Page 1

3.1m SU-26MM Sukhoi ARF

Assembly Manual

Page 2

Notice

All instructions, warranties and other collateral

documents are subject to change at the sole discretion

of Horizon Hobby, Inc. For up-to-date product

literature, visit http://www.horizonhobby.com and click

on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm

when operating this product:

NOTICE: Procedures, which if not properly followed, create

a possibility of physical property damage AND a little or no

possibility of injury.

CAUTION: Procedures, which if not properly followed,

create the probability of physical property damage AND a

possibility of serious injury.

WARNING: Procedures, which if not properly followed,

create the probability of property damage, collateral damage,

and serious injury OR create a high probability of superficial

injury.

WARNING: Read the ENTIRE instruction manual to

become familiar with the features of the product before

operating. Failure to operate the product correctly can result

in damage to the product, personal property and cause

serious injury.

This is a sophisticated hobby product and NOT a toy. It must

be operated with caution and common sense and requires

some basic mechanical ability. Failure to operate this Product

in a safe and responsible manner could result in injury or

damage to the product or other property. This product is not

intended for use by children without direct adult supervision.

Do not attempt disassembly, use with incompatible

components or augment product in any way without the

approval of Horizon Hobby, Inc. This manual contains

instructions for safety, operation and maintenance. It is

essential to read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in order to

operate correctly and avoid damage or serious injury.

Table of Contents

Intro ................................................................................. 2

Product Support ..............................................................2

Specifications ................................................................... 2

Included Parts ................................................................. 3

Contents of Kit and Parts Number .................................... 4

Safety Precautions and Warnings .................................... 4

3.1m Sukhoi Operating Recommendations ...................... 5

Important Information Regarding Warranty ..................... 5

Using the Manual ............................................................. 5

Aileron Servos Installation ............................................... 7

Elevator Servo Installation ............................................. 11

Rudder Installation ......................................................... 13

Rudder Servos Installation ............................................. 14

Main Gear and Tail Gear Installation ............................... 15

Pipes/Canisters Mount Installation and Assembly ......... 18

Cowl Mounting ............................................................... 22

Engine, Throttle Servo and DA Muffler Installation ........ 24

Fuel Tank, Fill and Over Flow Installation ........................ 25

Ignition Module, Battery,

Regulator and Switch Installation .............................. 27

Receiver Mount and

Throttle Servo Regulator Installation ......................... 29

Receiver Battery Installation .......................................... 30

Satellite Receiver and Receiver Switch Installation ........ 31

Pilot/Panel Assembly and Installation ............................ 32

Center of Gravity ............................................................ 33

Applying Decals .............................................................34

Control Throws .............................................................. 36

Pro-Tips ......................................................................... 36

Preflight ......................................................................... 37

Range Test Your Radio ................................................... 37

Safety Do’s and Don’ts for Pilots ....................................37

Daily Flight Checks ......................................................... 37

Warranty and Repair Policy ............................................ 38

Warranty Services .......................................................... 38

Compliance Information for the European Union ........... 39

2010 Official Academy of

Model Aeronautics Safety Code .................................40

Intro

Intrigued by the challenge of creating model of the famed

full-scale SU-26 Sukhoi that would hold its own against the

best of scale acrobatic monoplane designs, Mike McConville

stepped up and designed this masterpiece that has exceeded

even his highest expectations. The 3.1m wingspan SU-26MM

Sukhoi is a no-holds-barred IMAC and 3D/freestyle machine

that has already proven itself at the highest levels of IMAC

competition.

Finished in Mike’s new signature trim scheme for maximum

visibility, top to bottom contrast and overall great looks,

the 3.1m SU-26MM Sukhoi will deliver best of class

performance for any serious pilot wanting uncompromised

precision. Having meticulously designed the model to

eliminate all roll and virtually all pitch coupling this the

Sukhoi has arrow-like tracking that will let you concentrate

on perfecting the maneuver at hand without the need to

worry about correcting for any unwanted tendencies in the

model.

All guess work had been taken out of this ARF, most

popular choices for engine, exhaust system and even servo

arrangements are covered in the manual. The Hangar 9 3.1m

SU-26MM Sukhoi is the ultimate in giant scale acrobatic

performance, solid construction, great looks and optimized

visual presentation in the air. Enjoy your new Sukhoi and

start turning heads at the flying field.

Product Support

For technical assistance with this product, please contact the

appropriate Horizon Product Support office.

Specications

Wingspan 122 in (3.1m)

Length 116 in (3m)

Wing Area 2770 sq in (179 sq dm)

Weight 38–42 lb (17.2–19.2 kg)

Radio 4-channel (or greater) with 9–13

servos

Engine 150cc - 170cc gas engine

2 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual2

Page 3

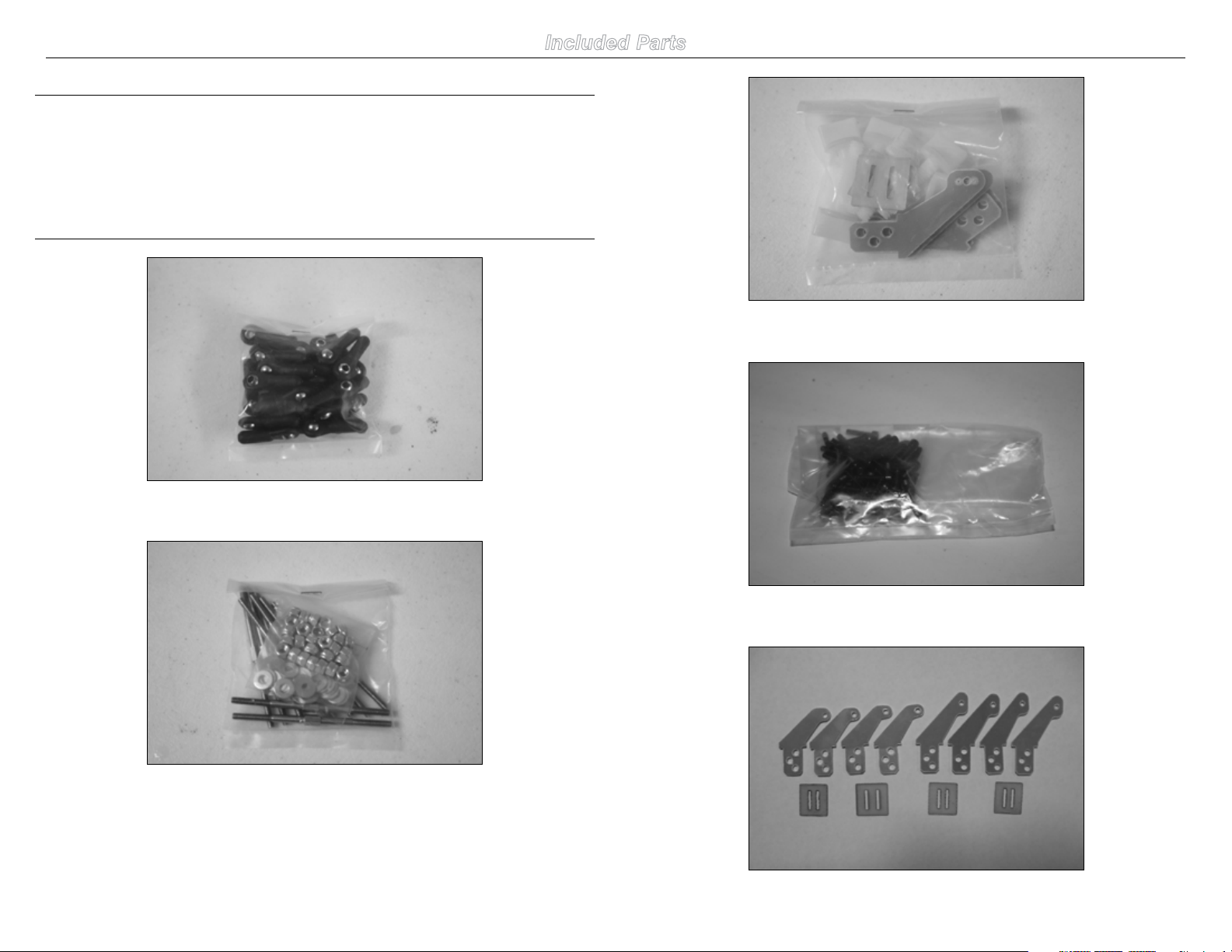

PACKAGED IN KIT

Fuselage with hinged rudder 1

Right horizontal stabilizer with hinged elevator 1

Left horizontal stabilizer with hinged elevator 1

Wings with hinged aileron 1

Cowl 1

HARDWARE BAGS

Included Parts

Aileron and Elevator Control Horns, Plates and Nylon Wing Bolts

Ball Links

Pushrods, Washers and Locknuts

2.5mm and 4-40 Screws

Left Horns (Shorter) are for Elevators and Longer Ones for Aileron

3Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 4

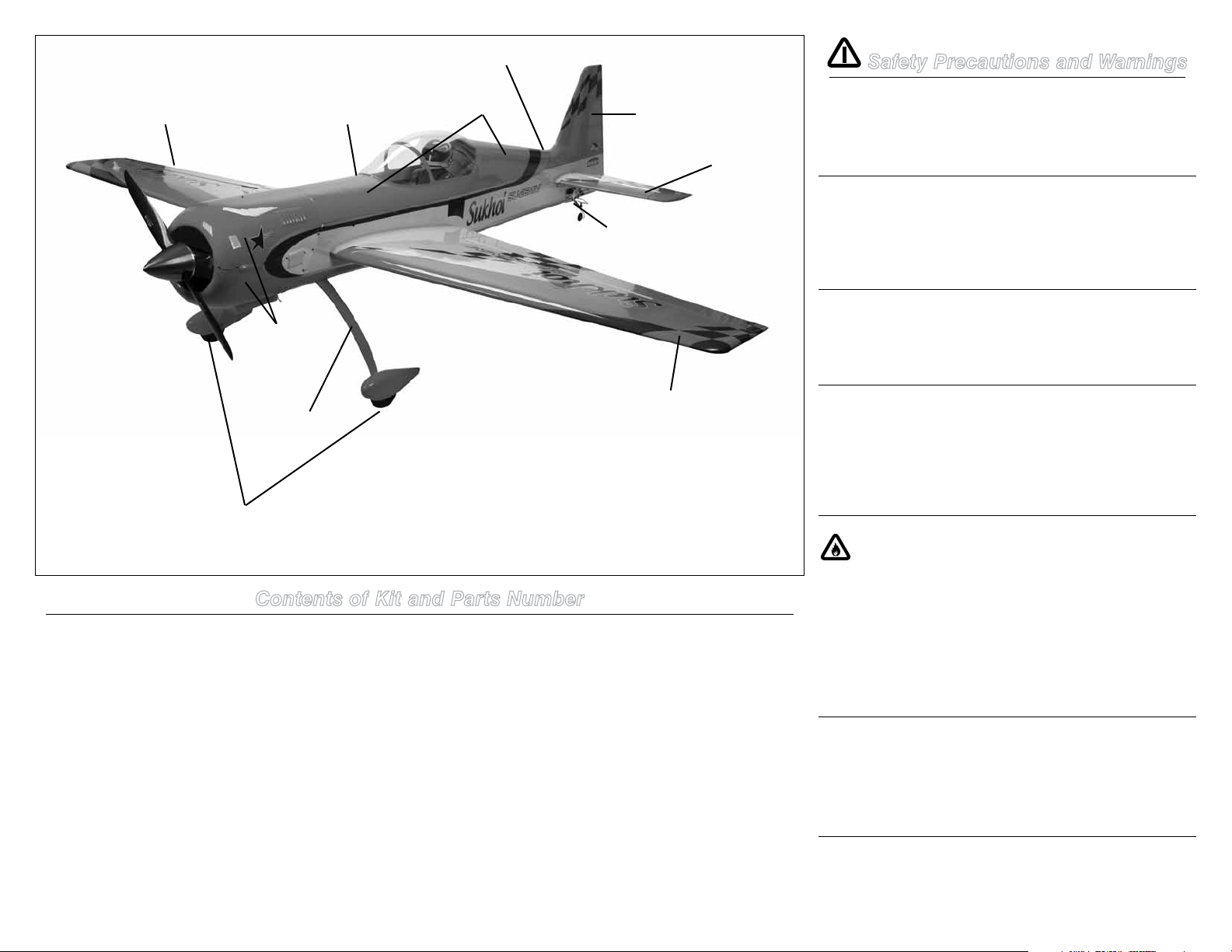

7

Safety Precautions and Warnings

4

5

15

2

11

1

8

6

17

3

Read and follow all instructions and safety precautions

before use. Improper use can result in fire, serious injury

and damage to property.

COMPONENTS

Use only with compatible components. Should any

compatibility questions exist please refer to the product

instructions, the component instructions or contact Horizon

Hobby, Inc.

FLIGHT

Fly only in open areas to ensure safety. It is recommended

flying be done at AMA (Academy of Model Aeronautics)

approved flying sites.

PROPELLER

Keep loose items that can get entangled in the propeller

away from the prop, including loose clothing, neck strap or

other objects such as pencils and screwdrivers. Especially

keep your hands away from the propeller as sever injury can

occur. Using a thick glove is highly recommended.

BATTERIES

Notes on Lithium Polymer Batteries

Contents of Kit and Parts Number

Replacement Parts

1. HAN106001 Fuselage w/ Hatch, 3.1m Sukhoi MM ARF

2. HAN106002 Hatch w/ Canopy, 3.1m Sukhoi MM ARF

3. HAN106003 Left Wing Panel, 3.1m Sukhoi MM ARF

4. HAN106004 Right Wing Panel, 3.1m Sukhoi MM ARF

5. HAN106005 Cowl (2 piece), 3.1m Sukhou MM ARF

6. HAN106006 Left Stab Panel, 3,1m Sukhoi MM ARF

7. HAN106007 Right Stab Panel, 3.1m SukhoiMM ARF

8. HAN106008 Rudder, 3.1m Sukhoi MM ARF

9. HAN106009 Carbon Wing Tube, 3.1m Sukhoi MM ARF

10. HAN106010 Carbon Stab Tube, 3.1m Sukhoi MM ARF

11. HAN106011 Landing Gear, 3.1m Sukhoi MM ARF

12. HAN106012 Linkage Hdwr Set, 3.1m Sukhoi MM ARF

4 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Replacement Parts

13. HAN106013 Wheel Pant Set, 3.1m Sukhoi MM ARF

14. HAN106014 Painted Pilot, 3.1m Sukhoi MM ARF

15. HAN106015 Main Wheel Set, 3.1m Sukhoi MM ARF

16. HAN106016 Main Axle Set, 3.1m Sukhoi MM ARF

17. HAN106017 Tail Wheel Assy, 3.1m Sukhoi MM ARF

18. HAN106018 55oz Gas Tank, 3.1m Sukhoi MM ARF

19. HAN106019 Exhaust/Batt Mnt, 3.1m Sukhoi MM ARF

20. HAN106020 Cowl/Cnpy screws, 3.1m Sukhoi MM ARF

21. HAN106021 Decal Set

22. HAN106022 Wing Bolts (6), 3.1m SukhoiMM ARF

23. HAN106023 Fiberglass Control Horn Set

When misused Lithium Polymer batteries are significantly

more volatile than alkaline or Ni-Cd/Ni-MH batteries used

in RC applications. Always follow the manufacturer’s

instructions when using and disposing of any batteries.

Mishandling of Li-Po batteries can result in fire and rupture

causing serious injury and damage.

SMALL PARTS

This kit includes small parts and should not be left

unattended near children as choking and serious injury could

result.

Age Recommendation:

For advanced fliers ages 14 and above. This is not a toy.

Page 5

3.1m Sukhoi Operating Recommendations

• Inspectyourmodelbeforeeveryflighttomakecertainit

is airworthy.

• Beawareofanyotherradiofrequencyuserwhomay

present an interference problem.

• Alwaysbecourteousandrespectfulofotherusersof

your selected flight area.

• Chooseanareaclearofobstaclesandlargeenoughto

safely accommodate your flying activity.

• Makecertainthisareaisclearoffriendsandspectators

prior to launching your aircraft.

• Beawareofotheractivitiesinthevicinityofyourflight

path that could cause potential conflict.

• Carefullyplanyourflightpathpriortolaunch.

• AbidebyanyandallestablishedAMANationalModel

Aircraft Safety Code.

Important Information

Regarding Warranty

Please read our Warranty and Liability Limitations section

before building this product. If you as the purchaser or user

are not prepared to accept the liability associated with the

use of this Product, you are advised to return this Product

immediately in new and unused condition to the place of

purchase.

UltraCote® Covering Colors

•Cream HANU878

•Orange HANU877

•PearlPurple HANU847

•Silver HANU881

Recommended Setup–2-Stroke Gas

•DA150

•DA-170

Recommended Spinner

5-inch purple Tru-Turn Ultimate Style with solid back

plate.

•DA150,TT-5052-B-M-3W120-AP

•DA-170,TT-5052-B-M-DA170-AP

Optional Tuned Pipe and Canister

Installation

If you are installing the optional tuned pipe, the following

items will be required:

•50mmdropheader,14-inchlongfortunedpipe(MTW,

RE3) and 8 to 9-inch for canister (MTW TD110)

•Clamps

•Couplers

Radio Equipment Requirements

The following items are recommended when installing the

9-Channel AR91000 (SPMAR9100) in your aircraft:

DS8911HV Digital Servo (8–12) JRPS8911HV

JR 537 Servo (1) JRPS537

12-inch Servo Extension (2) (Ailerons) JRPA098

18-inch Servo Extension (2) (Ailerons) JRPA099

24-inch Servo Extension (1) (Throttle) JRPA102

36-inch Servo Extension (2) (Ailerons) JRPA103

48-inch Servo Extension (2) (Rudder) JRPA104

48-inch Servo Extension (2) (Elevators) JRPA104

(2) Receiver Packs, 4000mAh Spektrum SPMB4000LP

Ignition Pack 2000mAh Spektrum SPMB2000LP

JR Charge Switch JRPA004

JR MatchBox (4) JRPA900

Using the Manual

This manual is divided into sections to help make assembly

easier to understand, and to provide breaks between each

major section. In addition, check boxes have been placed

next to each step to keep track of each step completed.

Steps with a single box () are performed once, while

steps with two or more boxes () indicate that the step

will require repeating, such as for a right or left wing panel,

two servos, etc. Remember to take your time and follow the

directions.

Transmitter Requirements

The 3.1m Sukhoi requires a minimum of a 4-channel radio

to operate all the functions of your aircraft. However to get

the best performance from the Sukhoi, a radio with mixing

functions is recommended. We suggest the following radio

systems available through Horizon Hobby or your local

hobby distributor.

Spektrun DX8 SPM8800

JR Systems X9503 2.4GHz JRP2930

JR Systems 11X 2.4GHz JRP1100

JR Systems 12X 2.4GHz JRP1200

The Spektrum trademark is used with permission

of Bachmann Industries, Inc.

5Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 6

Additional Required Tools

Additional Required Adhesives

Cut-off wheel Sanding drum

Drill Epoxy brush

Felt-tipped pen Ruler

Hex wrench: 1.5mm, 2.5mm, 3mm, 4mm, 4.5mm, 3/32-

inch, 5/32-inch Iron

Hobby knife with #11 blade Mixing cup

Mixing stick Paper towel

Pencil Hemostat

Shoo Goo or Zap-A-Dap-A-Goo

Phillips screwdriver: #1, #2 Pin vise

Vise grip Masking tape

Rotary tool Rubbing alcohol

Nut driver: 1/4-inch Heat gun

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm),

3/32-inch (2.5mm), 3/16-inch (5mm)

Medium CA (PAAPT02)

Thin CA (PAAPT08)

CA remover/debonder (PAAPT16)

CA accelerator (PAAPT15)

Threadlock (PAAPT42)

30-Minute Epoxy, 8 oz (PAAPT39)

Before Starting Assembly

Before beginning the assembly of your model, remove

each part from its bag for inspection. Closely inspect the

fuselage, wing panels, rudder and stabilizer for damage. If

you find any damaged or missing parts, contact the place of

purchase.

If you find any wrinkles in the covering, use a heat gun or

covering iron to remove them. Use caution while working

around areas where the colors overlap to prevent separating

the colors.

HAN100 – Heat Gun

HAN150 – Covering Glove

HAN101 – Sealing Iron

HAN141 – Sealing Iron Sock

6 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 7

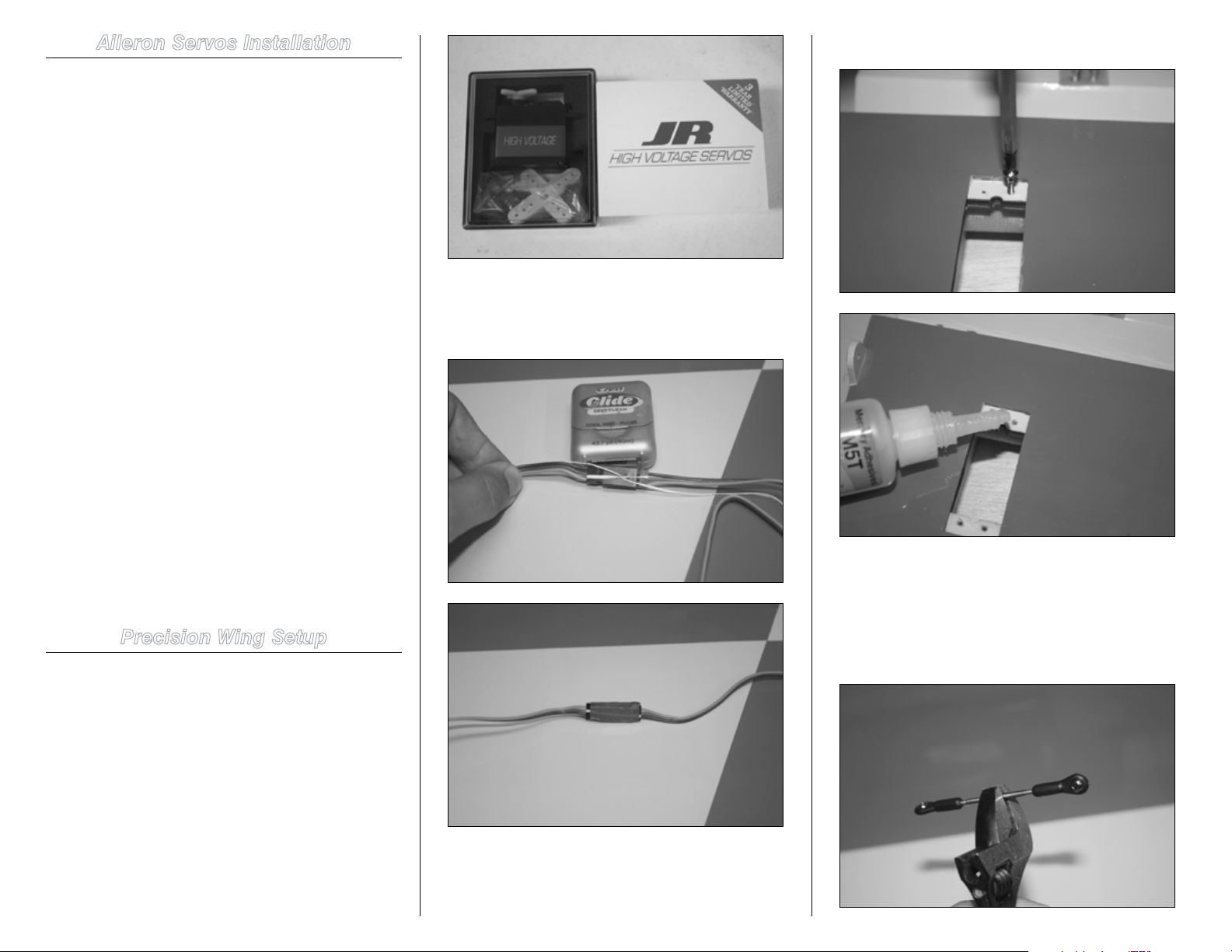

Aileron Servos Installation

Required Parts

Wing panel Ball link (12)

Control horns (4) (3D wing setup only)

4-40 screws (12)

7

2

/16-inch aileron pushrod (6) Locknuts (12)

Required Parts (not included)

JR 8911HV with hardware (4) or (6) or similar digital

servo

JR 1-1/2-inch servo arm (4) or (6)

JR heavy-duty servo extension, 36-inch (2)

JR heavy-duty servo extension, 18-inch (2)

Required Tools and Adhesives

Pin vise Iron

Thin CA Phillips screwdriver: #1

Drill bit: 1/16-inch 30-minute epoxy

String (Dental floss) Masking tape

Adhesive-backed hook and loop

3/32-inch ball driver Hobby knife

Wings will be setup with two different configurations,

precision and 3D. For the precision setup two servos will be

used one is mounted inboard and second servo outboard

of the wing. Middle servo bay will be left unused. This is

the configuration as the wings come out of the box. For 3D

setup, all 3 servos will be installed and middle servo control

horns need to be glued in. Follow the below steps.

be installed in.

2. Secure a 36-inch servo extension to the outboard

aileron servo lead using string or a commercially available

connector. This will prevent the extension from accidentally

disconnecting inside the wing.

4. A string has been installed in the wing to pull the

aileron servo extension through the wing. Tie or tape the

string to the end of the extension and pull the lead to the

wing root.

Precision Wing Setup

1. Prepare the aileron servos by installing the rubber

grommets and brass eyelets.

Hint: Prepare all servos for the wing at this time.

5. Mount the servo such that the output shaft faces the

leading edge and prepare the linkage for installation.

3. In order to harden the servo mounting holes in

the bays, mount the servo screws, back them out and

apply some thin CA in the hole. Wait until CA is dry before

installing the servo. Do this for every bay that a servo is to

7Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 8

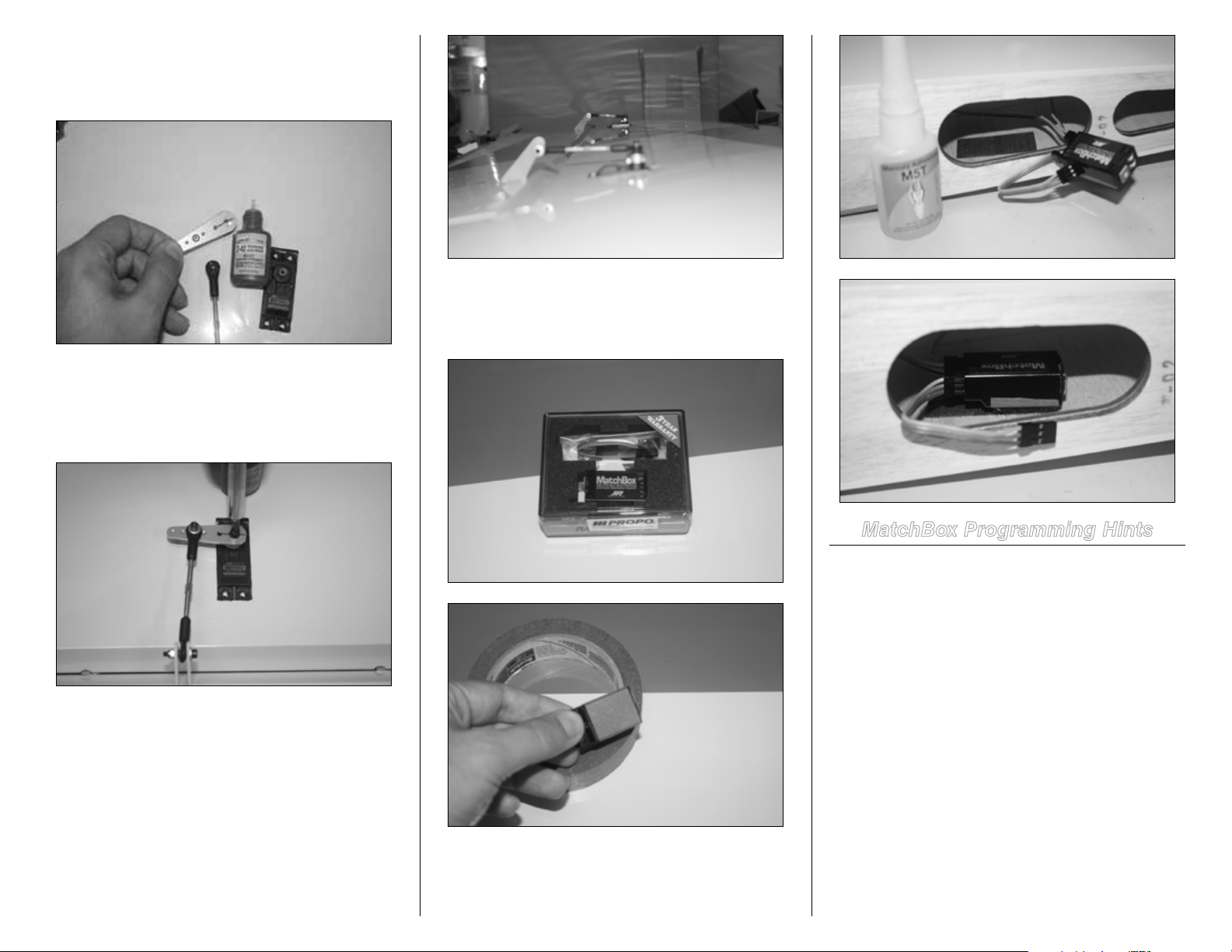

6. Attach the linkage to the servo arm at the 1 inch

hole. If using aluminum JR arms, use the second hole from

center outward. Use threadlock on all the screws except for

the two setscrews of the arm.

7. To adjust the length of linkages, servos need to be

powered and at center. The arm should be mounted parallel

to the aileron hinge line; small adjustments can be made

using sub-trim. Adjust the length of linkage so the aileron is

centered and servo arm is parallel to the hinge line.

9. Mount the MatchBox™ in the wing root using sticky

back hook and loop. Before applying the hook and loop

to the MatchBox, apply masking tape to the back of the

MatchBox so it can easily be removed when need be.

MatchBox Programming Hints

The pointers below can help make matching servos easier.

This is not to take the place of the MatchBox instruction

manual.

1. Connect the inboard servo to the MatchBox and then

make all adjustments to servo center and travel adjustments

in the transmitter programming. No adjustments to this

servo should be made in the MatchBox.

8. Mount the inboard servo following the same method

as outboard but no extension is required.

8 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

2. Connect the second servo to the MatchBox to center it,

then install the servo arm onto the servo on the spline that

gets it as close to parallel with the hinge line as possible.

Then use the MatchBox to set the center of this servo so the

servo arm is exactly parallel to the hinge line. Now adjust the

linkage length so the hole in the ball link directly aligns with

the appropriate hole in the servo arm.

Now deflect the servo to full stick in one direction and use

the MatchBox to set the endpoint so the ball link directly

lines up with the hole in the servo arm. Repeat this with the

stick fully deflected in the opposite direction. Once the center

and both endpoints are set for the second servo, remember

Page 9

to turn the dial on the MatchBox back to the 0 position to

save the settings before powering off the receiver. Hint,

when adjusting for endpoints (full deflection), it is hard to

hold the sticks and adjust the MatchBox at the same time.

It is best to move the sticks to full deflection and while

holding the stick, turn off the radio. This will put the receiver

into hold and makes adjustment easier working only the

MatchBox and observing the linkage position over the servo

arm.

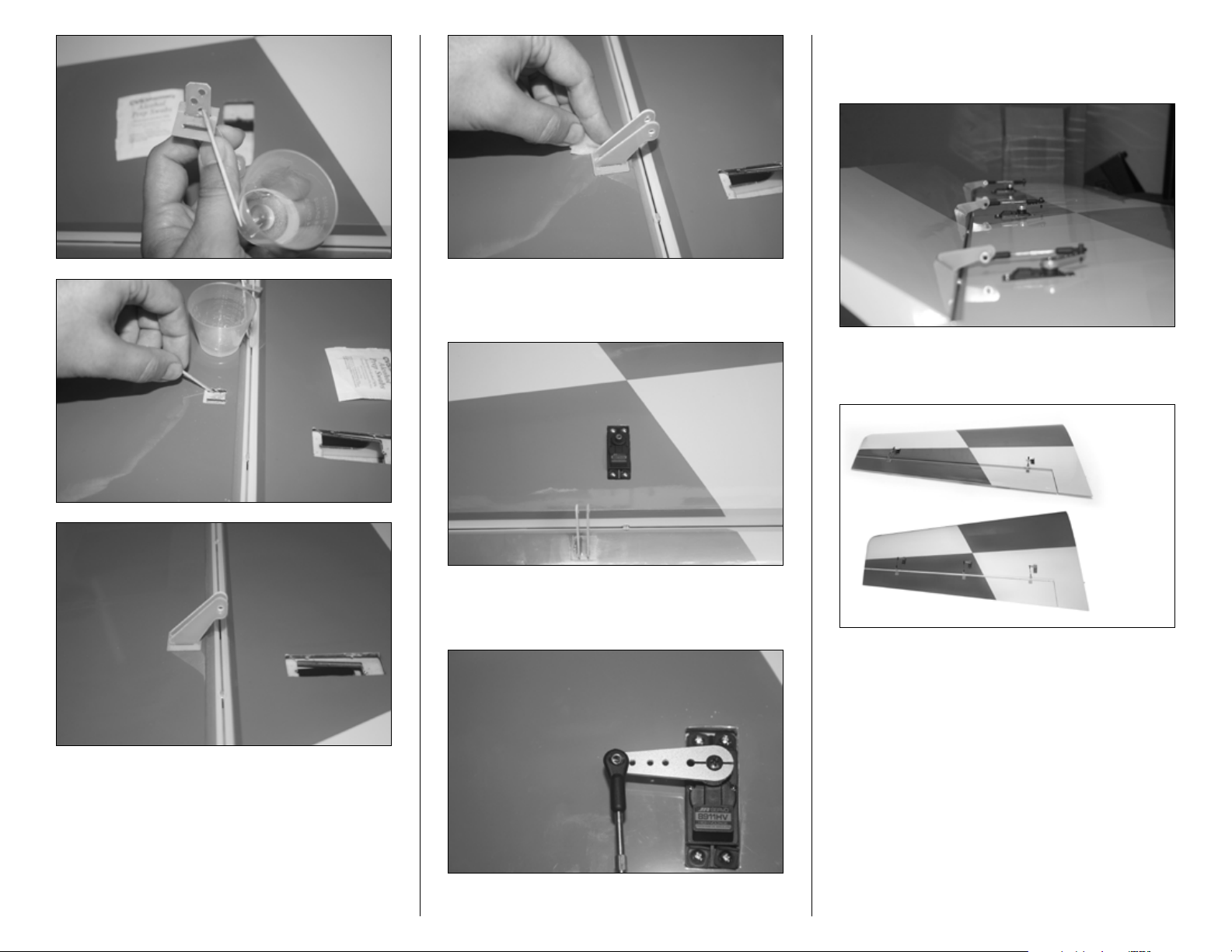

3D Wing Setup

1. 3D flying is more demanding and the addition of the

middle servo can help reduce the level of abuse servos and

wings will see. Open up the middle servo bay. Iron down the

edges. The middle servo bay is located approximately 16

inches away from the inboard servo. Rub your finger over

the covering in that vicinity to find it.

3. Find the location for control horns and remove the

covering in between the two slots. Now place the plate over

the slots and mark a slightly smaller area than the plate and

remove the covering.

2. To harden the servo mounting holes in the bay,

mount the servo screws, back them out and apply some

thin CA in the hole. Wait until CA is dry before installing the

servo. See step 3 in precision wing setup for detail.

4. Mix 30-minute epoxy and glue the horns and plate

such that the control horn pivot point is aligned with aileron

hinge line. Apply epoxy to both slots on the aileron and

control horn and plate. Clean excess with alcohol swabs.

9Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 10

5. Attach an 18-inch JR Heavy-Duty extension to the

middle servo. Mount the servo such that the output shaft is

towards the leading edge of the wing.

7. The picture below shows the wing with a 3-servo setup

at full deflection. For MatchBox setup, refer to previous

section.

The picture below shows the comparison of precision

wing and 3D wing setup.

6. 1.5-inch servo arms are used for 3D wing setup.

Assemble the linkages and use threadlock on all the screws.

Setscrews need only tightening and no threadlock.

10 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 11

Elevator Servos Installation

Required Parts

Elevator panel 4-40 screws (8)

Locknuts (8) Ball link (8)

Control horns (4) (3D elevator setup only)

7

2

/16-inch elevator pushrod (4)

Required Parts (not included)

JR 8911HV or similar digital servo (2) or (4)

JR 1.5-inch servo arm (2) or (4)

JR heavy-duty servo extension, 48-inch (2)

Required Tools and Adhesives

Pin vise Iron

Thin CA Phillips screwdriver: #1

Drill bit: 1/16-inch 30-minute epoxy

String (Dental floss) Masking tape

Adhesive-backed hook and loop

3/32-inch ball driver Hobby knife

2.5mm ball driver

Note: Elevators will be set up for both precision and 3D

flying. Due to extra demand in power and deflection of

3D flying, two servos will be used for that style.

towards the leading edge of the stab. The servo arm needs

to be 1.25 inch; if in case of using a JR aluminum servo

arm, this would be the third outermost hole.

2. Mount the servo screws and back them out.

4. Mount the servo so the output shaft is towards the

leading edge of the stab.

5. Prepare the ball link and pushrod. Attach the ball

link to the control horn using a 2.5mm ball driver and hold

the locknut with help of a vise grip or nut driver.

Precision Setup

1. For precision setup one servo per elevator is used.

Prepare the servo by installing the rubber grommets and

brass eyelets.

Servo needs to be installed in such way that output shaft is

3. To harden the servo mounting holes in the bay

apply some thin CA in the hole. Wait until CA is dry before

installing the servo.

6. Connect the ball link to the 1.25-inch hole on a JR

aluminum servo arm. This would be the third outermost hole

from the center of the arm. Mount the servo arm parallel to

the elevator hinge line. Use threadlock on the center servo

arm screw. Use a 48-inch JR Heavy-Duty extension from

elevator to receiver.

11Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 12

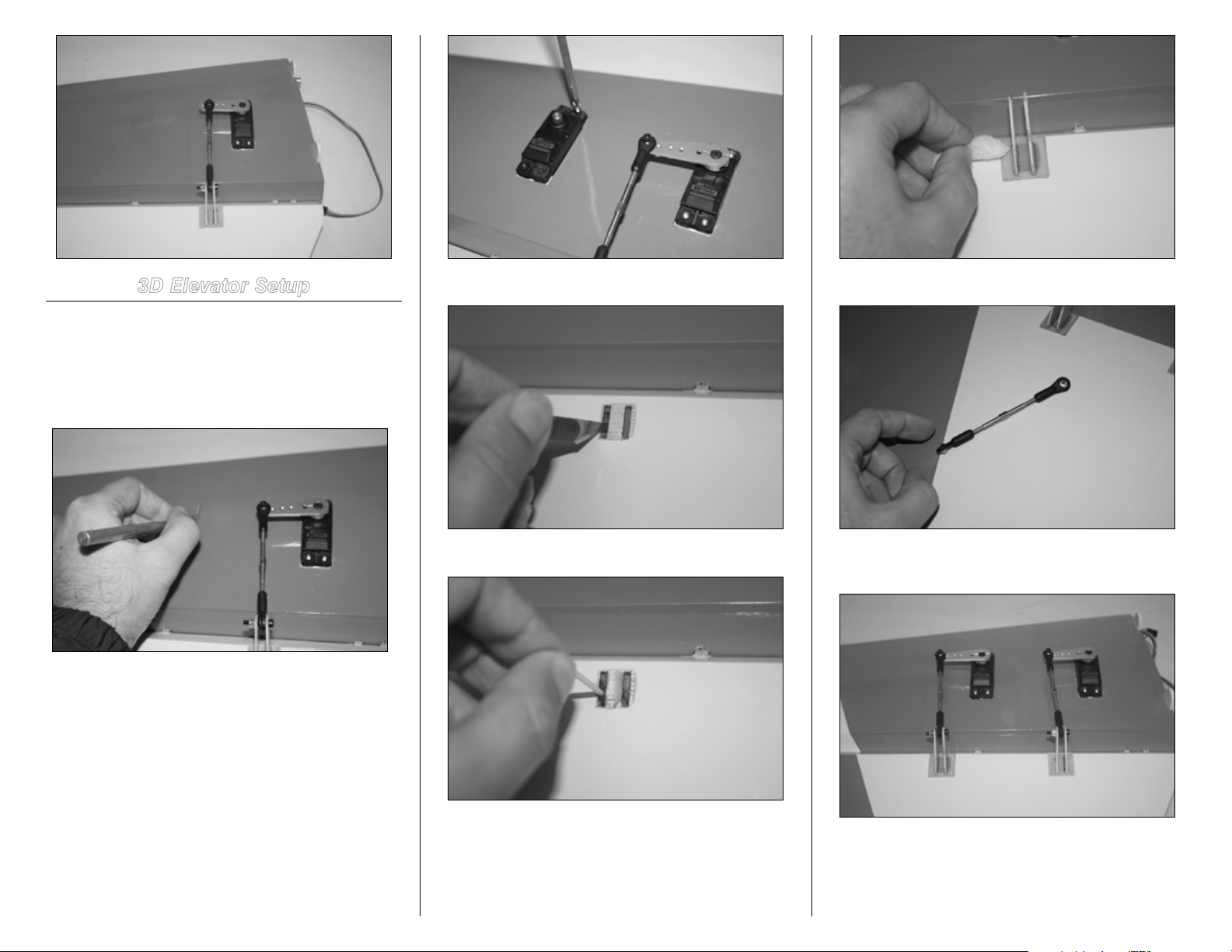

3D Elevator Setup

1. The second servo bay needs to be opened and

control horns and plate need to be glued using 15- to

30-minute epoxy. This step is also very similar to Aileron

Servo Installation in 3D section. Follow the same steps and

make sure to line up the control horn pivot point to the

elevator hinge line.

4. Remove the covering to mount the control horns.

7. Prepare the ball link and pushrod for installation.

5. Mix 30-minute epoxy and fill the control horn slots.

8. Install the ball links at the 1.5-inch hole on the arm.

Use threadlock on the center servo arm screw.

2. Mount the servo screws and back them out. Apply

some CA to harden the wood. This step is the same as steps

2 and 3 in the elevator precision setup section.

3. Mount the servo once the glue is dry.

6. Install the control horns and plate, make sure to

line up the control horns hole and elevator hinge line. Clean

excess epoxy using alcohol swabs.

12 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

9. MatchBox is installed in the stab root. Apply a piece

of masking tape to the bottom of the MatchBox and using CA

glue a piece of hook and loop to the MatchBox.

Page 13

Note: Refer to MatchBox setup in the wing section.

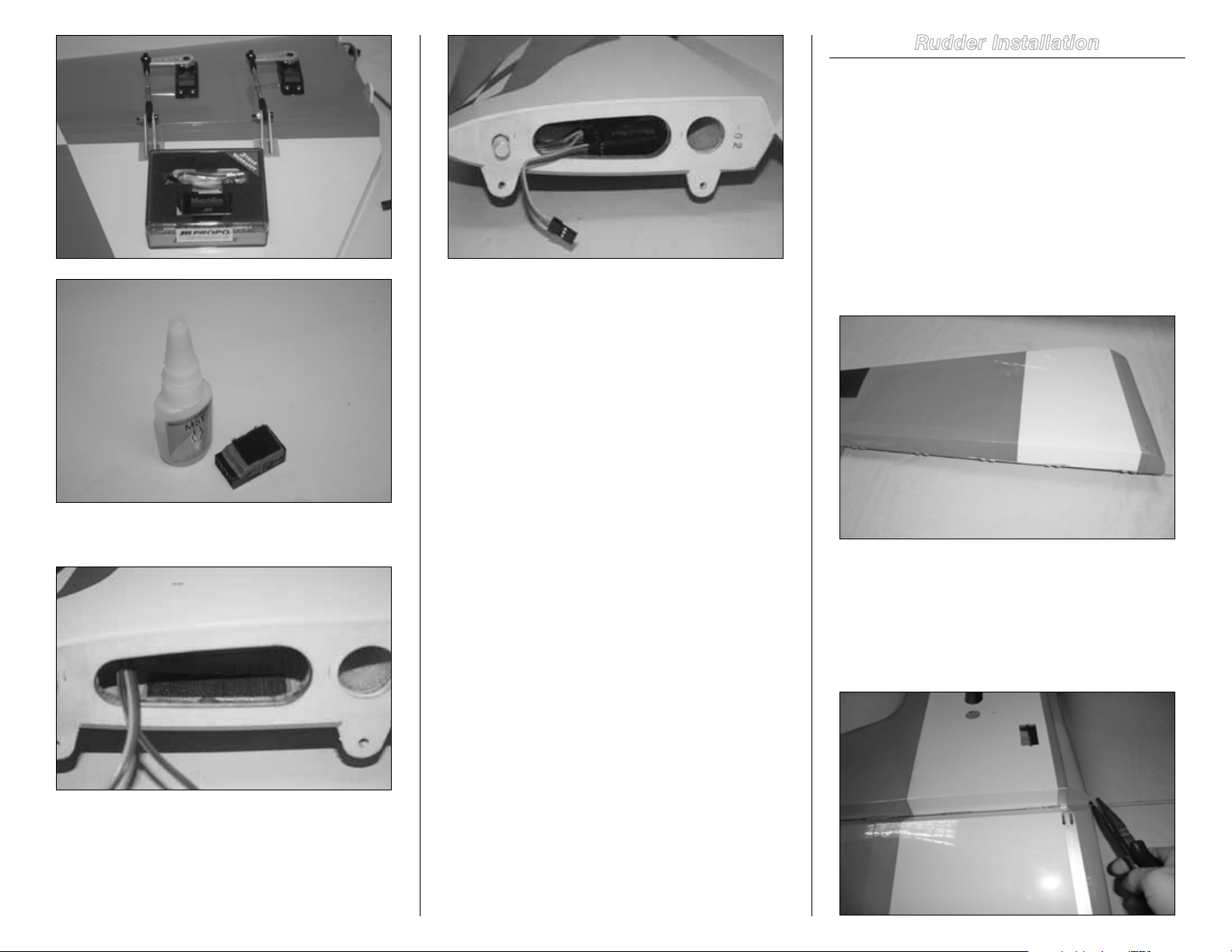

Rudder Installation

Required Parts

Fuselage Rudder

Hinge rod

Required Tools and Adhesives

Drill Pliers

Petroleum Jelly/Industrial lubricant

1. Apply some industrial lubricant to the rod. Pass the

rod through the hinges in rudder and fuselage vertical fin

separately. This helps remove any possible dirt in the hinges

and makes for easier final assembly.

10. Glue opposite side of hook and loop to stab root

with CA.

11. Mount the MatchBox. Use 48-inch extension from

MatchBox to the receiver.

2. Mate the rudder and fuselage vertical stabilizer

and carefully pass the rod through hinges. This can be

accomplished by two ways. 1. Use a drill on slow speed

and gently pass through the rod. If there is any resistance,

back out and repeat. 2. Use a pair of pliers and push the rod

through the hinges. Make sure not to buckle the rod. This is

a rather slow process and needs attention.

13Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 14

3. Cut excess rod long enough (1mm) that it is easy to

grab and pull out when needed for transportation. The tail

wheel bracket will stop the rod from backing out of the

hinges.

The picture below shows the rod at top end of the vertical

fin.

Rudder Servos Installation

Required Parts

Fuselage 4-40 screws (4)

Ball link (4) Locknuts (4)

3

3

/16-inch rudder pushrod (2)

Required Parts (not included)

JR 8911HV or similar digital servo (2)

JR 1.5-inch servo arm (2)

JR heavy-duty servo extension, 48-inch (2)

Required Tools and Adhesives

Pin vise Phillips screwdriver: #1

String (Dental floss) Masking tape

3/32-inch ball driver

Note: The fuselage is made to accept 4 rudder servos,

however if the recommended servos are used, only two

servos are needed even for the most extreme 3D flying.

If using servos with lower torque, remove the covering

from one or both of the additional servo bays and

connect linkages as needed.

2. Servo is mounted with output shaft facing aft. Mark the

servo mounting lugs.

1. Prepare the servo by attaching the 48-inch extension

and securing the connector with a string and masking tape

over it.

3. Use a pin vise to drill the holes.

14 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 15

4. Mount the servo screws and remove.

5. Apply some thin CA to harden the wood. Once glue is

dry, mount the servo.

servo arm so it is pointing to the bottom of the fuse and is

parallel to the rudder hinge line. Use sub-trim if needed.

Note: Since there are two rudder servos used (one on

each side), they can be matched in the radio using an

Aux and P-Mix or using a MatchBox.

8. Apply threadlock on main mounting servo screw.

Tighten the setscrews without use of threadlock.

6. Prepare the servo arm by mounting the ball link and

pushrod at 1.5-inch hole out.

7. Power up the servo and with sub-trim at 0, mount the

9. Connect other side of pushrod to control horns.

10. Adjust the length of pushrod to achieve rudder center

while the arm is parallel to the hinge line.

15Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 16

Main Gear and Tail Gear Installation

Required Parts

Landing gear Landing gear hardware

Wheel pants Wheels

Required Tools and Adhesives

2.5mm ball driver 10mm wrench and socket

Crescent wrench 4.5mm ball driver

Threadlock Felt-tipped pen

Thin CA Pin vise

1. Locate all the hardware necessary to mount the wheels

and wheel pants.

2. Mount the axles with locknut and washer provided in the

kit using a crescent and a #10 wrench.

3. Install the wheel using the two wheel collars provided;

apply threadlock to the setscrews and slightly tighten them.

6. Tighten the setscrews and wheel pant screws using a

1.5mm and 2.5mm ball driver respectively.

4. Temporarily install the pant and center the wheel.

7. Mount the main gear using (4) 5mm bolts/washers and

5. Once the wheel is centered, remove wheel pant and

mark the axle where wheel collars sit and file a flat spot for

each collar location. Note that the collar shoulder is facing

the wheel hub.

16 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

locknuts. Use threadlock on the bolts. Hold the nut either from

inside the canister tunnel or from the top through the slots in

the fuselage floor at the sides of the tank tray. Here the locknut

is shown being held using a ratchet with a #10 socket from

inside the canister tunnel. Gear needs to be installed with

Page 17

angle slightly swept forward.

8. Tail gear is mounted using (3) 4-40 ½ inch screws and

3 washers included in the kit.

9. Mount the T-bracket and mark the holes.

11. Apply thin CA in the holes and wait until it is dry, this

will harden the wall.

12. Mount the T-bracket using small wood screws and

the tail gear using washers and screws; make sure to use

threadlock on the bolts. Hook the springs from the tiller arm

to the T-bracket and secure them.

10. Drill a pilot hole using a pin vise, then mount the

screws and remove them.

17Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 18

Pipes/Canisters Mount Installation and

Assembly

4. Prepare the fuselage for pipe installation. Remove the

covering as pictured and iron down the edges. Masking tape

can be used to give good guidance when cutting.

Required Parts

Pipe or canister mounts Silicone tubing

Required Parts (not included)

MTW RE3 Pipe MTW 110 Canister

50mm drop header, 14-inch for RE3 tuned pipe setup

50mm drop header, 8-9-inch for MTW 110 canister setup

Couplers Clamps

Required Tools and Adhesives

Hobby knife Felt-tipped pen

5-and 30-minute epoxy Clamps

Vise grip Iron

Rotary tool with cutter disk Ruler

Masking tape Industrial lubricant

Acid brush Mixing cup and sticks

Pipes Mount Installation

1. Kit comes with 4 pipe mounts, 2 canister mounts

and silicone tubing. Two support locations are selected for

pipe installation. Pipe mounts need to be doubled up for

increased glue surface area and strength. Scratch the surface

of each mount with a hobby knife.

Note: Final picture is shown below to give a good

perspective as where to remove the covering.

2. Glue the layers using a thin layer of 5-minute epoxy.

Clamp until glue cures.

The picture below is of the bay immediate aft of landing

gear.

3. Pass the silicone tubing through the middle hole and

go through each hole in the circumference of the mount

from the inside until you are back at the same middle hole

that you started. Cut off the silicone tubing to prepare the

next pipe mount.

18 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 19

The picture below is of the tail end of the pipe tunnel.

5. Temporarily mount the pipe mounts and install pipes

to center the mounts before they are glued. Use lubricant on

the pipes for easier passage through the mounts when they

are not glued yet. Pipe mounts will not touch the floor of

the fuselage and need to be glued to the sides and bottom

former.

6. Once mounts are centered mark the spot on the sides

and formers.

7. Remove the pipes and use an acid brush to apply

30-minute epoxy to the sides of the mount and fuselage.

8. Reinstall the mounts and allow time for epoxy to cure.

19Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 20

Pipe Header Assembly

1. Recommended header length for MTW RE3 tuned pipe

and DA-170 is 14 inches. Assemble the pipe/header using a

vice-grip. Open the clamps and slide them over the header.

pipe and header, such that is it forward the bump on the

header and over the grooves on the pipe/canister.

3. Once everything is assembled, heat the couplers where

clamps are using a heat gun at high setting. Do this for a few

minutes and allow some time for cooling. Repeat this one

more time. This will create a good grip and reduces chance

of pipe/header slipping out in flight. It is also recommended

to do this before the first flight. Let engine idle for 3 to 4

minutes to warm up the couplers, gradually increasing the

throttle to half to get the engine hot and then allow a cooldown period before the first flight. This should not need

repeating and when done right, header/pipe will not slip out.

Canisters Mount Installation

1. Kit comes with 2 canister mounts and silicone tubing.

There is only one support location for the canister mount

that is under the landing gear area. Scratch the surface of

each mount with a hobby knife and glue the layers using a

thin layer of 5 to 15-minute epoxy. Clamp until glue is cured.

Pass the silicone tubing through the mount start with top

middle hole and end at bottom middle hole as shown in

Pipes Mount Installation section.

2. Prepare the fuselage for canister installation. Remove

the covering as pictured in first bay, under the landing gear

and iron down the edges.

2. Insert the header and pipe into coupler, leave 1/8--1/4

inch gap between header and pipe. Slide the clamps on the

20 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 21

Canister/Header Assembly

1. Recommended header length for MTW TD110 canister

and DA-170 is 8--9-inches. Cut 1 inch off the stock header.

Assemble the canister/header using a vice-grip to open the

clamps and slide them over the header first then insert the

header and canister into coupler. Leave 1/8--1/4 inch gap

between header and pipe. Since the bump on the header has

to be cut for optimum performance, tap a button head 4-40

screw on the header and slide the slot of the clamp over the

button head screw and coupler to avoid slippage.

3. Temporarily mount the canister mounts and install

canisters to center the mount. Use lubricant on the canisters

for easier passage through the mounts before they are glued.

The canister mount touches the floor of the fuse and needs

to be glued to the sides and bottom former. Once mount is

centered, mark the spot on the sides and formers. Remove

the canisters and apply glue to the sides of the mount and

fuselage where they contact using 30-minute epoxy to

enough have time for adjustment.

.

21Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 22

Cowl Mounting

Required Parts

Cowl mounting ring Gussets

Lower cowl

Lower cowl mounting hardware

Required Tools and Adhesives

30-minute epoxy Hobby knife

Iron 3/32-inch ball driver

1. The pictures below show the cowl mounting ring

and 3 gussets. They assemble as pictured. Mount the cowl

mounting ring and open the slots where the gussets sit on

and around the engine box.

2. Dry fit everything and temporarily mount the bottom

cowl to ensure correct alignment. Adjust if necessary.

22 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 23

3. Mark where the cowl mounting ring and gussets touch

the engine box and remove the covering before applying

epoxy. The picture below shows where the gusset attaches

to the cowl mounting ring and engine box.

4. Mix 30-minute epoxy and apply glue to the gussets

and cowl mount ring, also rub some epoxy in the slots

where the gusset tabs interlock, then glue the mounts in

place. Attach bottom cowl and wait until epoxy is set before

removing the cowl. This ensures the cowl mount ring and

gussets are glued and aligned properly. Clean excess epoxy

with alcohol swabs.

5. Mount the lower half cowl.

6. Mount the upper half cowl. At the mid-point that both

lower and upper half meet, use colored washers and 1/4 inch

4-40 screws.

23Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 24

Engine, Throttle Servo and DA Muffler

Installation

Required Parts

1/4-20 1-inch bolts (4)

Required Parts (not included)

DA-170 Engine DA stock muffler

JR-537 servo (1)

JR 24-inch servo extension

Required Tools and Adhesives

Threadlock 4.5mm hex wrench

Hobby knife with #11 blade Felt-tipped pen

Pin vise Phillips screwdriver

Rotary tool with sanding drum

1. Mount the engine using 1-inch ¼-20 bolts provided

and make sure to apply threadlock to all the bolts.

2. Mount the throttle servo so that the servo output shaft

is closer to the front of the engine. DA-170 comes with a

4-40 ball link attached to the throttle lever. Screw the 6 1/2inch 4-40 rod into DA ball link and ball link provided with the

kit. Apply threadlock to the servo arm screw. Throttle servo

needs 24-inch extension.

24 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

3. Install the mufflers so DA logo on the muffler is

pointed towards the front and smoke nipples are facing

outboard of the plane on both sides. Use gasket provided or

high-temperature RTV and apply threadlock to the muffler

bolts.

Page 25

4. Use cutting disk, drum sander and a rotary tool to

cut the cowl. Holes need to be at least 1/4 inch larger than

muffler stack diameter.

Fuel Tank, Fill and Over Flow

Installation

Required Parts

Fuselage Fuel tank

Required Parts (not included)

Hangar 9 Fuel filler and T

Required Tools and Adhesives

Drill and bits (1/16-inch, 1/8-inch)

Zip tie Hemostat

Double-sided tape or adhesive-backed hook and loop

Medium CA Hook and loop staps

Rotary tool Sanding Drum (3/8-inch)

1. Fuel tank comes assembled but not installed. It is

recommended that lines be checked every 2–3 months and

replace them if they have hardened.

2. Fill line is installed at the front left side of the

fuselage using Hangar 9 fuel filler. Drill a small hole; then

using a rotary tool and 3/8-inch diameter sanding drum

or grinding bit, open the side of the fuselage for the fuel

filler.

3. Tank fill line goes to a T. Use the straight path outlet

to connect to carb and other to fuel filler. Wrap safety wires

around the lines.

25Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 26

6. Glue two pieces of hook and loop to the tank tray using

medium CA.

4. To secure the fuel tank from forward/aft motion,

double-sided or servo tape should be applied to the bottom

of the tank. There is no foaming issue with hard-mounted

tanks in gas engines.

For removable setup, apply a couple of pieces of masking

tape to the bottom of the tank.

5. Glue a piece of hook and loop to the masking tape using

medium CA.

9. Mount the lower cowl and mark behind the bottom left

louver. Use rotary tool to open the lower cowl, big enough to

pass the overflow line.

7. Strap the tank with hook and loop strips provided.

Loop the overflow line around the tank.

8. Overflow line goes through the fuselage floor opening

to the lower bottom cowl.

10. Cut 1/4-inch fuel line.

26 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 27

Ignition Module, Battery, Regulator

and Switch Installation

Required Parts

Fuselage

Required Parts (not included)

JR 5203 regulator Ignition Module

Ignition Battery, 2000 2-cell Spektrum

JR heavy-duty switch or similar

JR heavy-duty 6-inch extension

11. To help prevent the line from going back inside the

cowl, open up the fuel line with use of hemostat and pull

over the overflow line.

Required Tools and Adhesives

Hobby knife Iron

Masking tape Medium CA

Hook and loop Double-sided tape

1. Locate the ignition switch cut out in the right front of

the fuselage and remove the covering. Mount the ignition

switch.

2. Locate the slots for the ignition module behind the

cowl mounting ring and remove the covering.

3. Iron down the edges and the covering on the engine

box.

4. The ignition module and battery will be installed as one

piece, on top of each other. Apply masking tape to both sides

of battery and bottom side of ignition module.

27Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 28

5. Apply servo/double-sided tape between battery and

ignition module.

7. Apply opposite side of adhesive-backed hook and loop

to the engine box.

9. Ignition will be mounted next to ignition module

and battery. Glue a piece of hook and loop next to ignition

module and battery.

6. Glue ¼-inch thick DuBro foam to the bottom of the

battery using CA. Glue a piece of hook and loop to the foam.

8. Mount the ignition and battery as one piece and strap

it with hook and loop straps. Provide an overlap of 2 inches

for the strap to wrap around the battery and ignition module

through the slots.

10. Apply a piece of masking tape to the bottom of

regulator and glue opposite side of hook and loop using CA.

28 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 29

11. Mount the regulator.

Receiver Mount and Throttle Servo

Regulator Installation

Required Parts

Receiver tray and stands Fuselage

Required Parts (not included)

JR 5203 regulator Receiver

Required Tools and Adhesives

Masking tape CA thin and medium

CA accelerator 5-minute epoxy

Dubro 1/4-inch foam Hook and loop

Hook and loop

1. Prepare the receiver to mount on the tray, similar to

the ignition battery preparation in the previous section. Put

two rounds of masking tape at the bottom of the receiver.

Using CA glue 1/4-inch DuBro foam to the masking tape and

glue a piece of hook and loop to the foam.

3. Throttle servo regulator is mounted next to the receiver

using two pieces of hook and loop similar to step 1.

12. Use the excess strap from the ignition module and

pull it over the ignition.

Note: Connect battery to switch, output of the switch

to regulator (6-inch extension is needed) and regulator

output to ignition. With this method, battery can be

charged directly through the switch charge port.

4. Glue balsa sticks using thin CA to the floor of the

fuselage.

2. Glue opposite side of the hook and loop to the tray and

mount the receiver.

29Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 30

5. Glue the tray on the balsa stick using either Medium

CA or 5-minute epoxy. Hold pressure on the tray until glue

dries or epoxy sets.

Receiver Battery Installation

Required Parts

Fuselage

Required Parts (not included)

(2) Spektrum 4000 2-cell LiPo

(2) 12-inch EC3™ extensions

Required Tools and Adhesives

Medium CA Masking tape

Hook and loop Hook and loop straps

1. Apply masking tape to the bottom of the batteries.

Glue hook and loop using CA to the masking tape. Applying

CA in addition to the adhesive already on the hook and loop

ensures glue does not come undone on hot days.

the kit and secure the batteries by passing the strips through

the top and bottom slots.

The picture below shows the right battery setup.

6. Strap the receiver using hook and loop.

The picture below shows the left battery setup.

2. Glue using CA opposite side of hook and loop to the

sides of the fuselage as shown below.

3. Overlap 2 inches of hook and loop straps provided in

30 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 31

Satellite Receiver and Receiver Switch

Installation

Required Parts

Fuselage

Required Parts (not included)

(3 to 4) Satellite receivers

Receiver switch

Required Tools and Adhesives

Double-sided tape Masking tape

Hook and loop Threadlock

Medium CA

Note: It is best to use 4 satellite receivers as this is

a large model, however, with proper placement of

the satellite receivers, 3 would be adequate. A Flight

Log can help with correct placement of the satellite

receivers. Check the health of the system before first

flight.

1. Remove the covering from the right side of the

fuselage and mount the receiver switch. Apply a small

amount of threadlock to the screws.

2. There are two ways to mount the satellite receivers.

One way is to simply apply a piece of double-sided/servo

tape to the back of the satellite receiver and attach to the

fuselage. See step 3 for the alternative method.

4. Using the same method glue the opposite side of

the hook and loop to those parts of the fuselage where

the satellite receivers will attach. Note the recommended

locations in the following pictures.

3. Attach a piece of masking tape to the back of the

satellite receiver; apply a couple of drops of CA to the

masking tape and stick a piece of hook and loop to the

masking tape. Note that even if the hook and loop is

adhesive-backed, CA helps hold the hook and loop to the

masking tape in high temperatures.

31Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 32

Pilot/Panel Assembly and Installation

Required Parts

Pilot Pilot hardware

Required Tools and Adhesives

3/32-inch ball driver Threadlock

Music wire, .050-inch (not included)

Flexible adhesive (Shoo Goo or Zap-A-Dap-A-Goo)

Foam-Safe CA

1. Pilot head comes in two pieces with two screws and

washers. Apply threadlock to bolts and pass them through

the lower body of the pilot through the head.

2. Glue the pilot using Shoo Goo to the place allocated in

the canopy.

3. Locate the foam pilot panel and pilot panel decal.

32 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 33

3. Peel the decal and stick to the foam pilot panel.

Center of Gravity

An important part of preparing the aircraft for flight is

properly balancing the model.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location for your

model is 10.5 inches forward from the trailing edge of the

wing tip as shown. Mark the location of the CG on the top

of the wing with a felt-tipped pen.

Use help to lift the plane from the marked position.

For 3D flying 10 inches forward of trailing edge is

recommended; however, the 10.5 inches is the best overal

CG for both precision and 3D flying.

4. Glue the foam panel using foam-safe CA to the canopy.

5. Canopy bolts to the fuselage using 4 (4mm) screws

provided.

After the first flights, the CG position can be adjusted for

your personal preference.

33Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 34

Applying Decals

Kit comes with decal sets and all decals are die-cut. All large decals should be applied wet so the bubbles can be worked out by squeegee. Allow 24 hours for decals to dry and adhesive to

set.

It is important to take all the wrinkles in the covering out and would be best to apply the decals after the plane has been taken to a flying field a couple of times and all the wrinkles have

been removed. The following pictures show the location of decals.

Wing Decal Close-up

34 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 35

Applying Decals

Fuselage Decal Close-up

35Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 36

Control Throws

Aileron:

Pro-Tips

1. Turn on the transmitter and receiver of your model.

Check the movement of the rudder using the transmitter.

When the stick is moved right, the rudder should also move

right. Reverse the direction of the servo at the transmitter if

necessary.

2. Check the movement of the elevator with the radio

system. Moving the elevator stick toward the bottom of the

transmitter will make the airplane elevator move up.

3. Check the movement of the ailerons with the radio

system. Moving the aileron stick right will make the right

aileron move up and the left aileron move down.

4. Use a throw meter to adjust the throw of the elevator,

ailerons and rudder.

Mike McConville has three flight modes as follows:

1. Normal: This flight mode is used for most precision

maneuvers.

2. Roller: This flight mode is used for spins, hammer head

and rolling circles. It has more rudder and elevator compared

to Normal flight mode.

3. High (3D): All surfaces at full deflection for 3D flying.

Mike’s plane uses 1% down elevator mix to throttle for down

lines and 5% up elevator to eliminate the pitch coupling in

knife edge. Please note this is very C.G dependant.

See Pro-Tips section for more details.

High Rate: Expo

Up: 34 degrees 45%

Down: 33 degrees 45%

Roller Rate: Expo

Up: 25.5 degrees 46%

Down: 25 degrees 46%

Normal Rate: Expo

Up: 28.5 degrees 45%

Down: 28 degrees 45%

Rudder:

High and Roller Rate: Expo

Right: 40 degrees 56%

Left: 40 degrees 56%

Normal Rate:

Right: 23 degrees 45%

Left: 23 degrees 45%

These are general guidelines measured from our own flight

tests. You can experiment with higher rates to match your

preferred style of flying.

Note: Travel Adjust, Sub-Trim and Dual Rates are

not listed and should be adjusted according to each

individual model and preference.

Important mixes that should be done correctly for precision

flying are as follows; this is besides the pitch coupling

mixes.

1. Downline Mix: Mike McConville’s plane needs only 1%

of down elevator that comes on at low end of idle. It is

important that this is done correctly to avoid inadvertent

down elevator when it is not needed.

2. For roller flight mode, Mike uses an elevator to elevator

mix that allows the elevator feel around center stick to be

the same as normal flight mode and increases elevator

throw at the extreme stick movement for spins and other

maneuvers that need extra elevator deflection. This is without

compromising the precision feel of the elevator.

Elevator:

High Rate: Expo

Up: 43 degrees 70%

Down: 43 degrees 70%

Roller: Expo

Up: 14.5 degrees 42% See Pro-Tips

Down: 14.5 degrees 42%

Normal: Expo

Up: 10.5 degrees 42%

Down: 10.5 degrees 42%

36 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 37

Preight

Safety Do’s and Don’ts for Pilots

Check Your Radio

Before going to the field, be sure your batteries are

fully charged per your radio’s instructions. Charge the

transmitter and motor battery for your airplane. Use the

recommended charger supplied with your particular radio

system, following the instructions provided with the radio.

In most cases, the radio should be charged the night before

going out flying.

Before each flying session, be sure to range check your

radio. See your radio manual for the recommended

range and instructions for your radio system. Each radio

manufacturer specifies different procedures for their radio

systems. Next, run the motor. With the model securely

anchored, check the range again. The range test should not

be significantly affected. If it is, don’t attempt to fly! Have

your radio equipment checked out by the manufacturer.

Double-check that all controls (aileron, elevator, rudder and

throttle) move in the correct direction.

Check the radio installation and make sure all the control

surfaces are moving correctly (i.e., the correct direction and

with the recommended throws).

Check all the control horns, servo horns, and clevises to

make sure they are secure and in good condition.

Range Test Your Radio

Before each flying session, and especially with a new model,

it is important to perform a range check. It is helpful to have

another person available to assist during the range check. If

you are using a Spektrum transmitter, please refer to your

transmitter’s manual for detailed instructions on the range

check process.

• Consultlocallawsandordinancesbeforechoosinga

location to fly your aircraft.

• Checkallcontrolsurfacespriortoeachtakeoff.

• Donotflyyourmodelnearspectators,parkingareasor

any other area that could result in injury to people or

damage of property.

• Donotflyduringadverseweatherconditions.Poor

visibility can cause disorientation and loss of control of

your aircraft. Strong winds can cause similar problems.

• Donottakechances.Ifatanytimeduringflight

you observe any erratic or abnormal operation, land

immediately and do not resume flight until the cause of

the problem has been ascertained and corrected. Safety

can never be taken lightly.

• Donotflynearpowerlines.

Daily Flight Checks

• 1.Checkthebatteryvoltageofthetransmitterbattery.

Do not fly below the manufacturer’s recommended

voltage. To do so can crash your aircraft.

When you check these batteries, ensure you have the

polarities correct on your expanded scale voltmeter.

• 2.Checkallhardware(linkages,screws,nuts,andbolts)

prior to each day’s flight. Be sure that binding does not

occur and that all parts are properly secured.

• 3.Ensureallsurfacesaremovinginthe

proper manner.

• 4.Performagroundrangecheckbeforeeachday’s

flying session.

• 5.Priortostartingyouraircraft,turnoffyour

transmitter, then turn it back on. Do this each time you

start your aircraft. If any critical switches are on without

your knowledge, the transmitter alarm will sound a

warning at this time.

• 6.Checkthatalltrimleversareintheproperlocation.

• 7.Allservopigtailsandswitchharnessplugsshouldbe

secured in the receiver. Make sure the switch harness

moves freely in both directions.

37Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 38

Warranty and Repair Policy

WARRANTY PERIOD

Exclusive Warranty- Horizon Hobby, Inc., (Horizon)

warranties that the Products purchased (the “Product”) will

be free from defects in materials and workmanship at the

date of purchase by the Purchaser.

LIMITED WARRANTY

Horizon reserves the right to change or modify this

warranty without notice and disclaims all other

warranties, express or implied.

(a) This warranty is limited to the original Purchaser

(“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT

AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE

REMEDY OF THE PURCHASER. This warranty covers only those

Products purchased from an authorized Horizon dealer. Third

party transactions are not covered by this warranty. Proof of

purchase is required for all warranty claims.

(b) Limitations- HORIZON MAKES NO WARRANTY OR

REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT

THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF

THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall

be that Horizon will, at its option, (i) repair or (ii) replace, any

Product determined by Horizon to be defective. In the event of

a defect, these are the Purchaser’s exclusive remedies. Horizon

reserves the right to inspect any and all equipment involved in a

warranty claim. Repair or replacement decisions are at the sole

discretion of Horizon. This warranty does not cover cosmetic

damage or damage due to acts of God, accident, misuse, abuse,

negligence, commercial use, or modification of or to any part

of the Product. This warranty does not cover damage due to

improper installation, operation, maintenance, or attempted

repair by anyone other than Horizon. Return of any Product

by Purchaser must be approved in writing by Horizon before

shipment.

DAMAGE LIMITS

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT

OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY

CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM

IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY. Further, in no event shall the liability of

Horizon exceed the individual price of the Product on which

liability is asserted. As Horizon has no control over use,

setup, final assembly, modification or misuse, no liability

shall be assumed nor accepted for any resulting damage or

injury. By the act of use, setup or assembly, the user accepts

all resulting liability.

If you as the Purchaser or user are not prepared to accept

the liability associated with the use of this Product, you

are advised to return this Product immediately in new and

unused condition to the place of purchase.

Law: These Terms are governed by Illinois law (without

regard to conflict of law principals).

Warranty Services

QUESTIONS, ASSISTANCE, AND REPAIRS

Your local hobby store and/or place of purchase cannot

provide warranty support or repair. Once assembly, setup

or use of the Product has been started, you must contact

Horizon directly. This will enable Horizon to better answer

your questions and service you in the event that you may

need any assistance. For questions or assistance, please

direct your email to productsupport@horizonhobby.com, or

call 877.504.0233 toll free to speak to a Product Support

representative. You may also find information on our website

at www.horizonhobby.com.

INSPECTION OR REPAIRS

If this Product needs to be inspected or repaired, please

use the Horizon Online Repair Request submission process

found on our website or call Horizon to obtain a Return

Merchandise Authorization (RMA) number. Pack the Product

securely using a shipping carton. Please note that original

boxes may be included, but are not designed to withstand

the rigors of shipping without additional protection. Ship

via a carrier that provides tracking and insurance for lost

or damaged parcels, as Horizon is not responsible for

merchandise until it arrives and is accepted at our facility.

An Online Repair Request is available at http://www.

horizonhobby.com under the Repairs tab. If you do not have

internet access, please contact Horizon Product Support to

obtain a RMA number along with instructions for submitting

your product for repair. When calling Horizon, you will be

asked to provide your complete name, street address, email

address and phone number where you can be reached during

business hours. When sending product into Horizon, please

include your RMA number, a list of the included items, and a

brief summary of the problem. A copy of your original sales

receipt must be included for warranty consideration. Be sure

your name, address, and RMA number are clearly written on

the outside of the shipping carton.

Notice: Do not ship batteries to Horizon. If you have

any issue with a battery, please contact the appropriate

Horizon Product Support office.

38 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 39

WARRANTY INSPECTION AND REPAIRS

To receive warranty service, you must include your original

sales receipt verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product will be

repaired or replaced free of charge. Repair or replacement

decisions are at the sole discretion of Horizon.

NON-WARRANTY REPAIRS

Should your repair not be covered by warranty the repair

will be completed and payment will be required without

notification or estimate of the expense unless the expense

exceeds 50% of the retail purchase cost. By submitting the

item for repair you are agreeing to payment of the repair

without notification. Repair estimates are available upon

request. You must include this request with your repair.

Non-warranty repair estimates will be billed a minimum of ½

hour of labor. In addition you will be billed for return freight.

Horizon accepts money orders and cashiers checks, as well

as Visa, MasterCard, American Express, and Discover cards.

By submitting any item to Horizon for inspection or repair,

you are agreeing to Horizon’s Terms and Conditions found

on our website under the Repairs tab.

Please note: non-warranty repair is only available on

electronics and model engines.

United States:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

USA

All other Products requiring warranty inspection or repair

should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

USA

United Kingdom:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Hobby Limited

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

Please call +44 (0) 1279 641 097 or e-mail us at sales@

horizonhobby.co.uk with any questions or concerns

regarding this product or warranty.

Germany:

Electronics and engines requiring inspection or repair

should be shipped to the following address:

Horizon Technischer Service

Hamburger Strasse 10

25335 Elmshorn

Germany

Please call +49 4121 46199 66 or e-mail us at service@

horizonhobby.de with any questions or concerns regarding

this product or warranty.

France:

Horizon Hobby SAS

14 Rue Gustave Eiffel

Zone d’Activité du

Réveil Matin

91230 Montgeron

Please call +33 (0) 1 60 47 44 70 with any questions or

concerns regarding this product or warranty.

Compliance Information for the

European Union

INSTRUCTIONS FOR DISPOSAL OF WEEE BY

USERS IN THE EUROPEAN UNION

This product must not be disposed of with other waste.

Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated

collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling

of your waste equipment at the time of disposal will help to

conserve natural resources and ensure that it is recycled in

a manner that protects human health and the environment.

For more information about where you can drop off your

waste equipment for recycling, please contact your local city

office, your household waste disposal service or where you

purchased the product.

Please call 877-504-0233 or e-mail us at productsupport@

horizonhobby.com with any questions or concerns regarding

this product or warranty.

39Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 40

2010 Official Academy of Model

Aeronautics Safety Code

GENERAL

1. A model aircraft shall be defined as a non-humancarrying device capable of sustained flight in the

atmosphere. It shall not exceed limitations established

in this code and is intended to be used exclusively for

recreational or competition activity.

2. The maximum takeoff weight of a model aircraft,

including fuel, is 55 pounds, except for those flown

under the AMA Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules established

for the flying site I use. I will not willfully fly my model

aircraft in a reckless and/or dangerous manner.

4. I will not fly my model aircraft in sanctioned events,

air shows, or model demonstrations until it has been

proven airworthy.

5. I will not fly my model aircraft higher than approximately

400 feet above ground level, when within three (3) miles

of an airport without notifying the airport operator. I will

yield the right-of-way and avoid flying in the proximity of

full-scale aircraft, utilizing a spotter when appropriate.

6. I will not fly my model aircraft unless it is identified with

my name and address, or AMA number, inside or affixed

to the outside of the model aircraft. This does not apply

to model aircraft flown indoors.

7. I will not operate model aircraft with metal-blade

propellers or with gaseous boosts (other than air),

nor will I operate model aircraft with fuels containing

tetranitromethane or hydrazine.

8. I will not operate model aircraft carrying pyrotechnic

devices which explode burn, or propel a projectile of

any kind. Exceptions include Free Flight fuses or devices

that burn producing smoke and are securely attached

to the model aircraft during flight. Rocket motors up

to a G-series size may be used, provided they remain

firmly attached to the model aircraft during flight. Model

rockets may be flown in accordance with the National

Model Rocketry Safety Code; however, they may not be

launched from model aircraft. Officially designated AMA

Air Show Teams (AST) are authorized to use devices

and practices as defined within the Air Show Advisory

Committee Document.

9. I will not operate my model aircraft while under the

influence of alcohol or within eight (8) hours of having

consumed alcohol.

10. I will not operate my model aircraft while using any drug

which could adversely affect my ability to safely control

my model aircraft.

11. Children under six (6) years old are only allowed on a

flightline or in a flight area as a pilot or while under flight

instruction.

12. When and where required by rule, helmets must be

properly worn and fastened. They must be OSHA, DOT,

ANSI, SNELL or NOCSAE approved or comply with

comparable standards.

RADIO CONTROL

1. All model flying shall be conducted in a manner to avoid

over flight of unprotected people.

2. I will have completed a successful radio equipment

ground-range check before the first flight of a new or

repaired model aircraft.

3. I will not fly my model aircraft in the presence of

spectators until I become a proficient flier, unless I am

assisted by an experienced pilot.

4. At all flying sites a line must be established, in front of

which all flying takes place. Only personnel associated

with flying the model aircraft are allowed at or in front of

the line. In the case of airshows demonstrations straight

line must be established. An area away from the line

must be maintained for spectators. Intentional flying

behind the line is prohibited.

5. I will operate my model aircraft using only radiocontrol frequencies currently allowed by the Federal

Communications Commission (FCC). Only individuals

properly licensed by the FCC are authorized to operate

equipment on Amateur Band frequencies.

6. I will not knowingly operate my model aircraft within

three (3) miles of any preexisting flying site without

a frequency-management agreement. A frequency

management agreement may be an allocation of

frequencies for each site, a day-use agreement between

sites, or testing which determines that no interference

exists. A frequency-management agreement may exist

between two or more AMA chartered clubs, AMA

clubs and individual AMA members, or individual

AMA members. Frequency-management agreements,

including an interference test report if the agreement

indicates no interference exists, will be signed by all

parties and copies provided to AMA Headquarters.

7. With the exception of events flown under official AMA

rules, no powered model may be flown outdoors closer

than 25 feet to any individual, except for the pilot and

located at the flightline.

8. Under no circumstances may a pilot or other person

touch a model aircraft in flight while it is still under

power, except to divert it from striking an individual.

9. Radio-controlled night flying is limited to lowperformance model aircraft (less than 100 mph). The

model aircraft must be equipped with a lighting system

which clearly defines the aircraft’s attitude and direction

at all times.

10. The operator of a radio-controlled model aircraft shall

control it during the entire flight, maintaining visual

contact without enhancement other than by corrective

lenses that are prescribed for the pilot. No model aircraft

shall be equipped with devices which allow it to be flown

to a selected location which is beyond the visual range

of the pilot.

40 Hangar 9 3.1m Sukhoi SU-26MM ARF Assembly Manual

Page 41

27162

© 2011 Horizon Hobby, Inc.

horizonhobby.com

Hangar9.com

Printed 01/2011

Loading...

Loading...