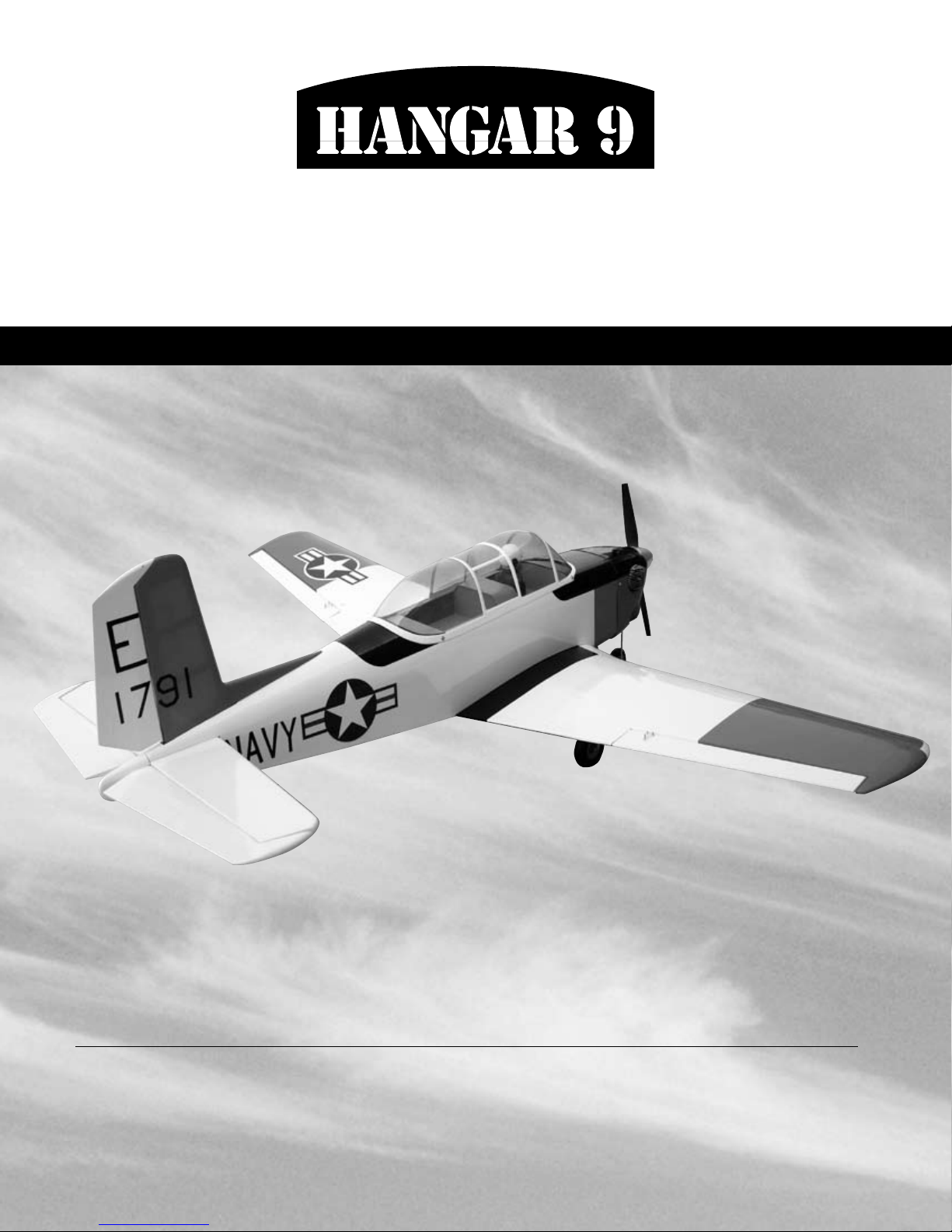

Hangar 9 T-34 Mentor 40 ARF, T-34 Mentor Assembly Manual

T-34 Mentor 40 ARF

®

Assembly mAnuAl

Specifications

Wingspan .................................. 57.75 in (1454mm)

Wing Area

Length ............................................ 45 in (1146mm)

........................... 555 sq in (35.8 sq dm)

Weight ................................. 6–7 lb (2.7 kg–3.2 kg)

Radio................................. 4-Channel w/5–7 servos

Engines ............ .40–.52 2-stroke, .56–.72 4-stroke

Table of Contents

Contents of Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

UltraCote Covering Colors

Radio and Power Systems Requirements

Field Equipment Required

Optional Field Equipment

Required Tools and Adhesives

Other Items Needed (not included in the kit)

Limited Warranty Period

Limited Warranty & Limits of Liability

Safety Precautions

Questions, Assistance, and Repairs

Questions or Assistance

Inspection or Repairs

Warranty Inspection and Repairs

Non-Warranty Repairs

Safety, Precautions, and Warnings

Before Starting Assembly

Using the Manual

Section 1: Joining the Wing Halves

Section 2: Installing the Horizontal Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3: Installing the Vertical Stabilizer

Section 4: Installing the Ailerons

Section 5: Installing the Elevators

Section 6: Installing the Rudder

Section 7: Fixed Gear Installation

Section 8: Retract Installation

Section 9: Retract Linkage Installation

Section 10: Engine Installation

Section 11: Throttle Pushrod Installation

Section 12: Fuel Tank Installation

Section 13: Electric Motor Installation

Section 14: Radio Installation

Section 15: Linkage Installation

Section 16: Cowling Installation

Section 17: Canopy and Decal Installation

Recommended CG Location

Recommended Control Throws

Adjusting the Engine

Pre-Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Range Test Your Radio

2006 Official AMA National Model Aircraft Safety Code

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

2

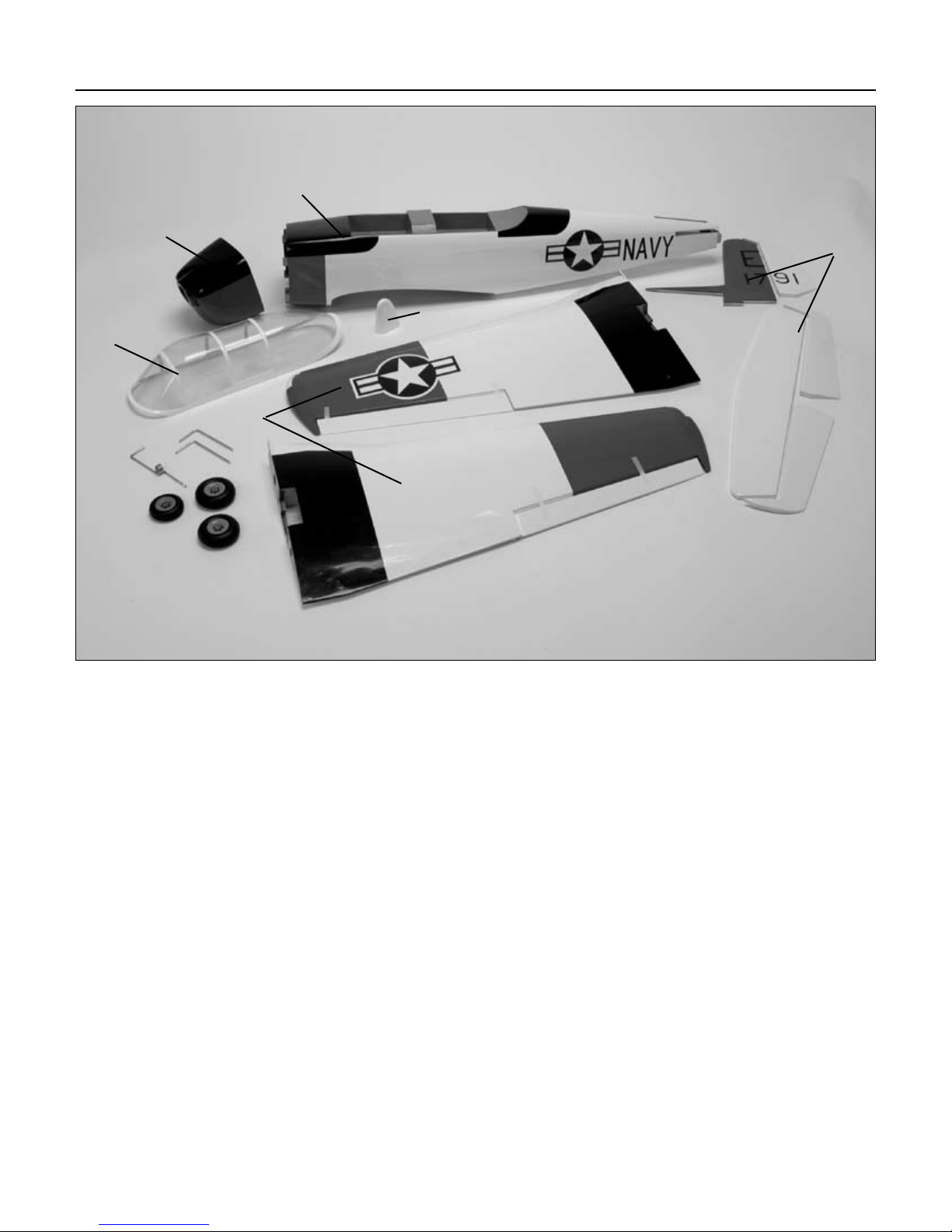

Contents of Kit

E

D

B

A

C

F

Replacement Parts

Large Parts

A. Fuselage HAN4326

B. Wing Set w/Joiner and Ailerons HAN4327

C. Tail Set HAN4328

D. Canopy HAN4330

E. Painted Cowl HAN4331

F. Tail Cone HAN4329

Items Not Shown

Fixed Landing Gear Set HAN2432

Decal Set HAN2433

3

UltraCote® Covering Colors

• White HANU870 • True Red HANU866

• Black HANU874

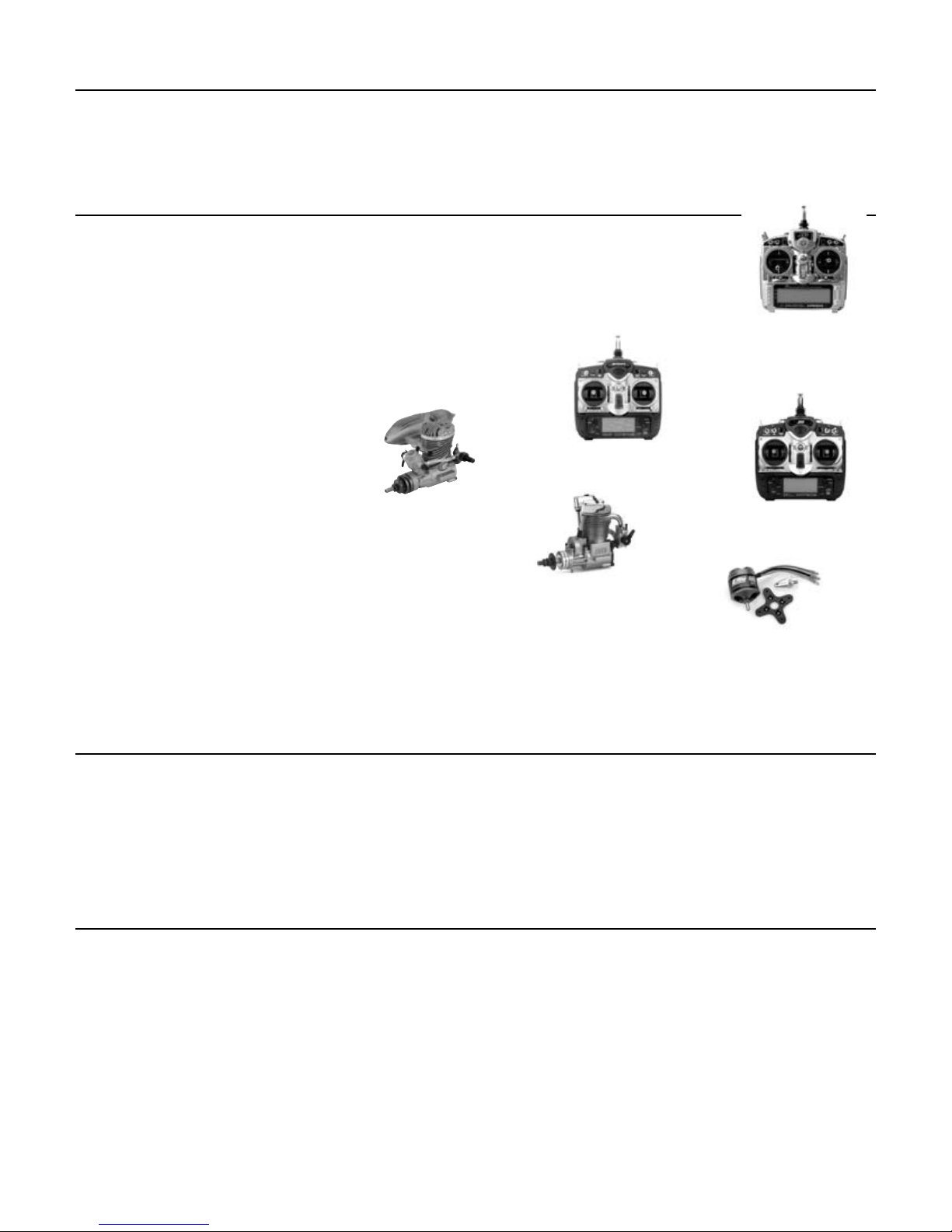

Radio and Power Systems Requirements

Radio Equipment

• 4-channel radio system (minimum)

(5 if using retracts)

• 5 standard servos (JRPS821, JSPST47BB recommended or equivalent)

(2 retract servos required if using retracts)

Recommended JR® or JR SPORT™ Systems

• XP9303

• XP7202

• XP6102

• XP662

• SX600

• S400

Recommended Power Systems

• .40–.52 2-stroke

• .56–.82 4-stroke

• Power 46 Brushless Outrunner

• EP Motor Mount (HAN4245) for electric motor installation

Evolution .46NT

EVOE0460

JR XP6102

Saito .82 AAC

SAIE082A

JR XP9303

JR XP7202

Power 46 Brushless

Outrunner Motor, 670KV

EFLM4046A

Field Equipment Required

• Propeller • Fuel

• Long Reach Glow Plug Wrench (HAN2510) • Metered Glow Driver w/Ni-Cd & Charger (HAN7101)

• 2-Cycle Sport Plug (HAN3001) • 2-Cycle Super Plug (HAN3006)

• 4-Cycle Super Plug (HAN3011) • Manual Fuel Pump (HAN118)

Optional Field Equipment

• 12V 7Ah Sealed Battery (HAN102) • PowerPro™ 12V Starter (HAN161)

4

Required Tools and Adhesives

Tools

• Canopy Scissors • Drill

• Square • Flat blade screwdriver

• Foam: 1/2" (6mm) • Hobby knife

• Masking tape • Phillips screwdriver (large)

• Phillips screwdriver (small) • Pliers

• Ruler • Sandpaper

• Drill Bit: 1/16" (1.5mm), 3/32" (2.5mm), 1/8" (3mm), 7/32" (5.5mm), 1/4" (6mm)

Adhesives

• 6-minute epoxy • 30-minute epoxy

• Thin CA (cyanoacrylate) glue • Thick CA (cyanoacrylate) glue

• CA remover/debonder • Pacer Z-42 Threadlock

• Canopy glue (RC-56) • Masking tape (3M blue recommended)

Other Required Items

• Epoxy brushes • Felt-tipped pen or pencil

• File • Measuring device (e.g. ruler, tape measure)

• Mixing sticks for epoxy • Paper towels

• Petroleum jelly • Rubbing alcohol

• Sanding bar • Sandpaper (medium)

• String • T-pins

• Wax paper

Other Items Needed (not included in the kit)

• Propeller (consult engine instructions) • JRPS821, JSPST47BB or equivalent recommended

• 9" Servo Lead Extension (JRPA097) (2) • Mechanical Retracts, Tricycle (HAN157)

• JRPS791 Hi-Torque Low profile Retract Servo,

JSP RT-88 low profile retract servo, or equivalent

is recommended

5

Limited Warranty Period

Horizon Hobby, Inc. guarantees this product to be free from defects in both material and workmanship at the date

of purchase.

Limited Warranty & Limits of Liability

Pursuant to this Limited Warranty, Horizon Hobby, Inc. will, at its option, (i) repair or (ii) replace, any product determined

by Horizon Hobby, Inc. to be defective. In the event of a defect, these are your exclusive remedies.

This warranty does not cover cosmetic damage or damage due to acts of God, accident, misuse, abuse, negligence,

commercial use, or modification of or to any part of the product. This warranty does not cover damage due to improper

installation, operation, maintenance, or attempted repair by anyone other than an authorized Horizon Hobby, Inc. service

center. This warranty is limited to the original purchaser and is not transferable. In no case shall Horizon Hobby’s

liability exceed the original cost of the purchased product and will not cover consequential, incidental or collateral

damage. Horizon Hobby, Inc. reserves the right to inspect any and all equipment involved in a warranty claim. Repair

or replacement decisions are at the sole discretion of Horizon Hobby, Inc. Further, Horizon Hobby reserves the right to

change or modify this warranty without notice.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER.

HORIZON HOBBY, INC. SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

As Horizon Hobby, Inc. has no control over use, setup, final assembly, modification or misuse, no liability shall be

assumed nor accepted for any resulting damage or injury. By the act of use, setup or assembly, the user accepts all

resulting liability.

If you as the purchaser or user are not prepared to accept the liability associated with the use of this product, you are

advised to return this product immediately in new and unused condition to the place of purchase.

Safety Precautions

This is a sophisticated hobby product and not a toy. It must be operated with caution and common sense and requires

some basic mechanical ability. Failure to operate this product in a safe and responsible manner could result in injury or

damage to the product or other property. This product is not intended for use by children without direct adult supervision.

The product manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the

instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage

or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once assembly, setup or use

of the product has been started, you must contact Horizon Hobby, Inc. directly. This will enable Horizon to better answer

your questions and service you in the event that you may need any assistance.

Questions or Assistance

For questions or assistance, please direct your email to productsupport@horizonhobby.com, or call 877.504.0233 toll

free to speak to a service technician.

6

Inspection or Repairs

If your product needs to be inspected or repaired, please call for a Return Merchandise Authorization (RMA). Pack the

product securely using a shipping carton. Please note that original boxes may be included, but are not designed to

withstand the rigors of shipping without additional protection. Ship via a carrier that provides tracking and insurance for

lost or damaged parcels, as Horizon Hobby, Inc. is not responsible for merchandise until it arrives and is accepted at

our facility. Include your complete name, address, phone number where you can be reached during business days, RMA

number, and a brief summary of the problem. Be sure your name, address, and RMA number are clearly written on the

shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-of-purchase date. Providing

warranty conditions have been met, your product will be repaired or replaced free of charge. Repair or replacement

decisions are at the sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty and the expense exceeds 50% of the retail purchase cost, you will be

provided with an estimate advising you of your options. You will be billed for any return freight for non-warranty repairs.

Please advise us of your preferred method of payment. Horizon Hobby accepts money orders and cashiers checks, as

well as Visa, MasterCard, American Express, and Discover cards. If you choose to pay by credit card, please include your

credit card number and expiration date. Any repair left unpaid or unclaimed after 90 days will be considered abandoned

and will be disposed of accordingly.

Electronics and engines requiring inspection or repair should be shipped to the following address (freight prepaid):

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other products requiring inspection or repair should be shipped to the following address (freight prepaid):

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

7

Safety, Precautions, and Warnings

As the user of this product, you are solely responsible for operating it in manner that does not endanger yourself and

others or result in damage to the product or the property of others.

Carefully follow the directions and warnings for this and any optional support equipment (chargers, rechargeable battery

packs, etc.) that you use.

This model is controlled by a radio signal that is subject to interference from many sources outside your control. This

interference can cause momentary loss of control so it is necessary to always keep a safe distance in all directions around

your model, as this margin will help to avoid collisions or injury.

• Always operate your model in an open area away from cars, traffic, or people.

• Avoid operating your model in the street where injury or damage can occur.

• Never operate the model out into the street or populated areas for any reason.

• Never operate your model with low transmitter batteries.

• Carefully follow the directions and warnings for this and any optional support equipment (chargers, rechargeable

battery packs, etc.) that you use.

• Keep all chemicals, small parts and anything electrical out of the reach of children.

• Moisture causes damage to electronics. Avoid water exposure to all equipment not specifically designed and protected

for this purpose.

Before Starting Assembly

Before beginning the assembly of the Sopwith Camel, remove each part from its bag for inspection. Closely inspect the

fuselage, wing panels, rudder, and stabilizer for damage. If you find any damaged or missing parts, contact the place of

purchase.

If you find any wrinkles in the covering, use a heat gun or sealing iron to remove them. Use caution while working around

areas where the colors overlap to prevent separating the colors.

HAN101 – Sealing Iron

HAN141 – Sealing Iron

Sock

HAN100 – Heat Gun

HAN150 – Covering Glove

Using the Manual

This manual is divided into sections to help make assembly easier to understand, and to provide breaks between each

major section. In addition, check boxes have been placed next to each step to keep track of each step completed. Steps

with a single box (

repeating, such as for a right or left wing panel, two servos, etc. Remember to take your time and follow the directions.

) are performed once, while steps with two boxes ( ) indicate that the step will require

8

Section 1: Joining the Wing Halves

Required Parts

• Left and right wing panels

• Wing joiner (large & small)

• Wing dowels (2)

Required Tools and Adhesives

• Ruler • Masking tape

• 30-minute epoxy • Epoxy brush

• Mixing stick • Rubbing alcohol

• Paper towels

Step 1

Test the fit of the wing joiners into the right and left wing

panels. The joiners should slide into the panels with little

resistance. The larger joiner is located in the slot towards

the leading edge of the wing. Lightly sand the joiners if

they are a tight fit.

Step 3

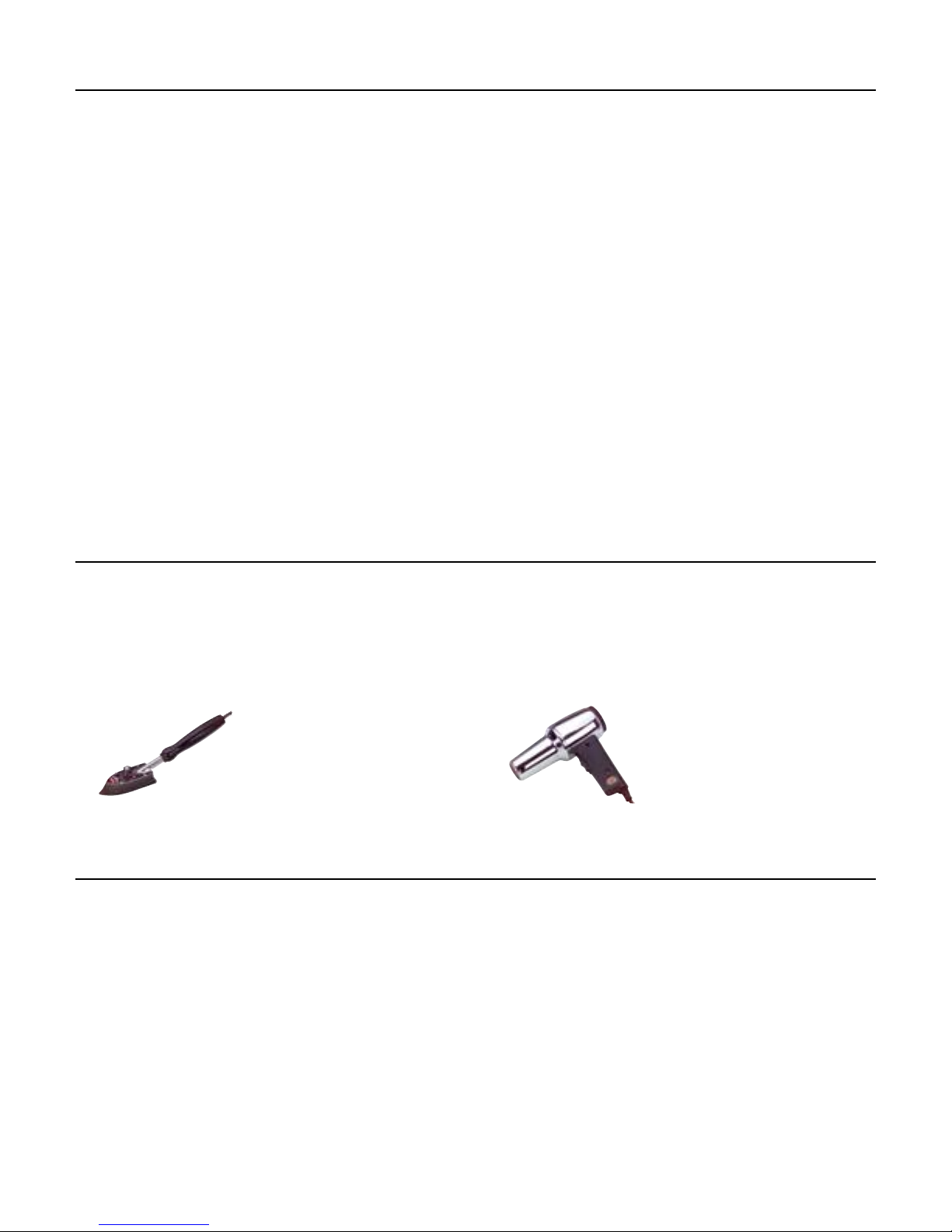

With the wing panels together, check for correct dihedral.

Place the wing on a large flat surface with one panel

resting flat on the surface. The center of the opposite

wing tip should be 6

work surface. Once satisfied with the fit, separate the wing

panels and remove the wing joiner.

Note: Read through the remaining steps

of this section before mixing any epoxy.

7

/8" to 7" (175mm–178mm) from the

Step 2

Without using any glue, test fit the wing panels together

using the wing joiners. The panels must fit together

without any gaps top or bottom. If any gaps do exist, use

a sanding bar to lightly sand the root ribs of both panels

until the panels fit together perfectly.

Hint: It is extremely important to use

plenty of epoxy when joining the wing

panels. It will also be helpful to use

wax paper under the wing joint to avoid

gluing the wing to your work surface.

Step 4

Mix approximately 1 ounce of 30-minute epoxy. Using

an epoxy brush, apply a generous amount of epoxy to the

wing joiner cavities of one wing panel.

9

Section 1: Joining the Wing Halves

Step 5

Completely coat one half of the each wing joiner with

epoxy. Be sure to apply epoxy to the top and bottom of the

joiner also. Insert the epoxy-coated side of the joiner into

the wing joiner cavity up to the mark on the joiner. If you

have used enough epoxy, it will ooze out of the cavity as

the joiner is installed. Remove any excess epoxy using a

paper towel and rubbing alcohol.

Step 6

Apply a generous amount of epoxy to the joiner cavity of

the opposite wing panel.

Step 7

Apply epoxy to the exposed portion of the wing joiner.

Step 9

Carefully slide the wing panels together. Apply enough

pressure to firmly seat the two wing panels together,

causing any excess epoxy to ooze out from between the

panels. Use rubbing alcohol and a paper towel to remove

the excess epoxy. Check to make sure there are no visible

gaps between the panels.

Step 10

Use masking tape to securely hold the wing panels

together. Place the wing assembly back onto the work

surface (covered with wax paper) and check the dihedral

angle. Allow the epoxy to fully cure before continuing to

the next section.

Step 8

Apply epoxy to root wing rib of both panels.

10

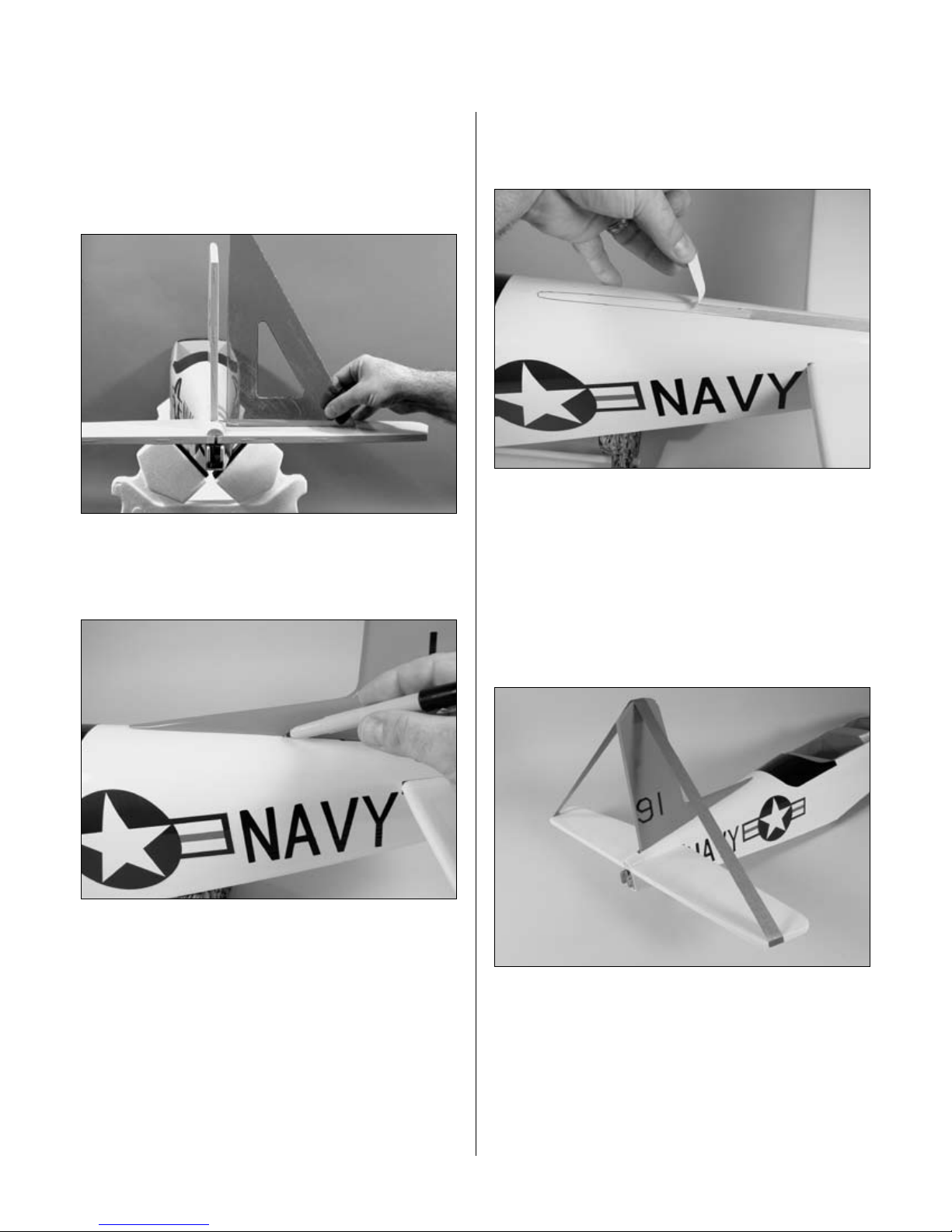

Section 2: Installing the Horizontal Stabilizer

Required Parts

• Assembled wing • Fuselage

• Stabilizer

• 1/4-20 x 2" nylon bolts (2)

Required Tools and Adhesives

• Screwdriver (slotted) • Hobby knife

• Felt-tipped pen • Drill

• Drill bit: 1/4" (6mm) • Square

Step 1

Place the wing onto the fuselage and check the fit. Make

any adjustments necessary to the wing bolt holes and

attach the wing using the two 1/4-20 x 2" nylon bolts.

Step 3

Measure from the trailing edge of the stabilizer 1

(30mm). Use a felt-tipped pen to mark this location.

3

/16"

Step 4

Drill a hole at the location marked in the previous step

using a 1/4" (6mm) drill bit. It is highly suggested to use

a drill press to make sure the hole is perpendicular to the

stabilizer.

Step 2

Measure and mark a centerline on the stabilizer.

11

A

A

A=A

A A

A=A

A A

A=A

Section 2: Installing the Horizontal Stabilizer

Step 5

Slide the stab into the fuselage. Center the stab in the

opening by measuring the distance from the fuselage to

each tip. The stab is aligned when both measurements are

identical.

Step 6

Step 7

Check to make sure the wing and stabilizer are parallel. If

they are not, lightly sand the opening in the fuselage for

the stab until the stab is parallel to the wing.

Step 8

Use a felt-tipped pen to trace the outline of the fuselage on

the stab.

Check the distance from each stab tip to each wing tip.

These measurements must be equal for the stab to be

aligned.

12

Section 2: Installing the Horizontal Stabilizer

Step 9

Remove the stab and use a hobby knife with a brand new

blade to remove the covering 1/16" (1.5mm) inside the

lines just drawn. Use rubbing alcohol and a paper towel to

remove the lines once they are no longer needed.

Step 10

Mix 1/2 ounce (15ml) of 30-minute epoxy. Apply epoxy to

the top and bottom of the exposed wood of the stabilizer.

Apply epoxy to the corresponding surfaces of the slot in

the fuselage for the stabilizer. Slide the stabilizer into the

slot in the fuselage. Double-check the alignment to verify

it’s correct. Remove any excess epoxy using a paper towel

and rubbing alcohol.

Note: Use care not to cut into the underlying

wood and weaken the structure. Doing

so could cause the stab to fail in flight,

resulting in the loss of your airplane.

13

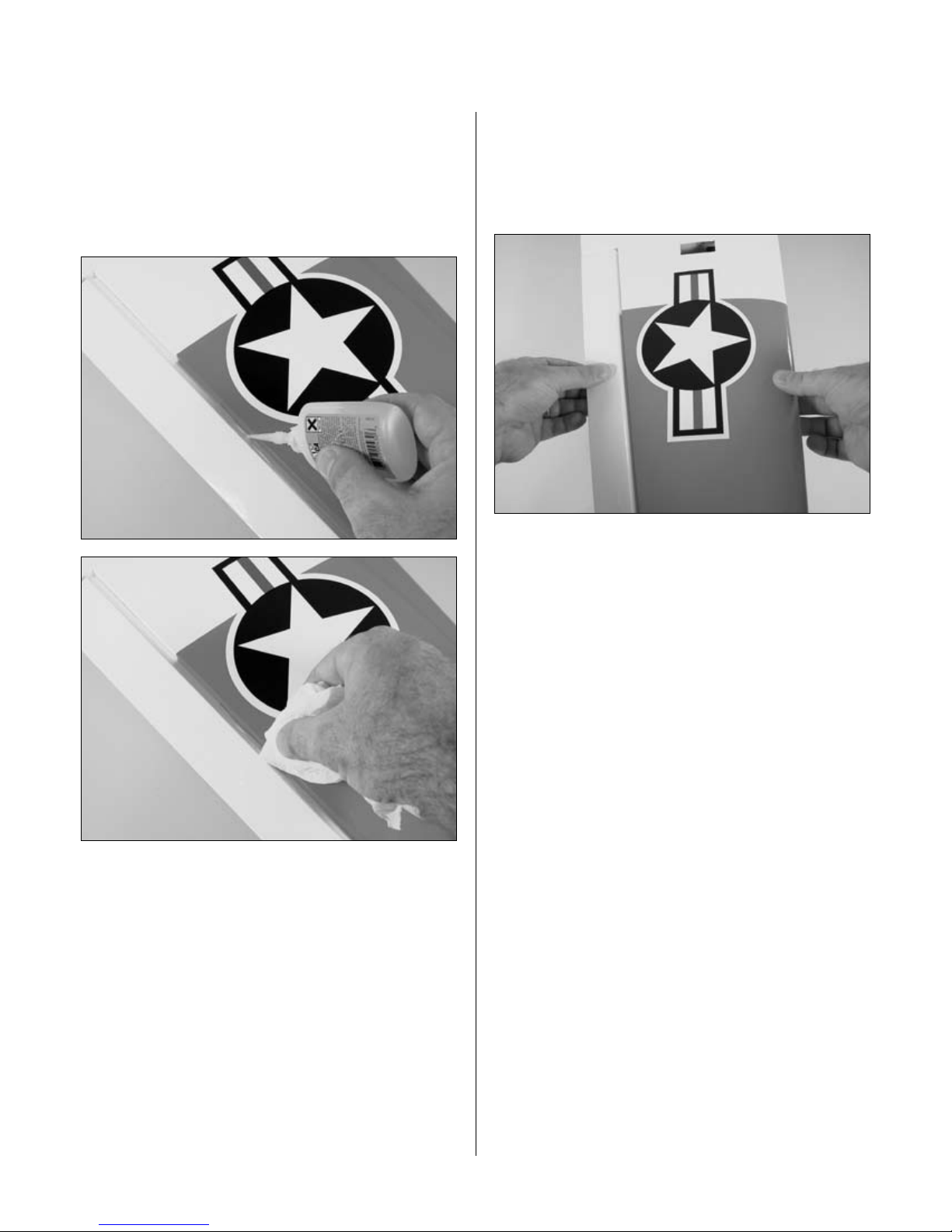

Section 3: Installing the Vertical Stabilizer

Required Parts

• Fuselage assembly • Fin

• Rudder control rod

Required Tools and Adhesives

• 30-minute epoxy • Square

• Drill • Drill bit: 1/4" (6mm)

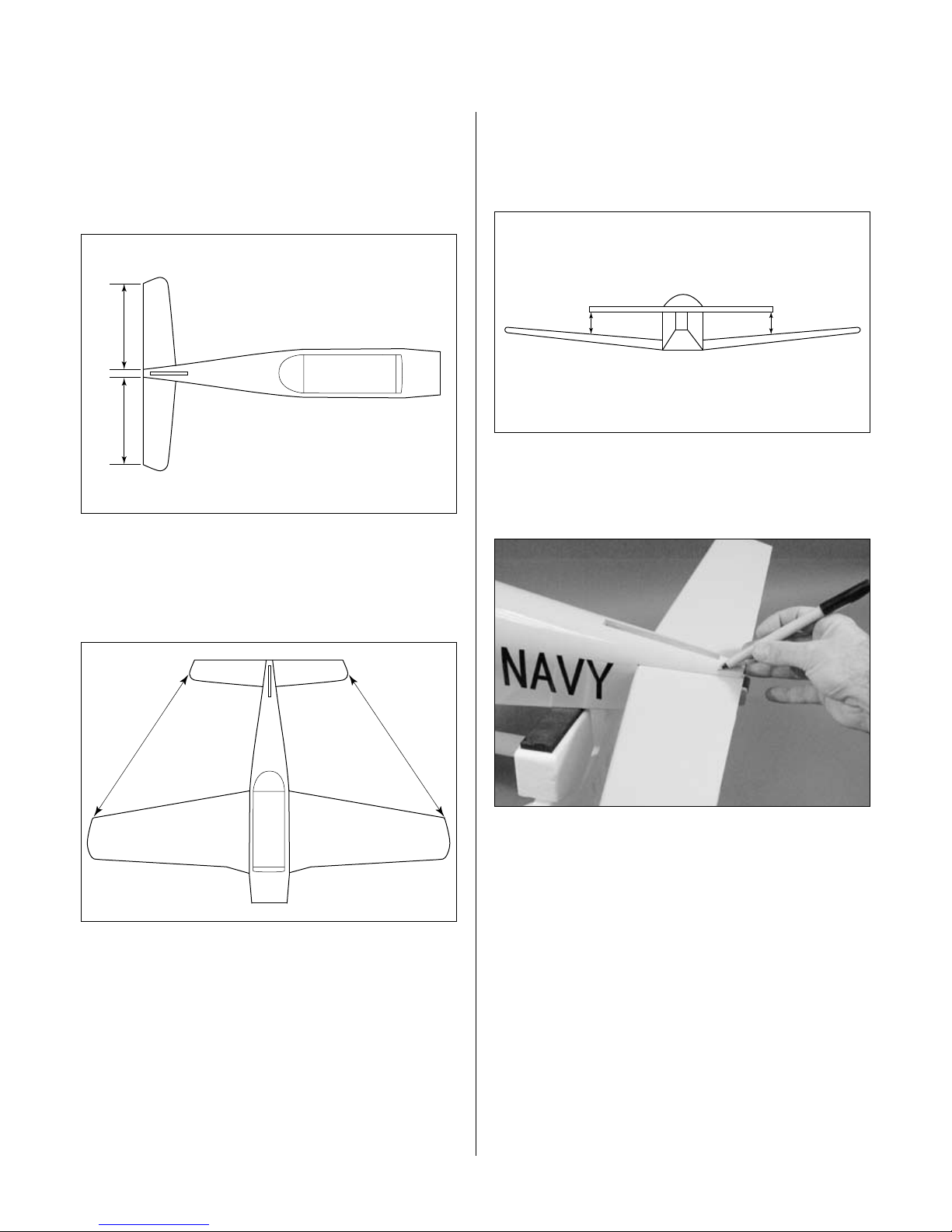

Step 1

Locate the rudder control rod. Insert the threaded end of

the control rod through the hole drilled in the stabilizer.

It may be necessary to slightly enlarge the hole in the

stabilizer and fuselage slightly to make the installation

easier.

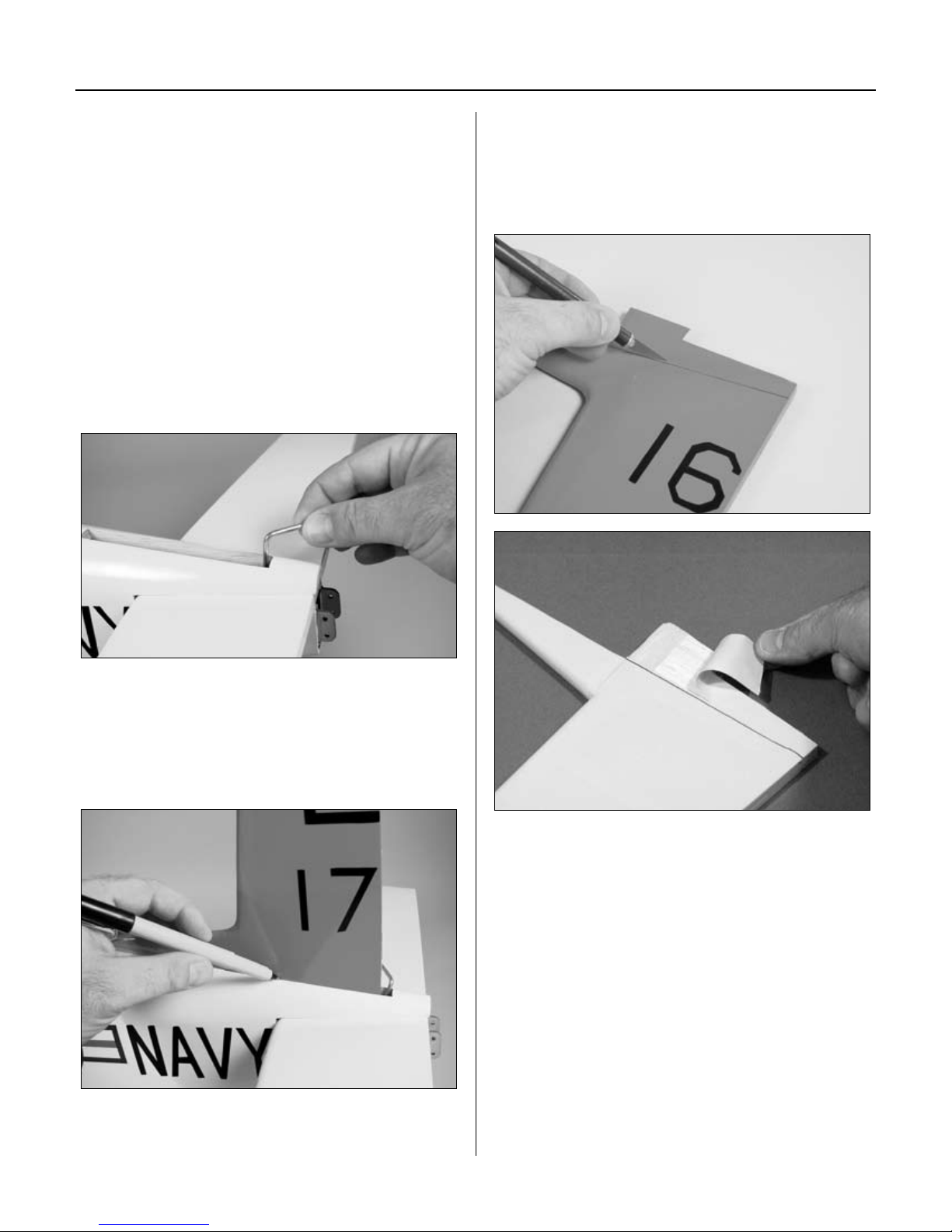

Step 3

Remove the fin and use a hobby knife with a brand new

blade to remove the covering 1/16" (1.5mm) below the

lines just drawn. Use rubbing alcohol and a paper towel to

remove the lines once they are no longer needed.

Step 2

Test fit the fin to the fuselage. Slide the fin as far forward

in the slot as possible to provide clearance for the rudder

control rod. Trace the outline of the fuselage onto the fin

using a felt-tipped pen.

Note: Use care not to cut into the underlying

wood and weaken the structure. Doing

so could cause the fin to fail in flight,

resulting in the loss of your airplane.

14

Section 3: Installing the Vertical Stabilizer

Step 4

Check the alignment of the fin to the stabilizer using a

square. The fin must be 90 degrees to the stabilizer when

properly aligned. If not, carefully sand the bottom of the

fin to provide the clearance to align the fin.

Step 5

Trace the outline of the fin extension onto the fuselage

using a felt-tipped pen.

Step 6

Remove the covering 1/16" (1.5mm) inside the lines

drawn on the fuselage using a sharp hobby knife.

Step 7

Mix 1/2 (15ml) ounce of 30-minute epoxy. Apply the

epoxy to both the exposed wood on the fin and the slot

in the fuselage. Also apply epoxy to the exposed wood

on the top of the fuselage where the fin extension will be

glued. Use care not to get epoxy on the rudder control

rod. Insert the fin and use tape to hold the fin in position

until the epoxy fully cures.

Note: Check the alignment of the

fin periodically to make sure it isn’t

moving while the epoxy cures.

15

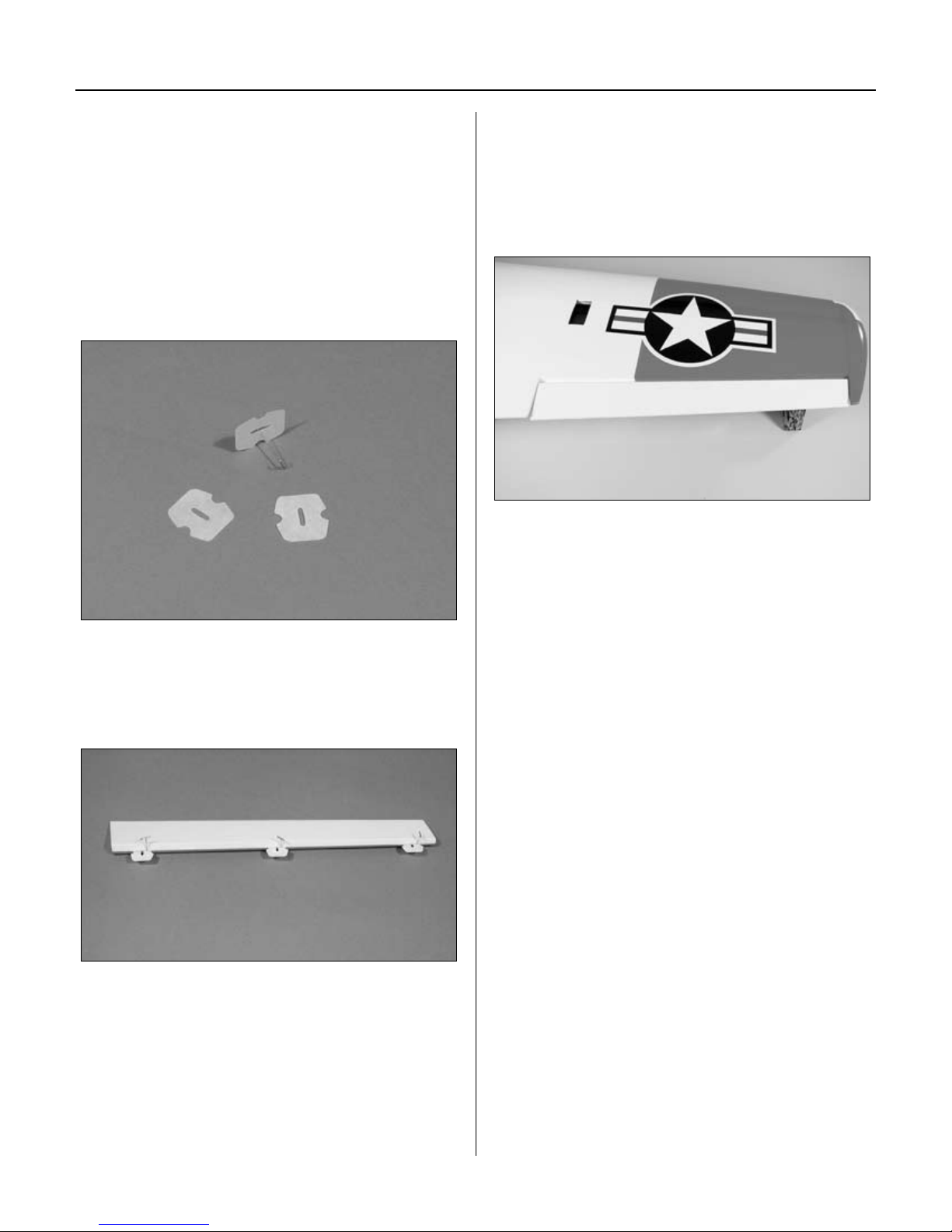

Section 4: Installing the Ailerons

Required Parts

• Wing • Aileron (left and right)

• CA hinges (6)

Required Tools and Adhesives

• Thin CA • T-pins

Step 1

Locate six of the CA hinges. Place a T-pin in the center of

three of the hinges.

Step 3

Slide the aileron and wing together. The gap between

the leading edge of the aileron and wing should be a

maximum of approximately 1/64" (.5mm). Check to make

sure the gap at both ends of the aileron are equal and it

can move without rubbing on the wing.

Note: Do not use CA accelerator during

the hinging process. The CA must be

allowed to soak into the hinge to provide

the best bond. Using accelerator will not

provide enough time for this process.

Step 2

Place the hinges in the precut slots in the aileron. The

T-pin will rest against the leading edge of the aileron when

installed correctly.

16

Section 4: Installing the Ailerons

Step 4

Remove the T-pins and move the aileron to provide the

best access to the hinge. Apply thin CA to each hinge.

Make sure the hinge is fully saturated with CA. Use a

paper towel and CA remover/debonder to clean up any

excess CA from the wing and/or aileron.

Step 5

Firmly grasp the wing and aileron and gently pull on the

aileron to ensure the hinges are secure and cannot be

pulled apart. Use caution when gripping the wing and

aileron to avoid crushing the structure.

Step 6

Work the aileron up and down several times to work in the

hinges and check for proper movement.

Step 7

Repeat Steps 1 through 6 for the remaining aileron.

17

Section 5: Installing the Elevators

Required Parts

• Fuselage assembly

• Elevator joiner wire • CA hinge (6)

• Elevator (left and right)

Required Tools and Adhesives

• Thin CA • T-pins

• 30-minute epoxy • Sandpaper (medium)

Step 1

Locate the elevator joiner wire. Use medium sandpaper to

roughen the portion of the wire that will be inserted in the

elevators.

Step 4

Place the hinges into the elevator halves.

Step 5

Slide the elevator and stab together. The horn on the

elevator joiner wire will face towards the bottom of the

fuselage.

Step 2

Insert the joiner into each of the elevator halves as shown.

Step 3

Locate six of the CA hinges. Place a T-pin in the center of

the hinges.

18

Loading...

Loading...