Page 1

Wing Span .64-3/4 inches

Wing Area .712-1/4 inch2

Approx. Weight .4-3/4-5 1/2 lbs.

Engine Requirements .40-.46 2-cycle

.40-.50 4-cycle

• True UltraCote™ covering

• Positive self-righting flight characteristics

• 90% pre-built

• Extensive hardware kit included

• Break away motor mount prevents engine

damage during minor nose-overs

Specifications

Raising the Standard of Quality

in Almost-Ready-To-Fly Aircraft

ALMOST READY-TO-FLY

PRE-BUILT

90

%

9

HANGAR

TM

INSTRUCTION MANUAL

Page 2

2

TICKET TO FLY

R/C Pilot Program

The Total Training Package

Congratulations on your selection of the Hangar 9 Easy Fly

40! Your kit comes complete with the “T

ICKET

TO F

LY R/C

Pilot Program,” a detailed video instruction guide designed

to help beginners become successful pilots.

This video guides you through every step of the learning

process — from building tricks and tips through your first solo flights. The

video shows in-depth procedures on radio setup, trimming the plane, and

breaking-in and tuning your engine. It covers the basic flight concepts you

need to know, like takeoffs, landings and, most importantly, how to find and

work with a qualified instructor. You’ll find out just what to expect when

you arrive at the flying field… before you even get there.

When you use the video in conjunction with the complete, photo-illustrated

instruction manual, you’ll gain the confidence and ability to successfully

meet the challenge of R/C flight. This video is an invaluable teaching aid

which will shorten the time it takes to properly learn to operate and fly the

Easy Fly 40.

Good Luck and Good Flying!

TM

Page 3

3

Table Of Contents

Introduction 3

Contents Of Kit 4

Equipment Required 5

Tools And Supplies Required 5

Field Equipment Required 6

Optional Field Equipment 7

Section 1: Assembling The Wings 8

Section 2: Joining The Wing Halves 9

Section 3: Hinging The Rudder And Elevator 12

Section 4: Installing The Aileron Servo Trays 13

Section 5: Assembling The Fuselage 16

Section 6: Installing The Nose Gear 17

Section 7: Installing The Wing Dowels 18

Section 8: Assembling The Fuel Tank 19

Section 9: Installing The Fuel Tank 21

Section 10: Installing The Control Horns 22

Section 11: Installing The Horizontal & Vertical Stabilizers 24

Section 12: Installing The Engine 26

Section 13: Installing The Radio 29

Section 14: Installing The Linkages 32

Section 15: Setting Up The Radio 38

Section 16: Balancing The Model 39

Pre-Flight Check 40

Pre-Flight At The Field 41

Flight Instructions 42

AMA Safety Codes 43

Glossary 44

Page 4

Introduction

Congratulations!

You are the proud owner of the highest quality almost-ready-to-fly (ARF) sport trainer available. The Easy Fly

40 is professionally built and pre-covered by craftsmen using genuine UltraCote®covering. The positive selfrighting flight characteristics and excellent slow-speed handling make the Easy Fly 40 one of the easiest-to-fly

airplanes available. Beyond its positive, gentle flight mannerisms, the Easy Fly 40 also offers outstanding

sport aerobatic capabilities. Loops, rolls, sustained inverted flight, and even outside maneuvers are all well

within its flight envelope.

In order for you to get the best performance and most enjoyment from your Easy Fly 40, it is important to

carefully read and follow this manual. If you’re a first-time flier, we strongly suggest that you seek qualified

help during your first flights. Your local hobby shop will be able to put you in touch with qualified pilots and a

local club.

Note: Due to temperature changes during shipping, the covering on your Easy Fly may be slightly wrinkled.

The careful use of a heat gun or iron is recommended to shrink the UltraCote

®

until its taut.

Warning

An R/C aircraft is not a toy! If misused, it can cause serious bodily harm and damage to property. Fly only in

open areas, preferably AMA (Academy of Model Aeronautics) approved flying sites, and have an experienced

modeler/pilot preflight your aircraft before its first flight and perform the aircraft’s first test flights. Please

follow all instructions included with your radio and engine. We cannot stress strongly enough the importance

of having an experienced pilot preflight your aircraft and be present during your first test flights!

4

The Easy Fly 40 is professionally built and

pre-covered by craftsmen using genuine UltraCote®

covering. UltraCote is completely reparable and can

be found at your local hobby shop.

ULTRACOTE

UltraCote is a registered trademark of Carl

Goldberg Models

®

Page 5

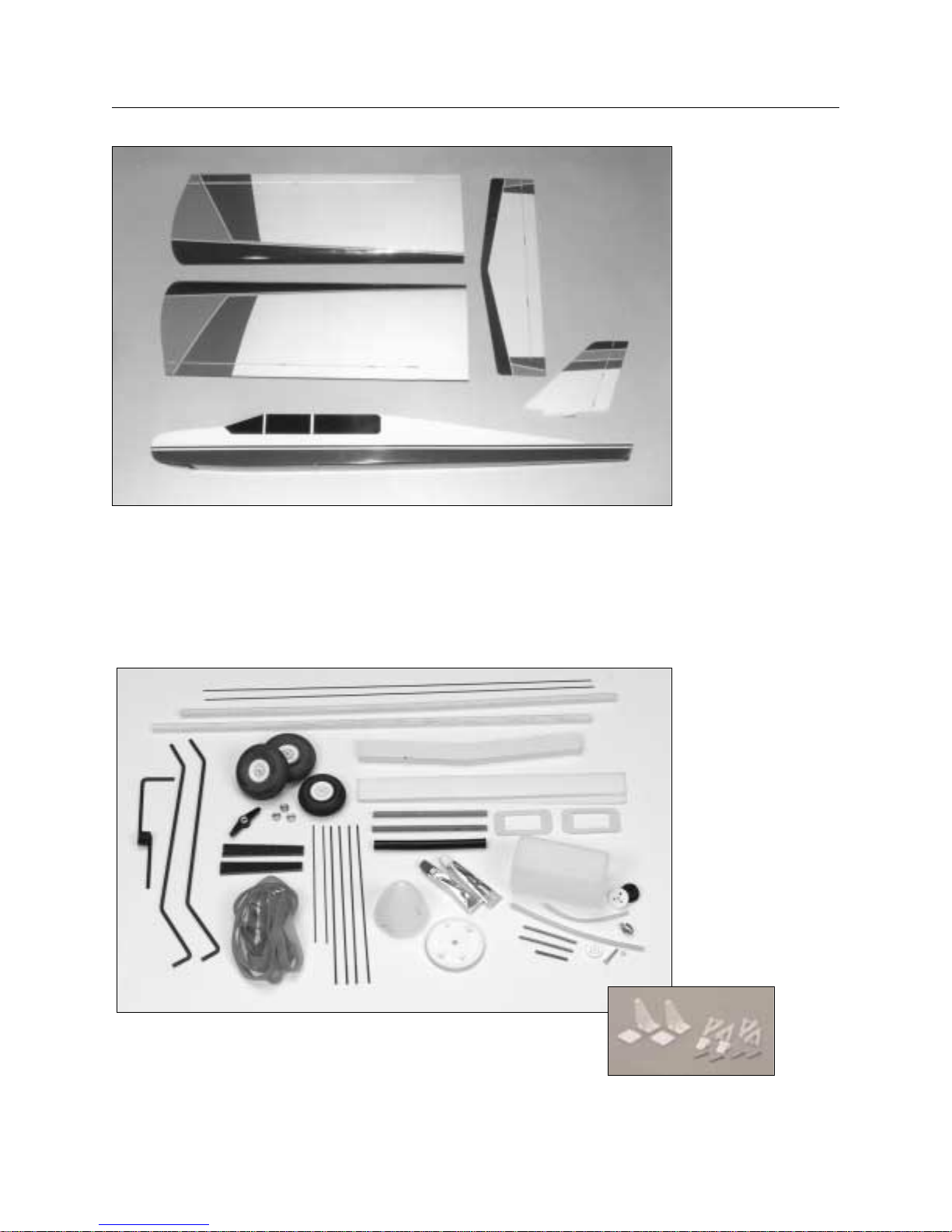

Contents Of Kit

5

A. Fuselage (#HAN1401)

B. Right wing half with aileron (#HAN1402)

C. Left wing half with aileron (#HAN1402)

D. Vertical stabilizer with rudder (#HAN1403)

E.

Horizontal stabilizer with elevator

(#HAN1404)

1. Pushrods

2. Aileron servo mounts (2)

3. Main landing gear

4. Nose landing gear

5. Spinner

6. Motor mounts and hardware

7. Wheels (3)

8. Fuel tank and hardware

9. Rubber bands (8)

10. Control horns

11. Wing joiner

A

B

C

E

D

1

11

9

8

7

6

5

4

3

2

10

Page 6

R/C Radio System

4 Channels (minimum)

4 Standard Servos

Standard 450-650 mAh Battery

Recommended JR Systems

JR F400 FM

JR XP642

JR XP783

JR XP8103

R/C Engine

.40-.45 2-Cycle with Muffler

Recommended Thunder Tiger Engine

GP .42 with Muffler

R/C Aircraft Propeller

10-6 Prop with a .40-.46 Size Engine

6

Equipment Required

Adhesives

CA (cyanoacrylate) Glue (instant/thin and medium viscosity)

CA Remover (dissolve)

5-Minute Epoxy

30-Minute Epoxy

Tools

Clips (e.g. clothespins, binder clips)

Cloth

Drill and Assorted Drill Bits

Heat Gun

Heat Iron

Hobby Knife

Masking Tape

Needle Nose Pliers

Paper Towels

Pencil

#1 and #2 Phillips Screwdrivers

Rubbing Alcohol

Ruler (straight edge)

Sandpaper

Scissors

Straight Screwdriver

Thread Lock (e.g., Loc Tite Blue)

Toothpicks

90-Degree Triangle

Wax Paper

Z-Bender Pliers

Tools And Supplies Required

Page 7

Field Equipment Required

HAN3000 – 2-cycle Performance Plug MDC101 Glow Driver Model Airplane Fuel

HAN 3005 – Extra Life Sport Plug

HAN104 12V Super Starter HAN102 12V Battery HAN118 Fuel Pump

HAN2510 Glow Plug Wrench

7

Page 8

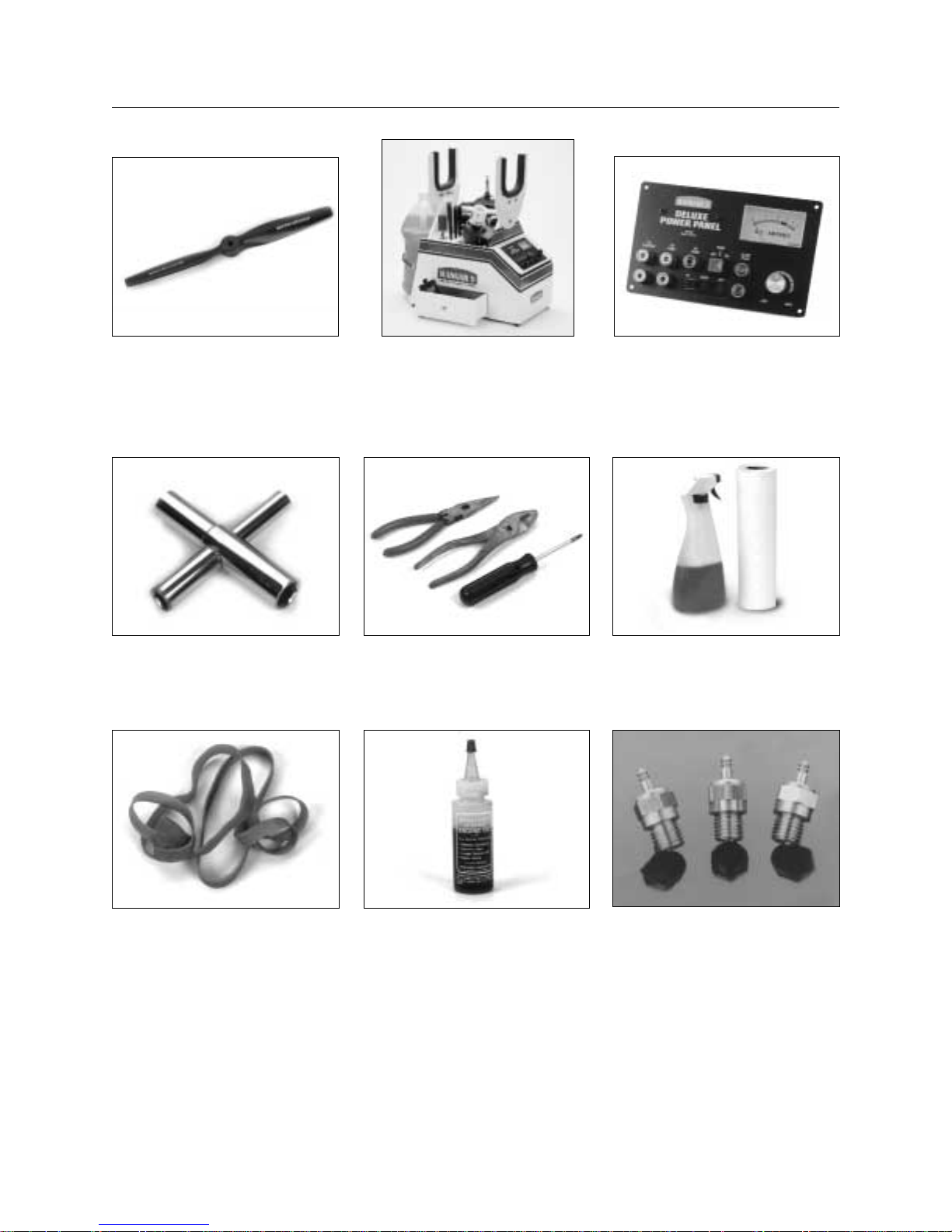

Optional Field Equipment

Extra Propellers Flight Box Power Panel

Prop Wrench Miscellaneous Tools Paper Towels

#64 Rubber Bands After Run Oil Extra Glow Plugs

8

Page 9

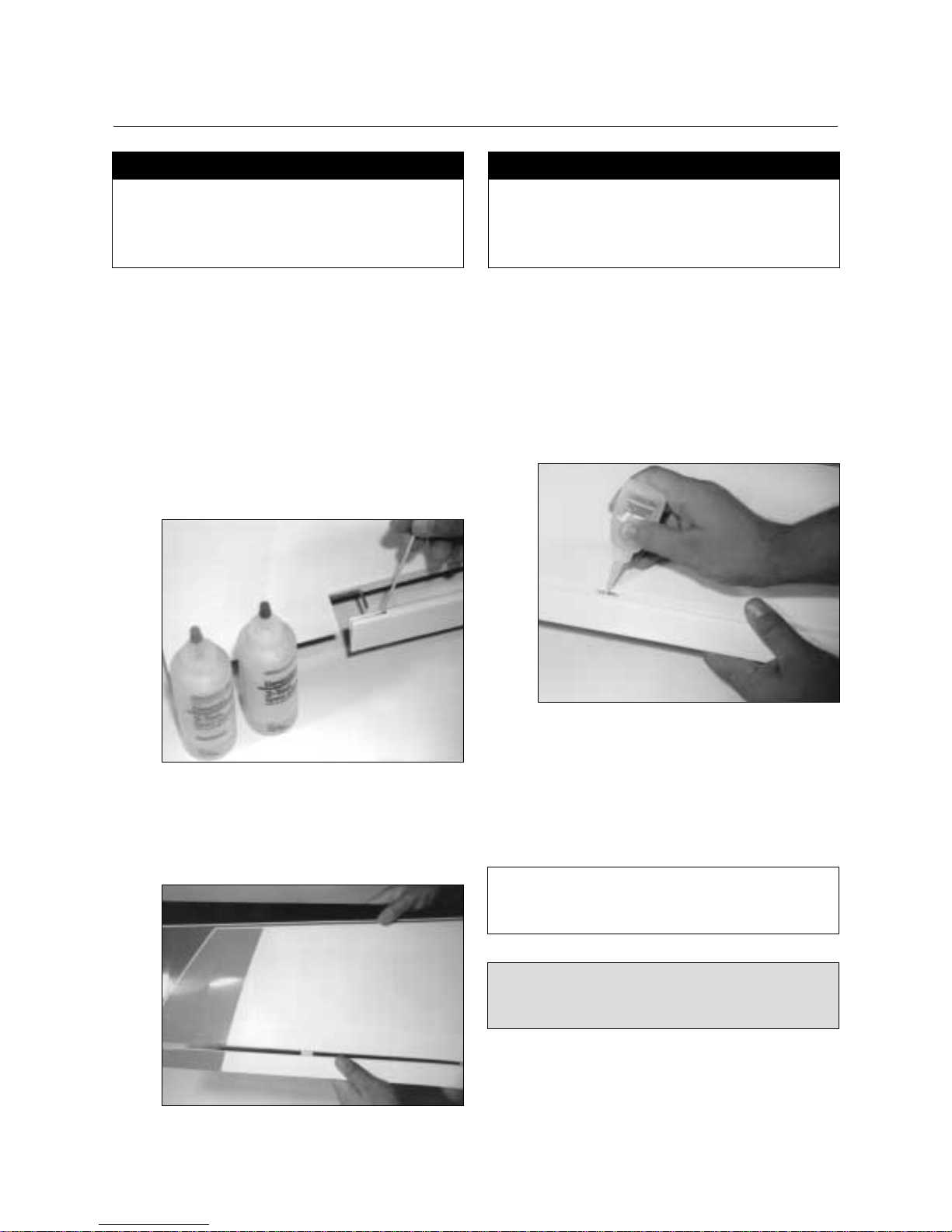

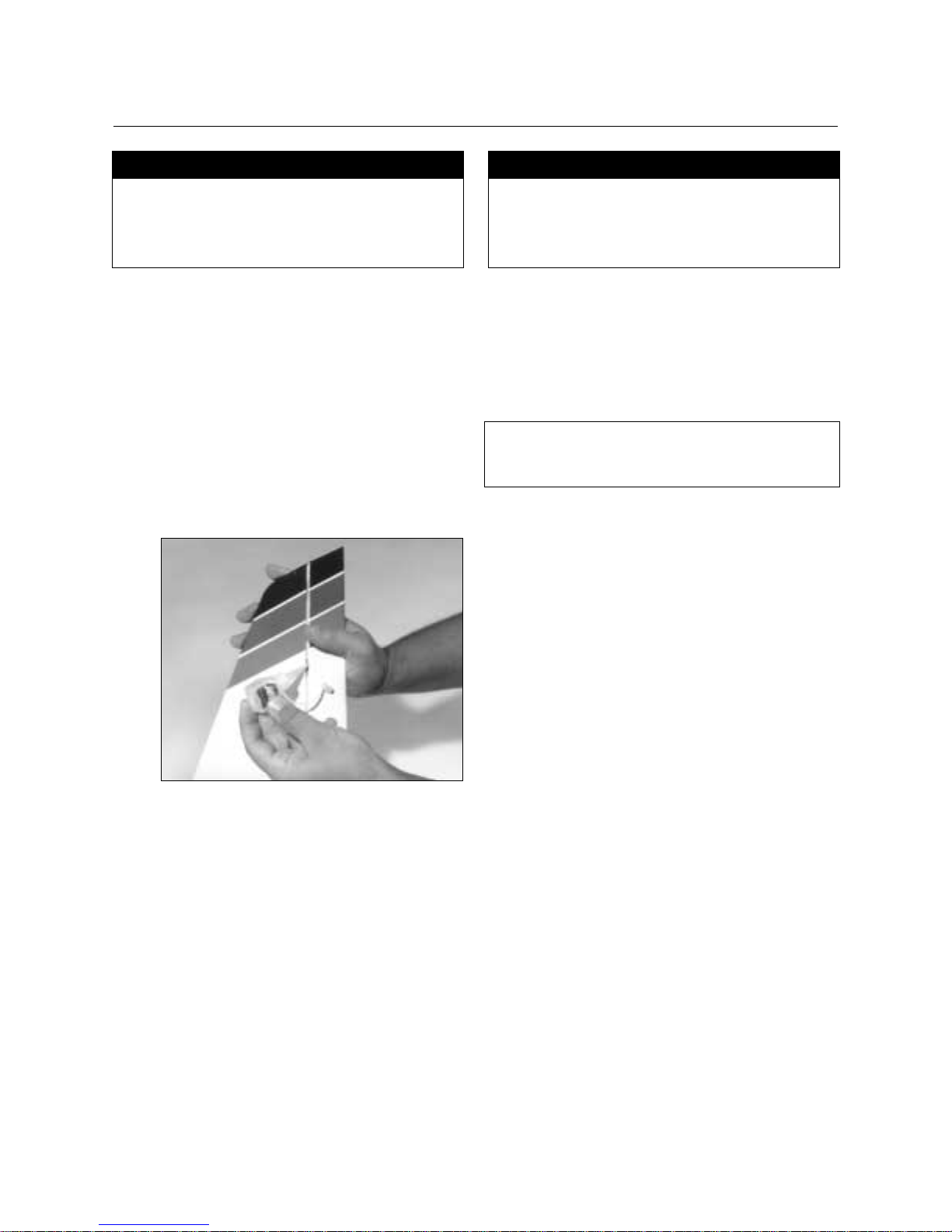

❑ 1. Carefully remove the aileron from the right wing panel.

Note where the hinges and the aileron torque rod fit into

the aileron.

❑ 2. Mix a small amount of 30-minute epoxy, carefully

following the instructions included with the epoxy.

❑ 3. Using a toothpick, apply epoxy into the ailerons’ torque

rod hole. Fill the hole 1/2 full.

❑ 4. Replace the aileron on the right wing half. Make sure

the hinges slide in place and the aileron torque rod

inserts into its respective hole in the aileron. The gap

between aileron and wing should be a constant 1/16”.

❑ 5. Wipe off any excess epoxy using a paper towel and

rubbing alcohol.

❑ 6. Deflect the aileron and apply a small amount of thin CA

glue to each hinge. Make sure that the CA glue

penetrates into the aileron and wing while maintaining a

1/16” aileron gap.

❑ 7. Wipe off any excess CA glue using CA remover and a

paper towel.

❑ 8. Repeat this process for the left wing (Steps 1-7).

Note:

After the CA has dried completely, check to ensure that

the hinges are secure by pulling firmly on the ailerons.

Important:

The ailerons are fitted in place but not glued in. They

must be correctly glued prior to flying.

9

Left Wing Panel with Aileron and Hinges

Right Wing Panel with Aileron and Hinges

CA Remover

30-Minute Epoxy

Thin Instant CA Glue

Paper Towels

Rubbing Alcohol

Toothpicks

Section 1: Assembling The Wings

Parts Needed Tools Needed

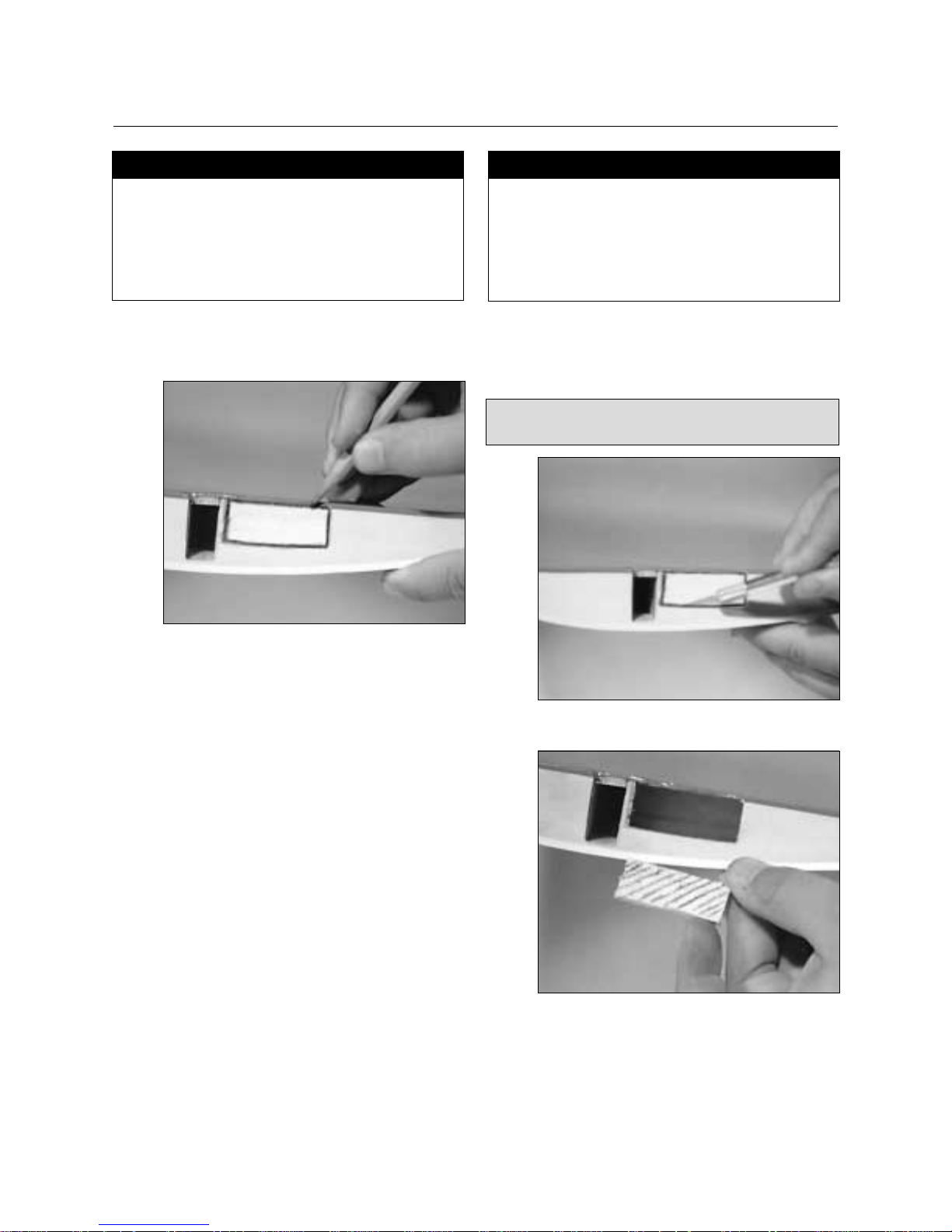

Page 10

❑ 1. Using a pencil, mark both wing roots (the exposed

wood end of the wing halves) as shown.

❑ 2. Using a hobby knife, carefully cut out the marked

section.

Important:

Do not cut into hard wood wing joiner section.

10

Aileron Servo Mounts (2)

Dihedral Brace

Left Wing Half from Section 1

Right Wing Half from Section 1

Standard Servo (1)

30-Minute Epoxy

Hobby Knife

Masking Tape

Paper Towels

Pencil

Rubbing Alcohol

Ruler

Wax Paper

Section 2: Joining The Wing Halves

Parts Needed Tools Needed

Page 11

❑ 3. Locate the dihedral brace (also called the wing joiner).

Using a ruler and pencil, mark the exact center of the

brace as shown.

❑ 4. Mix approximately 2 ounces of 30-minute epoxy. In

this step, be sure to use plenty of epoxy. Using a scrap

piece of wood, smear the epoxy into the wing joiner

cavity of both wings. (Remember, use plenty of epoxy.)

❑ 5. Coat one half of the dihedral brace with epoxy up to the

line. Note the orientation of the V of the dihedral

brace. Install the epoxy-coated side of the dihedral

brace into a wing half up to the line, making sure the V

of the dihedral brace is positioned correctly as shown.

11

Section 2: Joining The Wing Halves

CONTINUED

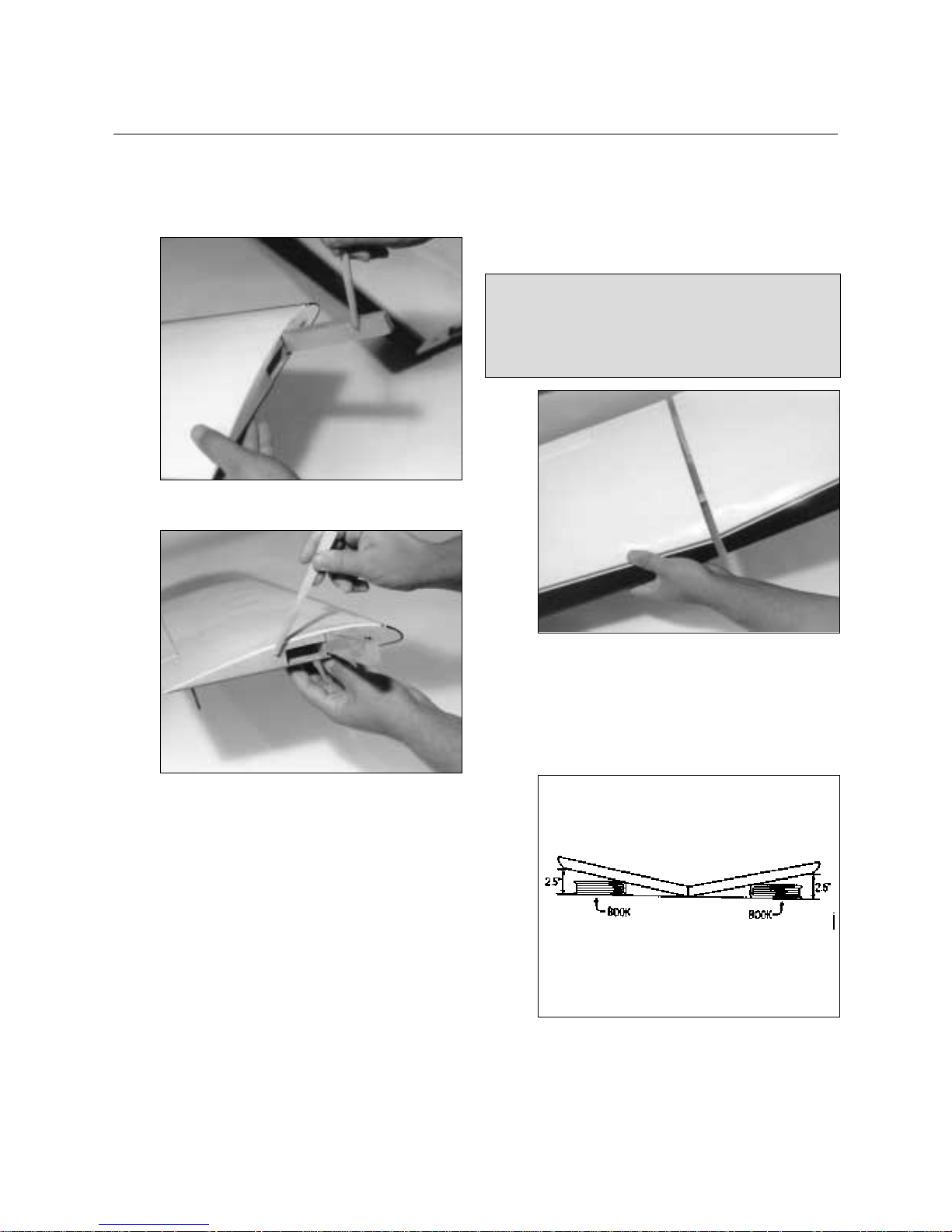

Page 12

❑ 6. Apply epoxy to the exposed area (other end) of the

dihedral brace. Uniformly coat both wing roots with

30-minute epoxy.

❑ 7. Carefully slide the two wing halves together. Firmly

press the two halves together, allowing the excess

epoxy to run out. Using rubbing alcohol and a paper

towel, clean off the excess epoxy.

Important:

Be sure the wings are pressed firmly together at the

center section. Be sure that the leading and trailing

edges line up properly. Use masking tape as necessary

to hold the wing halves in position.

❑ 8. Place a 12” x 12” sheet of wax paper on the edge of a

flat table. Place the center section of the wing on the

wax paper with the aileron torque rod hanging off the

edge of the table. Prop up each wing tip 2-1/2 inches

off the table as shown. Books work well for this.

❑ 9. Wipe off any excess epoxy using rubbing alcohol and

paper towels. Allow the wing to set undisturbed

overnight to dry completely.

12

Section 2: Joining The Wing Halves

CONTINUED

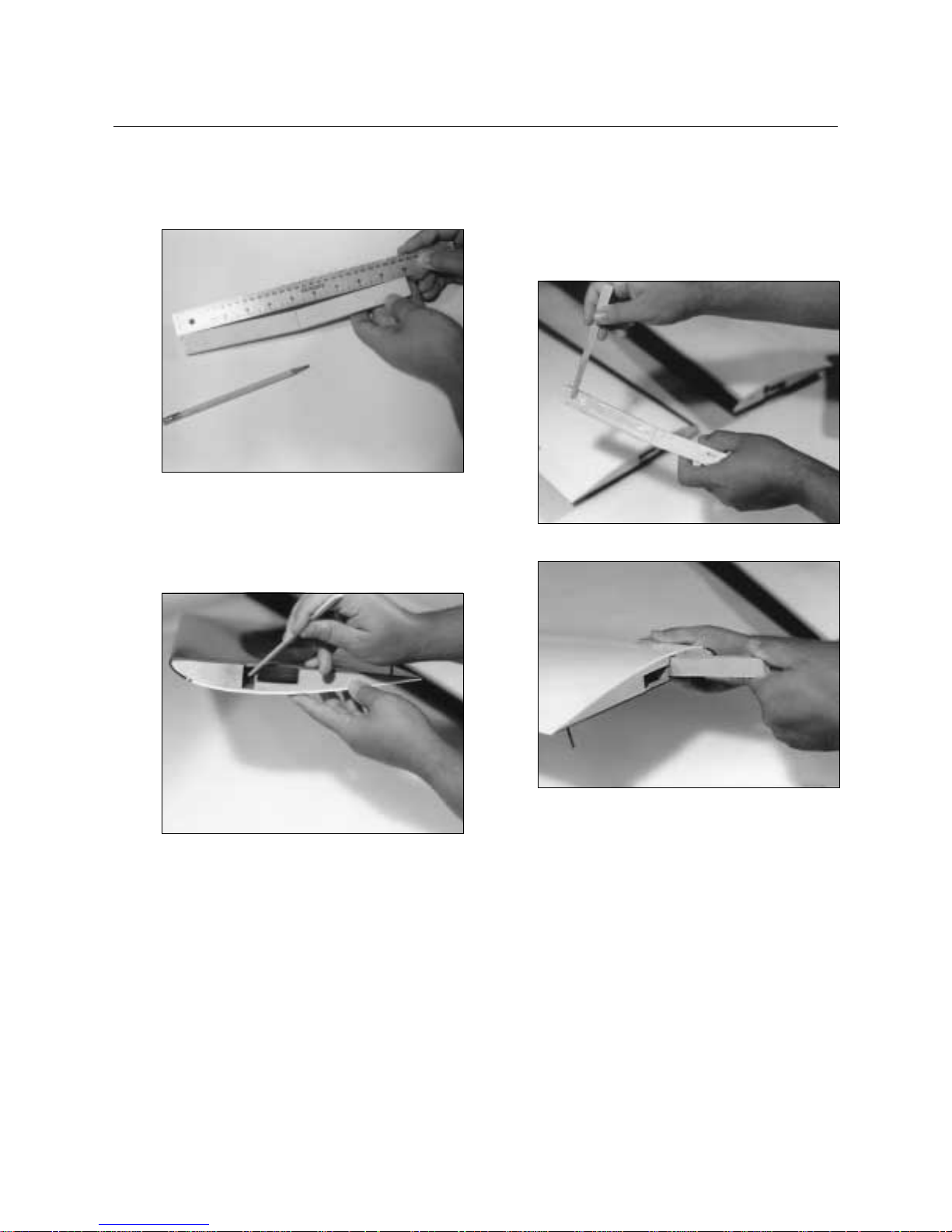

Page 13

13

Horizontal Stabilizer with Elevator and Hinges

Vertical Stabilizer with Rudder and Hinges

CA Remover

Paper Towels

Thin Instant CA Glue

Section 3: Hinging The Rudder And Elevator

Parts Needed Tools Needed

❑

1. Push the elevator and horizontal stabilizer together until

there is a constant 1/16” gap between the two and the

edges are lined up correctly.

❑ 2. Deflect the elevator and apply thin CA glue at the

hinges so that it absorbs both into the stabilizer and the

elevator (4 places).

❑ 3. Using the same technique, hinge the rudder to the

vertical stabilizer.

❑ 4. Wipe off any excess CA using CA remover and a paper

towel. Set these assemblies aside for now.

Note: After CA has dried completely, check to ensure that the

hinges are secured by pulling firmly on the control

surfaces.

Page 14

14

❑ 1. Mix a small amount of 5-minute epoxy as per the

instructions included with the epoxy. Remember, once

this epoxy is mixed, you have only 5 minutes of

working time until it dries.

❑ 2. Spread a thin layer of epoxy over the entire surface of

one side of an aileron tray.

❑ 3. Join the two aileron trays as shown and clamp them

together using four clips. Be sure the two trays are

properly aligned. Wipe off any excess epoxy with a

paper towel and set aside to dry for 15 minutes.

❑ 4. Using a ruler, measure the distance on the bottom of

the wing at the center line 5-1/2 inches from the trailing

edge and mark with a pencil.

❑ 5. Next, measure 3-3/4 inches from the leading edge back

to the center line and mark with a pencil.

Aileron Servo Trays (2)

Wing Center Section Tape

Clips (e.g., clothespins,

binder clips) (4)

5-Minute Epoxy

Hobby Knife

Masking Tape

Paper Towels

Pencil

Ruler

Section 4: Installing The Aileron Servo Trays

Parts Needed Tools Needed

Page 15

15

❑ 6. Unclamp the aileron tray when dry and position it on

the center line so the two marks are visible on the

inside of the aileron tray.

❑ 7. Carefully trace around the outside of the aileron tray

using a pencil.

❑ 8. Remove the aileron tray. Using a sharp hobby knife,

carefully cut through the plastic covering. Be careful

not to cut into the wood on the line you just made in

Step 7.

❑ 9. Carefully remove the covering in the aileron tray area.

This is necessary so that the tray will properly adhere to

the wing.

❑ 10. Mix a small amount of 5-minute epoxy and spread it

over the entire area of one side of the servo tray.

S

ection

4: Installing The Aileron Servo Trays

CONTINUED

Page 16

16

❑ 11. Place the aileron tray, glue side down, on the exposed

wood area on the bottom of the wing and gently press it

into position. Use masking tape if necessary to hold in

position until dry. Allow 15 minutes for the epoxy to

cure.

❑ 12. Using a sharp hobby knife, carefully cut out the balsa

wood from the inside section of the aileron tray and

remove.

❑ 13. Locate the wing center tape (white adhesive-backed

tape) and remove the adhesive backing. Starting at the

edge of the aileron tray, apply the tape around the wing

at the center section, ending at the other side of the

tray. Use a hobby knife to trim the excess length of

tape. Your wing is now complete.

❑ 14. Locate the small blue decal (square in shape) on the

decal sheet included with your kit. Apply this decal to

the leading edge of the wing to cover the wing center

tape that you have just applied. Press firmly to ensure

that the decal adheres properly to the wing.

S

ection

4: Installing The Aileron Servo Trays

CONTINUED

Page 17

17

❑ 1. Locate the main landing gear slot in the bottom of the

fuselage. Position the two landing gear straps across

the slot as shown and drill four 1/16” holes using the

straps as a guide. Remove the straps after all four holes

are drilled.

❑ 2. Locate the two main landing gear struts and insert them

into the landing gear slot as shown. Make sure the ends

fit into the holes in the edges of the slot.

❑ 3. Reposition the landing gear straps over the 1/16” hole

you drilled in Step 1. Screw into position with the four

sheet metal screws provided.

❑ 4. Place the wheels on the ends of the struts and secure

them with the supplied wheel collars. Use thread lock

on the collar screws.

Fuselage

Main Landing Gear (2 pcs)

Main Landing Gear Hardware

Wheels (2 pcs)

Wheel Collars with Screws (2 pcs)

Drill with 1/16” Drill Bit

#1 and #2 Phillips Screwdrivers

Thread Lock

Section 5: Assembling The Fuselage

Parts Needed Tools Needed

Page 18

18

❑ 1. The nose gear mount is pre-assembled onto the front

firewall of the fuselage. Locate the nose gear. On the

straight end, first slide the steering arm onto the nose

gear (note the orientation as shown in the photo). Use

thread lock and a #2 Phillips screwdriver to secure the

steering arm in place. Next, install a collar and secure it

in place with the thread lock and a machine screw. Now

slide the spring into position.

❑ 2. Insert the nose gear assembly from Step 1 into the nose

gear mount (attached to the front of the fuselage). Be

sure the spring stays in position and rests against the

nose gear mount. Install the collar on the top end of the

landing gear flush with the landing gear, and secure it

into position with a screw and the thread lock.

❑ 3. Attach the nose wheel and hold it in place using a

wheel collar and screw.

Nose Gear Wheel (1)

Spring Wheel Collar with Screws (2)

Steering Arm

#2 Phillips Screwdriver

Thread Lock

Section 6: Installing The Nose Gear

Parts Needed Tools Needed

Page 19

19

❑ 1. Using a sharp hobby knife, carefully cut the covering

around the four holes as shown, leaving a circle that the

dowel will be pressed into.

❑ 2. Install the two dowels and position them so that an

equal amount of dowel extends from each side of the

fuselage. Using thin CA glue, apply five drops around

each side of the wing dowel (4 places) where the dowel

touches the fuselage.

❑ 3. If necessary, use a paper towel and CA remover to wipe

off any excess CA glue.

Fuselage

Wing Dowels (2)

CA Remover

Hobby Knife

Paper Towel

Thin Instant CA Glue

Section 7: Installing The Wing Dowels

Parts Needed Tools Needed

Page 20

20

Clunk (brass fuel pickup)

Copper Tube, Long (vent)

Copper Tube, Short (pickup)

Fuel Line, Small

Fuel Tank

Plastic Cups (2)

Rubber Stopper

3mm Screw and 3mm Nut

Hobby Knife

#1 Phillips Screwdriver

Section 8: Assembling The Fuel Tank

Parts Needed Tools Needed

❑

1. Locate the black rubber stopper. Insert the short copper

tube into one of the open holes in the stopper so that an

equal amount of tube extends from each side. This tube

will be the fuel tank pickup tube.

❑ 2. Locate the long copper tube and bend it using your

fingers, as shown. This tube will be the fuel tank vent

tube.

❑ 3. Slide this tube into the other open hole of the stopper,

as shown.

❑ 4. Slide the two white plastic caps over the copper tubes

as shown. Note the orientation of the caps. The small

inside cap and the three “pegs” face away from the

black rubber stopper. The large outside cap and the

“raised center” go away from the black rubber stopper.

Page 21

21

❑ 5. Locate the small diameter fuel tubing and cut it to 3”

in length. This tubing will be used for the fuel pick-up

inside the fuel tank. Insert the brass clunk into one end

of the fuel tubing.

❑ 6. Install the open tube end of the clunk and tubing

assembly on the short copper tubing.

❑ 7. Press the 3mm locknut between the three pegs on the

inside white plastic cap as shown.

❑ 8. Carefully insert the assembly into the fuel tank. Note the

position of the vent tube. It must be at the top of the fuel

tank to function properly.

Section 8: Assembling The Fuel Tank

CONTINUED

Page 22

22

Section 8: Assembling The Fuel Tank

❑ 9. Insert a 3mm screw into the center hole of the stopper

and tighten.

Important:

Remember which tube is the fuel pick-up and which is

the vent so that you can properly connect the fuel tank

to the engine in Section 12.

CONTINUED

Fuel Tank Assembly (from Section 8)

Fuselage

None

Section 9: Installing The Fuel Tank

Parts Needed Tools Needed

❑

1. Note that the fuel stopper is mounted closer to one

edge of the tank than the other. This “closer edge” is

the top of the tank. Slide the tank into the fuselage

stopper first. Make sure that the top of the tank is

positioned towards the top of the fuselage.

❑ 2. Press the tank into position until the stopper inserts

into the hole in the firewall. The white plastic cap will

be nearly flush with the firewall.

Page 23

23

❑ 1. Position one of the control horns on the bottom of the

elevator as shown. The vertical section of the control

horn must be positioned exactly in line with the cutaway portions of the covering, and the four holes must

be in line with the hinge.

❑ 2. Using a pencil, mark the position of the two screws on

the elevator. Next, drill two 1/16” holes through the

elevator where marked.

❑ 3. Install the control horn using the two screws and the

back plate and tighten the screws with a #1 Phillips

screwdriver.

❑ 4. Using a pencil, measure up 1/2” from the bottom of the

rudder and mark.

Control Horn with Backplate (2)

Horizontal Stabilizer with Elevator

Small Phillips Screw (4)

Vertical Stabilizer with Rudder

Drill with 1/16” Drill Bit

Pencil

#1 Phillips Screwdriver

Ruler

Section 10: Installing The Control Horns

Parts Needed Tools Needed

Page 24

24

❑ 5. Position the rudder control horn as shown, with the

mark just below the edge of the control horn.

❑ 6. Now mark, drill, and install the horn as you did

previously for the elevator.

Section 10: Installing The Control Horns

CONTINUED

Page 25

25

Section 11: Installing The Horizontal & Vertical Stabilizers

❑ 1. Using a hobby knife, carefully cut out the covering at

the front of the horizontal stabilizer slot as shown. The

vertical stabilizer will later be inserted into this slot.

❑ 2. Using a hobby knife, carefully cut out the openings on

the top rear of the fuselage. Also, cut out the plywood

section in the rear-most slot. The rear-most cutout is

where the vertical fin will fit; the forward cutout is for

the rudder pushrod exit.

❑ 3. Position the horizontal stabilizer in place on the

fuselage and trial fit the vertical stabilizer in place.

Using a pencil, mark where the horizontal stabilizer and

vertical stabilizer meet on the vertical fin on both sides.

❑ 4. Remove the vertical stabilizer and cut away the covering

below the marked section. Be careful not to cut into the

wood. A ruler is helpful in making a straight cut.

Fuselage

Horizontal Stabilizer Assembly

Vertical Stabilizer Assembly

Hobby Knife

Ruler

30-Minute Epoxy

90-Degree Triangle

Pencil

Rubbing Alcohol

Paper Towels

Parts Needed Tools Needed

Page 26

26

Section 11: Installing The Horizontal & Vertical Stabilizers

❑ 5. Mix approximately 1 ounce of 30-minute epoxy. Apply

a generous amount of epoxy to the rear fuselage section

where the horizontal stabilizer mounts. Also apply

epoxy to the exposed balsa wood on the bottom of the

horizontal stabilizer.

❑ 6. Install the horizontal stabilizer by pressing it into

position. Carefully align the horizontal stabilizer to the

fuselage.

❑ 7. Apply 30-minute epoxy to the area on the vertical

stabilizer

wood section from which you cut the covering

in Step 4

.

❑ 8. Carefully insert the vertical stabilizer into the horizontal

stabilizer as shown. Be sure that it fully seats. Wipe

away the excess epoxy with rubbing alcohol and a

paper towel.

❑ 9. Using a 90-degree triangle, align the vertical stabilizer

exactly perpendicular to the horizontal stabilizer.

APPLYING THE DECALS

Using the box cover as a guide, simply apply the decals

to their proper locations.

CONTINUED

Page 27

27

Engine (not included)

Engine Mounts (2)

Engine Screws, Nuts, Washers (8)

Fuel Tubing

Fuselage

❑ 1. Locate the two engine mounts. Note that they are cut on

an angle. They are designed to put right thrust into the

engine.

❑ 2. Place the engine mounts, as shown, in the front of the

fuselage, noting the angled edges. Position the engine

to the right (right thrust). Trial fit the engine in place.

Using a pencil, mark the position of the four holes that

secure the mounts to the fuselage, as shown.

❑ 3. Remove the mounts and drill four 1/8” holes at the

points you marked.

❑ 4. Reposition the engine mounts and engine on the

fuselage, making sure right thrust is achieved, and

mark through the holes in the engine mount with a

pencil.

Note: Motor mount in fuselage is designed with 8° of

downthrust.

Drill with 1/8” Drill Bit

Pencil

#2 Phillips Screwdriver

Section 12: Installing The Engine

Parts Needed

Tools Needed

Page 28

28

❑ 5. Remove the engine and mounts and drill four 1/8”

holes through the fuselage where marked.

❑ 6. Place the motor mounts back into the fuselage and

fasten them into place with four of the screws, washers,

and nuts provided.

❑ 7. Place the engine and the motor mounts in the desired

position. It is helpful to have the prop and spinner

installed at this time to check the clearance. Using a

pencil, carefully mark the engine mount through the

holes in the engine mount flange. Remove the engine

and drill four 1/8” holes where marked.

❑ 8. Secure the engine in place using the four remaining

screws, nuts, and washers.

Section 12: Installing The Engine

CONTINUED

Page 29

29

❑ 9. Install the muffler per the instructions included with the

engine. Now install the fuel tubing. Connect the vent

tube from the fuel tank to the muffler nipple and the

other tube from the fuel tank to the carburetor nipple.

Special Instructions for Installing a 4-Cycle

Engine

The Easy Fly 40 is designed to also accept .40-.65

4-cycle engines. The installation is similar to the

2-cycle engine installation except that it may be

necessary to trim away some of the plywood in the

nose of the fuselage in order to allow the wider 4-cycle

engine ease of clearance.

Section 12: Installing The Engine

CONTINUED

Page 30

30

Installing the Aileron Servo

❑

1. Locate the wing and one of the standard servos. Put

the servo grommets and eyelets in the servo and place

the servo in the aileron mount. Using a pencil, mark the

four places to be drilled.

❑ 2. Remove the aileron servo and drill four 1/16” holes

where marked.

❑ 3. Place the aileron servo back in its mount and secure it

in place with the four screws included with the servo.

4-Channel Radio System with 4 Standard Servos and

Hardware (not included)

Fuselage

Radio Packing Foam (not included)

Wing

Drill with 1/16” Drill Bit

Hobby Knife

Pencil

#1 Phillips Screwdriver

Section 13: Installing The Radio

Parts Needed Tools Needed

Page 31

31

Installing the Rudder, Elevator, and Throttle

Servos

❑

1. Locate the other three servos and install the grommets

and eyelets in all three per the instructions included

with the radio. Place the servos in the servo tray in the

fuselage as shown, noting the position of the output

horns. Using a pencil, mark the 12 servo mounting hole

positions.

❑ 2. Remove the servos and drill twelve 1/16” holes where

marked. Install the servos, noting the position of the

output horns. Screw in place with the 12 screws

included with the servos.

Installing the Receiver and Battery

❑

1. Radio packing foam (available at your local hobby

shop) should be used to install the receiver and battery.

With a sharp hobby knife, cut a layer of foam the size of

the compartment in front of the servo tray and place it

in the bottom of the fuselage. Then, cut out another

layer of foam and cut out the center section to match

your battery pack.

❑ 2. Cut out another layer of foam and place it on top of the

battery. Cut out the next layer so that it clears the

receiver. You then have a solid top layer over the top of

the receiver.

Important:

Run the antenna through the fuselage and out the rear.

Section 13: Installing The Radio

CONTINUED

Page 32

32

Installing the Switch

❑

1. The switch should be mounted on the left side of the

fuselage, away from the exhaust gases. Place the

switch plate against the side of the fuselage, as shown,

and mark the position of the holes and square.

❑ 2. Using a sharp hobby knife, cut out the marked area and

drill holes to allow the switch to be mounted. Mount

the switch using the hardware provided.

Section 13: Installing The Radio

CONTINUED

Page 33

33

Installing the Aileron Linkage

❑

1. Locate the wing, two aileron horns, two threaded rods,

and two clevis. Using the Z-Bender pliers, make a zbend 4-1/8 inches from the threaded end of both rods

and cut off the extra length of rod.

❑ 2. Screw a clevis onto the threaded portion of both rods.

❑ 3. Select an X servo horn and trim the long arms off as

shown.

❑ 4. Install the servo horn on the aileron servo, as shown.

Install the z-bends in the second, outermost hole from

the center of the servo horn, as shown.

Aileron Horn (2)

Balsa Dowel (2)

Fuselage and Wing

Heat Shrink Tubing

1/16” Plain Rod, Long (2)

1/16” Plain Rod, Short (2)

Plastic Clevis (4)

1/16” Threaded Rod (4)

Drill with 1/16“ Drill Bit

Heat Gun

Hobby Knife or Scissors

Needle Nose Pliers

Thick CA Glue

Z-Bender Pliers

Section 14: Installing The Linkages

Parts Needed Tools Needed

Page 34

34

❑ 5. Screw both aileron horns onto the aileron torque rods

until the threaded portion is flush with the aileron horn.

❑ 6. Center the servo horn and adjust the aileron torque rod

length by screwing in or out until the aileron is exactly

in the neutral position when the servo is centered and

the clevis is in the aileron horn. Adjust both sides.

Assembling the Pushrods

❑

1. Locate the two balsa dowels, the two remaining

threaded rods, two short plain rods, and the black heat

shrink tubing. Cut the heat shrink tubing into four

equal pieces with a knife or scissors.

❑ 2. Using a pencil, make a mark two inches from each end

of both balsa dowels.

Section 14: Installing The Linkages

CONTINUED

Page 35

35

❑ 3. Drill four 1/16” holes through the balsa dowel at the

marks, as shown.

❑ 4. Locate the two remaining threaded rods. Using a pair of

needle nose pliers, bend a 90-degree angle 1/4" from

the unthreaded end of the rod. Repeat this procedure for

the other rod. Now locate the two short plain rods.

Using needle nose pliers bend a 90-degree angle 1/4”

from one end of the rods. Repeat this procedure for the

other rod.

❑ 5. Locate one balsa dowel and insert the 90-degree end of

one threaded rod into the previously drilled 1/16” hole.

Cover the portion of the rod that touches the dowel with

thick CA glue.

❑ 6. Slide a piece of the heat shrink tubing over the end of

the balsa dowel and shrink it into place using a heat gun.

Section 14: Installing The Linkages

CONTINUED

Page 36

36

❑ 7. Locate the short plain rod and insert the 90-degree

angle into the opposite end of the balsa dowel. Using

thick CA glue, adhere and heat shrink it into place.

❑ 8. Repeat Steps 5-7 to complete the other pushrod.

Installing the Pushrods

❑

1. Insert one of the pushrods, threaded rod first, into the

tail of the fuselage so that the threaded rod exits the

rudder pushrod exit hole.

❑ 2. Screw on a clevis for 20 full turns. Fasten the clevis in

the third hold from the inside of the rudder control

horn.

Section 14: Installing The Linkages

CONTINUED

Page 37

37

❑ 3. Center the rudder and the rudder servo so that the servo

arm is perpendicular to the fuselage. Mark the plain

rod where it crosses the holes in the servo horn. Using

Z-Bender pliers, make a z-bend at the marked location

and cut off the excess plain rod.

❑ 4. Insert the z-bend in the second hole out on the servo

horn. Center the servo so that the horn is exactly

perpendicular to the fuselage and adjust the clevis on

the rudder horn by screwing it in or out until the rudder

is exactly neutral when the servo is centered.

❑ 5. Use the same procedure to install the elevator pushrod,

noting that the elevator pushrod exits the rear opening

of the fuselage.

❑ 6. The two remaining long plain rods are for the throttle

and nose wheel linkage. Using a sharp knife, cut out

the opening just behind the nose wheel where the nose

wheel pushrod exits.

Section 14: Installing The Linkages

CONTINUED

Page 38

38

❑ 7. Using the same technique as above with the rudder,

make a z-bend at both ends of the plain rod with one

end attached to the steering arm and the other attached

to the opposite side of the rudder servo horn. With the

servo horn centered, adjust the nose wheel so it’s

straight. Tighten the Phillips screw in the steering arm.

❑ 8. A 1/16” hole is pre-drilled through the fire wall. This is

for the throttle linkage. Insert the remaining plain rod

through the fire wall and make a z-bend at both ends as

before, being especially careful that the length is correct

so that when the servo is centered, the throttle is half

open.

Section 14: Installing The Linkages

CONTINUED

Page 39

39

❑ 1. Carefully hook up your servos to the receiver as shown

in the instructions included with your radio. Also hook

up your battery and switch. If you haven’t already done

so, charge your batteries (both transmitter and receiver)

per the radio instructions.

❑ 2. Remove all four servo horns from the servos. Center

the trims on the transmitter and move the throttle to the

middle position. Turn on the transmitter and then the

receiver. Now reinstall the servo horns with the radio

on, making sure each is perpendicular to the fuselage

or wing. Reinstall the servo horn screws and make any

minor adjustments necessary to the length of the

pushrods so that all the control surfaces are neutral

when the trims on the transmitter are centered.

❑ 3. Check the throttle stroke. At full throttle the carburetor

barrel should be fully open but not binding. At low

throttle, middle trim position, the carburetor barrel

should be open 1/16”. Adjust the linkage until this is

achieved. If you need a longer stroke, move the push

rod one hole out on the screw. If less stroke is needed,

move the push rod in one hole.

Important:

It may be necessary to reverse the throttle reversing

switch if the carburetor works in reverse (e.g., full

throttle closes the carburetor).

❑ 4. Cut out the control throw gauges in the back of this

manual. Then place the elevator gauge on the elevator.

Give a full up elevator command and notice how far the

elevator moves. It should move up 1/4” and down

1/4”. If necessary, move the clevis in on the elevator to

achieve more throw, or out to achieve less throw.

❑ 5. Do the same with the aileron gauge and the rudder

gauge. Adjust the control throw to the indicated values:

aileron 1/4” up, 1/4” down; rudder 1/4” right, 1/4” left.

Control Throw Gauges #1 Phillips Screwdriver

Section 15: Setting Up The Radio

Parts Needed Tools Needed

Neutral

1/4”

1/4”

Neutral

1/4”

1/4”

Neutral

1/4”

1/4”

The control throw gauges are located on page 47.

ELEVATOR THROW GAUGE

EASY FLY 40

HINGE

LINE

AILERON THROW GAUGE

EASY FLY 40

HINGE

LINE

RUDDER THROW GAUGE

EASY FLY 40

HINGE

LINE

Page 40

40

❑ 1. Measure back 3-1/4” from the wing’s leading edge and

put a mark on the bottom of the wing, (approximately 6”

out from the center section).Repeat this procedure for

the opposite wing half.

❑ 2. Install the wing with rubber bands and place your two

index fingers on the marks on the bottom of the wing.

The model should balance level. If not, add weight to

the tail or nose as necessary until the model balances

perfectly level. Stick-on weights are available at your

local hobby shop and work well for this purpose.

Rubber Bands Pencil

Ruler

Section 16: Balancing The Model

Parts Needed Tools Needed

Page 41

41

❑ 1. Check that all control functions move in the correct

direction. If not, use the respective reversing switch to

correct the direction.

❑ 2. Check that each clevis is securely snapped into

position.

❑ 3. Check that all servo horn screws are tight.

❑ 4. Charge the transmitter and receiver battery per the

instructions included with the radio system.

❑ 5. Read and follow all the instructions included with the

engine and follow the recommended break-in

procedure.

Pre-Flight Check

ELEVATOR

ELEVATOR

CARBURETOR

1/16”

THROTTLE

RUDDER

AILERON

AILERON

RUDDER

AILERON

Page 42

42

Pre-Flight At The Field

Range Test Your Radio

❑

1. Before each flying session range check your radio. This

is accomplished by turning on your transmitter with the

antenna collapsed. Turn on the radio in your airplane.

With your airplane on the ground, you should be able

to walk 30 paces away from your airplane and still have

complete control of all functions. If not, don't attempt to

fly! Have your radio equipment checked out by the

manufacturer.

❑ 2.

Double check that all controls (aileron, elevator, throttle,

rudder) move in the correct direction. See page 40.

❑ 3. Be sure that your batteries are fully charged per the

instructions included with your radio.

Adjusting the Engine

❑

1. Completely read the instructions included with your

engine and follow the recommended break-in

procedure. At the field adjust the engine to a slightly

rich setting at full throttle and adjust the idle and low

speed needle so that a consistent idle is achieved.

Before you fly be sure that your engine idles, transitions

and runs at all throttle settings reliably. Only when this

is achieved should any plane be considered ready for

flight.

Page 43

43

Flight Instructions

For first time pilots the thought of flying their Easy Fly 40

through loops, rolls and perfect three-point landings can be

thrilling. Learning to fly, however, takes time, patience and most

importantly, a good instructor. If you’re a first time pilot don't try

to fly your Easy Fly 40 alone. Seek an experienced instructor.

Your local hobby shop can put you in touch with an instructor in

your area who can fly and trim your Easy Fly 40 and then give

you your first chance on the “sticks" with very little risk of

damage to the airplane. We cannot overemphasize the

importance of having a qualified instructor to help you through

your first flight. Don't try it alone!

Experienced pilots will find the Easy Fly 40 to be a confidence

inspiring airplane. Super stable and slow flight characteristics

make pinpoint landings a breeze. At full throttle with a strong

.40 engine, the Easy Fly is more than capable of most sport

aerobatic maneuvers. The self righting stability of the Easy Fly

40, helps to make it one of the easiest airplanes you'll ever fly.

Page 44

44

1994 Official AMA National Model Aircraft Safety Code

Effective January 1, 1994

Model flying must be in accordance with this Code in

order for AMA liability protection to apply

General

1. I will not fly my model aircraft in sanctioned events, air shows, or

model flying demonstrations until it has been proven to be airworthy

by having been previously, successfully flight tested.

2. I will not fly my model higher than approximately 400 feet within 3

miles of an airport without notifying the airport operator. I will give

right-of-way and avoid flying in the proximity of full-scale aircraft.

Where necessary, an observer shall be utilized to supervise flying to

avoid having models fly in the proximity of full-scale aircraft.

3. Where established, I will abide by the safety rules for the flying site I

use, and I will not willfully and deliberately fly my models in a

careless, reckless and/or dangerous manner.

4. At all flying sites a straight or curved line(s) must be established in

front of which all flying takes place with the other side for spectators.

Only those persons essential to the flight operations are to be

permitted on the flying side of the line; all others must be on the

spectator side. Flying over the spectator side of the line is prohibited,

unless beyond the control of the pilot(s). In any case, the maximum

permissible takeoff weight of the models is 55 pounds.

5. At air shows or model flying demonstrations a single straight line

must be established, one side of which is for flying, with the other

side for spectators. Only those persons accredited by the contest

director or other appropriate official as necessary for flight operations

or as having duties or functions relating to the conduct of the show or

demonstration are to be permitted on the flying side of the line. The

only exceptions which my be permitted to the single straight line

requirements, under special circumstances involving consideration of

side conditions and model size, weight, speed, and power, must be

jointly approved by the AMA President and the Executive Director.

6. Under all circumstances, if my model weighs over 20 pounds, I will

fly it in accordance with paragraph 5 of this section of the AMA Safety

Code.

7. I will not fly my model unless it is identified with my name and

address or AMA number, on or in the model. Note: This does not

apply to models flown indoors.

8. I will not operate models with metal-bladed propellers or with

gaseous boosts, in which gases other than air enter their internal

combustion engine(s); nor will I operate models with extremely

hazardous fuels such as those containing tetranitromethane or

hydrazine.

9. I will not operate models with pyrotechnics (any device that explodes,

burns, or propels a projectile of any kind) including, but not limited

to, rockets, explosive bombs dropped from models, smoke bombs,

all explosive gases (such as hydrogen-filled balloons), ground

mounted devices launching a projectile. The only exceptions

permitted are rockets flown in accordance with the National Model

Rocketry Safety Code or those permanently attached (as per JATO

use); also those items authorized for Air Show Team use as defined

by AST Advisory Committee (document available from AMA HQ). In

any case, models using rocket motors as primary means of

propulsion are limited to a maximum weight of 3.3 pounds and a G

series motor. Note: A model aircraft is defined as an aircraft with or

without engine, not able to carry a human being.

10. I will not operate any turbo jet engine (axial or centrifugal flow)

unless I have obtained a special waiver for such specific operations

from the AMA President and Executive Director and I will abide by

any restriction(s) imposed for such operation by them. (Note: This

does not apply to ducted fan models using piston engines or electric

motors.)

11. I will not consume alcoholic beverages prior to, nor during,

participation in any model operations.

Radio Control

1. I will have completed a successful radio equipment ground range

check before the first flight of a new or repaired model.

2. I will not fly my model aircraft in the presence of spectators until I

become a qualified flier, unless assisted by an experienced helper.

3. I will perform my initial turn after takeoff away from the pit or

spectator areas, and I will not thereafter fly over pit or spectator areas,

unless beyond my control.

4. I will operate my model using only radio control frequencies currently

allowed by the Federal Communications Commission. (Only properly

licensed Amateurs are authorized to operate equipment on Amateur

Band frequencies.) Further, any transmitters that I use at a sanctioned

event must have a certified R/CMA-AMA gold sticker affixed

indicating that it was manufactured or modified for operation at 20

kHz frequency separation (except 27 MHz and 53 MHz).

5. I will not knowingly operate an R/C system within 3 miles of a preexisting model club flying site without a frequency sharing agreement

with that club.

AMA Safety Code

Page 45

45

Adverse Yaw. Some airplanes, especially high-wing airplanes

with flat-bottom airfoils, have a tendency to yaw in the opposite

direction of the bank. This is most common when flying at low

speeds with high angles. Adjusting the ailerons can help reduce

the yaw.

Ailerons. Each side of this airplane has a hinged control

surface, called an aileron, located on the trailing edge of the

wing. Move the left aileron up and the right aileron down, and

the airplane will turn or roll to the right. Perform the opposite

actions, and the airplane will roll to the left. This is how you

control the airplane's direction in flight.

Carburetor. By adjusting the needle valve in the carburetor,

you control the engine’s lean/rich fuel mixture and determine the

airplane's speed.

Charger. This is the device used to charge/recharge batteries.

If NiCad batteries are provided with the radio, a charger is

usually provided as well.

Clevis. The clevis connects the wire end of the pushrod to the

control horn of the control surface. A small clip, the clevis has

fine threads so that you can adjust the length of the pushrod.

Clunk. Located in the fuel tank, a clunk is weighted and

ensures that the intake line has a steady supply of fuel.

Computer Radio. By using the advanced programming

functions of the transmitter, you can adjust the airplane without

changing any mechanical structures.

Control Horn. This arm connects the control surface to the

clevis and pushrod.

Dead Stick. When the airplane is in flight gliding, without the

engine running, it is called “dead stick.”

Dihedral. The degree of angle (V-shaped bend) at which the

wings intersect the plane is called dihedral. More dihedral gives

an airplane more aerodynamic stability. Some sailplanes and

trainer planes with large dihedral dispense with ailerons and use

only the rudder to control the roll and yaw.

Electric Starter. This is the small motor commonly used to

start the airplane's engine.

Elevator. The hinged control surface functions as an elevator,

which you adjust to control the airplane's pitch axis. Pulling the

transmitter's control stick toward the bottom of the transmitter

adjusts the elevator upward, and the airplane begins to climb.

Push the control stick forward, and the airplane begins to dive.

Expanded Scale Voltmeter (ESV). This device is used to

check the voltage of the battery pack.

Flight Box. The box in which you store and transport your

flying equipment is called a flight box.

Flight Pack or Airborne Pack. These interchangeable terms

describe the radio equipment that is installed on the airplane.

Foam Rubber. Material that is used to dampen the airplane's

vibrations and protect the airplane's battery and receiver.

Fuel Overflow Line (Vent). This line pressures the fuel tank

and provides an even fuel flow to the engine. It also functions

as an overflow line when the fuel tank is full.

Fuel Pickup Line. This line connects the fuel tank to the

carburetor, usually with a clunk on the tank end to keep the fuel

flowing while the aircraft is in flight.

Fuselage. The main body of an airplane.

Glow Plug Clip/Battery. A 1.2-volt battery with a clip which

is connected to your engine’s glow plug used to start the engine.

You remove it once the engine is running smoothly.

High Wing. This term describes an airplane that has its wings

mounted on the top of the fuselage.

Hinge. The hinges are the moving blades on the control

surface that allow you to control the airplane's movement. All

hinges must be glued properly and securely to prevent the

airplane from crashing.

Horizontal Stabilizer. The horizontal surface of the tail gives

the airplane stability while in flight.

Main Landing Gear. The wheel and gear assembly the

airplane uses to land. It is attached to the bottom of the

fuselage.

Muffler. This device muffles engine noise and increases the

back pressure from the engine’s exhaust stack, which can

improve the airplane's performance at low speeds. Mufflers are

usually required by R/C Clubs.

Needle Valve. This mechanism within the carburetor adjusts

the fuel mixture and throttle. Refer to your engine’s

manufacturer instructions for directions on how to adjust the

needle valve.

Glossary

Page 46

46

NiCad. This abbreviation stands for Nickel Cadmium, the

chemical compound used in rechargeable batteries.

Nitro. Short for nitromethane, a fuel additive that improves an

airplane's high-speed performance. Check your engine’s

instructions to determine the ideal nitro content for your engine.

Nose Gear. The part of the landing gear that is attached to the

nose of the fuselage. The nose gear is usually connected to the

rudder servo to help you steer the airplane on the ground.

Pitch Axis. The horizontal plane on which the airplane's nose

is raised or lowered. By adjusting the elevator, you can raise the

airplane's nose above the pitch axis (climb) or lower it below the

pitch axis (dive).

Pushrod. The rigid mechanism that transfers movement from

the servo to the control surface.

Receiver (RX). The receiver unit in the airplane receives your

signals from the ground transmitter and passes the instructions

along to the airplane's servos.

Roll Axis. The horizontal plane on which the airplane's wings

are raised or lowered. By adjusting the ailerons, you can drop a

wing tip below the roll axis and cause the airplane to bank or

roll.

Rudder. The hinged control surface on the vertical stabilizer

that controls the airplane's yaw. Moving the rudder to the left

causes the airplane to yaw left; moving the rudder to the right

causes it to yaw right.

Servo. The servo transforms your ground commands into

physical adjustments of the airplane while it’s in the air.

Servo Output Arm. A removable arm or wheel that connects

the servo to the pushrod.

Single Stick. A special kind of transmitter that has only one

stick, with special movements to control the airplane's flight.

Not common.

Spinner. Term describing the nose cone that covers the

propeller hub.

Switch Harness. This switch is commonly located on the

fuselage and governs the on/off mechanism for the flight pace.

Tachometer. A device the measures the engine’s RPM

(rotations per minute) by counting light impulses that pass

through the spinning propeller.

Torque Rods. Inserted into ailerons, these rigid wire rods run

along the wings’ trailing edge, then bend downward and connect

to the pushrods.

Trainer Airplane. Designed to fly with high stability at low

speeds, a trainer model airplane allows new users some extra

reaction time as they learn to control the airplane's movements.

Transmitter (Tx). The device used on the ground to transmit

instructions to the airplane. Three transmitter modes are used

in model airplanes. The most common is Mode II, where the left

stick controls the throttle and rudder and the right stick controls

the elevator and aileron.

Vertical Stabilizer. The vertical surface of the tail gives the

airplane stability while in flight.

Wheel Collar. The round retaining piece that anchors wheels

in place on the axle.

Wing. Because wings provide the primary lift force on an

airplane, adjustments to the wings affect the airplane's

movements while in flight.

Yaw Axis. The vertical plane through which the airplane's

nose passes as it yaws to the left or to the right. The rudder

controls the yaw axis.

Z-Bend. The wire ends of pushrods have Z-shaped bends,

which attach to the servo.

Z-Bend Pliers. Used for crimping wire ends into Z bends.

Glossary

CONTINUED

Page 47

47

Page 48

Neutral

1/4”

1/4”

ELEVATOR THROW GAUGE

Neutral

1/4”

1/4”

Neutral

1/4”

1/4”

EASY FLY 40

HINGE

LINE

AILERON THROW GAUGE

EASY FLY 40

HINGE

LINE

RUDDER THROW GAUGE

EASY FLY 40

HINGE

LINE

Page 49

© Copyright 1994, Horizon Hobby Distributors, Inc.

Loading...

Loading...