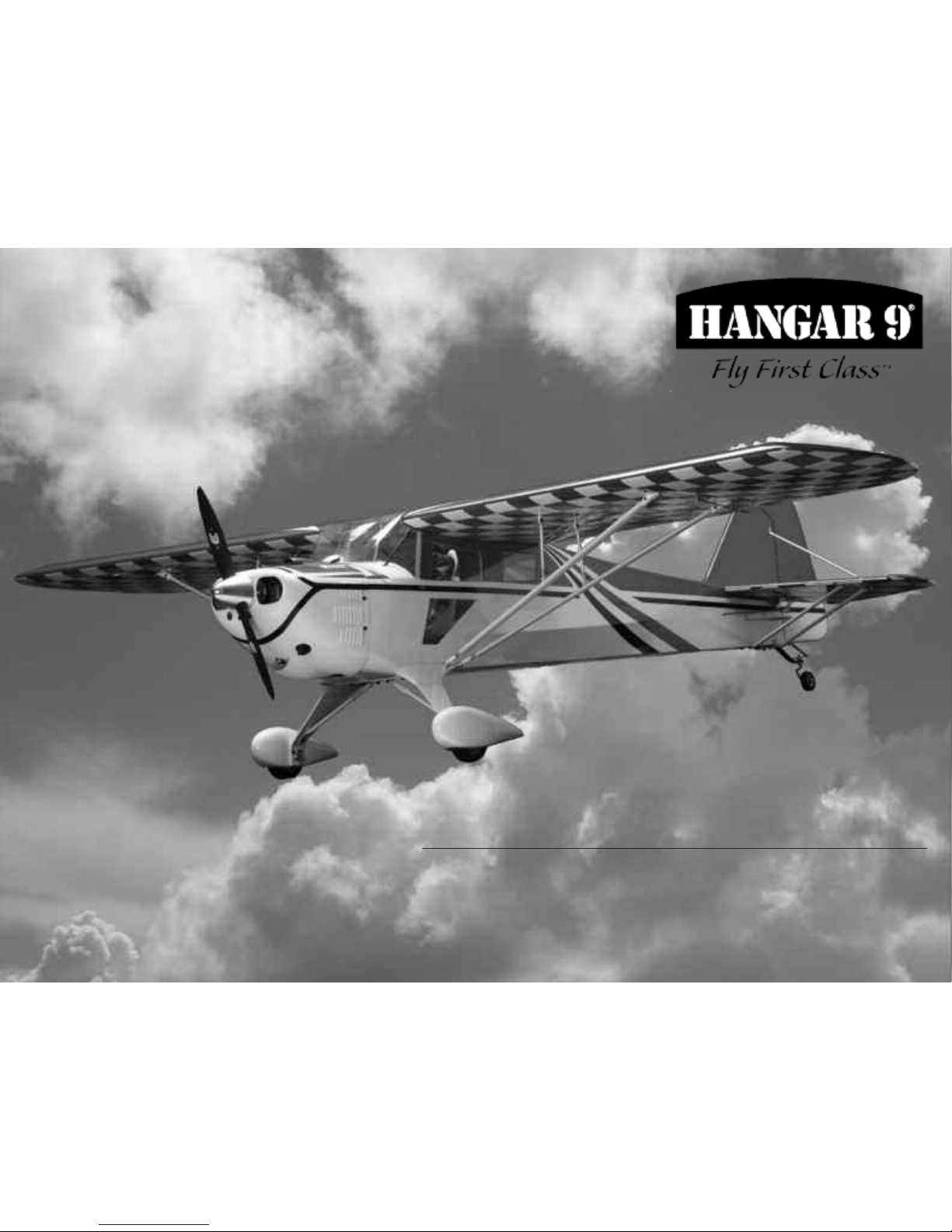

Hangar 9 Taylorcraft 20cc ARF Assembly Manual

Taylorcraft 20cc ARF

Assembly Manual

Specifications

Wingspan: ..........................................................................................80.5 in (2045.5mm)

Length: ..................................................................................................63.7 in (1618mm)

Wing Area: ............................................................................1152.73 sq in (74.4 sq dm)

Weight: .....................................................................................13-14.5 lb (5.90-6.58 kg)

Radio: ..........................................................................................4-channel w/6 servos

Engine: ....................1.00–1.60 2-stroke; 1.20–1.80 4-stroke; 20–26cc gas; Power110

Table of Contents

Contents of Kit and Parts Layout............................................2

Included Hardware.................................................................3

Using the Manual....................................................................4

UltraCote Covering Colors......................................................4

Before Starting Assembly........................................................4

Workspace Preparation..........................................................4

Radio SystemRequirements..................................................4

Recommended Power Setups................................................4

Important Information Regarding Warranty.........................4

Required Tools and Equipment......................................5

RequiredAdhesives................................................................5

Other Required Items.............................................................5

Product Registration...............................................................5

Rudder and Elevator Servo Installation..................................6

Tail Installation........................................................................7

Elevator Pushrod and Rudder Pull-Pull Cable Installation....9

Tailwheel Installation.............................................................14

Tail Brace Installation............................................................16

Landing Gear Installation......................................................19

Gas Engine Installation.........................................................21

Ignition and Engine Installation.............................................25

Throttle Servo, Linkage & Carburetor Installation................27

Cowling Installation...............................................................30

Fuel System Connections.....................................................33

Aileron Servo Installation......................................................34

Wing Strut Assembly.............................................................38

Radio Installation..................................................................41

IgnitionBattery Installation....................................................43

Windshield and Landing Gear Cuff Installation....................44

FinalAssembly......................................................................45

Center of Gravity...................................................................48

Control Throws.....................................................................49

Flight Preparations................................................................49

Maintaining Your Model........................................................50

Safety Do’s and Don’ts for Pilots..........................................51

Dual Rate..............................................................................51

Age Requirements................................................................51

Daily Flight Checks...............................................................51

Safety, Precautions and Warnings.......................................52

Warranty Information............................................................52

2009 Official Academy of

ModelAeronautics Safety Code............................55

2

Hangar 9 Taylorcraft 20cc Assembly Manual

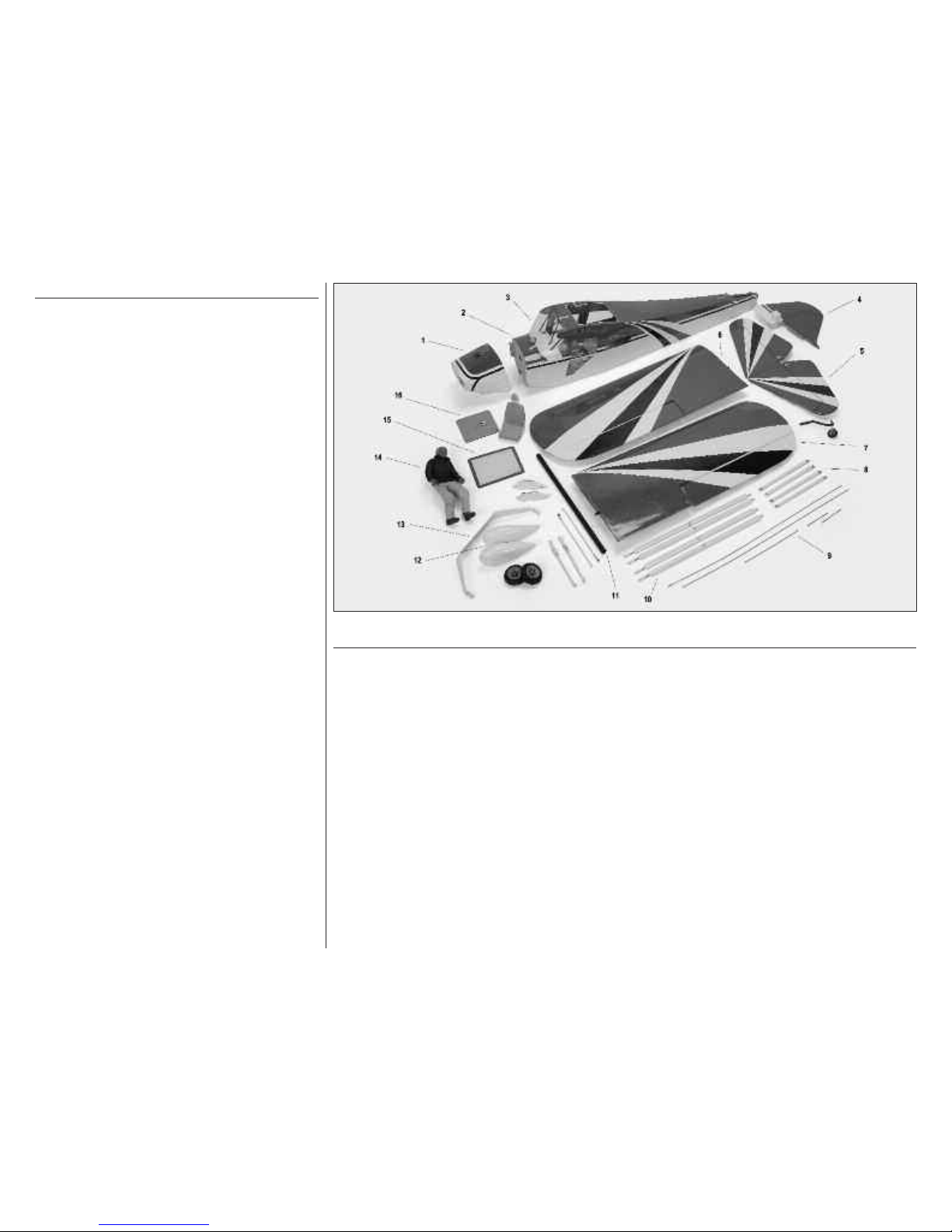

Contents of Kit and Parts Layout

Replacement Parts

1. HAN4907 Cowl

2. HAN4901 Fuselage with Top Hatch

3. HAN4906 Windshield

4. HAN4913 Fin and Rudder

5. HAN4905 Stabilizer

6. HAN4903 Left Wing Panel

7. HAN4904 Right Wing panel

8. HAN4909 Stabilizer Strut Parts

9. HAN4917 Pushrods

10. HAN4911 Wing Strut Assembly LR

11. HAN4910 Wing Tube

12. HAN4912 Wheel Pants

13. HAN4908 Landing Gear

14. HAN4566 Pilot

15. HAN4902 Top Window

16. HAN4915 Seat and Mounting Panel

Not Illustrated

HAN4914 Engine Standoffs for G20EI

HAN4916 Small Parts Bag

3

Hangar 9 Taylorcraft 20cc Assembly Manual

Included Hardware

Packaged in Kit

Fuselage (1)

Right Wing with aileron & control horn (1)

Left Wing with aileron & control horn (1)

Fin with rudder & control horn (1)

Stabilizer with elevators & control horns (1)

Cowling (1)

Windshield (1)

Wheel pants (pair) (1)

Landing gear (1)

3-inch Pro-Lite wheel (2)

Window and Seat Bag

Top window (1)

#4 x 1/4-inch screw (12)

Seat (1)

Radio compartment cover (1)

22-inch hook & loop strap (1)

Landing Gear Bag

Simulated springs (2)

Landing gear cuffs (2)

6-32 x 3/4-inch button head hex screw (6)

6-32 x 1/2-inch button head hex screw (4)

#6 steel washers (12)

6-32 nylon lock nut (2)

5/16-inch wheel collars (2)

3mm x 6mm socket head cap screws (4)

7/64-inch Allen wrench (1)

4-40 x 1/2-inch socket head cap screw (4)

#4 steel washers (4)

1 3/4-inch axle with nut (2)

Aileron Bag

#2 x 1/4-inch self-tapping screws (8)

20mmx 20mm x 10mm hardwood block (4)

Fuel Tank Bag

17oz assembled fuel tank (1)

#64 rubber band (2)

Aluminum fuel line stopper (1)

Engine Mount Bag

28mm Aluminum standoff (4)

8-32 x 1 1/2-inch button head Allen screw (4)

8-32 x 1 1/4-inch machine screw (4)

8-32 x 3/4-inch button head Allen screw (4)

8-32 blind nut (4)

8-32 nylon lock nut (4)

#8 steel washers (8)

Aluminum engine mount (2)

4-40 x 1/2-inch button head Allen screw (4)

#4 steel washer (4)

Tailwheel Bag

Tailwheel assembly with wheel (1)

Springs (2)

Tiller arm (1)

#2 x 5/8-inch self-tapping screws (2)

#4 x 3/4-inch socket head wood screws

(2)

#4 steel washers (2)

Tail Flying Wire Bag

Bottom strut supports (4)

Top flying wire (2)

4-40 steel rod end (2)

4-40 hex nut (2)

4-40 x 1/4-inch button head Allen screw (4)

4-40 x 5/8-inch button head Allen screw (5)

#4 steel washers (6)

Brass tab (2)

Aluminum tab (1)

Control Hardware Bag

89-inch coated control cable (1)

4-40 steel clevis (6)

4-40 rigging coupler (4)

4-40 hex nut (6)

6-32 x 1-inch button head Allen screw (4)

#6 steel washer (4)

Copper crimp (4)

Nylon clevis (1)

Snap link (1)

2-56 ball link with hardware (1)

4-40 ball link with hardware (6)

1/4-20 x 1 1/2-inch nylon bolt (2)

Silicone clevis keepers (10)

Strut Hardware Bag

4-40 x 3/8-inch button head Allen screw (4)

4-40 x 1/2-inch button head Allen screw (4)

4-40 x 5/8-inch socket head cap screw (4)

4-40 nylon lock nut (8)

#4 steel washer (4)

5mm hex nut (4)

Silicone pin spacer (4)

Strut pin & keeper (4)

Strut end (4)

Strut bracket (fuselage) (2)

Strut bracket (wing) (4)

Jury strut fitting (4)

Jury strut (6)

Forward strut (2)

Rear strut (2)

Pushrod Bag

4-40 x 32 1/4-inch pushrod (2)

4-40 x 4 5/16-inch pushrod (2)

2-56 x 13-inch pushrod (1)

8-inch nylon pushrod housing (1)

21 3/4 x 3/4-inch aluminum wing tube (1)

4

Hangar 9 Taylorcraft 20cc Assembly Manual

Using the Manual

This manual is divided into sections to help make

assembly easier to understand, and to provide breaks

between each major section. In addition, check boxes

have been placed next to each step to keep track of

completed sections. Steps with a single box () are

performed once, steps with two boxes () indicate

that the step needs to be repeated, such as for left

and right wing panel, or two servos etc.

Before beginning it is a good idea to read through the

manual completely to familiarize yourself with the

assembly process. Remember to take your time and

follow the directions.

UltraCote®Covering Colors

● White HANU870

● Black HANU874

● True Red HANU866

● 2-inch squares, Red/White HANU944

Before Starting Assembly

Before beginning the assembly of your model, remove

each part from its bag for inspection. Closely inspect

the fuselage, wing panels and tail section for

condition. If you find any damaged or missing parts

contact the place of purchase.

Any wrinkles in the covering can be removed with a

heat gun or covering iron. Use caution while working

around edges and areas where colors overlap to

prevent separating the covering.

Workspace Preparation

During the course of building your Taylorcraft we

suggest that you use a soft base on the building

surface. Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well and

help protect the model from damage during assembly.

A flat area measuring at least 24 x 72-inches is

required to work on the model sub-assemblies

comfortably. The completed and assembled model

requires a space of 72 x 90-inches. Ensure you have

adequate lighting, and a place to set aside parts that

have been completed.

Radio System Requirements

Spektrum Radio System

● DX7 7-channel radio with receiver (SPM2710)

● JRPS821 DS821 Digital Sport servo (5)

● JRPS537 Standard servo for throttle

(not required for EP version)

● JRPA098 12-inch servo extension (4)

● JRPA004 Deluxe Chargeswitch

● JRPB5008 2700mAh receiver battery

Optional Item

● 2-1/2" Aluminum Spinner (TRU2502B120)

Recommended Setup–Gas

● Zenoah G20EI (ZENE20EI)

● Evolution propeller 16x6 (EVO16060)

● Deluxe Chargeswitch (JRPA004)

● Ignition Battery 4500mAh (JRPB5004)

● Gas fuel tubing (DUB799)

Recommended Setup–Electric

● E-flite Power 110 (EFLM4110A)

● Phoenix HV-85 ESC (CSEPHX85HV)

● Thunder Power 4S 5000mAh Li-Po (2)

● APC Propeller 18x8E (APC18080E)

Recommended Setup–2-stroke Glow

● Evolution 1.20NX with muffler (EVOE1200)

● Evolution propeller 16x6 (EVO16060)

Recommended Setup–4-stroke Glow

● Saito FA-125A (SAIE125A)

● Evolution propeller 16x6 (EVO16060)

Important Warranty Information

Please read our Warranty and Liability Limitations section

on Page 52 before assembling this product. If you as the

purchaser are not prepared to accept the liability

associated with the use of this Product, you are advised

to return this Product immediately in new and unused

condition to the place of purchase.

5

Hangar 9 Taylorcraft 20cc Assembly Manual

Required Tools and Equipment

Drill Pin vise

Low-tack tape Pliers

Ruler Sidecutters

File Felt-tipped pen

Pencil Medium grit sandpaper

Tapered reamer Hobby knife (#11 blade)

Dental floss Manila card stock

Alcohol Paper towels

Crimping pliers Double-sided adhesive tape

Mixing sticks Mixing cups

Needle nose pliers Scissors

Rotary tool with sanding drum

Cable ties: small (4-inch), medium (7-inch)

Phillips screwdriver: #0, #1

Hex wrench or balldriver: 5/64, 3/32, 1/8-inch

: 1.5, 2.5, 3, 4mm

open-end wrench: 3/16, 1/4, 9/32, 5/16-inch

: 10, 13mm

Drill bit: 1/32, 11/64, 3/32, 11/64, 3/16, 13/64,1/4-inch

Required Adhesives

Thin CA (PAAPT08)

Medium CA (PAAPT02)

12-minute epoxy (HAN8001)

Threadlock (PAAPT42)

Canopy glue (PAAPT56)

Other Required Items

12-inch extension leads (JRPA098) (4)

Fuel dot filler (HAN115)

Heavy-duty servo arms (JRPA215)

1/4-inch foam rubber (DUB513)

Product Registration

Horizon Hobby wants to ensure that you get

maximum enjoyment from your Hangar 9 products.

We strongly encourage you to register your product

using the online Product Registration tool so we can

notify you when there are service bulletins, new option

parts or accessories, or updates available for your

product.

Register your product today at:

http://www.hangar-9.com/Register/

Optional Accessory

Setting up servos is a whole lot easier with a JR

®

MatchMaker™. It lets you accurately center servos,

evaluate endpoints, and cycle servos at varying

speeds, without ever having to switch on a transmitter.

It allows the precise digital centering of up to 2 servos

at a time to help with setup on the building bench.

Work Area Cleanliness

It is a good practice to maintain a clean work area,

both to prevent damage to your model and to keep

track of parts and hardware. Put away any tools not

being used, and set aside parts of the model that are

not being worked on.

Of special importance is keeping debris out of

sensitive components such as the radio and engine or

motor. Tape over engine intake and exhaust ports

when drilling or cutting the firewall and cowling to

prevent causing damage to the internal components.

Hardware Practices

When installing hardware that consists of a button

head machine screw, washer and nut, use an openended or box wrench to tighten the nut while holding

the fastener with a hex wrench. The washer provides

a bearing surface for the nut while it is being turned,

holding the screw with a wrench prevents damage to

the part, particularly on painted components.

6

Hangar 9 Taylorcraft 20cc Assembly Manual

Rudder and Elevator Servo

Installation

Required Parts

Fuselage Servos with hardware (3)

Required Tools

Thin CA #1 Phillips screwdriver

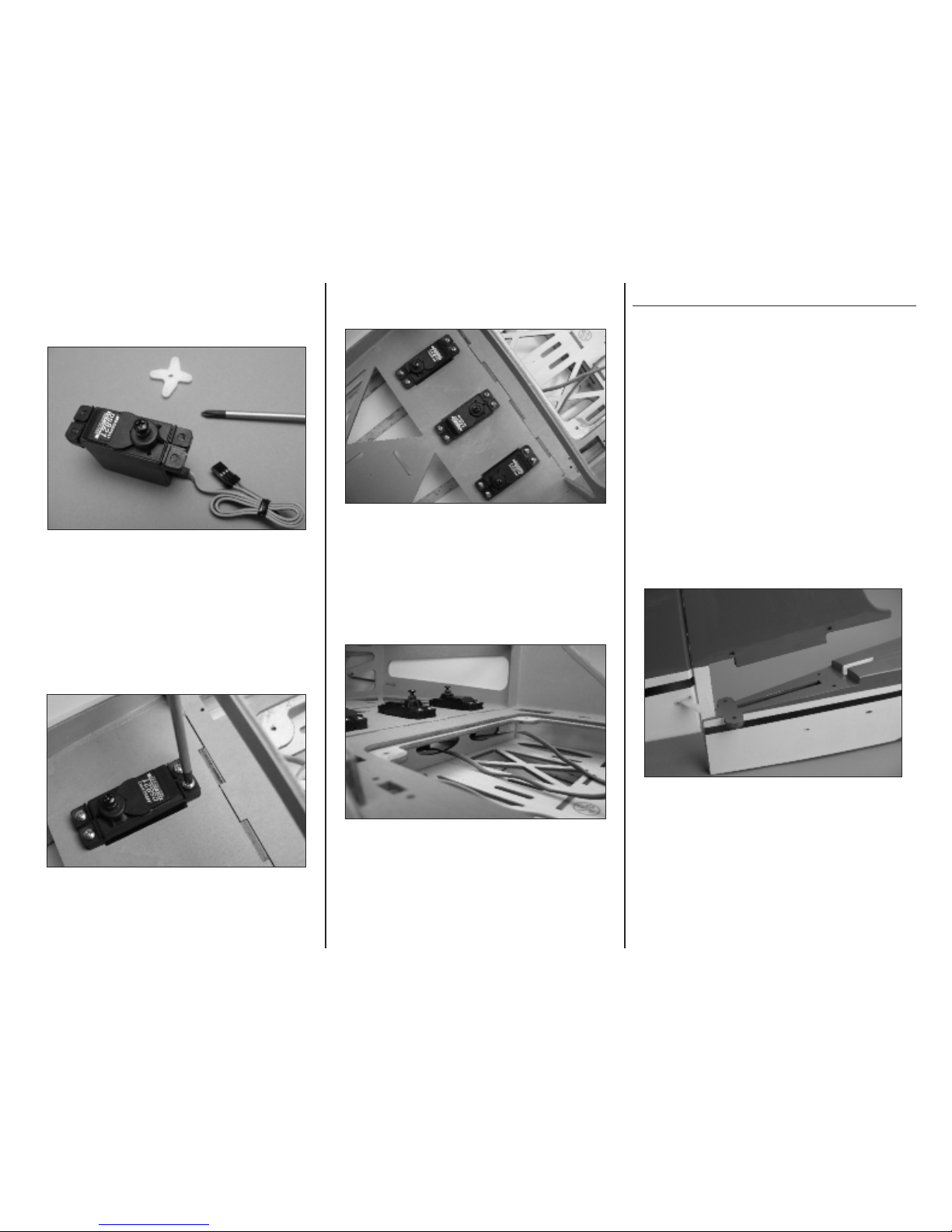

Step 1

Open the cockpit door by pulling on the handle. The

door is held closed with magnets, the handle does not

need to be turned.

Step 2

Insert the rubber grommets into the servos.

Step 3

Insert the brass bushings in the servos. Note that the

flange is located on the lower side of the servo.

Step 4

Use a #1 Phillips screwdriver to install a servo screw

in each of the pre-drilled holes in the servo tray.

Step 5

Remove the servo screw and apply a drop of thin CA

in each hole to strengthen the wood.

7

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 6

Use a #1 Phillips screwdriver to remove the stock

servo arms from the servos. Replace the servo screw.

Step 7

Use a #1 Phillips screwdriver to install the rudder and

elevator servos. The elevator servos (outer locations)

have the output shaft towards the tail, the rudder servo

mounts in the center with the output shaft forward.

Step 7

This shows the rudder and elevator servos installed.

Step 8

Route the servo leads forward into the radio

compartment through the holes in the bulkhead.

Tail Installation

Required Parts

Fuselage Fin with rudder

Stabilizer with elevators

Required Tools

Threadlock 3/32-inch hex wrench

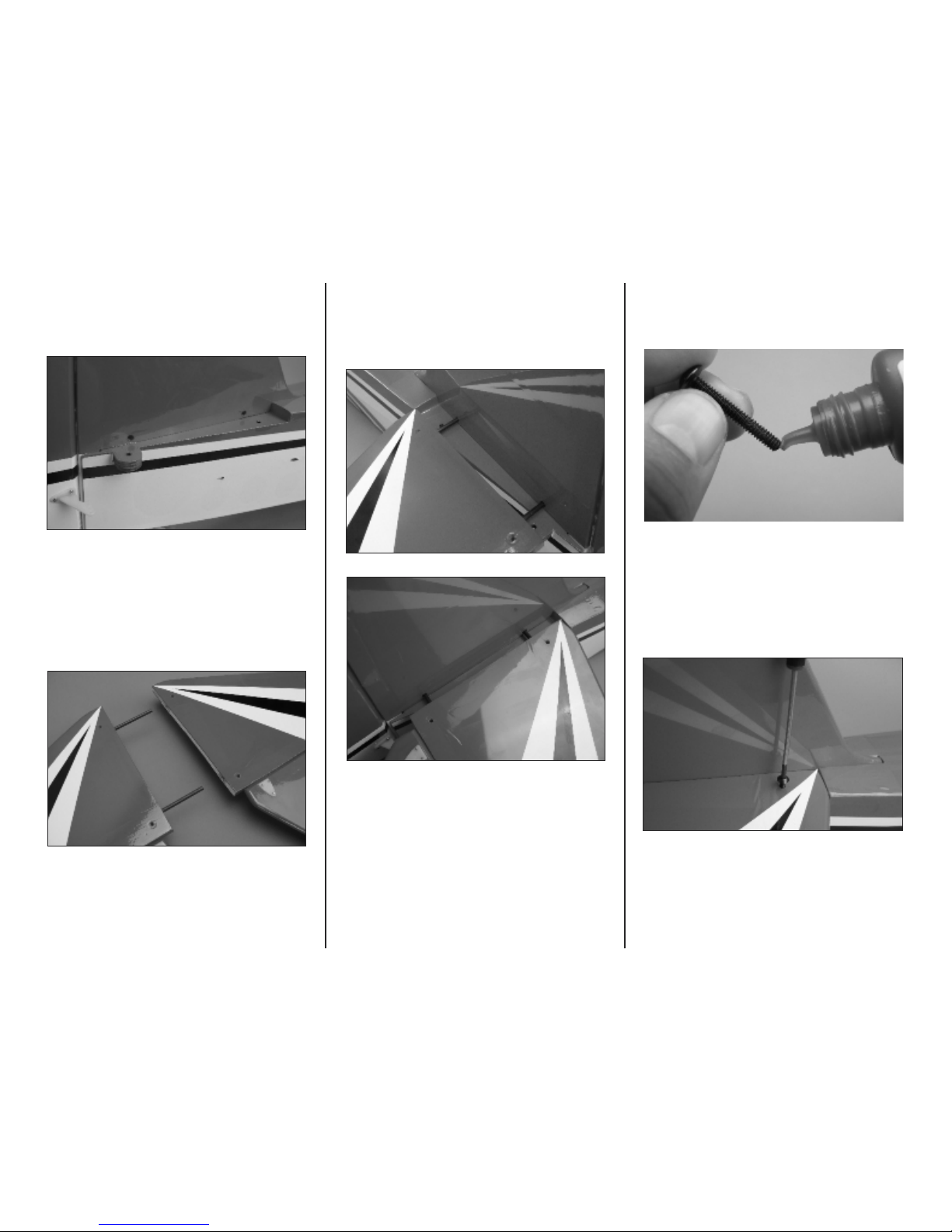

Step 1

Engage the fin post in the slot in the rear of the

fuselage behind the hold-down plate.

8

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 2

Slide the fin down until it is fully engaged in the

fuselage slots.

Step 3

Separate the stabilizer halves from each other.

Step 4

Slide the stabilizer joiner rods through the holes in the

base of the fin and slide the stabilizer halves against

each side of the fin.

Step 5

Locate the four 6-32 x 1-inch button head hex bolts.

Place a drop of threadlock on the end of the threads.

Step 6

Use a 3/32-inch hex wrench to install the four

stabilizer bolts. Use care to not tighten the bolts

excessively and crush the stabilizer structure.

9

Hangar 9 Taylorcraft 20cc Assembly Manual

Elevator Pushrod and Rudder

Pull-Pull Cable Installation

Required Parts

Fuselage Elevator pushrods (2)

4-40 hex nut (6) Pull-pull cable

4-40 clevis (6) 4-40 ball link (6)

Copper crimp (4) 4-40 rigging coupler (4)

HD servo arm 180-degree servo arm (2)

Required Tools

Pin vise 3/32-inch drill bit

1/4-inch wrench 5/64-inch hex wrench

Threadlock Pliers

Sidecutters Crimping pliers

3/16-inch wrench

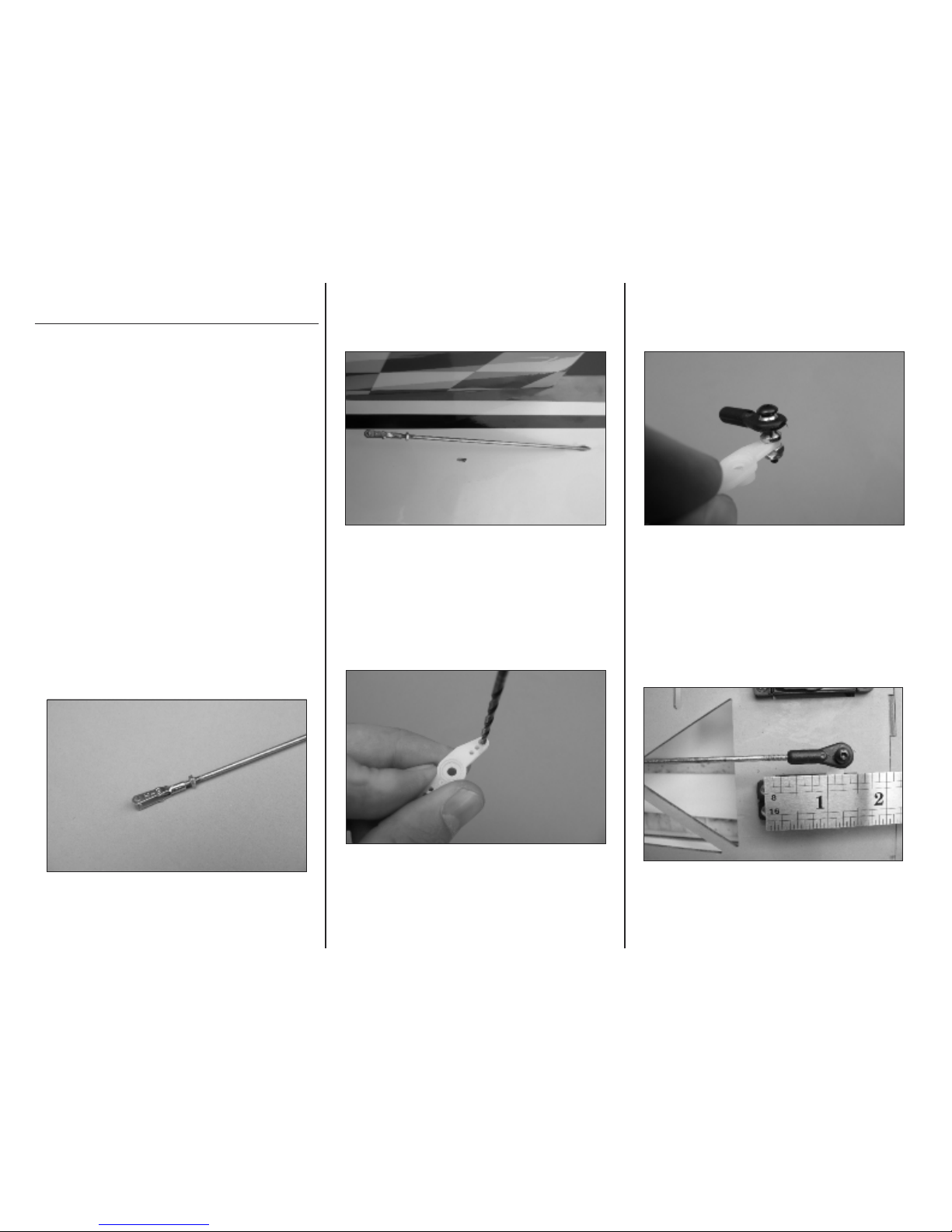

Step 1

Prepare the elevator pushrods by threading a 4-40

hex nut and 4-40 clevis onto one end.

Step 2

Insert the elevator pushrod into the pushrod housing

opening in the rear of the fuselage side.

Step 3

Use a 3/32-inch drill bit in a pin vise to enlarge the

outer hole in a standard 180 degree servo arm.

Step 4

Use a 5/64-inch hex driver and 1/4-inch wrench to

install a 4-40 ball link onto the servo arm.

Step 5

Thread the ball link and servo arm onto the servo end

of the elevator pushrod until approximately 3/8-inch of

thread remains exposed.

10

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 6

Use your radio or a JR MatchMaker to center the

elevator servo and install the servo arm using a #1

Phillips screwdriver.

Step 7

Adjust the clevis so that the elevator is centered when

connected to the center hole in the elevator horn.

Step 8

Use a ruler to check the alignment of the elevator with

the stabilizer as the clevis is being adjusted.

Step 9

Locate the coil of coated steel pull-pull cable. Uncoil

the cable and fold it against itself to find the center.

Use sidecutters to cut the cable into two equal lengths.

Step 10

Use a hobby knife with a #11 blade to debur the inside

of each end of the copper crimp. This will make it easier

to double the cable through the crimp.

Step 11

Slide a copper crimp onto the end of the pull-pull

cable.

11

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 12

Slide a 4-40 rigging coupler onto the cable next to the

copper crimp.

Step 13

Fold the cable back on itself and insert the free end

through the copper crimp. Form a loop approximately

5/8-inch long containing the rigging coupler, and leave

about 3/16-inch protruding from the crimp.

Step 14

Use crimping pliers or sidecutters on the copper crimp

to secure the cable end. Use care not to cut

completely through the cable.

Step 15

Thread a 4-40 ball link assembly onto the rigging

coupler. Use pliers to grip the coupler while threading

the ball link on.

Step 16

Use a 3/32-inch drill bit in a pin vise to enlarge the

outer hole in each end of a JR heavy-duty servo arm.

Step 17

Use a 5/64-inch hex wrench and 1/4-inch open-end

wrench to install the ball link and cable assemblies

onto the servo arm.

12

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 18

Feed the free end of each rudder pull-pull cable into

the guide tubes inside the fuselage. The tubes are

located in the first bulkhead behind the servo tray.

Step 19

Use your radio or JR Matchmaker to center the rudder

servo, and use a #1 Phillips screwdriver to secure the

arm to the servo.

Step 20

Invert the fuselage on the work table. Install a 4-40

hex nut and clevis on a rigging coupler so that about

three threads protrude from the barrel of the clevis.

Attach the clevis to the middle hole in the rudder horn.

Step 21

Slide a copper crimp onto the pull-pull cable.

Step 22

Insert the free end of the pull-pull cable through the

hole in the end of the rigging coupler.

Step 23

Insert the free end of the pull-pull cable through the

copper crimp.

13

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 24

Adjust the pull-pull cables in the rigging couplers to

center the rudder and remove slack from the cables.

Use a ruler to check the alignment of the rudder to the

fin while making the adjustments.

Step 25

Check that the rudder servo arm and rudder are

centered then use crimping pliers or sidecutters to

secure the copper crimp to the pull-pull cables.

Step 26

Use sidecutters to trim the excess cable protruding

from the crimp.

Step 26

Place a drop of threadlock on the threads of the

rigging coupler between the clevis and the hex nut.

Step 27

Use a 3/16-inch open-end wrench to tighten the hex

nut against the clevis.

Step 28

Repeat steps 26 and 27 to secure the hex nuts

against the elevator clevises.

14

Hangar 9 Taylorcraft 20cc Assembly Manual

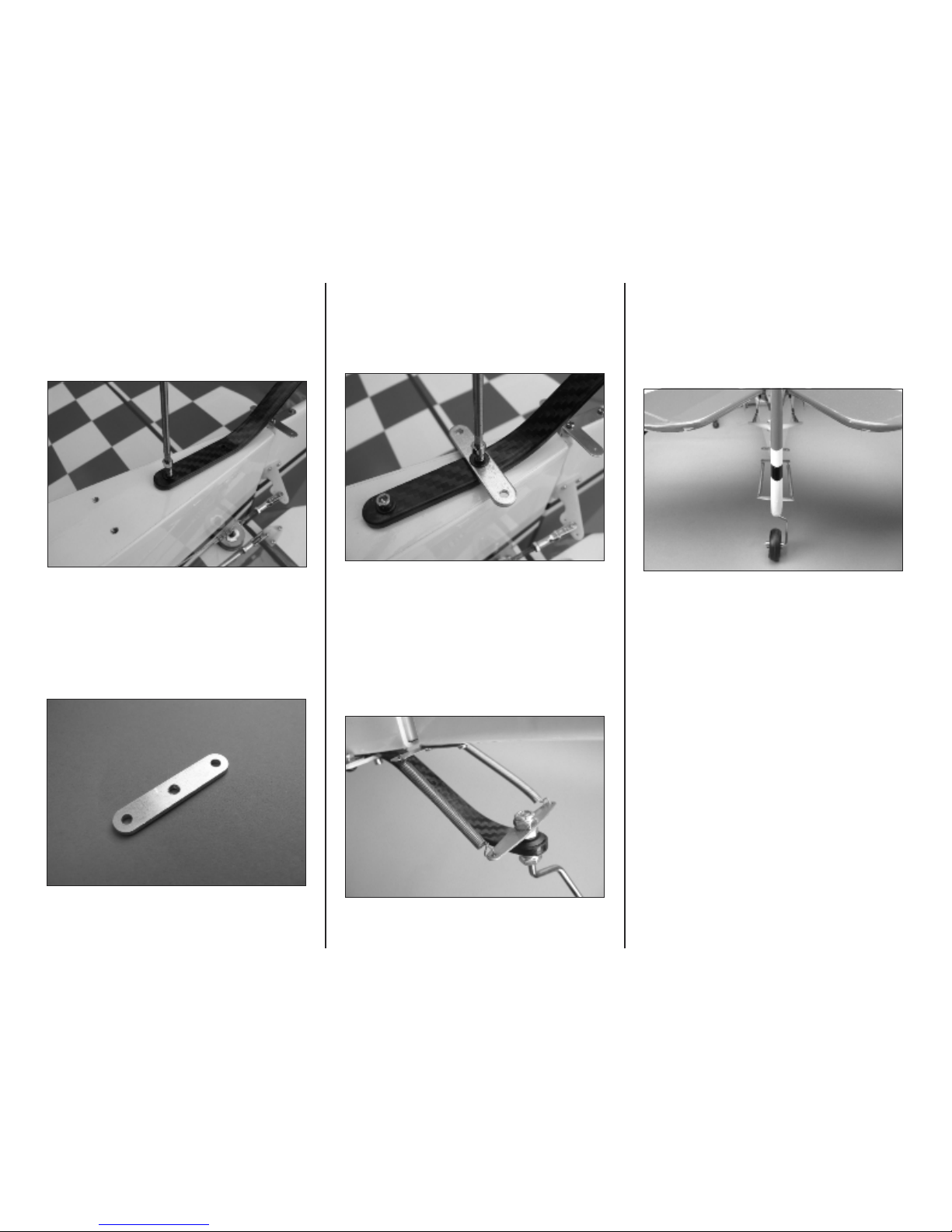

Tailwheel Installation

Required Parts

Fuselage Tailwheel assembly

Tiller arm Springs

#4 washer (2)

#4 x 3/4-inch socket head cap screw

#2 x 5/8-inch self-tapping screws

Aluminum tab from tail brace parts bag

Required Tools

Pin vise 1/32-inch drill bit

Felt-tipped pen Thin CA

2.5mm hex wrench Needle nose pliers

3/32-in hex wrench #1 Phillips screwdriver

Step 1

Invert the fuselage on the work table. Place the tiller

arm on the bottom of the rudder with its edge aligned

with the forward edge of the rudder. Mark the

mounting holes with a felt-tipped pen.

Step 2

Use a 1/32-inch drill in a pin vise to drill the mounting

holes for the tiller arm screws.

Step 3

Place 3–4 drops of thin CA in each of the holes to

strengthen the wood around the holes. Do not use

accelerator as the CA needs to fully penetrate the wood.

Step 4

Use a #1 Phillips screwdriver to install the tiller arm

with two #2 x 5/8-inch self-tapping screws.

Step 5

Apply a 1–2 drops of thin CA to each of the tailwheel

mounting holes. Do not use accelerator as the CA

needs to fully penetrate the wood.

15

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 6

Place the tailwheel assembly over the mounting holes

on the rear fuselage. Use a 3/32-in hex wrench to

install a #4 x 3/4-in socket head wood screw and #4

steel washer in the forward mounting hole.

Step 7

Locate the aluminum mounting tab from the tail brace

parts bag.

Step 8

Place the aluminum tab on the tailwheel assembly

over the rear hole. Use a 3/32-in hex wrench to install

the second mounting screw and washer.

Step 9

Use needle nose pliers to bend a loop in each end of

the tailwheel steering springs and attach them to each

end of the steering tiller on the rudder and tailwheel

assembly.

Step 10

The springs should be under slight tension when

installed. Form the springs to approximately equal

lengths and adjust as necessary to align the tailwheel

with the rudder.

17

Hangar 9 Taylorcraft 20cc Assembly Manual

Step 6

Locate the 10 1/4-inch lower rear stabilizer strut.

Install it on the lower surface of the stabilizer over the

screw inserted in Step 5 and thread on a 4-40 nylon

lock nut.

Step 7

Use a 5/64-inch hex wrench and 1/4-inch open-end

wrench to tighten the brass strap and rear strut to the

stabilizer.

Step 8

Attach the inboard end of the rear strut to the top of

the aluminum tab with a 4-40 x 1/4-inch button head

machine screw and 4-40 nylon locknut.

Step 9

Use a 5/64-inch hex wrench and 1/4-inch open-end

wrench to tighten the rear strut to the aluminum tab.

Step 10

Thread a 4-40 rod end onto the threaded section of

the upper brace wire and adjust it until the hole is

aligned with the hole in the brass tab.

Step 11

Place a small amount of threadlock on a 4-40 x 1/4inch button head machine screw and install it with a

5/64-inch hex wrench.

16

Hangar 9 Taylorcraft 20cc Assembly Manual

Tail Brace Installation

Parts Required

Fuselage Lower strut (4)

Brass tab (2) Upper brace wire (2)

4-40 rod end (2) 4-40 hex nut (2)

#4 washer (6) 4-40 nylon lock nut (6)

4-40 x 5/8-inch button head machine screw (5)

4-40 x 1/4-inch button head machine screw (4)

Tools Required

5/64-in hex wrench Threadlock

Needle nose pliers 1/4-inch open-end wrench

Step 1

Insert a #4 washer and 4-40 x 5/8-inch button head

machine screw through the mounting tab of the upper

wire brace and into the rear hole in the fin. Whether

the bolt head is on the left or right side is not critical.

Step 2

On the opposite side of the fin, place the other wire

brace over the protruding screw, then a #4 washer

and 4-40 nylon lock nut.

Step 3.

Use a 5/64-inch hex wrench and 1/4-inch open-end

wrench to tighten the upper brace wires against the

fin. Only a snug fit is necessary so as not to crush the

structure.

Step 4

Use a pair of needle nose pliers to form a bend in the

center of each of the brass tabs.

Step 5

Install the brass tab to the rear hole on the upper

surface of the stabilizer with a #4 washer and 4-40 x

5/8-in button head hex screw.

Loading...

Loading...