Hangcha 1-1.5t Service Manual

CPD10/15/18/20/25/30J

CPD10/15/18/20/25/30J D1

CPD10/15/18/20/25/30/35J C1

CPD10/15/18/20/25/30/35J C2

CPD40/45/50J D1

CPD40/45/50J C2

1~5t J Series Counterbalanced Battery Forklift Truck

OPERATION AND MAINTENANCE

MANUAL

Original Instruction

HANGCHA GROUP CO., LTD.

Dec. 2010 5th edition

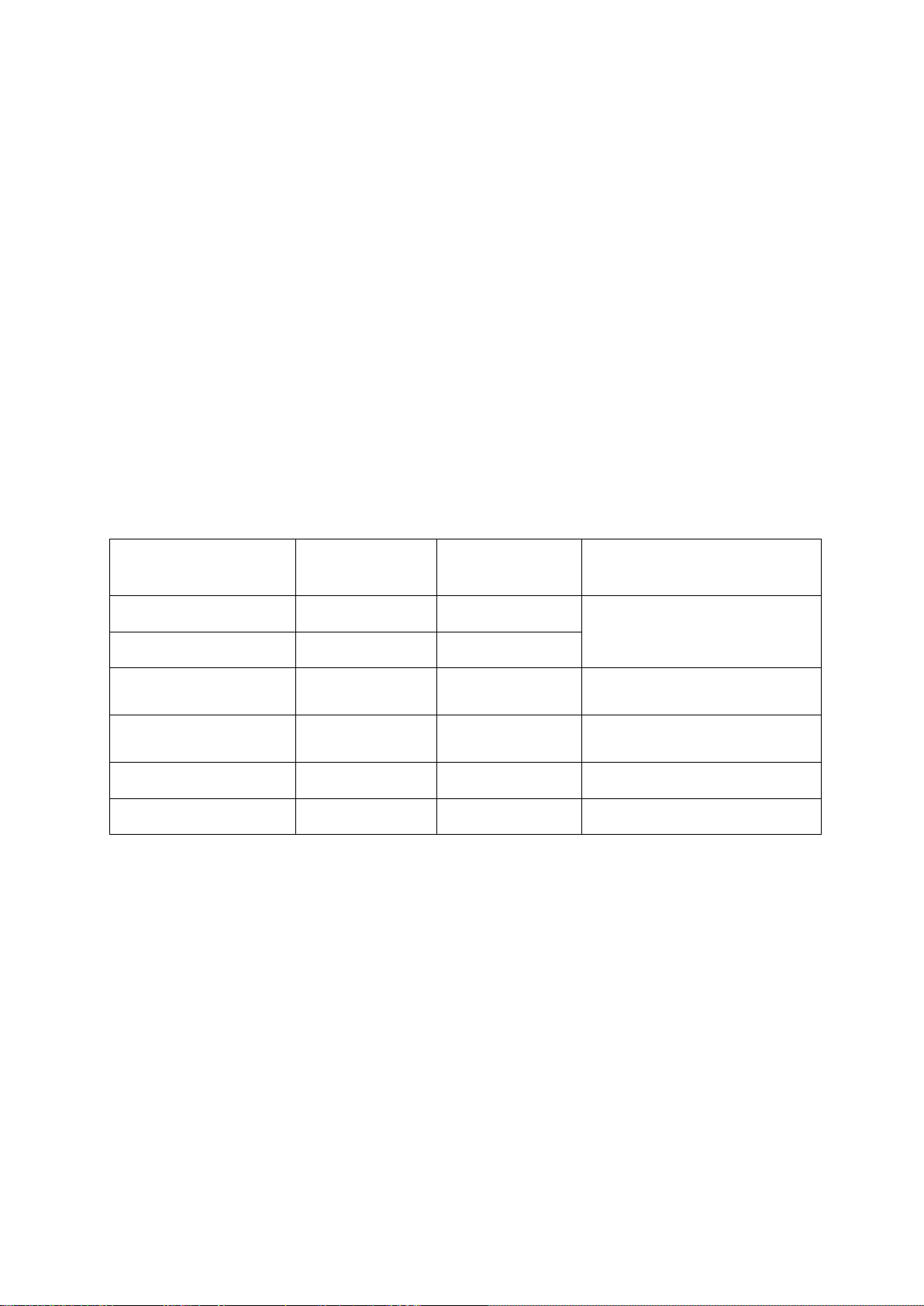

Truck model

Tow electric

control

Rise electric

control

Rated capacity(t)/

load centre distance(mm)

CPD10/15/18/20/25/30J

1244(CURTIS)

EVC255(CURTIS)

1.0/500,1.5/500,1.8/500,2.0/500,

2.5/500,3/500

CPD10/15/18/20/25/30J D1

ACS(Danaher)

ACS((Danaher)

CPD10/15/18/20/25/30/35J C1

1238(CURTIS)

EVC255(CURTIS)

1.0/500,1.5/500,1.8/500,2.0/500,

2.5/500,3/500,3.5/300

CPD10/15/18/20/25/30/35J C2

1238(CURTIS)

1236(CURTIS)

1.0/500,1.5/500,1.8/500,2.0/500,

2.5/500,3/500,3.5/300

CPD40/45/50J D1

ACS(Danaher)

ACS(Danaher)

4.0/500,4.5/500,5.0/500

CPD40/45/50J C2

1238(CURTIS)

1238(CURTIS)

4.0/500,4.5/500,5.0/500

FOREWORD

Thanks for you purchasing our J series battery forklift truck.

Four wheel counterbalanced battery forklift truck is our company‟s new product. It has the character of

small turning radius, beautiful shape, small dimensions, low gravity, good stability, superior performance.

This operation manual is the explanations that how to use 1-5tJ series forklift truck correctly. It will instruct

you how to operate safety and precautionary maintenance. To ensure safety and exert the truck‟s potential,

all the personnel that in charge of operation, maintenance and management must read this manual

thoroughly before starting work with the forklift.

As the improvements of products of our company, maybe there are some differs between this operation

manual with your forklift truck.

If you have any questions please keep touches with HANGCHA GROUP CO., LTD. sales department or

let the agents know.

Dec. 2010 5th edition HANGCHA GROUP CO., LTD.

©

CONTENT

Foreword

1. Name of main parts or component ......................................................................................... 1

2.Instrument and Controls .......................................................................................................... 2

Meter Panel ......................................................................................................................... 3

Controls ............................................................................................................................... 8

3.Body and Others .................................................................................................................... 10

4.Safety instructions ................................................................................................................. 12

5.The structure and stability of truck ....................................................................................... 17

6.Running-in of the new truck .................................................................................................. 20

7.Daily maintenance ................................................................................................................. 21

8.Driving and operation ............................................................................................................ 25

Driving .............................................................................................................................. 25

Traveling ........................................................................................................................... 25

Turning .............................................................................................................................. 25

Stopping or parking ........................................................................................................... 26

Loading .............................................................................................................................. 26

Stacking load ..................................................................................................................... 27

Un-stacking load ............................................................................................................... 27

Check after operation ........................................................................................................ 28

9.Deposit .................................................................................................................................. 29

10.Storage battery ..................................................................................................................... 30

The Automatic Watering System of the Forklift Battery................................................... 38

11.Maintenance summarization ................................................................................................ 42

Preventive maintenance schedule ...................................................................................... 43

Replace the key safe parts termly ...................................................................................... 49

Table for bolt‟s tight torque ............................................................................................... 50

Table for oil used in the truck ............................................................................................ 50

12.Truck‟s convey, lifting, towing ............................................................................................ 51

13.Parameters ........................................................................................................................... 52

14.Scutcheon ............................................................................................................................ 61

15.The use, assembly and safe rules of attachment .................................................................. 66

16.Related safety instruction and standard ............................................................................... 68

17.Maintenance record ............................................................................................................. 70

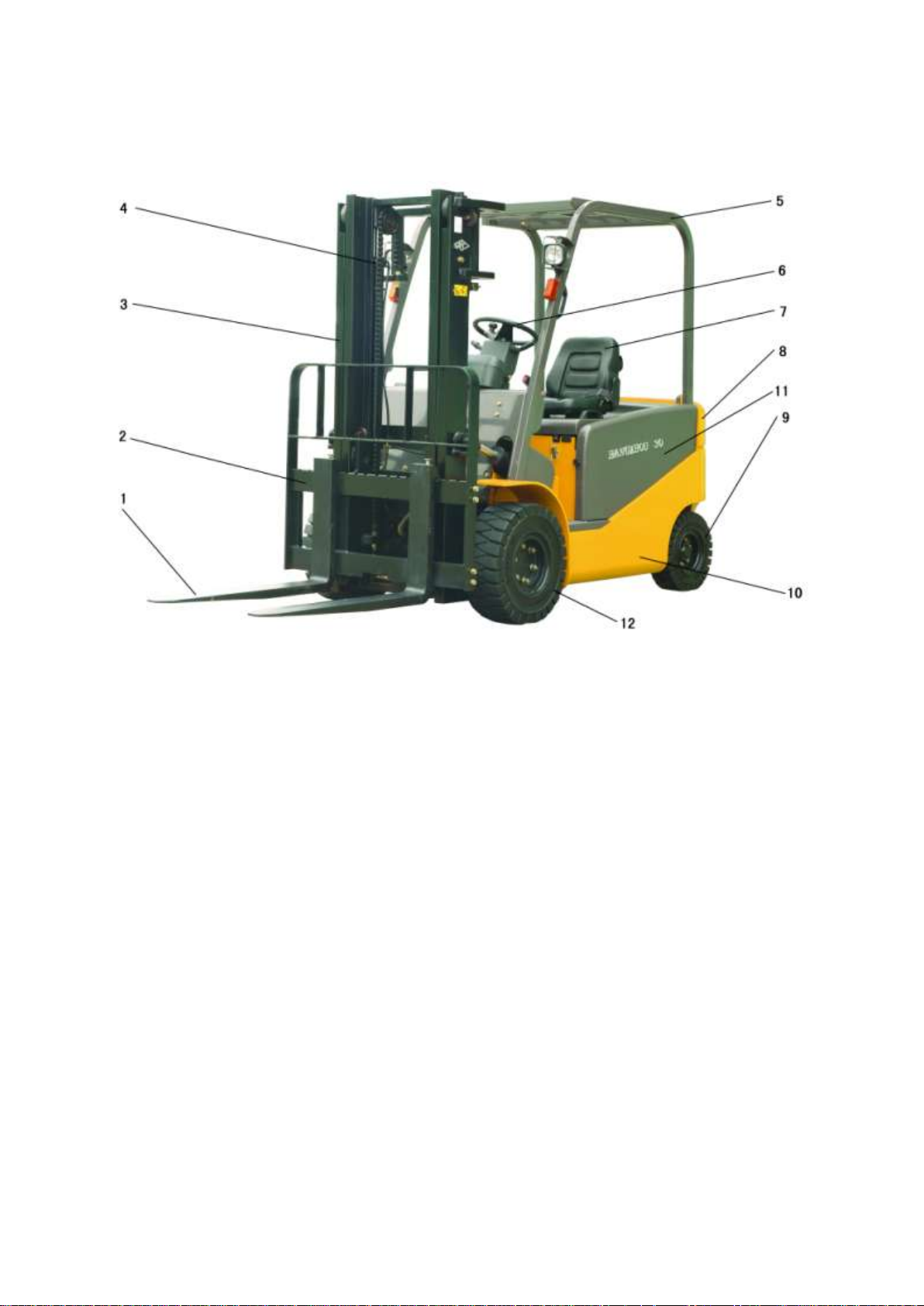

1

1. Fork

2. Fork carriage

3. Mast

4.Lifting cylinder

5. Overhead guard

6.Steering wheel

7. Seat

8. Counterbalance

9. Rear wheel

10. Chassis

11. Left and Right battery

cover hood

12. Front wheel

1. Name of main parts or component

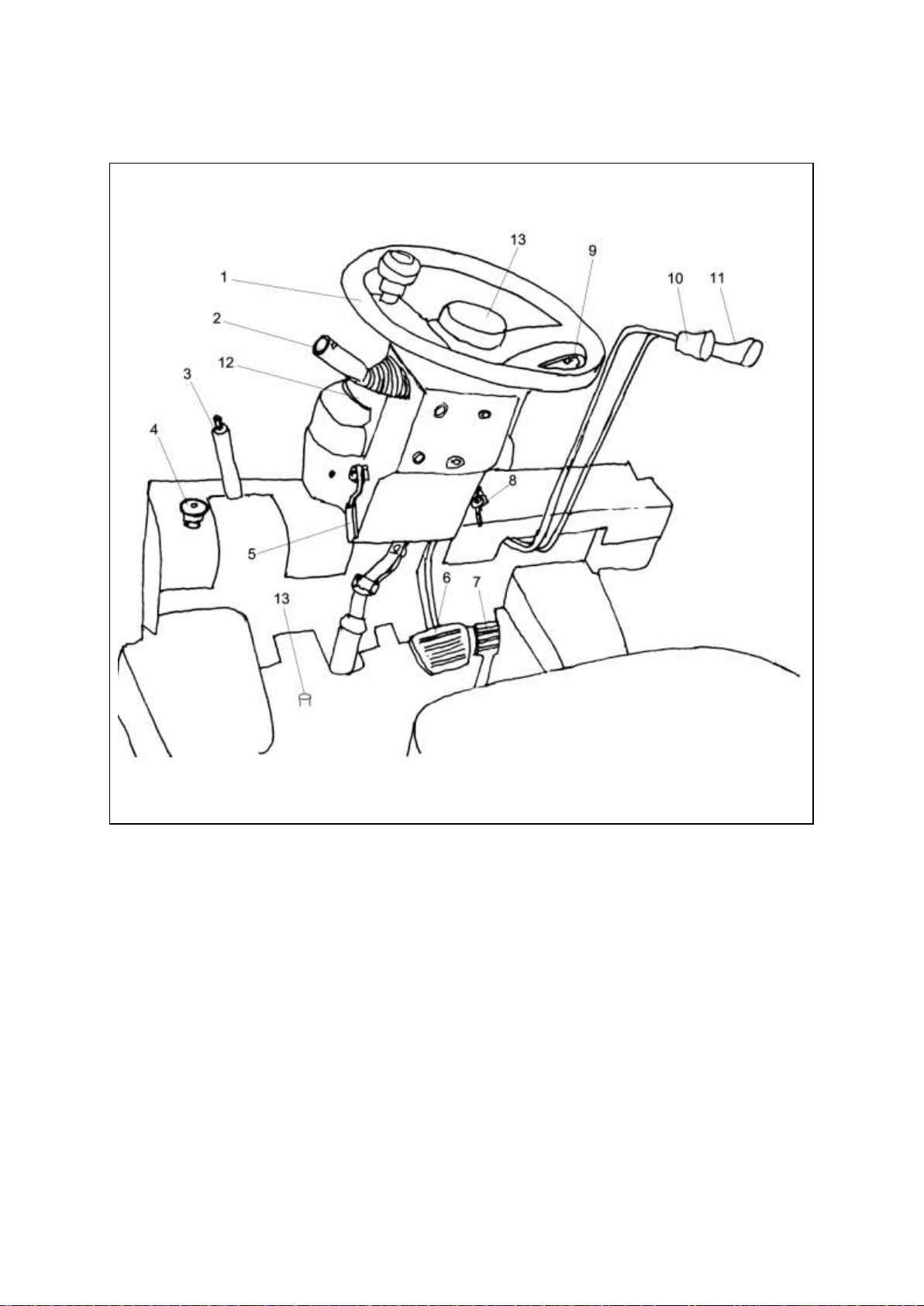

2

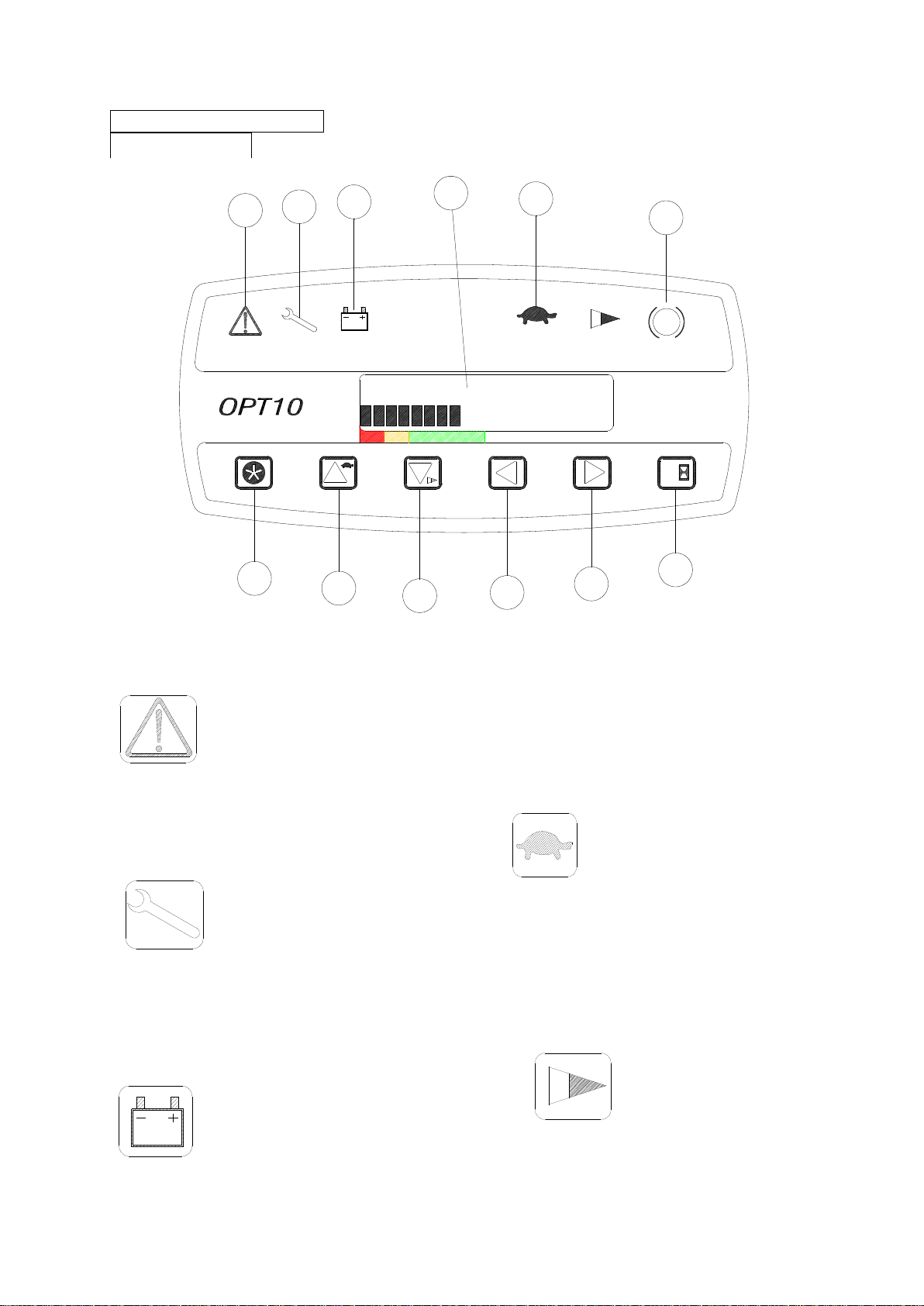

2.Instrument and Controls

1. Steering wheel

2. Direction switches

3. Parking brake lever

4.Emergency disconnect switch

5. Adjusting lever

6. Brake pedal

7. Accelerator

8. Key switch

9.Turning signal switch

10. Lifting lever

11. Tilting lever

12. Meter panel

13. Horn button

3

CPD10/15/18/20/25/30/35JC1

CPD10/15/18/20/25/30/35JC2

Meter Panel

CPD10/15/18/20/25/30J

CPD40/45/50J C2

A、Battery warning

As the following diagram shows, from

the left to the right, the battery decreases

from full state to the only one case, which

represents that the battery leaves only 20%.

Thus the whole battery indicator bar will

twinkle, and the state indicator lamp will be

bright, now please stop working and charge

immediately.

gradient and so on is much higher. It is

applied for transporting mass of good in

short time and climbing big gradient slop,

but it costs more energy,so the mode will not be

used in normal state except emergency.

Mode P is power mode. All kinds of

index are lower than that of super mode. It is

applied for the case of long distance

transporting and needing higher power or

speed.

Mode E is economical mode. All the

parameters are optimized. Working in this

mode can save power so it is applied for a

long time work after charging, and it is

suggested to work in this mode in normal

work-time.

Mode SPE is safe mode. Thus the max

vehicle speed is limited to about 7km/h. It is

applied for working in busy storage and

cabined room.

Notice: the default mode is mode E. after

power cutting every time, the work mode

resets to mode E no matter which mode it is

before power cutting, but the switch key is

still in the mode before turn off.

The mode can be switched through the

mode switch button (G) among the mode of

S, P, E, SPE, as the above diagram shows.

C、Parking brake indicator lamp

Notice:Charging in time is very important,

otherwise it will affect the lift-span of

battery!

B、Mode indication

When using the parking brake, the lamp will

As the diagram shows, the pictures

be bright.

from the left to the right represent the mode

of S, P, E, SPE respectively;

Mode S is super mode, thus the truck‟s

D、State indicator lamp

acceleration, deceleration rate, max climbing

4

When there is something wrong with

the electrical controller, or operate

improperly, the battery is in lower power,

the lamp will be bright and twinkles.

E、Error code display area

Display the error code of electrical

controller.

Notice:“TRAVEL” is the error code of tow

electrical controller, “HYD” is the error

code of pump controller. “TRAVEL OK”

means it works without error。

Notice: the error code of tow electrical

controller refers to the appendix.

F、Work-time accumulate timer

When the truck key switch turns on, the

left hour timer will start to time. The

minimal resolution is 10% of an hour, the

other two hour timers are not used.

5

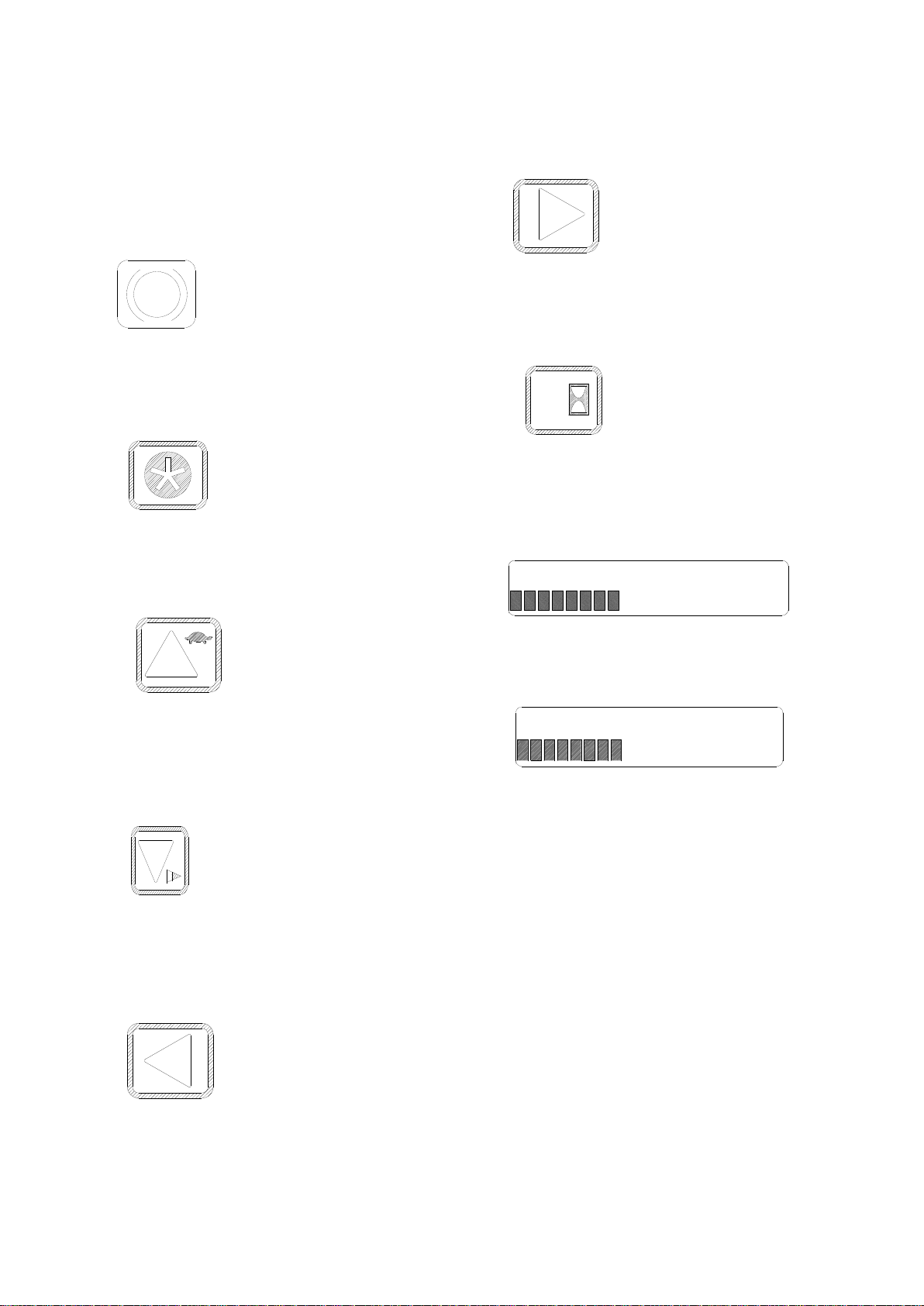

CPD10/15/20/25/30/35J D1

S P E E

D

1

B

AT%

8

2

k

m

/

h

0

P

1

2

3

4

5

A

B

C

D

F

G

H

I

J

K

L

M

CPD40/45/50J D1

The meanings of 6 indicators:

Communicate indicator (A)

Only lights on when record program,

usually it is no use.

Error indicator (B)

When operation is wrong or the truck is

in trouble, error code will display on the

dashboard. The error indicator lights on.

Low battery warning (C)

When battery quantity is lower than 20%

of maximum capacity, the indicator lights

are on, at the same time, buzzer beep.

When LED shows no power, please

charge battery as quick as possible.

Speed limited indicator (D)

When this lamp lights, it meanings the

truck working at low speed mode. The

maximum speed of truck decreased.

Press button 1, you can switch the high

speed and low speed mode.

6

P

1

2

3

4

5

Y

K

E

8

T

B

A

%

N

O

0

T

H

IME

2

8

T

R

H

%

A

B

T

E

C

A

T

T

I

M

1

8

0

8

Accelerate indicator (E)

When this lamp lights on, it means the

truck working at low acceleration mode.

The maximum acceleration decreased.

Press button 2, you can switch the high

acceleration and low acceleration mode.

Parking brake indicator (F)

When pulling on the parking brake lever,

this lamp lights on.

Entrance button (G)

Backup button (J)

This button is no use for operator.

Backup button (K)

This button is no use for operator

Switch button of hour indication(L)

Push this button, it will display the total

hours of truck, as follow figure:

This button is no use for operator.

Speed limited button (H)

Press this button to switch the high speed

and low speed.

Accelerator limited button (I)

Press this button to switch the high

acceleration and low acceleration.

Push again, it switch to the total traction

hour.

Push the button once again, it switch to

speed display mode.

Dashboard display LED (M)

When turn on the key switch, the system

will self-diagnose, the lamp will lights on

one by one. After self-diagnose, LED

will display truck speed and battery

capacity. You can know your truck‟s

working condition through the LED

dashboard.

Key switch

The key switch has two “on/ off”

position, you should push the Direction

switch lever to neutral and loose the

accelerator pedal, then turning the key

switch to “on” position clockwise.

7

Caution!

1. Turning the key switch “on” does not

make the forklift truck move, if the

Direction switch lever is not in the neutral

position or the accelerator pedal is pushing.

2. Error code maybe appear, don‟t worry

about it.

3. The Direction switch lever should be

returned to neutral and move you foot from

the accelerator pedal. Then the truck can be

operated.

4. Then the error code should be

disappeared.

Forward

Left turning lamp flashes

Neutral

Lamp goes off

Backward

Right turning lamp flashes

Connector

Position

battery

Far light

0 × 1 ×

×

Rear big lamp switch (optional)

Rear big lamp switch (push\pull) has

only one shift.

× Means connected

Caution!

This light does not relate to key switch

position, so please don‟t forget to turn off

the rear big lamp when you leave the

truck.

Horn button [13]

Press the rubber cover at the center of

steering wheel to sound horn. The horn

sounds even when the key switch is in

the “off” position.

Combined light switch [9]

This combined light switch is composed

of turning light switch and big/small

lamp switch. Turning light indicates the

traveling direction. When turn on the

switch, the lamp flashes.

Caution!

The turn signal lever does not

automatically return to the neutral

position. Reset it by your hand.

Big/small lamp switch has two shifts.

First shift small lamp lights on; second

shift big and small lamp both light up.

Emergency disconnect switch [4]

When happen emergency, presses down

the emergency disconnect switch, and

then the main power of the truck will be

cut off, the truck stops working.

Caution!

Please don‟t use the emergency

disconnect switch to substitute the

function of key switch.

Fuse box

J\JC1\JC2 Series

1st is a diode preventing from connecting

in reverse.

2nd is a control circuit fuse (10A).

3rd and 4th are fuses for light and horn

circuit. (10A respectively)

5th is light fuse 10A.

6th is spare fuse 10A.

JD1 系列

1st is control circuit10A.

2nd is main contact circuit fuse 10A.

3rd is instrument fuse 10A.

4th and 5th is light fuse 10A.

6th is spare fuse 10A.

Caution!

When replace a new fuse, please choose the

same capacity fuse of the old one.

8

Controls

Steering wheel [1]

The steering hand-wheel is operated

in the conventional manner, that is, when

the wheel is turn right, the truck will turn

to the right; when the wheel is turn left,

the truck will turn to the left. The steer

wheels are located at the rear of the truck.

These cause the rear of the truck to swing

out when a turn is made.

Warning!

This truck is provided with the

power steering, so heavy hand-wheel

operation is caused when the steering

motor comes to a stall. To put the power

steering in operation again, restart the

steering motor without delay.

Parking brake lever [3]

pressed, the forklift trucks moved

forward. When the lever is pushed

backward, the forklift trucks moved

backward.

Caution!

While traveling, if change the

Forward- Reverse lever, electric braking

will operate,speed will lower until stop,

then travel to the opposite direction.

Warning!

Turning the key switch “on” does not

make the forklift truck move, if the

Forward-Reverse lever is not in the

neutral position or the accelerator pedal

is being pressed. In this case, the

Forward-Reverse lever should be

returned to neutral and move you foot

from the accelerator pedal. Then the

truck can be operated.

Use this parking brake lever to park

the lift truck. And the parking brakes are

applied on the front two wheels by

pulling up on this lever. To release the

parking brakes, move the lever forwards.

There is a micro switch at the left

side of the parking brake lever, tense the

lever makes running invalid.

For the truck of CE: if you leave the seat

without tensing the lever, it will warn and

remind you to tense the lever.

Warning!

If parking on a grade is unavoidable, be sure to

block the wheel.

Forward-reverse lever [2]

The forward-reverse lever is used for

switching between forward and

backward moves. When the lever is

pushed forward and accelerator pedal

Lifting lever [10]

The forks can be raised or fell by

pulling backwards or pushing the lever.

Lifting speed can be controlled by tilt

backwards angle of lever and the

lowering speed can be controlled by tilt

forwards angle of the lever.

9

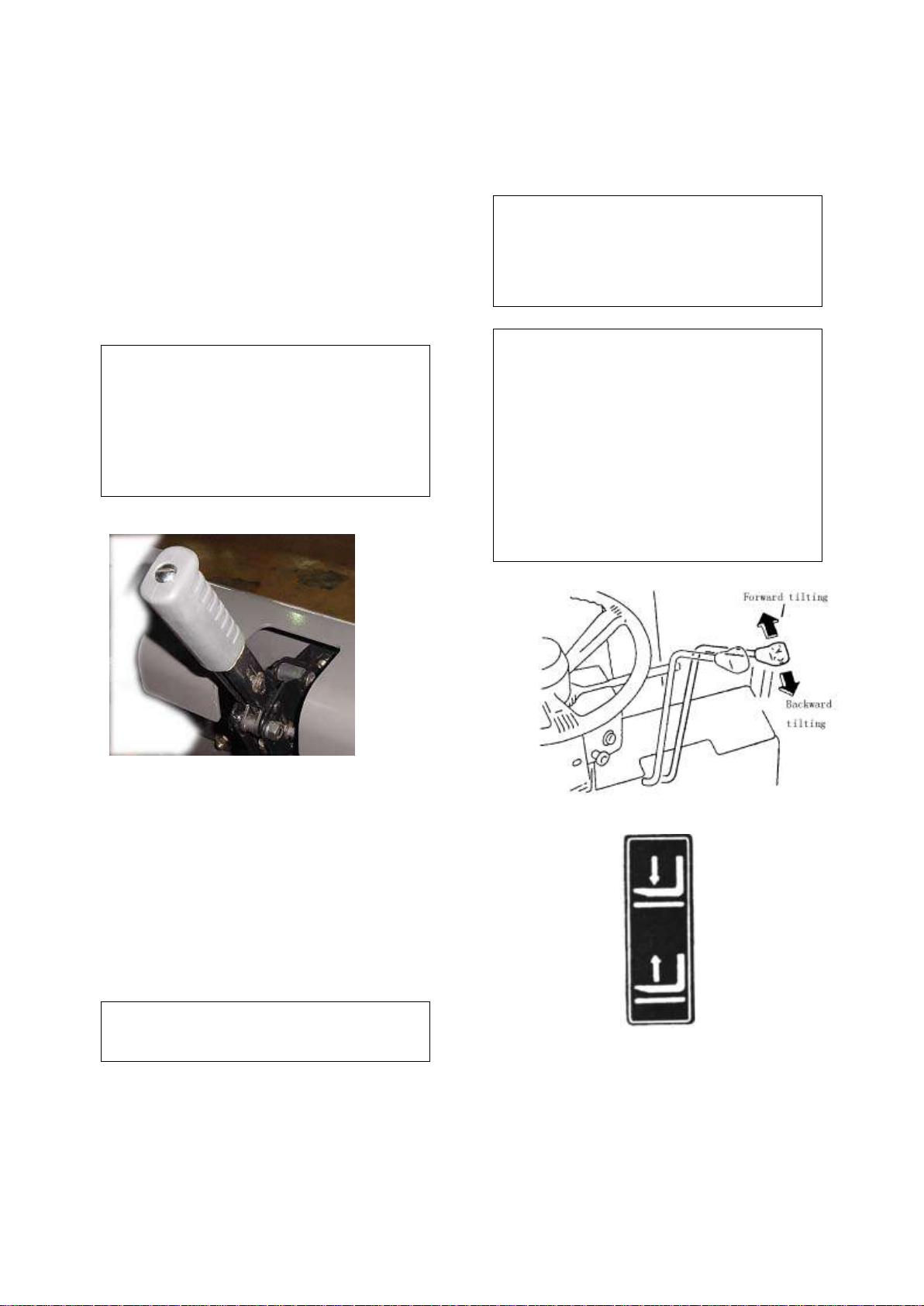

Tilting lever [11]

The mast can be tilted by operation

of this tilt lever. Pulling on this lever

backwards will tilt the mast backwards,

and pushing it forwards will tilt the mast

forwards. The tilt speed can be controlled

by tilt angle of the lever.

Caution!

The tilt lock mechanism built in the

hydraulic control valve does not allow

the mast to tilt forwards while the

electricity is being shut down even if the

tilt lever is pushed forwards.

Pedals

Brake pedal [6]

Press this pedal to slow or stop the

truck. At the same time, the brake light

comes on.

Caution!

No permitted to press the brake pedal and

the accelerator pedal at same time,

otherwise, it is harmful to the traveling

motor.

Accelerator pedal [7]

As the accelerator pedal is slowly

pressed, the drive motor start turning and

the forklift truck will start to move.

According to the force applied to the

pedal, the speed is adjusted with not

steps.

Warning!

Before open the key switch to press

the accelerator pedal, the more function

digital indicator shall show alarm

information. Then you must release the

accelerator pedal.

Caution!

Loosen the accelerator pedal when truck

is working, truck can make soft brake

10

3.Body and Others

Seat

Adjust operator‟ seat to the position

where is comfortable for you and

provides easy controls. Before

proceeding with work, adjust operator‟s

seat and make sure that it is securely

locked. Adjust the operator‟ weight

through rock- suspends system level. The

rear of the seat is adjustable.

Seat switch (only for trucks exporting

to Europe or option)

For the safe of truck, when you leave

the seat longer than 5 seconds, the truck

will stop traveling.

Safety belt

Please keep back and waist close to

seat as far as possible, and fix safety belt

at the same time.

Inspect whether bolts fixed belt are

loose or not. Do not use belt with a knot.

Do not make belt press on stiff or fragile

things, and do not make belt attrite with

sharp things to avoid wearing. Do not

make seat backrest too be tilted;

otherwise safety belt may not extend

correctly.

Do not remove any part of belt at

will. Please often inspect the belt used

frequently, if found any abnormal,

replace it at once. And the life for use is

3-5 years, scrap it ahead of schedule if

found any abnormal.

There is a safety belt on the seat,

before you operate the forklift truck,

please fasten the seat belt to protect

yourself.

Overhead safe guard

The overhead guard used is strong

enough to meet safety standard, and

protects the operator from falling

materials. The top gap is used to lift the

batteries. It is forbidden for use a truck

that does not with safeguard.

Hood

The hood can be swung up fully to

provide easy examining and maintenance of

the storage batteries.

You can lift up the hood with little

effort with an aid of hood damper. To

lock the hood, push down on the front of

hood until it covered.

Caution!

Be careful do not to catch you fingers in

the hood when closing it.

Depress the spring insurance before you close

the hood, then press the head of the hood.

Left & Right battery cover hood

The battery is covered hood, one left

and one right. When you want to take off

the hood, you should take off the knob at

first.

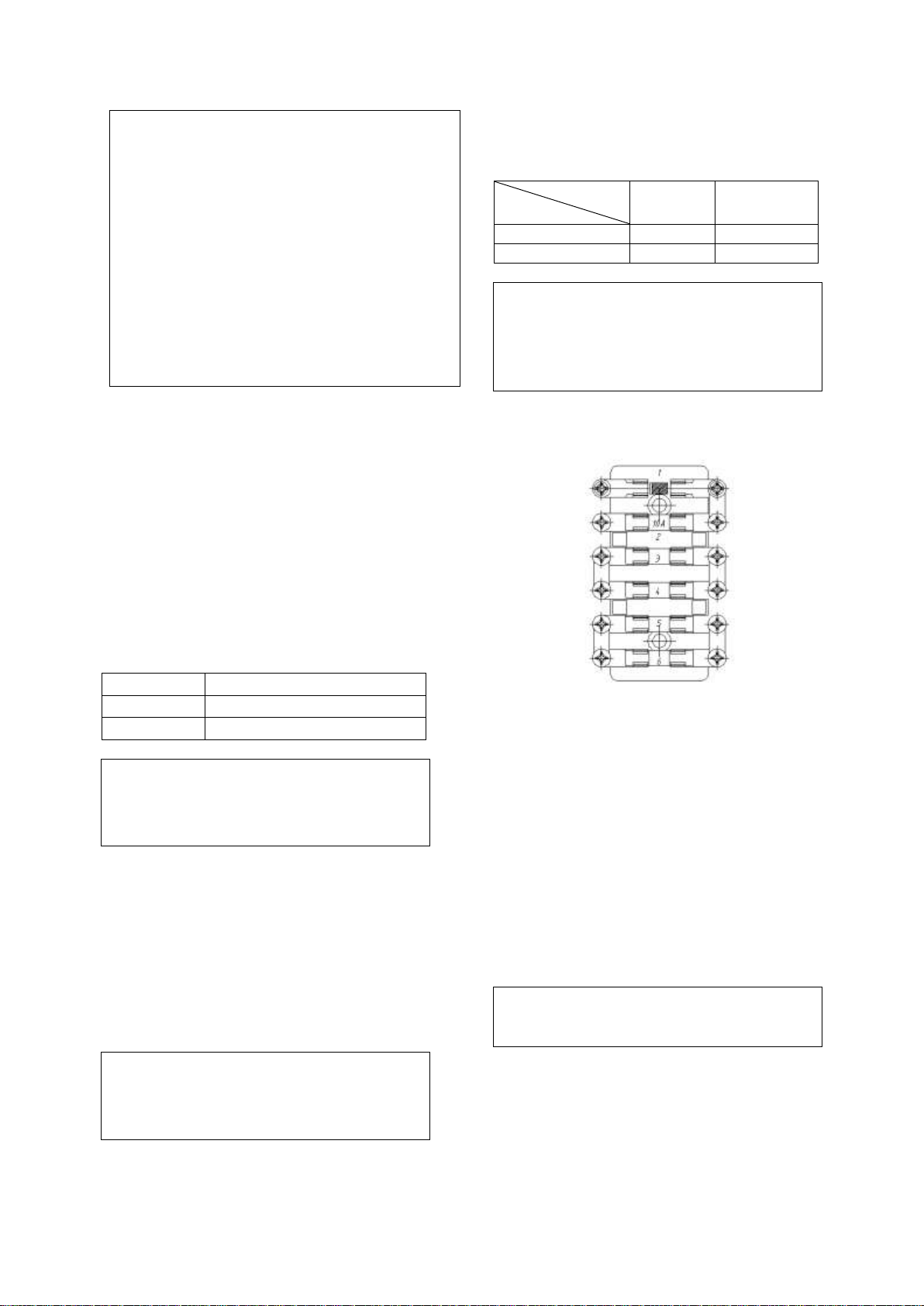

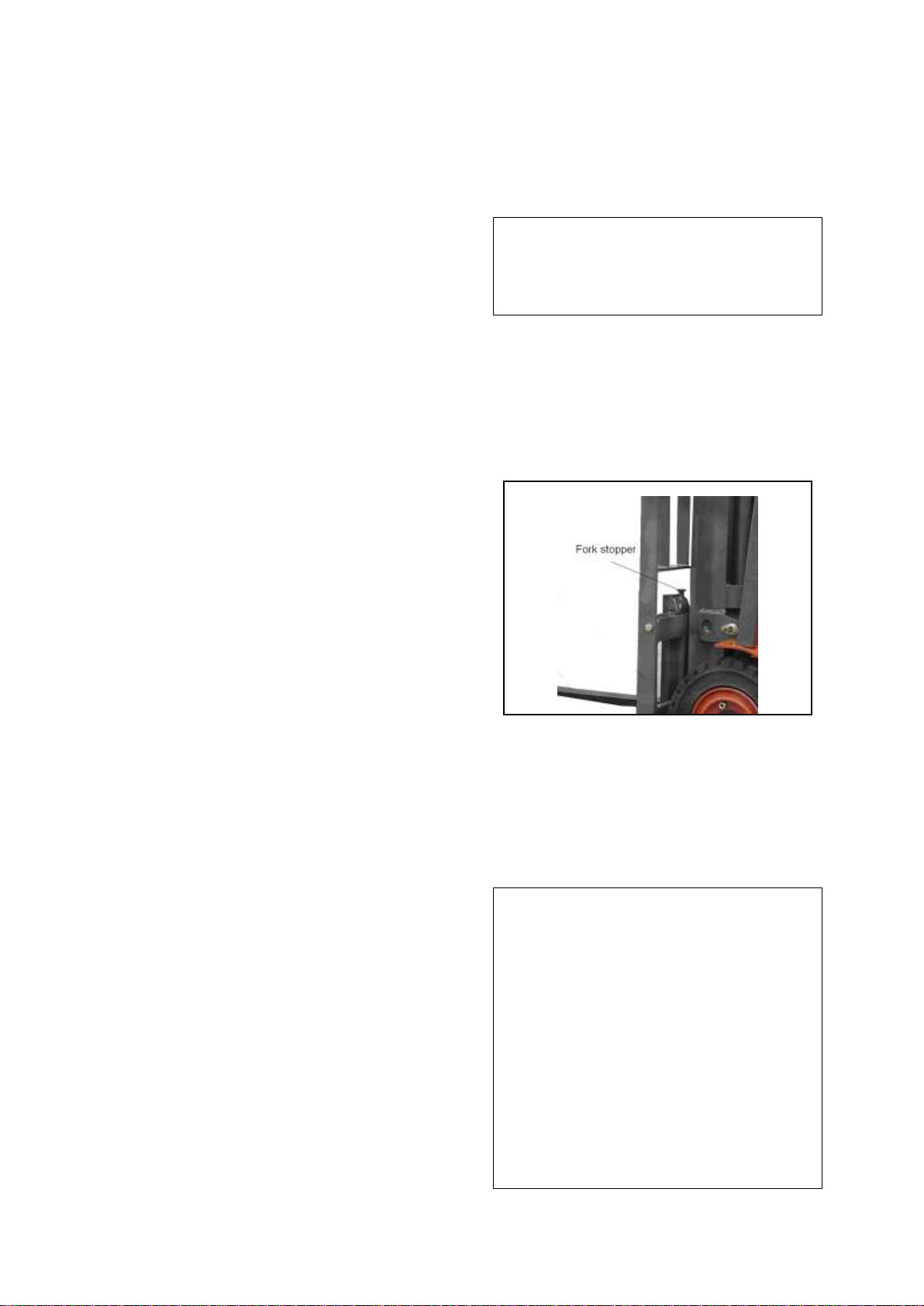

Fork stopper

Fork stoppers are locked the forks in

position. To adjust fork spacing, pull up

fork stoppers, turn 90°and shift the forks

to the desired position. The fork spacing

should be adjusting according to loads to

be handled.

Warning!

The forks should be set

symmetrically to machine centerline and

fork stoppers should always be locked

again.

There are one gap on the below

beam. It is used to attach goods.

It is forbidden to lock the fork on the gap

position, to prevent the fork fall off from

the gap.

In the middle of the above beam, a

bolt used to prevent fork works here.

Please change the bolt as soon as it is

damaged.

11

Change fork

Take down the old fork: Firstly,

locate the fork to the middle, decline it to

the ground and make the mast forward,

then operate the truck traveling backward,

the fork will be taken down.

Change new fork: Firstly, make the

fork dead against the truck and forklift‟s

mast to the bottom, then operate the truck

traveling forward, aim at the two gaps

and beams, and raise the mast. Adjust the

position of the fork.

Safety step and safety grip

The safely steps are provided on

both side of the truck body. The safely

grip is provided on the front left pillar of

the overhead guard. Use the safely step

and safely grip when mounting and

dismounting the truck.

Brake fluid reservoir cup

The brake fluid reservoir cup is

located at the meter board.

Caution!

The brake fluid is poisonous, be

careful do not drop down. When add

brake fluid, be careful do not let dirt and

other thing drop into reservoir cup.

Head lights and combination lights

Two headlights and combination

lights (turn signal, show width lamp) are

installed at the front side of the truck.

Take care of the lights, and wipe dirt, if

any, and replace any damaged light

immediately.

Rear combination lights

The combination lights at the rear

side serve as turn signal, show width

lamp, brake lamp, and back-up lamp. Pay

attention to keep them from being

damaged or covered with dust, if any,

clean or replace immediately.

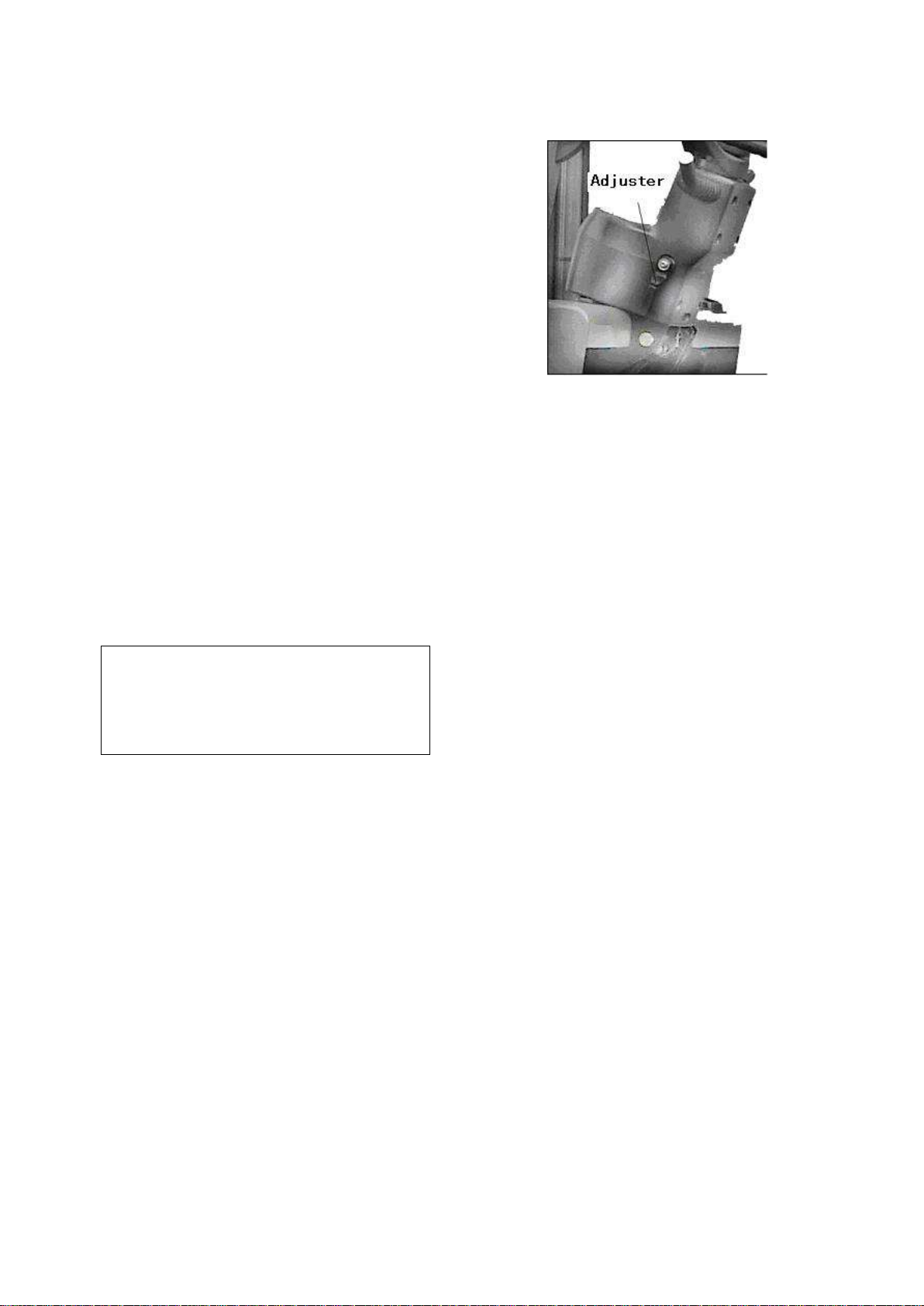

Steering column tilting angle adjuster

The tilting angle of the steering

column is adjustable to suit individual

operators. Turn the hand lever upward to

release the steering column and locked

by turning it downward.

Hydraulic oil reservoir cap

The hydraulic oil reservoir cap is

located at the right rear end, below the

battery hood; open the right side battery

hood when adding oil. After fill in clean

hydraulic fluid, tighten lock the cap.

Air leakage plug

There is an air leakage plug on the

oil tank to let air in the tank goes out.

You‟d better often check the plug and see

whether been jammed.

Chair disconnecting switch

When the operator leaves seat, this

switch cut off, and the power of truck is

cut off.

Safety seat belt (for the trucks

exporting to Europe or option)

There is a safety belt on the seat,

before you operate the forklift truck,

please fasten the seat belt to protect

yourself.

Rear big lamp (for the trucks

exporting to Europe or option)

The rear big lamp is set on the

safeguard. If it is broken, please replace a

new one at once.

12

4.Safety instructions

1. Only trained and authorized

operator shall be permitted to operate the

truck.

2. Inspect the truck at periodic

intervals for oil or water leak,

deformation, lousiness, etc. If neglected,

short life of components will be caused

and in the worst case a fatal accident

would occur.

·make sure having replaced good

parts during periodic check.

·Wipe off oil, grease or water from the

floor board and foot and hand controls, if

any.

·Strictly prohibit smoking and spark

nearby the storage battery when checking

it.

· If maintenance on high position,

such as mast, front and rear lamp, please

be careful to prevent fall down or be

clamped.

·Be careful do not be scalded when

inspect the motor, controller and etc.

3·whatsoever in trouble, you must

stop the forklift, hang a mark of “danger”

or “trouble” and take off the key, at the

same time inform the manager. Only

after the trouble is removed, you may use

the forklift.

·If trouble occurs when lifting cargo,

to Climb or descend, or the storage

battery electrolyte, the hydraulic fluid,

the brake fluid has the revelation, please

organizes the personnel to repair

immediately.

4. Operator must wear helmet, safety

shoes and work clothes.

5. Because there will bring

exploding gas in the bosom of the battery,

prohibit any flame nearby it absolutely.

·Do not let any tools close the two

terminal of the battery to avoid spark or

short circuit.

6. The movement road of forklift

should be solid and smooth coagulation

road or similar to the road suitable for

vehicle. Recheck the state of working

ground.

The considered climatic conditions

when the forklift designs are:

Temperature - 20℃-50℃; the wind

speed does not surpass 5m/s; the air

relative humidity is not bigger than 90%

(temperature 20℃). The forklift is not

suitable in the flammable explosive

working conditions.

7. Never mount or dismount the

moving truck. Use the safety step(s) and

safety grip facing the truck when

mounting or dismounting the truck.

13

8. Never attempt to work the

controls unless properly seated.

Before starting, adjust the seat so

you can get easy access to all hand and

foot control.

9. Before starting up, make sure that:

·Please fasten seat bolts.

·The parking brake lever is applied

securely.

·The forward-reverse lever is in

neutral.

·Before staring, make sure no one is

under, on and close to the truck.

·Don‟t step the accelerate pedal or

control the lifting lever or tilting lever

before turning on power.

10. Operate the controls smoothly.

Avoid sudden stops or turns.

· It is dangerous to make a sharp

brake. Otherwise the truck has the

possibility of overturn.

11. Pay attention to the route of the

truck; be sure to make a wide sight.

12. Never allow other person(s) to

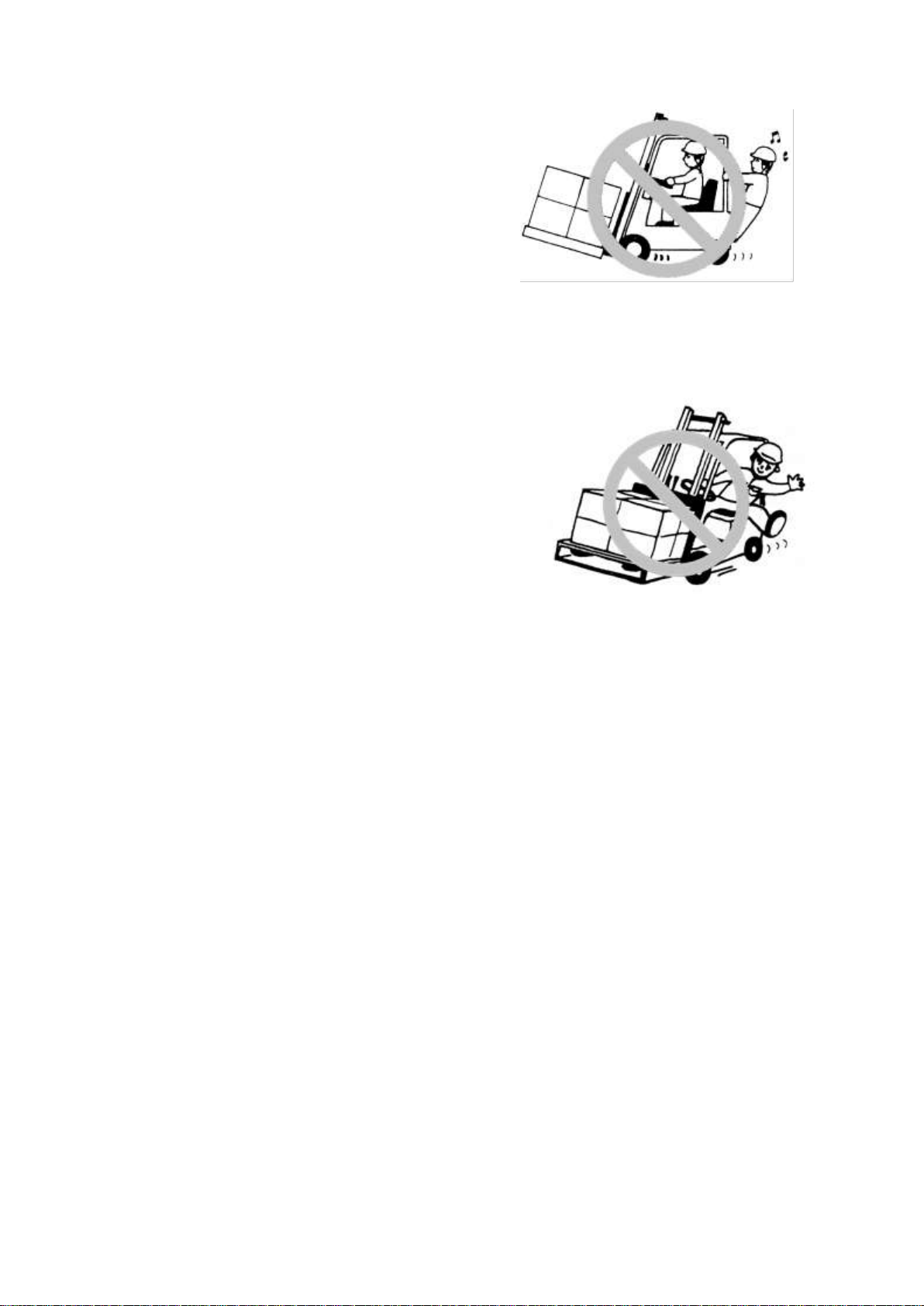

ride on the forks, pallets or on the truck.

13. Taking account of the shape and

material of loads to be handled, use a

proper attachment and tools.

·Avoid hoisting the load, with wire

rope hung on the forks or attachment,

since the wire rope may slide off. If

needed, a qualified personnel for slinging

operation should perform, making use of

a hook or crane arm attachment.

·Take care not to protrude the forks

out of the load. The protruded fork tips

may damage or turn over the adjacent

load.

14. Know the rated capacity of your

lift truck and its attachment, if any, and

never exceed it.

·Do not use a man as an additional

counterweight. It‟s quite dangerous.

15. Keep your mind on your work.

16. Keep your head, hands, arms,

feet and legs within the confines of the

operator‟s compartment. Never stretch

out for any reason.

17. The pallet and skid used should

be strong enough to endure the load.

Never use damaged or deformed ones.

18. We afford all type of attachment,

such as rotating roll clamp, bale clamp,

side shifter, and crane jib etc. You should

refit the truck under ours license if you

want. It is forbidden to refit it by

yourself.

19. Safeguard protect you do not be

hurt by the goods fallen. Load bracket

protect you load goods smoothly. It is

forbidden to use truck without safeguard

or load bracket.

20. It is forbidden to walk down the

fork or the attachment.

·It is forbidden to walk up the fork or

stand on the fork.

14

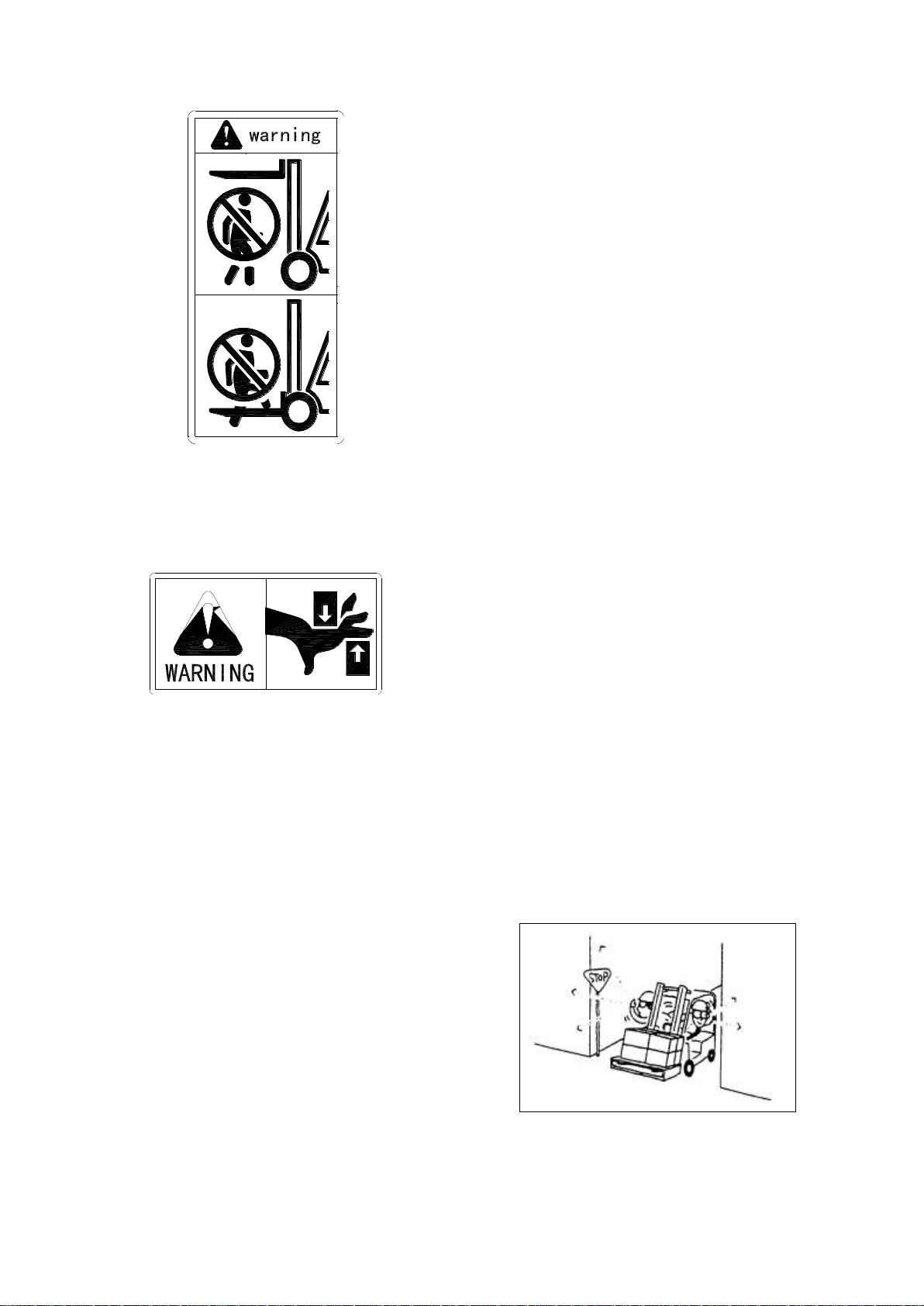

21. It is forbidden to put your hands,

arms or head stretch between the mast

and safeguard. Once clamped, the life

has danger.

·It is forbidden to put your hands in

inner and outer mast.

22. The goods is liable to drop

turning or passing rough road when it

departures the center. And the forklift

may turn over more probably.

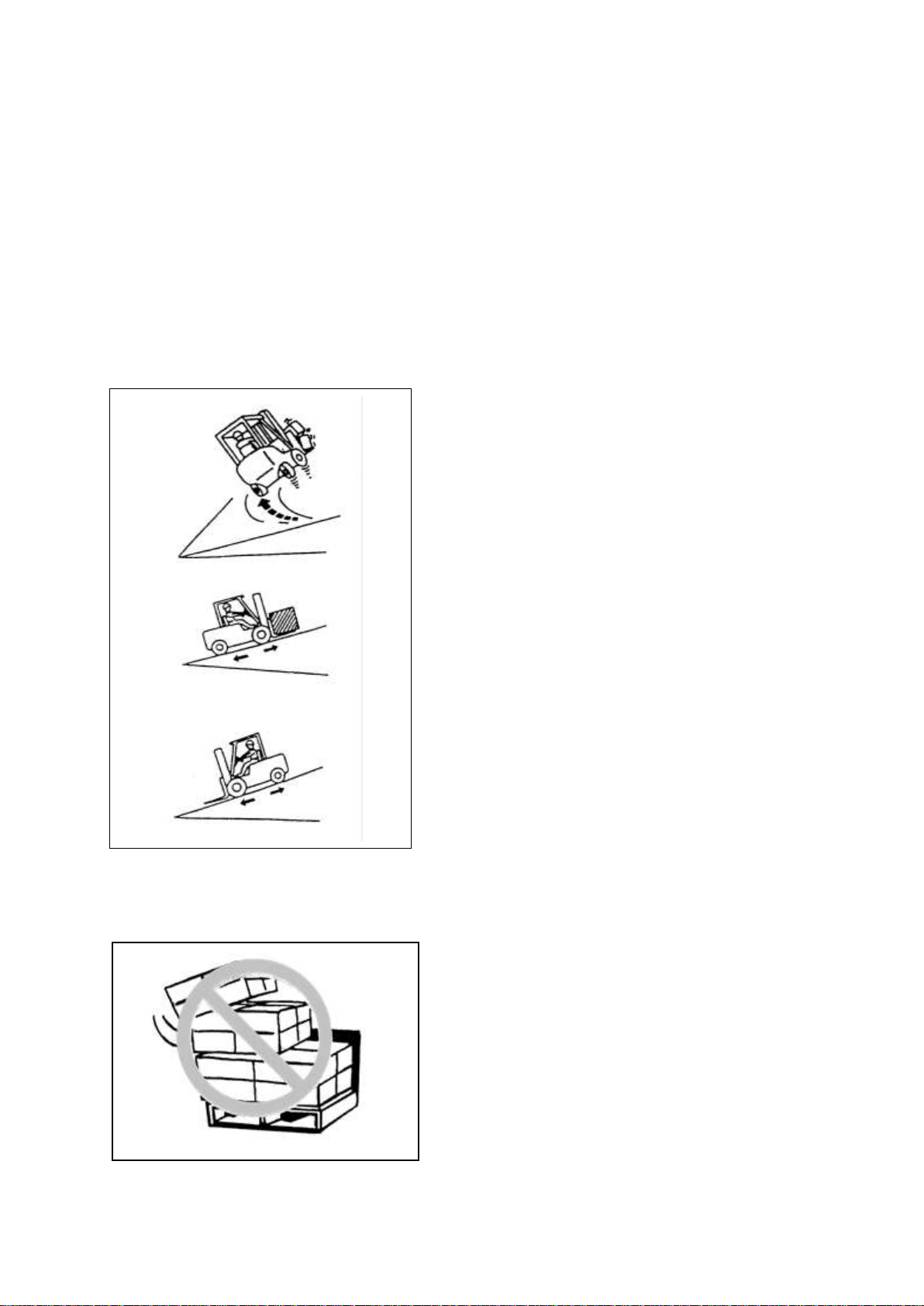

23. Don‟t stack loads on forks in

such a way that the top of loads exceeds

the load backrest height. If unavoidable,

make sure the load is fastened. When

handling bulky loads that restrict your

vision operate the truck in reverse or

have a guide. When lead by a guide,

make sure you understand hand, flag,

whistle or other signals. When handling

long loads such as pipe, lumber etc or in

the case of the Large-sized model, or

operate with long attachment, be

extremely careful of load end swing at

corners or in narrow aisles. Be alert for

others.

24. Use minimum forward and

reverse tilt when stacking and

un-stacking loads. Never tilt forward

unless load is over stack or at low lift

height.

· When stacking loads on a high

place, once make the mast vertical at a

height of 15 to 20 cm above the ground

and then lift the load farther. Never

attempt to tilt the mast beyond vertical

when the load is raised high.

·To un-stack loads from a high place,

insert forks into the pallet and drive

backwards, then lower the load. Tilt the

mast backwards after lowering. Never

attempt to tilt the mast with the load

raised high.

25. It is dangerous to travel with

forks higher than appropriate position

regardless of whether loaded or not.

Keep the good traveling posture. (When

traveling, the forks should be 15 to 30 cm

above the ground or floor and the mast

tilted backward)

·Do not operate the side shift

mechanism, if equipped, when the forks

are raised and loaded, since this will

cause the truck to be unbalanced.

26. Watch for branches, cables,

doorways, or overhangs. Pay caution

when working in congested areas.

·Slow down and sound horn at cross

aisles and other locations where vision is

restricted.

·When make a turn, be sure the

speed of the truck is lower than the 1/3

max. of allowable speed.

27. Affirm keeping some distance

from roadside and flat roof.

15

28. Before driving over a dock-board

or bridge-plate, be sure that it is properly

secured and strong enough to sustain the

weigh.

29. When operating loaded truck,

have the rear end of your machine

pointed downhill.

·When operating unloaded truck,

have the rear end of your machine

pointed upgrade.

Do not make a turn on the grade, in

order to avoid overturn.

30.the goods is liable to drop turning or

passing rough road when it departures the

center. And the forklift may turn over more

probably.

31. Never lift loads with the truck

inclined. Avoid loading work on a grade.

32. Never permit anyone to stand or

walk under upraised forks or other

attachments if machine is so equipped. If

unavoidable, use a safety stand or block

to prevent a possibility of fork

attachments falling down or moving

unexpectedly.

33. Inspect the surface over which

you will run. Look for holes, drop-offs,

obstacles, and look for rough spots. Look

for anything that might cause you to lose

control, bog down or upset.

·Clear away trash and debris. Pick up

anything that might puncture a tire or let

the load lose balance.

·Slow down for wet and slippery

roads. Stay away from the edge of the

road. If unavoidable, pay more attention.

·Do not operate the truck when the

weather is execrable, such as windy,

thunder storm, snow and etc. Especially

when wind speed is higher than 5m/s,

don‟t operate the truck outside.

34.An accumulator is required for

controller. Forbid to touch within B+ and

B- to prevent from wounding by

electricity. Before checking or cleaning,

please connect loads (contactor circuit or

horn for example) between B+ and Bfirst to discharge for capacitor of

controller.

35. Pulling the hand brake when

parking on flat. If necessarily parking on

ramp, you should place the wedges under

wheels.

·Descending the fork to the ground

and keeping a little forward tilting, shut

off key switch and take off key.

·Pull out the battery plug.

·The parking place must be far away

from fireworks.

16

36. You can tow the forklift to the

safe place with towing pin when the

forklift can‟t run.

·Don‟t tow the truck which steering

system or brake system has been

damaged.

37. There is operating method and

warning label on the truck. Please

operate the truck obey the rules on the

label and this manual. Often inspect the

nameplate, when damaged or lost please

replace it.

38. Fire extinguisher must be

prepared at working place. Users can

select fire extinguisher along with truck,

and it usually is fixed on rear supported

leg of safety shelf, it is easy to pick.

Driver and manager should be

familiar with the position and operation

of fire extinguisher.

39. Please use stock when conveying

little goods, it is forbidden to use fork

directly.

40.The work road surface for forklift

should be stability and unknit, cement,

blacktop or beton. If there are snow, ice,

water or other eyewinker, bar. Eliminate

all, then work. Otherwise the truck will

be out of control and lead the safety

accident.

41. Move the truck to the place which

respects traffic when it anchors. If the

reason is brake or turn system, move it

by a suitable truck (Reference the part of

truck move); Other reasons, use a suitable

truck to traipse, tie the cord outside of

truck. Please abide by the traffic

regulations when traipse the truck on

calzada.

42. After take-down the hood, water

tank cover board, overhead, backrest of

mast, unallowed to operate the truck or

load cargo.

43. There are enough light at truck

work ground. At night, open the head

lamp to collocate enough lamp-house.

44. Only in the event that the truck

manufacturer is no longer in business and

there is no successor in the interest to the

business, the user may arrange for a

modification or alteration to a powered

industrial truck provided, however, that

the user shall:

a) Arrange for the modification or

alteration to be designed, tested and

implemented by an engineer(s) expert in

industrial trucks and their safety;

b) Maintain a permanent record of

the design, test(s) and implementation of the

modification or alteration;

c) Approve and make appropriate

changes to the capacity plate(s), decals,

tags and instruction handbook;

d) Affix a permanent and readily

visible label to the truck stating the

manner in which the truck has been

modified or altered together with the date

of the modification or alteration, and the

name and address of theorganisation that

accomplished the tasks.

17

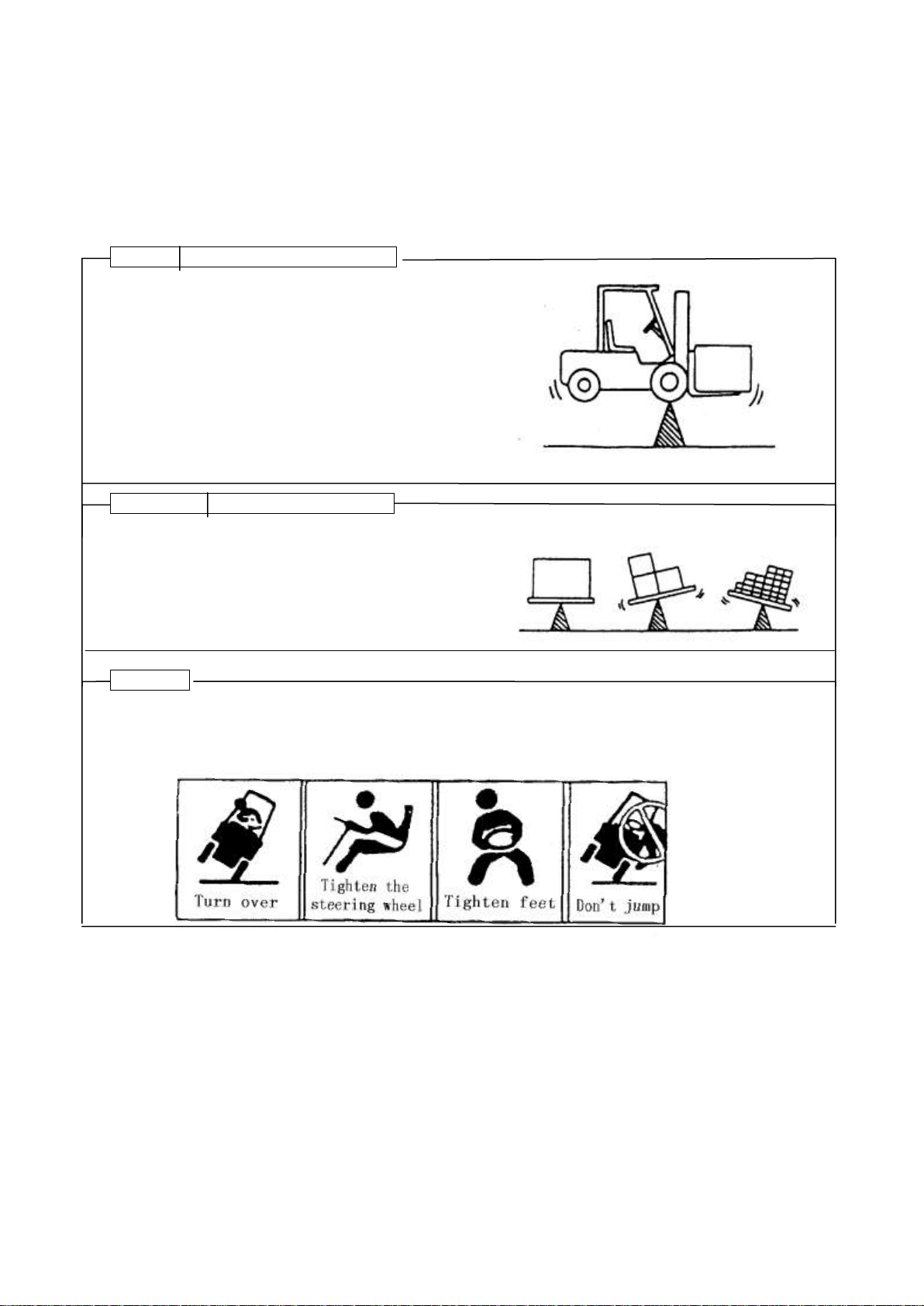

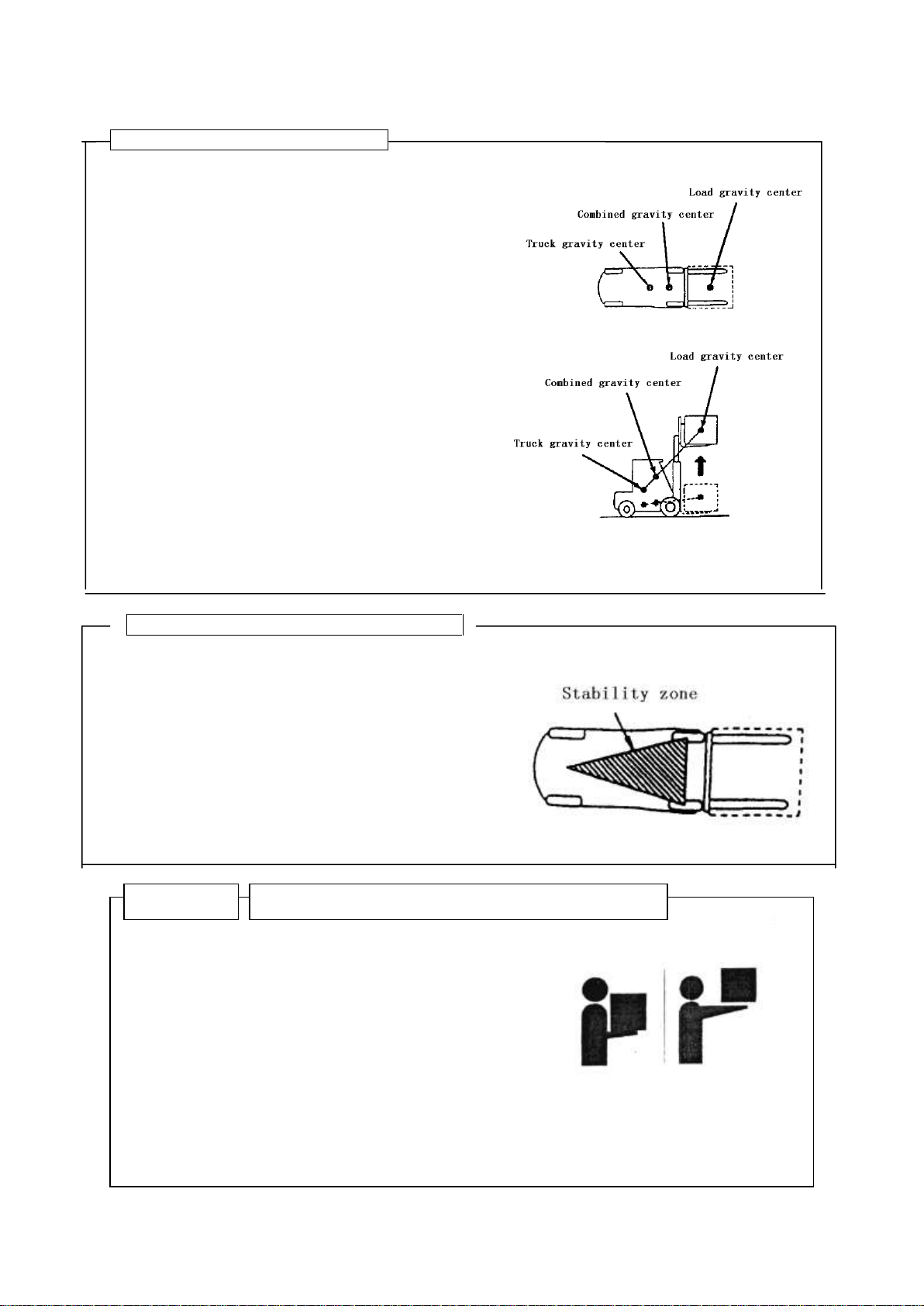

5.The structure and stability of truck(Prevent the forklift to turn

over!)

It is very important for operator to know the truck‟s structure and relationship between

load and stability.

Caution the structure of the truck

The basic structure of the truck is mast (include mast and

forks) and body (include tire).

The lift truck keeps the balance of weight between

the truck body and the load on the forks with the center

of the front wheels as a fulcrum when the rated

capacity load is placed in position.

Due care should be paid to the gravity center of

loads and forklift to maintain the stability of the truck.

Caution Load center

There is difference in gravity because of the loads‟

shape, such as box, board and large roller. It is very

important to distinguish the difference of the gravity

center of loads for evaluating the truck‟s stability.

Warning!

If the truck will turn over, do not attempt to get out of the truck because the speed of

overturn is much faster than your speed. You should hold the steering wheel handle, stretch

your feet, and this practice will let you in the seats. Operator fastens the safety belt please.

18

The load center distance is defined that: the

distance between the load center and the fork

carriage or the front of the fork carriage. The max.

load means the maximum load the truck can charge

at the normal load center distance. The relation

between the max. load and load center distance

shows on the capacity chart. You should reduce the

weight of load if the load center distance inclines to

the fork carriage.

The max. load(weight and load center distance)

Caution

Caution Gravity center and stability

The combined gravity center that is

composed of the forklift center and the load

gravity center determine the stability of lift

trucks.

When unloaded, the barycenter does not

change; when loaded, the barycenter is

determined by the truck and the load‟s center.

The barycenter is also determined by the

tilting and lifting of the mast.

The combined center is determined by these

factors:

Load‟s size, weight and shape

The lifting height

The tilting angle

The acceleration

The radius of turning

The road and grade‟s angle

The attachments

Caution! The stability zone of the barycenter

In order to make the truck stable, the combined

center must be in the triangle which is made up of

two points that the two front wheels attach ground

and the midpoint of the back axle.

If the combined center is in the front driving

axle, the two front wheels become two fulcrums,

the truck will overturn. If the combined center

departures the triangle, the trucks shall overturn in

the corresponding direction.

Loading...

Loading...