Hangcha 1-3.5t R Maintenance Manual

1-3.5t R Series Internal Combustion

Counterbalanced Forklift Truck

OPERATION AND MAINTENANCE MANUAL

Original Instruction

ZHEJIANG HANGCHA ENGINEERING MACHINERY CO., LTD.

DEC.2009 4th EDITION

FOREWORD

This operation manual is the explanations that how to use 1-3.5t R series forklift truck

correctly. It will instruct you how to operate safety and precautionary maintenance. To

ensure safety and exert the truck’s potential, all the personnel that in charge of

operation, maintenance and management must read this manual thoroughly before

starting work with the forklift.

Compared with 1-3.5t N series internal combustion forklift truck, 1-3.5t R series

forklift truck has the following strengths: enhancing the power, improving the outline,

using buffer steering axle, in addition, besides the TCM and NISSAN main

transmission are configured in our trucks, we also configure Okamura main

transmission in our trucks. And there is different between masts of import and export

trucks, N series masts are used in the import trucks, R series masts are used in export

trucks.

This manual also applies to container forklift truck and forklift truck assembled

attachments.

Our product design will update and perform better, so the content in this manual may

be not the same as the forklift you owned.

If you have any questions please keep touches with ZHEJIANG HANGCHA

ENGINEERING MACHINERY CO., LTD. sales department or let the agents know.

CDEC.2009 4

○

th

EDITION

Content

Foreword

1. GENERAL RULES.....................................................................................................................1

2. NAME OF MAIN PARTS OR COMPONENT........................................................................3

Instruments..............................................................................................................................3

Switches....................................................................................................................................5

Controls....................................................................................................................................6

Body and others.......................................................................................................................9

3. SAFETY INSTRUCTIONS......................................................................................................13

4. MAINTENANCE......................................................................................................................19

8 hour (daily or every shift) check.......................................................................................19

Weekly maintenance (40 hours)...........................................................................................22

Maintain monthly (180-200 hours)......................................................................................25

Maintain semiannually (1000 hours)...................................................................................27

Maintain annually (2000 hours)........................................................................................... 29

5. STRUCTURE AND STABILITY OF TRUCK.......................................................................33

6. OPERATION.............................................................................................................................35

Star-up....................................................................................................................................35

Traveling ................................................................................................................................36

Pick up....................................................................................................................................37

Stacking load..........................................................................................................................37

Remove load ..........................................................................................................................38

7. DEPOSIT...................................................................................................................................39

8. MAINTENANCE......................................................................................................................41

Preventive maintenance schedule........................................................................................41

Maintenance of chassis and body.........................................................................................43

Periodic replacement of key safe parts................................................................................45

Table for the oil used in the truck ........................................................................................46

Lubrication system drawing.................................................................................................48

Environment protection........................................................................................................49

Scutcheons .............................................................................................................................50

9. TRUCK’S CONVEY , LIFTING, TOWING...........................................................................58

10. TYPE SIGNIFICATION........................................................................................................59

11. PERFORMANCE PARAMETERS OF R SERIES IC FORKLIFT..................................62

12. OPERATION, DISASSEMBLY AND INSTALLATION OF CAB.....................................81

13. OPERATION AND NOTICE ABOUT LPG FORKLIFT...................................................83

14. OPERATIONAL METHOD OF MAINTENANCE FREE LEAD ACID BATTERY......95

15. USE, INSTALLATION AND SAFETY RULES OF ATTACHMENT...............................97

16. RELATED SAFETY INSTRUCTION AND STANDARD (FOR TRUCKS EXPORTING

TO EUROPE OR OPTION)........................................................................................................

17. MAINTAIN RECORD..........................................................................................................103

99

1. GENERAL RULES

To make the truck and you safety, operator should obey these rules below:

1. Only trained and authorized operator shall be permitted to operate the truck.

2. Before start truck you should check all control and alarm device, if there are

any damaged or objection, you could not operate it until repaired it.

3. When carry the load, the weight should not much overload. The fork shall

insert in the load entirely and well proportioned. It is not permitted use only

one fork to load.

4. You should operate the truck smoothly when start, turning, travel, brake and

parking. On a slick or wet road, you should decrease speed when turning.

5. Load travel should lower the goods down and tilt the mast backwards.

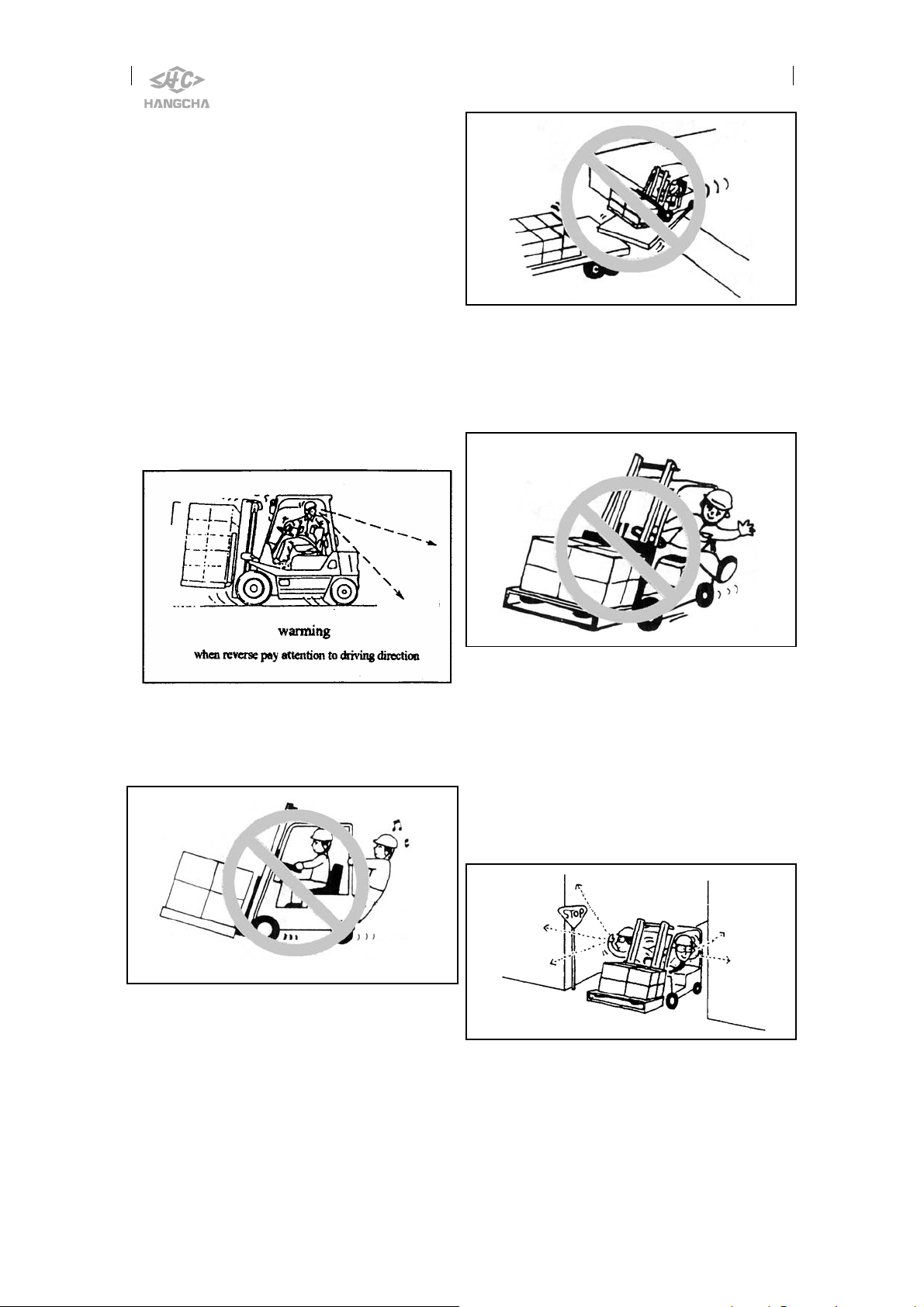

6. Be carefully when traveled on a grade. If the slope angle is bigger than 10%,

travel forward up slope and backward down slope. Never turn sideways and

stack load on an incline.

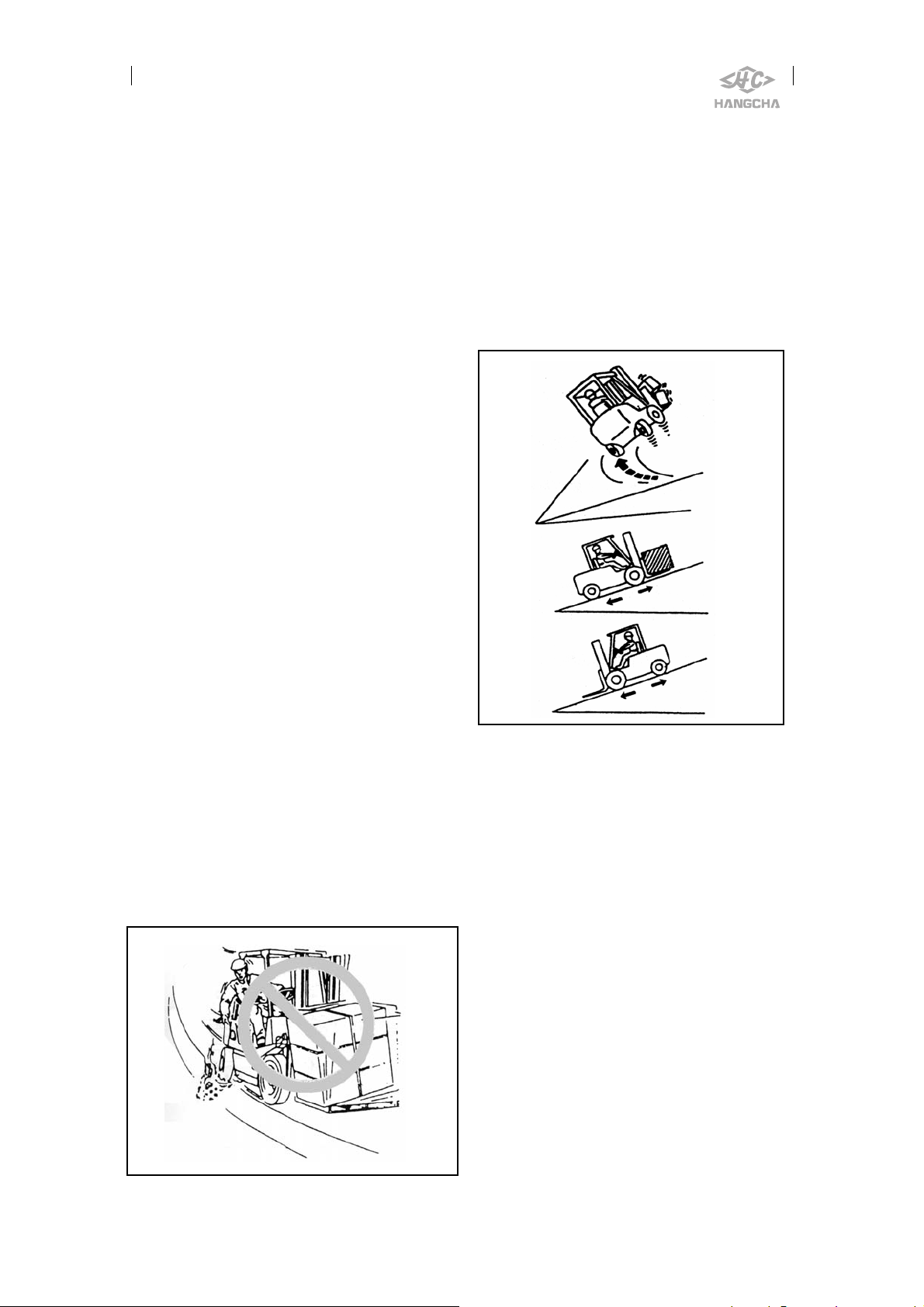

7. Notice the foot passenger, barrier, pothole and the clearance upside.

8. It is prohibit picking up a man or standing on the fork.

9. No permitted to stand or walk under the fork.

10. No permitted to operate the truck or attachment on other position except the

operator’s seats.

11. Do not carry the load unpackaged. Be carefully to carry these goods with large

size.

12. Notice the load not drop from the load bracket for those trucks that overall

maximum lift height is higher than 3 meters. If necessary, make some

protective measure.

13. Travel with load as low as possible and tilt back the mast.

14. Before driving over a dock-board or bridge-plate, be sure that it is properly

secured and strong enough to sustain the weight.

15. Make sure that there is no naked flame near the area, never smoke. The driver

should not remain seated when adding fuel.

16. The truck with attachments should be treated as a loaded truck.

17. When leave the truck, you should let the fork down, make the shift lever neutral

shut down the engine and cut the power. Parking on a grade, make sure to

tighten the brake lever. If necessary, use a block when parking on a grade for a

long time.

18. If the truck suddenly get out of order, or for leakage of electrolyte,hydraulic oil

or brake oil, when lifting goods or grade climbing, it needs to rush to repair and

let the truck be in safe state, then connect with maintainer or sales

representative.

19. In the process of install and assemble, it will be noise and libration. Please

1

choose the right tool and assembly method. Depress the noise and libration as

soon as possible to reduce the noise pollute to circumstance.

20. The work road surface for forklift should be stability and unknit, cement,

blacktop or beton. If there are snows, ice, water or other eyewinker, bar.

Eliminate all, and then work. Otherwise the truck will be out of control and

lead the safety accident.

21. Move the truck to the place which respects traffic when it anchors. If the reason

is brake or turn system, move it by a suitable truck (Reference the part of truck

move); Other reasons, use a suitable truck to traipse, tie the cord outside of

truck. Please abide by the traffic regulations when traipse the truck on calzada.

22. After take-down the hood, water tank cover board, overhead, backrest of mast,

unallowed to operate the truck or load cargo.

23. There are enough light at truck work ground. At night, open the head lamp to

collocate enough lamp-house.

24. Only in the event that the truck manufacturer is no longer in business and there

is no successor in the interest to the business, the user may arrange for a

modification or alteration to a powered industrial truck provided, however, that

the user shall:

a) Arrange for the modification or alteration to be designed, tested and

implemented by an engineer(s) expert in industrial trucks and their safety;

b) Maintain a permanent record of the design, test(s) and implementation of the

modification or alteration;

c) Approve and make appropriate changes to the capacity plate(s),decals, tags and

instruction handbook;

d) Affix a permanent and readily visible label to the truck stating the manner in

which the truck has been modified or altered together with the date of the

modification or alteration, and the name and address of the organisation that

accomplished the tasks.

2

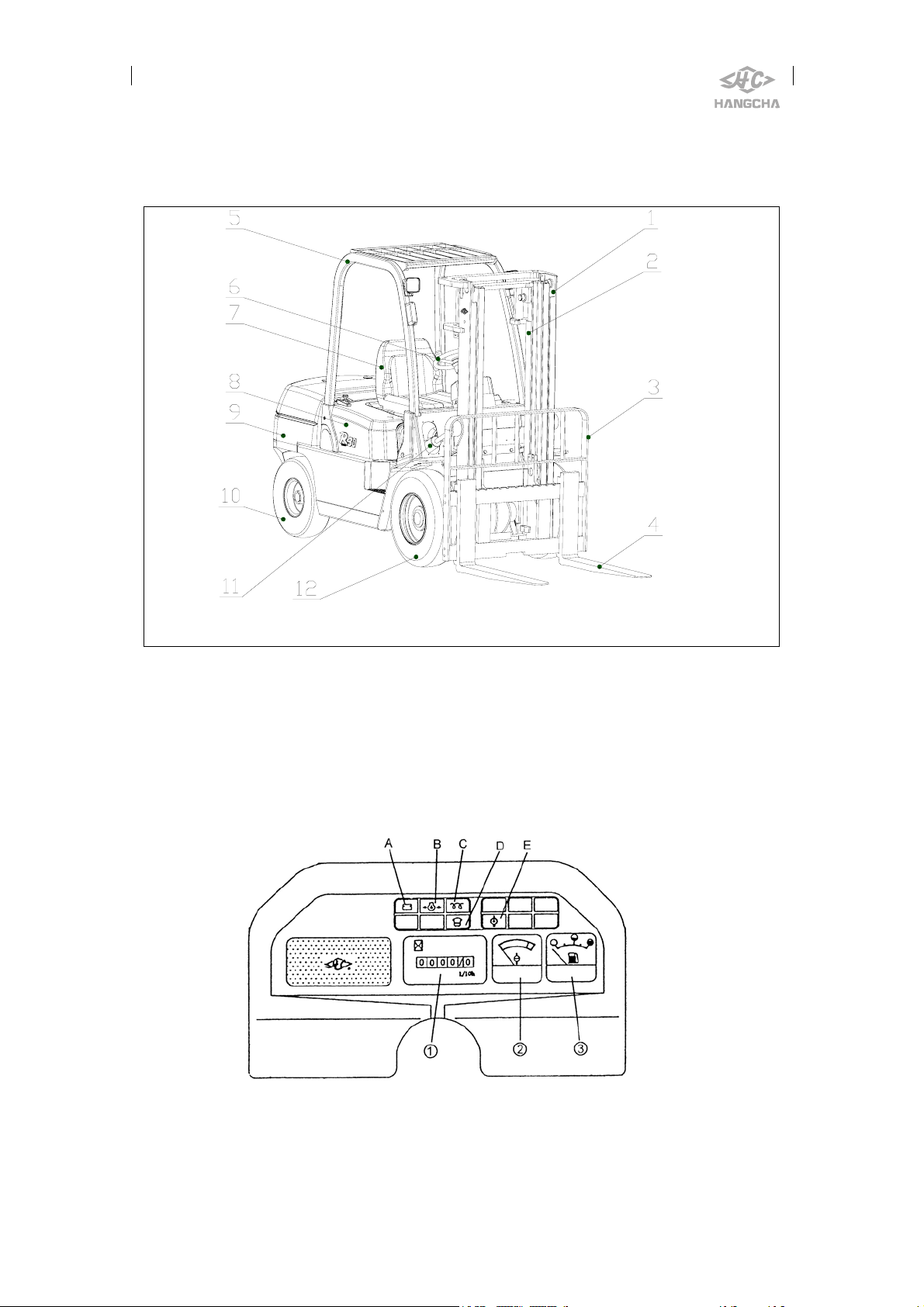

2. NAME OF MAIN PARTS OR COMPONENT

1. Mast 2. Lifting cylinder 3. Backrest 4. Fork 5. Overhead guard

6. Steering wheel 7. Seat 8. Cover hood 9. Counterbalance weight

Rear wheel 11. Tilting cylinder 12. Front wheel

10.

Instruments

3

Hour meter [1]

This meter measures working time

of engine. Use meter to schedule

lubrication and maintenance periods.

Water temperature gauge [2]

This gauge indicates the oil

temperature in the torque converter

transmission box. In normal status, the

pointer is in green zone. (60~115℃)

Caution

If the pointer points red zone, please stop

the truck at once. Decrease the engine speed

to make the engine cool. Check the cooling

fluid if enough and the fan belt ’s elasticity i f

fit.

Fuel gauge [3]

The gauge indicates the fuel level in the

tank when the key is at (ON) position.┃

Charge (A)

This lamp indicates the battery

condition of charge. The lamp comes on

when the ignition switch is set at “ON”,

but it goes out as the engine starts and

accelerator pedal is pressed.

Caution

If the light continues to stay lit or

lights up during operation, the charging

rate is low and should be checked

immediately.

Oil pressure alert lamp (B)

This lamp indicates the pressure

condition of engine lube oil. Although it

lights up when the engine switch is set at

“ON”, once the engine starts up and the

accelerator pedal is pressed, this lamp

goes out.

Caution

If this light continues to stay lit or

lights up during operation, the pressure

is lower than 0.05Mpa and should be

checked immediately.

Glow indicator (C) [Diesel truck]

Turn the key to “ON” position and

the indicator lights up for a moment.

After the indicator goes out, turn the key

to . “Start” position

Sedimentor indicator (D) [Use in W9、

W13、W15A diesel truck]

In normal state, once the starter is

set to “ON” position, this lamp

lights up. After the engine is started up,

it goes out.

This lamp lights up when water in

sedimentor reaches to a certain level,

while the engine is running.

If this lamp continues to stay lit or

lights up during the engine running,

stopping the engine and discharge water

immediately.

Caution

Fuel injection pump will be damaged

if continue working when the light is up.

Engine coolant temperature [E]

In normal state, once the starter is

set to “ON” position, this lamp

lights up. After the engine is started up,

it goes out.

During work time if the oil

temperature exceed the normal

rang(60~120℃) the indicator light on.

Caution

If the pointer enters the red range,

stop the operation instantly and slow

down engine speed to cool the coolant

and wait until the pointer goes into the

green range, and have a check then.

4

Switches

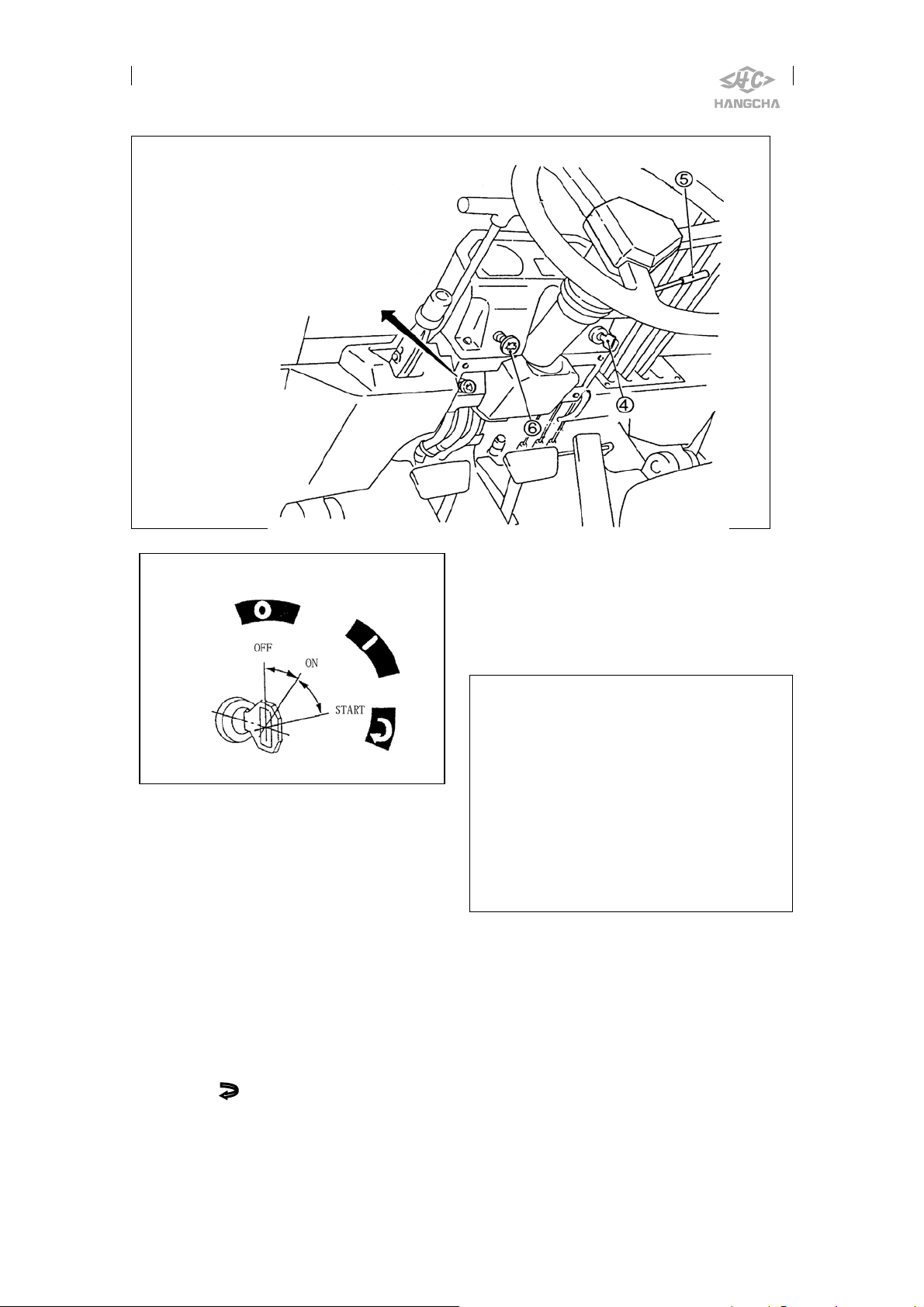

Key [4]

OFF (O)

This is the position at which the

key inserted or drawn out.

Gasoline engine and diesel engine

stop at this position.

ON ( )┃

The electric circuit is closed with

the starter switch at “”┃ (ON). After the

engine is started, the key is at this

position.

START ( )

As the key is placed in the

“START” position, the starter motor is

engaged. When removing hand off key,

it is automatically returned to the “ON”

position by spring force.

Diesel engine

Turn the key to “ON” position and

the indicator lights up for a moment.

After the indicator goes out, turn the key

to “Start” position.

Caution

1.Do not keep the starter switch in the

“ ”(ON) ┃ position while engine is shut

down. This result in a discharge

battery.

2.With the engine running, do not turn

the starter switch into the (START)

position, since there is a danger of the

starter motor being damaged.

3.Do not keep the starter engaged for

more than 5 seconds at a time. Wait

about 120 seconds before trying again.

Turn signal lever [5]

Use this lever which is at the right

side of turning rod to indicate the

turning direction of the truck. R-turn

right, N-neutral, L-turn left.

The turn signal level does not

automatically return to the neutral

position unlike general passenger cars.

Reset it by hand.

5

Light switch [6]

This light switch can be pulled out

at two steps.

Light

Stage

Power

Near

light

Far

light

0 ×

1st × × ×

2nd × × ×

(×) means connected

Clear

-ance

Horn button [7]

Press the rubber cover at the center

of steering wheel to sound horn.

Controls

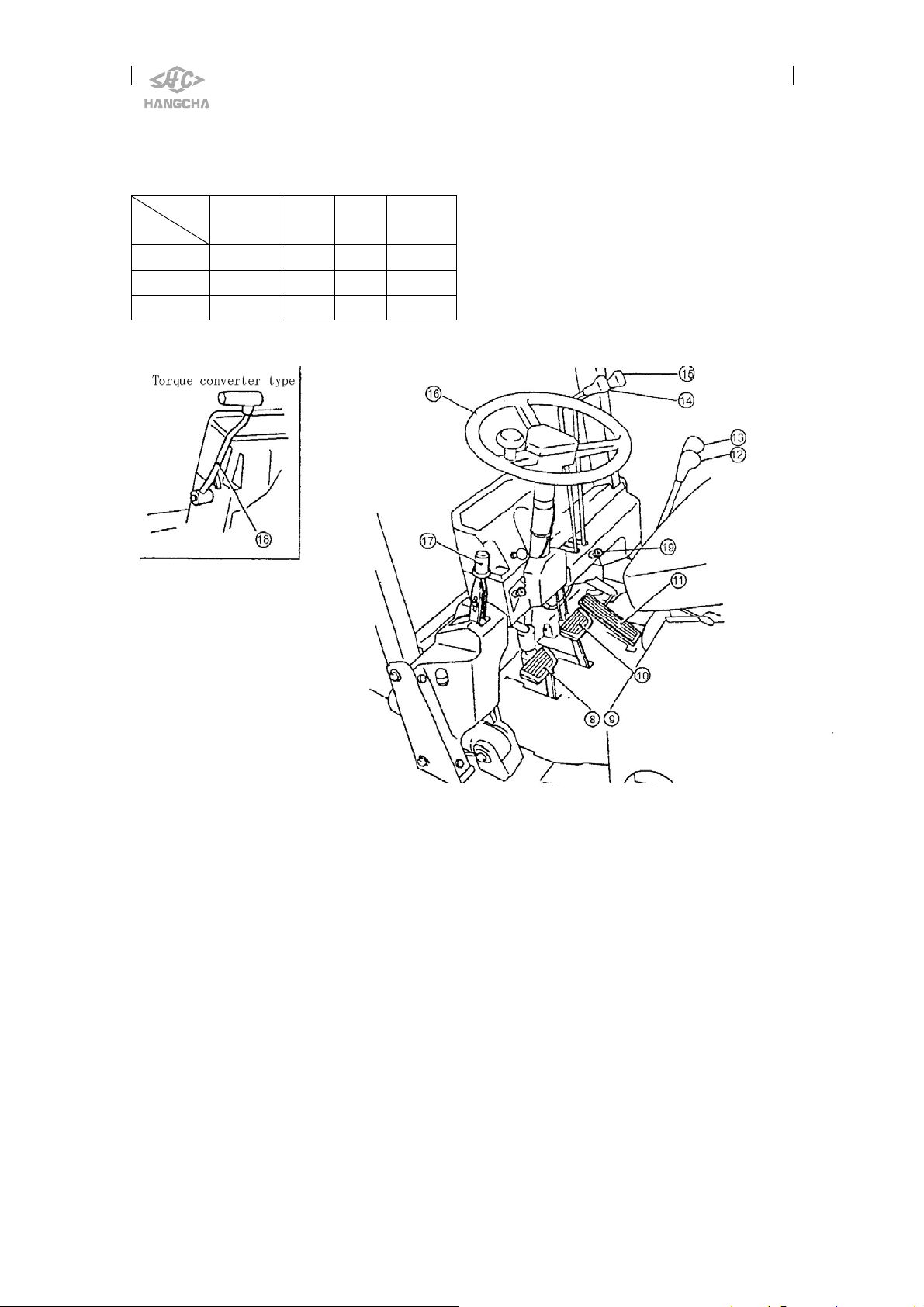

8. Clutch pedal (frictional clutch type) 9. Inching pedal (torque converter type)

10. Brake pedal 11. Accelerator pedal 12. Forward reverseand Speed slect lever (frictional

clutch type) 13. Shift lever 14. Tilt lever 15. Lift lever 16. Steering hand wheel

17. Parking brake lever 18. Forward reverse lever (Torque converter type

Non-electric-switch) 19. Choke line 20. Forward reverse lever(Torque converter type

Switch)

6

Clutch pedal [8] (frictional clutch type)

Press the clutch pedal fully, the

operator can uncouple the engine and

transmission.

When the clutch pedal released, it

allows power to flow through the clutch

from the engine to transmission.

Caution:

Do not run the lift truck with the

clutch in a half-clutch condition as much

as possible.

Inching pedal [9] (Torque converter type)

As the inching pedal is pressed, the

oil pressure in the hydraulic clutch drops

accordingly (the needle of the oil

pressure gauge swings to the left)

allowing the operator to perform inching

operation. Use this pedal to inch the

truck while operating the hoist system at

a high speed.

When pressed to the full, this

inching pedal serves as a brake pedal

also.

Caution:

Do not use the inching pedal too

much. Long time use or use as rest would

cause high temperature of transmission

oil, or result in slipping of clutch.

Accelerator pedal [11]

Press down the accelerator pedal,

engine rotating speed increase, traveling

speed of truck increased. On the contrary,

when loosen the pedal, engine rotating

speed and truck traveling speed will

decrease.

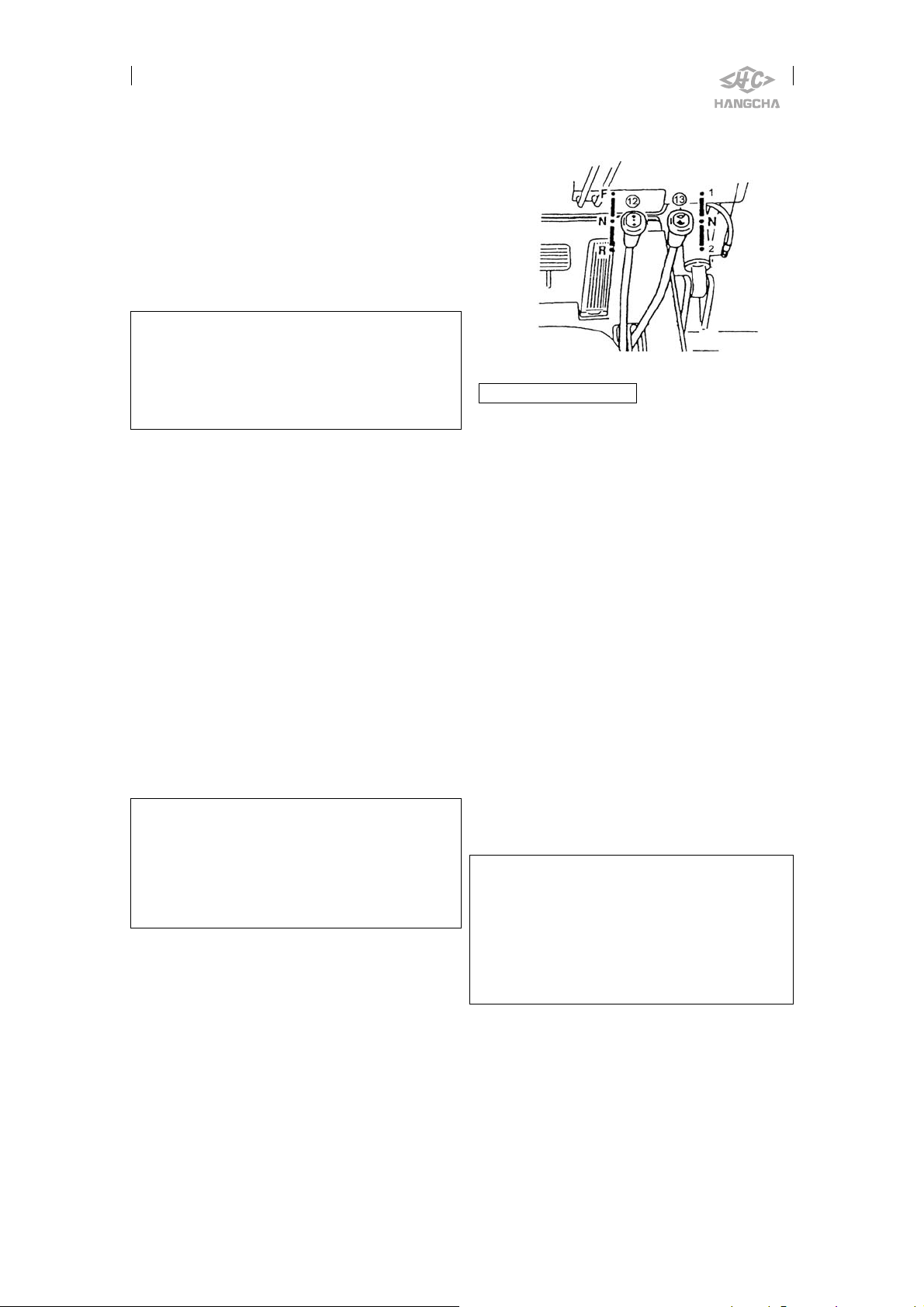

Forward-reverse [12]

Speed-select lever [13]

Machinery transmission

[12]F-front N-neutral R-backward

[13]1-low N-neutral 2-high

Machinery gear box have four shifts, tow

are frontward and tow are backward.

Before gear-shifting, be sure to

press the clutch pedal to the full. Always

brake to a full stop before reversing the

direction of travel. Shifting the level in

reverse the back-up lights turn on.

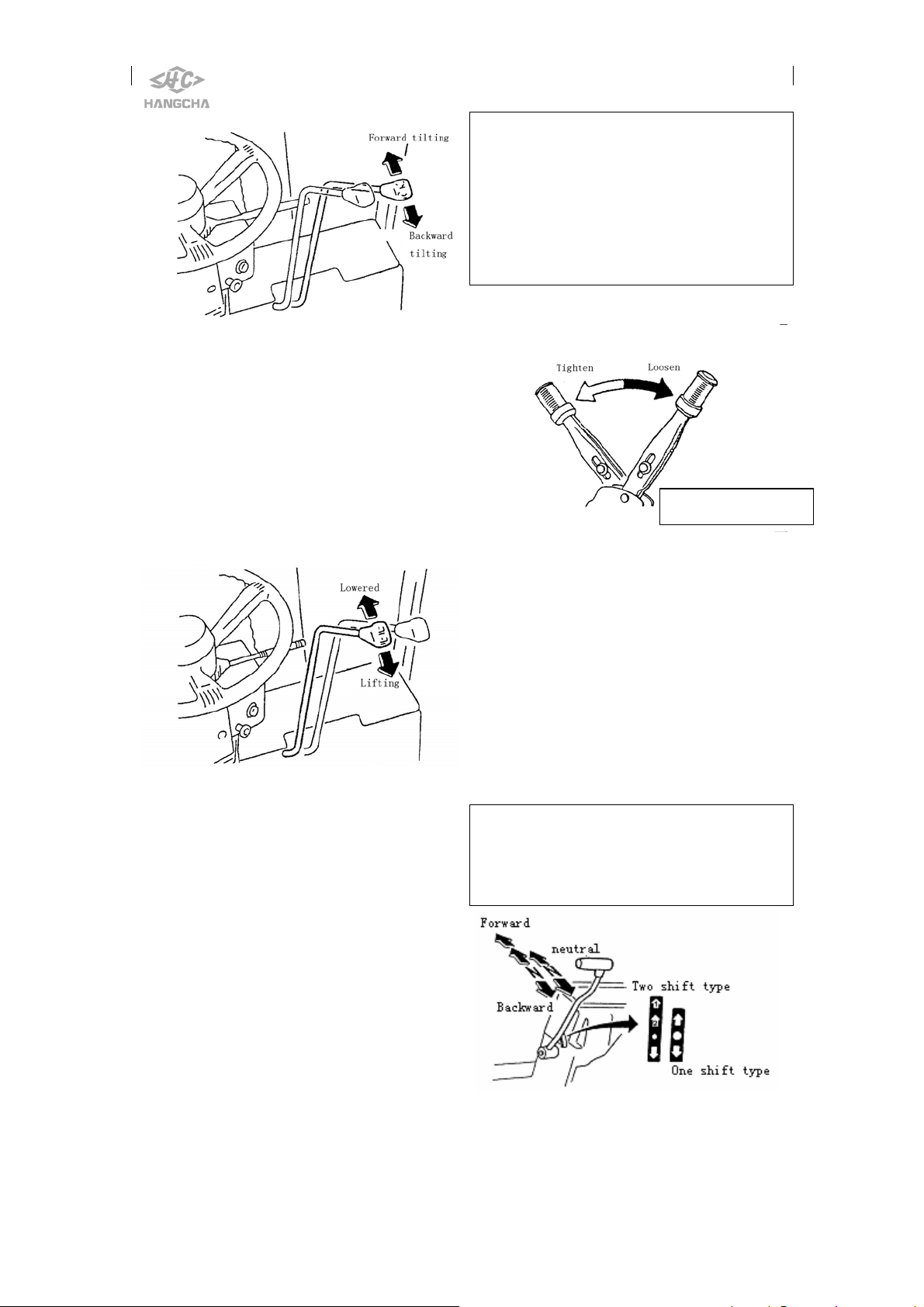

Tilt level [14]

The mast can be tilted by operation

of this tilt lever: pulling on this lever

backwards will tilt the mast backwards,

and pushing it forwards will tilt the mast

forwards.

The tilt speed can be controlled by

tilt angle of the lever and accelerator

pedal effort.

Caution

The tilt lock mechanism built in the

hydraulic control valve does not allow

the mast to tilt forwards while the engine

is being shut down even if the tilt level

is pushed forwards.

7

Lift lever [15]

Control the forks’ up or down.

Pulling: up, Pushing-down.

Lifting speed can be controlled by

tilt backwards angle of lever and

accelerator pedal, the lowering speed

can be controlled by tilt forwards angle

of the lever.

Steering wheel [16]

The steering hand-wheel is

operated in the conventional manner,

that is, when the wheel is turn right, the

truck will turn to the right; when the

wheel is turned left, the truck will turn

the left. The steer wheels are located at

the rear of the truck. These cause the

rear of truck to swing out when a turn is

made.

Warning

This truck is provided with the

power steering, so heavy hand-wheel

operation is caused when the engine

comes to a stall. To put the power

steering in operation again, restart the

engine without delay.

Parking brake lever [17]

Direction to driver

Pull the parking brake lever

backward to park, push it forward to

release, must pull the parking brake

lever backward before driver leaving

truck.

Forward reverse lever [18]

[Non-electric-switch]

F-forward N-neutral R-backward

Torque converter type truck have a

forward shift and a backward shift.

When shift must stop the truck first.

Caution

Do not fail to place the forward-reverse

lever in the neutral position before

starting the engine.

8

Choke line [19]

To pull out the choke line, the

engine will stop. Some of the model

forklift has no choke line. When turn off

the key switch, the engine will stop.

Forward-reverse lever [20]

[Electrical Switch]

The forward reverse lever of truck

installed with electronic reserving is set

on the left of turning rod。

Forward—Forward N—neutral

allocation

—backward

After

Caution:

Do not forget to place the forward-reverse

lever in the neutral position before starting

the engine.

Body and others

Load bracket

Load bracket can ensure stabilization

when loading the goods. It’s forbidden

to use the forklift truck without the load

bracket.

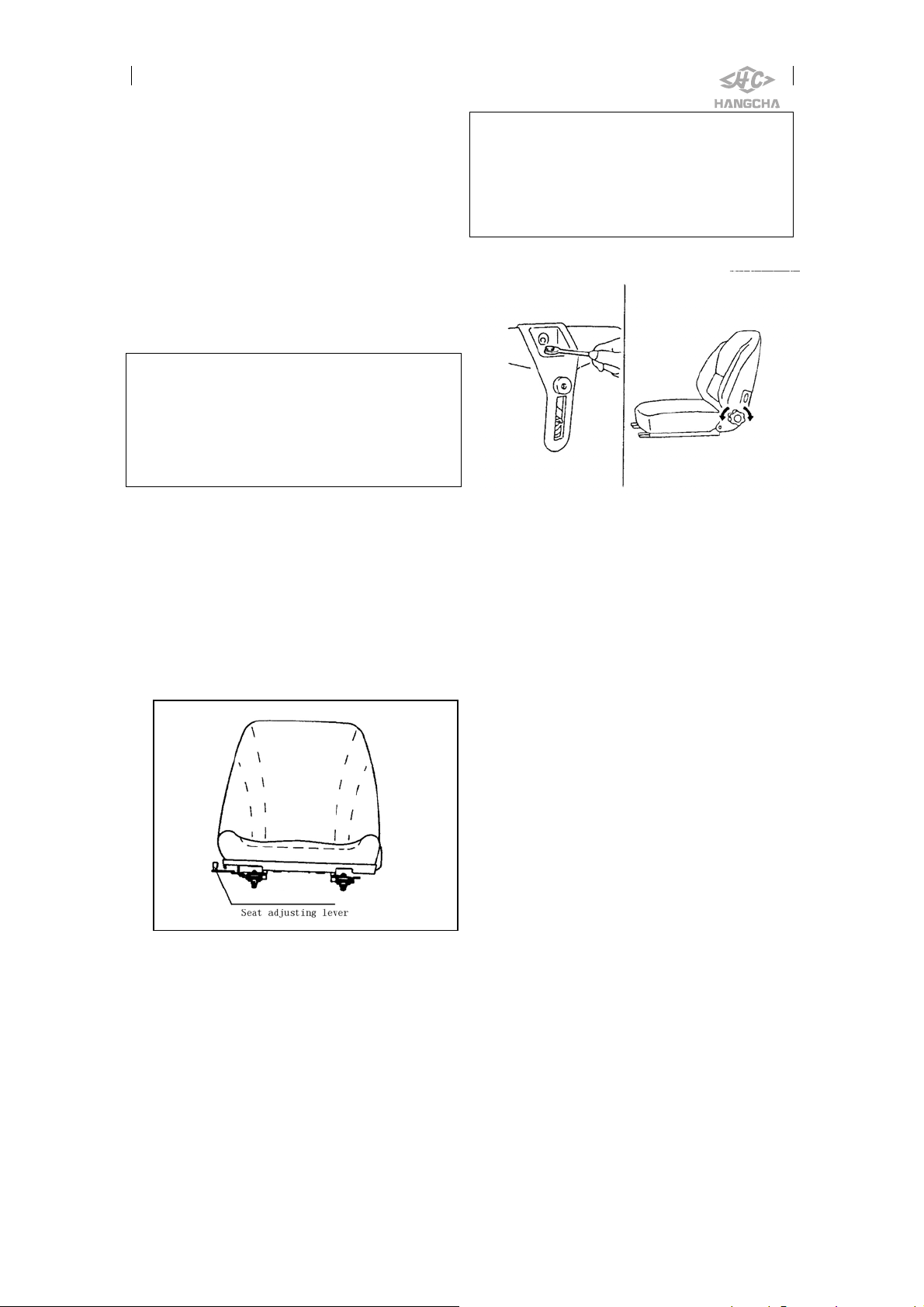

Seat and seat adjusting lever

Adjust operator’s seat to position,

which is comfortable for you and

provides easy access to all hand and foot

controls. The seat is unlocked by

moving the adjusting lever to the right.

Before proceeding with work, adjust

operator’s seat and make sure that it is

securely locked.

Warning!

a. Before adjusting the lever, you’d

better turn off the key switch.

b. Must stop the truck to adjust the

seat .

Seat weight support adjusting

Use spanner to adjust the bolt

which is at the back of seat, or adjust the

knob for supporting the weight on seat at

the lift side of seat, adjust the hanging’s

weight basing on person’s weight.

It’s better to sit on the seat when

adjusting.

Seat switch

While you are on the vehicle and

wearing the Safety belt, at the same time,

your back and waist should close to the

seat as much as possible.

Check whether the bolts which fixed

seat belt were loose frequently. It is

forbidden to use the Safety belt when

the belt was tie a knot. Do not let the

belt press on the hard or fragile objects.

And also do not make friction with the

sharp edge to avoid damaging the belt.

Do not let the seat back tilted too much;

otherwise the safety belt will not be able

to correctly elongation.

The components which are on the

safety belt can not be removed randomly.

If the safety belt used frequently, you

9

should always do exterior inspection,

when found something abnormal, please

immediately replace new belt. The belt

can be used for 3 to 5 years, when found

something abnormal, it should be

scrapped early.

Overhead guard

The overhead guard used is strong

enough to meet safety standard, and

protects the operator from falling

materials. It’s forbidden to use forklift

without overhead guard.

Hood and snap close

To avoid opening the hood at

discretion, a snap close is set here. Open

the snap close first then the hood can be

open.

Guy head

To avoid opening the hood at

discretion, the hood only can be opened

by specified tools. The guy head is the

specified tool.

Hood

The hood can be swung up fully to

provide easy maintenance service. You

can lift up the hood with little effort with

an aid of hood damper. To lock the hood,

push down on the front of hood until it

covers.

! Caution

△

While maintaining under the cover hood, the

engine must be flameout to avoid hands or

other parts of the body being clamped by

running assembly. The engine can be

no-flameout only when human body does not

touch parts under cover hood, and to examin e

where the fault is by hearing.

Radiator cover hood

Must use special tools (socket spanner)

to open radiator cover hood.

You can open the radiator cover hood

even close the engine hood, so to inspect

the coolant fluid.

Caution

Before open the hood, the handle of

the snap close should be pulled out first.

Use caution not to catch your

fingers in the hood when closing it.

10

Caution:

Retighten the bolt on the cover hood.

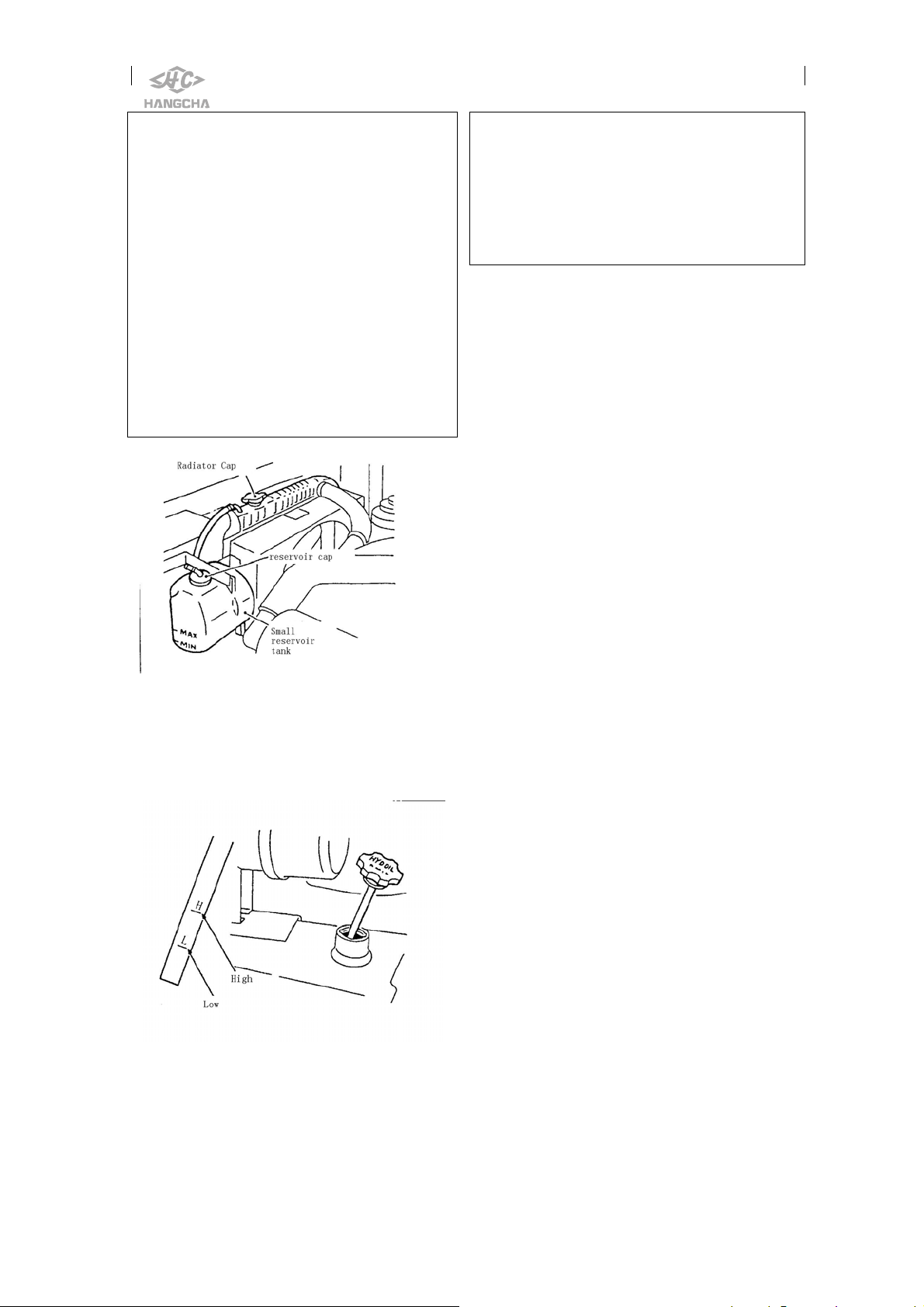

Radiator cap and coolant reservoir

The reservoir is located inside the

hood.

The radiator is located under the

cover plate at the rear of the hood.

Warning!

Do not open the radiator cap

abruptly while water’s temperature is

higher than 70℃. Turn the cap a little to

the left to relieve the pressure in the

pressure in the radiator, and then remove

the cap.

Do not wear glove when removing

radiator cap.

The antifreeze fluid is dangerous

for your health, if touched to skin, please

wash clean by water. Do not allow

children access to antifreeze.

Fork stopper

It’s used to adjust fork spacing and

to lock the forks in position. Pull up fork

stoppers, turn 90°, according to loads

to handle the forks spacing.

Warning!

The forks should be set symmetrically

to machine centerline and fork stoppers

should always be set.

The lower beams of fork have a hatch

to load or unload forks.

The fork is forbidden to fix on the

location where the hatch locates. Check

the bolt at the middle of the fork bracket

which is used to prevent load fork at the

hatch.

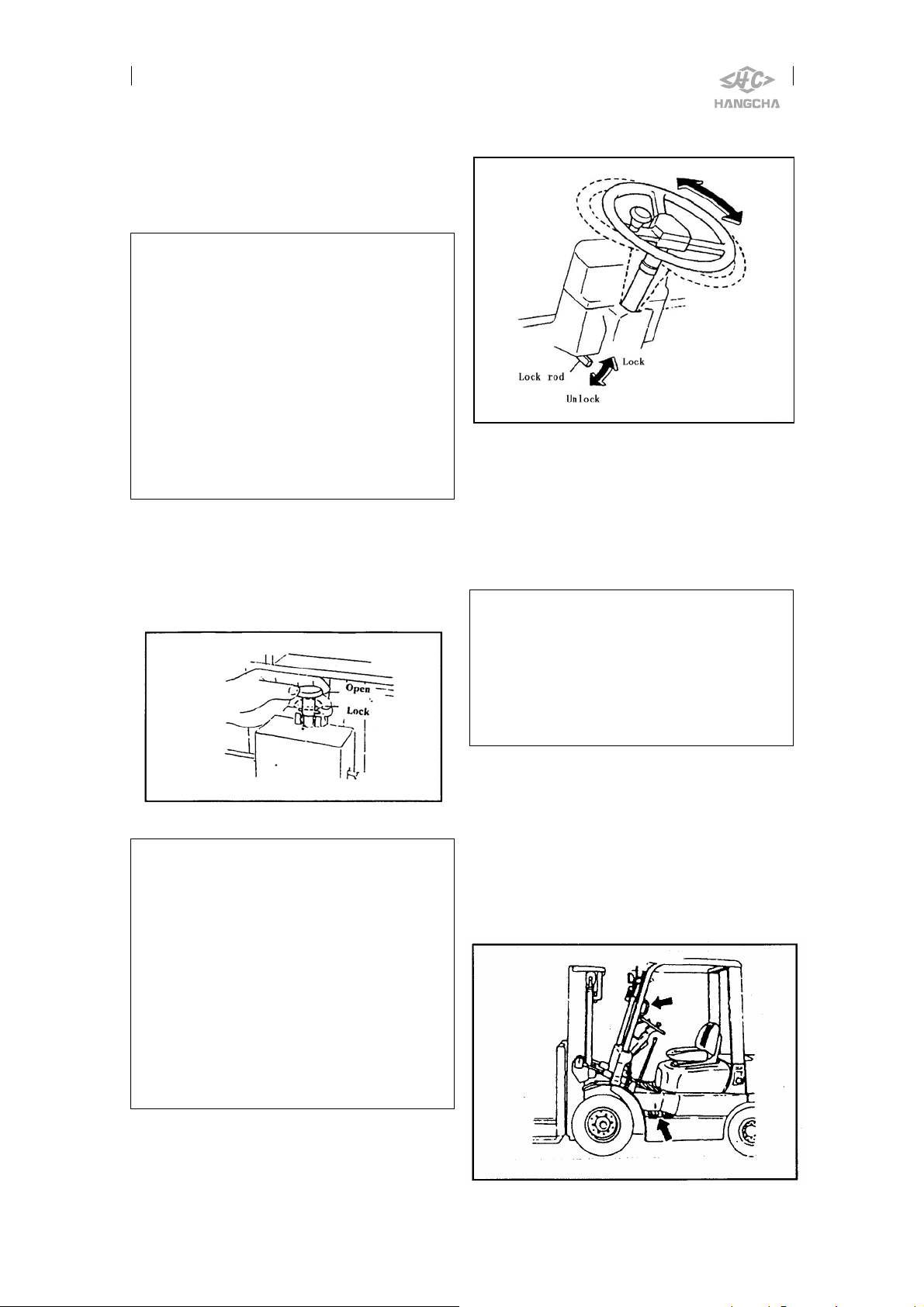

Steering column tilting angle

adjustment

The tilting angle of the steering wheel is

adjustable to suit individual operators.

The steering column is unlocked by

pushing down the lever at the left side of

turning rod, then adjust the angle suit to

the driver, and pull up the lever to lock.

Caution:

a. After stop the truck and pull on the

parking brake lever then to adjust the

tilting angle of steering column.

b. After adjust the angle and pull the

steering wheel to make sure tighten the

lock rod.

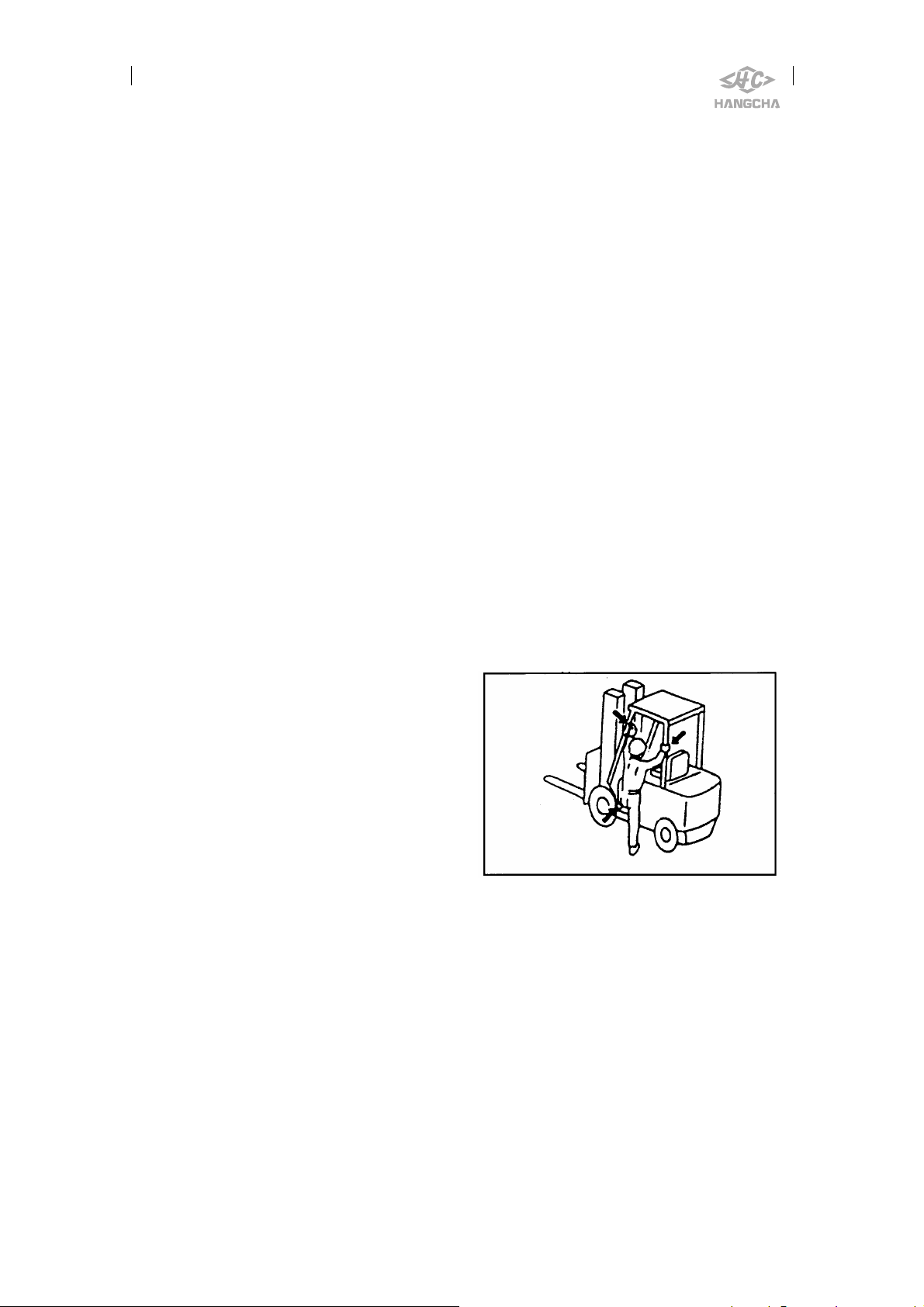

Safety step and safety grip

The safety steps are provided on

both sides of the truck body. The safety

grip is provided on the front left pillar of

the overhead guard. Use the safety step

and safety grip facing the truck when get

on and get off the truck.

11

Brake fluid reservoir

The brake fluid reservoir is

provided at the left of the cabinet.

Hydraulic fluid reservoir cap

The hydraulic fluid reservoir cap is

located at the right side in the hood. Fill

hydraulic fluid through this filler port.

The cap is provided with the dipstick.

After fill in clean hydraulic fluid, lock

the cap.

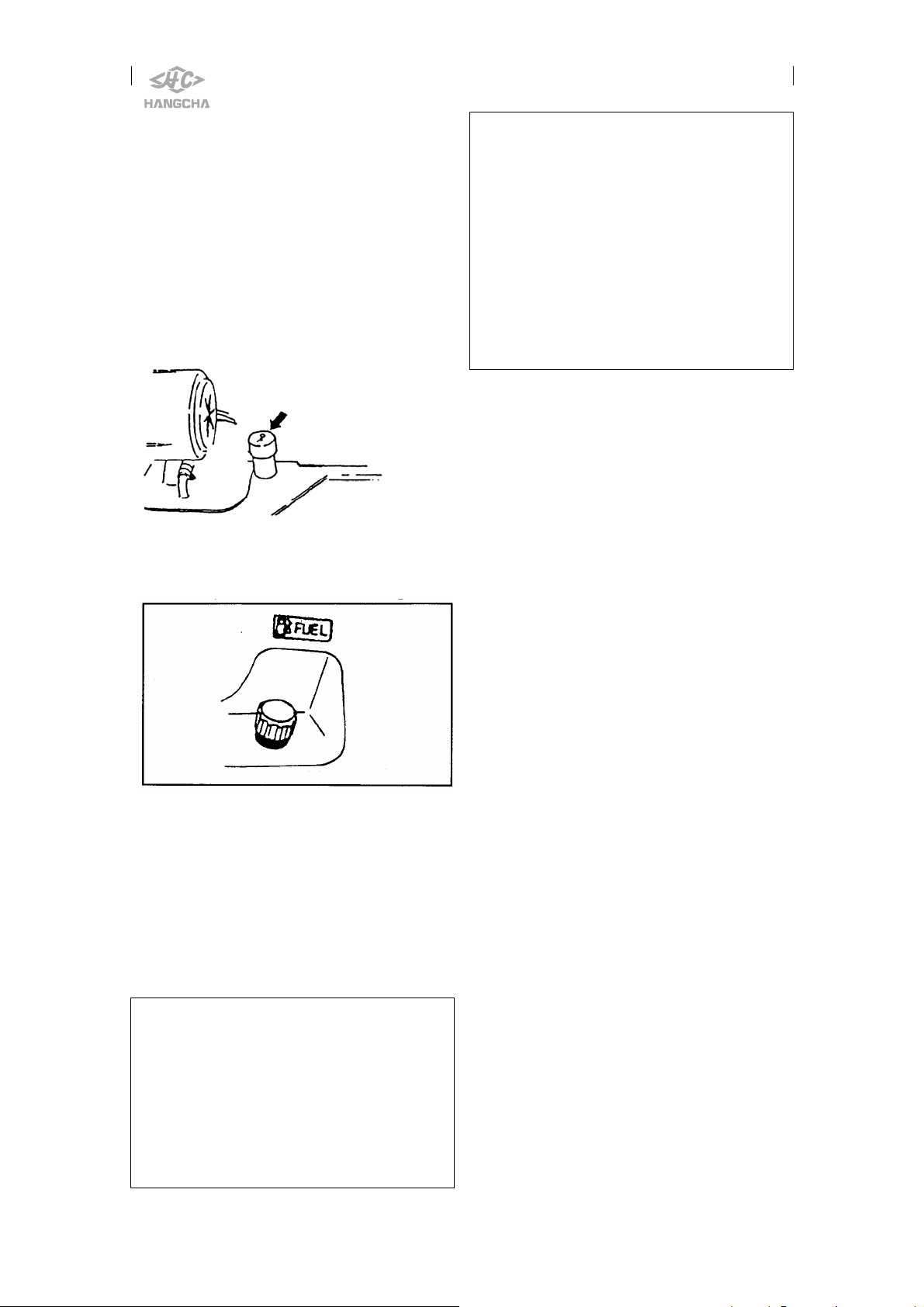

Fuel reservoir cap

The fuel reservoir cap is located at

the rear left side of the truck body. The

fuel reservoir cap has the breather inside

it to allow air to enter the reservoir.

Check to see that the breather is in good

condition every time addition of fuel is

made.

Warning!

--- Fuel handling---

1.Stop the truck, shut down the engine

and apply the parking brake securely.

Make sure that there is no naked flame

near the area. Never smoke. The driver

should not remain seated when adding

fuel.

2.After addition of fuel is finished,

securely close the reservoir cap. A

loose cap could cause fuel leak or fire

hazard in the worst case.

3.Before attempting to start the engine,

make certain that the fuel reservoir cap

is securely tightened and that no fuel is

split on or around the truck.

4.For the purpose of fuel level

inspection, never use naked flame such

as a match or lighter.

Rearview mirror

There are two rearview mirrors on

the safeguard for operator to see rear

accident.

12

3. Safety instructions

1. Only trained and authorized

operator shall be permitted to operate

the truck.

2. Inspect the truck at periodic

intervals for oil or water leak,

deformation, lousiness, etc. If neglected,

the life of the truck will be shortened

and in the worst case a fatal accident

would occur.

Make sure to replace the “key safe

parts” at periodical inspection.

Wipe off oil, grease or water from

the floor board and foot and hand

controls, if any.

Shut down the engine before

inspecting the engine and its allied

components. Especially use caution to

the engine fan.

When inspecting the radiator or

muffler, exercise caution not to get

burnt.

3. Any time you find that the trucks

are not functioning properly, operation

of the truck should be halted and the

condition reported to the supervisor.

should be prepared.

Never fill the fuel tank with the

engine running.

5. Warm up the temperature of water

to 70℃ before operation; and cool down

the temperature of water to lower than

70℃ after work.

If the temperature of the water tank

is higher than 70℃ , never open the tank

cap.

6. When using your tr uc k in an enclosed

space, make sure there is enough

ventilation. If needed, use a ventilation fan.

Don’t work in a closed working space

because of the tail gas of truck is

dangerous to health.

It’s forbidden to use truck under a

circumstance of flammability and easy

to blast.

7. Never mount or dismount the

moving truck. Use the safety step(s) and

safety grip facing the truck when

mounting or dismounting the truck.

When doing maintenance in the

high place (such as mast, front and rear

lights) should be care of slide and

clamped.

If any warning lamp comes on,

move to a safe place and check or repair

the trouble.

When doing maintenance, take care

of edges and corners to lacerate hands,

head and other parts of body.

The sign of defect should be put on

the defecting forklift truck.

4. Don’t use an open flame to check

level, or for leakage, of fuel, electrolyte

or cooling water.

Never smoke while inspecting the

battery, handling fuel or working on the

fuel system. There is a danger of

explosion.

At working place fire extinguisher

8. Never attempt to work the controls

unless properly seated.

Before staring, adjusting the seat so

you can get easy access to all hands and

foot controls.

9. Before staring, make sure no one is

under, on and close to the truck.

The forward-reverse lever is in

neutral.

10. Park the truck on a level surface

and apply the parking brake securely. If

13

parking on a grade is unavoidable, be

sure to block the wheel.

Put the forks on the ground or floor

and tilt a little forwards. Shut down the

engine and remove the key.

11. Operate the controls smoothly-don’t

jerk the steering wheel. Avoid sudden

stops, starts or turns.

12. Control speed and observe traffic

signs.

When traveling on public roads or

streets, obey all local traffic regulations

13. Pay attention to the route of the

truck , be sure to make a wide sight.

14. Never allow other person(s) to ride

14.Does not allow other people sitting

on the forks, pallets or on the truck.

16. Keep your mind on your work.

17. Keep your head, hands, arms, feet

and legs within the cab. Never let them

out of cab for any reason.

18. When handling bulky loads, which

restrict your vision, operate the truck in

reverse or have a guide.

19. Slow down and sound horn at

cross aisles and other locations where

vision is restricted. The speed should be

keep slower than 1/3 of max speed.

15. Before driving over a dock-board

or bridge-plate, be sure that it is properly

secured and strong enough to sustain the

weigh. Check the ground or floor

condition of working area in advance.

14

20. Keep fluid cans, row cotton, paper

or chemicals away from the truck during

operation since there is a danger of their

firing or exploding due to exhaust gas

from the muffler.

21. Use head lights and required work

light and clearance lights at night. And

travel at a low speed.

22. The work surface should be

solidity and flatness such as cement road

surface, bituminous macadam and beton

road surface.

The climatic conditions that the

trucks designed for are: temperature is

–20℃—50 ; wind speed is lower than ℃

5m/s; air relative humidity is less than

90%(20 ).℃

Inspect the surface over which you

will run. Look for holes, drop-offs,

obstacles, and look for rough spots.

Look for anything that might cause you

to lose control, bog down or upset.

Clear away trash and debris. Pick

up anything that might puncture a tire or

let the load lose balance.

Slow down for wet and slippery

roads. Stay away from the edge of the

road. If unavoidable, use extreme

caution.

Rugged surface would cause

vibration of truck and noise. The high

air pressure of tyres will cause vibration

and noise, too.

Do not operate the truck when the

weather is execrable, such as windy,

thunder storm, snow and etc.

23. When operating loaded truck, have

the rear end of your machine pointed

downhill. When operating unloaded

truck, have the rear end of your machine

pointed upgrade.

Never turn sideways on an incline.

There is danger of the truck turning

over.

24. When running down on a grade,

use engine idle speed. At the same time

use the brake pedal intermittently.

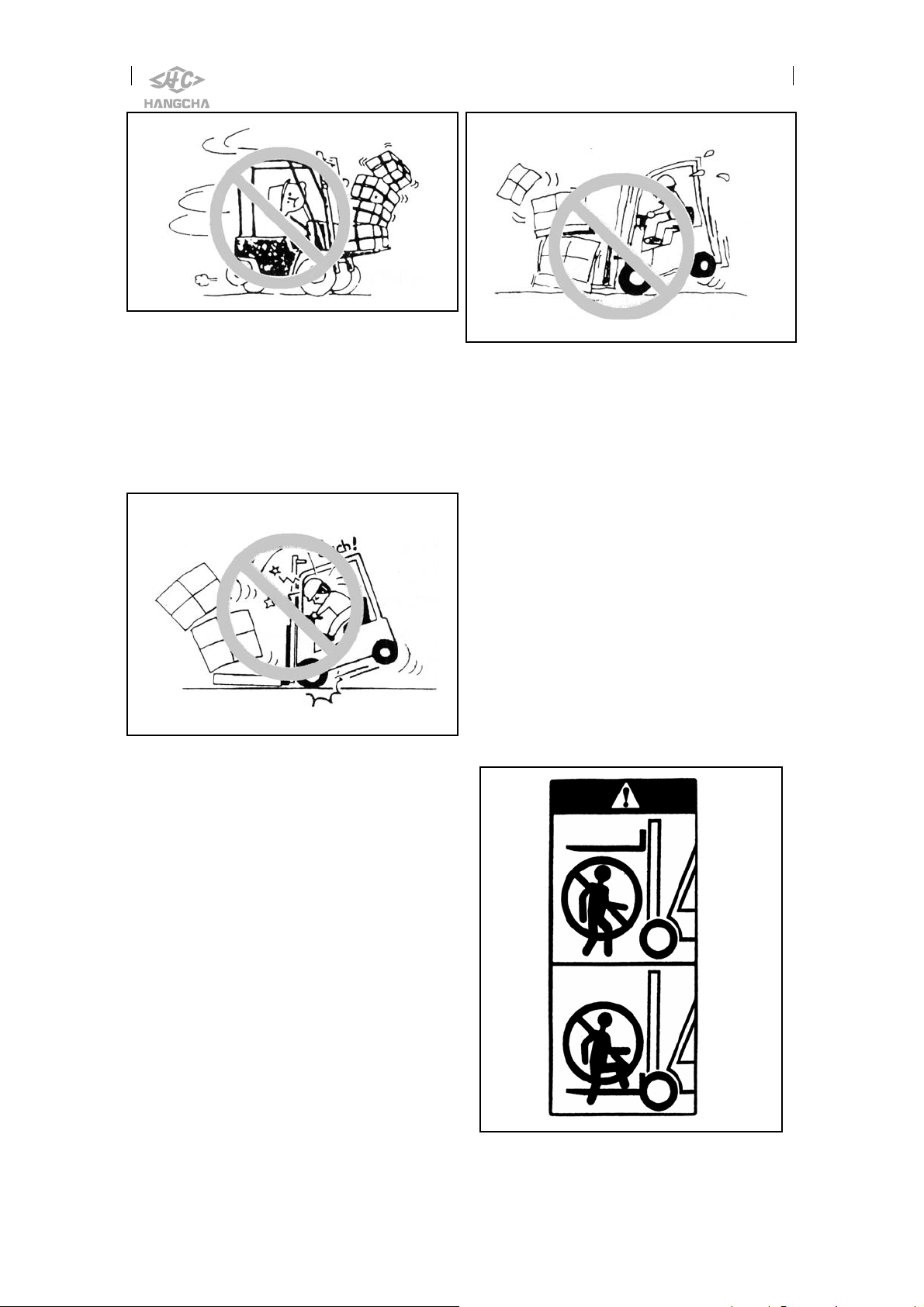

25. It is dangerous to travel with forks

higher than appropriate position

regardless of whether loaded or not.

Keep the good traveling posture. (When

traveling, the forks should be 15 to 30

cm above the ground or floor.)

Do not operate the side shift

mechanism, if equipped, when the forks

are raised and loaded, since this will

cause the truck to be unbalanced.

A truck with attachments should be

considered as with loads.

15

26. Travel with load as low as possible

and tilted back.

27. Avoid braking too sharply or

descending on a grade at a high speed.

There is danger of loads falling down or

the truck turning over.

28. Always brake to full stop before

reversing direction of travel.

29. Taking account of the shape and

material of loads to be handled, use a

proper attachment and tools.

Avoid hoisting the load, with wire

rope hung on the forks or attachment,

since the wire rope may slide off. If

needed, a qualified personnel for

slinging operation should perform,

making use of a hook or crane arm

attachment.

Take care not to protrude the forks

out of the load. The protruded fork tips

may damage or turn over the adjacent

load.

Do not use a man as an additional

counterweight. It’s quite dangerous.

31. ZHEJIANG HANGCHA

ENGINEERING MACHINEARY CO.,

LTD. offers a variety of attachments,

such as forks, bucket, rotating roll clamp,

load grab or hinged forks. Don’t use

such attachments and special equipment

for applications other than specified.

32. Safeguard is used to prevent us

from hitting of the higher goods. Load

bracket is used to ensure loading stable.

The forklift truck without two items is

forbidden to be used.

33. Never permit anyone to stand or

walk under upraised forks or other

attachments if machine is so equipped.

30. Know the rated capacity of your

lift truck and its attachment, if any, and

never exceed it.

16

Never permit anyone to stand on

the forks.

34. Don’t put your head or body into

the interspace of mast and safeguard,

what may cause life risk

Don’t put your hand into the

interspace of inner mast and outer mast

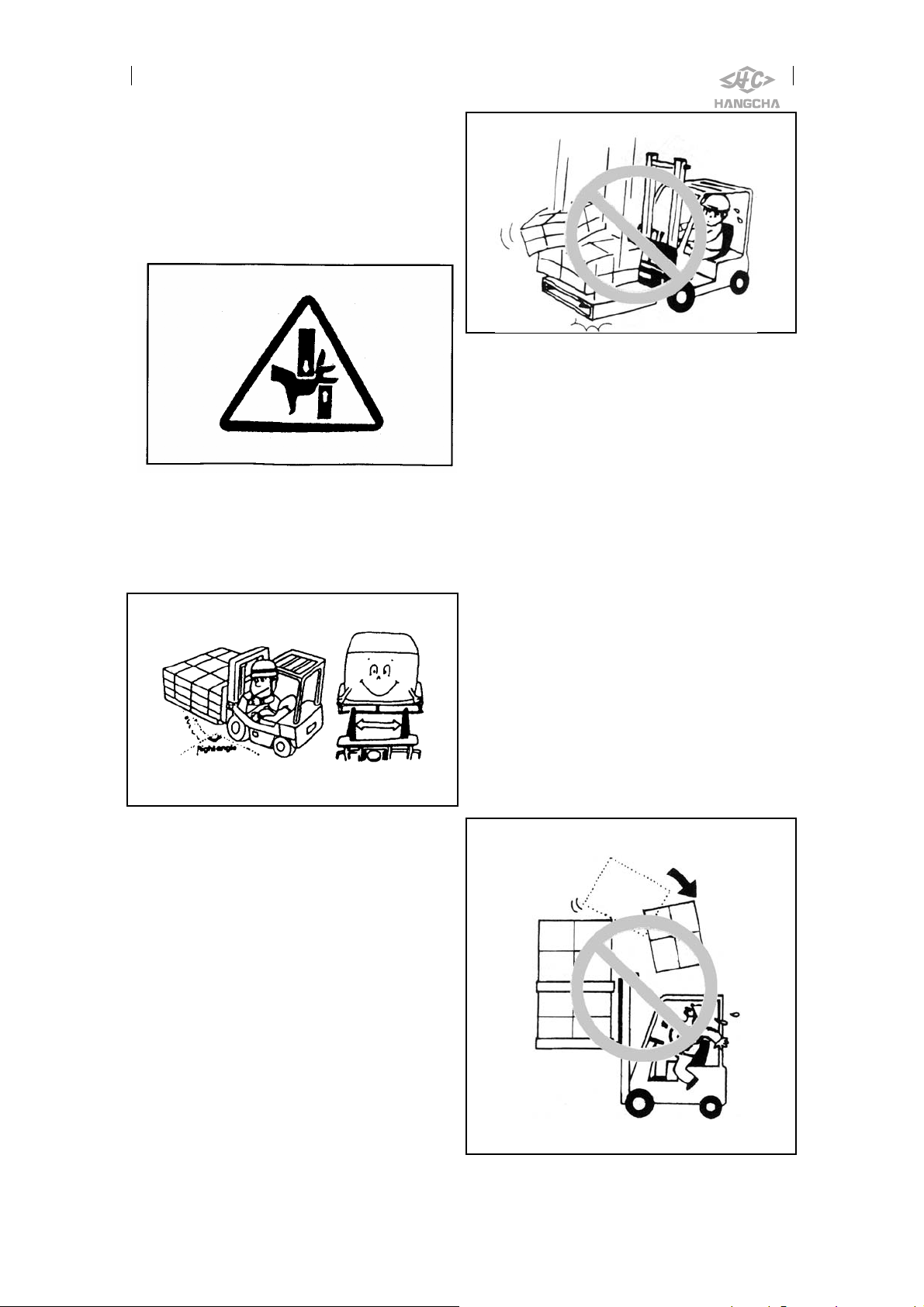

35. When load is to be retrieved from

a pile, enter the area squarely. Engage

forks into the pallet carefully.

36. Don’t enter into loads at a high

speed. Always make certain that your

load is stable before lifting the forks.

Be sure to once stop in front of the

load to be lifted, and make certain that

there is no obstacle, then engage the

load by driving forwards.

37. Make certain that your load is well

stacked and evenly positioned across

both forks. Don’t attempt to lift a load

with only one fork.

On the truck with an attachment

such as a load grab, make certain that

the load is securely and correctly

grabbed, and pull the loading control

level to the full (increase to relief

pressure).

38. Never lift loads with the truck

inclined. Avoid loading work on a grade.

39. Don’t stack loads on forks in such

a way that the top of loads exceeds the

load backrest height. If unavoidable,

make the load stable securely. When

handling bulky loads that restrict your

vision, operate the truck in reverse or

have a guide.

17

40. Use minimum forward and reverse

tilt when stacking and unloading loads.

Never tilt forward unless load is over

stack or at low lift height.

When stacking loads on a high

place, once make the mast vertical at a

height of 15 to 20 cm above the ground

and then lift the load farther. Never

attempt to tilt the mast beyond vertical

when the load is raised high.

To unloading loads from a high

place, insert forks into the pallet and

drive backwards, then lower the load.

Tilt the mast back after lowering. Never

attempt to tilt the mast with the load

raised high.

41. Don’t tow the truck that its engine

is in trouble, or steering system doesn’t

work correctly or its braking system has

been disabled.

Obey the communication rules on

the road when towing the truck.

42. Dress the overalls or other

protective uniforms, suck as safety

helmet, safety shoes etc. Don’t dress

necktie or other accouterments.

43. The workplace should be equipped

fire extinguisher. In order to get the

with

fire extinguisher easily, it’s usually

installed on the safety frame rear

supporting leg. The operator should be

familiar with position of the fire

extinguisher and its application.

44.

Not allowed to carry small goods with

fork, should carry small goods with pallet.

45. Markings on the machine describe

warning and methods to operate the lift

truck. When operating the machine,

observe and follow all markings on the

machine in addition to this operator’s

manual.

Replace damaged or missing decals

and name plate.

18

4. Maintenance

More details for maintenance see

《Preventive maintenance schedule》.

8 hour (daily or every shift) check

1). Check leaks: electrolyte, hydraulic

oil, brake fluid, coolant, oil in hydraulic

transmission gear box.

Check if the engine, connector of

hydraulic pipe, radiator and driving

system are leakage or not. Do not use an

open flame to check level, or for leakage,

of fuel, electrolyte or cooling water.

! Warning!

△

Don’t attempt to operate the truck if

leaked fuel is found through

pre-operational check. Correct the leak

before starting engine

2) Check appearance

Check the lamps and meters are normal

or not.

Check the tires, air pressure and bolts

are loose or not.

Check whether tires are damaged or

pressure of tires is normal or not.

3) Check fuel mass

4) Engine oil level check Caution

When checking the engine oil,

should let the forklift truck on the level

ground.

When check the engine oil, it is exact

when the engine is cool.

Remove the dipstick, clean the rod

and reinstall. Pull it out again and check

the oil level. The level should be within

the mark on the dipstick.

5) Check water level in the radiator

Inspect the small reservoir tank to

see the coolant level is between Min and

Max position when the engine is cool. If

there is no coolant any more in the

reservoir tank, please add some coolant to

radiator, its freezing point is -35℃,and

add sub-radiator to MAX position.

! Warning!

△

When the water temperature of the

engine is higher than 70 degree, please do

not open the pressure cap of the radiator.

Loosen cap slowly to allow steam to

The fuel level gauge is provided on

the indicator panel. Check that fuel level

is sufficient for the day’s work. The fuel

filler port is provided at the rear left

pillar of the overhead guard.

19

escape. After that, tighten cap securely. It

is good practice to use thick waste cloth

or the like when removing the cap. Avoid

putting on gloves, since you may get

burnt at your hand if hot water splashes

on it.

Caution

Adding clean water to radiator. If

you use antifreeze, use the same brand of

antifreeze.

Pay attention to water reservoir and

cooling system in the hot season..

! warning

△

·antifreeze is harmful to person, if

swallow, disgorge at once and go to

hospital.

·do not let children add antifreeze.

6) Hydraulic oil level

Check the oil level in the hydraulic

oil tank.

The oil level should be in the place

between two slots,

7) Brake fluid level check

Check the fluid level in the brake

fluid reservoir. The level should be

between the two seams of the reservoir.

When adding fluid, due care should be

taken prevent air entering the brake tube.

Caution

When adding fluid, due should be

taken to prevent dirt or water from

entering the reservoir.

Brake fluid is dangerous to health,

you should avoid touching it by skin.

Replacing of brake oil

A. Lay forklift truck at designated

ground, and lay it on level ground,

fall down fork to ground, loosen park

brake, put transmission gear neutral

position, cut off engine.

B. Remove rubber dustproof cap of

oil-drain port, insert tube into

oil-drain port and wasted oil

collection bottle, and loosen oil-drain

screw, at the same time, the other

person on truck press brake pedal

again and again. So the brake oil

flows out from oil-drain port, watch

the liquid level of brake fluid

reservoir, add new oil as the fallen

liquid level until the oil from oil-drain

port is clean, and then screw down

screw of oil-drain port.

C. The person on truck press down brake

pedal to the end and keep it, at the

same time, the person at the oil-drain

port loosen oil-drain port screw, tell

the person on truck to release brake

pedal when the brake oil flows out

and screw down oil-drain port screw.

Repeat above operation several times

till there is no bubble in the brake oil.

Watch the liquid level in brake oil

reservoir; add new brake oil as the

liquid level is falling.

Notice :

The truck of Korea transmission system:

The brake oil(in the brake oil can) is

Mobil Delvac hydraulic oil SAE10W。

Other types: choice HZY3 brake oil (add

20

when leaving the factory) or DOT3

brake oil.

8) Head lamp check

Make sure that the head lamp is

lighting when the key is at “ON”

position.

9) Turn signal check

Make sure that the turn signal operates

properly by moving the turn signal lever.

10) Hand brake check

drive truck slowly.①

loosen hand brake lever, stop the ②

truck, and truck has no deviation.

11) Back-up lamp and buzzer check

The back-up lamp comes on and

buzzer sounds when the shift lever or

directional control lever is placed in

reverse position.

12) Turning

Operate the truck running slowly.

Turn the steering wheel to left and

right 3 round respectively.

Check that the steering forces are

equal in right and left.

13) Horn

Press the horn button to make

certain the horn sounds is normal or not.

14) Drivers seat adjustment

Make sure the driver’s seat is

properly located. If not properly, shift

the adjusting lever to back and move the

driver’s seat to a position which

provides easy access to all foot and hand

controls.

15) Shift lever(s) check

Check the shift lever(s) for

looseness and operation for smooth.

16) Lifting lever, tilting lever and

attachment lever check

Check the loading levers (for lift,

tilt and optional attachment) for

looseness and smooth operation.

Increase the rotate speed of engine ,

make certain that the lifting lever, tilting

lever and attachment lever in good work

condition.

17) Instruments and sensors

Make sure that hour meter, water

temperature indicator, oil temperature

indicator, transmission fluid sensor and

fuel sensor etc., properly.

18) Brake pedal, inching pedal and

clutch pedal check

Drive truck slowly, press down brake

pedal, and brake lamp lights.

Drive truck slowly, press down

inching pedal, the speed of truck

becoming decrease, and press downward

more ,truck will be braked and stop

Check function of clutch pedal, see

page 5《clutch pedal》。

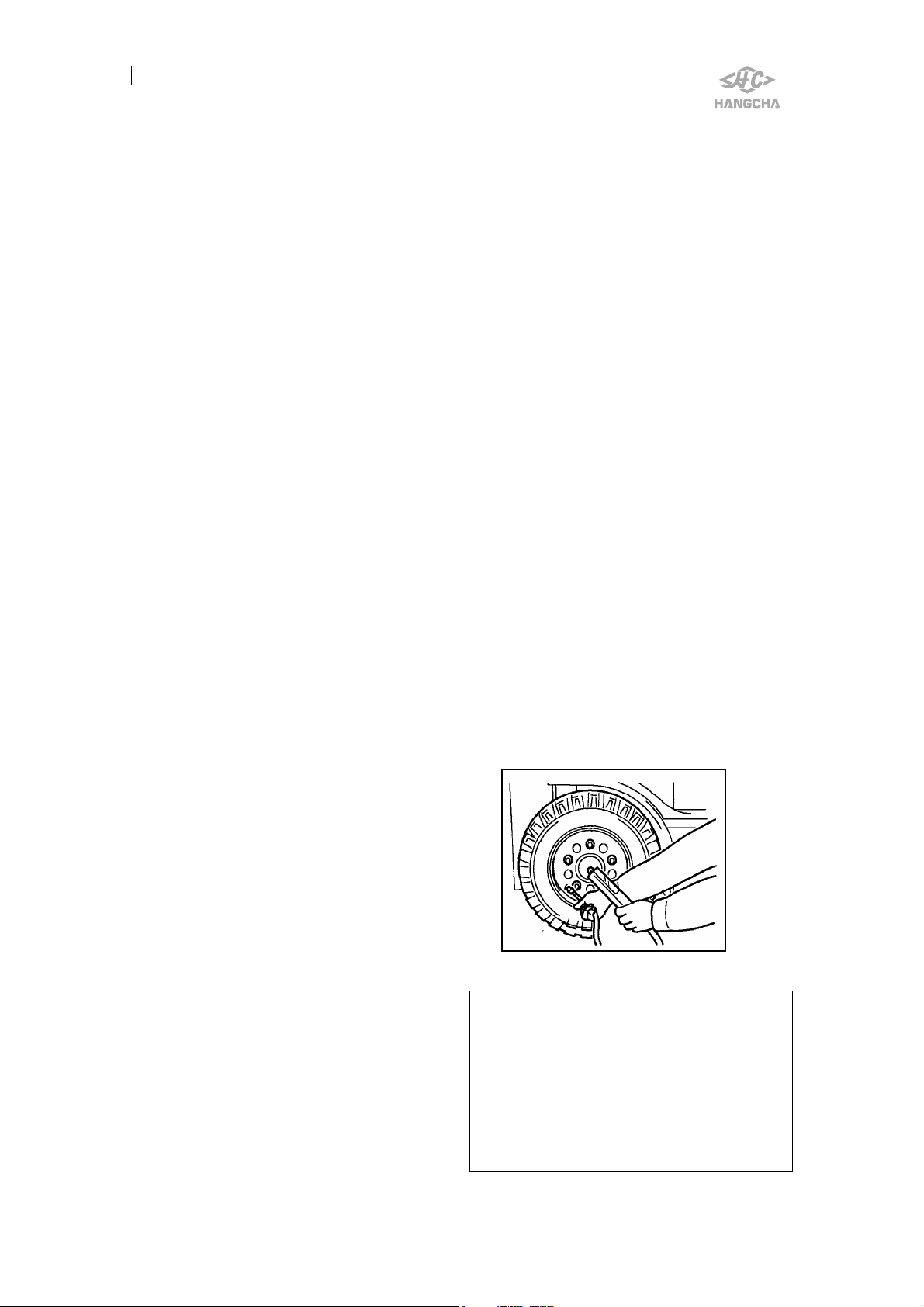

19) Tire pressure

Turn the tire valve cap counter

clock-wise and move it. Using a tire

pressure gauge, measure the inflation

pressure, and adjusting it to the specified

pressure, if needed. After making sure

there is no sir leakage from the tire valve,

reinstall the cap. Check that each tire does

not get damaged at the tread surface or

side face or bending at the rim.

! Warning!

△

Since the forklift truck needs tires

that have a high inflation pressure to

carry heavy loads, even a small bending

of rims or damage at the tread surface

could cause an accident.

21

! Warning!

△

When using an air compressor, first

adjust the air pressure of the

compress-or. Failure to do so will cause

a serious accident, since the compressor

delivers the maximum pressure.

! Warning

△

Please maintain the air cleaner when truck

works 50-250 hours.

After six times, please change air cleaner.

Note:If the working condition is bad,

the cycle of maintain and change air

cleaner need more frequency.

The badly work condition with dust,

the cycle of maintain and change air

cleaner will be short. Advice maintains

one time between 8-50 hours; change it

between 100-300 hours.

Maintain method:

1. Take apart the cover of air cleaner.

2. Take out air cleaner.

3. Clean the inside or outside of dust

by compress air.

All nuts and bolts should be

properly installed and tighten before

inflating tire and rim assembly. An

inflated tire contains potentially

explosive energy. Don’t over inflate.

Tire pressure GB/T2982-2001:

Driving

Truck type

1-1.8t 790KPa 1000KPa

2-2.5t 860KPa 860KPa

3-3.5t 830KPa 790KPa

Weekly maintenance (40 hours)

Increase the below content base on

maintain daily.

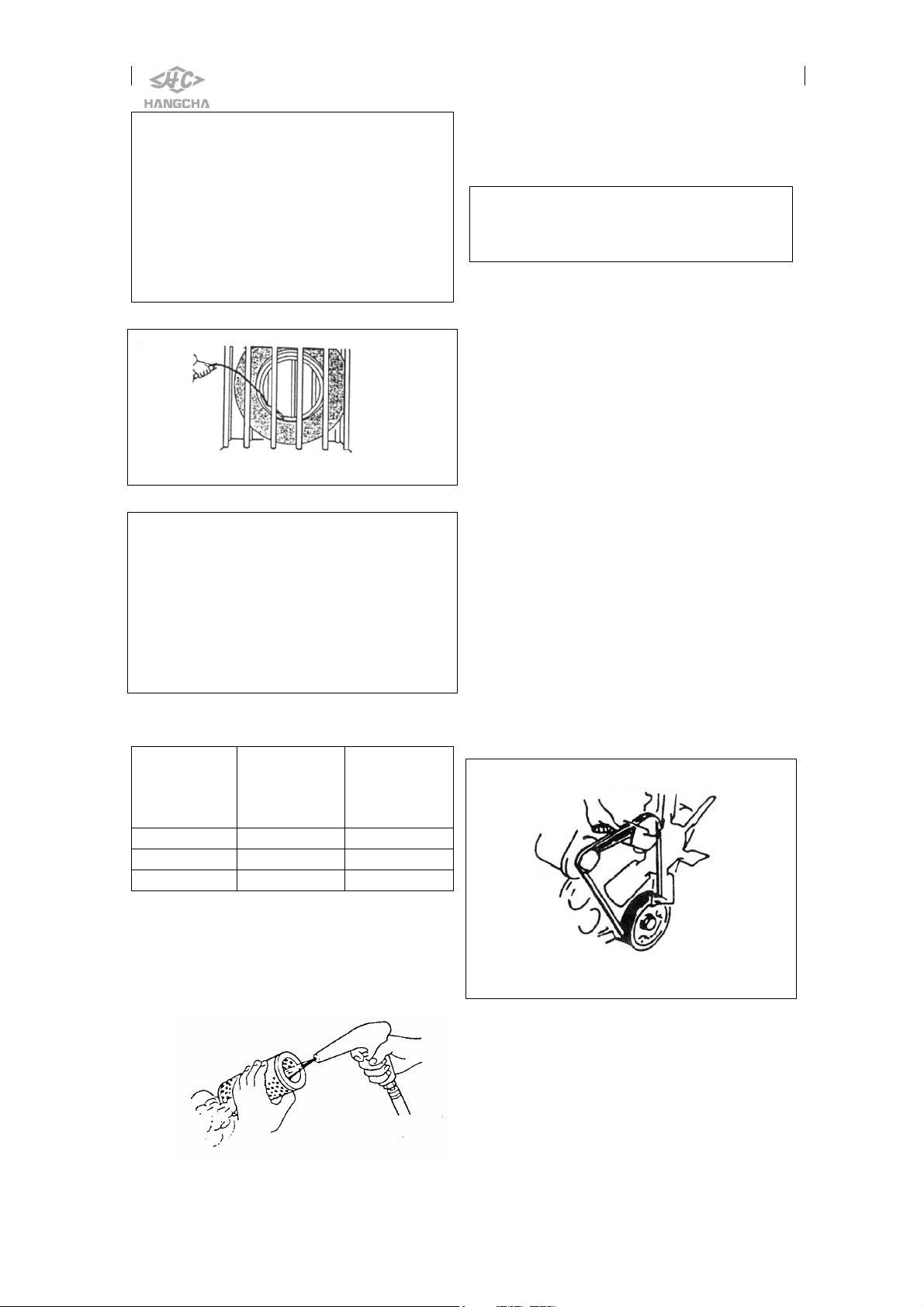

1) Air cleaner

wheels

(Front

wheel)

Turning

wheels

(Rear

wheel)

! Caution:

△

1、Please wear defend glass to avoid the

dust fly up into your eyes.

2、 It will damage the engine if not

maintain and change air cleaner on time.

2) Fan belt tension check

Stop the engine.

Use finger to press the belts at the

midway between the water pump pulley

and the generator pulley by 10kg press,

and check the drop distance if is up to

standard.

22

Engine

A498BT1-1

Drop distance

(mm)

10-15

K21,K25 11-13

WF491GP 汽油机 New 5-7,old 7-9

4TNE92

4TNE98

ISUZU

C240PKJ-30

TD27

New 8-12,old

10-14

8-12

New 9-11,old

11-13

Warning!

If the belt has already been pulled

long, cut out or has no surplus, it should

be changed.

If the engine is still running, it’s not

permitted to carry on this check avoiding

fingers or sleeves being caught up in.

Check if there have leakage of oil ②

cylinder and tubing.

Check the rollers’ rotation.③

Check the mast if there have crack ④

and bend.

Operate the lever of ⑤ lifting, tilting

and attachment, check the mast if it’s in

good condition, and pay attention to

system operating sound.

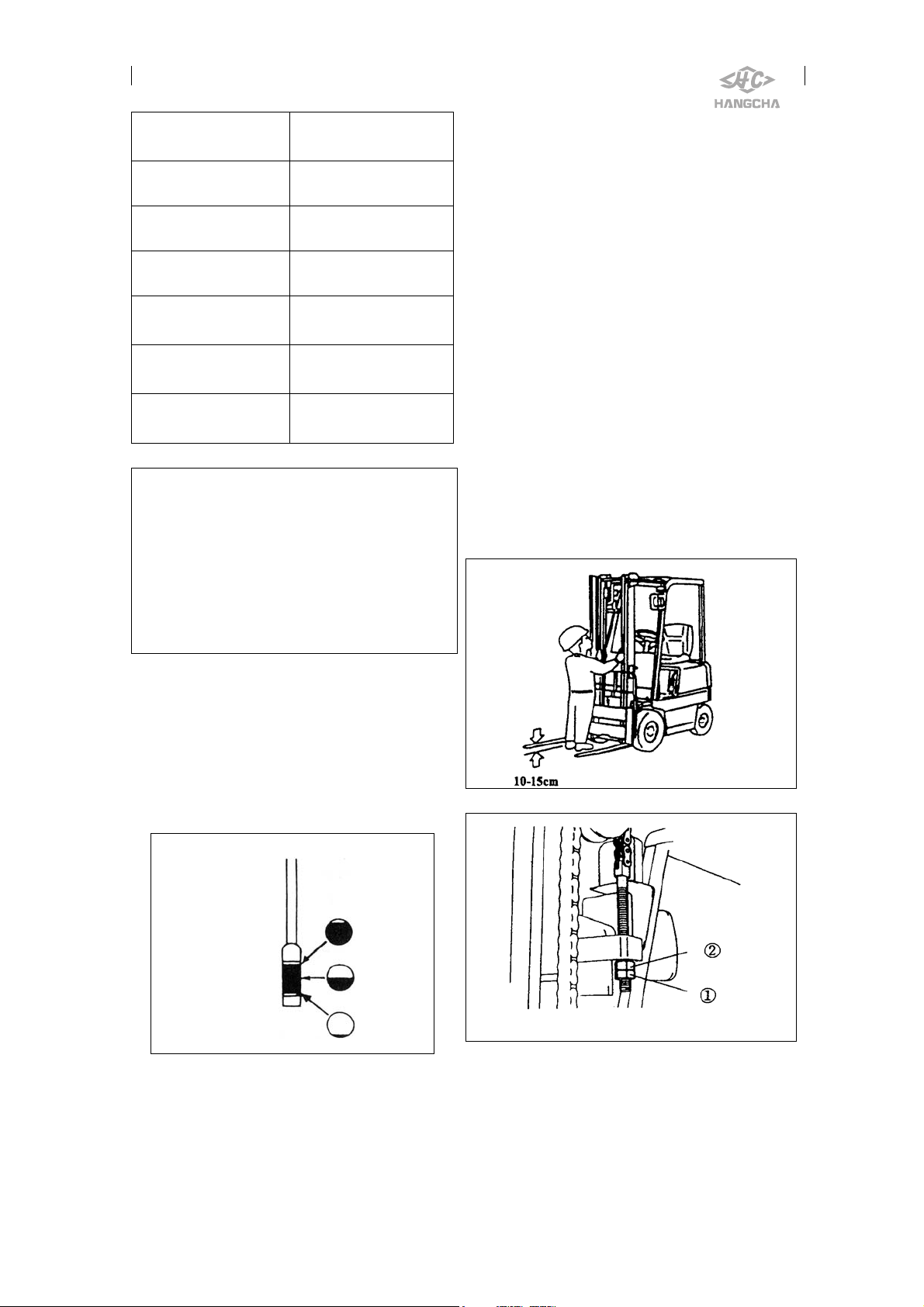

5) Lift chain tension check ①Raise the fork about 10-15 cm above

the ground and make it vertical.

②Press middle of the chain by thumb.

Make certain the tension for the right and

left chains are even.

③Adjust the tension: Loosen the lock nut

1, screw the nut 2 and adjust the chain to

make the equal tension, turning the

adjusting nut 1 of the chain anchor pin.

3) Power shift transmission fluid level

Open the inspections cover and

remove the filler cap. Inspect the lever

gauge to make sure that the fluid level is

on the upper mark of the gauge.

4) Mast and forks

Check the mast and forks to make

sure:

①There is no crack and bend on

the forks, and the forks are installed on

the fork bracket strongly.

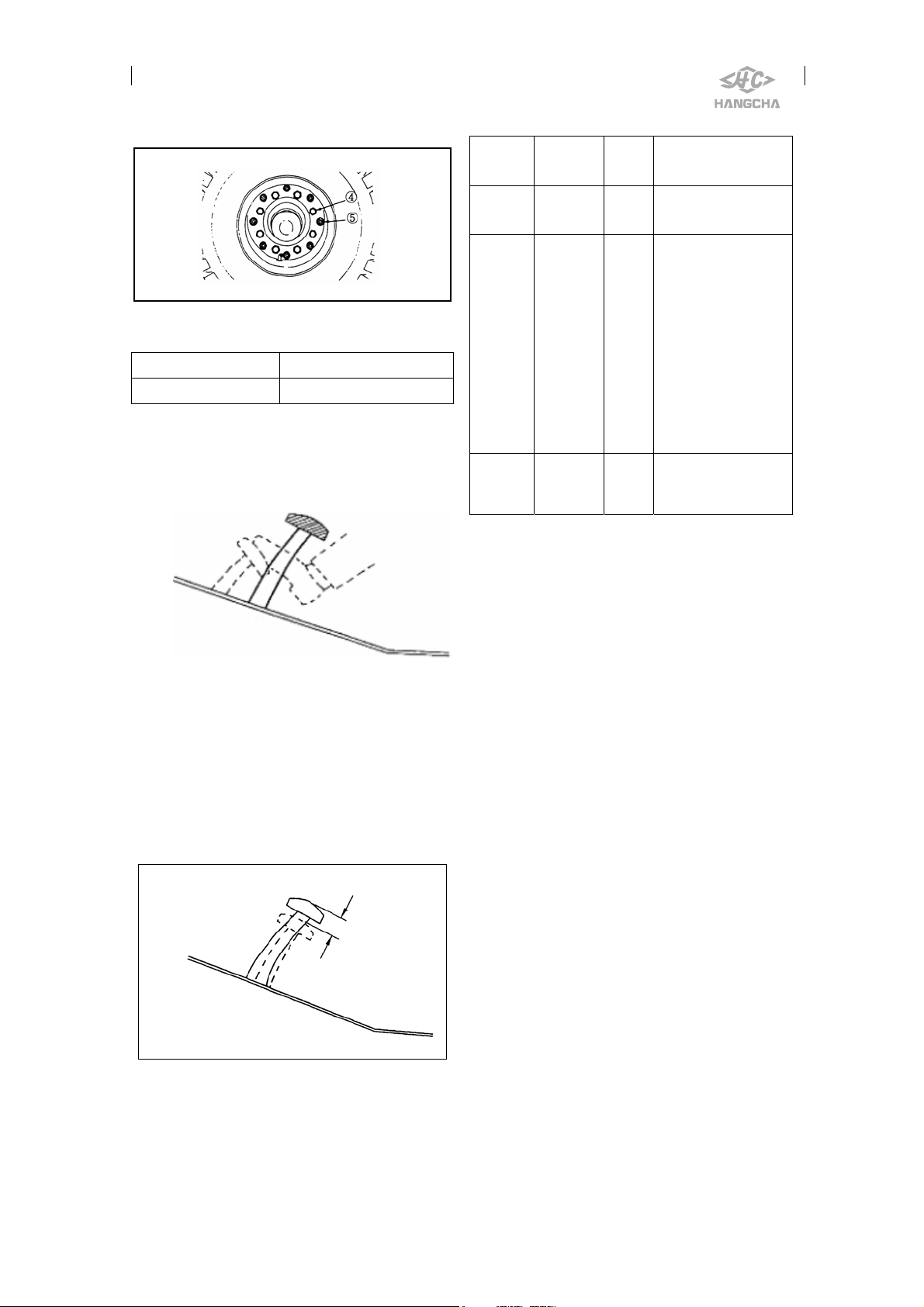

6) Lubrication of mast

Lubrication here on schedule, refers

to figure as below:

23

Mast

Paint lubrication grease on the slide

support.

Note:

a). The periods of paint lubrication

grease depend on the truck’s work

condition. If works heavy, please paint

much more grease on mast.

b). To assort with the truck’s operation,

paint some lubrication grease on the

surface where the idler pulley and inside

and outside masts touchs.

8) Lubrication grease to below parts,

the detail please see <<Lubrication

system drawing >>

(1) mast bear lubricate

(2) Brake pedal(clutch type) lubricate

(3) Inching pedal(tor-con type) lubricate

(4) Steering axle shaft lubricate

(5) Steering knuckle main bearing

lubricate

(6) Steering rod bar pin lubricate

(7) Steering cylinder pin lubricate

9) Bolt, nut tighten

Referrence the <<Maintain cycle chart>>

10) Hub nut torque check

Check hub nuts should be tightened

to the specified torque securely.

Driving wheel (front wheel)

! Caution

△

Paint some lubrication grease; put

the truck stop on a smooth road, engine

flameout and tight hand brake. Prevent

hand or body is clamped, and prevents

falling off from high place. Keep safe.

7) Chain Lubrication

Take one brush with engine oil paint

two sides on chain.

24

A. Hub nut

B. Divided rim bolt (only for 1-1.8 ton)

C. Drive shaft bolt

Specified torque N.m

1-1.8t 2-3.5t

Hub nut 157-176 441-588

–

Turning wheel(rear wheel)

D. Rear hub nut

Specified torque N.m

1-3.5t

Hub nut 157-176

E. Divided rim bolt

11) Brake pedal, inching pedal and

clutch pedal check

Press the brake pedal fully when the

engine is running, the distance between

brake pedal and front soleplate should

be more than 60 mm.

Check the inching pedal and clutch

pedal through the same method.

Height and the free clearance H:

Brake

pedal

Inching

pedal

Clutch

pedal

Notice :QN-RW22A is the shortening of

CPQD20/25/30/35N-RW22A、RW15A is

shorteningCPCD20/25/30/35N-RW15A.

Maintain monthly (180-200 hours)

maintain per week.

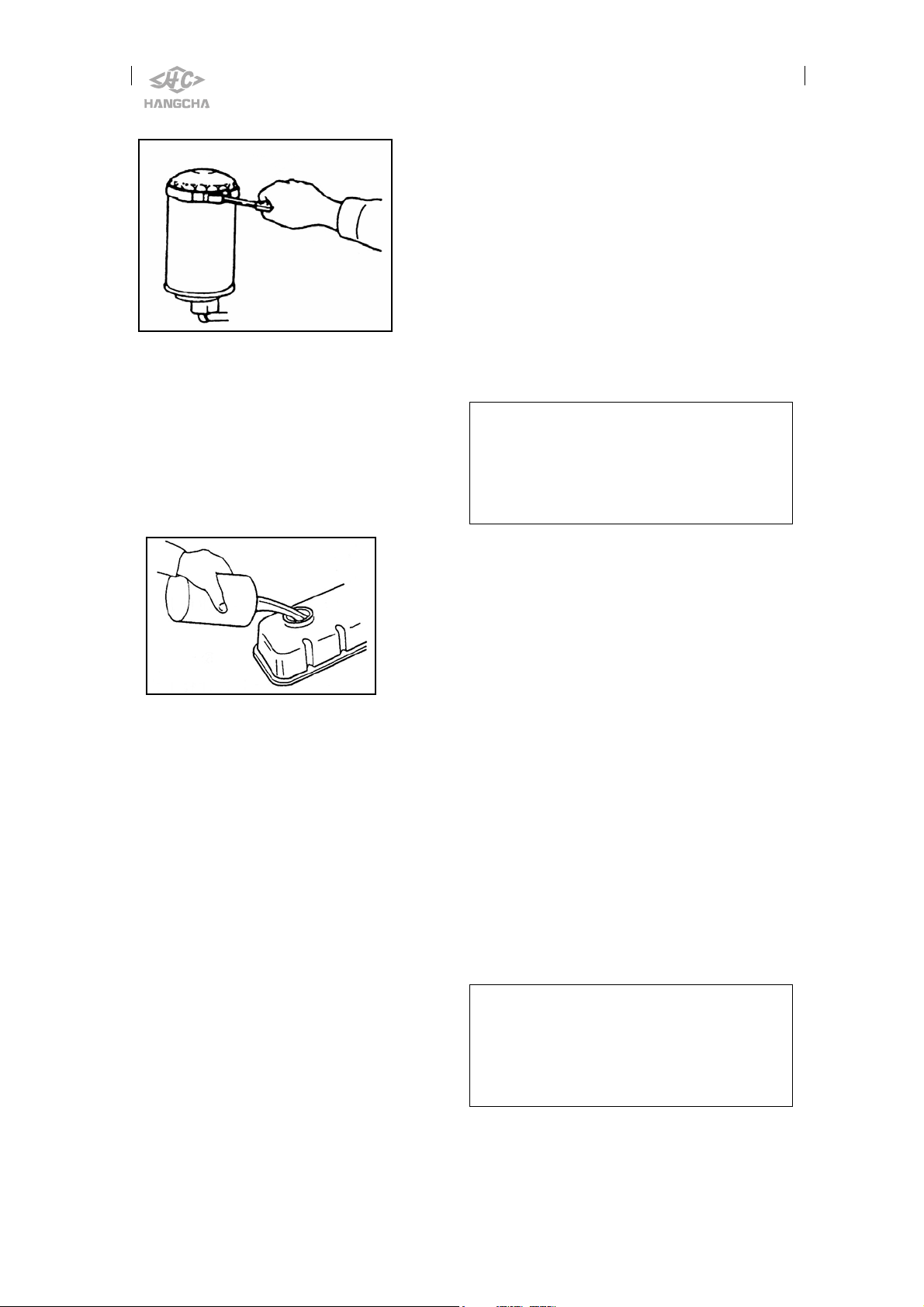

1. Change engine oil and oil filter

1) Start the engine, warm-up enough, then

flameout.

2) Take out the oil cover and bottom shell

to plug, release the oil.

△

cooling fluid in it, find out the reason and

revise.

contains gasoline.

3) Wipe up and fit tuck and gasket.

Screws down moment of oil tuck:

29~39 N·m

Free

height

120-130 ≥60 1-3

120-130 ≥60

120-130 ≥60 2-5

Increase the below content base on

! Caution

Be careful about the hot oil.

·Milky oil shows there is some

·Oil is very rare show that the oil

Press

height

free clearance

touching bolt of

inching pedal

brake pedal:

①0.9-3.4mm

(NRW15A,QNR

W22A)

②0 mm(besides

NRW15A,QNR

W22A)

25

4) Dismantle the oil filter by tool.

5) Use cloth clean the surface of oil

filter.

6) Lay on little oil on the rubber ring of

new oil filter.

7) Install new oil filter by hand,not

spanner.

8)Referrence <<Table for the oil used in

the truck>>,oil preferred.

9)Start the engine,check leak oil around

oil tuck and filter.

If leak obviously,this part is wrong

install.

10) Warm-up engine enough,then

flameout,check oil level later.fill if

need.

Check the oil fluid surface,put the truck

at ground flatly.

2.Plus lubricate to front and rear of

pin roll of Tilt cylinder

Clean the plus place,pile out the past oil.

3.Check the gear oil of drive Axle

housing

If there is more dust at work place, after

200 hours use, it need consider that

change the gear oil of drive axle

housing.

4. Change transmission oil filter

Check the hydraulic transmission oil

fluid, if more dust, change the

hydraulic oil of transmission. It is first

time.

Let the truck at level ground,

play-down the fork to floor, inclined back

the mast, strain brake handle, when

transmission is at neutral position, engine

is cut off.

! Caution

△

Hot hydraulic oil and part will hurt

Body. Do not touch the hot hydraulic

oil and part.

1) Dismantle rubber mat and front

soleplate.

2) Dismantle filter, deal with

located statute.

3) Clean pedestal of filter, confirm

that the old gasket of pedestal have

be cleaned.

4) Plus less hydraulic oil on the new

filter gasket.

5) Install filter by hand. When the

filter get to pedestal, screw down

1/2-3/4 laps.

6)

5.Change hydraulic transmission

oil(first time, then semiannually)

Let the truck at level ground, play-down

the fork to floor, inclined back the mast,

strain brake handle. When transmission is

at neutral position, engine is cutoff.

! Caution

△

Hot hydraulic oil and part will hurt

Body. Do not touch the hot hydraulic

oil and part.

1) Put one case(cubage is over 20 litre)

under the transmission.

2) Dismantle oil tuck,put oil in it.

26

Loading...

Loading...