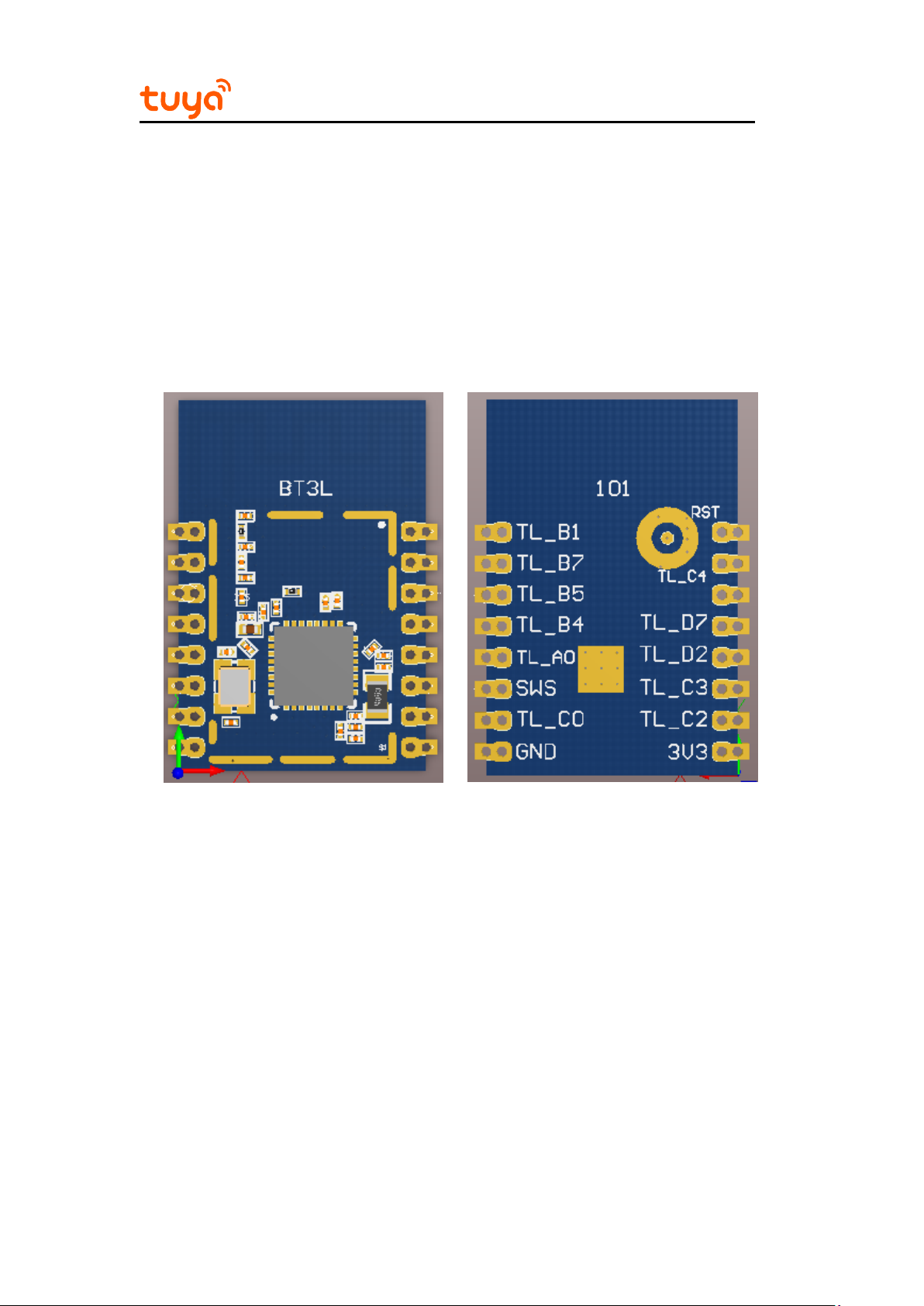

2 Module Interfaces

2.1 Dimensions and Footprint

BT3L has two rows of pins with a 2 mm pin spacing.

The BT3L dimensions (H x W x D) are 3.3±0.15 mm x 16±0.35 mm x 24±0.35 mm. The

PCB thickness is 0.8±0.1 mm. Figure 2-1 shows the BT3L pins.

Figure 2-1 BT3L pins

BT3L Datasheet

7

2.2 Interface Pin Definition

Pin

No.

Symbol

I/O

Type

Function

1

RST

I/O

Hardware reset pin, which is active at a low level

and is connected to pin 25 on the IC

2

ADC

AI

12-bit ADC, which is connected to pin 24 on the

IC3NC

I/ONC4

TL_D7

I/O

GPIO, which is connected to pin 2 on the IC

5

TL_D2

I/O

Common I/O, which can be used as a PWM

output of the LED drive and is connected to pin 31

on the IC

6

TL_C3

I/O

Common I/O, which can be used as a PWM

output of the LED drive and is connected to pin 23

on the IC

7

TL_C2

I/O

Common I/O, which can be used as a PWM

output of the LED drive and is connected to pin 22

on the IC

8

VDD_BAT

P

Power supply pin (3.3 V)

9

GND

P

Power supply reference ground pin

10

TL_C0

I/O

GPIO, which is connected topin 20 on the IC

11

SWS

Input

Programming pin, which is connected to pin 5 on

the IC

Table 2-1 BT3L interface pins

BT3L Datasheet

8

Pin

No.

Symbol

I/O

Type

Function

12

TL_A0

I/O

GPIO, which is connected to pin 3 on the IC

13

TL_B4

I/O

Common I/O, which can be used as a PWM

output of the LED drive and is connected to pin 14

on the IC

14

TL_B5

I/O

Common I/O, which can be used as a PWM

output of the LED drive and is connected to pin 15

on the IC

15

TL_B7

I/O

Serial interface receiving pin (UART RX), which is

connected to pin 17 on the IC

16

TL_B1

I/O

Serial interface transmission pin (UART TX),

which is connected to pin 6 on the IC

Note:

1. P indicates power supply pins, I/O indicates input/output pins, and AI indicates analog

input pins.

2. If you have special requirements for light colors controlled by PWM outputs, contact

Tuya business personnel.

BT3L Datasheet

9

3 Electrical Parameters

Parameter

Description

Minimum

Value

Maximum

Value

Unit

Ts

Storage

temperature

–65

150°CVCC

Power supply

voltage

–0.3

3.9

V

Static electricity voltage

(human body model)

Tamb = 25°C

N/A

2

kV

Static electricity voltage

(machine model)

Tamb = 25°C

N/A

0.5

kV

Parameter

Description

Minimum

Value

Typica

l Value

Maximum

Value

Unit

Ta

Working

temperature

–20

N/A

85°CVCC

Working

voltage

2.8

3.3

3.6

V

V

IH

I/O high-

VCC x 0.7

N/A

VCC

V

3.1 Absolute Electrical Parameters

Table 3-1 Absolute electrical parameters

3.2 Electrical Conditions

Table 3-2 Normal electrical conditions

BT3L Datasheet

10

Parameter

Description

Minimum

Value

Typica

l Value

Maximum

Value

Unit

level input

V

OL

I/O low-

level output

VSS

N/A

VCC x 0.1

V

V

OH

I/O high-

level output

VCC x 0.9

N/A

VCC

V

3.3 Working Current

Symbol

Description

Typical

Value

Unit

I

tx

Constant transmission, 0 dBm

output power

6.7

mA

IrxConstant receiving

6.3mAIDCConnected to a mesh network

7.4

mA

I

deepsleep1

Deep sleep mode 1 (16 KB

RAM is reserved.)

1.2μAI

deepsleep2

Deep sleep mode 2 (No RAM

is reserved.)

0.4

μA

Table 3-3 Current during constant transmission and receiving

BT3L Datasheet

11

4 RF Features

Parameter

Description

Frequency band

2.4 GHz ISM band

Wireless standard

BLE 5.0

Data transmission rate

1 Mbit/s or 2 Mbit/s

Antenna type

Onboard PCB antenna

Parameter

Minimum

Value

Typical

Value

Maximum

Value

Unit

Average RF output power

–221010.5

dBm

20 dB modulation signal

bandwidth (1 Mbit/s)

N/A

2500

N/A

kHz

20 dB modulation signal

bandwidth (2 Mbit/s)

N/A

1400

N/A

kHz

4.1 Basic RF Features

Table 4-1 Basic RF features

4.2 RF Output Power

Table 4-2 Power during constant transmission

BT3L Datasheet

12

4.3 RF RX Sensitivity

Parameter

Minimum

Value

Typica

l Value

Maximum

Value

Unit

1 Mbit/s

N/A

–94.5

N/A

RX sensitivity

2 Mbit/s

N/A

–91

N/A

dBm

1 Mbit/s

–250

N/A

+300

Frequency offset

2 Mbit/s

–300

N/A

+200

kHz

Co-channel interference

suppression

N/A

N/A

–10

N/A

dB

Table 4-3 RX sensitivity

5 Antenna Information

5.1 Antenna Type

BT3L uses an onboard PCB antenna.

5.2 Antenna Interference Reduction

To ensure optimal RF performance, it is recommended that the antenna be at least 15 mm

away from other metal parts. If metal materials are wrapped around the antenna, the

wireless signals will be reduced greatly, deteriorating the RF performance. Because BT3L

is inserted to the PCB, sufficient space needs to be reserved for the antenna.

BT3L Datasheet

13

6 Packaging Information and Production Instructions

6.1 Mechanical Dimensions

Figure 6-1 BT3L mechanical dimensions

Note:

The default dimensional tolerance is ±0.35 mm, and the tolerance for some

measurements is ±0.1 mm. If a customer has other requirements, clearly specify them in

the datasheet after communication.

BT3L Datasheet

14

6.2 Production Instructions

1. Use an SMT placement machine to mount components to the stamp hole module that

Tuya produces within 24 hours after the module is unpacked and the firmware is

burned. If not, vacuum pack the module again. Bake the module before mounting

components to the module.

(1) SMT placement equipment

i. Reflow soldering machine

ii. Automated optical inspection (AOI) equipment

iii. Nozzle with a 6 mm to 8 mm diameter

(2) Baking equipment

i. Cabinet oven

ii. Anti-static heat-resistant trays

iii. Anti-static heat-resistant gloves

2. Storage conditions for a delivered module are as follows:

(1) The moisture-proof bag is placed in an environment where the temperature is

below 30°C and the relative humidity is lower than 70%.

(2) The shelf life of a dry-packaged product is six months from the date when the

product is packaged and sealed.

(3) The package contains a humidity indicator card (HIC).

Figure 6-2 HIC for BT3L

BT3L Datasheet

15

3. Bake a module based on HIC status as follows when you unpack the module package:

(1) If the 30%, 40%, and 50% circles are blue, bake the module for 2 consecutive

hours.

(2) If the 30% circle is pink, bake the module for 4 consecutive hours.

(3) If the 30% and 40% circles are pink, bake the module for 6 consecutive hours.

(4) If the 30%, 40%, and 50% circles are pink, bake the module for 12 consecutive

hours.

4. Baking settings:

(1) Baking temperature: 125±5°C

(2) Alarm temperature: 130°C

(3) SMT placement ready temperature after natural cooling: < 36°C

(4) Number of drying times: 1

(5) Rebaking condition: The module is not soldered within 12 hours after baking.

5. Do not use SMT to process modules that have unpacked for over three months.

Electroless nickel immersion gold (ENIG) is used for the PCBs. If the solder pads are

exposed to the air for over three months, they will be oxidized severely and dry joints

or solder skips may occur. Tuya is not liable for such problems and consequences.

6. Before SMT placement, take electrostatic discharge (ESD) protective measures.

7. To reduce the reflow defect rate, draw 10% of the products for visual inspection and

AOI before first SMT placement to determine a proper oven temperature and

component placement method. Draw 5 to 10 modules every hour from subsequent

batches for visual inspection and AOI.

6.3 Recommended Oven Temperature Curve

Perform SMT placement based on the following reflow oven temperature curve. The

highest temperature is 245°C.

Based on the IPC/JEDEC standard, perform reflow soldering on a module at most twice.

BT3L Datasheet

16

Figure 6-3 Oven temperature curve

BT3L Datasheet

17

6.4 Storage Conditions

BT3L Datasheet

18

7 MOQ and Packing Information

MOQ and Packing Information

Product Model

MOQ (PCS)

Packing

Method

Number of

Modules in

Each Reel Pack

Number of Reel

Packs in Each

Box

BT3L

3600

Carrier tape and

reel packing

900

4

8 Appendix: Statement

Federal Communications Commission (FCC) Declaration of Conformity

FCC Caution: Any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate this equipment.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This device and its antenna(s) must not be co-located or operating in conjunction with any

other antenna or transmitter.

15.105 Information to the user.

(b) For a Class B digital device or peripheral, the instructions furnished the user shall include

the following or similar statement, placed in a prominent location in the text of the manual:

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

BT3L Datasheet

19

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20

cm between the radiator and your body.

Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment.

This transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

The availability of some specific channels and/or operational frequency bands is country

dependent and firmware programmed at the factory to match the intended destination.

The firmware setting is not accessible by the end user.

The final end product must be labeled in a visible area with the following:

"Contains Transmitter Module 2ANDL-BT3L"

This radio module must not be installed to co-locate and operating simultaneously with

other radios in host system, additional testing and equipment authorization may be

required to operating simultaneously with other radio.

BT3L Datasheet

20

Declaration of Conformity European notice

Hereby, Hangzhou Tuya Information Technology Co., Ltd. declares that this Wi-Fi module

product is in compliance with essential requirements and other relevant provisions of

Directive 2014/53/EC. A copy of the Declaration of conformity can be found at

https://www.tuya.com.

EN 300 328 V2.1.1

EN 301 489-1 V2.1.1; EN 301 489-17 V3.1.1

EN 62311:2008

EN 60950-1:2006+A11:2009+A1:2010+A12:2011+A2:2013

Loading...

Loading...