Page 1

ASSEMBLY MANUAL

Specifications

Wingspan: .............. 97 in (2463.8mm)

Length: ................... 83 in (2108.2mm)

Wing Area: ............ 1750 sq in (112.9 sq dm)

Weight:................... 24.75–25.5 lb (11.2 kg–11.5 kg)

Radio: ..................... 4-channel w/9 servos

Engines: ................... 3.8–4.8 cu in

Extra 330S

TM

• Superior controllability and aerobatic flight characteristics

• Lightweight construction

• Designed by veteran TOC competitor Mike McConville

• 90% built 1/3-scale ARF

• Plug-in wings and stabilizers for easy transport and field assembly

®

WE GET PEOPLE FLYING

Page 2

2

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contents of Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Other Items Needed (not included in the kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Required Tools and Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Hangar 9 1/3 Scale Hardware Package (HAN1220, JR/HAN1221, Futaba) . . . . . . . . . . . . . . 4

Servo Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Starting Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 1 – Aileron Servo Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 2 – Aileron Control Horn Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 3 – Hinging and Sealing the Control Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 4 – Sealing the Hinge Gaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 5 – Aileron Linkage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 6 – Wing Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 7 – Rudder and Elevator Servo Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 8 – Elevator Linkage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 9 – Rudder Linkage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Section 10 – Landing Gear Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 11 – Wheel Pant Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 12 – Tail Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Section 13 – Receiver, Battery and Fuel Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Section 14 – Mounting the Engine and Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section 15 – Hatch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 16 – Balancing the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Section 18 – Control Throws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Section 17 – Radio Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Preflight at the Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup and Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Extra 330S–3D at its Best . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2003 Official AMA National Model Aircraft Safety Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Using the Manual

This manual is divided into sections to help make assembly easier to understand and to provide breaks between

each major section. Remember to take your time and follow the directions.

Page 3

3

Contents of Kit

Large Parts

A. Fuselage w/Hatch HAN1176

B. Right Wing Panel w/Aileron HAN1177

C. Left Wing Panel w/Aileron HAN1178

D. Right Stabilizer w/Elevator HAN1179

E. Left Stabilizer w/Elevator HAN1180

F. Rudder HAN1181

G. Canopy HAN1182

H. Painted Cowl HAN1184

I. Aluminum Landing Gear HAN1185

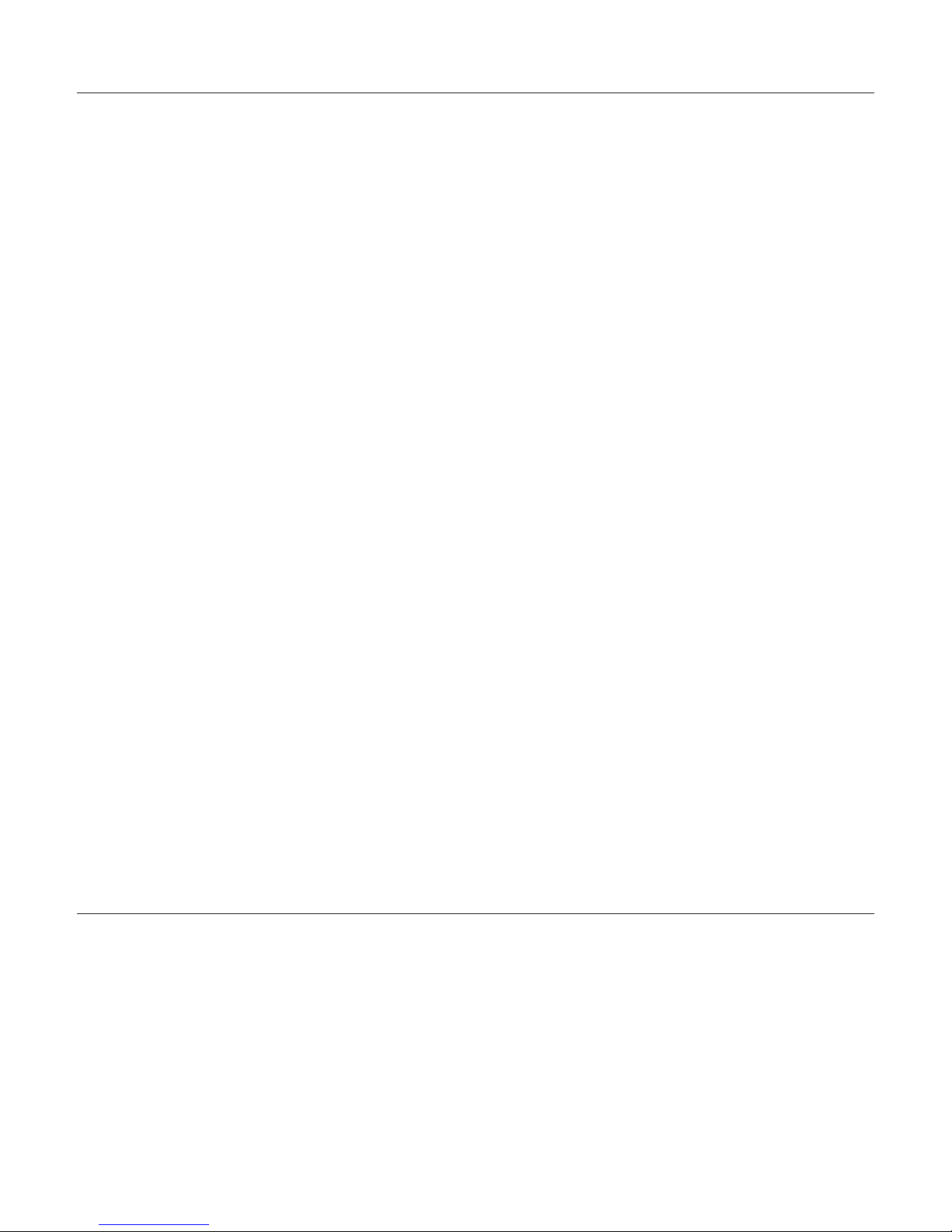

Additional Required Equipment

Radio Equipment

• 4-channel radio system (minimum)

• 1 standard servo for throttle (JRPS537

recommended or equivalent)

• 8 hi-torque servos (JRPS8411

recommended or equivalent)

Recommended JR™ Systems

• PCM10X

• XP8103

• X-378

• XP662

• XF631

• XF421

• Quattro

Recommended Engines

•G-62, GT-80

JR XP8103

JR PCM 10X

Zenoah®GT-80

ZENE80T

Zenoah®G62

ZENE62A

A

B

C

D

E

Other Items Needed (not included in the kit)

• Propeller (consult engine instructions)

• 12" Servo Extension (JRPA098)

• 18" Servo Extensions (JRPA099) (4)

• 24" Servo Extensions (JRPA102) (5)

• 1/8" light plywood

• Y-Harness (JRPA133) (2)

• MatchBox™ (JRPA900) (4)

F

G

H

I

Items not shown:

Canopy Hatch HAN1183

Landing Gear Fairing HAN1186

Decal Set HAN1187

Page 4

4

Additional Required Tools and Adhesives

Tools

• 4-40 tap

• 8-32 tap

• Adjustable wrench (small)

• Canopy scissors

• Drill (drill press preferred)

• Drill bit: 1/16", 3/32", 7/32", 1/4", #43, 1/2",

5/32", 9/64"

• Drum sander

• Cut-off wheel

• Velcro straps

• Flat blade screwdriver w/short handle

• Foam: 1/2"

• Hex wrench: 3/32"

• Hobby knife

• Masking tape

• Phillips screwdriver (small)

• Pliers

• Ruler

• Sandpaper

• Scissors

• Square

• Syringe

• Tap handle

• Toothpicks

Adhesives

• 6-minute epoxy

• 30-minute epoxy

• Thick CA (cyanoacrylate) glue

• CA remover/debonder

• Pacer Z-42 Threadlock

• Formula 560-canopy glue

• Shoo Goo

• Masking tape (3M blue recommended)

Other Required Items

• Epoxy brushes

• Felt-tipped pen or pencil

• File

• Measuring device (e.g. ruler, tape measure)

• Mixing sticks for epoxy

• Paper towels

• Petroleum jelly

• Rubbing alcohol

• Sanding bar

• Sandpaper (coarse)

• Clear UltraCote® (HANU964)

• Covering Iron (HAN101)

• Dental floss or string

Optional Hangar 9®1/3 Scale Hardware Package

(HAN1220, JR/HAN1221, Futaba)

• Tail Wheel Assembly with Hardware (OHI130)

• 4-40 1/2 3D arm (11/4") Futaba (2) (HAN3579)

• 4-40 Ball Links (7) (ROC87)

• 4-40 1/2 HD Arm (1") Futaba (4) (HAN3575)

• 8-32 Swivel Control Horns (6) (ROC01B)

• 4-40 Solder Link (2) (DUB305)

• 4-40 Rod, Threaded one end (6) (DUB802)

• 3/16" Wheel Collars (2) (DUB141)

• 31/2" Wheels (2) (DUB350L)

• 3/16" Main Axles (DUB249)

• 4

1

/2" 4-40 Threaded Pro-Links (2) (HAN3556)

• Super Hinge Points (24) (ROB309)

• 5" 4-40 Threaded Pro-Links (2) (HAN3557)

• 4-40 1/2 3D Arm (11/4") JR (4) (HAN3578)

• 32 oz Fuel Tank (DUB690)

• 4-40 1/2 HD Arm (1") JR (4) (HAN3574)

Page 5

5

Before Starting Assembly

Before beginning the assembly of the Extra 330S, remove each part from its bag for inspection. Closely inspect

the fuselage, wing panels, rudder, and stabilizer for damage. If you find any damaged or missing parts, contact

the place of purchase.

If you find any wrinkles in the covering, use a heat gun or covering iron to remove them. Use caution while

working around areas where the colors overlap to prevent separating the colors.

Warranty Information

Horizon Hobby, Inc. guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any parts damage by use or modification. In no case shall Horizon

Hobby's liability exceed the original cost of the purchased kit. Further, Horizon Hobby reserves the right to

change or modify this warranty without notice.

In that Horizon Hobby has no control over the final assembly or material used for the final assembly, no liability

shall be assumed nor accepted for any damage of the final user-assembled product. By the act of using the

product, the user accepts all resulting liability.

Once assembly of the model has been started, you must contact Horizon Hobby, Inc. directly regarding any

warranty question that you have. Please do not contact your local hobby shop regarding warranty issues, even if

that is where you purchased it. This will enable Horizon to better answer your questions and service you in the

event that you may need any assistance.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to

return this kit immediately in new and unused condition to the place of purchase.

Horizon Hobby

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

www.horizonhobby.com

Warning

An RC aircraft is not a toy! If misused, it can cause serious bodily harm and damage to property. Fly only in

open areas, preferably at AMA (Academy of Model Aeronautics) approved flying sites, following all instructions

included with your radio and engine.

Servo Selection

The servos used for the control surfaces of the Extra 330S must have a minimum of 80 ounce inch of servo

torque. In the prototype Extras, we used JR8411 servos.

Page 6

6

Section 1 – Aileron Servo Installation

Required Parts

• Wing panel (right and left)

Required Tools and Adhesives

• Phillips screwdriver (small)

• Drill bit: 1/16"

• Drill

• 12" Servo Extension (JRPA098)

• 24" Servo Extension (JRPA102)

Step 1

Install the servo hardware (grommets and eyelets)

included with the servo.

Step 2

Plug a 12" and a 24" servo extension onto two of

the servos. Either tie the servo leads together, using

a commercially available connector, or use unwaxed

dental floss to secure the extensions to prevent them

from coming loose during flight.

Step 3

Tie a weight to a piece of string. A wheel collar works

great in this application. Lower the string into the

wing from the aileron servo opening. Let the weight

drop out through the wing root for the servo.

Page 7

Section 1 – Aileron Servo Installation

7

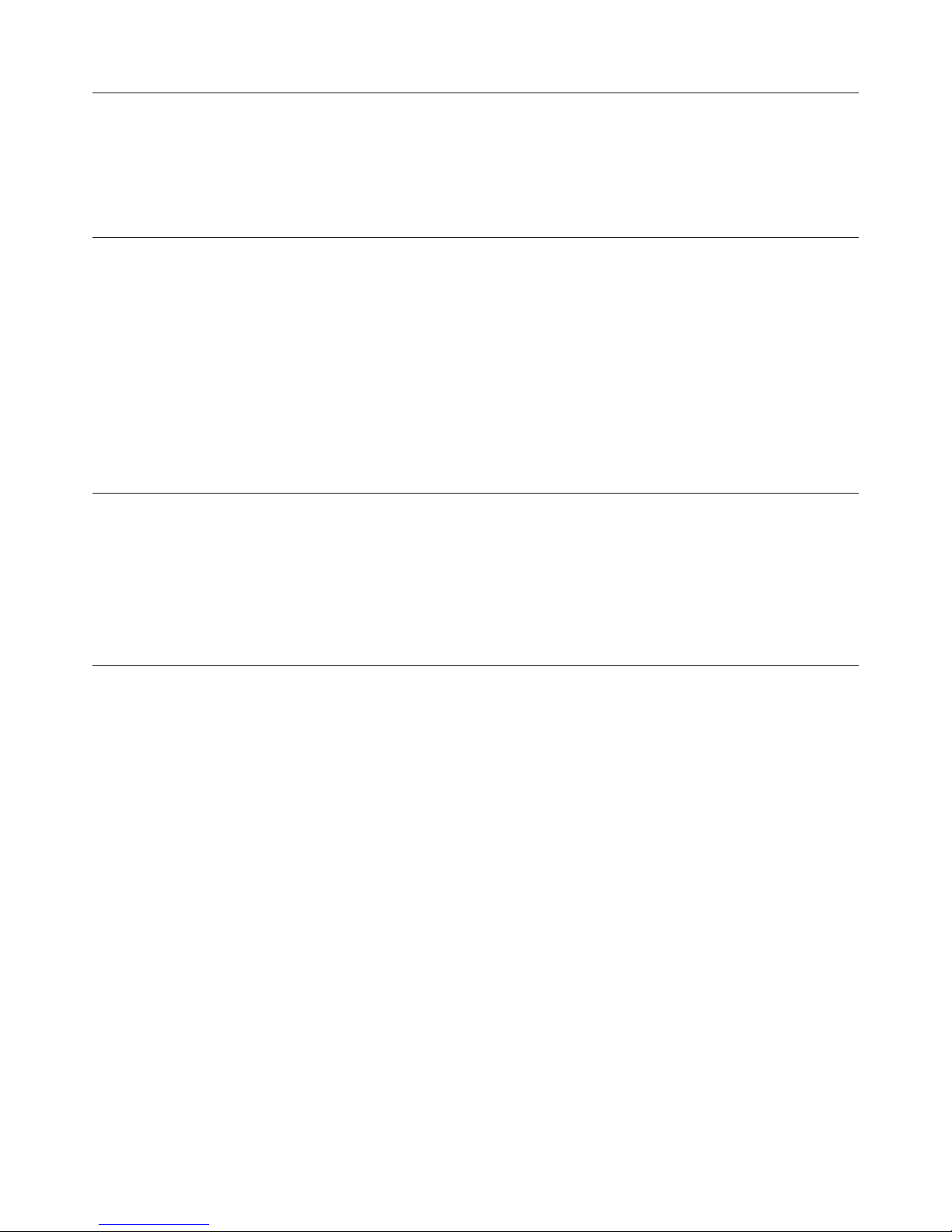

Step 4

Insert the servo with the 24" extension towards the

tip of the wing. Use the string to pull the servo lead

through the wing. Position the servo so the output

shaft is towards the trailing edge of the wing. Use

a 1/16” drill bit to drill the locations for the servo

screws. Mount the servos using the hardware

provided with the servos.

Step 5

Repeat Steps 3 and 4 for the servo near the root of

the wing panel.

Step 6

Repeat Steps 1 through 5 for the remaining

wing panel.

Photo for Step 4

Photo for Step 4

Page 8

8

Section 2 – Aileron Control Horn Installation

Required Parts

• Wing panel (left and right)

• Aileron (left and right)

Required Tools and Adhesives

• Felt-tipped pen • Drill bit: 5/32"

• 8-32 tap • Tap handle

• Square • Ruler

• 30-minute epoxy • Rubbing alcohol

• Drill (drill press preferred)

• 8-32 x 2" Hangar 9

®

control horn screw (4)

(Included in HAN1220 (JR™) or HAN1221 (FUT))

• Hangar 9 control horn A-nut (4) (Included in

HAN1220 (JR™) or HAN1221 (FUT))

Step 1

Tape the aileron to the wing. Make a mark 1/2"

away from the edge of the servo towards the tip

of the wing. Using a square held in alignment (90°)

with the mark and with the trailing edge, mark the

aileron with a pen where the straight edge intersects

the aileron hinge bevel.

Step 2

Measure exactly 3

3

/8" forward from the trailing edge

of the aileron and make another mark using a felttipped pen. The intersection of the line from Step 1

and this line will be the position for the control horn.

Step 3

Repeat Steps 1 and 2 for the second control

horn location.

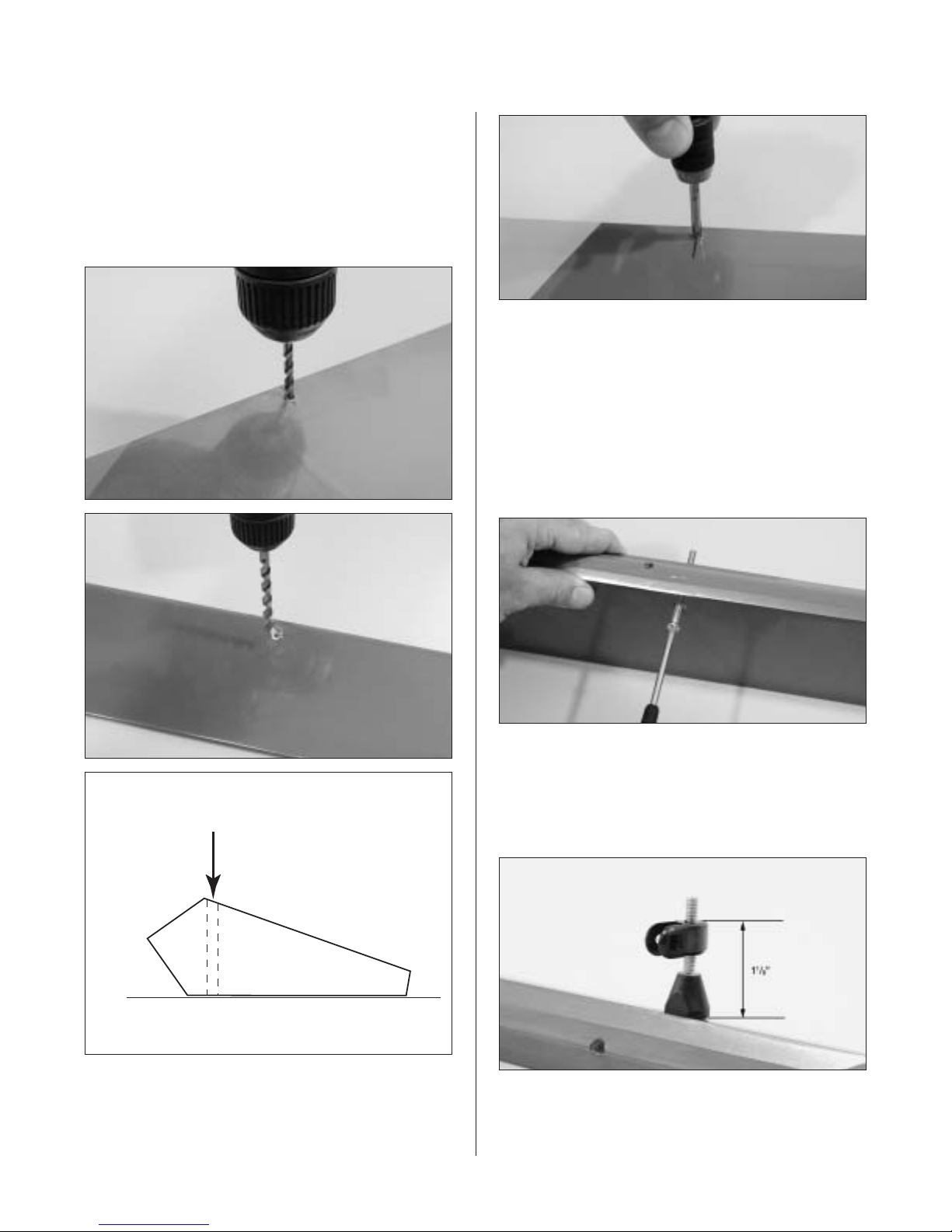

Step 4

Remove the ailerons from the wing. Use rubbing

alcohol to remove any tape residue.

Step 5

Using a 5/32" drill bit and drill press, carefully drill

through the aileron at the marked position. Be

especially careful when penetrating through the top

surface of the aileron, as it’s easy to split out the

wood and rip the covering. Placing a wooden block

under the aileron and drilling slowly will prevent

these problems. If you choose to use the counter

sink screws included in the Hangar 9® Hardware

Package, counter sink the top of the aileron to allow

the screws to fit flush.

Page 9

Section 2 – Aileron Control Horn Installation

9

Note: A hardwood block (hard point) is

located below the sheeting; you will be drilling

through this. Make sure to drill the hole

perpendicular to the top of the aileron.

It is highly recommended to use a drill press

to achieve this.

Step 6

Using an 8-32 tap, tap the hole just drilled

in the aileron.

Step 7

Mix a small amount of 30-minute epoxy and lightly

coat the inside of the tapped hole and the 8-32 x 2"

Hangar 9 control horn screw. From the top of the

aileron, screw the 8-32 x 2" into the tapped hole and

securely tighten. Wipe away any excess epoxy with

rubbing alcohol and a paper towel. Screw the A-nut

in place as shown. Allow the epoxy to fully cure.

Step 8

Screw the molded swivel link onto the 8-32 screw

until the distance from the aileron surface to the

top of the link is 1

1

/8".

Step 9

Repeat Steps 1 through 8 for the remaining aileron.

Photo for Step 6

Photo for Step 5

Photo for Step 5

Drill

Work Surface

Page 10

10

Section 3 – Hinging and Sealing the

Control Surfaces

Required Parts

• Wing panel (right and left)

• Aileron (left and right)

Required Tools and Adhesives

• 30-minute epoxy • Syringe

• Sandpaper (coarse) • Toothpicks

• Robart hingepoints

Properly hinging the control surfaces on giant-scale

models is vitally important! Poorly installed hinges

affect the model’s precision and control response and

can also be dangerous. Each and every hinge needs

to be securely bonded in place in both the flying

surface and the control surface. The hinge pivot

points need to be exactly parallel to each other and

precisely located on the center of the hinge line. We

regularly use Robart Super Hinge Points in all giantscale aircraft. They are easy to install, very strong,

and offer smooth friction-free control. The

Hangar 9

®

Extra 330S control surfaces are predrilled

to use Robart’s Super Hinge Points.

Step 1

Sand each end of the hinge point hinge using

coarse sandpaper. This will improve the bond of

the epoxy to the hinge.

Step 2

Mix 1 ounce of 30-minute epoxy. Using a glue

syringe or toothpick, place a sufficient amount of

30-minute epoxy into one of the hinge pockets in the

aileron leading edge. Install one of the hinge points

until the hinge pin center is flush with the leading

edge of the aileron. Some epoxy should ooze out of

the pocket as the hinge is installed. If not, remove the

hinge and apply more epoxy. After gluing a few

hinges, you’ll get the hang of just how much epoxy is

needed. Wipe away any excess epoxy with rubbing

alcohol. Recheck that the center of the hinge pin is

flush and parallel with the leading edge. Continue

installing hinges in the leading edge of the aileron.

The control surfaces (ailerons) will be installed after

the epoxy is fully cured.

Note: Be sure that the hinge pivot pins are

parallel and flush to the aileron leading edge.

It’s important to frequently mix a fresh batch

of 30-minute epoxy in order to achieve good

glue joint penetration. If you notice the epoxy

becoming thicker, then mix a new batch!

Page 11

Section 3 – Hinging and Sealing the Control Surfaces

11

Step 3

Allow the epoxy to fully cure for at least 6 hours.

When cured, work each hinge throughout its full

motion several times using your hands. This will

break free any epoxy that may have found its way into

the hinge joint. Move the hinge throughout its full

travel until no resistance is felt. This may take as

many as 40 or 50 times.

Step 4

Mix 1 ounce of 30-minute epoxy. Using a syringe or

toothpick, place a sufficient amount of epoxy in each

of the hinge pockets in one wing panel.

Step 5

Carefully attach the aileron to the wing, making sure

the hinges are inserted in their respective hinge

pockets. Press the aileron and wing together such

that less than a 1/64" hinge line gap exists between

the aileron and wing. The bevels should virtually

touch. Use a paper towel and rubbing alcohol to wipe

away any visible epoxy around the hinges.

Step 6

Double-check the hinge gap and allow the epoxy

to fully cure for at least 6 hours. Now is a good

time to repeat Steps 1 through 5 for the remaining

wing panel and aileron.

Page 12

12

Section 3 – Hinging and Sealing the Control Surfaces

Step 7

When fully cured, move each control surface

throughout its travel range several times to

break away any epoxy in the hinge. Be sure to

deflect the surface fully.

Section 4 – Sealing the Hinge Gaps

Step 1

Cut a piece of Clear UltraCote (not included) for

sealing the ailerons to approximately 3" x 42". Fold

the UltraCote down the center with the adhesive side

to the outside making a sharp crease at the fold.

Required Parts

• Wing panel (right and left)

• Aileron (left and right)

Required Tools and Adhesives

• Straight edge/ruler • Felt-tipped pen

• Scissors • Hobby knife w/#11 blade

• Clear UltraCote® (HANU964)

• Covering Iron (HAN101)

It’s imperative that the aileron and elevator hinge

lines be sealed airtight to prevent flutter. Sealing the

hinge line has several advantages. A sealed hinge

line gives a greater control response for a given

control deflection. It also offers more precise,

consistent control response and makes trimming

easier. Sealing the aileron and elevator hinge line is

mandatory. Failure to do so may cause control

surface flutter, resulting in a crash.

Page 13

Section 4 – Sealing the Hinge Gaps

13

Step 2

Using a ruler, measure 1/2" from the folded crease

and mark two places with a felt-tipped pen.

Step 3

Using a sharp #11 blade and a straight edge,

carefully cut through both layers of UltraCote

®

covering at the 1/2" point marked in Step 2.

Step 4

Mark and cut the folded covering to an overall length

of 40". This piece will be inserted and ironed down

into the hinge bevel on the bottom of the aileron.

Step 5

Remove the backing from the UltraCote. Place

the folded crease side into the center of the hinge

line on the bottom of the wing. Using a straight edge

as shown, hold one side of the covering in place

while ironing down the opposite side with a sealing

iron. We recommend setting the iron temperature to

320° for this procedure.

Step 6

Fully deflect the aileron in the up position. Place the

straight edge over the hinge line covering that you

just ironed down in Step 5 with the edge of the

straight edge placed firmly at the bottom of the hinge

line as shown. Iron down this side of the covering,

making sure the aileron is fully deflected.

Page 14

14

Section 5 – Aileron Linkage Installation

Required Parts

• Aluminum servo arms (4)

• Control horn ball ends (4)

• 4

1

/2" 4-40 linkage (4)

Required Tools and Adhesives

• Phillips screwdriver (small)

• Threadlock

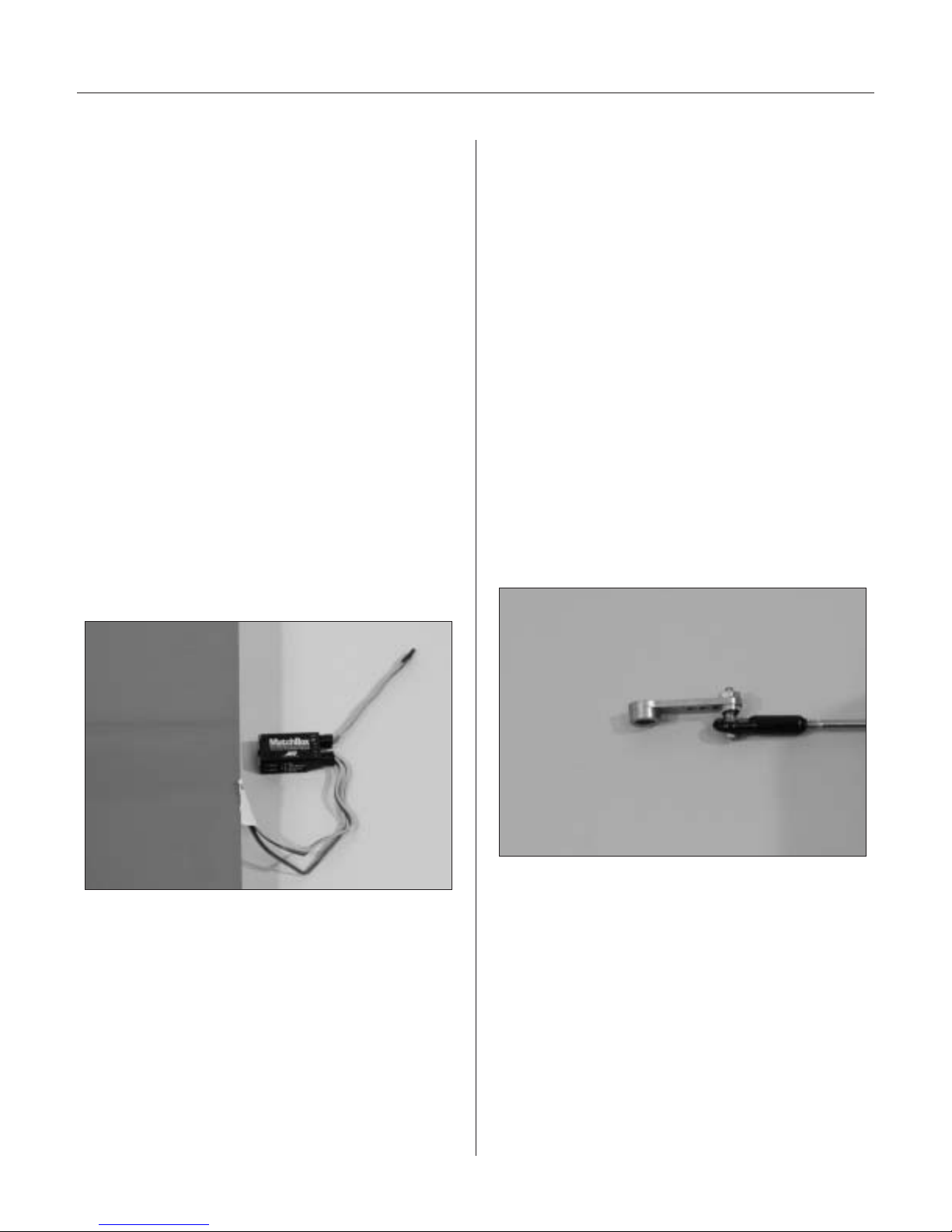

MatchBox Option: To simplify the installation of

the aileron servo linkages, you may want to use the

JR™ MatchBox™ servo matching/power system

(JRPA900). Four MatchBoxes would be used in this

application—one for each wing panel, one for the

rudder and one for the elevator servo configuration.

The MatchBox allows easy adjustment of the servo’s

center and endpoints, making radio setup a snap.

You can also use a separate battery to run the

Matchbox, reducing the load on the flight battery

powering the receiver.

Step 1

Screw a 4-40 ball link 5 to 6 turns onto each end of

a 4

1

/2" long 4-40 linkage. Adjust the linkage length

until the hole in the ball link aligns with the outer

hole in the servo arm when the aileron is neutral

and the servo arm is centered.

Note: Hangar 9®Titanium Pro-Links feature

right-hand threads on one end and left- hand

threads on the other, allowing for easy,

accurate adjustment without disconnecting

the linkages. Consistently putting the righthand threads toward the servo arms on all

servos will prevent you from getting confused

as to which way to turn the linkage to lengthen

or shorten the link. Hangar 9 also offers a

Pro-Link™ Wrench (HAN3558) to make

adjustments easier.

Step 2

Using the 4-40 screws (don’t substitute a standard

screw) and nuts included in the Hangar 9 package,

attach the ball link to the outer hole in the arm from

the bottom side as shown. The sequence is screw,

tapered standoff, ball link, servo arm and nut. Don’t

forget to use threadlock.

Step 3

Attach the servo horn to the servo using the screw

provided with the servo.

Page 15

Section 5 – Aileron Linkage Installation

15

Step 4

Attach the linkage to the servo horn on the aileron.

Adjust the link so the aileron is centered at the same

time as the servo.

Step 5

Repeat Steps 1 through 4 for the second servo.

Step 6

Repeat Steps 1 through 5 for the remaining servos in

the opposite wing panel.

Photo for Step 4

Page 16

16

Section 6 – Wing Tube Installation

Required Parts

• Wing panels • Fuselage

• Wing tube

• 1/4-20 x 2" nylon bolts (2)

Required Tools and Adhesives

• Flat screwdriver w/short handle

• Thick CA

• Sandpaper (medium)

Step 1

Be sure the anti-rotation pins are secure in the

wing halves before installing the wings. If they are

not, remove the pin and lightly san the pins using

medium grit sandpaper. Apply a small amount of

thick CA into the tube socket and reinstall the

pin.Locate the wing tube and carefully slide it into

one wing panel. Slide the wing (with tube) into

the wing tube opening in the fuselage. Make sure

the wing panel anti-rotation pins slide into the

holes provided in the fuselage.

Note: It may be necessary to slightly enlarge

the holes in the fuselage for the anti-rotation

pins using a small round file.

Step 2

Carefully slide the remaining wing panel onto the

wing tube that projects from the fuselage. The fit

may be tight; use caution when inserting the wing

panels onto the wing tube and fuselage.

Step 3

Secure the wing panels using the 1/4-20 x 2"

nylon wing bolts.

Page 17

Section 7 – Rudder and Elevator Servo Installation

17

Required Parts

• Fuselage

Required Tools and Adhesives

• Drill • Drill bit: 1/16"

• 24" Servo Extensions (JRPA102) (4)

or

• 18" Servo Extensions (JRPA099) (4)

• Y-Harness (JRPA133) (2)

• Dental floss or string

The rudder and elevators require a minimum of 80

ounce inch of servo torque. In the prototype

Extras we used JR8101s and JR8411 servos with

excellent results. Using servos with less torque

could cause a crash.

Computer Radio

Step 1

If using a 7-channel or greater computer radio with

mixing (highly recommended) or JR™ MatchBoxes,

install four 24" servo extensions, one on each servo.

Either tie the servo leads together, using a

commercially available connector, or use unwaxed

dental floss to secure the extensions to prevent them

from coming loose during flight. Also install the

servo hardware (grommets and eyelets) at this time.

Non-Computer Radio

Step 1

If using a non-computer radio, install four 18" servo

extensions, one on each servo. Either tie the servo

leads together, using a commercially available

connector, or use unwaxed dental floss to secure the

extensions to prevent them from coming loose

during flight. Install one side only of the two Yharnesses to two of the servos, also tying knots to

prevent disconnection. The other two servos will be

hooked up to the Y-harness when installed in the

airplane. One elevator servo will need to be a

reversed-direction servo.

Step 2

Install the servos in the fuselage tail section with the

output shaft to the rear as shown in the photo. If

using a non-computer radio, be sure to install one of

the servos with the Y-harness attached in the top

opening (elevator) and the other servo with the Yharness attached in the bottom opening (rudder).

Install the other servos in the opposite side of the

fuselage, being sure to connect the servo to the other

open connector of the respective Y-harnesses.

Step 3

Using the screws included with the servos, fasten the

servos in place. You may find it helpful to drill a

1/16" pilot hole before installing the screws.

Page 18

18

Section 8 – Elevator Linkage Installation

Required Parts

• Fuselage • Short stabilizer tube

• Long stabilizer tube

• Stabilizer half (left and right)

Required Tools and Adhesives

• 4-40 tap • Drill

• #4 lock washer (2) • Clear UltraCote®

• Drill bit: #43 or 3/32" (for 4-40 tap)

• 4-40 x 1/2" socket head bolt (2)

• Aluminum servo arms (2)

• Control horn ball ends (2)

• 4

1

/2" 4-40 linkage (2)

The technique for installing the control horns in

the elevators is similar to the aileron control

horn installation.

Step 1

To properly locate the position of the control horn

on the bottom of the elevator, measure inward 1"

from the root and rearward 1/4" from the top of

the bevel. Mark this position on both elevators.

Step 2

Using a 5/32" drill bit and drill press, carefully drill

through the elevators at the above marked position.

It’s important to drill 90°to the top of the elevator.

Be especially careful when penetrating through the

bottom surface of the elevator, as it’s easy to split

out the wood and rip the covering. Placing a wooden

block under the elevator and drilling slowly will

prevent these problems. If you choose to use the

counter sink screws included, counter sink the

top of the elevator to allow the screws to fit flush.

Step 3

Using an 8-32 tap, thread the holes just drilled

in the elevators.

Step 4

Mix a small amount of 30-minute epoxy and lightly

coat the inside of the threaded holes and the

8-32 x 2" Hangar 9

®

screw. From the top of the

elevator, thread the 8-32 screws into the tapped

holes and tighten. Wipe away any excess epoxy

with rubbing alcohol and paper towels.

Step 5

Screw the molded swivel link onto the 8-32 screw

until the distance from the elevator surface to

the bottom of the link is 1

1

/16". Repeat this for

the other elevator.

Page 19

Section 8 – Elevator Linkage Installation

19

Step 6

Cut off the first section of two of the hinges. This is

done to clear the tube installed in the elevator.

Step 7

Glue the elevator hinges in place using the same

techniques used to hinge the ailerons. The shortened

hinges will be installed into the stabilizer towards the

root. After hinging the elevator, use the same

technique to seal the elevator’s hinge gaps. Use Clear

UltraCote® for the bottom of the elevator.

Step 8

Insert the longer tube into the aft hole in the fuselage.

Measure the distance of the exposed tube and adjust

until both side are equal.

Step 9

Mark the tube on both side of the fuselage using a

felt-tipped pen.

Page 20

20

Section 8 – Elevator Linkage Installation

Step 10

Remove the tube and install it into one stabilizer halfway up to the first line on the tube. Drill through the

hole into the stabilizer and tap for a 4-40 bolt. Install

the bolt to secure the tube in the stabilizer.

Step 11

Install the shorter tube into the stabilizer half with

the secured tube. Slide the assembly into the

fuselage. Slide the remaining stab half onto the tubes

and drill and tap the location for the 4-40 retaining

bolt. Install the bolt to complete the procedure.

Step 12

Remove the stock servo arms from the elevator

servos and replace them with heavy-duty 1" arms.

The arms need to face down as shown. Be sure to

use a drop of threadlock on the servo arm screw if

using metal-geared servos.

Page 21

Section 8 – Elevator Linkage Installation

21

Step 13

Screw a 4-40 ball link 5 to 6 turns onto a 4

1

/2" long

4-40 linkage. Screw the opposite end of the linkage

into the swivel control horn on the elevator. Adjust

the linkage length until the hole in the ball link lines

up with the outer hole in the servo arm when the

elevator is neutral and the servo arm is centered.

Step 14

Using the 4-40 screws and nuts included in the

Hangar 9

®

package, attach the ball link to the outer

hole in the arm. The correct sequence is 4-40 screw,

ball link, standoff, servo arm and 4-40 nut. Be sure

to use threadlock.

Section 9 – Rudder Linkage Installation

Required Parts

• Rudder • Fuselage assembly

Required Tools and Adhesives

• 8-32 tap • Drill Bit: 5/32"

• Drill • Tap handle

• Thick CA • Rotary tool

• Cut-off wheel • Ruler

• 4-40 linkage

Note: The elevators have been removed for

clarity.

Step 1

Mark the position for the rudder control horn with

a pen. The correct location is 1" up from the bottom

of the rudder and 1/4" rearward from the edge of

the rudder bevel.

Page 22

22

Section 9 – Rudder Linkage Installation

Step 2

Using a 5/32" drill bit and drill press, carefully drill

a 5/32" hole through the rudder perpendicular (90°)

to the rudder centerline at the marked position. Be

especially careful when penetrating through the

backside of the rudder.

Step 3

Using an 8-32 tap, thread the hole that you just

drilled in the rudder.

Step 4

Use a rotary tool and cut-off wheel to remove the

head of the 4" bolt.

Step 5

Measure and mark the center of the bolt.

Step 6

Measure the width of the rudder. Divide the

measurement by 2 and make marks on either side

of the center mark the distance calculated.

Step 7

Apply a few drops of thick CA on the bolt at the

center. This will secure the bolt and prevent it

from loosening during flight. Install the bolt using

the lines drawn in the previous step to center the

bolt in the rudder.

Step 8

Thread an A-nut (included with swivel clevis) onto

each side of the threaded rod and securely tighten

against the rudder.

Page 23

Section 9 – Rudder Linkage Installation

23

Step 9

Screw a molded swivel link onto each side of the

8-32 threaded rod so the top of the link is 1

1

/4" from

the surface of the rudder.

Step 10

Hinge the rudder using the same technique as with

the aileron and elevator.

Step 11

Remove the stock servo arms and replace them with

heavy-duty 1

1

/4" arms. The arms need to be

positioned as shown.

Step 12

Screw a 4-40 ball link 5 to 6 turns onto a 5" long

4-40 linkage. Screw the opposite end of the linkage

into the swivel control horn that was installed in

Section 6. Adjust the length until the hole in the ball

link lines up with the outer hole in the servo arm

when the rudder is at neutral and the arm is centered.

Step 13

Using the 4-40 screws and nuts included in the

Hangar 9® package, attach the ball link to the outer

hole in the arm. The correct sequence is 4-40 screw,

ball link, standoff, servo arm and 4-40 nut. Be sure

to use threadlock.

Step 14

Repeat Step 9 through Step 13 for the other

rudder servo.

Page 24

24

Section 10 – Landing Gear Installation

Required Parts

• Fuselage • Landing gear fairing

• 10-32 x 1" socket head bolt (4)

• 10-32 nylon lock nut (4)

• #10 lock washer (4)

• 1/4-20 x 2” nylon bolt

Required Tools and Adhesives

• Hobby knife • 5/32" hex wrench

• Adjustable wrench (small)

Step 1

Install the axles in the landing gear. Secure the

axles using an adjustable wrench and the nuts

provided with the axles.

Step 2

Install the landing gear using four 10-32 x 1" socket

head bolts, four #10 lock washers and four

10-32 nylon lock nuts. (The lock nuts are placed

inside the fuselage.)

Step 3

Press the landing gear fairing into position to transfer

the location of the bolt heads into the foam. Use a

hobby knife to remove the foam to provide clearance

for the heads of the bolts.

Step 4

Attach the landing gear fairing using a 1/4-20 x 2"

nylon bolt.

Page 25

Section 11 – Wheel Pant Installation

25

Required Parts

• Wheel (2) • 3/16" wheel collar (4)

• #4 washer (2) • #4 lock washer (2)

• Fuselage w/landing gear

• Wheel pant (left and right)

• 4-40 x 1/2" socket head screw (2)

Required Tools and Adhesives

• Drill • Drill bit: 1/2" and 9/64"

• Felt-tipped pen • Square

• Ruler

Step 1

Center a wheel in the opening of the wheel pant. Use

a felt-tipped pen to mark the location of the hole for

the axle on the pant. Make sure you are marking the

side that has the plywood reinforcement.

Step 2

Place the pant on a flat surface and use a square to

draw a 1

1

/2" line through the mark made in the

previous step. Mark the wheel pant 3/4” from the

surface for the location of the axle.

Step 3

Use a rotary tool or drill to make a 1/2" hole at the

location made in the last step.

Note: When using drill bits, it is best to start

small and work up to the larger size bit.

Step 4

Fit the pants over the axle on the landing gear. Align

the line made in Step 2 with the hole directly above

the axle. Use a felt-tipped pen to transfer the location

of the hole onto the pant.

Page 26

26

Section 11 – Wheel Pant Installation

Step 5

Remove the pant and use a 9/64" drill bit to drill the

location marked in the previous step.

Step 6

Install a 4-40 blind nut into the hole from the inside

of the pant. The nut will be drawn into the plywood

later in this section.

Step 7

Install the following items onto the axle: wheel pant,

3/16" wheel collar, wheel then another 3/16" wheel

collar. It will be necessary to fit the parts inside the

wheel pant and slide them onto the axle.

Note: It may be necessary to drill the hole in

the wheel to fit onto the axle.

Step 7

Secure the pant in place using a 4-40 x 1/2" socket

head screw, #4 lock washer, and #4 washer. Use

threadlock on the screw to prevent it from coming

loose in flight.

Step 8

Center the wheel in the wheel pant and tighten the

collars to prevent the wheel from moving side to

side. Use threadlock on both set screws.

Step 9

Repeat Steps 1 through 8 for the remaining

wheel pant.

Page 27

Section 12 – Tail Wheel Installation

27

Required Parts

• Fuselage • Tail wheel assembly

Required Tools and Adhesives

• Drill • Drill bit: 3/32"

• #6 x 3/4" screw (2) (not included)

• Felt-tipped pen

Step 1

Assemble the tail wheel per the instructions included

with the tail wheel assembly. The nylon control horns

included with the tail wheel assembly are not used.

Step 2

Position the tail wheel in place as shown, centered

on the rear of the fuselage. Using a felt-tipped pen,

mark the positions for the mounting screws through

the tail wheel bracket.

Step 3

Remove the bracket and drill 3/32" pilot holes at the

previously marked positions.

Step 4

Use two #6 x 3/4" sheet metal screws to secure the

tail wheel bracket in place. A hardwood plate is

positioned in the rear of the fuselage, allowing these

screws to be firmly tightened.

Hint: Remove the #6 x 3/4" screws and wick

thin CA into the holes to strengthen the

threads. When dry, reinstall the screws.

Step 5

Using the provided spring, hook up the tiller arm

to the rudder per the instructions included with

the tail wheel.

Page 28

28

Section 13 – Receiver, Battery and Fuel Tank

Installation

Required Parts

• Fuselage

Required Tools and Adhesives

• 1/8" light plywood • Velcro straps

• 6-minute epoxy

Step 1

Remove the hatch to allow access to the interior of

the fuselage. Use the included templates on the back

cover of the manual to cut out the receiver and

battery trays from 1/8" light plywood (not included).

Step 2

Using 6-minute epoxy, fasten the receiver mount in

place as shown.

Step 3

Use foam and rubber bands (or Velcro® straps) to

secure the receiver to the battery tray.

Note: We have also mounted MatchBoxes

for the rudder and elevator servos next

to the receiver.

Step 4

If using the Zenoah® GT80, it will be necessary to

mount the battery pack slightly near the wing’s

trailing edge to properly balance the model. The

lighter weight Zenoah G62 requires that the battery

be mounted in the nose.

Step 5

Wrap the receiver battery in foam and use rubber

bands or Velcro straps to secure the battery to the

battery tray. Use 6-minute epoxy to attach the battery

tray in the fuselage in the correct location for your

engine selection.

Page 29

Section 13 – Receiver, Battery and Fuel Tank Installation

29

Step 6

Assemble the tank per the instructions included with

the tank. Be sure to use the gas-compatible stopper

and fuel tubing.

Step 7

Place foam on the floor of the tank compartment.

Secure the tank in place by wrapping rubber bands

or Velcro straps around the tank and tank floor. Cup

hooks can be used to hook the rubber bands to the

tank floor. Later we will run the fuel lines.

Step 8

Mount the receiver switch in a convenient location in

the side of the fuselage.

Page 30

30

Section 14 – Mounting the Engine and Cowl

Required Parts

• Fuselage assembly • Engine

• 1/4" lock washer (4) • 4-40 Ball Links

• Fuel Filler (HAN115) • 1/8" plywood

• Kill Switch (ZEN20000)

• 4-40 x 12" threaded rod (2)

• Engine mounting adapter plate (G62 only)

• 1/4-20 x 1

1

/2" socket head cap screw (4) (G62)

• Cup engine Mount (B&B6202) (G62)

• 1/4-20 x 1/2" socket head cap screw (4) (GT80)

• 2' Gas-Compatible Fuel Tubing (DUB800)

• 18" Servo Extension (JRPA099)

• 6" 4-40 Threaded Rod (DUB802)

Required Tools and Adhesives

• Rotary tool • Cut-off wheel

• Drum sander • Drill

• Drill bit: 1/16" • Hobby knife w/#11 blade

• Phillips screwdriver

The Hangar 9

®

Extra 330S accepts gas engines

ranging from 60 through 80cc. The prototype Extras

were flown using Zenoah®G62s and Zenoah GT80s.

The G62 offers good sport performance and is a

good choice for doing all IMAC basic and sportsman

maneuvers. While the G62-equipped Extra doesn’t

quite provide unlimited vertical performance, most

experienced sport flyers find that the G62 offers

plenty of power for all but the most aggressive

types of aerobatics.

If you’re a 3D fanatic or an Advanced or Unlimited

IMAC class competitor, Zenoah’s GT80 offers power

for vertical multiple snaps, hovers and torque rolls.

GT80 Installation

Step 1

Fit the engine to the firewall using four

1/4-20 x 1/2” socket head screws, split washers

and blind nuts provided.

Step 2

The GT80 throttle servo is positioned as shown in

the top of the engine box. Cut the opening for the

throttle servo in the top of the engine box. The servo

is located 2

5

/8" from the left side and centered in the

top of the engine box. Mount the servo using the

hardware supplied with the servo.

Page 31

Section 14 – Mounting the Engine and Cowl

31

Step 3

Make up the throttle linkage using a 4-40 rod and

two ball links. Carefully tap the throttle arm of the

carburetor with a 4-40 tap and connect the ball link

to the throttle arm. Use the remaining ball end to

attach the linkage to the servo arm.

Step 4

Attach a 4-40 rod with a ball link to the choke lever.

Route the linkage to the bottom of the fuselage

where it can be easily accessed during the starting

of the engine.

G62 Installation

Step 1

Remove the metal engine mount (if attached) from

the G62. Attach the B+B Cup engine mount. Attach

the cup mount to the adapter plate using the

hardware supplied with the cup mount.

Step 2

Install the adapter plate and engine to the firewall

using 1/4-20 x 1

1

/2" socket head screws (not

included), split washers and blind nuts.

Page 32

32

Section 14 – Mounting the Engine and Cowl

Step 3

Mount the throttle servo on the bottom of the engine

box 3/4" back from the front edge of the box. Use the

hardware supplied with the servo to attach the servo

to the engine box.

Step 4

Use a 4-40 threaded rod and two clevises to make a

throttle pushrod of the appropriate length. Make any

necessary bends in the linkage to prevent binding

during operation.

Step 5

Attach a 4-40 rod with a ball link to the choke lever.

Route the linkage to the bottom of the fuselage

where it can be easily accessed during the starting

of the engine.

Completing the Engine Installation

Step 1

Run the fuel lines from the pick up in the tank to

the carburetor and run the vent line out the bottom of

the firewall. We recommend using a fuel filter and a

kill switch mounted on the fuselage for convenient

fueling and safety.

Step 2

Use a rotary tool with a cut-off wheel and drum

sander to cut out a large air outlet at the aft edge of

the cowling. Also make any necessary cutouts for

items such as mufflers, carburetors, linkages, etc.

Step 3

Mount the cowl using five 4-40 x 3/4" socket head

screws and #4 washers. Use a small piece of fuel

tubing between the cowl and washer to prevent the

screws from vibrating loose during flight. Mount the

propeller and spinner to complete the procedure.

Page 33

Section 15 – Hatch Assembly

33

Required Parts

• Hatch • Canopy

• 4-40 x 1/2" screw (4) • #4 washer (4)

• Decals • 1/3-scale pilot

Required Tools and Adhesives

• Hex wrench: 3/32" • Formula 560-canopy glue

• Shoo Goo • Masking tape

Step 1

The Extra hatch comes pre-installed on the

fuselage and is held on with four 4-40 socket head

cap screws. Remove these and lift the hatch from

the fuselage.

Step 2

Cut out the instrument panel decal from the decal

sheet. Attach it to the hatch as shown.

Step 3

Install a 1/3-scale pilot figure to the hatch using

Shoo Goo or similar adhesive that will remain

flexible. Let the glue dry before securing the

canopy in place.

Step 4

Position the canopy onto the canopy hatch. Trace

around the canopy and onto the hatch using a

felt-tipped pen.

Page 34

34

Step 5

Lightly sand the inside edge of the canopy and

slightly inside the line drawn on the hatch using

medium sandpaper.

Step 6

Apply a bead of RCZ56 Canopy Glue (ZINJ5007)

around the inside edge of the canopy. Position the

canopy onto the hatch. Use tape to hold the canopy

secure until the glue fully cures.

Step 7

Apply the decals using the photos on the box

as a guide.

Section 16 – Balancing the Model

Correctly balancing an aerobatic model is critical to

its performance and flight characteristics. Checking

the balance on giant-scale models is best done with

two people.

Step 1

On the top of the wing tips, measure back 4

1

/2" and

53/4" from the leading edge and mark both places

with a felt-tipped pen. This is the recommended

center of gravity (CG) range.

Step 2

Fully assemble the model. With a helper, lift the

airplane with your index fingers to find the balance

point. The balance point (CG) should lie between

the two marks on the wing tip. If not, add the

necessary weight to the nose or tail to obtain

the correct balance.

Page 35

Section 17 – Radio Setup

35

A 7-channel or greater computer radio is highly

recommended. This allows the following features:

• Mixing the right aileron to the left aileron

(flaperon mix)

• Electronically adjustable aileron differential

• Mixing the right elevator to the left elevator (dual

elevator mixing)

• Independent travel and trim adjustments of each

elevator half

• Mixing the right rudder servo to the left rudder

servo

• Rudder-to-elevator mixing to correct rudder-to-

elevator coupling

• Rudder-to-aileron mixing to correct rudder-to-

aileron coupling

When using a 7-channel or greater computer radio,

each servo is plugged into its own separate channel.

Consult your radio manual for specific details on

hookup and programming.

If using a 6-channel radio with flaperon mix, the

aileron servos are each plugged into their own

channels. The right aileron plugs into the aileron

socket in the receiver, while the left aileron plugs into

channel 6. With flaperon activated in the

programming, this allows for independent travel

adjustment of each aileron in each direction and

electronic aileron differential. Consult your manual

for more programming details.

With a 6-channel computer radio, it will be necessary

to Y-harness the two rudder and elevator servos; a

reversed elevator servo is needed to achieve the

correct control direction. A servo reverser can be

used here. Special attention must be taken with

the rudder servos so that they don’t fight each

other throughout the rudder travel. This is caused

by nonsymmetrical pushrod geometry from right to

left. It may be necessary to rotate the arm on the

servo one or two splines (most of the time toward

the rear) and readjust the linkage length in order

to prevent binding.

Using a non-computer radio will require that the

aileron, elevator and rudder be Y-harnessed. Be sure

to use a reversed servo (or a reverser) for one of the

elevator servos. Special attention must be taken with

the rudder servos so that they don’t fight each other

throughout the rudder travel. This is caused by nonsymmetrical pushrod geometry from right to left. It

may be necessary to rotate the arm on the servo one

or two splines (most of the time toward the rear) and

readjust the linkage length in order to prevent

binding. If you’ve ever thought about purchasing a

computer radio, now is a good time to do it!

Section 18 – Control Throws

Standard 3D

Aileron

1

1

/2" up (18° up) 21/2" up (37° up)

11/8" down (17° down) 21/4" down (35° down)

Elevator

1

3

/8" up (16° up) 4" up (42° up)

1

1

/2" down (15° down) 41/4" down (44° down)

Standard 3D

Rudder

4

1

/2" right (26°) 8" right (44°)

41/2" left (26°) 8" left (44°)

Page 36

36

Preflight at the Field

Range Test Your Radio

Step 1

Before each flying session, be sure to range check

your radio. This is accomplished by turning on your

transmitter with the antenna collapsed. Turn on the

receiver in your airplane. With your airplane on the

ground and the engine running, you should be able

to walk 30 paces (approximately 100 feet) away from

your airplane and still have complete control of all

functions. If not, don’t attempt to fly! Have your radio

equipment checked out by the manufacturer.

Step 2

Double-check that all controls (aileron, elevator,

rudder and throttle) move in the correct direction.

Step 3

Be sure that your batteries are fully charged, per the

instructions included with your radio.

Setup and Flying by Mike McConville

Our new Extra 330S will blow away almost any pilot

wanting to fly aerobatics. When designing this

model, I incorporated design features and

enhancements that have been learned from several

years of Tournament of Champions and IMAC

competition.

Does this mean the Extra is only for the serious

competitor? Absolutely not! What this does mean is

that the Extra is fine-tuned and tweaked to excel in

both precision aerobatics and wild freestyle type

3D, so doing any aerobatics will be easier than

it has ever been.

Preflight

Before getting to the really fun stuff—flying— I’d

like to reiterate some very important steps that were

covered in the assembly instructions. For those of

you who are veterans of large models, this is old

news. But to you newcomers to the world of large

models, this is very important info.

While many smaller models are very tolerant of

improper control linkage setups and flying

techniques, large models are not. Don’t let that scare

you away from large models; they are truly one of the

best flying experiences in RC that money can buy.

However, please pay particular attention to the

following areas:

Seal the aileron and elevator hinge gaps.

This should be considered part of finishing the

model, and is as important as installing the fuel tank

or battery pack. On large aerobatic models, this is

absolutely necessary. Failure to do this may very well

cause control surface flutter, and on a large model,

this will most likely cause a crash. Putting safety and

model preservation to the side, there are several

other reasons to do this on an aerobatic model. It will

increase the effectiveness of the control surfaces, and

the model will track more true and precise. Hinge

gaps sealed? CHECK!

Maintain the proper mechanical advantage

on all control surface linkages.

Same as unsealed hinge gaps, this is often the cause

of flutter. Please follow the control horn and servo

arm lengths recommended in this manual. Shorter

arms on the servo or longer control horns on the

elevator and ailerons are fine, but do not try to

go the other way to increase throw. It will cause

flutter on the Extra. The recommended linkage

setups are more than adequate to achieve full 3D

throws. That’s straight off of the prototypes. Linkages

are set? CHECK!

Never attempt to make full throttle dives!

Large models perform much more like full-size

aircraft than small models. If the airframe goes too

fast, such as in a high throttle dive, it may fail. The

Extra should be flown like a full-scale Extra. Throttle

management is absolutely necessary. If the nose is

down, the throttle comes back. CHECK!

Page 37

37

The Prototype Model Setup

All of the recommended settings in this manual

are a result of the flight testing on the prototype

Extras. There are no secrets. If you follow the

instructions and these tips, your Extra will be

set up just like mine.

Although a computer radio is not mandatory, it is

preferable in this model. I use Exponential on all

controls to soften the feel around neutral. This makes

it easier to fly smooth in precision maneuvers and

also makes it less likely to over-control in 3D mode. I

use the following expo values:

Elevator +38% Low Rate, +70% 3D Rate

Aileron +40% Low Rate, +55% 3D Rate

Rudder +25% Low Rate, +50% 3D Rate

Note that + expo values soften the neutral with JR™

radios. Other brand systems may require “-”

(negative) expo values to soften the neutral.

I have flown Extras equipped with both JR 8101

servos and JR 8411 digital servos. While both are

excellent choices for the Extra, I personally prefer

the feel with the digital 8411 servos; the model feels

slightly more responsive with these servos. I

use a 6V Ni-Cd battery pack equipped with a 5.7V

regulator for maximum speed and torque

from the servos.

The prototype Extras were tested on both the

Zenoah® G62 as well as the Zenoah GT80. With the

G62 for power, the performance was very good sport

power. Vertical performance was good but not

unlimited. I used a Pro-Zinger 22 x 10 prop for all

testing. Even some 3D maneuvers such as Harriers,

Blenders, and Harrier landings were possible;

anything that did not require unlimited vertical.

My personal favorite powerplant is the Zenoah GT80.

I use a Bolly 24 x 10 propeller, which the GT80 turns

at approximately 7000 rpm, and a preshaped and

balanced Bolly 24 x 10 at 7700 rpm. Both work well,

but I feel the preshaped prop has the edge in

hovering maneuvers. This combination has proven to

be totally unlimited and allows anything imaginable

from torque rolls just a few inches off the ground to

multiple vertical snaps.

I found that adequate engine cooling is very

important with the GT80 and strongly recommend

adding the cowl baffles and cutting the cowl bottom

hole to the size recommended in the instructions.

When this was done, the performance difference was

dramatic. If you aren’t getting this kind of

performance, take a look at the cowl and how well

the GT80 is being cooled.

Performance Tip: Drill eight 5/16" diameter

holes through the internal baffle plate in the

GT80 mufflers. I drilled seven through the

intake opening and one up through the

exhaust stack. Just be sure to flush out all

of the metal shavings from the mufflers.

This little 10-minute trick will add 300 rpm

to the top end.

Computer Radio Enhancements

A computer radio will allow you to do quite a bit

of fine-tuning of the feel of the Extra, which will

make aerobatics even easier. Below are the

programming enhancements I normally use

to trim out an aerobatic model.

Differential Mixing

This is a great mixing feature of many computer

radios that allows you to dial in the aileron

differential, which is how the roll axis of the model is

set. The best method for setting this is to use the

Travel Adjust (ATV) of aileron and flap channels to

set the up and down movement of each aileron

exactly the same. Set it to the maximum throw of

21/2" (37°). Then set the differential by going to the

appropriate screen in the radio and adjusting the

differential value to reduce the down movement of

each aileron to 21/4" (35°).

Page 38

38

Rudder-to-Elevator and Rudder-toAileron Mixing

This mix is used to dial out unwanted pitch and roll

caused by the rudder. The Extra has very little

coupling, but dialing it out will make knife-edge

maneuvers easier. Use a preprogrammed mix if your

radio has this feature, or if not, use a P-mix feature.

Assign rudder as the master channel and elevator as

the slave. Set the mixing values so when the rudder

is deflected all the way in either direction on high

rate, the elevator moves up 1/4" (2

1

/2°).

In another P-mix, assign rudder as the master and

aileron as the slave. Deflect the rudder to full left on

high rate and set the mix value so that the ailerons

deflect to the right 1/16" (1°). Then deflect the rudder

to full right and set the mix value so the ailerons

deflect left 1/16" (1°). You may have to tweak

your values a few percent to get it perfect. When its

right, the Extra should fly straight when on knifeedge and not roll at all or track to the top or bottom

of the fuselage.

Spoileron Mixing

This can be achieved by using either a

preprogrammed elevator-to-flap mix or a P-mix.

Assign elevator as the master channel and flap as the

slave. Set the mix values so that when full up, 3D

elevator is given, both ailerons also go up 7/16"

(16°). This mix helps stabilize the model in some 3D

maneuvers such as the Elevator and Harrier.

Throttle Curve

This is normally a preprogrammed function. It can

also be achieved in radios that do not have this

premix but do have curve type P-mixing by mixing

throttle as the master and slave channels. Then

adjust the curve to get the desired throttle servo

response. This is particularly useful to get an engine

to “act” linear throughout the entire throttle stick

movement. I also use this at times to make the

throttle response less sensitive in the rpm ranges

used for hovering the model. This makes altitude

control easier and smoother when doing torque rolls.

Rates and Expos: when and where to

use them

I always use Expo to soften the feel of the model. On

high 3D rates I use quite a bit. The goal on 3D rates

is to get the model to feel the same around neutral as

it does on low rates.

I use low rate settings for all flying except for 3D

aerobatics. For precision flying or general sport

hot-dogging, the low rate throws are perfect, even

for snap rolls. The only exception is rudder rates.

I go to 3D rate when doing stall turns and rolling

circles, since the more rudder the better for these.

When doing 3D aerobatics, I normally flip to 3D

rates just before the maneuver. As soon as the

maneuver is done, I flip back down to low rate to

avoid over-controlling the model.

Let’s Get Down To It

When flying aerobatics with a larger model, you will

find that it will do everything just like a smaller

model… only better and easier. There are just a few

exceptions to how things are done.

Throttle management is a must. You have to throttle

back to idle when the nose is pointed down.

Snap Rolls

Just like the need to be throttle-managed like a fullscale airplane, larger aerobatic airplanes need to be

snapped like a full-scale. Don’t feel bad if this seems

like a big “What are you talking about?” to you. It

took me quite a while to figure this out. Let’s back up

to how we all learned to do a snap roll. If it’s an

inside (positive) snap, we pull the sticks into the

corner, i.e. full up, full aileron, and full rudder in the

same direction as aileron. When we want to stop

snapping, we release the controls. For smaller

models, this technique not only works, but is

normally the only way to get the model to snap. In a

full-scale aerobatic plane, as well as with large

models, snaps are different, particularly on the new

breed of aerobatic birds like the Extra 330S, which

have large control surfaces.

Page 39

39

Unloading Snaps

That’s the whole trick. To start a snap roll, the same

method as with a smaller model is used. Pull full up,

full rudder and aileron in the same direction. But as

soon as the sticks reach the corners, neutralize the

elevator, while keeping the rudder and ailerons at full

deflection. When you do this correctly, the Extra will

not get “deep” into snaps. This allows it to keep

more airspeed as it exits the snap, so it stops

snapping where you what it to and flies out with

more air speed. You’ll also find that it will be a lot

easier to exit a snap heading the same direction you

were going when you entered the snap. It’ll take a

little practice to get the hang of “flying” the snaps,

but I’ll bet you’ll see a big improvement in the

quality of your flying.

Extra 330S-3D at its Best

3D maneuvers (in simplest terms) are maneuvers

performed by an airplane that are not usually done in

a normal airplane flight path. What can be done with

a 3D-capable plane is to make it fly like no other. For

example, hovering in the air nose high at a

45-degree descent, floating along in level flight,

hanging on the prop, or tumble tail-over-nose in a

rapid flipping motion. When you sprinkle these

maneuvers together with other loops, rolls, snaps

and spins, it seems like the aerobatic options are

endless.

To fly 3D, you must have a plane that’s capable.

What’s capable? Well, it starts with having outlandish

pitch control from having huge elevators. The same

applies, but not to the same extent, with rudder and

ailerons. When it comes to 3D aerobatics, our Extra

330S is second to none, and has already proven

itself in “combat” having placed first and second in

its first freestyle competition.

The Maneuvers

Let’s cover the seven 3D maneuvers where the Extra

330S really excels.

Page 40

40

The Blender

What it is: The Blender or Panic maneuver is a

vertical diving roll that virtually stops its descent as it

instantaneously enters into a flat spin.

Setup: Follow the 3D setup as described in the

manual. Be sure to use Expo. Setting the CG toward

the aft location will help, but I have had great results

even at the forward CG location. This is a wing tester

and can be extremely violent but will always generate

gasps of excitement. But done correctly, the Extra

330S can handle the challenge.

How to do it: Start from about 400–500 feet

straight and level, chop throttle, and push the nose

straight down. As soon as the model is diving

straight down at low throttle, add full left aileron. Let

the model compete two or three rolls and then

quickly transition the sticks to an inverted snap

roll position (left aileron, right rudder, down elevator)

all at the same time. As soon as the Extra enters a

spin, quickly neutralize the ailerons while holding

full right rudder and down elevator. If you do it right,

the airplane will instantly transition from a left roll

to a flat spin in the same direction, and the decent

will all but stop.

Tip: Add full throttle just after the spin goes

flat. That’ll keep fuel going to the engine, make

the rotation speed high, and help stop the

vertical descent.

Recovery: Simply release rudder and hold just a

little down elevator. The model will stop rotating and

begin to fly out. As it gains airspeed, roll back to

upright. Since you’re in 3D mode, make sure you

don’t do anything abrupt, or you’ll stall again.

Page 41

41

The Elevator

What it is: The plane drops vertically while in a

nose high attitude. Depending on the head wind

conditions, the model will drop anywhere from about

a 45-degree angle in calm conditions to vertical or

even a little backwards in more windy conditions.

Throttle is used to determine rate of descent and the

nose high attitude of the model.

Setup: Same as the Blender, only for this one, flip

the switch to turn on the spoilerons. This will help to

keep the Extra 330S from teetering back and forth.

How it’s done: At near stall airspeed up high,

slowly feed in up elevator until you have the full 3D

rate up in it. With low throttle, the Extra will fall like a

rock. To guide it around, use the rudder, not ailerons.

Just keep the wings level. Add power to change the

attitude of your Extra 330S.

Trickiest part: Aside from steering it with the

rudder, you’ll quickly see that this maneuver is a

matter of juggling the throttle and rudder to get the

plane to go where you want it to go.

Recovery: Basic recovering—add full power, flip to

normal rate elevator, and fly out.

Advanced Recovery: Take the elevator all the way

to the ground—adding some power before it touches

down to slow the descent and transition into a

Harrier and land.

OR

Add power to get the nose to rise to vertical and

transition into a torque roll. Elevator down from a

hundred feet down to 20 feet (or less) and power up

into a torque roll. Ooh!!

Worst way to mess up: Let your direction control

(rudder) get away from you after starting too low—

you could snap it right into the ground. Ouch!

Page 42

42

The Harrier

What is it: It is very slow forward flight in a very

nose high (about 45 degrees) attitude.

Setup: Same as the Elevator, and the raised ailerons

help in this maneuver even more.

How it’s done: Start by entering an Elevator

maneuver. Let the Extra drop a small amount, then

slowly add power until the vertical descent stops and

the model begins to fly forward with the nose very

high, all the while your holding full up-elevator (on

3D rate). Juggle the power to control the attitude and

forward speed of the model. In a head wind, you may

also have to juggle the elevator some to keep the

model from pitching up to a vertical attitude. Use the

rudder to steer the model around in the Harrier

attitude. Try to use the ailerons very little, as they

will cause the model to wobble side to side.

Trickiest Part: Keeping up with the model if it

begins to wobble.

Recovery: Simply add full power and reduce

elevator to transition into normal forward flight.

Advanced Recovery: After you get the hang of

flying around in the Harrier, juggle the throttle to

slowly lose altitude and do a Harrier landing. The

model will land on the rear of the rudder first, and

then add a little power so it doesn’t smack the

landing gear too hard.

Page 43

43

The Torque Roll

What it is: The Extra 330S “hovers” vertically in

place, rotating left around its roll axis.

Setup: Full 3D throws in elevator and rudder are a

must. An aft CG helps a little. Also gyros provide

the best aid to stabilize the aircraft. They won’t do

the maneuver for you but they’ll help. I found them

a fantastic tool in learning to torque roll, kind of

like training wheels. A few years ago gyros made a

big difference for me; now I don’t use them

anymore. You’ll need to use the Zenoah

®

GT80 or an

engine that will give you unlimited vertical

before you try this one.

How it’s done: Fly low along the ground at low

throttle and gently add power with up elevator to

bring the model into a vertical position. Add throttle

to keep the nose pointed up and make corrections

with rudder and elevator to keep things straight. If the

model hovers but won’t start rolling left, quickly blip

the throttle up and down. The torque change will

usually get it going.

Trickiest part: Recognizing your correction when

the model’s belly is toward you.

Tip: Think: push the rudder toward the low wing

when the belly is toward you. You have to be fast

with throttle corrections. Add bursts of power, along

with rudder/elevator corrections. If you simply hold

full throttle, you’ll climb out of the maneuver.

Recovery: Fly out at full throttle.

Worst way to mess up: Have an unreliable

engine. Torque Rolls are tough on engines because

there’s only prop-induced airflow over the cylinders.

I’d really recommend putting the baffling in the cowl

if you are running a twin-cylinder engine and plan on

doing Torque Rolls.

Page 44

44

The Parachute

What it is: The Parachute is a vertical dive that

instantly decelerates in its descent as it

instantaneously corners into an Elevator.

Setup: Same as the Elevator, and the raised ailerons

help in this maneuver too.

How to do it: Start from about 400-500 feet straight

and level, chop throttle, and push the nose straight

down. As soon as the model is diving straight down

at low throttle, add full up-elevator. If you do it right,

the Extra 330S will instantly transition from a vertical

dive to an Elevator.

Tip: Add a little throttle just after transition to an

Elevator. That’ll keep fuel going to the engine and

keep it from quitting.

Recovery: Simply add full power and reduce

elevator to transition into normal forward flight.

Advanced Recovery: Juggle the throttle to slowly

lose altitude and do a Harrier landing. The model will

land on the rear of the rudder first, and then add a

little power so it doesn’t smack the landing gear too

hard.

Worst way to mess up: To build up too much

speed. This maneuver has a huge “WOW” factor but,

just like a Blender, too much speed and it overstresses the wing. Watch the speed.

Page 45

45

The Wall

What it is: The Wall is a Parachute turned on end.

The model starts in normal level flight and suddenly

corners nose up 90 degrees, as if it hit a wall.

Setup: Same as the Elevator, and the raised ailerons

help in this maneuver too.

How to do it: Start from about 100 feet straight and

level, chop throttle, and as the model begins to slow

down, quickly pull full up-elevator. When the Extra

330S corners to vertical, add full power and release

the up-elevator.

Tip: Start a low speed and add power at the same

time that you begin to pull full up-elevator.

Recovery: Simply release the elevator, go to full

throttle, and fly out upward.

Advanced Recovery: Juggle the throttle to sustain

a hover and transition into a torque roll.

Worst way to mess up: Don’t get the throttle in

quickly enough and the model falls backward.

Great combo: This has become one of my favorites

to do with the Extra 330S. Takeoff normally, but as

soon as the Extra is airborne, chop the throttle and

do the Wall, then transition into a Torque Roll over

the runway. Practice all of this stuff up high before

you try that.

I hope you enjoy your Extra 330S as much as I do!

Happy Landings!

Mike McConville

Page 46

46

GENERAL

1) I will not fly my model aircraft in sanctioned events, air

shows or model flying demonstrations until it has been

proven to be airworthy by having been previously,

successfully flight tested.

2) I will not fly my model higher than approximately 400

feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid flying

in the proximity of full-scale aircraft. Where necessary, an

observer shall be utilized to supervise flying to avoid

having models fly in the proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules for

the flying site I use, and I will not willfully and

deliberately fly my models in a careless, reckless and/or

dangerous manner.

4) The maximum takeoff weight of a model is 55 pounds,

except models flown under Experimental Aircraft rules.

5) I will not fly my model unless it is identified with my

name and address or AMA number, on or in the model.

(This does not apply to models while being flown

indoors.)

6) I will not operate models with metal-bladed propellers

or with gaseous boosts, in which gases other than air

enter their internal combustion engine(s); nor will I

operate models with extremely hazardous fuels such as

those containing tetranitromethane or hydrazine.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind)

including, but not limited to, rockets, explosive bombs

dropped from models, smoke bombs, all explosive gases

(such as hydrogen filled balloons), ground mounted

devices launching a projectile. The only exceptions

permitted are rockets flown in accordance with the

National Model Rocketry Safety Code or those

permanently attached (as per JATO use); also those items

authorized for Air Show Team use as defined by AST

Advisory Committee (document available from AMA HQ).

In any case, models using rocket motors as a primary

means of propulsion are limited to a maximum weight of

3.3 pounds and a G series motor. (A model aircraft is

defined as an aircraft with or without engine, not able to

carry a human being.)

8) I will not consume alcoholic beverages prior to, nor

during, participation in any model operations.

9) Children under 6 years old are only allowed on the

flight line as a pilot or while under flight instruction.

RADIO CONTROL