Page 1

35% Extra 260

Assembly mAnuAl

Specifications

Wingspan ......................................105 in (2667mm)

Overall Length ............ 98 in (2489mm) with spinner

Wing Area ...........................2003 sq in (129 sq dm)

Flying Weight .......................... 27–30 lb (12–14 kg)

Engine Size ......................................100–116cc gas

Radio........................................... 4-channel or more

Servos .........................................................8 servos

(9 if using two rudder servos instead of 1)

Spinner Size .............................................. 4

Hardware Included ..............................................Yes

1

/2-inch

Page 2

Table of Contents

Using the Manual ..................................................................3

Required Tools and Adhesives ........................................................3

UltraCote Covering Colors ...........................................................3

Before Starting Assembly ............................................................3

Radio and Power Systems Requirements ................................................4

Recommended JR, JR

Recommended Engine Setup .........................................................4

FS One ..........................................................................4

Warranty Period ...................................................................5

Limited Warranty...................................................................5

Damage Limits ....................................................................5

Safety Precautions .................................................................5

Questions, Assistance, and Repairs ....................................................6

Inspection or Repairs ...............................................................6

Warranty Inspection and Repairs.......................................................6

Non-Warranty Repairs...............................................................6

SPORT and Spektrum Systems ......................................4

Safety, Precautions, and Warnings .....................................................7

Contents of Kit ....................................................................7

Aileron Servo Installation ............................................................8

Elevator Servo Installation ..........................................................12

Rudder and Rudder Servo Installation..................................................13

Landing Gear Installation ...........................................................16

Stabilizer Installation...............................................................19

Engine Installation (DA100) .........................................................21

Engine Installation (Evolution 116GX) .................................................26

Receiver Installation ...............................................................30

Pilot and Canopy Installation ........................................................32

Radio Setup .....................................................................33

Control Throws ...................................................................34

Computer Radio Enhancements ......................................................34

Recommended Center of Gravity (CG) .................................................35

Rates and Expos ..................................................................35

Preflight ........................................................................36

Range Test Your Radio .............................................................37

Instructions for Disposal of WEEE by Users in the European Union...........................37

2007 Official AMA National Model Aircraft Safety Code ................................ 38–39

2

Page 3

Using the Manual

This manual is divided into sections to help make assembly easier to understand, and to provide breaks between each

major section. In addition, check boxes have been placed next to each step to keep track of each step completed. Steps

with a single box (

repeating, such as for a right or left wing panel, two servos, etc. Remember to take your time and follow the directions.

) are performed once, while steps with two boxes ( ) indicate that the step will require

Required Tools and Adhesives

Tools

• Rotary tool (Dremel) • Hobby scissors

• Pliers • Clamp

• T-pins • Crimping tool/vice grips

• Solder • String

• Solder gun • 1/4-inch (6mm) foam

• Tape • Hobby knife

• Phillips screwdriver • Drill

• Felt-tipped pen • Nut driver: 1/4-inch

• Hex wrench: 5/64-inch, 3/32-inch, 7/64-inch, 1/8-inch • Angle Pro Incidence Meter (HAN192)

• Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm), 5/32-inch (4mm), 3/16-inch (4.5mm)

Adhesives

• Thin CA (PAAPT08) • Medium CA (PAAPT02)

• 30-Minute Epoxy (HAN8002) • Formula 560 Canopy Glue (PAAPT56)

• CA Remover/Debonder (PAAPT16) • Pacer Z-42 Threadlock (PAAPT42)

UltraCote Covering Colors

• White (HANU870) • Cub Yellow (HANU884)

• True Red (HANU866) • Pearl Purple (HANU847)

Before Starting Assembly

Before beginning the assembly of the 35% Extra 260, remove each part from its bag for inspection. Closely inspect

the fuselage, wing panels, rudder, and stabilizer for damage. If you find any damaged or missing parts, contact the

place of purchase.

If you find any wrinkles in the covering, use a heat gun or sealing iron to remove them. Use caution while working around

areas where the colors overlap to prevent separating the colors.

HAN101 – Sealing Iron

HAN100 – Heat Gun

HAN141 – Sealing Iron

Sock

HAN150 – Covering Glove

3

Page 4

Radio and Power Systems Requirements

• 7-channel computer radio system (minimum) w/receiver • Large Servo Arms (JRPA236) (8 pkgs)

• 24-Inch Servo Lead Extension (JRPA102) (5) • JR Charge Jack Switch (JRPA004) (3)

• 36-inch Servo Lead Extension (JRPA103) (3) • Choke Ring (JRPA029) (For throttle servo lead)

• JR 8611A or 8711 Metal Geared high torque servos (7) or equivalent

Caution: Only metal-geared servos of 180 oz in torque or greater should be used on the control surfaces.

• 2700mAh or larger for receiver (2) (A minimum of 3000mAh is required when using super high-torque servos)

• 1500mAh or larger for ignition (4.8 or 6.0V for DA-100, 3-cell Li-Po for Evolution

The elevator installation will require:

Two servos and mixing through the radio

Or

Two servos and a JR® MatchBox™ (JPA0900)

®

116cc))

Recommended JR, JR SPORT and Spektrum Systems

• JR 10X

• JR XP9303

• JR X9303 2.4

• JR XP7202

• Spektrum DX-7

JR XP9303

Spektrum DX7

JR 10X

Recommended Engine Setup

DA-100

• In cowl mufflers

or

• MTW 75 canisters with headers

• 27 x 10 propeller

Evolution 116

• In cowl mufflers

or

• MTW 75 canisters with headers

• 28 x 10 propeller

FS One

With FS One® you get more than photorealistic fields, gorgeous

skies and realistic-looking aircraft. You get incredibly advanced

aerodynamic modeling that simulates every possible aspect

of real-world flight.

4

HANS2000

Page 5

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties that the Products purchased (the "Product") will be free

from defects in materials and workmanship at the date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original Purchaser ("Purchaser") and is not transferable. REPAIR OR REPLACEMENT

AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This warranty covers only

those Products purchased from an authorized Horizon dealer. Third party transactions are not covered by this warranty.

Proof of purchase is required for warranty claims. Further, Horizon reserves the right to change or modify this warranty

without notice and disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NON-

INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCT. THE

PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET

THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon's sole obligation hereunder shall be that Horizon will, at its option, (i) repair or (ii)

replace, any Product determined by Horizon to be defective. In the event of a defect, these are the Purchaser's exclusive

remedies. Horizon reserves the right to inspect any and all equipment involved in a warranty claim. Repair or replacement

decisions are at the sole discretion of Horizon. This warranty does not cover cosmetic damage or damage due to acts of

God, accident, misuse, abuse, negligence, commercial use, or modification of or to any part of the Product. This warranty

does not cover damage due to improper installation, operation, maintenance, or attempted repair by anyone other than

Horizon. Return of any goods by Purchaser must be approved in writing by Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCT, WHETHER SUCH CLAIM

IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY. Further, in no event shall the liability of

Horizon exceed the individual price of the Product on which liability is asserted. As Horizon has no control over use,

setup, final assembly, modification or misuse, no liability shall be assumed nor accepted for any resulting damage or

injury. By the act of use, setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept the liability associated with the use of this Product, you are

advised to return this Product immediately in new and unused condition to the place of purchase.

Law: These Terms are governed by Illinois law (without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a toy. It must be operated with caution and common sense and requires

some basic mechanical ability. Failure to operate this Product in a safe and responsible manner could result in injury

or damage to the Product or other property. This Product is not intended for use by children without direct adult

supervision. The Product manual contains instructions for safety, operation and maintenance. It is essential to read

and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly

and avoid damage or injury.

5

Page 6

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide warranty support or repair. Once assembly, setup or

use of the Product has been started, you must contact Horizon directly. This will enable Horizon to better answer your

questions and service you in the event that you may need any assistance. For questions or assistance, please direct your

email to productsupport@horizonhobby.com, or call 877.504.0233 toll free to speak to a service technician.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call for a Return Merchandise Authorization (RMA). Pack

the Product securely using a shipping carton. Please note that original boxes may be included, but are not designed

to withstand the rigors of shipping without additional protection. Ship via a carrier that provides tracking and insurance

for lost or damaged parcels, as Horizon is not responsible for merchandise until it arrives and is accepted

at our facility. A Service Repair Request is available at www.horizonhobby.com on the “Support” tab. If you do not

have internet access, please include a letter with your complete name, street address, email address and phone number

where you can be reached during business days, your RMA number, a list of the included items, method of payment

for any non-warranty expenses and a brief summary of the problem. Your original sales receipt must also be included

for warranty consideration. Be sure your name, address, and RMA number are clearly written on the outside of the

shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original sales receipt verifying the proof-of-purchase

date. Provided warranty conditions have been met, your Product will be repaired or replaced free of charge. Repair or

replacement decisions are at the sole discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will be completed and payment will be

required without notification or estimate of the expense unless the expense exceeds 50% of the retail

purchase cost. By submitting the item for repair you are agreeing to payment of the repair without notification. Repair

estimates are available upon request. You must include this request with your repair. Non-warranty repair estimates will

be billed a minimum of ½ hour of labor. In addition you will be billed for return freight. Please advise us of your preferred

method of payment. Horizon accepts money orders and cashiers checks, as well as Visa, MasterCard, American Express,

and Discover cards. If you choose to pay by credit card, please include your credit card number and expiration date. Any

repair left unpaid or unclaimed after 90 days will be considered abandoned and will be disposed of accordingly. Please

note: non-warranty repair is only available on electronics and model engines.

Electronics and engines requiring inspection or repair should be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other Products requiring warranty inspection or repair should be shipped to the following address:

Please call 877-504-0233 with any questions or concerns regarding this product or warranty.

6

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

Page 7

Safety, Precautions, and Warnings

This model is controlled by a radio signal that is subject to interference from many sources outside your control. This

interference can cause momentary loss of control so it is advisable to always keep a safe distance in all directions around

your model, as this margin will help to avoid collisions or injury.

• Always operate your model in an open area away from cars, traffic, or people.

• Avoid operating your model in the street where injury or damage can occur.

• Never operate the model into the street or populated areas for any reason.

• Never operate your model with low transmitter batteries.

• Carefully follow the directions and warnings for this and any optional support equipment (chargers, rechargeable

battery packs, etc.) that you use.

• Keep all chemicals, small parts and anything electrical out of the reach of children.

• Moisture causes damage to electronics. Avoid water exposure to all equipment not specifically designed and protected

for this purpose.

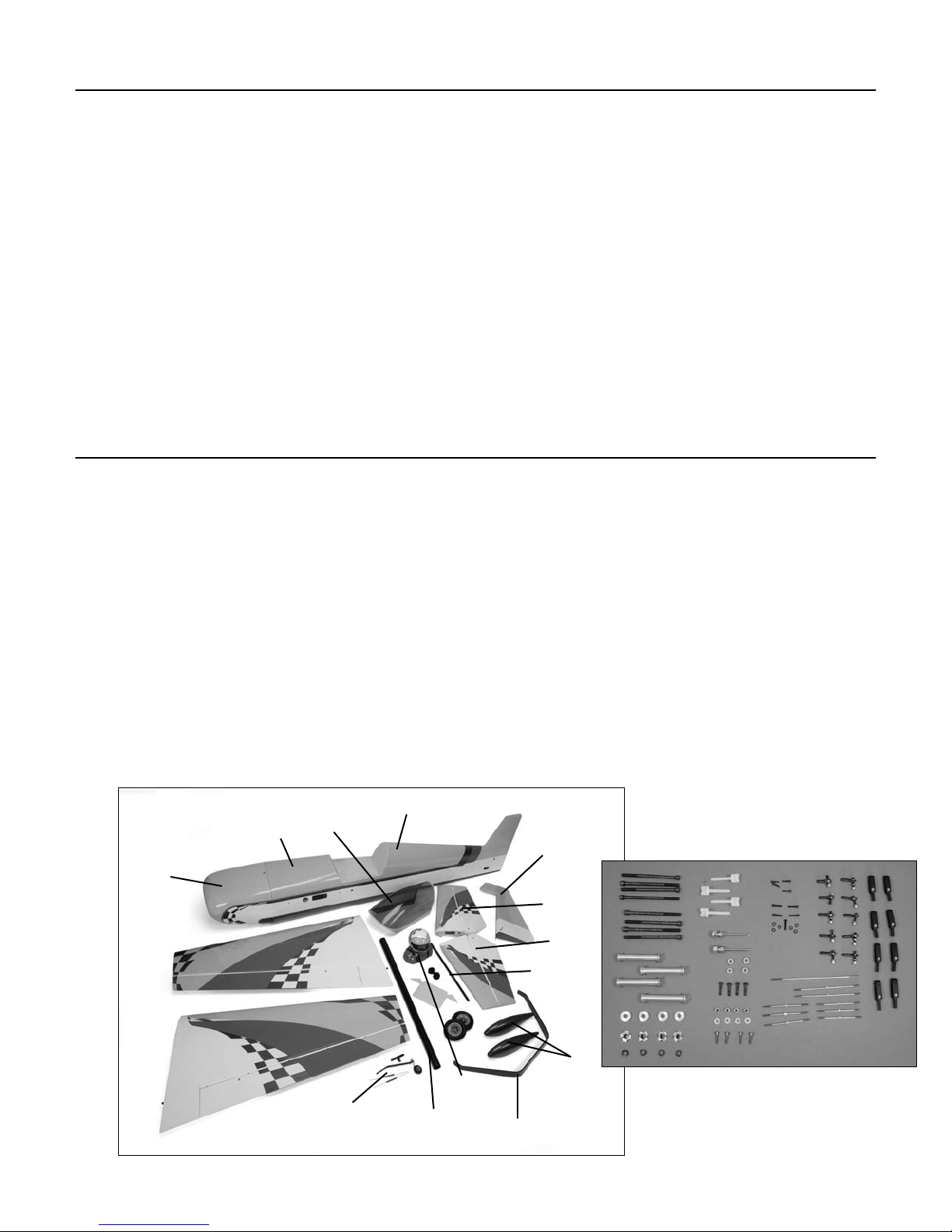

Contents of Kit

Replacement Parts

A. HAN1001 Fuselage w/Hatch

B. HAN1002 Right Wing Panel w/Aileron

C. HAN1003 Left Wing Panel w/Aileron

D. HAN1004 Right Stabilizer w/Elevator

E. HAN1005 Left Stabilizer w/Elevator

F. HAN1006 Anodized Wing Tube

G. HAN1007 Anodized Stabilizer Tube

H. HAN1008 Rudder

I. HAN1009 Canopy

J. HAN1010 Canopy Hatch

K. HAN1011 Fiberglass Painted Cowl

L. HAN1012 Landing Gear

M. HAN1014 Painted Wheel Pants

N. HAN331 Tailwheel Assembly

O. HAN1015 Hardware Kit

P. HAN360 Painted Pilot Helmet

Not Shown

HAN1013 Decal Set

J

K

B

I

A

H

D

E

C

G

O

M

P

N

F

L

7

Page 8

Aileron Servo Installation

Required Parts

• Wing panel (left and right)

• Ball end w/hardware (4) • Control horn (4)

• 3-inch (76mm) linkage (4)

Required Tools and Adhesives

®

• JR

MatchBox™ (2) • Phillips screwdriver

• Ruler • Nut driver: 1/4-inch

• Hex wrench: 3/32-inch • String w/weight

• Servo extension, 24-inch (610mm) (2)

1

• 1

/2-inch Single Side Alum Adj.

Spline Servo Arm (4)

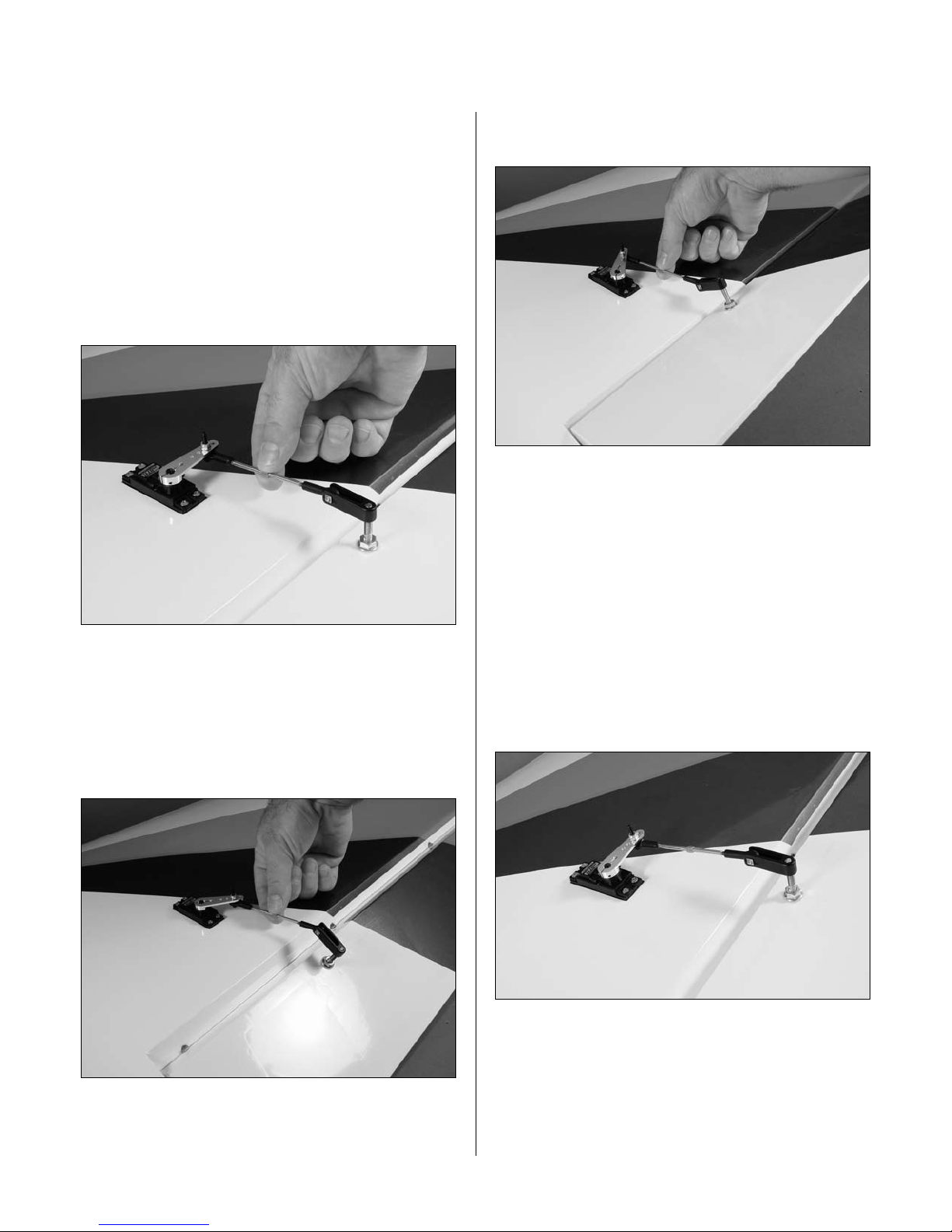

Step 1

Secure a 24-inch (610mm) servo extension to the

outboard aileron servo.

Step 3

Tip the wing so the root is facing down and lower the

weight through the wing.

Step 4

Tie the string to the servo extension.

Step 2

Tie a weight to a piece of string. Lower the weight into the

opening for the outboard aileron servo.

8

Page 9

Step 5

Step 7

Use the string to pull the extension through the wing. Tape

the extension so it will not fall back into the wing.

Step 6

Secure the servo using the hardware provided with the

servo. The output of the servo faces the trailing edge.

Thread the control horn onto the control horn screw so the

bottom of the horn is 1 inch (25mm) from the surface of

the aileron.

Step 8

Install the inboard aileron servo and the control horn.

Thread the control horn so it is 13/16-inch (21mm) from

the aileron surface as shown.

Step 9

Plug both aileron servos into the receiver. Center the

aileron trim and stick to center the aileron servos. Also

make sure any sub-trims have been set to zero in the radio

memory. Check the operation of the servos at this time.

9

Page 10

Step 10

Step 12

Attach the ball end to the bottom side of the servo

arm using the ball end hardware. The hole used will be

1

1

/4-inch (32mm) from the center of the servo arm.

Step 11

With the servo at the neutral position and radio on, attach

the servo arm to the servo. Place it on the spline that sets

the arm closest to parallel with the hinge line. (This will

be fine tuned later.) Turn off the receiver and manually turn

the arm so it is parallel with the hinge line.

Assemble and install the 3-inch (76mm) linkage for the

outboard aileron servo ONLY at this time. Adjust the

linkage to center the aileron and attach the linkage to the

horn with the setscrew. Remember to keep the servo arm

parallel to the hinge line while adjusting the linkage.

Step 13

Plug the aileron servos into a JR MatchBox

servo plugs into Port 1 and the inboard servo plugs into

Port 2. The MatchBox is used to link the two servos to

operate properly. Plug the MatchBox into the aileron

channel of your receiver.

.

The outboard

10

Step 14

With only the outboard aileron linkage attached to the

control horn, turn on the radio and adjust the sub-trim in

the transmitter until the aileron is at the neutral position.

Deflect the stick to full right aileron and adjust the travel

adjust so the deflection is 34.4 degrees. Repeat this for

full left deflection and adjust for 33 degrees.

Page 11

Step 15

Step 18

Turn the dial on the MatchBox to position 2.

Step 16

Use the MatchBox to adjust the center position of the

inboard servo, aligning the servo arm parallel to the hinge

line. Assemble and install the 3-inch (76mm) linkage

for the outboard aileron servo, but do not attach it to the

control horn at this time. Confirm that the hole in the ball

end is perfectly aligned with the hole in the control horn.

Repeat for full left aileron.

Step 19

BEFORE turning off the power to the receiver, turn the dial

on the MatchBox back to the 0 position to save the data.

Step 20

Step 17

Deflect the aileron stick to full right and check the

alignment of the hole in the ball end with the hole in the

control horn. If they are misaligned (likely), adjust the

travel of the servo with the MatchBox while holding full

right stick, until the holes align perfectly.

Recheck to be sure the neutral and full deflection in

each direction are correct and the holes are aligned in

all 3 positions BEFORE securing the ball end to the

control horn.

Step 21

Install the screw to secure the ball end to the control horn.

Step 22

Repeat steps 1 through 21 for the remaining wing panel,

only plug the matchbox into the auxiliary channel that is

being mixed to the aileron channel for this wing panel.

11

Page 12

Elevator Servo Installation

Required Parts

• Ball end w/hardware (2) • Control horn (2)

• Stabilizer/elevator (left and right)

• 3-inch (76mm) linkage (2)

Required Tools and Adhesives

• Hex wrench: 3/32-inch

• Nut driver: 1/4-inch

1

• 1

/2-inch Single Side Alum Adj. Spline Servo Arm

(2)

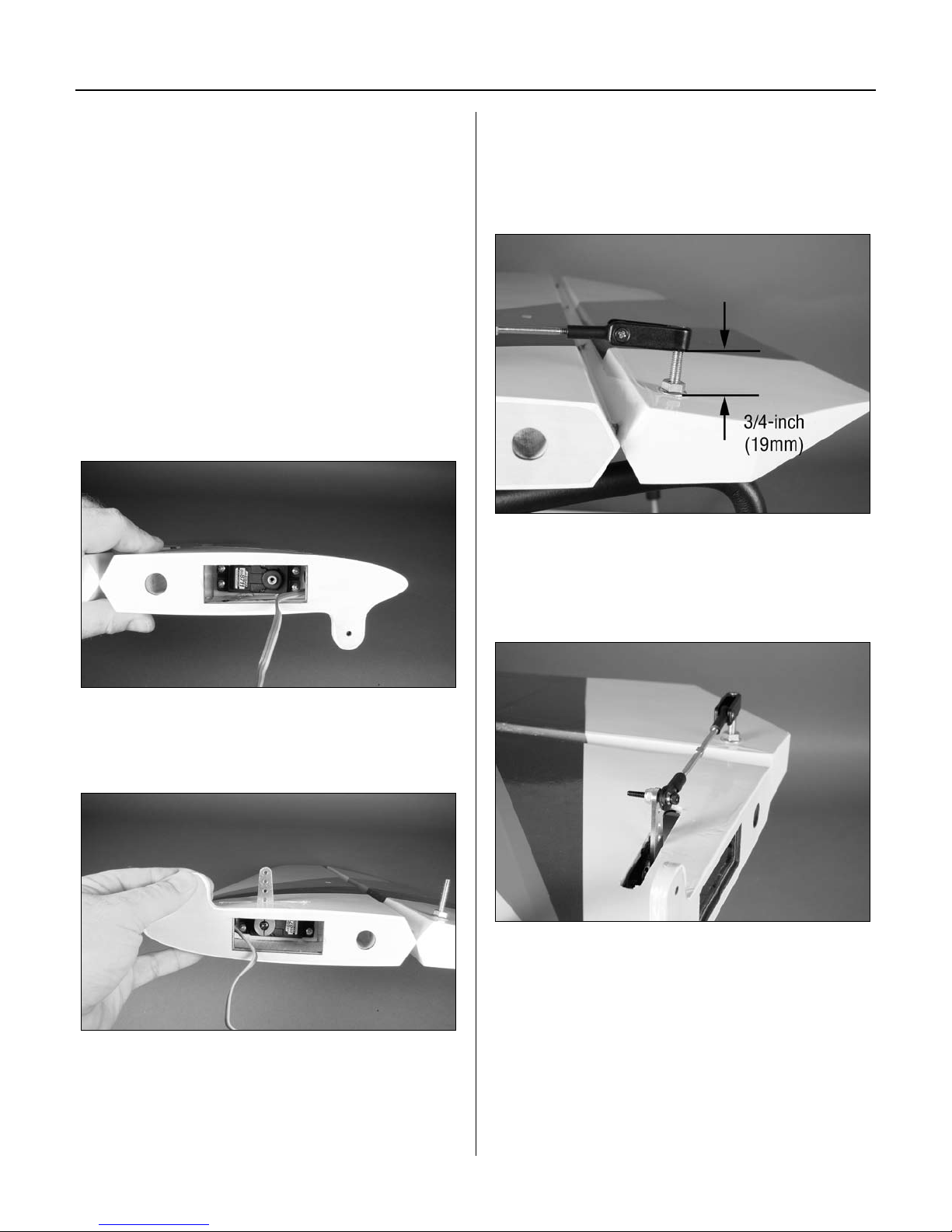

Step 1

Install the elevator servo into the stabilizer. Make sure to

pull the servo lead through the opening toward the leading

edge before placing the servo.

Step 3

Assemble the linkage for the elevator using a ball end,

control horn and a 3-inch (76mm) linkage. Thread the

horn onto the screw so the bottom of the horn is 3/4-inch

(19mm) from the surface of the elevator.

Step 4

Step 2

Install the servo arm onto the elevator servo. Use the radio

system to center the servo beforehand.

Attach the ball end to the servo horn using the hardware

provided with the ball end. The attachment point will be

1

1

/2-inch (38mm) from the center of the servo horn.

Step 5

Repeat Steps 1 through 4 for the remaining elevator servo

and linkage.

12

Page 13

Rudder and Rudder Servo Installation

Required Parts

• Ball end w/hardware (2) • Control horn (2)

• Rudder • Fuselage

• Removable hinge pin • Tiller arm

• Tail gear assembly • Steering spring (2)

• #6 x 5/8-inch socket head sheet metal screws (4)

1

• 4

/2-inch (114mm) linkage

Required Tools and Adhesives

• Thin CA • Drill

• Drill bit: 3/32-inch (2.5mm)

• Hex wrench: 3/32-inch

• Nut driver: 1/4-inch

1

• 1

/2-inch Single Side Alum Adj. Spline Servo Arm

Note: When using a servo with less than

300 oz/in of torque, it is highly recommended

to use two rudder servos and link them

together using a JR MatchBox. An additional

servo location on the opposite side of the

fuselage will require the removal of the

covering to install your second servo.

Step 2

Assemble the rudder linkage using a 4

linkage, ball end and control horn. The control horn is

then threaded on the control horn screw so the bottom of

the horn is 5/8-inch (16mm) from the control surface.

1

/2-inch (114mm)

Step 3

Attach the rudder to the fin/fuselage using the hinge pin

located in the hinges.

Step 1

Secure a 24-inch (610mm) servo extension to the rudder

servo. Mount the servo in the fuselage as shown.

Hint: Use a drill to aid in installing

the hinge wire. This will help guide the

wire through each of the hinges.

13

Page 14

Step 4

Step 6

Attach the ball end to the servo horn using the hardware

provided with the ball end. The attachment point will be

1

1

/2-inch (38mm) from the center of the servo horn.

Step 5

Position the tail gear assembly on the bottom of the

fuselage. Use a felt-tipped pen to mark the locations for

the two screws.

Drill each of the locations using a drill and 3/32-inch

(2.5mm) drill bit.

Step 7

Thread a #6 x 5/8-inch socket head sheet metal screw into

the holes, then remove the screw.

Note: The tail gear will keep the rudder

hinge in position. You will need to trim the

removable hinge pin so it is 1/4-inch (4mm)

above the tail gear when it has been installed.

14

Page 15

Step 8

Step 10

Apply a few drops of thin CA into each of the two holes to

harden the wood. This will help in preventing the screws

from vibrating loose.

Step 9

Follow Steps 5 through 8 to attach the tiller arm to the

bottom of the rudder with two #6 x 5/8-inch socket head

sheet metal screws.

Attach the tail gear assembly to the bottom of the fuselage

using two #6 x 5/8-inch socket head sheet metal screws.

Step 11

Complete the rudder installation by connecting the tail

wheel to the tiller arm with two steering springs.

15

Page 16

Landing Gear Installation

Required Parts

• Fuselage assembly • Main landing gear

• #8 washer (4) • 8-32 locknut (4)

• Axle w/nut (2) • #4 washer (4)

• 4-40 blind nut (4)

1

• 4

/2-inch (114mm) wheel (2)

• 4-40 x 1/2-inch socket head screw (4)

• 5/32-inch wheel collar w/setscrews (4)

Required Tools and Adhesives

• Threadlock • Drill

• Drill bit: 9/64-inch (3.5mm)

• Hex wrench: .050-inch, 3/32-inch

Step 1

Attach the landing gear to the fuselage using four

8-32 x 3/4-inch socket head screws, four #8 washers

and four 8-32 lock nuts.

Step 2

Secure the axle to the main landing gear.

Step 3

Use a file to create a flat on the axle for the setscrews in

the collars to tighten onto. This will help in preventing

them from loosening in flight.

16

Page 17

Step 3

Step 5

Attach the wheel to the axle using two 5/32-inch wheel

collars. The collars are placed on either side of the wheel.

Note: Always use threadlock on

metal-to-metal fasteners to prevent

them from vibrating loose.

Mark the location for the two screws through the landing

gear and onto the wheel pant using a felt-tipped pen.

Step 6

Drill the locations marked in the previous step using a

drill and 9/64-inch (3.5mm) drill bit.

Step 4

Place the fuselage on a level surface. Slide the wheel pant

into position. The pant must be positioned so it will not

come in contact with the surface.

17

Page 18

Step 7

Step 8

Use pliers to install the two 4-40 blind nuts in the wheel

pant as shown.

Secure the wheel pant to the landing gear using two

4-40 x 1/2-inch socket head screws and two #4 washers.

Note: Always use threadlock on

metal-to-metal fasteners to prevent

them from vibrating loose.

18

Page 19

Stabilizer Installation

Required Parts

• Fuselage assembly • Stabilizer/elevator (2)

• Stabilizer tube • #4 washer (4)

• 4-40 x 1/2-inch socket head screw(4)

Required Tools and Adhesives

• Threadlock • Hobby knife

• Hex wrench: 3/32-inch • Tap handle

• 4-40 tap • Drill

• Drill bit: 1/16-inch (1.5mm), 1/8-inch (3mm)

Step 1

Slide the stabilizer tube into one of the stabilizer halves.

Step 3

Secure a 24-inch (610mm) servo extension to the elevator

servo lead. Pass the extension into the fuselage, then slide

the tube into the fuselage.

Step 4

Use a 4-40 x 1/2-inch socket head screw and #4 washer

to secure the position of the stabilizer.

Step 2

Use a hobby knife to remove the covering from the

opening in the fuselage for the servo lead.

Note: Always use threadlock on

metal-to-metal fasteners to prevent

them from vibrating loose.

Step 5

Repeat Steps 2 through 4 for the remaining stabilizer.

19

Page 20

Step 6

Step 8

Drill a pilot hole in the stabilizer tube using a drill and

1/16-inch (1.5mm) drill bit.

Step 7

Remove the stabilizer tube and use a drill and 1/8-inch

(3mm) drill bit to drill a hole in the stabilizer tube.

Secure the position of the tube using a 4-40 x 1/2-inch

socket head screw and #4 washer. The screw will thread

into a blind nut that is installed inside the stabilizer.

Step 9

Repeat Steps 6 through 8 for the remaining stab

tube screw.

20

Page 21

Engine Installation (DA100)

Required Parts

• Fuselage assembly

Required Tools and Adhesives

• Threadlock

Note: For simplicity the DA will be shown

with canister installation and the Evolution

with Muffler installation. Either engine

can be used with either exhaust option.

Step 1

Collect the items shown for the installation of your

particular engine.

Step 3

Use a drill and 5/16-inch (8mm) drill bit to drill the holes

in the firewall for mounting the engine.

Step 4

Install the 1/4-20 blind nuts from the back side of the

firewall. You can use the bolts and standoffs to pull the

blind nuts into position.

Step 2

Measure mark and drill firewall to correct dimensions and

offset to the left side.

Step 5

Install engine using four 2

aluminum standoffs and four 1/4-20 x 3

head bolts and four 1/4-inch lock washers.

7

/8-inch (73mm) machined

3

/4-inch socket

21

Page 22

Step 6

Step 7

Use a hobby knife to trim the covering from the opening

on the bottom of the fuselage. Leave enough material

that you can use the covering to seal the opening with a

covering iron.

Install silicone tubes (8 total) in each of the two canister

mounts.

22

Page 23

Step 8

Step 9

Install throttle servo and attach the linkage (supplied) with

a 4-40 ball link on each end.

Slide the canister mufflers into model and attach the

headers to the engine.

23

Page 24

Step 10

Step 11

Secure the ignition module to the engine box. Make

the connections between the ignition box and engine

at this time.

Install the switch for the ignition at the front of the

fuselage as shown.

Step 12

Secure the battery for the ignition inside the fuselage

using a hook and loop strap. Make sure to add a few

pieces of foam between the fuselage and battery to prevent

damage to the battery caused by vibration. Connect the

battery to the ignition switch.

24

Step 13

Attach the fuel line from the fuel tank to the carburetor.

Mak sure the line is from the clunk and not the vent line.

Page 25

Step 14

Step 17

Cut the line between the carburetor and fuel tank to install

a Fuel Dot (HAN115). This will make fueling the tank

much easier when the cowl is installed.

Step 15

Route the vent line from the fuel tank out the bottom

of the cowl.

Make a circular opening under the carb in the cowling so

the choke butterfly can be manually operated.

Step 16

Make any necessary cutouts to clear the engine

components in the cowl. Remove a section from the

bottom of the cowling near the mufflers for cooling

outlet as shown. This opening is necessary to allow

cooling air to pass through the cowling to prevent

overheating of your engine.

25

Page 26

Engine Installation (Evolution 116GX)

Required Parts

• Fuselage assembly

Required Tools and Adhesives

• Threadlock

Step 1

Collect the items shown for the installation of your

particular engine.

Step 3

Install the tapered aluminum adapter plate to the right side

of the engine with a short 1/4-20 bolt and AC nut through

the top mounting hole and don't tighten yet.

Step 4

Measure, mark and drill firewall to correct dimensions and

offset to the left side.

Step 2

Install the short aluminum adapter to the top left mounting

hole on the engine using the short 1/4-20 bolt and aircraft

nut. Don't tighten yet.

26

Page 27

Step 3

Use a drill and 5/16-inch (8mm) drill bit to drill the holes

in the firewall for mounting the engine.

Step 5

Install the 1/4-20 blind nuts from the back side of the

firewall. You can use the bolts and standoffs to pull the

blind nuts into position.

Step 6

Install engine using four 2

aluminum standoffs, one 3/16-inch (5mm) aluminum

spacers and four 1/4-20 x 4-inch socket head bolts and

four 1/4-inch lock washers.

7

/8-inch (73mm) machined

Step 7

Cut the top of the motor box to mount the throttle servo as

photos and install it top down.

Step 8

Drill a hole in the firewall for the throttle linkage to pass.

27

Page 28

Step 9

Install the (supplied) throttle linkage.

Step 10

Attach the fuel line from the fuel tank to the carburetor.

Make sure the line is from the clunk and not the vent line.

Cut the line between the carburetor and fuel tank to install

a Fuel Dot (HAN115). This will make fueling the tank

much easier when the cowl is installed.

Step 11

Secure the battery for the ignition inside the fuselage

using a hook and loop strap. Make sure to add a few

pieces of foam between the fuselage and battery to prevent

damage to the battery caused by vibration. Connect the

battery to the ignition switch. The EVO 116 requires a

3-cell Li-Po ignition battery.

Step 12

Use 30-minute epoxy to glue in cover plate to the fuselage

for pipe tunnel.

Step 13

Bolt the mufflers onto engine using the hardware provided

with the mufflers.

28

Page 29

Step 14

Make any necessary cutouts to clear the engine

components in the cowl. Remove a section from the

bottom of the cowling near the mufflers for cooling

outlet as shown. This opening is necessary to allow

cooling air to pass through the cowling to prevent

overheating of your engine.

Step 15

Route the vent line from the fuel tank out the bottom

of the cowl.

29

Page 30

Receiver Installation

Required Parts

• Fuselage assembly

• Hook and loop strap (4)

Required Tools and Adhesives

• Threadlock • Hobby knife

• Receiver • Switch harness

• 1/4-inch (6mm) foam) • Receiver battery

• Ignition battery

• 24-Inch Servo Lead Extension (JSP98040) (3)

• 36-inch Servo Lead Extension (JSP98050) (3)

IMPORTANT: Two receiver

batteries of at least 2700mAh or

larger are needed. Two 4000 2S2P

Li-Po receiver packs are shown.

Step 1

Install both receiver batteries with two layers of padded

2-sided servo tape and then secure in place with the

supplied hook and loop straps.

30

Page 31

Step 4

Step 7

Use a hobby knife to remove the covering from the holes

in the sides of the fuselage for the two radio switches.

Secure any switches to the fuselage using the hardware

provided with the switches.

Step 10

Put foam rubber or thick padded 2-sided tape under the

receiver. Use a hook and loop strap to secure the receiver

to the cross brace inside the fuselage. Plug the servos

into the receiver and route the servo leads neatly along the

side of the fuselage. Route the antenna wire (if necessary)

at this time as well.

31

Page 32

Pilot and Canopy Installation

Required Parts

• Fuselage assembly • Pilot bust

• Canopy

Required Tools and Adhesives

• Canopy glue • Felt-tipped pen

• Painter's tape • Waxed paper

• 30-minute epoxy • Sandpaper

• Rubbing alcohol • Paper towel

Step 1

Be sure the visor screws are tight. It is recommended to

remove the screws and use a drop of threadlock on them

to prevent vibrations from causing them to vibrate loose.

Step 3

Trim the instrument panel from the decal sheet. Apply the

decal in position in the cockpit.

Step 4

Position the canopy onto the hatch. Use a felt-tipped pen

to trace the outline of the canopy onto the hatch.

Step 2

Use 30-minute epoxy to secure the pilot bust to the

canopy hatch.

Step 5

Sand the hatch and canopy where they contact each other

using sandpaper. Clean the area using rubbing alcohol

and a paper towel.

32

Page 33

Step 6

Slip a piece of waxed paper between the hatch and

fuselage. Use canopy glue to attach the canopy to the

canopy hatch. Use painter's tape to keep the canopy in

position until the glue fully cures.

Radio Setup

A 7-channel or greater computer radio is highly

recommended. This allows the following features:

• Mixing the right aileron to the left aileron (flaperon mix)

• Electronically adjustable aileron differential

• Mixing the right elevator to the left elevator (dual

elevator mixing)

• Independent travel and trim adjustments for each

elevator half

When using a 7-Channel or greater computer radio,

each servo is plugged into its own separate channel.

Consult your radio manual for specific details on

hookup and programming.

33

Page 34

Control Throws

Setting the control throws for your Extra 260 does require

some attention to detail. To correctly set the throws, it

is highly suggested to use the following procedure to

achieve the greatest mechanical advantage from your

servos.

Step 1

Determine the maximum amount of control surface throw

from the throws listed. Use the high rate throws listed

to set the maximum amount of throw, then use your

computer radio for the lower rate listed.

Step 2

Set the Travel Adjust (ATV on a Futaba transmitter) to

about 15% under the max. (On a JR transmitter, that

is 135%.) Make sure to set both directions during this

process.

Step 3

Adjust the position of the clevis on the control horn and

position of the ball link on the servo arm to achieve the

throw decided in Step 1. It is highly recommended not to

change the position on the servo arm unless absolutely

necessary. Use Travel Adjust (ATV) to finalize the throws.

That is why we left a little margin in the percentages back

in Step 2.

Step 4

If setting a dual elevator or aileron, match the linkage

locations used back in Step 3. Increase or decrease the

Travel Adjust (ATV) a few points as necessary to fine-tune

the throws to match up left and right sides and up and

down throws so all is symmetrical.

This is all necessary to tune the mechanical advantage as

good as possible. When setting up a model for 3D, the

mechanical advantage will be less because of the large

throws, and thus the servo will work harder and wear

faster. Using an insufficient servo for the job, or trying

to get too much throw, will cause something to give,

probably the servo.

There isn’t an exact geometry to the linkage, as it depends

on how much throw each individual modeler requires.

The linkage geometry should always be maximized so the

servo isn’t working any harder than it has to.

Aileron:

High Rate: 34.4 Degrees up, 54% Exponential

33 Degrees down, 54% Exponential

Low Rate: 23 Degrees up, 40% Exponential

22 Degrees down, 40% Exponential

Elevator:

High Rate: 48.5 Degrees up, 75% Exponential

47 Degrees down, 75% Exponential

Low Rate: 13 Degrees up, 45% Exponential

13 Degrees down, 45% Exponential

Rudder:

High Rate: 44 Degrees right, 50% Exponential

44 Degrees left, 50% Exponential

Low Rate: 30 Degrees right, 50% Exponential

30 Degrees left, 50% Exponential

Computer Radio Enhancements

A computer radio will allow you to do quite a bit of

fine-tuning to the feel of the Extra 260, which will make

aerobatics even easier.

34

Page 35

Rates and Expos

Use Expo to soften the feel of the model. On high 3D

rates, use quite a bit of expo. The goal on 3D rates is to

get the model to feel the same around neutral as it does

on low rates.

Use low rate settings for all flying except for 3D

aerobatics. For precision flying or general sport hotdogging, the low rate throws are perfect, even for snap

rolls. The only exception is rudder rates. Use 3D rudder

rate when doing stall turns and rolling circles, since

the more rudder the better for these. When doing 3D

aerobatics, flip to 3D rates just before the maneuver. As

soon as the maneuver is done, flip back down to low rate

to avoid over-controlling the model.

Recommended Center of Gravity (CG)

An important part of preparing the aircraft for flight is

properly balancing the model. This is especially important

when various engines are mounted.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location for

your model is: 3

from leading edge of wing at the wing tip. Mark the

location of the CG onto the bottom of the wing using

a felt-tipped pen. With a helper, lift the aircraft with your

index finger at the location marked on the wing. Make

sure the aircraft is upright when checking the CG. If the

nose of your aircraft hangs low, add weight to the rear of

the aircraft. If the tail hangs low, add weight to the nose

of the aircraft. Stick-on weights are available at your local

hobby store and work well for this purpose.

1

/2 to 4 inches (89 to 102mm) back

35

Page 36

Preflight

For those of you who are veterans of large models, this

is old news. But to you newcomers to the world of large

models, this is very important information.

While many smaller models are not critical of proper

battery use, and are tolerant of improper control linkage

setups and flying techniques, large models are not. Don’t

let that scare you away from large models; they are truly

one of the best flying experiences in RC that money

can buy. However, please pay particular attention to the

following areas.

Maintain the proper mechanical advantage on all

control surface linkages.

Just as with unsealed hinge gaps, mechanical advantage

is often another cause of flutter. Please follow the control

horn and servo arm lengths recommended in this manual.

Shorter arms on the servo or longer control horns on the

elevator and ailerons are fine, but do not try to go the

other way to increase throw. It can cause flutter or servo

failure on the Extra 260. The recommended linkage setups

are more than adequate to achieve full 3D throws.

Check the radio installation and make sure all the

control surfaces are moving correctly (i.e. the correct

direction and with the recommended throws). Test

run the engine and make sure it transitions smoothly

from idle to full throttle and back. Also ensure the

engine is tuned according to the manufacturer’s

instructions, and it will run consistently and constantly

at full throttle when adjusted.

Check all the control horns, servo horns, and clevises to

make sure they are secure and in good condition. Replace

any items that would be considered questionable. Failure

of any of these components in flight would mean the loss

of your aircraft.

While many smaller models are very tolerant of improper

control linkage setups and flying techniques, large models

are not. Don’t let that scare you away from large models;

they are truly one of the best flying experiences in RC that

money can buy. However, please pay particular attention to

the following areas.

Never attempt to make full throttle dives!

Large models perform much more like full-size aircraft

than small models. If the airframe goes too fast, such as

in a high throttle dive, it may fail. The Extra 260 should be

flown like a full-scale Extra 260. Throttle management is

absolutely necessary.

Hardware checks

Double-check the setscrews in all contol horns to be sure

they are very tight. Periodically check these to be sure

they have not loosened over time. Always use threadlock

on metal-to-metal fasteners.

Receiver Battery Selection

Be sure adequate batteries are used to power the receiver.

It is STRONGLY recommended that two identical 6-volt

receiver packs are used. Each pack must have a minimum

of 2700mAh capacity. Use packs of 3000mAh when super

high torque servos are used.

Servo selection

Be sure all servos used on elevator, aileron and rudder are

metal geared type and have at least 188 oz in of torque.

Failure to do this will very likely result in a failure and

loss of the model.

Range check

Always range check the radio system per the

manufacturer's instructions before the initial test flight and

periodically afterward.

Check the voltage of the on-board packs

ALWAYS use an ESV with a 1-amp load to check the

receiver battery packs and the ignition pack before each

and every flight. If there is any doubt that the packs are

questionable, DO NOT FLY until the packs are recharged.

36

Page 37

Instructions for Disposal of WEEE by

Users in the European Union

This product must not be disposed of with other waste.

Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated

collection point for the recycling of waste electrical

and electronic equipment. The separate collection and

recycling of your waste equipment at the time of disposal

will help to conserve natural resources and ensure that it

is recycled in a manner that protects human health and

the environment. For more information about where you

can drop off your waste equipment for recycling, please

contact your local city office, your household waste

disposal service or where you purchased the product.

37

Page 38

2007 Official AMA

National Model Aircraft Safety Code

GENERAL

1. A model aircraft shall be defined as a non-humancarrying device capable of sustained flight in the

atmosphere. It shall not exceed limitations established

in this code and is intended to be used exclusively for

recreational or competition activity.

2. The maximum takeoff weight of a model aircraft,

including fuel, is 55 pounds, except for those flown

under the AMA Experimental Aircraft Rules.

3. I will abide by this Safety Code and all rules

established for the flying site I use. I will not willfully

fly my model aircraft in a reckless and/or dangerous

manner.

4. I will not fly my model aircraft in sanctioned events,

air shows, or model demonstrations until it has been

proven airworthy.

5. I will not fly my model aircraft higher than

approximately 400 feet above ground level, when

within three (3) miles of an airport without notifying the

airport operator. I will yield the right-of-way and avoid

flying in the proximity of full-scale aircraft, utilizing a

spotter when appropriate.

6. I will not fly my model aircraft unless it is identified

with my name and address, or AMA number, inside or

affixed to the outside of the model aircraft. This does

not apply to model aircraft flown indoors.

7. I will not operate model aircraft with metal-blade

propellers or with gaseous boosts (other than air),

nor will I operate model aircraft with fuels containing

tetranitromethane or hydrazine.

8. I will not operate model aircraft carrying pyrotechnic

devices which explode burn, or propel a projectile

of any kind. Exceptions include Free Flight fuses or

devices that burn producing smoke and are securely

attached to the model aircraft during flight. Rocket

motors up to a G-series size may be used, provided

they remain firmly attached to the model aircraft during

flight. Model rockets may be flown in accordance with

the National Model Rocketry Safety Code; however,

they may not be launched from model aircraft. Officially

designated AMAAir Show Teams (AST) are authorized

to use devices and practices as defined within the Air

Show Advisory Committee Document.

9. I will not operate my model aircraft while under the

influence of alcohol or within eight (8) hours of having

consumed alcohol.

10. I will not operate my model aircraft while using any

drug which could adversely affect my ability to safely

control my model aircraft.

11. Children under six (6) years old are only allowed on

a flightline or in a flight area as a pilot or while under

flight instruction.

12. When and where required by rule, helmets must be

properly worn and fastened. They must be OSHA, DOT,

ANSI, SNELL or NOCSAE approved or comply with

comparable standards.

38

Page 39

2007 Official AMA

National Model Aircraft Safety Code

Radio Control

1. All model flying shall be conducted in a manner to

avoid over flight of unprotected people.

2. I will have completed a successful radio equipment

ground-range check before the first flight of a new or

repaired model aircraft.

3. I will not fly my model aircraft in the presence of

spectators until I become a proficient flier, unless I am

assisted by an experienced pilot.

4. At all flying sites a line must be established, in front of

which all flying takes place. Only personnel associated

with flying the model aircraft are allowed at or in front

of the line. In the case of airshows demonstrations

straight line must be established. An area away from

the line must be maintained for spectators. Intentional

flying behind the line is prohibited.

5. I will operate my model aircraft using only radiocontrol frequencies currently allowed by the Federal

Communications Commission (FCC). Only individuals

properly licensed by the FCC are authorized to operate

equipment on Amateur Band frequencies.

6. I will not knowingly operate my model aircraft within

three (3) miles of any preexisting flying site without

a frequency-management agreement. A frequencymanagement agreement may be an allocation of

frequencies for each site, a day-use agreement between

sites, or testing which determines that no interference

exists. A frequency-management agreement may exist

between two or more AMA chartered clubs, AMA

clubs and individual AMA members, or individual

AMA members. Frequency-management agreements,

including an interference test report if the agreement

indicates no interference exists, will be signed by all

parties and copies provided to AMA Headquarters.

7. With the exception of events flown under official AMA

rules, no powered model may be flown outdoors closer

than 25 feet to any individual, except for the pilot and

located at the flight line.

8. Under no circumstances may a pilot or other person

touch a model aircraft in flight while it is still under

power, except to divert it from striking an individual.

9. Radio-controlled night flying is limited to lowperformance model aircraft (less than 100 mph).

The model aircraft must be equipped with a lighting

system which clearly defines the aircraft's attitude and

direction at all times.

10. The operator of a radio-controlled model aircraft shall

control it during the entire flight, maintaining visual

contact without enhancement other than by corrective

lenses that are prescribed for the pilot. No model

aircraft shall be equipped with devices which allow it

to be flown to a selected location which is beyond the

visual range of the pilot.

39

Page 40

10492.1

© 2007 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

horizonhobby.com

Loading...

Loading...