Page 1

™

HAN2660

Twist

3D .40 ARF

ASSEMBLY MANUAL

© 2010 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, IL 61822

USA

Horizon Hobby UK

Units 1-4, Ployters Road

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Horizon Hobby Deutschland GmbH

Hamburger Strasse 10

25335 Elmshorn

Germany

®

Hangar 9

DSM and DSM2 are trademarks or registered trademarks of Horizon Hobby, Inc. The Spektrum trademark is used with

permission of Bachmann Industries, Inc. Spektrum radios and accessories are exclusively available from Horizon Hobby, Inc.

products are distributed exclusively by Horizon Hobby, Inc.

Revised 11/09

6369.1

Specications

Wingspan: . . . . . . . . . . . . . . . . . . . 47.75 in (1212.85mm)

Length: ......................48.38 in (1228.73mm)

Wing Area: ................ 747.37 sq in (48.2 sq dm)

Weight: ..................5.0–6.0 lb (2.27 kg–2.72 kg)

• Great sport 3D performer

• Covered in genuine UltraCote

Engines: . . . . . . . . . . . . .40–.52 2-stroke/56–.82 4-stroke

Radio: ......................4-channel with 5 servos

®

Page 2

2

3

Table of Contents

Covering Colors .....................................................................................2

Contents of Kits

Contents of Kits .....................................................................................3

Required Radio and Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Field Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Additional Required Tools and Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Warning ...........................................................................................4

Before Starting Assembly ..............................................................................5

Using the Manual ....................................................................................5

Section 1: Attaching the Wing to the Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 2: Horizontal Stabilizer Installation .................................................................7

Section 3: Vertical Stabilizer Installation ...................................................................9

Section 4: Ailerons Installation .........................................................................10

Section 5: Elevators Installation ........................................................................12

Section 6: Tailwheel Installation ........................................................................14

Section 7: Rudder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Section 8: Engine Installation ..........................................................................16

Section 9: Throttle Pushrod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Section 10: Fuel Tank Installation .......................................................................19

Section 11: Landing Gear Installation ....................................................................20

Section 12: Radio Installation ..........................................................................21

Section 13: Linkage Installation ........................................................................24

Section 14: Canopy Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

E

A

C

Large Parts: Items Not Shown:

A. Wing Set HAN266001 • 2 ¾ in Wheels HAN305•

B. Fuselage HAN266002 • Fuel Tank HAN266007•

C. Tail Set HAN266003 • Engine Mount HAN266008•

D. Landing Gear HAN266004 • Decal Set HAN266005•

E. Canopy HAN266006 • Tailwheel Assembly HAN266009 •

• Control Hardware Set HAN266010

B

D

C

Adjusting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Control Throws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Recommeded CG ...................................................................................30

Preflight ..........................................................................................31

Range Testing the Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2010 Official Academy of Model Aeronautics Safety Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Warranty Information ................................................................................33

Instructions for Disposal of WEEE by Users inthe European Union ...............................................35

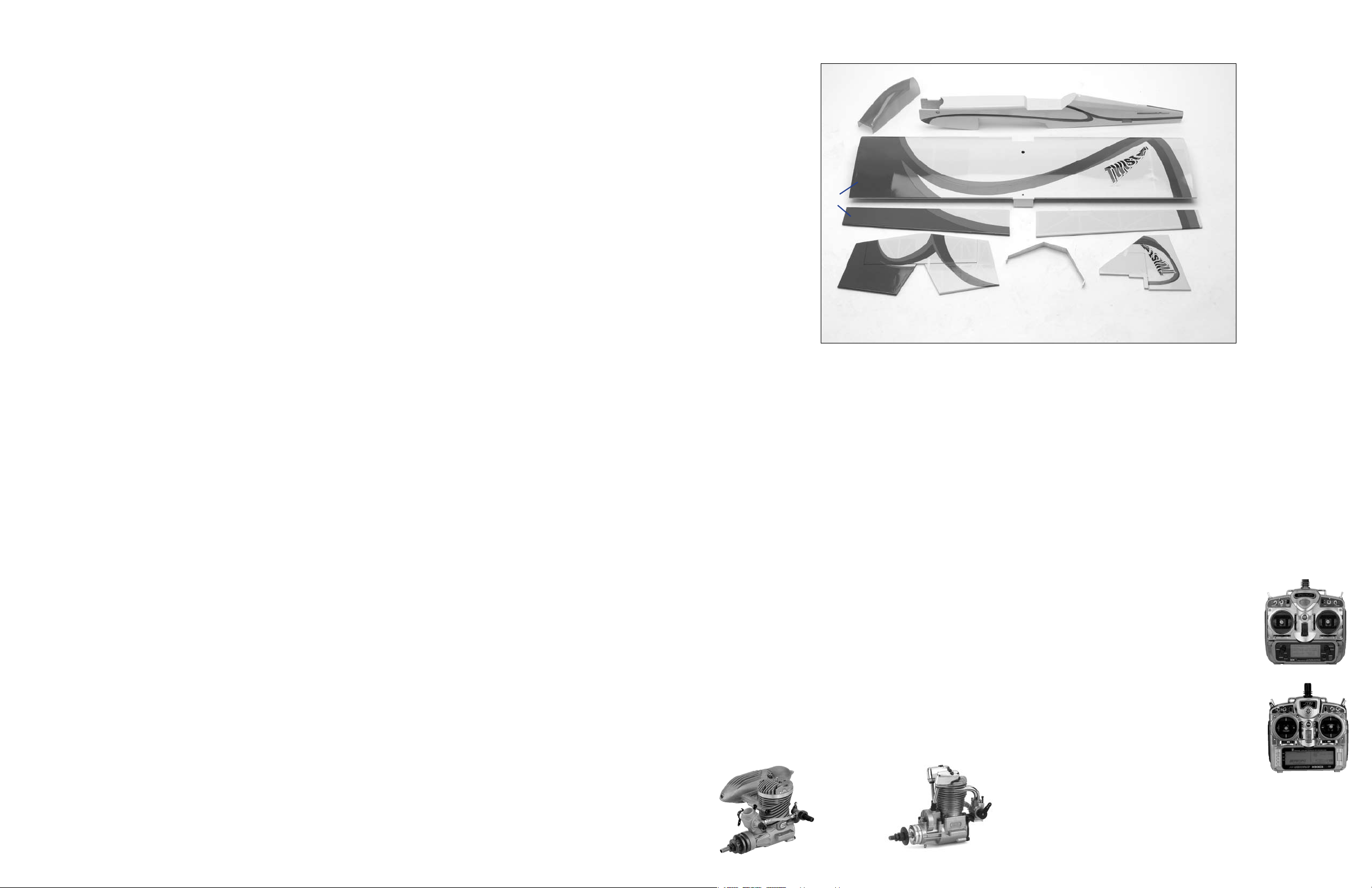

Covering Colors

Cream HANU878•

Flame Red HANU883•

Sky Blue HANU875•

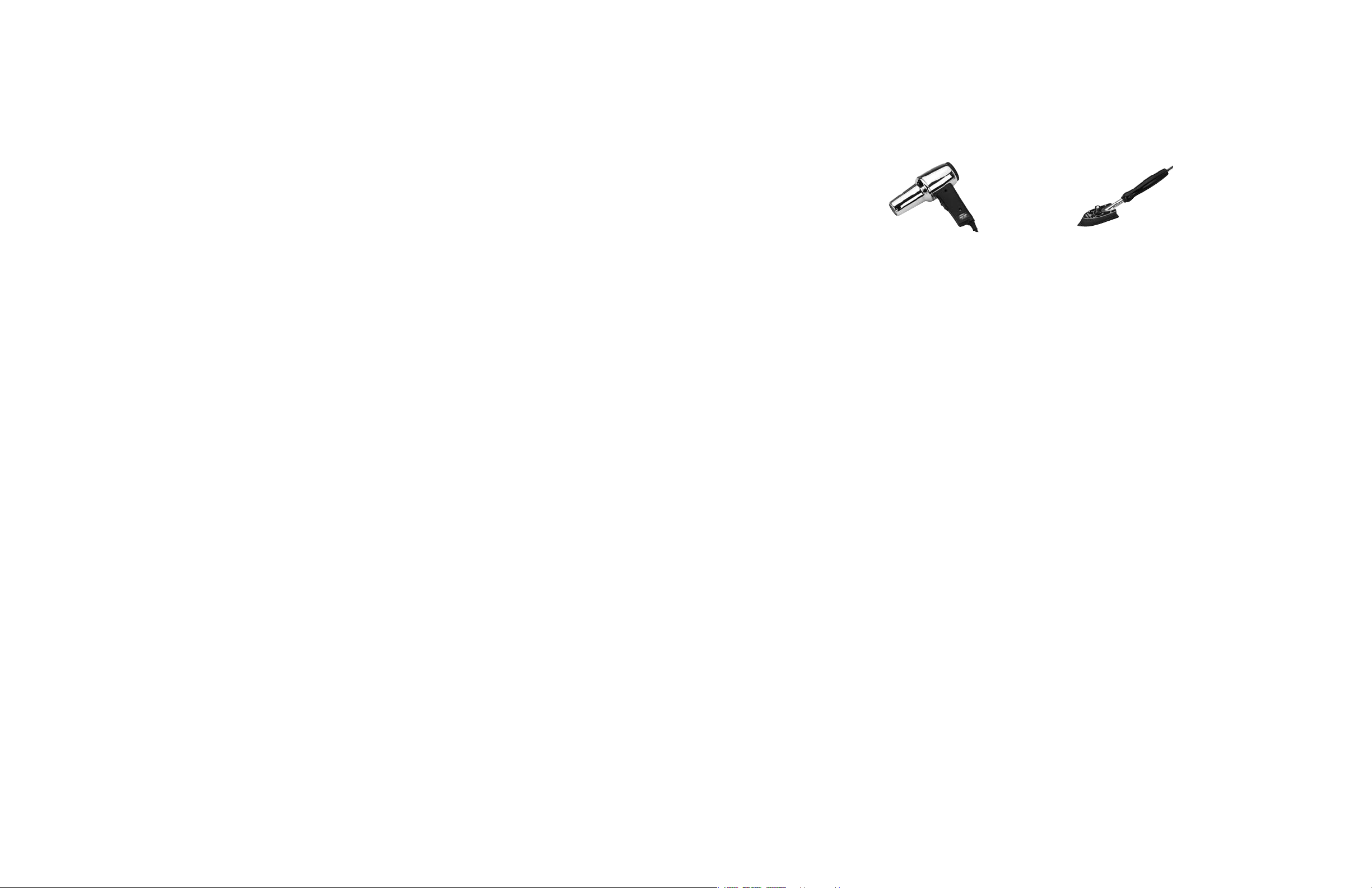

Required Radio and Engine

Radio Equipment Recommended Radio Systems

™

4-channel radio system (minimum) • Spektrum•

5 standard servos (JRPS821 recommended or equivalent) • Spektrum DX6i•

12-inch servo extension (JRPA098) (2) • Spektrum DX7•

Large servo arm (JRPA212) (2) • JR•

Y-harness (JRPA1350) or 3-inch servo extension (JRPA093) (2) • JR 12X•

Radio switch (JRPA003)•

Recommended Engines

.40–.52 2-stroke (EVOE0461 or EVOE0520)•

.56–.82 4-stroke•

Evolution® .46NX

EVOE0461

Saito™ .72 AAC

SAIE072B

®

9303

DX5e

DX7

JR 9303

Page 3

4

5

Field Equipment Required

Before Starting Assembly

Propeller (2-stroke (EVO11050) 4-stroke (EVO13080)) • Glow Plug Igniter with Charger (HAN7101)•

Fuel • Glow Plug (EVOGP1/HAN3011)•

Glow Plug Wrench (HAN2510) • Manual Fuel Pump (HAN118)•

12-Volt Starter (HAN162)•

Additional Required Tools and Adhesives

Tools: Adhesives:

Canopy scissors • 6-minute epoxy (PAAPT38)•

Drill • 30-minute epoxy (PAAPT39)•

Drill bits: 1/16-inch, 3/32-inch, 1/8-inch, 9/64-inch, 5/32-inch • Thin CA (PAAPT07)•

Felt-tipped pen • Medium CA (PAAPT01)•

Flat blade screwdriver • CA remover/debonder (PAAPT16)•

Foam: 1/2-inch • Masking tape (MMM20901)•

Hobby knife • Canopy glue (Formula 560)•

Making tape • Other Required Items:

Before beginning the assembly of your Twist, remove each part from its bag for inspection. Closely inspect the fuselage, wing

panels, rudder, and stabilizer for damage. If you find any damaged or missing parts, contact the place of purchase.

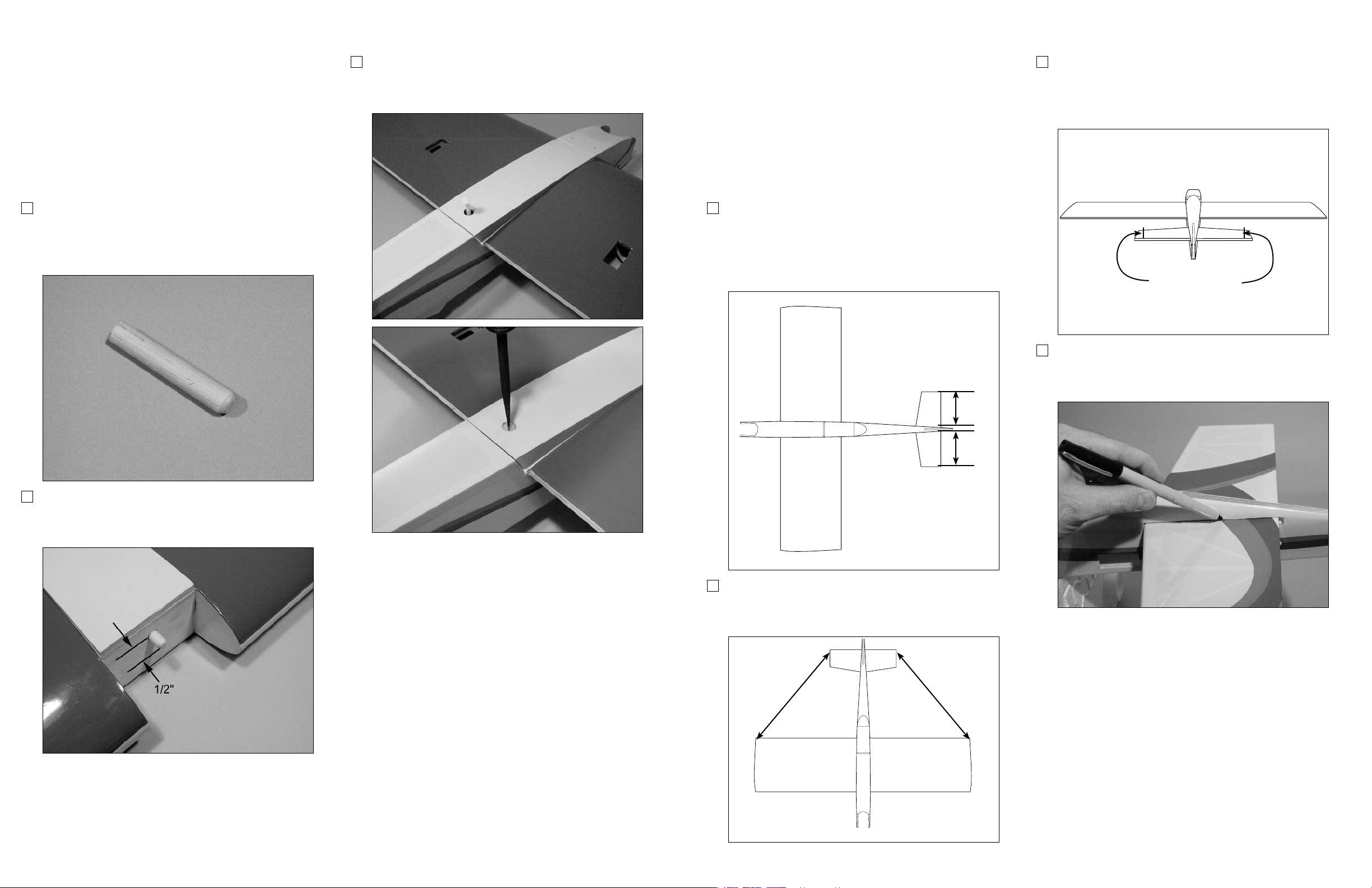

If you find any wrinkles in the covering, use a heat gun or covering iron to remove them. Use caution while working around areas

where the colors overlap to prevent separating the colors.

HAN100 – Heat Gun

HAN135 – Pro-Seal

Covering Iron

Using the Manual

This manual is divided into sections to help make assembly easier to understand and to provide breaks between each major

section. In addition, check boxes have been placed next to each step to keep track of each step completed. Steps with two boxes

indicate the step will require repeating, such as for a right or left wing panel, two servos, etc. Remember to take your time and

follow the directions.

Paper towels • 2 ¼-inch spinner (Red, DUB280)•

Petroleum jelly • Epoxy brushes (DUB345)•

Phillips screwdriver (large) • File•

Phillips screwdriver (small) • Measuring device (e.g. ruler, tape measure)•

Pliers • Mixing sticks for epoxy (DUB346)•

Rubbing alcohol • Paper towels•

Ruler • Rubbing alcohol•

Sandpaper • Wax paper•

Soldering iron•

Square•

T-pins•

Warning

An RC aircraft is not a toy. If misused, it can cause serious bodily harm and damage to property. Fly only in open areas, perferably

at AMA (Academy of Model Aeronautics) approved flying sites, following all instructions included with your radio and engine.

Age Recommendation: 14 years or over. Not a toy. Not intended for use by children without direct adult supervision.

Page 4

6

7

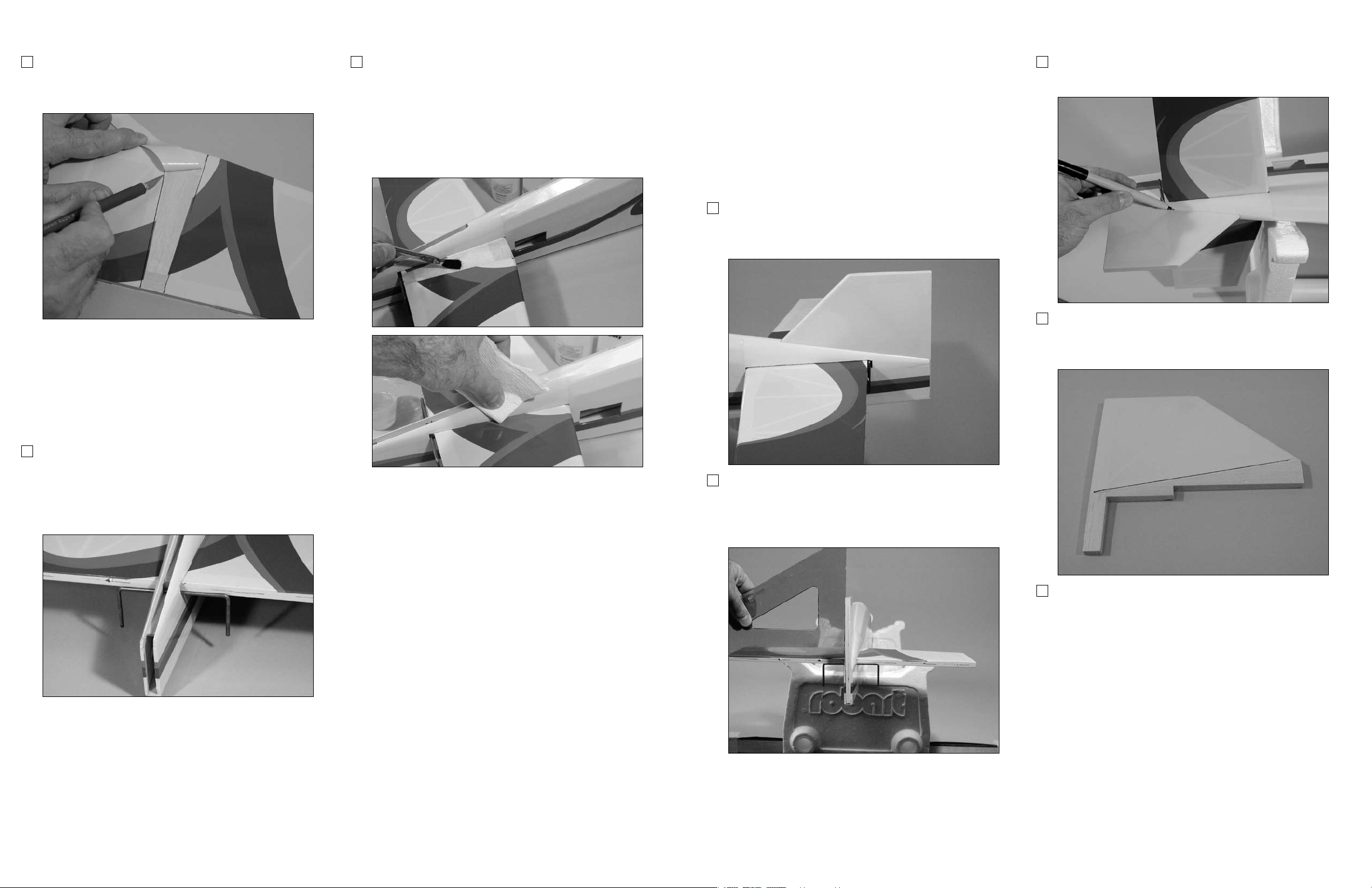

Section 1: Attaching the Wing to the Fuselage Section 2: Horizontal Stabilizer Installation

Required Parts

Wing • Fuselage•

1/4 x 1 3/4-inch wing dowel•

1/4-20 x 2-inch nylon bolt•

Required Tools and Adhesives

6-minute epoxy • Sandpaper•

Flat blade screwdriver•

Step 1

Locate the 1/4 x 1 3/4-inch wing dowel. Sand a small

taper on one end of the dowel to make it easier to attach the

wing to the fuselage.

Step 3

Place the wing onto the fuselage. Secure the wing using the

1/4-20 x 2-inch nylon bolt.

Required Parts

Wing • Fuselage•

Horizontal stabilizer • Elevator joiner wire•

Required Tools and Adhesives

Flat blade screwdriver • Sandpaper•

Felt-tipped pen • Paper towel•

Rubbing alcohol•

Step 1

Slide the stab into the slot in the fuselage, with the leading

edge pushed forward in the slot. Center the stab in the opening

by measuring the distance from the fuselage to each tip. The

stab is aligned when both measurements are identical.

A

Step 3

The last alignment step is making sure the wing and stabilizer

are parallel. If they are not, lightly sand the opening in the

fuselage for the stab until the stab rests parallel to the wing.

Equal Distances

Step 4

Use a felt-tipped pen to trace the outline of the fuselage on the

top and bottom of the stab.

Step 2

Glue the dowel into the wing using 6-minute epoxy. Make sure

there is about 1/2-inch of the dowel exposed.

A'

A=A'

Step 2

Check the distance from each stab tip to each wing tip. These

measurements must also be equal.

B B'

B=B'

Page 5

8

9

Section 2: Horizontal Stabilizer Installation (continued)

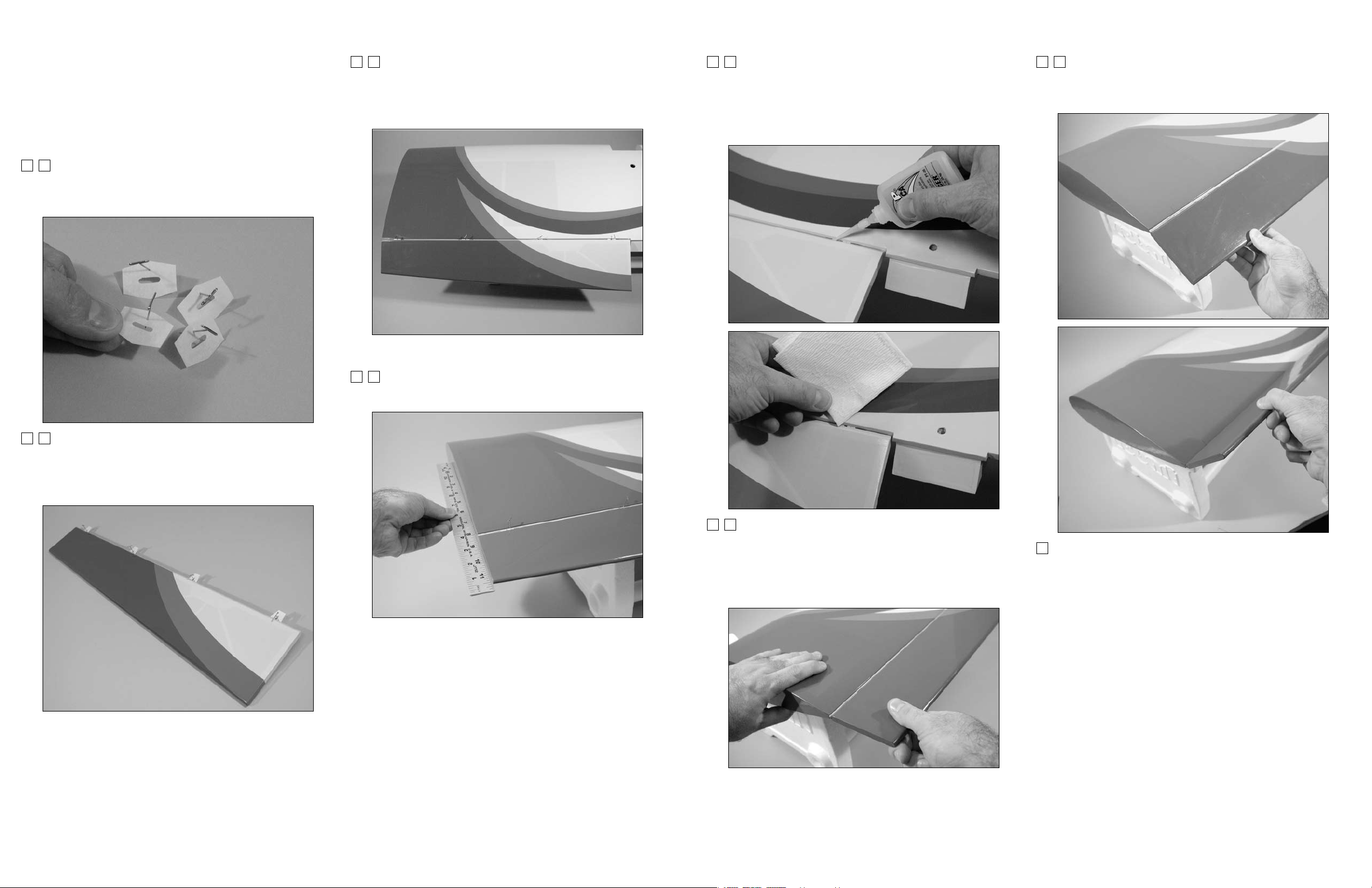

Section 3: Vertical Stabilizer Installation

Step 5

Remove the stab and use a hobby knife with a brand new blade

to remove the covering 1/16-inch inside the lines just drawn.

Note: DO NOT cut into the underlying wood. Let the

knife “float” across the covering. Cutting into the wood will

weaken the stabilizer and may cause it to fail in flight.

Step 7

Slide the stabilizer from the fuselage far enough to expose the

uncovered area. Mix 1/2 ounce of 30-minute epoxy. Apply the

epoxy to the exposed area on both the top and bottom of the

stab. Slide the stab back into position and double-check the

alignment of the stab. Remove any excess epoxy using a paper

towel and rubbing alcohol.

Required Parts

Wing • Fuselage•

Vertical stabilizer•

Required Tools and Adhesives

30-minute epoxy • Sandpaper•

Square • Ruler•

Felt-tipped pen•

Step 1

Locate the vertical stabilizer (fin) and slide it into position.

Position the fin so it is fully forward in the slot in the fuselage.

Step 3

Trace the outline of the fuselage onto the fin.

Step 4

Remove the covering 1/16-inch below the line drawn

in the last step.

Hint: You can use a soldering iron instead of a hobby knife

to remove the covering. Doing so will eliminate accidentally

cutting into the stabilizer.

Step 6

Place the elevator joiner wire into the slot for the stab.

Reposition the stab into the fuselage. It may be necessary

to trim the opening at the rear to allow for clearance for the

joiner wire.

Hint: Use a little rubbing alcohol and a paper towel to remove

the felt-tipped marker lines once they are no longer needed.

Hint: Use a little masking tape to keep the joiner wire out of

the way until it’s time to install the elevators. Also make sure

there is no epoxy on the joiner wire.

Step 2

Check the alignment between the fin and stab. The fin must be

90-degrees to the stab to be in alignment. Sand the opening in

the fuselage if necessary to get the perfect alignment.

Step 5

Mix 1/2 ounce of 30-minute epoxy. Apply the epoxy to the tab

on the fin and to the area on the top of the fuselage where the

covering was removed. Position the fin in the slot and check

the alignment. Use masking tape to hold the fin in position until

the epoxy fully cures.

Hint: Use rubbing alcohol and a paper towel to clean up any

excess epoxy.

Page 6

10

11

Section 4: Ailerons Installation

Section 4: Ailerons Installation (continued)

Required Parts

Wing • CA hinge (8)•

Aileron (left and right)•

Required Tools and Adhesives

Thin CA • T-pins•

Step 1

Locate 8 of the CA hinges. Place a T-pin in the center of four of

the hinges.

Step 3

Slide the aileron and wing together. The gap between

the aileron and wing should be infinitely small,

approximately 1/64-inch.

Hint: Be careful of the T-pins, as they can be sharp.

Step 4

Step 5

Remove the T-pins and apply thin CA to each hinge. Make sure

the hinge is fully saturated with CA. Use a paper towel and CA

remover/debonder to clean up any excess CA from the wing

and/or aileron.

Step 7

Work the aileron up and down several times to work in the

hinges and check for proper movement.

Step 2

Place the hinges in the precut slots in the aileron (or wing

if you prefer). The T-pin will rest against the edge when

installed correctly.

Use a ruler to align the end of the aileron to the wing.

Note: Do not use CA accelerator during the hinging process.

The CA must be allowed to soak into the hinge to provide the

best bond. Using accelerator will not provide enough time for

this process.

Step 6

Firmly grasp the wing and aileron and gently pull

on the aileron to ensure the hinges are secure and cannot be

pulled apart. Use caution when gripping the wing and aileron to

avoid crushing the structure.

Step 8

Repeat Steps 1 through 7 for the remaining aileron.

Page 7

12

13

Section 5: Elevators Installation

Section 5: Elevators Installation (continued)

Required Parts

Fuselage assembly • Elevator joiner wire•

Elevator (left and right) • CA hinge (6)•

Required Tools and Adhesives

Thin CA • T-pins•

30-minute epoxy • Sandpaper•

Drill • Drill bit: 9/64-inch•

Ruler•

Step 1

Locate three CA hinges. Place a T-pin in the center of the

hinges. Place the hinges into the elevator half.

Step 3

Mix 1/2 ounce of 30-minute epoxy and apply it to the

groove and hole in the elevator half. Insert the elevator joiner

wire. Remove any excess epoxy using rubbing alcohol and a

paper towel.

Note: You can combine this step with the following step if you

like. This will hold the elevator in position while the epoxy

cures.

Step 4

Check to make sure the elevator moves freely. It should not rub

against the stabilizer at the tip. Check to make sure the hinge

gap between the elevator and stabilizer is roughly 1/64-inch.

Apply thin CA to both sides of the hinge. Make sure to saturate

the hinge and don’t use accelerator.

Step 5

Once the CA and epoxy have fully cured, gently pull on the

elevator and stab to make sure the hinges are well glued. Flex

the elevators a few times to break in the hinges.

Step 2

Test fit the elevator and stab together. The elevator joiner wire

will be inserted into the pre-drilled hole.

Page 8

14

15

Section 6: Tailwheel Installation Section 7: Rudder Installation

Required Parts

Rudder • Tailwheel assembly•

Required Tools and Adhesives

Hobby knife • 6-minute epoxy•

Drill • Drill bit: 5/64-inch (2mm)•

Paper towel • Rubbing alcohol•

Step 1

Locate the pre-drilled hole in the bottom of the rudder. This is

the hole for the vertical shaft of the tailwheel assembly.

Step 2

Step 3

Mark where you drill the two locations for the

tailwheel support.

Step 4

Drill through the bottom of the rudder with the

5/64-inch (2mm) drill.

Required Parts

Fuselage assembly • Rudder•

CA hinge (3)•

Required Tools and Adhesives

Thin CA • T-pins•

6-minute epoxy•

Step 1

Locate the last three CA hinges, and place T-pins in the center,

as done for the ailerons and elevator.

Step 2

Install the hinges in the rudder.

Step 4

Check to make sure the rudder moves freely. It should not rub

against the fin at the tip. Apply thin CA to both sides of the

hinge. Make sure to saturate the hinge, and don’t use

accelerator. Use a paper towel and CA debonder/remover to

clean up any excess CA.

Step 5

Once the CA and epoxy have fully cured, give the rudder and

fin the tug test to make sure the hinges are well glued. Flex the

rudder a few times to break in the hinges.

Temporarily mount the tailwheel assembly to the bottom of

the rudder. Do not glue at this time. Slide the nylon tailwheel

support brackets to be evenly spaced along the tailwheel wire.

Step 3

Test fit the rudder to the fuselage. Make sure the rudder will

rest tight against the fin and fuselage.

Step 5

Mix up a small batch of 6-minute epoxy. Using a toothpick

insert a small amount of the epoxy in the hole in the bottom of

the rudder. Insert the vertical tailwheel wire into the hole with

the epoxy and mount the nylon brackets to the rudder with the

hardware included.

Page 9

16

17

Section 8: Engine Installation Section 9: Throttle Pushrod Installation

Required Parts

Fuselage assembly • Engine mount•

4mm x 20mm screw (4) • 4mm washer (4)•

4mm x 25mm screw (4) • 4mm lock nut (4)•

Required Tools and Adhesives

Drill • Drill bit: 11/64-inch (4.5mm)•

Engine • Pliers•

Clamp • Phillips screwdriver (large)•

Step 1

Attach the engine mount to the firewall using four

4mm x 20mm screws.

Step 3

Mark the locations for the engine mounting bolts.

Step 4

Remove the engine and drill the locations marked in the

previous step using a 11/64-inch (4.5mm) drill bit.

Required Parts

Fuselage assembly • 10 1/8-inch (260mm) outer •

pushrod tube

Clevis • 14 5/8-inch (370mm ) •

pushrod wire

Clevis retainer•

Required Tools and Adhesives

Drill • Drill bit: 5/32-inch•

Medium CA • Sandpaper•

Step 1

Determine the proper location for the throttle pushrod. Mark the

location with a felt-tipped pen. Remove the engine and drill the

firewall for the pushrod tube using a drill and 5/32-inch drill bit.

Step 2

Test fit the throttle pushrod tube through the firewall, through

former 2, and into the fuselage. Once satisfied with the fit,

roughen the tube using sandpaper. Slide the tube back into

position and use medium CA to glue it to the firewall and

former 2. Allow 1/4-inch of the pushrod to extend forward of

the firewall.

Step 2

Position the engine on the mount. Adjust the engine so the distance from the firewall to the drive washer is 4 1/4-inch. Use

clamps to hold the engine in position.

Hint: Use a drill press for the best results. This makes holes

perfectly perpendicular (square) to the mount.

Step 5

Attach the engine using four 4mm x 25mm socket head

screws, four 4mm washers and four 4mm lock nuts.

Page 10

18

19

Section 9: Throttle Pushrod Installation (continued)

Section 10: Fuel Tank Installation

Step 3

Slide a clevis retainer onto a nylon clevis. Thread a clevis onto a

14 5/8-inch (370mm) wire, a minimum of 10 turns.

Step 4

Attach the clevis to the throttle arm on the carburetor. Slide the

pushrod wire into the pushrod tube and reinstall the engine.

Bend the pushrod if necessary so it moves freely.

Required Parts

Fuselage assembly • Fuel tank assembly•

Fuel tubing (blue)•

Required Tools and Adhesives

Foam: 1/2-inch•

Step 1

Glue a piece of 1/2-inch foam to the sides of the fuel tank compartment. Glue two pieces of 1/2-inch foam to the upper inside

of the fuel tank compartment so there will be 1-inch of foam

between the upper inside of the fuselage and the fuel tank.

Step 3

Install the fuel tank into the fuselage. Make any necessary

supports to keep the tank from moving during flight.

Hint: Make sure the rear support brace will not interfere with

the installation of the wing.

Step 4

Attach the muffler to the engine. Make the proper connections

to the engine using the engine manufacturer’s instructions.

Step 2

Connect the two pieces of fuel tubing to the fuel tank’s pickup

and vent tubes. Note the vent and fuel line.

Page 11

20

21

Section 11: Landing Gear Installation Section 12: Radio Installation

Required Parts

Fuselage assembly • 2 3/4-inch wheel (2)•

4mm x 25mm axle with nut (2) • 1-inch wheel•

4mm wheel collar (2) • Landing gear•

4mm x 20mm screw (4) • Grub screw (2)•

Required Tools and Adhesives

Drill • Drill bits: 1/16-inch, •

1/8-inch, 5/32-inch

Phillips screwdriver (large) • Hex wrench (included in kit)•

Step 1

Locate the main landing gear and four 4mm x 20mm screws.

Attach the main landing gear using the screws. The angle on

the gear should be toward the rear of the plane.

Step 3

Attach the wheel to the axle using a wheel collar and grub

screw.

Hint: File a flat area where the screw contacts the axle, to

help prevent the screw from loosening during flight.

Required Parts

Fuselage assembly • Wing assembly•

Servo with hardware (5)•

Required Tools and Adhesives

Drill • Drill bit: 1/16-inch•

Phillips screwdriver (small) • Servo extension – •

12-inch (2)

Step 1

Install the recommended servo hardware (grommets and eyelets) supplied with your radio system onto five servos (elevator,

rudder, throttle, and aileron (2)).

Step 2

Temporarily install the rudder servo.

Step 3

Mark the locations for the servo screws using

a felt-tipped pen.

Step 5

Attach a 12-inch servo extension onto the rudder servo. Use

your favorite method to secure the extension to prevent it from

coming loose during flight. Secure the rudder servo using the

screws provided with the servo.

Step 6

Repeat Steps 1 through 5 for the elevator servo.

Step 2

Attach the axle to each landing gear leg with the included two

nuts and washers. Use threadlock when assembling the axle.

Step 4

Repeat Steps 2 and 3 for the remaining wheel.

Step 4

Remove the servo and drill the holes for the servo mounting

screws using a 1/16-inch drill bit.

Hint: Place a drop of thin CA onto each screw hole to harden

the wood around the hole. Allow the CA to fully cure before

installing the servos.

Step 7

Temporarily install the aileron servo and mark

the locations for the servo screws using a

felt-tipped pen.

Page 12

22

23

Section 12: Radio Installation (continued) Section 12: Radio Installation (continued)

Step 8

Remove the servos and drill the holes for the servo mounting

screws using a 1/16-inch drill bit.

Step 9

Use a piece of string with a small weight (such as a wheel

collar) attached as a device to pull the servo lead through the

wing. Lower the weight through the servo opening, allowing it

to pass through the ribs and out the hole in the center of the

wing.

Step 10

Tie the string onto the servo extension. Gently pull the

extension through the wing using the string. Untie the string

when the servo lead has been pulled through. Use tape to

secure the servo lead to the wing to prevent it from falling

back into the wing panel. Secure the aileron servo using the

hardware provided with the servo.

Step 11

Repeat Steps 7 through 10 for the other aileron servo.

Step 12

Step 13

Wrap the receiver and receiver battery in protective foam to

prevent damage that may be caused by engine vibration.

Step 14

Temporarily mount the receiver and battery into the fuselage.

It may be necessary to relocate the battery forward or aft to

balance the model as described in the section “Control Throws

and Center of Gravity.” Plug in any servo leads or extensions

at this time and connect any extensions necessary for the

aileron servos.

Step 15

Route the antenna out through the tube in the fuselage.

Step 16

Mount the radio switch in the side of the fuselage opposite the

throttle linkage.

Secure the throttle servo using the screws supplied with the

servo.

Page 13

24

25

Section 13: Linkage Installation

Section 13: Linkage Installation (continued)

Required Parts

Fuselage assembly • Wing assembly•

4 3/8-inch pushrod wire (2) • Nylon clevis (4)•

10 5/8-inch pushrod wire (2) • Clevis retainer (4)•

Nylon wire keeper (5) • Nylon control horn (4)•

1.5mm x 15mm screw (12)•

Required Tools and Adhesives

Drill bits: 1/16-inch, 3/32-inch • Drill•

Phillips screwdriver (small)•

Step 1

Slide a clevis retainer onto a nylon clevis. Thread a clevis onto a

105/8-inch wire, a minimum of 10 turns.

Step 3

Position the control horn on the elevator so the horn aligns

with the hinge line of the elevator. Mark the position for the

mounting holes using a felt-tipped pen.

Step 4

Drill three 3/32-inch holes through the elevator at the locations

marked in the previous step.

Step 5

Place 2–3 drops of thin CA into the hole to harden the wood.

Repeat this for each of the three holes.

Step 6

Attach the control horn using three 1.5mm x 15mm screws and

the control backplate.

Step 7

Center the elevator servo electronically using the radio system.

Install a servo arm onto the elevator servo. Attach the pushrod

with clevis to the control horn. Physically place the elevator

control surface in neutral. Mark the pushrod where it crosses

the holes in the servo arm.

Step 8

Bend the wire 90-degrees at the mark made in the

previous step.

Step 2

Remove the backplate from a control horn using side cutters or

a sharp hobby knife.

Step 9

Cut the wire 3/8-inch (10mm) above the bend.

Page 14

26

27

Section 13: Linkage Installation (continued) Section 13: Linkage Installation (continued)

Step 10

Slide the wire through the hole one in from the end of the

elevator servo arm. Secure the wire using a nylon wire keeper.

Step 11

Repeat Steps 1 through 10 for the rudder linkage.

Step 14

Position the control horn on the aileron so the horn aligns with

the hinge line of the aileron. Mark the position for the mounting

holes using a felt-tipped pen.

Step 15

Drill three 3/32-inch holes at the locations marked in the

previous step.

Step 16

Place 2–3 drops of thin CA into the hole to harden the wood.

Repeat this for each of the three holes.

Step 17

Attach the control horn using three 1.5mm x 15mm screws and

the control backplate.

Step 18

Center the aileron servo electronically using the radio system.

Install a servo arm onto the aileron servo. Attach the pushrod

with clevis to the control horn. Physically place the aileron

control surface in neutral. Mark the pushrod where it crosses

the holes in the servo arm.

Step 19

Bend the wire 90-degrees at the mark made in the previous

step. Cut the wire 3/8-inch (10mm) above the bend.

Step 20

Slide the wire through the outer hole in the aileron servo arm.

Secure the wire using a nylon wire keeper.

Step 22

Center the throttle stick and trim with both the receiver

and transmitter on. Install the throttle servo arm in the

neutral position.

Step 23

Move the servo to the throttle closed position using the radio

system. Manually move the throttle arm to the closed position.

Mark the location where the pushrod crosses the servo arm

using a felt-tipped pen.

Step 12

Slide a clevis retainer onto a nylon clevis. Thread a clevis onto a

4 3/8-inch wire a minimum of 10 turns.

Step 13

Remove the backplate from a control horn using side cutters or

a sharp hobby knife.

Step 21

Repeat Steps 12 through 20 for the other aileron servo.

Page 15

28

29

Section 13: Linkage Installation (continued)

Section 14: Canopy Installation

Step 24

Make a 90-degree bend at the mark made in the last step.

Temporarily connect the pushrod to the throttle arm. Check the

movement of the throttle to verify there is no binding at either

low or high throttle. If there is, make the necessary adjustment

to eliminate any binding.

Step 25

Secure the throttle pushrod to the servo arm using a nylon wire

keeper. Install the throttle servo arm screw when complete.

Required Parts

Fuselage assembly • Canopy•

Required Tools and Adhesives

Canopy glue (PAAPT56) • Sandpaper (medium grit)•

Step 1

Install a pilot of your choosing. Use epoxy to secure the pilot.

Step 2

Position the canopy onto the fuselage. Trace around the

canopy and onto the fuselage using a felt-tipped pen.

Step 3

Lightly sand the inside edge of the canopy and slightly inside

the line drawn on the hatch using medium sandpaper.

Step 4

Apply a bead of Formula 560 Canopy Glue (PAAPT56) around

the inside edge of the canopy. Position the canopy onto the

hatch. Use tape to hold it secure until the glue fully cures.

Page 16

30

31

Adjusting the Engine Preflight

Step 1

Completely read the instructions included with your engine and

follow the recommended break-in procedure.

Step 2

At the field, adjust the engine to a slightly rich setting at full

throttle and adjust the idle and low-speed needle so that a

consistent idle is achieved.

Control Throws

The amount of control throw should be adjusted as closely as

possible using mechanical means, rather than making large

changes electronically at the radio. By moving the position

of the clevis at the control horn toward the outermost hole,

you will decrease the amount of control throw of the control

surface. Moving it toward the control surface will increase the

amount of throw. Moving the pushrod wire at the servo arm

will have the opposite effect. Moving it closer to center will

decrease throw, and away from center will increase throw.

Work with a combination of the two to achieve the closest or

exact control throws listed.

Step 3

Before you fly, be sure your engine idles reliably,

transitions and runs at all throttle settings. Only when this is

achieved should any plane be considered ready for flight.

Low Rate High Rate

Aileron: 1-inch (15°) up 1 5/8-inch (23°) up

1-inch (15°) down 1 5/8-inch (23°) down

Elevator: 1-inch (14°) up 2-inch (25°) up

1-inch (14°) down 2-inch (25°) down

Rudder: 1 3/4-inch (18°) left 2-inch (22°) left

1 3/4-inch (18°) right 2-inch (22°) right

Note: Control throws are measured at the widest part of the

elevator, rudder, and aileron unless noted otherwise.

Charge both the transmitter and receiver pack for your

airplane. Use the recommended charger supplied with your

particular radio system, following the instructions provided with

the radio. In most cases the radio should be charged the night

before flying.

Range Testing the Radio

Check all the control horns, servo horns and clevises to make

sure they are secure and in good condition. Replace any items

that would be considered questionable. Failure of any of these

components in flight would mean the loss of your aircraft.

Check the radio installation and make sure all the control

surfaces are moving correctly (i.e. the correct direction and

with the recommended throws). Test-run the engine and

make sure it transitions smoothly from idle to full throttle and

back. Also ensure the engine is tuned according to the

manufacturer’s instructions, and it will run consistently and

constantly at full throttle when adjusted.

Before each flying session, range-check your radio. This is

accomplished by turning on your transmitter with the antenna

collapsed. Turn on the radio in your airplane. With your airplane

on the ground, you should be able to walk 30 paces away from

your airplane and still have complete control of all functions. If

not, don’t attempt to fly! Have your radio equipment checked

out by the manufacturer.

Recommeded CG

An important part of preparing the aircraft for flight is properly

balancing the model. This is especially important when various

engines are mounted.

Use the following throws for 3D aerobatics:

Aileron: 2 1/2-inch (35°) up 2 1/2-inch (35°) down

Elevator: 2 3/4-inch (35°) up 2 3/4-inch (35°) down

Rudder: 2 1/2-inch (28°) right 2 1/2-inch (28°) left

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) range for the Twist is

4–5-inches behind the leading edge of the wing against the

fuselage. It is suggested to start at the forward end of the

range until comfortable with the flight characteristics of your

aircraft. If necessary, move the battery pack or add weight to

either the nose or the tail until the correct balance is achieved.

Stick-on weights are available at your local hobby shop and

work well for this purpose.

Page 17

32

33

2010 Official Academy of Model Aeronautics Safety Code Warranty Information

GENERAL

1. A model aircraft shall be defined as a non-humancarrying device capable of sustained flight in the atmosphere. It shall not

exceed limitations established in this code and is intended to be used exclusively for recreational or competition activity.

2. The maximum takeoff weight of a model aircraft, including fuel, is 55 pounds, except for those flown under the AMA

Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules established for the flying site I use. I will not willfully fly my model aircraft in a

reckless and/or dangerous manner.

4. I will not fly my model aircraft in sanctioned events, air shows, or model demonstrations until it has been proven airworthy.

5. I will not fly my model aircraft higher than approximately 400 feet above ground level, when within three (3) miles of an airport without notifying the airport operator. I will yield the right-of-way and avoid flying in the proximity of full-scale aircraft,

utilizing a spotter when appropriate.

6. I will not fly my model aircraft unless it is identified with my name and address, or AMA number, inside or affixed to the

outside of the model aircraft. This does not apply to model aircraft flown indoors.

7. I will not operate model aircraft with metal-blade propellers or with gaseous boosts (other than air), nor will I operate model

aircraft with fuels containing tetranitromethane or hydrazine.

8. I will not operate model aircraft carrying pyrotechnic devices which explode burn, or propel a projectile of any kind. Exceptions include Free Flight fuses or devices that burn producing smoke and are securely attached to the model aircraft during

flight. Rocket motors up to a G-series size may be used, provided they remain firmly attached to the model aircraft during

flight. Model rockets may be flown in accordance with the National Model Rocketry Safety Code; however, they may not be

launched from model aircraft. Officially designated AMAAir Show Teams (AST) are authorized to use devices and practices

as defined within the Air Show Advisory Committee Document.

9. I will not operate my model aircraft while under the influence of alcohol or within eight (8) hours of having

consumed alcohol.

10. I will not operate my model aircraft while using any drug which could adversely affect my ability to safely control my

model aircraft.

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the “Product”) will be free from defects in materials and workmanship at the date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser (“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty covers only those Products purchased from an authorized Horizon dealer. Third party transactions are not covered by this warranty. Proof of purchase is required

for warranty claims. Further, Horizon reserves the right to change or modify this warranty without notice and disclaims all other

warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE

HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall be that Horizon will, at its option, (i) repair or (ii) replace, any

Product determined by Horizon to be defective. In the event of a defect, these are the Purchaser’s exclusive remedies. Horizon

reserves the right to inspect any and all equipment involved in a warranty claim. Repair or replacement decisions are at the sole

discretion of Horizon. This warranty does not cover cosmetic damage or damage due to acts of God, accident, misuse, abuse,

negligence, commercial use, or modification of or to any part of the Product. This warranty does not cover damage due to improper installation, operation, maintenance, or attempted repair by anyone other than Horizon. Return of any goods by Purchaser must

be approved in writing by Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR

COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY. Further, in no event shall the liability of Horizon exceed the individual price of the Product

on which liability is asserted. As Horizon has no control over use, setup, final assembly, modification or misuse, no liability shall

be assumed nor accepted for any resulting damage or injury. By the act of use, setup or assembly, the user accepts all resulting

liability.

11. Children under six (6) years old are only allowed on a flightline or in a flight area as a pilot or while under flight instruction.

12. When and where required by rule, helmets must be properly worn and fastened. They must be OSHA, DOT, ANSI, SNELL or

NOCSAE approved or comply with comparable standards.

RADIO CONTROL

1. All model flying shall be conducted in a manner to avoid over flight of unprotected people.

2. I will have completed a successful radio equipment ground-range check before the first flight of a new or repaired

model aircraft.

3. I will not fly my model aircraft in the presence of spectators until I become a proficient flier, unless I am assisted by an

experienced pilot.

4. At all flying sites a line must be established, in front of which all flying takes place. Only personnel associated with flying the

model aircraft are allowed at or in front of the line. In the case of airshows demonstrations straight line must be established.

An area away from the line must be maintained for spectators. Intentional flying behind the line is prohibited.

5. I will operate my model aircraft using only radio control frequencies currently allowed by the Federal Communications

Commission (FCC). Only individuals properly licensed by the FCC are authorized to operate equipment on

Amateur Band frequencies.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this Product, you are advised to

return this Product immediately in new and unused condition to the place of purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be operated with caution and common sense and requires some

basic mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury or damage to the

Product or other property. This Product is not intended for use by children without direct adult supervision. The Product manual

contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and warnings in

the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once assembly, setup or use of the

Product has been started, you must contact Horizon directly. This will enable Horizon to better answer your questions and service

you in the event that you may need any assistance. For questions or assistance, please direct your email to

productsupport@horizonhobby.com, or call 877.504.0233 toll free to speak to a Product Support representative.

Page 18

34

35

Inspection or Repairs

United States

If this Product needs to be inspected or repaired, please call for a Return Merchandise Authorization (RMA). Pack the Product

securely using a shipping carton. Please note that original boxes may be included, but are not designed to withstand the rigors

of shipping without additional protection. Ship via a carrier that provides tracking and insurance for lost or damaged parcels, as

Horizon is not responsible for merchandise until it arrives and is accepted at our facility. A Service Repair Request is available at

www.horizonhobby.com on the “Support” tab. If you do not have internet access, please include a letter with your complete name,

street address, email address and phone number where you can be reached during business days, your RMA number, a list of

the included items, method of payment for any non-warranty expenses and a brief summary of the problem. Your original sales

receipt must also be included for warranty consideration. Be sure your name, address, and RMA number are clearly written on the

outside of the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-of-purchase date. Provided warranty

conditions have been met, your Product will be repaired or replaced free of charge. Repair or replacement decisions are at the

sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will be completed and payment will be required without notification or

estimate of the expense unless the expense exceeds 50% of the retail purchase cost. By submitting the item for repair you are

agreeing to payment of the repair without notification. Repair estimates are available upon request. You must include this request with your repair. Non-warranty repair estimates will be billed a minimum of ½ hour of labor. In addition you will be billed for

return freight. Please advise us of your preferred method of payment. Horizon accepts money orders and cashiers checks, as well

as Visa, MasterCard, American Express, and Discover cards. If you choose to pay by credit card, please include your credit card

number and expiration date. Any repair left unpaid or unclaimed after 90 days will be considered abandoned and will be disposed

of accordingly. Please note: non-warranty repair is only available on electronics and model engines.

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

USA

All other Products requiring warranty inspection or repair should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

USA

Please call 877-504-0233 or e-mail us at productsupport@horizonhobby.com with any questions or concerns regarding this

product or warranty.

United Kingdom

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Hobby UK

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Please call +44 (0) 1279 641 097 or e-mail us at sales@horizonhobby.co.uk with any questions or concerns regarding this

product or warranty.

Germany

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Technischer Service

Hamburger Strasse 10

25335 Elmshorn

Germany

Please call +49 4121 46199 66 or e-mail us at service@horizonhobby.de with any questions or concerns regarding this product

or warranty.

Instructions for Disposal of WEEE by Users in

the European Union

This product must not be disposed of with other waste. Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling of your waste equipment at the time of disposal will

help to conserve natural resources and ensure that it is recycled in a manner that protects human health and the

environment. For more information about where you can drop off your waste equipment for recycling, please contact

your local city office, your household waste disposal service or where you purchased the product.

Loading...

Loading...