Hangcha CPD10-A, CPD15-A, CPD18-A, CPD20-A, CPD25-A Maintenance Manual

...

Electrical Forklift Truck

CPD10/15/18/20/25/30-A

CPD10/15/18/20/25/30/35-AC3

CPD10/15/18/20/25/30/35-AC3F

CPD10/15/18/20/25/30/35-AC4

CPD10/15/18/20/25/30/35-AC4F

CPD10/15/18/20/25/30/35-AD2

CPD25-ALC3 CPD25-ALC3F

CPD25-ALC4 CPD25-ALC4F

CPD25-ALD2

(Electric four-wheel Forklift Truck)

OPERATION AND MAINTENANCE

MANUAL

HANGCHA GROUP CO., LTD.

Original Instruction

5 / 2013

FOREWORD

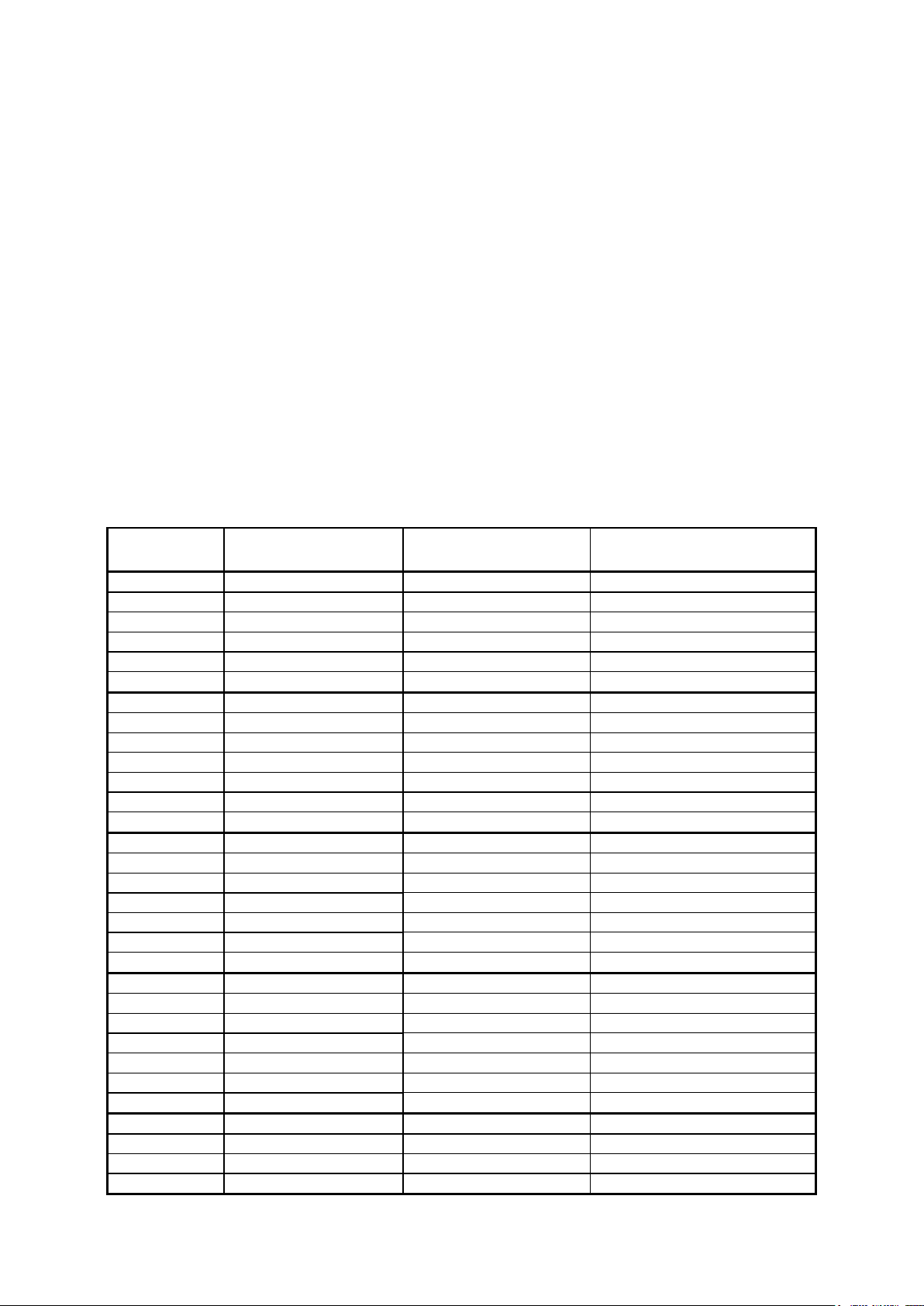

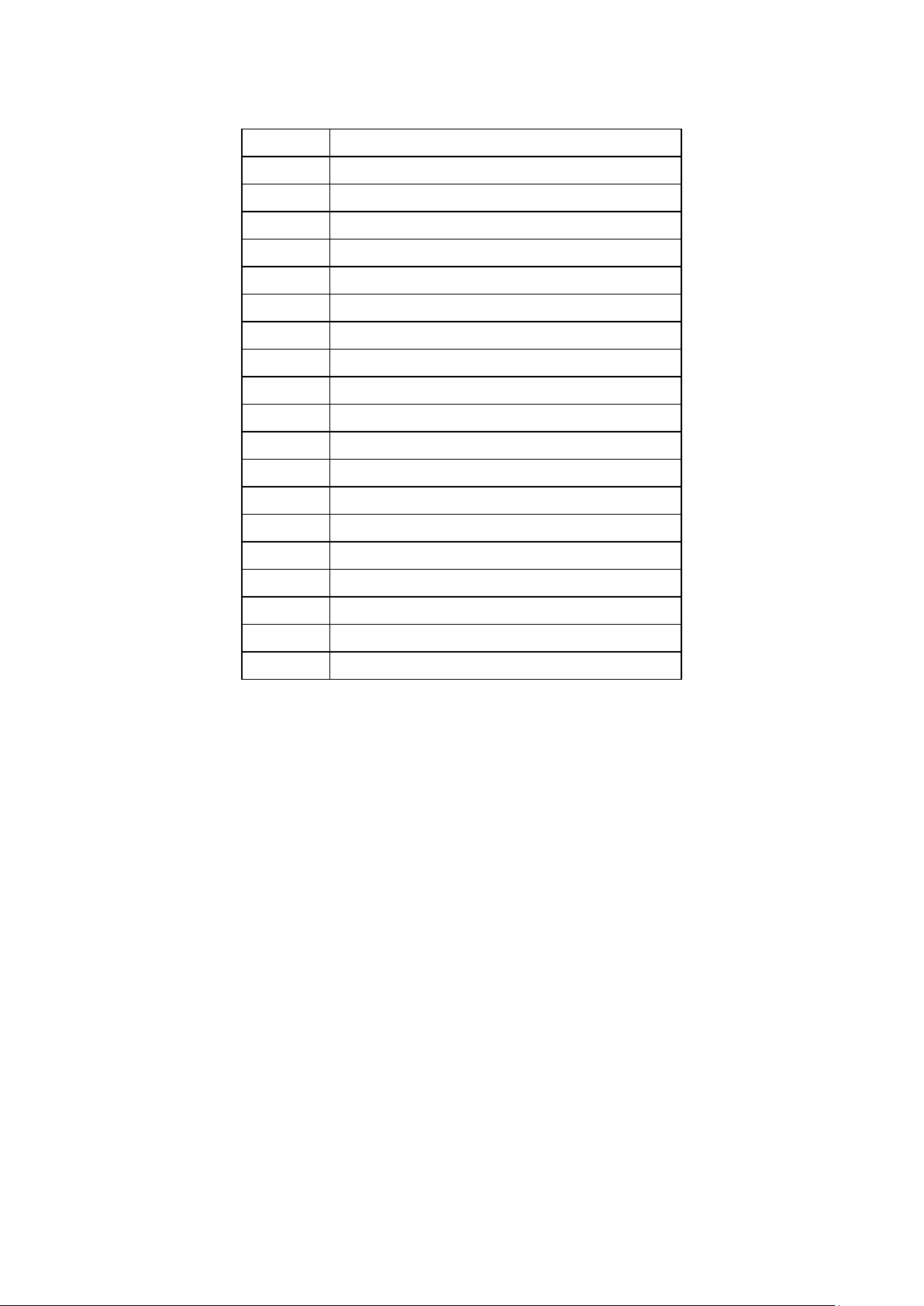

Model

Controller

(Drive motor)

Controller

(Pump motor)

Rated capacity(t) / Load

centre(mm)

CPD10-A

Curtis 1244

Curtis 1253

1.0 / 500

CPD15-A

Curtis 1244

Curtis 1253

1.5 / 500

CPD18-A

Curtis 1244

Curtis 1253

1.8 / 500

CPD20-A

Curtis 1244

Curtis 1253

2.0 / 500

CPD25-A

Curtis 1244

Curtis 1253

2.5 / 500

CPD30-A

Curtis 1244

Curtis 1253

3.0 / 500

CPD10-AC3

Curtis 1236

Curtis 1253

1.0 / 500

CPD15-AC3

Curtis 1236

Curtis 1253

1.5 / 500

CPD18-AC3

Curtis 1236

Curtis 1253

1.8 / 500

CPD20-AC3

Curtis 1236

Curtis 1253

2.0 / 500

CPD25-AC3

Curtis 1236

Curtis 1253

2.5 / 500

CPD30-AC3

Curtis 1236

Curtis 1253

3.0 / 500

CPD35-AC3

Curtis 1238

Curtis 1253

3.5 / 500

CPD10-AC4

Curtis 1236

Curtis 1236

1.0 / 500

CPD15-AC4

Curtis 1236

Curtis 1236

1.5 / 500

CPD18-AC4

Curtis 1236

Curtis 1236

1.8 / 500

CPD20-AC4

Curtis 1236

Curtis 1236

2.0 / 500

CPD25-AC4

Curtis 1236

Curtis 1236

2.5 / 500

CPD30-AC4

Curtis 1236

Curtis 1236

3.0 / 500

CPD35-AC4

Curtis 1238

Curtis 1236

3.5 / 500

CPD10-AD2

Danaher ACS48M-35P

Danaher ACS48M-23P

1.0 / 500

CPD15-AD2

Danaher ACS48M-35P

Danaher ACS48M-23P

1.5 / 500

CPD18-AD2

Danaher ACS48M-35P

Danaher ACS48M-23P

1.8 / 500

CPD20-AD2

Danaher ACS48M-35P

Danaher ACS48M-23P

2.0 / 500

CPD25-AD2

Danaher ACS48M-35P

Danaher ACS48M-23P

2.5 / 500

CPD30-AD2

Danaher ACS80M-35P

Danaher ACS80M-23P

3.0 / 500

CPD35-AD2

Danaher ACS80M-35P

Danaher ACS80M-23P

3.5 / 500

CPD10-AC3F

Curtis 1236

Curtis 1253

1.0 / 500

CPD15-AC3F

Curtis 1236

Curtis 1253

1.5 / 500

CPD18-AC3F

Curtis 1236

Curtis 1253

1.8 / 500

CPD20-AC3F

Curtis 1236

Curtis 1253

2.0 / 500

Thanks for you purchasing our A series electric four-wheel forklift truck.

A series electric four-wheel forklift truck is our company‟s new product. It has the character of

small turning radius, beautiful shape, small dimensions, low gravity, good stability, superior

performance.

This operation manual is the explanations that how to use 1.0t~3.5t A series electric four-wheel

forklift truck correctly. It will instruct you how to operate safety and precautionary maintenance. To

ensure safety and exert the truck‟s potential, all the personnel that in charge of operation,

maintenance and management must read this manual thoroughly before starting work with the

forklift.

As the improvements of products of our company, maybe there are some differs between this

operation manual with your forklift truck.

If you have any questions please keep touches with HANGCHA GROUP CO., LTD.sales

department or let the agents know.

Model

Controller

(Drive motor)

Controller

(Pump motor)

Rated capacity(t) / Load

centre(mm)

CPD25-AC3F

Curtis 1236

Curtis 1253

2.5 / 500

CPD30-AC3F

Curtis 1236

Curtis 1253

3.0 / 500

CPD35-AC3F

Curtis 1238

Curtis 1253

3.5 / 500

CPD10-AC4F

Curtis 1236

Curtis 1236

1.0 / 500

CPD15-AC4F

Curtis 1236

Curtis 1236

1.5 / 500

CPD18-AC4F

Curtis 1236

Curtis 1236

1.8 / 500

CPD20-AC4F

Curtis 1236

Curtis 1236

2.0 / 500

CPD25-AC4F

Curtis 1236

Curtis 1236

2.5 / 500

CPD30-AC4F

Curtis 1236

Curtis 1236

3.0 / 500

CPD35-AC4F

Curtis 1238

Curtis 1236

3.5 / 500

CPD25-ALC3

Curtis 1236

Curtis 1253

2.5 / 500

CPD25-ALC3F

Curtis 1236

Curtis 1253

2.5 / 500

CPD25-ALC4

Curtis 1236

Curtis 1236

2.5 / 500

CPD25-ALC4F

Curtis 1236

Curtis 1236

2.5 / 500

CPD25-ALD2

Danaher ACS80M-35P

Danaher ACS80M-23P

2.5 / 500

5/2013 HANGCHA GROUP CO., LTD

©

CONTENT

Foreword

1. Appearance and the main components ........................................................... 1

2. Displays and Controls ....................................................................................... 2

Multi-function display ........................................................................................... 4

Controls ............................................................................................................. 12

Seat ................................................................................................................... 17

Seat Aware System(For CE) ............................................................................. 20

3. Nameplate and Safety Labels ......................................................................... 22

4. Technical Specifications ................................................................................. 24

5. Safety Instructions ........................................................................................... 29

6. Forklift Transport,Lifting﹠Towing ................................................................. 35

Transport ........................................................................................................... 35

Lifting ................................................................................................................. 35

Towing ............................................................................................................... 36

7. The Structure and Stability of Truck .............................................................. 37

8. Running-in of the new truck ............................................................................ 40

9. Daily Maintenance ............................................................................................ 41

10. Driving and Operation ...................................................................................... 45

Driving ............................................................................................................... 45

Traveling ............................................................................................................ 45

Turning .............................................................................................................. 45

Stopping or parking ........................................................................................... 45

Loading .............................................................................................................. 46

Stacking load ..................................................................................................... 46

Un-stacking load ................................................................................................ 47

Check after operation ........................................................................................ 47

11. Deposit .............................................................................................................. 48

12. Battery ............................................................................................................... 49

13. Maintenance summarization ............................................................................ 58

Preventive maintenance schedule ..................................................................... 59

Replace the key safe parts termly ..................................................................... 66

Table for bolts tightening torque ........................................................................ 67

Table for oil used in the truck ............................................................................ 68

14. The use, Install and Safety Rules of attachment ........................................... 69

15. Battery automatic filling water system(Optional) .......................................... 71

16. Related Safety Instruction and Standard(For CE) ......................................... 76

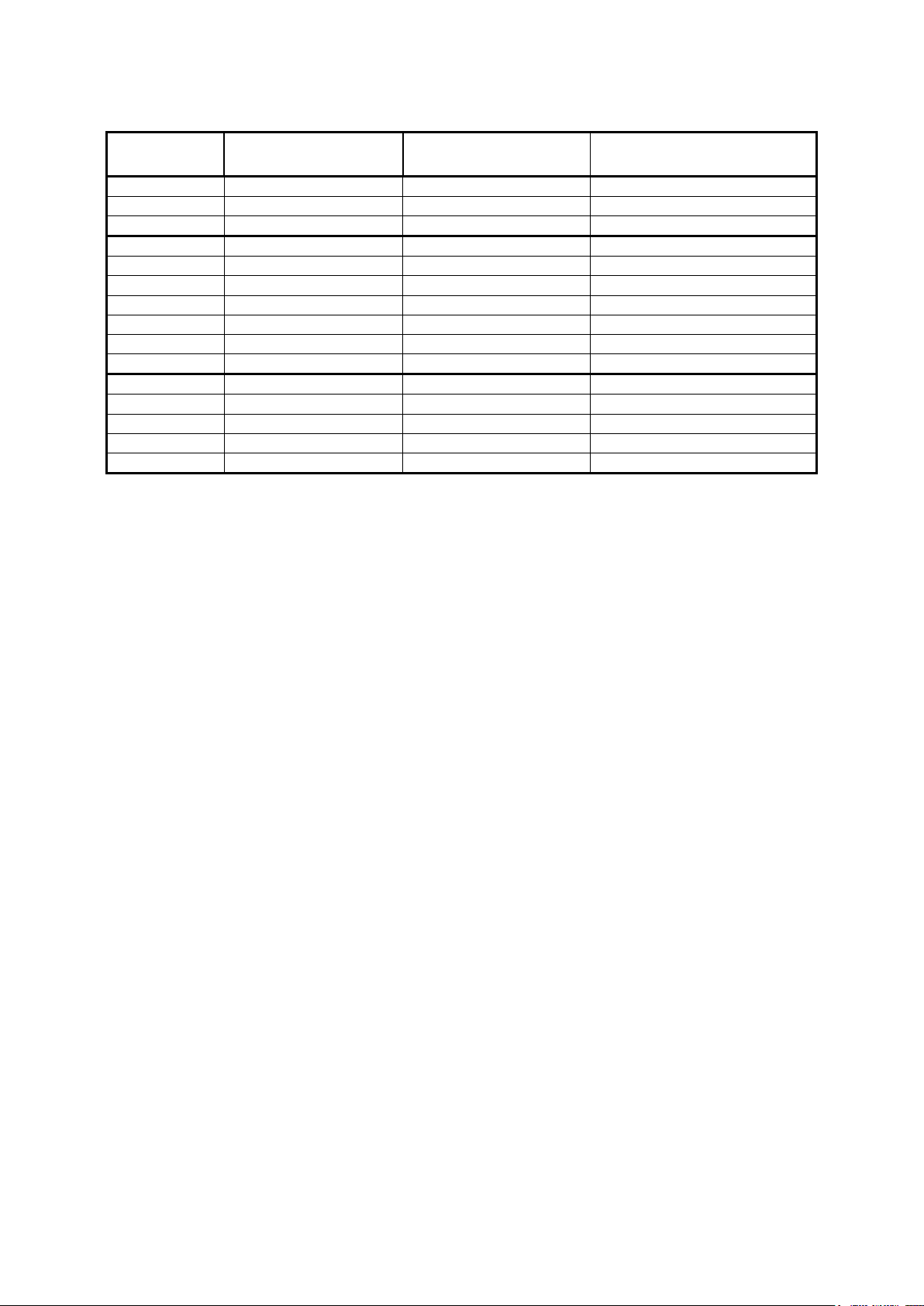

1. Appearance and the main components

Item

Description

1

Fork

2

Load backrest

3

Mast

4

Rearview mirror

5

Overhead guard

6

Driver‟s seat

7

Counterweight cover

8

Counterweight

9

Towing pin

10

Rear wheel

11

Battery behind cover hood

12

Front wheel

1

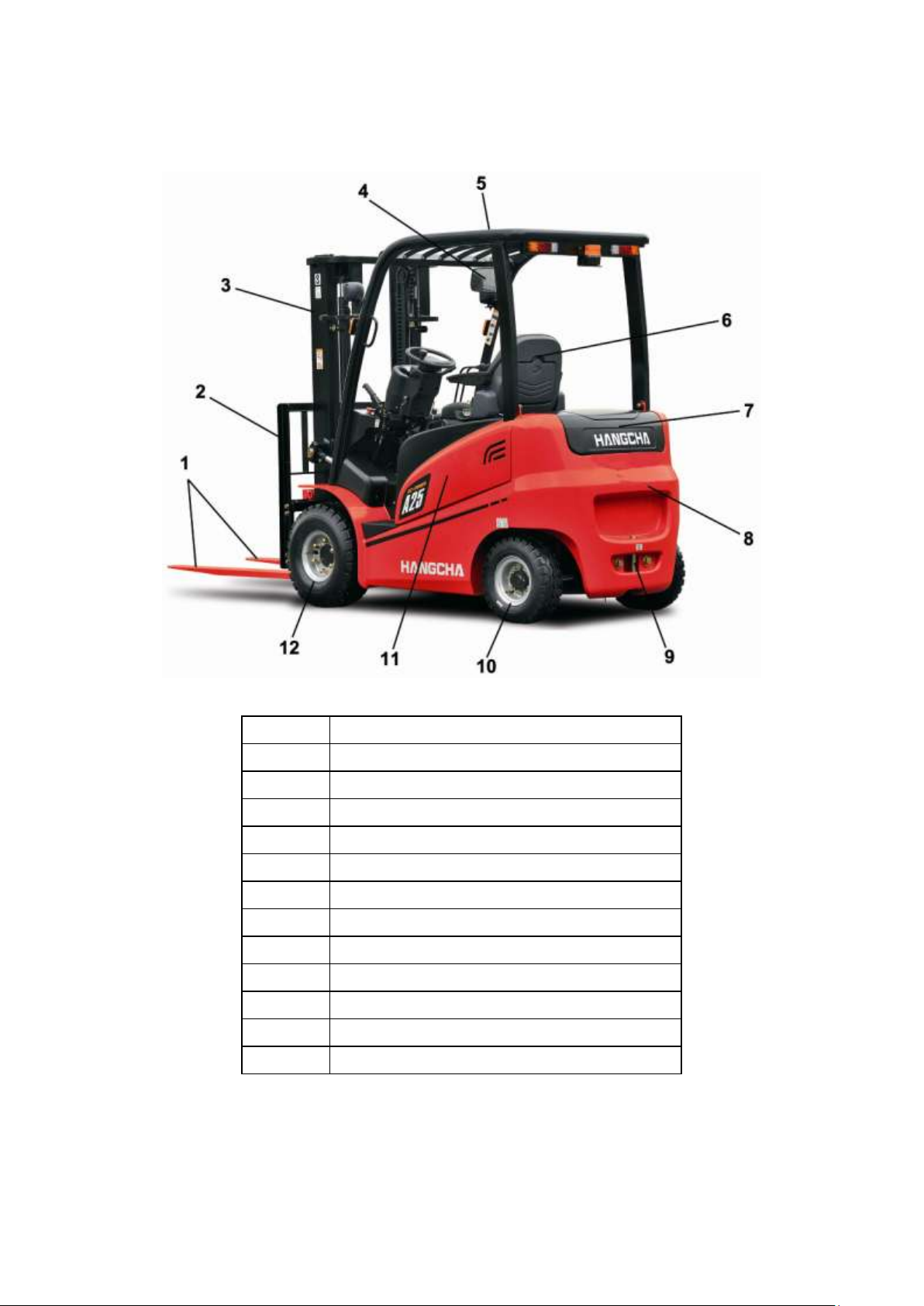

2. Displays and Controls

2

Item

Control / Display

13

Travel direction switch

14

Multi-function display

15

Horn

16

Combination light switch

17

Lifting lever

18

Tilting lever

19

Emergency disconnect switch

20

Parking brake lever

21

Warning light switch

22

Steering column positioning device

23

Brake pedal

24

Accelerator pedal

25

Steering wheel

26

Key switch

27

Locker of battery cover hood

28

Locking bolt of battery side plate

29

Air spring

30

Fuse box

31

Fork stopper

3

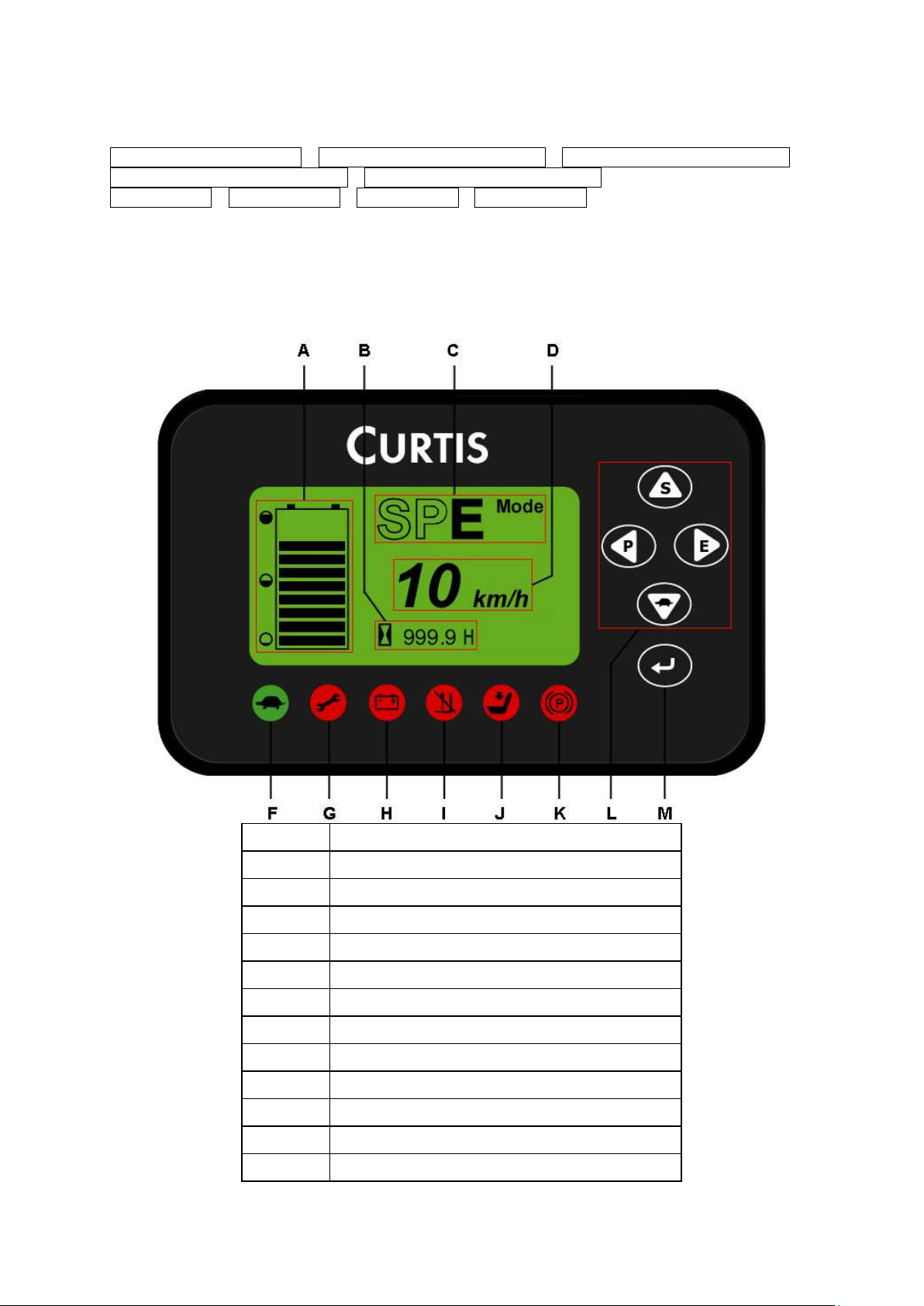

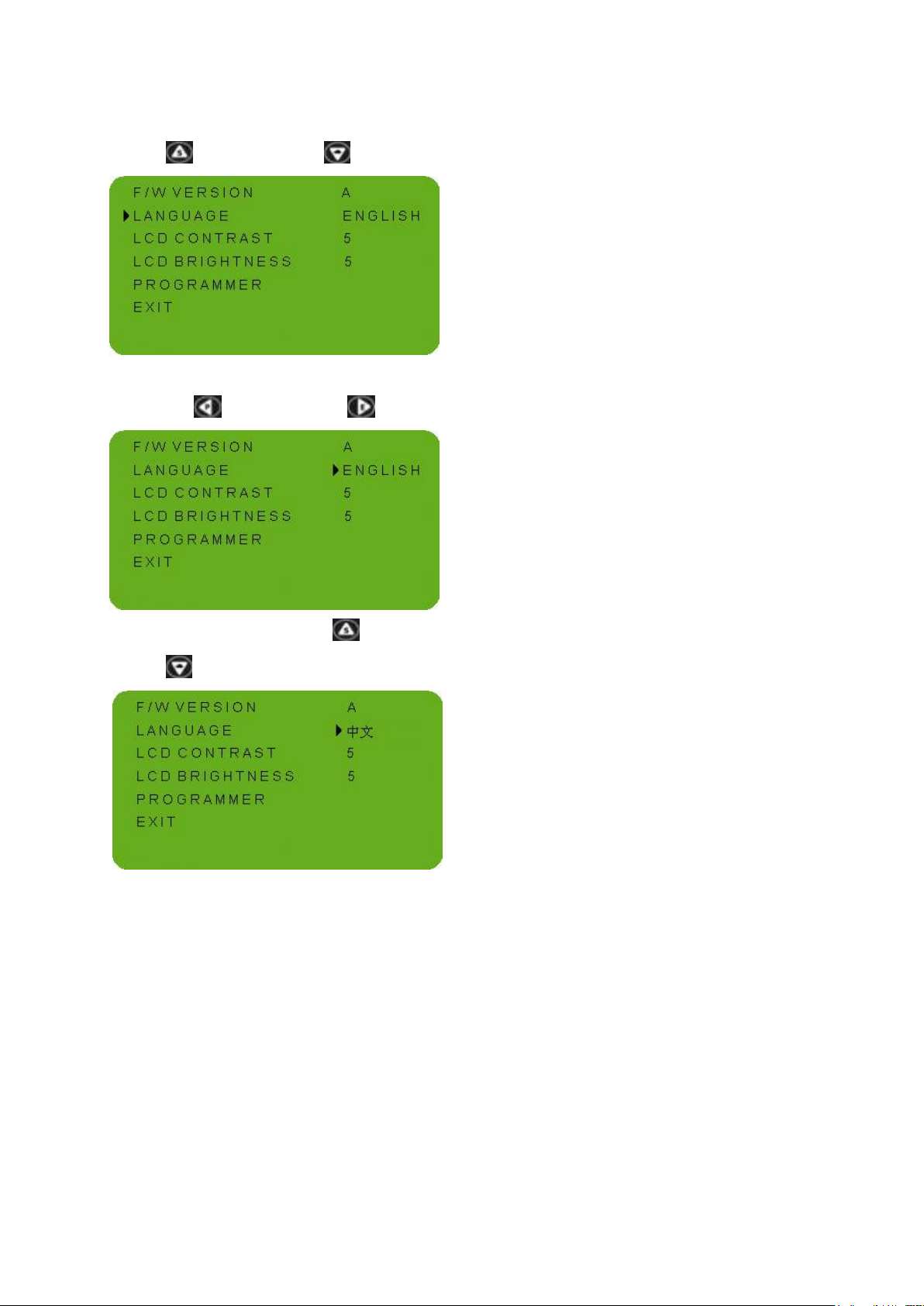

Multi-function display

Item

Display

A

Battery capacity display

B

Service hours display

C

Operating mode display

D

Travel speed or fault code display

F

Crawl speed indicator

G

Fault indicator

H

Battery low capacity indicator

I

Lifting low speed indicator

J

Seat switch indicator

K

Parking brake applied indicator

L

Mode settings or direction choosing button

M

Menu button

CPD10/15/18/20/25/30-A CPD10/15/18/20/25/30/35-AC3 CPD10/15/18/20/25/30/35-AC4

CPD10/15/18/20/25/30/35-AC3F CPD10/15/18/20/25/30/35-AC4F

CPD25-ALC3 CPD25-ALC3F CPD25-ALC3 CPD25-ALC3F

The multi-function display shows the battery capacity, the service hours, the operating mode, the

travel speed and fault code information. Graphic illustrations on the multi-function display act as

warning indicators. Through the multi-function display on the right button can also check fault code

and parameter setting.

4

Main display interface

CAUTION

Charging in time is very important,

otherwise it will affect the lift-span

of battery!

CAUTION

The default mode is mode E. after

power cutting every time, the work

mode resets to mode E no matter

which mode it is before power

cutting, but the switch key is still in

the mode before turn off.

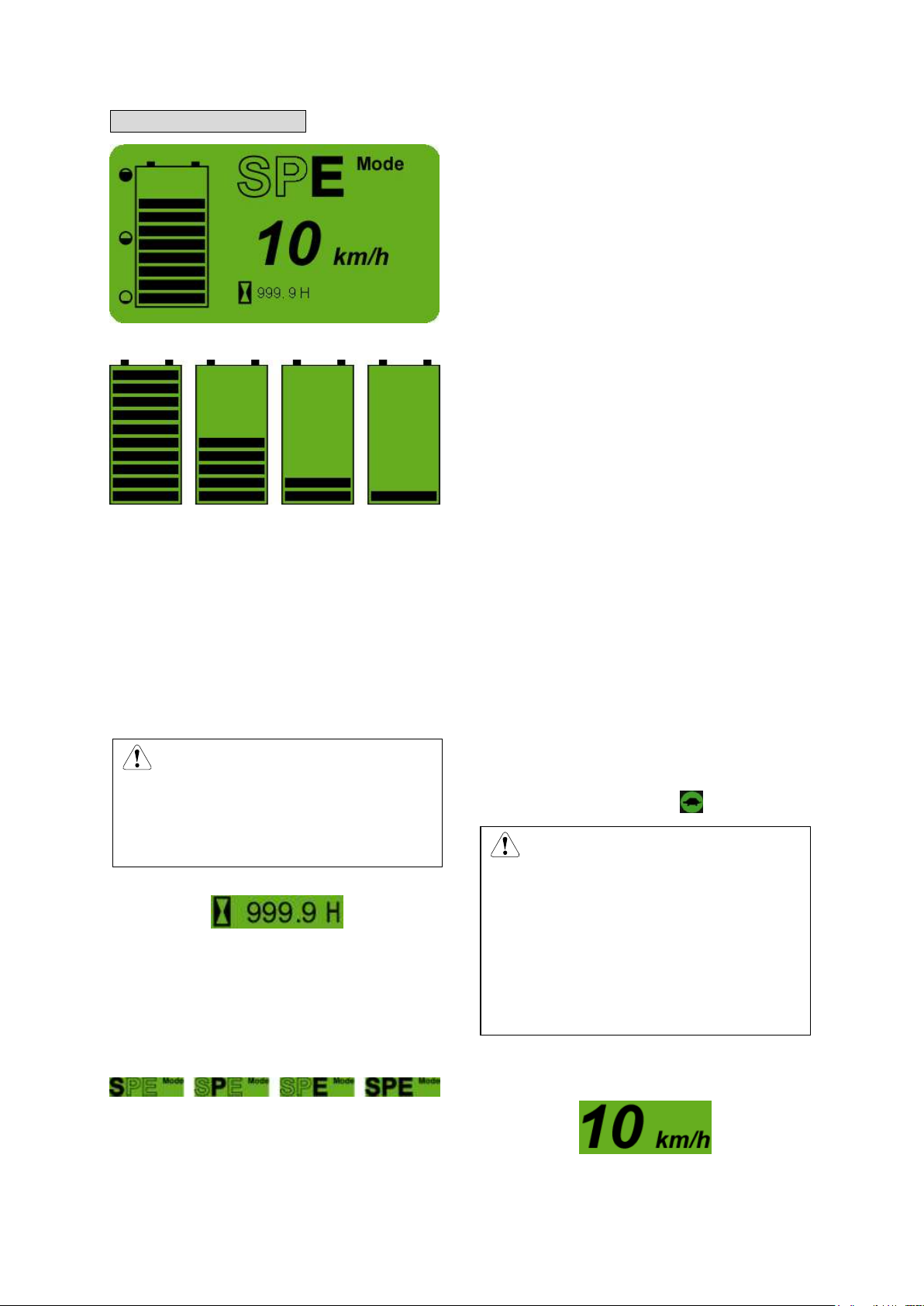

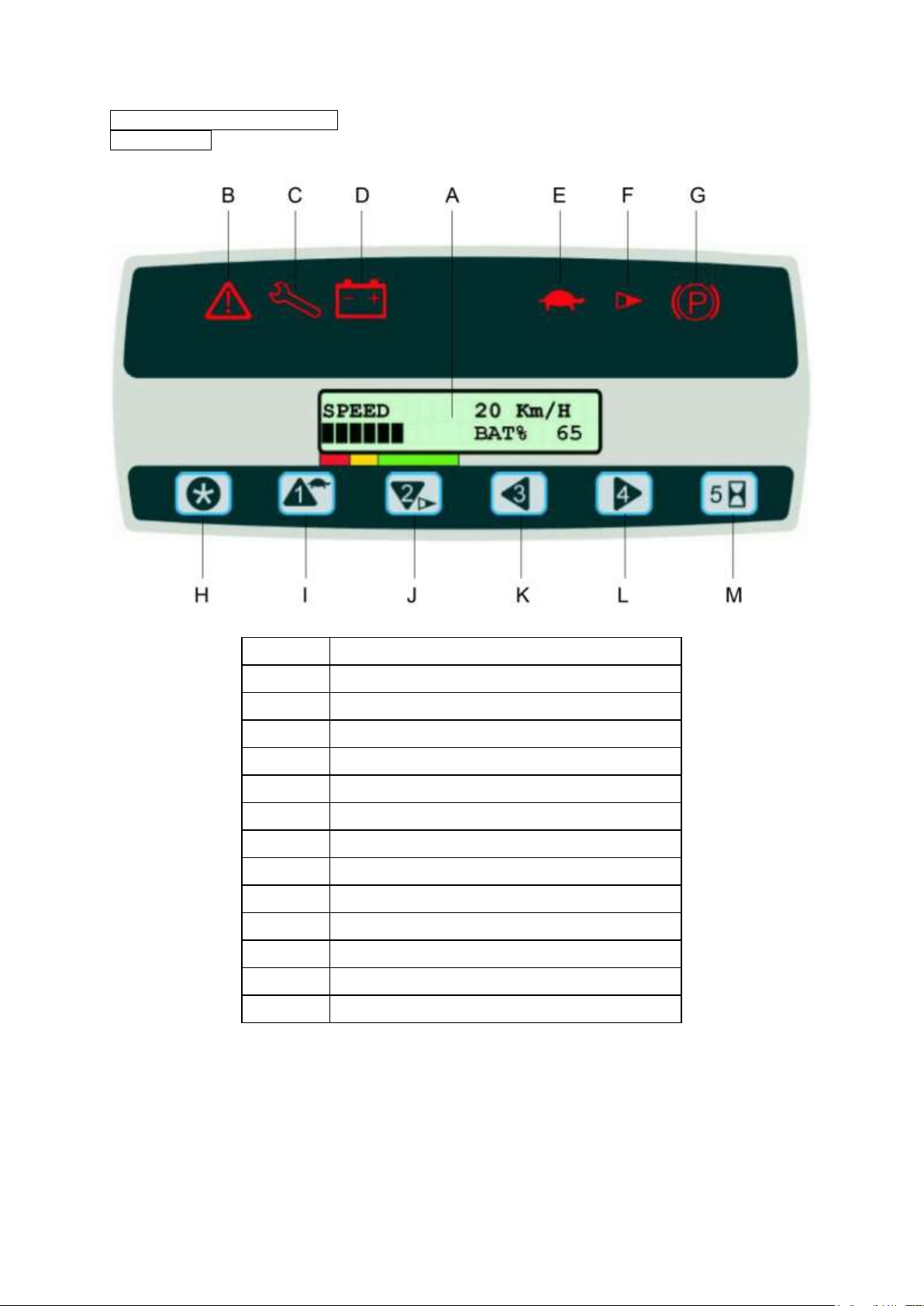

Battery capacity display[A]

Indicates the available residual capacity.

As the following diagram shows, from the left

to the right, the battery decreases from full

state to the only one case, which represents

that the battery leaves only 20%. Thus the

whole battery indicator bar will twinkle, and the

state indicator lamp will be bright, now please

stop working and charge immediately.

S mode is super mode, thus the truck‟s

acceleration, deceleration rate, max climbing

gradient and so on is much higher. It is applied

for transporting mass of good in short time and

climbing big gradient slop,but it costs more

energy,so the mode will not be used in normal

state except emergency.

P mode is power mode. All kinds of index are

lower than that of super mode. It is applied for

the case of long distance transporting and

needing higher power or speed.

E mode is economical mode. All the

parameters are optimized. Working in this

mode can save power so it is applied for a long

time work after charging, and it is suggested to

work in this mode in normal work-time.

SPE mode is safe mode. Thus the max

vehicle speed is limited to about 7km/h. It is

applied for working in busy storage and

cabined room.

SPE mode: The truck is in Safety Mode. In

this mode, maximum traveling speed is limited

to 7km/h. it is very good for working in a crowd

Service hours display[B]

Hourglass icon indicates that timing function.

When you turn off the key switch, the hour

meter will works and the minimum unit is 0.1

hour.

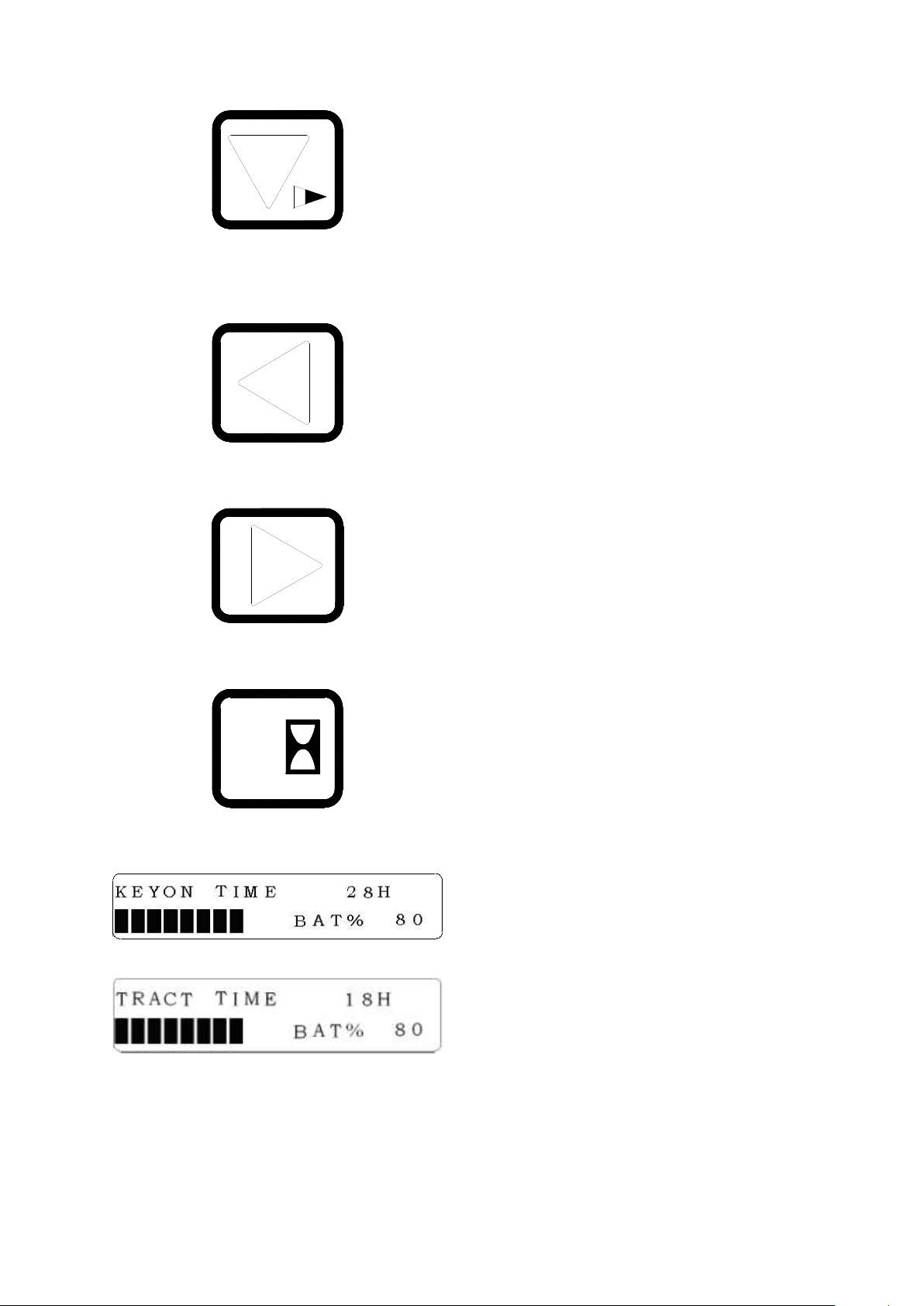

Operating mode display[C]

As the diagram shows, the pictures from the

left to the right represent the mode of S

mode→ P mode → E mode → SPE mode.

warehouse or other compact space. In this

mode, the slow indicator[F] will be on.

Travel speed or fault code display[D]

Travel speed display

Normal work, display the truck travel speed.

5

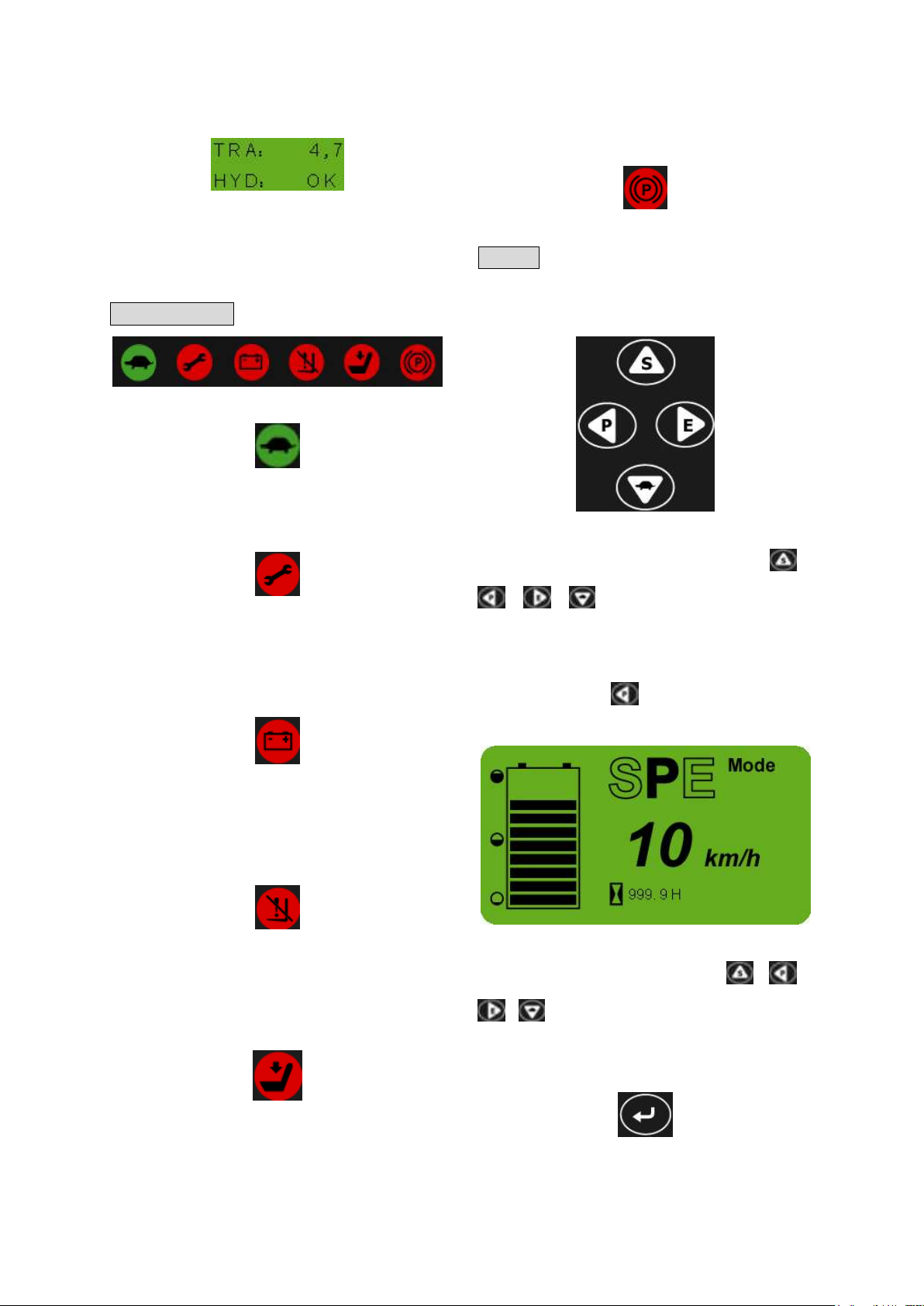

Fault code display

switch (optional).

Parking brake applied indicator[K]

Failure occurs, display the controller‟s fault

code.

Note: “TRA” means the traction controller,

“HYD” means the pump controller.

Indicator light

Crawl speed indicator[F](Green)

When the truck in SPE mode, the crawl speed

indicator light up.

Fault indicator[G](Red)

The light up when the controller is wrong or

operation mistake, and the fault code shows in

the main display screen.

When parking brake applied, the light up.

Button

Mode settings or direction choosing

button[L]

Mode settings

In the main display interface, the button 、

、 、 , corresponding S mode、P

mode、E mode、SPE mode.

For example: In the main display interface,

Battery low capacity indicator[H](Red)

When there is only one line for the power, the

indicator will be on to remind the user to

charge the battery.

Lifting low speed indicator[I](Red)

When there is 10% power, the indicator is on,

and the mast lifting speed drops, to remind

user to charge the battery as soon as possible.

Seat switch indicator[J](Red)

When operator leaves the seat, the light will be

on, and the truck will be unable to travel or lift.

This function needs the seat to equip with seat

press the button , the screen shows as

follows:

Direction choosing

In the menu interface, the button 、 、

、 , corresponding up、left、right、down

four direction choosing button keys.

Menu button[M]

(1)In the main display interface, press the

6

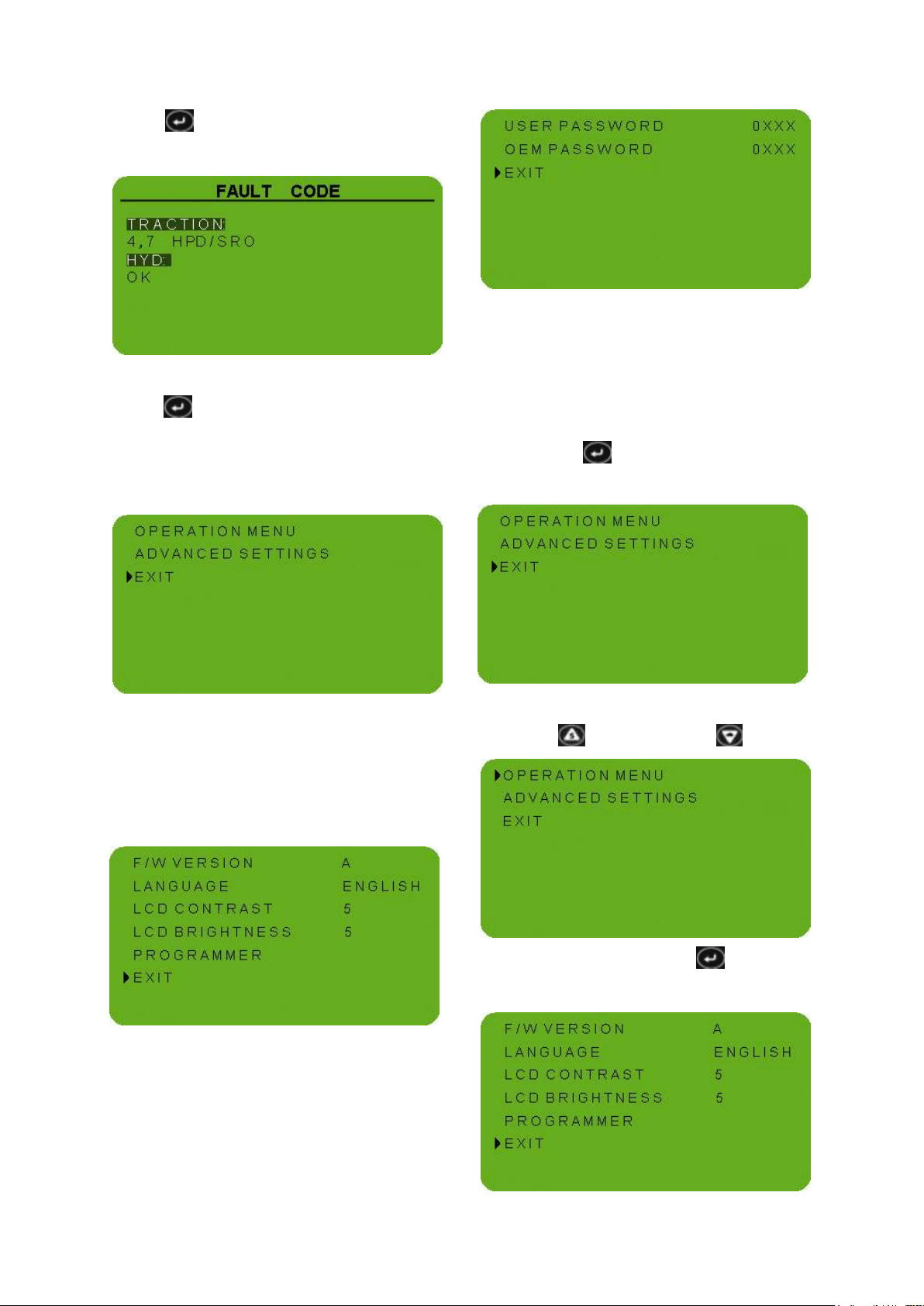

button , and then enter the fault code

interface. The fault code shows as follow:

(2)In the main display interface, press the

button over 2 seconds, and then enter

the main menu .

The main menu includes: operation

menu,advanced settings and exit.

Through the example below shows how to use

the button settings parameter .

For example: The language from english

switch to chinese.

① In the main display interface, press the

menu button( ) over 2 seconds, and then

enter the main menu .

OPERATION MENU

The operation menu includes : Software

version information, language settings, LCD

contrast settings, LCD brightness settings,

programmer settings and exit.

ADVANCED SETTINGS

This menu needs password.

② Select the “OPERATION MENU” through

up button( ) or down button( ) .

③ Press the menu button( ), enter the

opeation menu.

7

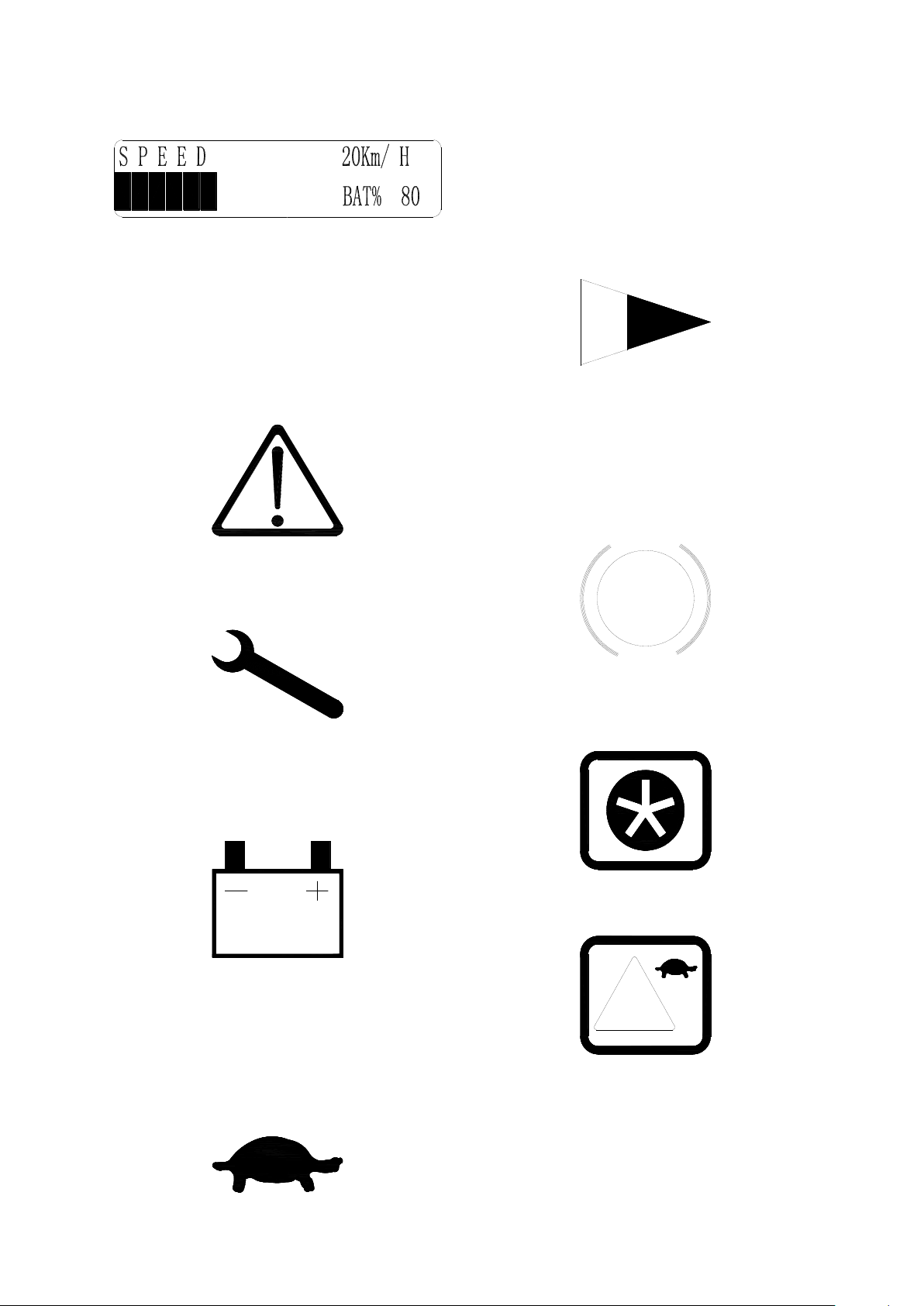

④ Select the “LANGUAGE” through up

button( ) or down button( ) .

⑤ Enter the language setting state through

left button( ) or right button( ).

⑥ Through the up button( ) or down

button( ), select the chinese language.

⑦ Refer the steps ⑤ ④ ③ ② ①, return the

main display interface.

The language has been set up .

Note: this instrument supports two languages

of Chinese and English, it will set to your

wanted language and if you want to switch the

language, please refer to the above example

for operation.

8

CPD10/15/18/20/25/30/35-AD2

Item

Display

A

Dashboard display LCD

B

Communicate indicator

C

Error indicator

D

Low battery warning

E

Speed limited indicator

F

Accelerate indicator

G

Parking brake indicator

H

Entrance button

I

Speed limited button

J

Accelerator limited button

K

Backup button

L

Backup button

M

Switch button of hour indication

CPD25-ALD2

9

Dashboard display LCD [A]

P

1

When turn on the key switch, the system will

self-diagnose, the lamp will lights on one by

one. After self-diagnose, LCD will display truck

speed and battery capacity. You can know

When this lamp lights, it meanings the truck

working at low speed mode. The maximum

speed of truck decreased. Press button 1, you

can switch the high speed and low speed

mode.

Accelerate indicator [F]

your truck‟s working condition through the LCD

dashboard.

Communicate indicator [B]

Only lights on when record program, usually it

is no use.

Error indicator [C]

When operation is wrong or the truck is in

trouble, error code will display on the

dashboard. The error indicator lights on.

When this lamp lights on, it means the truck

working at low acceleration mode. The

maximum acceleration decreased. Press

button 2, you can switch the high acceleration

and low acceleration mode.

Parking brake indicator [G]

When pulling on the parking brake lever, this

lamp lights on.

Entrance button [H]

Low battery warning [D]

When battery quantity is lower than 20% of

maximum capacity, the indicator lights are on,

at the same time, buzzer beep. When LED

shows no power, please charge battery as

quick as possible.

Speed limited indicator [E]

This button is no use for operator.

Speed limited button [I]

Press this button to switch the high speed and

low speed.

Accelerator limited button [J]

10

2

3

4

5

Press this button to switch the high

acceleration and low acceleration.

Backup button [K]

This button is no use for operator.

Backup button [L]

This button is no use for operator

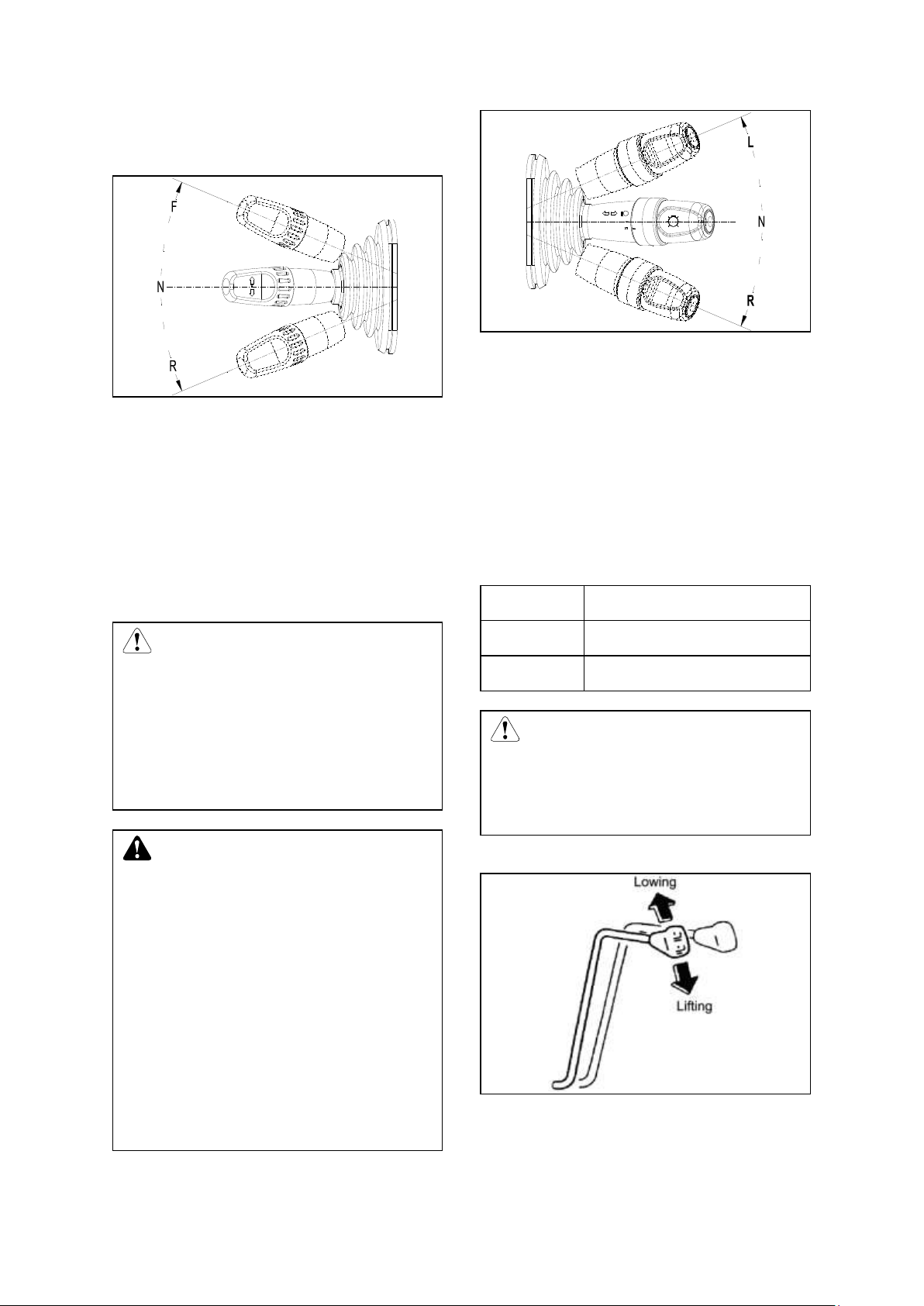

Switch button of hour indication [M]

Push this button, it will display the total hours

of truck, as follow figure:

Push again, it switch to the total traction hour.

Push the button once again, it switch to speed

display mode.

11

Controls

CAUTION

While traveling, if change the travel

direction switch, electric braking

will operate,speed will lower until

stop, then travel to the opposite

direction.

WARNING

Turning the key switch “on” does

not make the forklift truck move, if

the travel direction switch is not in

the neutral position or the

accelerator pedal is being pressed.

In this case, the travel direction

switch should be returned to neutral

and move you foot from the

accelerator pedal. Then the truck

can be operated.

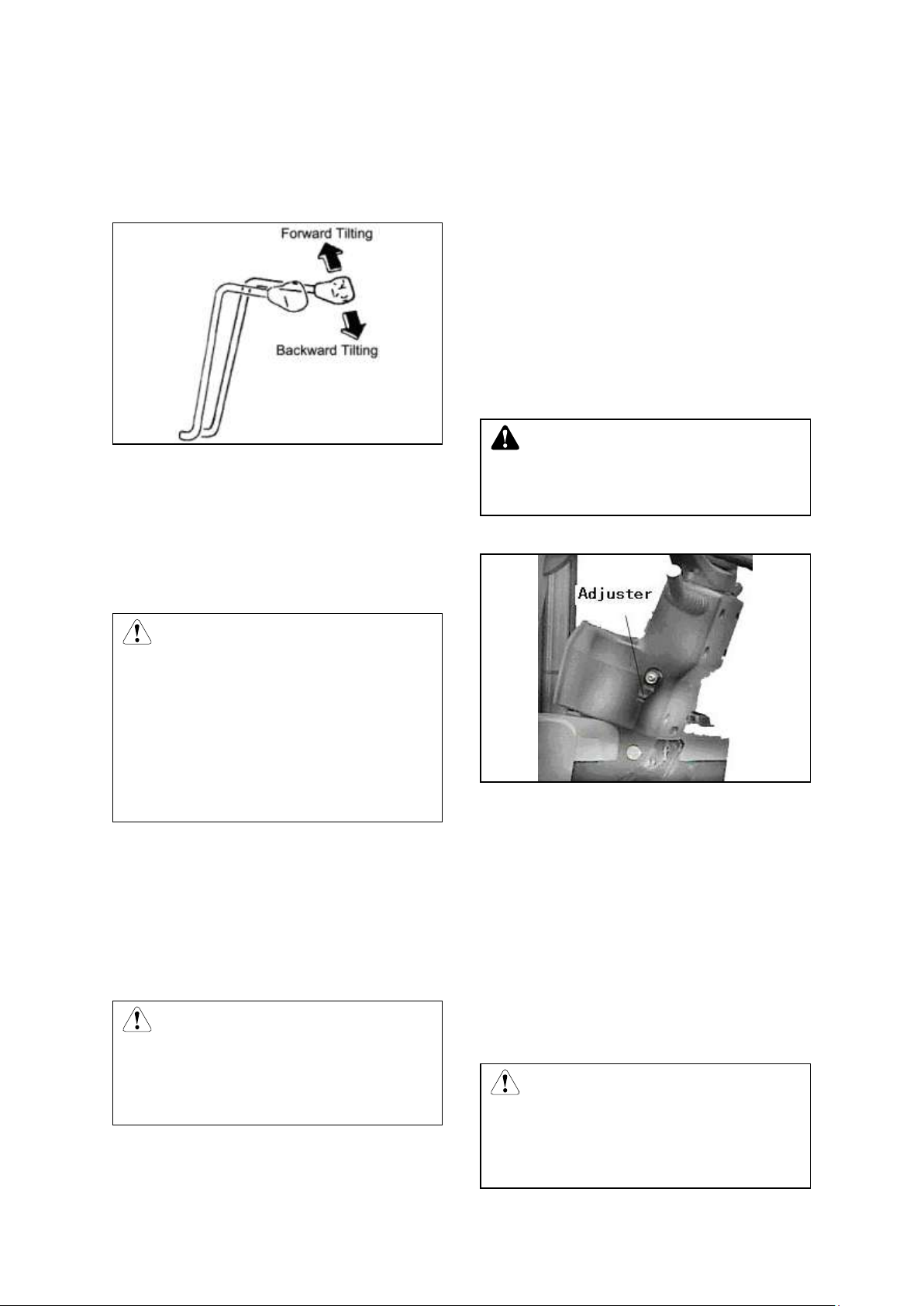

Forward

Left turning lamp flashes

Neutral

Lamp goes off

Backward

Right turning lamp flashes

CAUTION

The turn signal switch does not

automatically return to the neutral

position. Reset it by your hand.

Travel direction switch [13]

Control the turn signal lights, headlights and

front small lights working condition.

Sets the required travel direction.

The travel direction switch is used for

switching between forward and backward

moves. When the travel direction switch is

pushed forward and accelerator pedal pressed,

the forklift trucks moved forward. When the

travel direction switch is pushed backward, the

forklift trucks moved backward.

This combined light switch is composed of

turning light switch and big/small lamp switch.

Turning light indicates the traveling direction.

When turn on the switch, the lamp flashes.

The light switch has two shifts. First shift small

lights on; second shift headlights and small

lights both up.

Combined light switch [16]

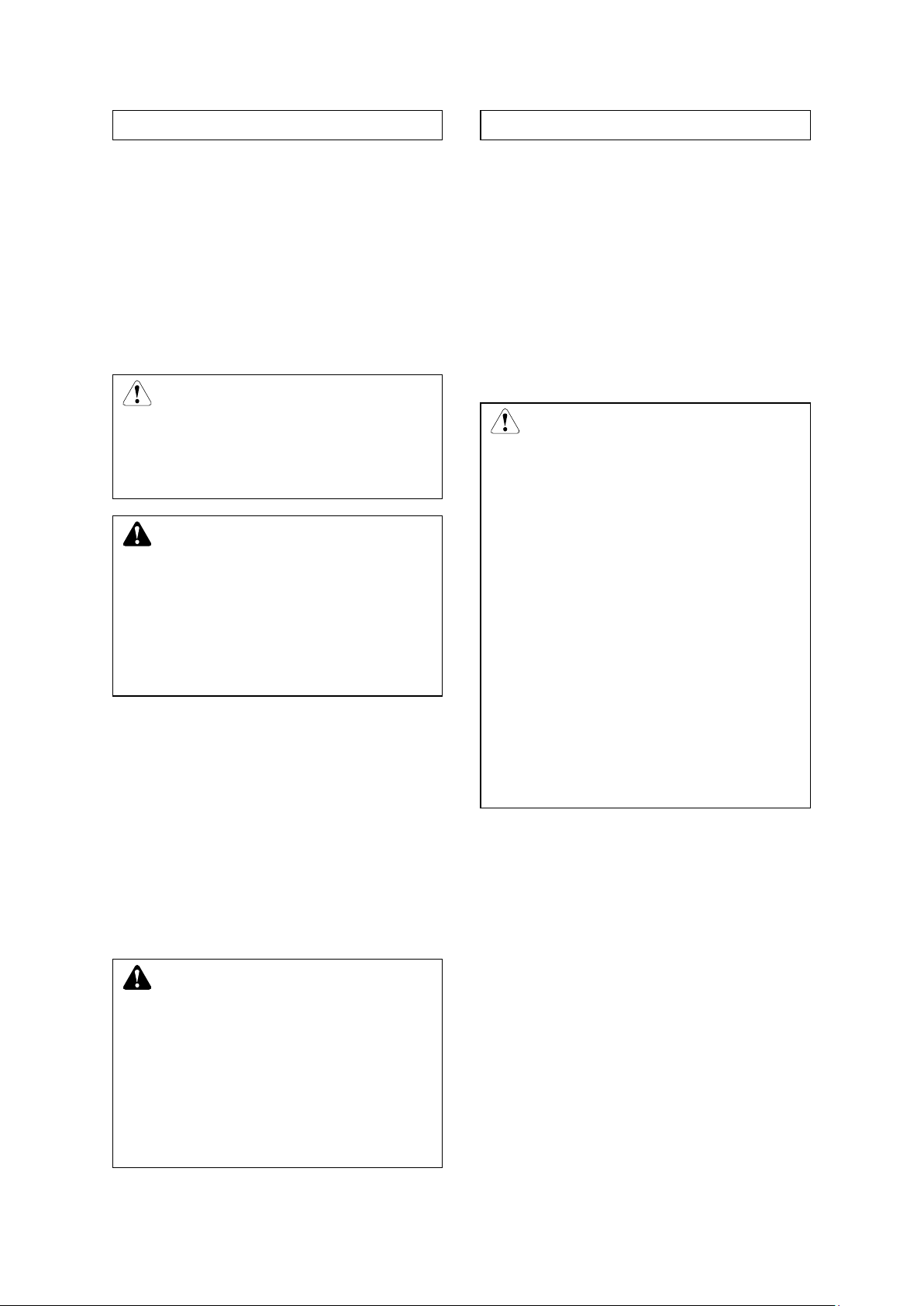

Lifting lever [17]

Lifts / lowers the forks.

The forks can be raised or fell by pulling

backwards or pushing the lever. Lifting speed

12

can be controlled by tilt backwards angle of

CAUTION

The tilt lock mechanism built in the

hydraulic control valve does not

allow the mast to tilt forwards while

the electricity is being shut down

even if the tilt lever is pushed

forwards.

CAUTION

Please don’t use the emergency

disconnect switch to substitute the

function of key switch.

WARNING

If parking on a grade is unavoidable,

be sure to block the wheel.

CAUTION

No permitted to press the brake

pedal and the accelerator pedal at

same time, otherwise, it is harmful

Use this parking brake lever to park the lift

lever and the lowering speed can be controlled

by tilt forwards angle of the lever.

Tilting lever [18]

Tilts the forks forward / backward.

The forks can be tilted by operation of this tilt

lever. Pulling on this lever backwards will tilt

the forks backwards, and pushing it forwards

will tilt the forks forwards. The tilt speed can be

controlled by tilt angle of the lever.

truck. And the parking brakes are applied on

the front two wheels by pulling up on this lever.

To release the parking brakes, move the lever

forwards.

There is a micro switch at the left side of the

parking brake lever, tense the lever makes

running invalid.

For the truck of CE: if you leave the seat

without tensing the lever, it will warn and

remind you to tense the lever.

Steering column positioning device [22]

Emergency disconnect switch [19]

Switches power supply on and off.

When happen emergency, presses down the

emergency disconnect switch, and then the

main power of the truck will be cut off, the truck

stops working.

Parking brake lever [20]

Secures the truck when stationary.

Adjusts and fixes the steering column to the

required distance.

The tilting angle of the steering column is

adjustable to suit individual operators. Turn the

hand lever upward to release the steering

column and locked by turning it downward.

Brake pedal [23]

Decelerates the truck.

Press this pedal to slow or stop the truck. At

the same time, the brake light comes on.

13

to the traveling motor.

Accelerator pedal [24]

CAUTION

Loosen the accelerator pedal when

truck is working, truck can make

soft brake.

WARNING

Before open the key switch to press

the accelerator pedal, the more

function digital indicator shall show

alarm information. Then you must

release the accelerator pedal.

WARNING

This truck is provided with the

power steering, so heavy

hand-wheel operation is caused

when the steering motor comes to a

stall. To put the power steering in

operation again, restart the steering

motor without delay.

CAUTION

Turning the key switch “on” does

not make the forklift truck move, if

the Direction switch lever is not in

the neutral position or the

accelerator pedal is pushing.

Error code maybe appear, don’t

worry about it.

The Direction switch lever should

be returned to neutral and move you

foot from the accelerator pedal.

Then the truck can be operated.

Then the error code should be

disappeared.

Key switch [26]

Provides infinitely variable control travel

speed.

As the accelerator pedal is slowly pressed, the

drive motor start turning and the forklift truck

will start to move. According to the force

applied to the pedal, the speed is adjusted with

not steps.

Switches control current on and off.Removing

the key prevents the truck from being switched

on by unauthorised personnel.

The key switch has two “on/ off” position, you

should push the Direction switch lever to

neutral and loose the accelerator pedal, then

turning the key switch to “on” position

clockwise.

Steering wheel [25]

It‟s can control the forklift steering.

The steering hand-wheel is operated in the

conventional manner, that is, when the wheel

is turn right, the truck will turn to the right;

when the wheel is turn left, the truck will turn to

the left. The steer wheels are located at the

rear of the truck. These cause the rear of the

truck to swing out when a turn is made.

Locker of battery cover hood [27]

Fixed the battery cover.

Locking bolt of battery side plate [28]

Locking the side plates on both of the battery

box.

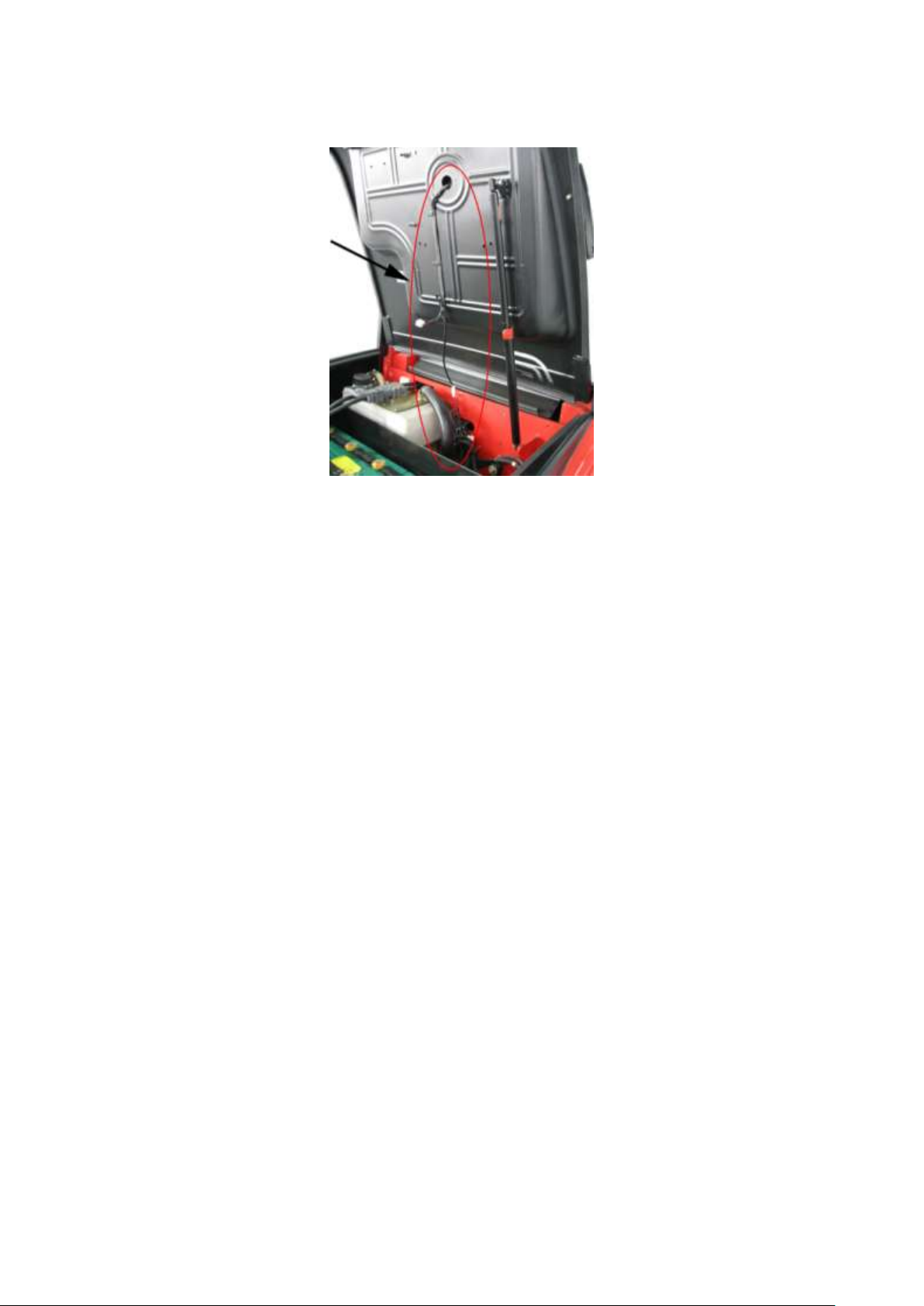

Air spring of battery cover [29]

When the battery cover hood opened, to

support the cover hood. When closed the

cover hood, press the red button, at the same

time hard to press the cover hood.

Fuse box [30]

14

CAUTION

When replace a new fuse, please

choose the same capacity fuse of

the old one.

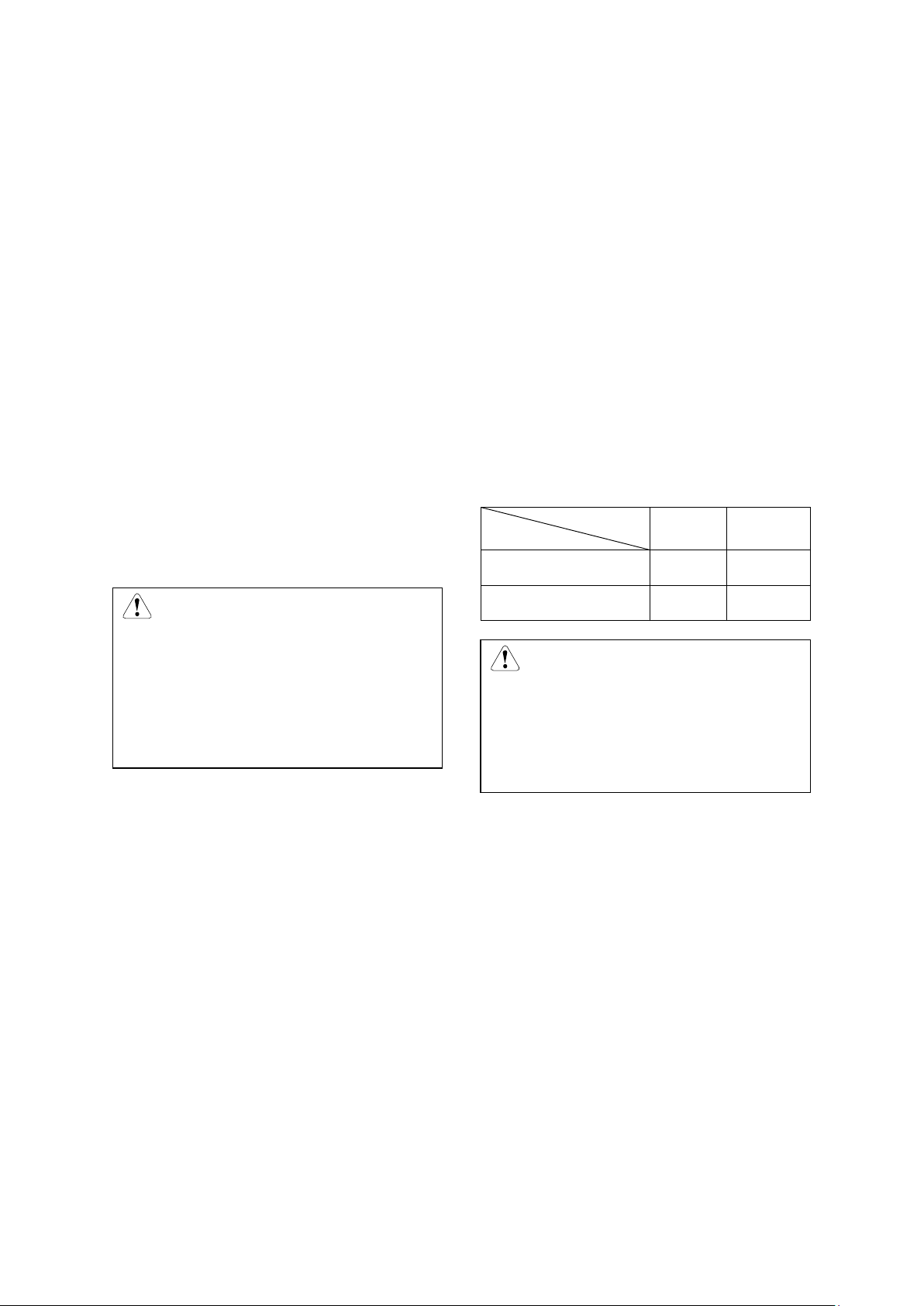

WARNING

The forks should be set

symmetrically to machine centerline

and fork stoppers should always be

locked again.

There are one gap on the below

beam. It is used to attach goods.

It is forbidden to lock the fork on the

gap position, to prevent the fork fall

off from the gap.

In the middle of the above beam, a

bolt used to prevent fork works

here. Please change the bolt as

soon as it is damaged.

Change fork

CAUTION

Be careful do not to catch you

fingers in the cover hood when

closing it.

Depress the spring insurance

before you close the cover hood,

then press the head of the cover

hood.

Take down the old fork: Firstly, locate the fork

to the middle, decline it to the ground and

make the mast forward, then operate the truck

Fork stopper [31]

Fork stoppers are locked the forks in position.

To adjust fork spacing, pull up fork stoppers,

traveling backward, the fork will be taken

down.

Change new fork: Firstly, make the fork dead

against the truck and forklift‟s mast to the

bottom, then operate the truck traveling

forward, aim at the two gaps and beams, and

raise the mast. Adjust the position of the fork.

Battery cover hood

The cover hood can be swung up fully to

provide easy examining and maintenance of

the storage batteries.

You can lift up the cover hood with little effort

with an aid of cover hood damper. To lock the

cover hood, push down on the front of cover

hood until it covered.

turn 90°and shift the forks to the desired

position. The fork spacing should be adjusting

according to loads to be handled.

Overhead guard

The overhead guard used is strong enough to

15

meet safety standard, and protects the

CAUTION

The brake fluid is poisonous, be

careful do not drop down. When add

brake fluid, be careful do not let dirt

and other thing drop into reservoir

cup.

Connector

Position

Battery

Far light

0

×

1 ×

×

CAUTION

This light does not relate to key

switch position, so please don’t

forget to turn off the rear big lamp

when you leave the truck.

light immediately.

operator from falling materials. The top gap is

used to lift the batteries. It is forbidden for use

a truck that does not with safeguard.

L.H. & R.H. battery side plate

The battery is covered hood, one left and one

right. When you want to take off the hood, you

should take off the locking bolts at first.

Safety step and safety grip

The safely steps are provided on both side of

the truck body. The safely grip is provided on

the front left pillar of the overhead guard. Use

the safely step and safely grip when mounting

and dismounting the truck.

Brake fluid reservoir cup

The brake fluid reservoir cup is located at the

meter board.

Rear combination lights

The combination lights at the rear side serve

as turn signal, show width lamp, brake lamp,

and back-up lamp. Pay attention to keep them

from being damaged or covered with dust, if

any, clean or replace immediately.

Rear big lamp [For CE or Option]

The rear big lamp is set on the safeguard. If it

is broken, please replace a new one at once.

Rear big lamp switch [optional]

Rear big lamp switch (push\pull) has only one

shift.

×—Means connected

Hydraulic oil reservoir cap

The hydraulic oil reservoir cap is located at the

right rear end, below the battery hood; open

the right side battery hood when adding oil.

After fill in clean hydraulic fluid, tighten lock the

cap.

Air leakage plug

There is an air leakage plug on the oil tank to

let air in the tank goes out. You‟d better often

check the plug and see whether been jammed.

Head lights and combination lights

Two headlights and combination lights (turn

signal, show width lamp) are installed at the

front side of the truck. Take care of the lights,

and wipe dirt, if any, and replace any damaged

16

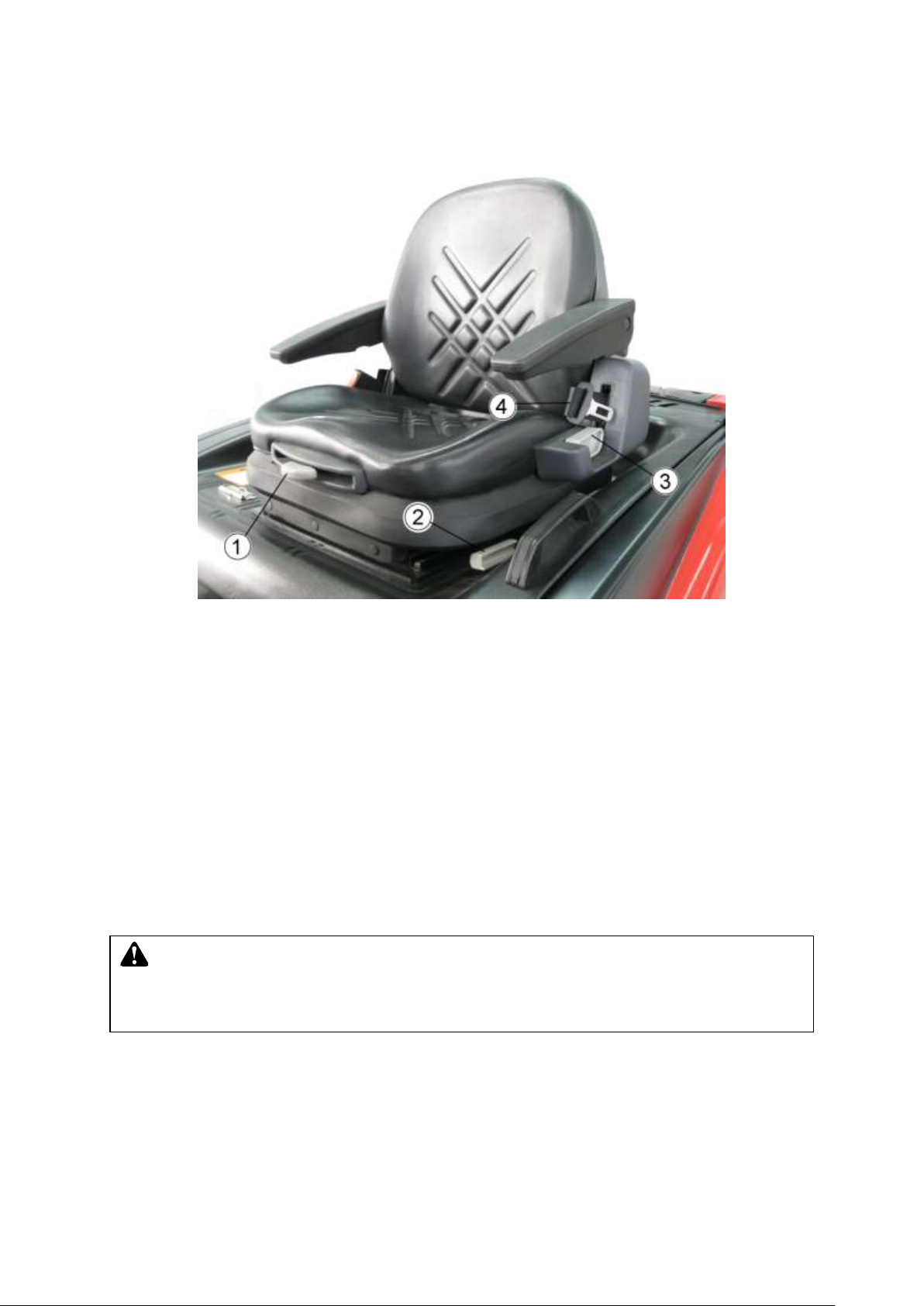

Seat

WARNING

The longitudinal adjuster must be securely located in the desired position. The

driver’s seat setting must not be changed during travel.

Desigend maximum comfort, this seat can be adjusted as follows.

Adjusting the seat to the driver's weight:

To achieve optimal seat cushioning the driver‟s seat must be adapted to the driver‟s weight.

– Sit on the driver‟s seat. When the correct weight adjustment has been made, the weight

adjustment lever should be aimed at the driver's weight. If the weight adjustment lever ① is

facing too far to the left or right, the seat must be adjusted to the driver's weight.

– To set the seat to a lesser weight, push the weight adjustment lever ① left.

– To set the seat to a greater weight, push the weight adjustment lever ① right.

To adjust the seat position:

– Pull up the longitudinal adjuster ② and push the driver‟s seat forwards or backwards to the

desired position.

– Engage the longitudinal adjuster ② in position again.

To adjust the backrest:

– Sit on the driver‟s seat.

– Press down the backrest adjustment button ③ and adjust the backrest tilt.

– Release the backrest adjustment button ③ to lock the backrest in position.

17

Safe belt

WARNING

In no event should the lift truck be used if the seat belt is defective (fixing, locking,

cuts, tears, etc.). Repair or replace the seat belt immediately.

Do not alter the belt setting. Always replace the seat belt after an accident.

Put on the seat belt④ each time before starting the truck. The belt protects against serious injury.

Protect the belt from contamination and clean it regularly.

Correct use the safe belt:

– Sit correctly on the seat.

– Check that seat belt is not twisted.

– Place the seat belt at hip level.

– Attach the seat belt and check that it locks.

– Adjust the seat belt to your body shape without squeezing your hip and without over-slack.

Regular verification of seat belt related to:

– Cut or frayed straps.

– Worn or damaged hardware, including anchor points.

– Buckle or retractor malfunction.

– Loose stitching.

18

How to act in unusual situations

– Fasten seat belt, stay in seat.

– Do not jump !

– Lean forward, hold on tight steering wheel,

brace feet.

– Lean your body away from inpact.

WARNING

If the truck is about to tip over, never undo the restraint belt and try to jump out. This

will only increase the risk of serious injury or death !

19

Seat Aware System(For CE)

Vehicle Forward/Reverse Control

When the vehicle is in static starting state, the driver sits incorrectly, there is no seat pressure

switch input, travel selector switch hangs in the forward or reverse gear, there is no corresponding

forward or reverse signal output, meanwhile, the alerting signal outputs, buzzer and indicator lights

are on, the park brake hangs or the driver sits correctly, then exits the alerting condition; if the

driver sits correctly and relieve the park brake, there is seat pressure switch input, travel selector

switch hangs in the forward or reverse gear, there is corresponding forward or reverse signal

output, the vehicle can travel forward or reverse. The driver leaves the seat (there is no seat

pressure switch input) over 1 second, control state is the same with the driver sitting incorrectly.

When the vehicle is traveling forward or reversely, the driver leaves the seat (there is no seat

pressure switch input) over 1 second, there is no corresponding forward or reverse signal output,

the vehicle forward and reverse power is cut off, meanwhile, the alerting signal outputs, buzzer

and indicator lights are on; when the park brake hangs or the driver sits correctly, it exits the

alerting condition, the driver sits down again, travel selector switch hangs in the forward or reverse

gear, the vehicle forward and reverse power recovers.

Forklift Working Device Control

When the vehicle starting in static condition or no starting in static condition (when it is in no

starting static condition, key switch should be in travel gear), the driver sits incorrectly or falling

signal switch is open, there is no seat pressure switch input, no working device pressure or falling

signal output, working device is locked; if the driver sits correctly, there is seat pressure switch

input and falling signal switch is closed, working device pressure and falling signal output, working

device can be operated normally. The driver leaves the seat (there is no seat pressure switch input)

over 1 second, control state is the same with that the driver sits incorrectly.

When the vehicle is traveling forward or reversely, the driver leaves the seat (there is no seat

20

pressure switch input) over 1 seconds, there is no working device pressure or falling signal output,

working device is locked; when the driver sit down again, there is seat pressure switch input, and

falling signal switch is closed ,working device pressure and falling signal output, working device

can be operated normally.

Attention: seat aware system including single locked and double locked:

– Single locked: it is said that the system limits the forklift‟s travel ,when the driver leaves the

seat, the traction motor will not work and the vehicle will stop.

– Double locked: it is said that the system limits the forklift‟s travel and mutil-way valve‟s work,

the masts will not lift or down.

Forklift Parking Brake Control

In any vehicle state, when the driver sits incorrectly, there is no seat pressure switch input,

meanwhile, do not pull the parking brake, there is alerting signal output, pull the parking brake or

the driver sits correctly, it can exit the alerting condition. The driver leaves the seat (there is no

seat pressure switch input) over 1 seconds, control state is the same with that the driver sits

incorrectly.

21

Loading...

Loading...